Metallic Glasses as Potential Reinforcements in Al and Mg Matrices: A Review

Abstract

:1. Introduction

2. Processing Methods

2.1. Conventional Methods

2.1.1. Squeeze Infiltration

2.1.2. Blend-Compact-Sinter

2.2. Advanced Processing Methods

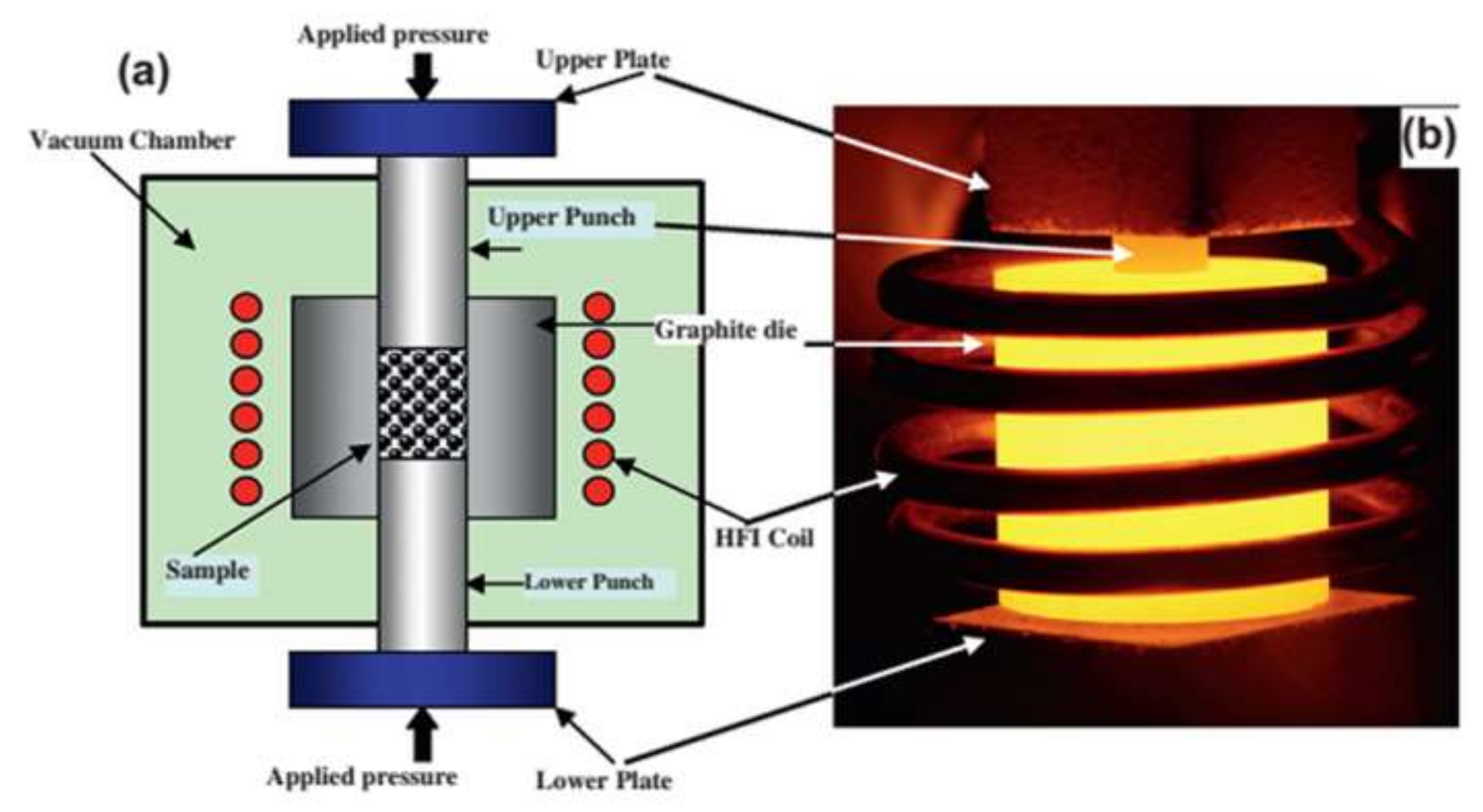

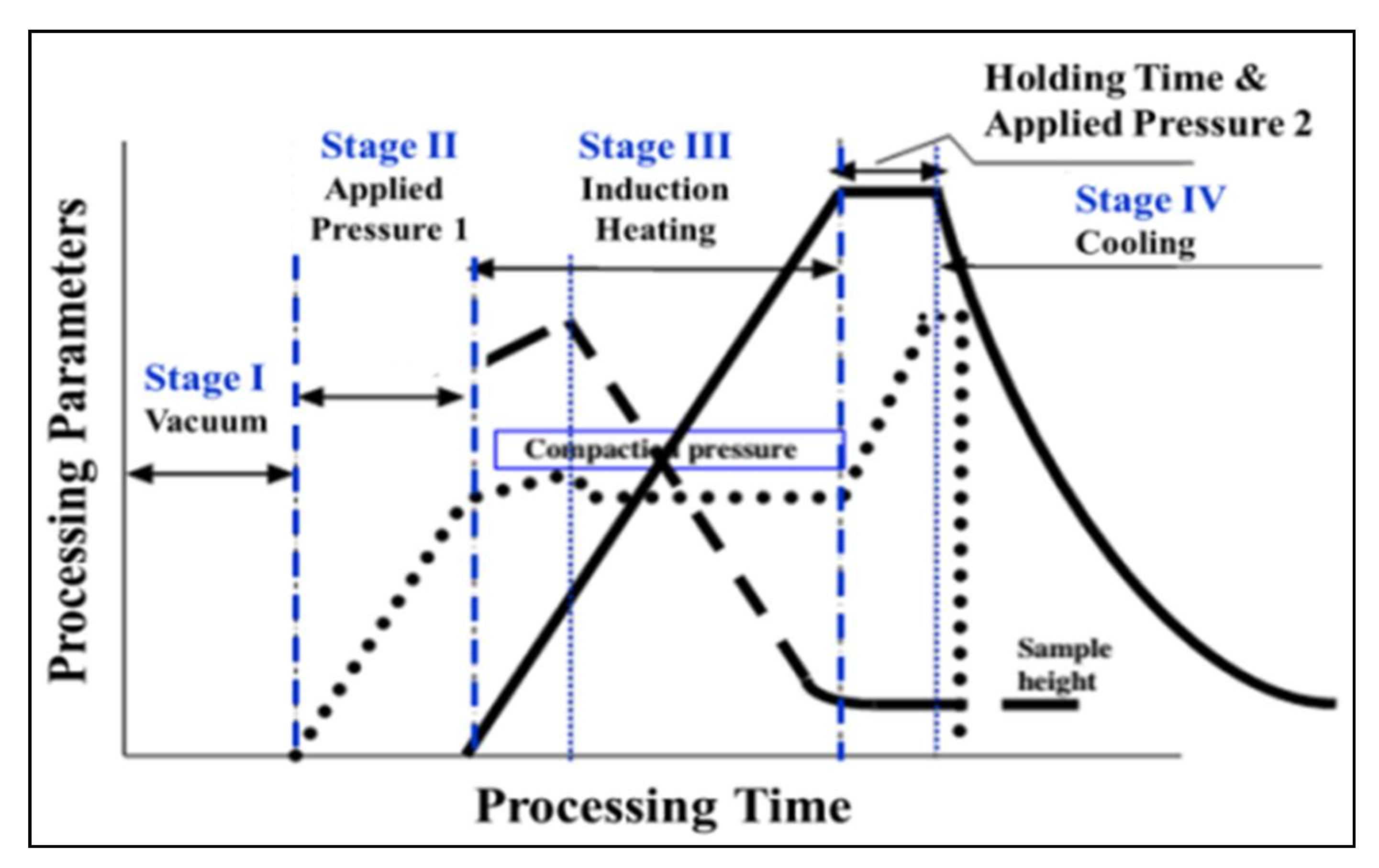

2.2.1. High Frequency Induction Heat Sintering

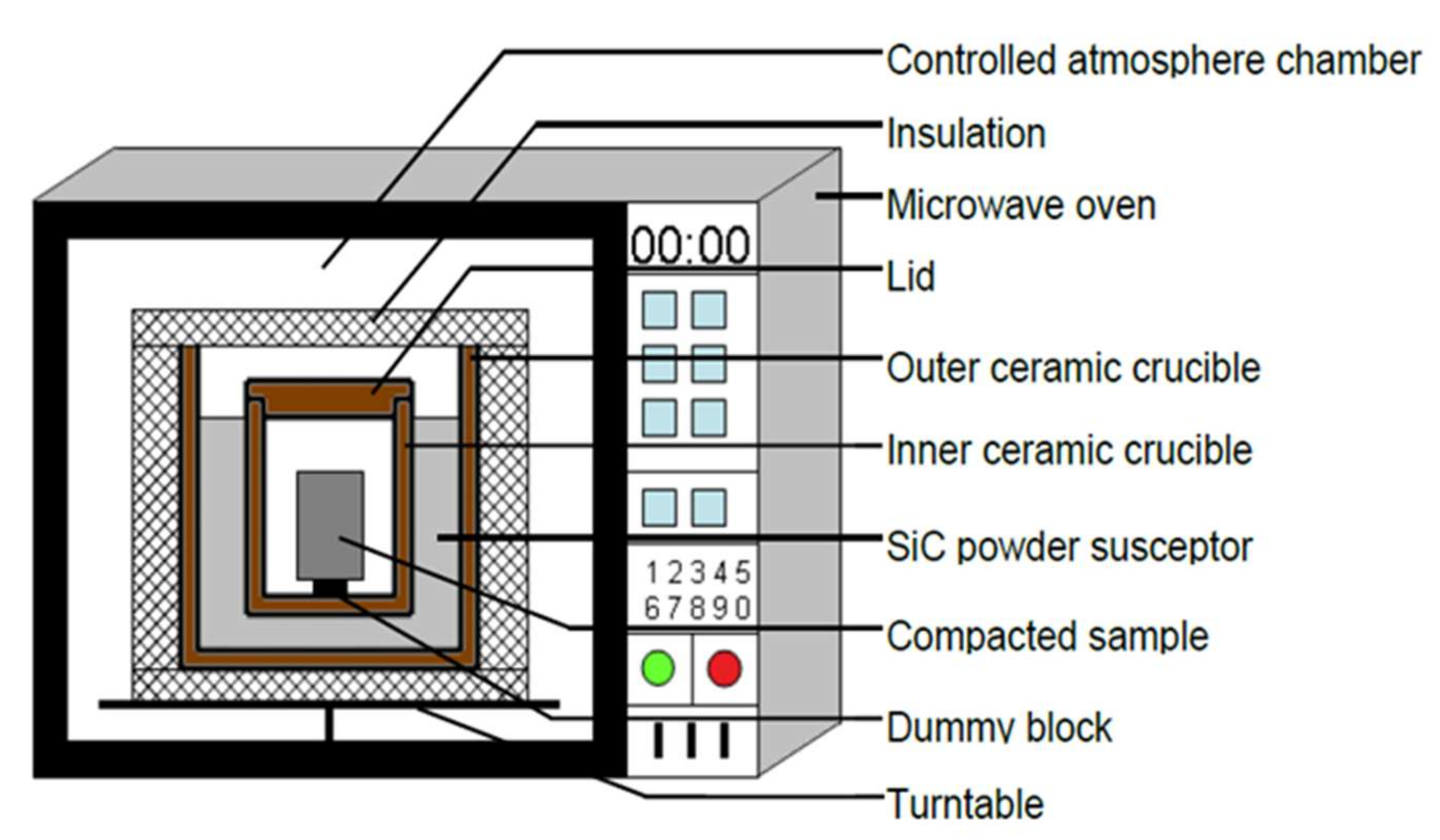

2.2.2. Microwave Sintering

2.2.3. Accumulative Roll Bonding

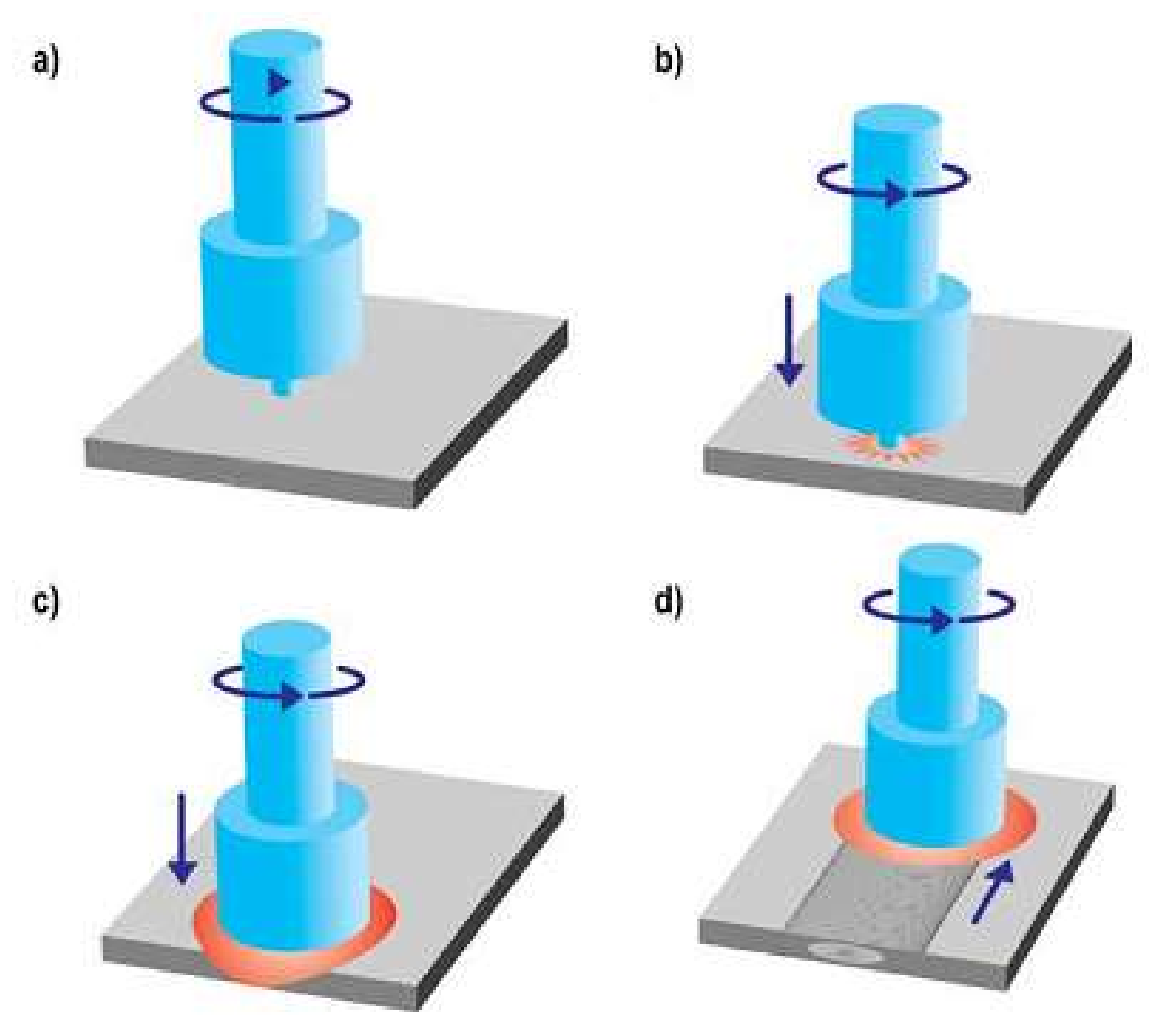

2.2.4. Friction Stir Processing

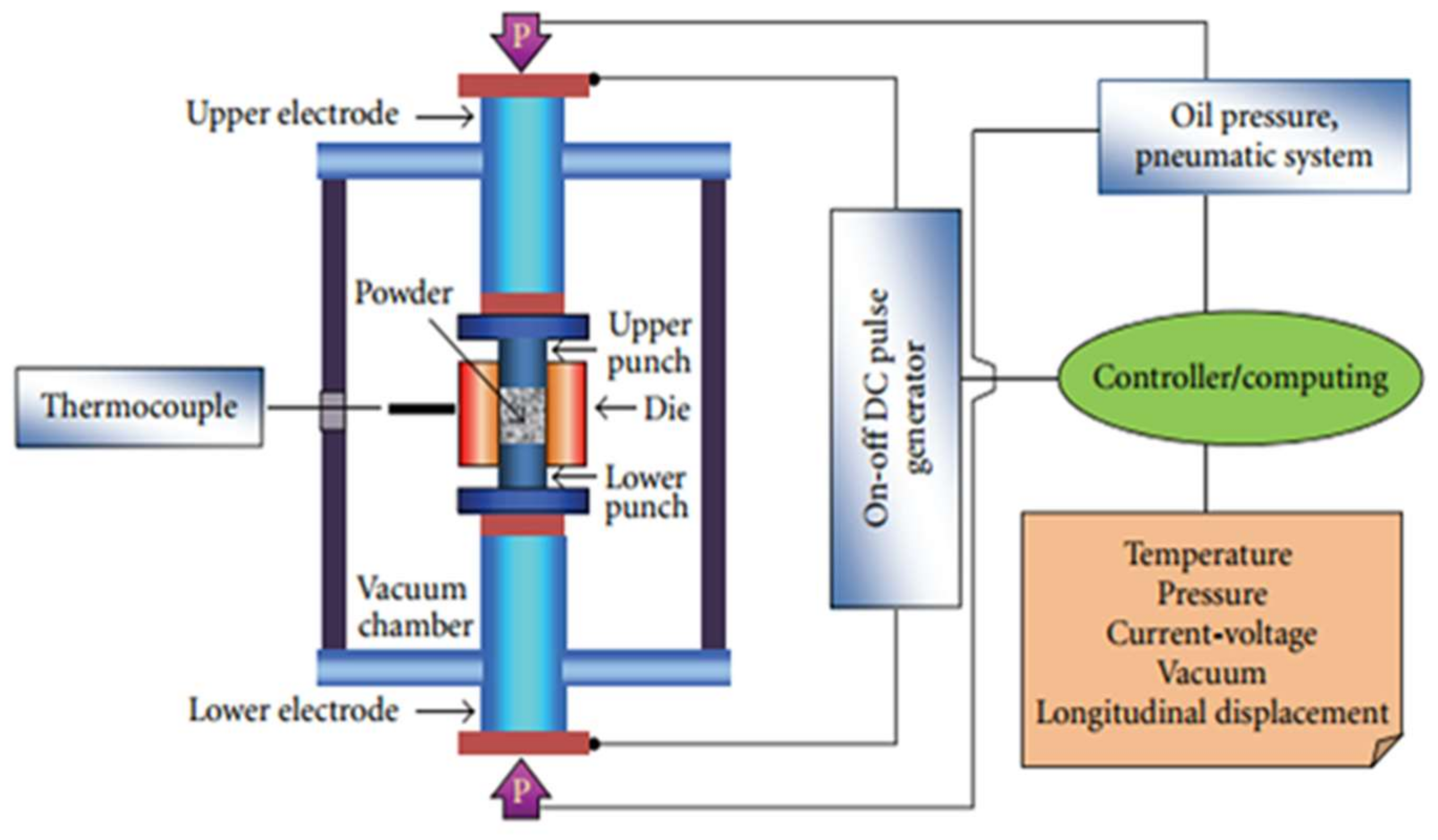

2.2.5. Spark Plasma Sintering

3. Microstructure and Properties of Al and Mg Composites Reinforced with Metallic Glass

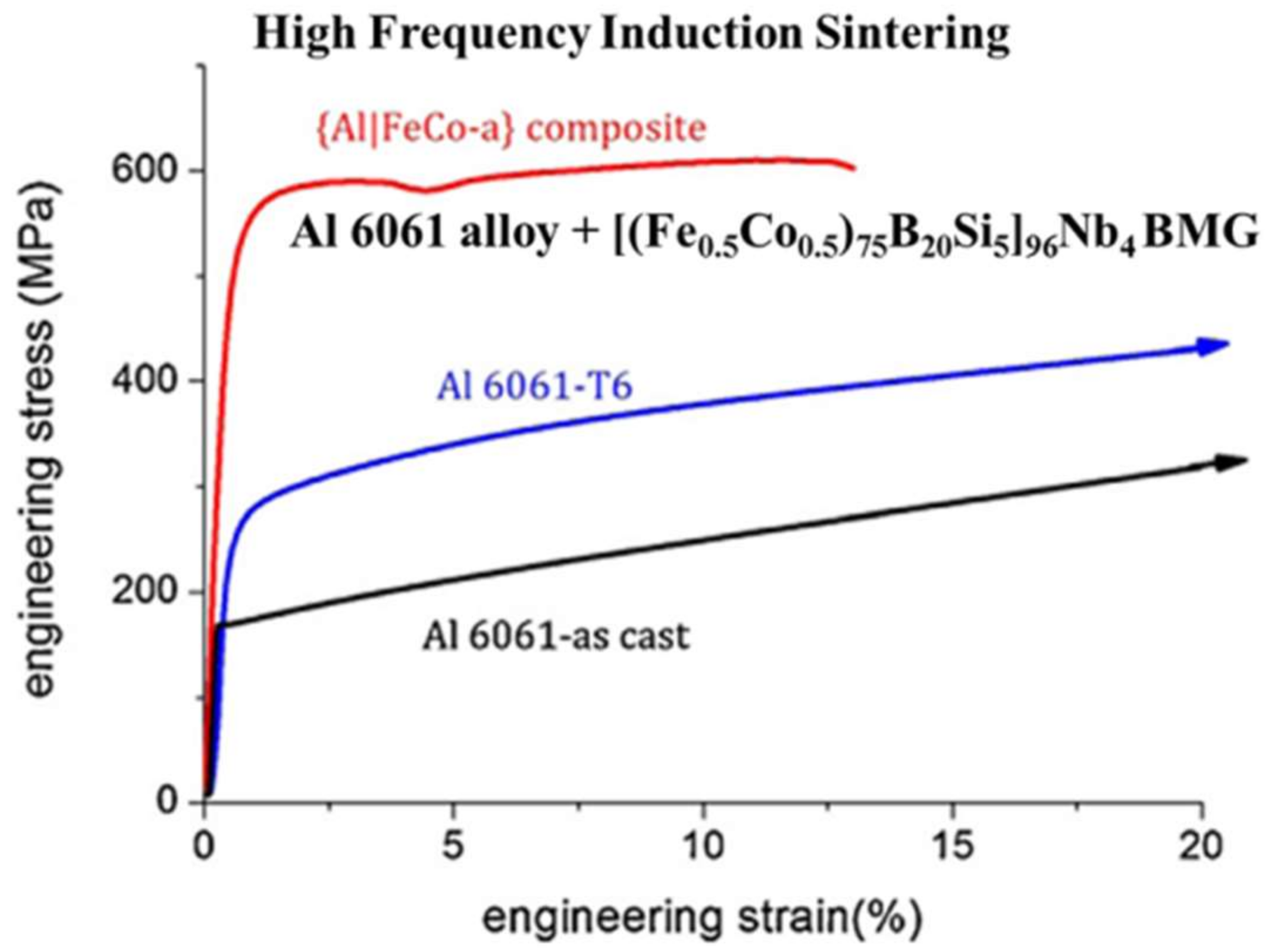

3.1. Al and Mg Composites Sintered by High Frequency Induction Heat Sintering

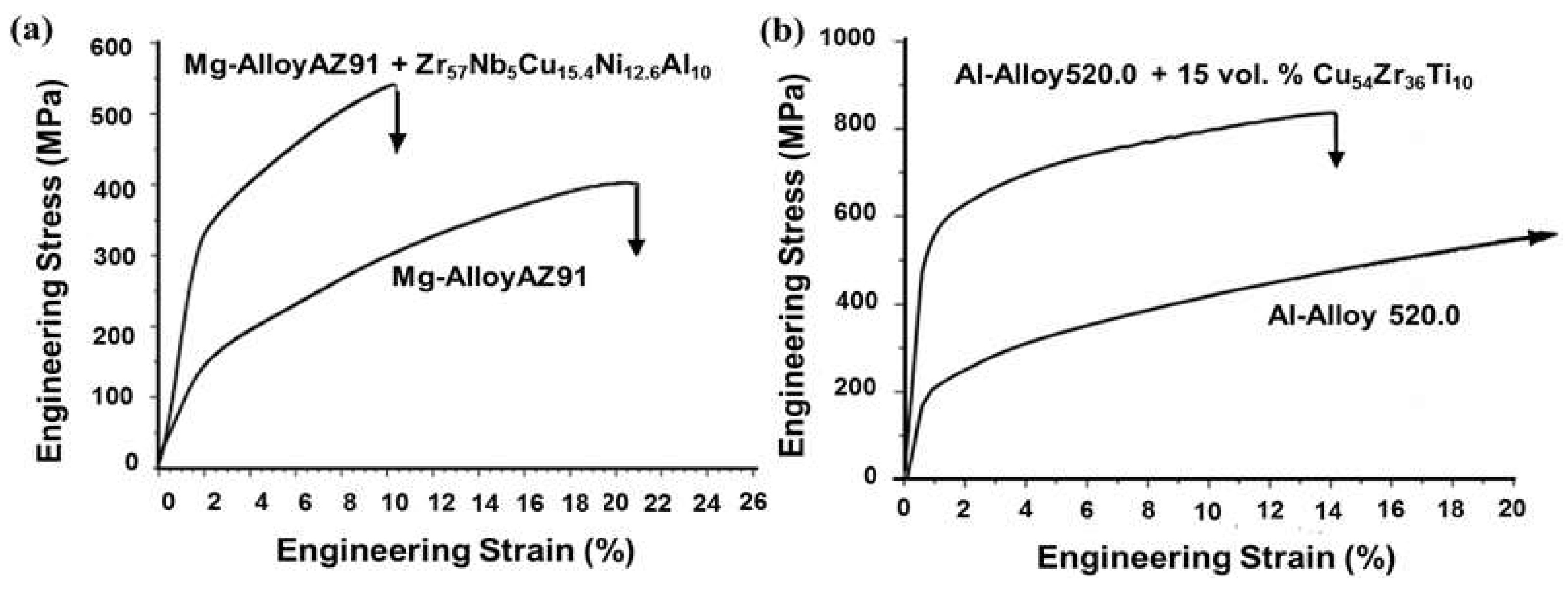

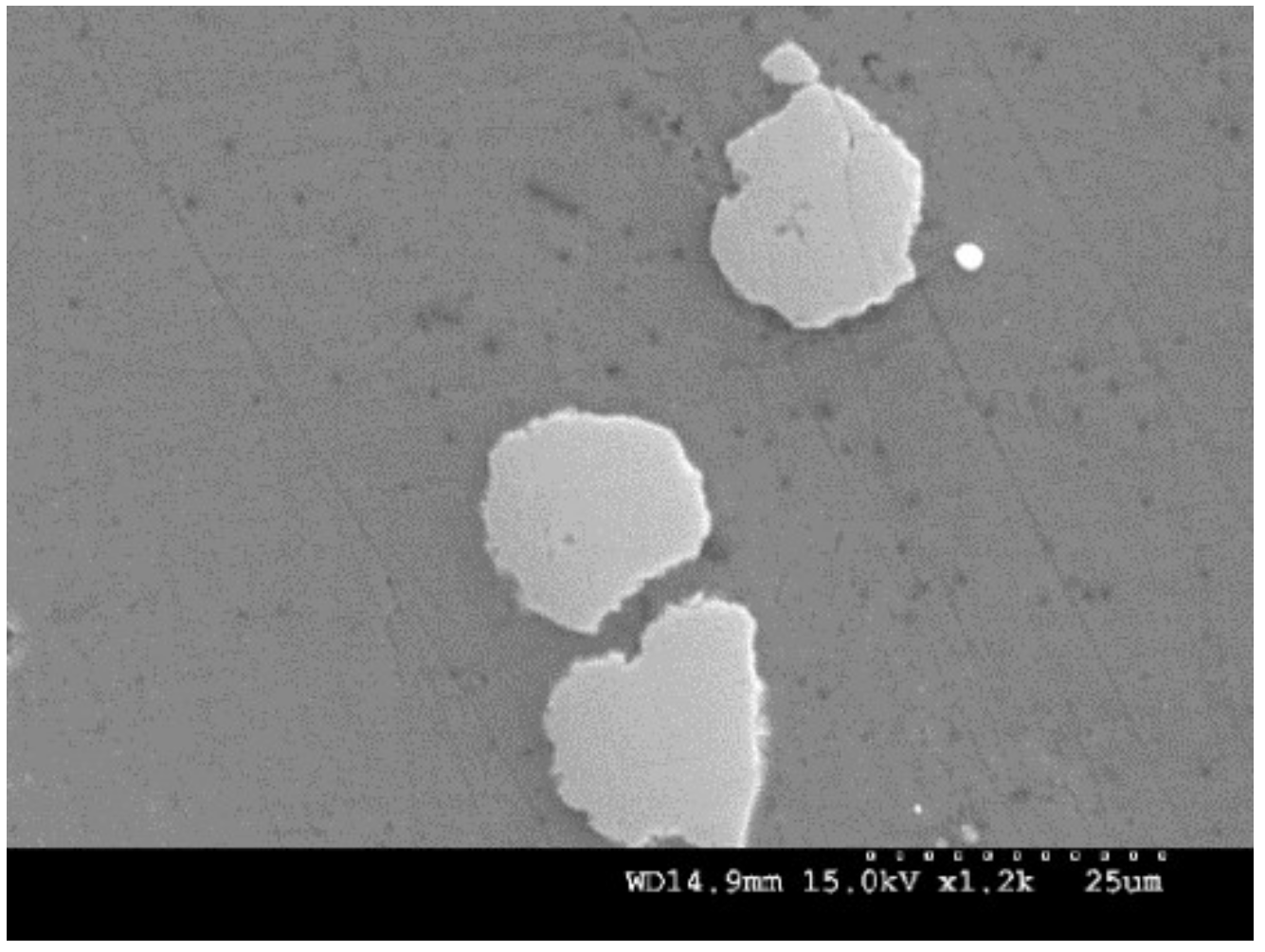

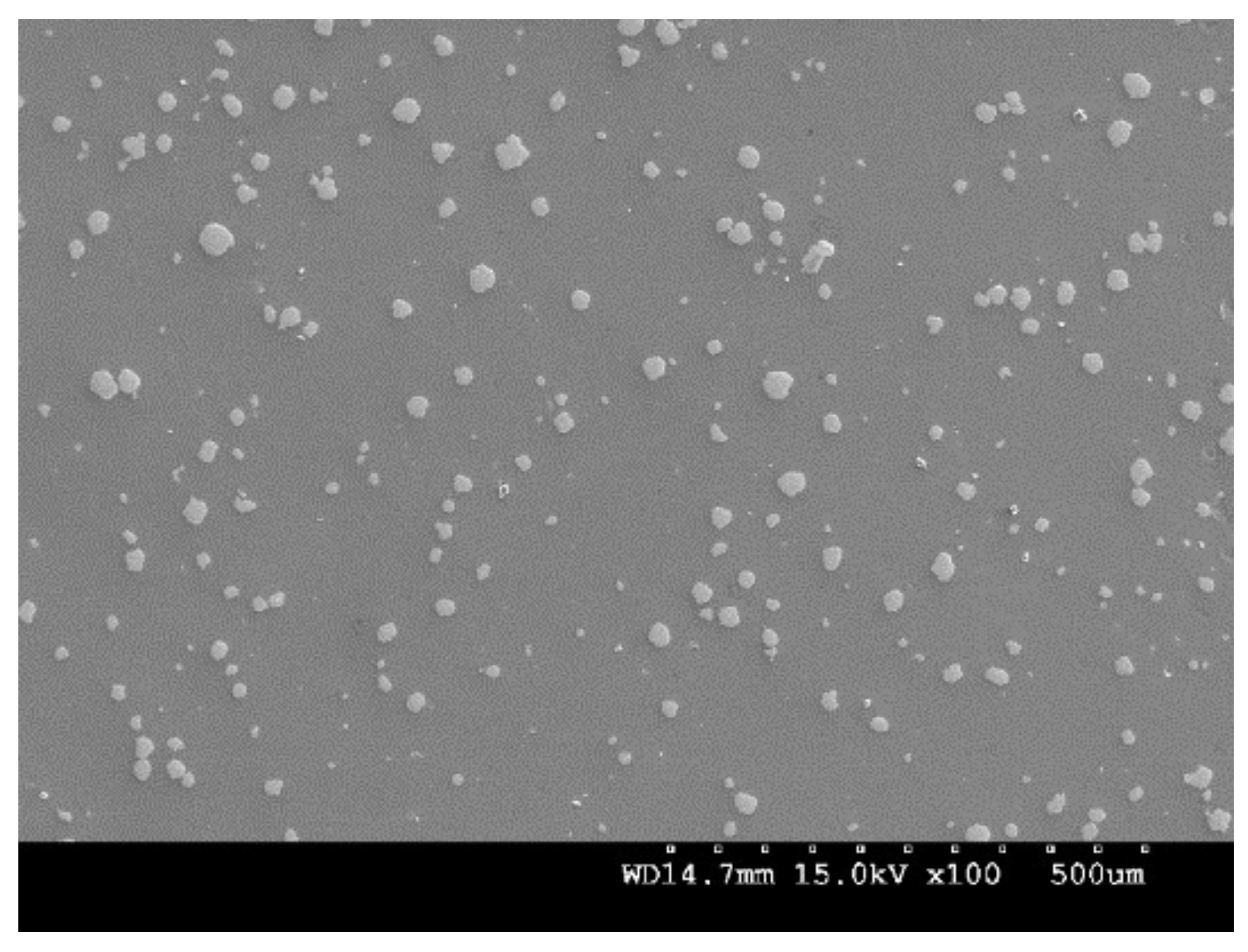

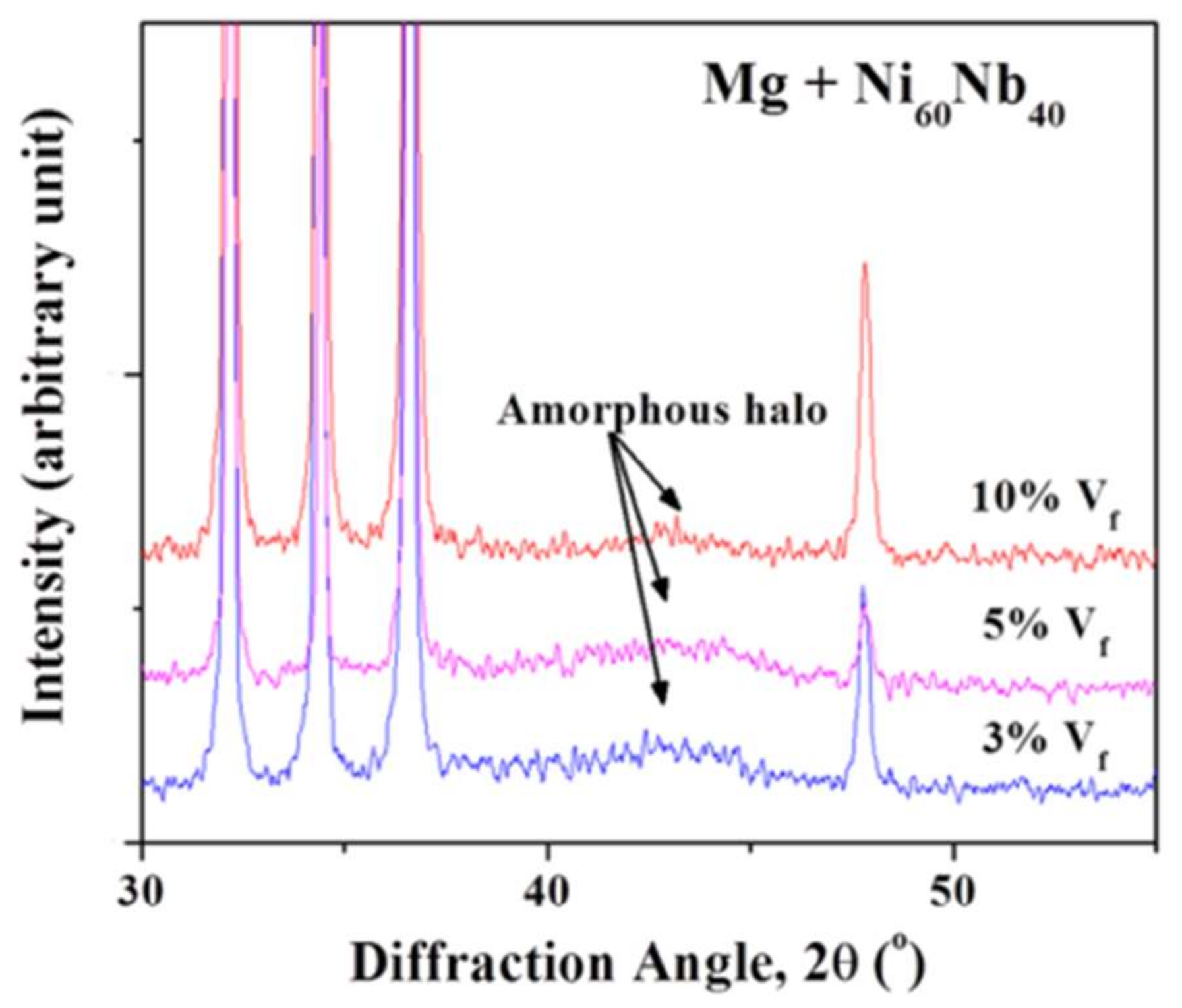

3.2. Al and Mg Composites Produced by Microwave Sintering

3.3. Al and Mg Composites Synthesized by Accumulative Roll Bonding

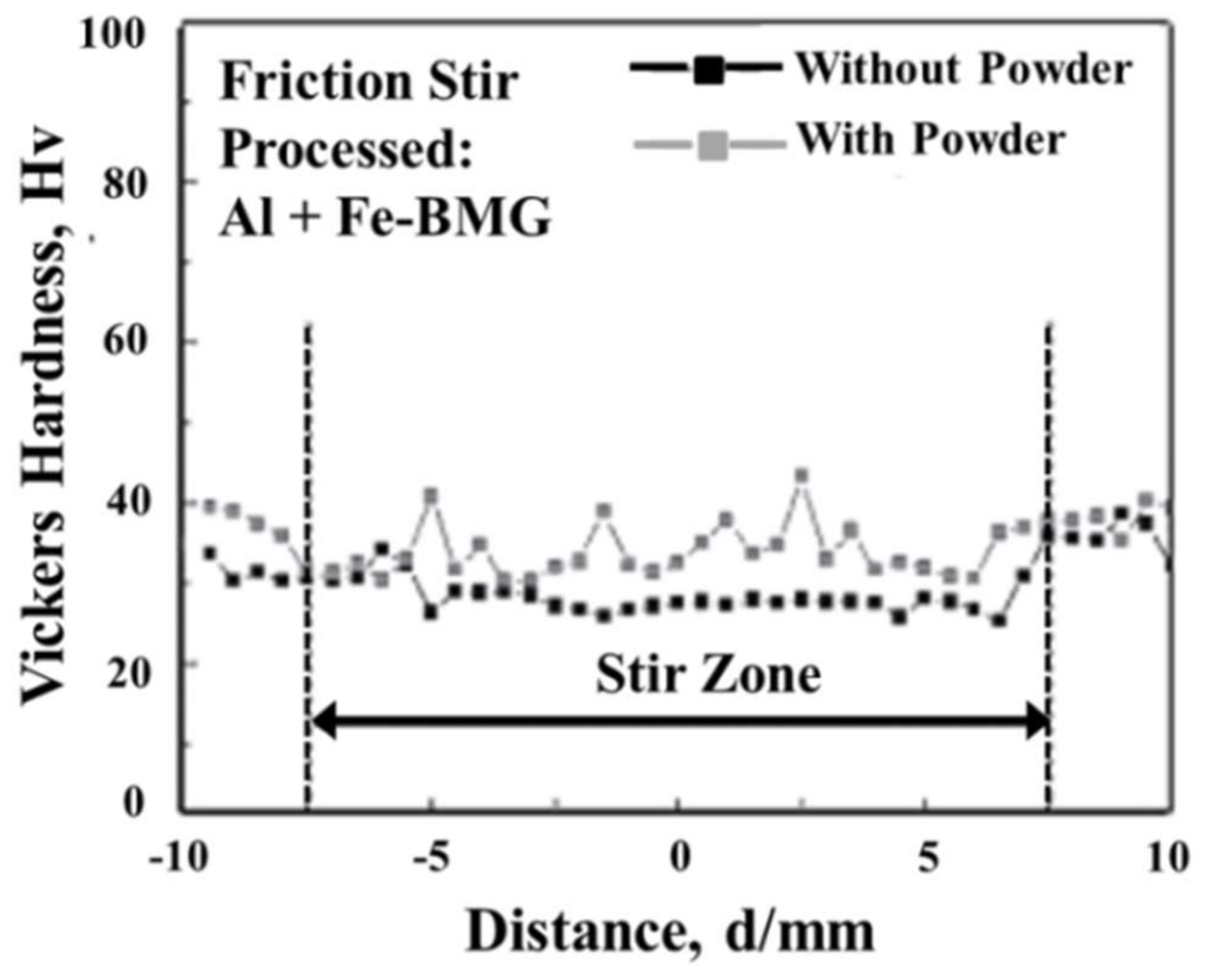

3.4. Al and Mg Composites Produced by Friction Stir Processing

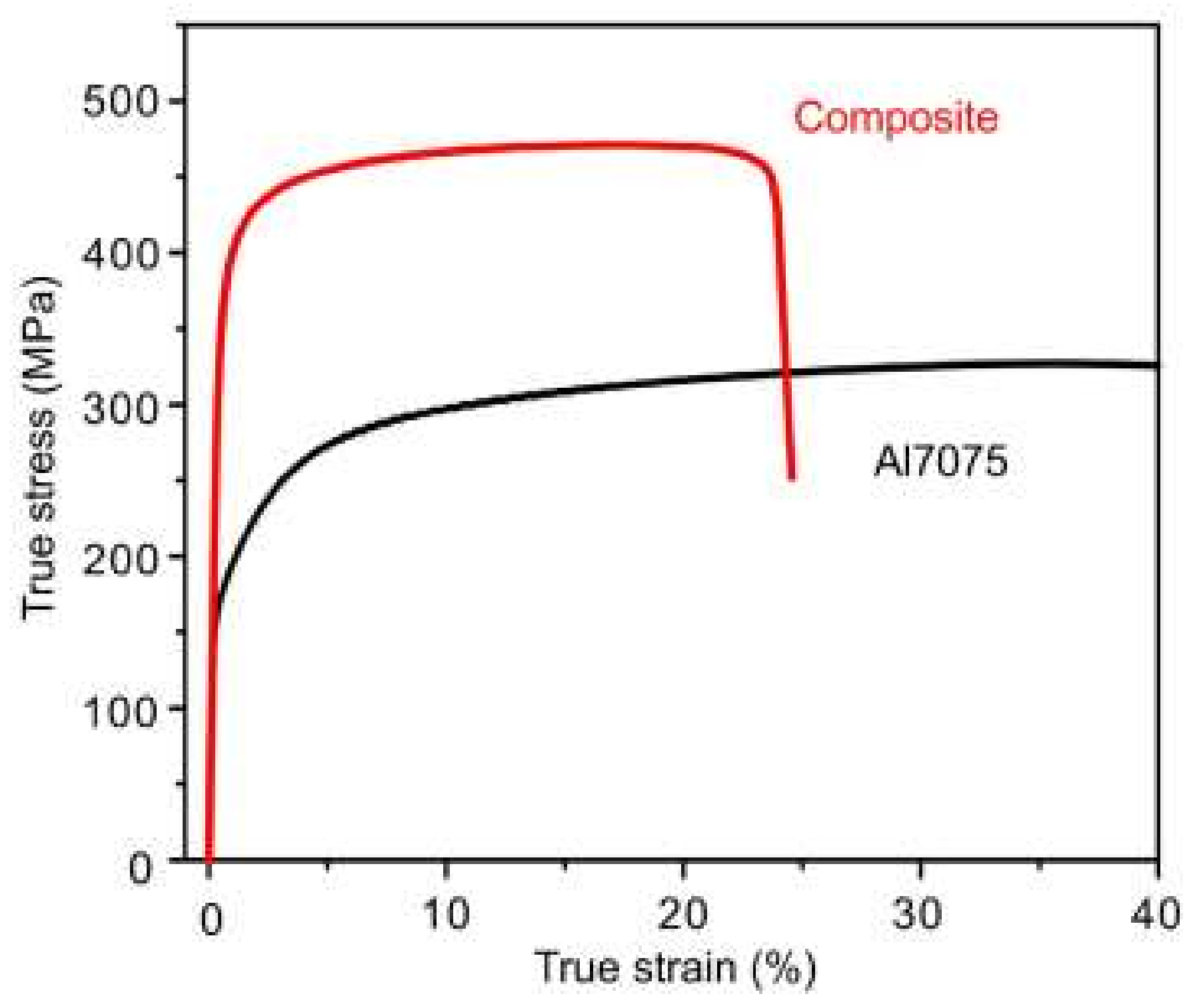

3.5. Al Composites Produced by Spark Plasma Sintering

3.6. Effect of Processing Method on the Composite Strength Properties

- (i)

- Hall–Petch effect: grain boundary strengthening due to fine grain size, which increases the yield strength due to the piling up of dislocations at grain boundaries;

- (ii)

- Orowan strengthening: dislocation bowing that occurs due to the obstruction for dislocation motion owing to its interaction with strong reinforcement particles (amorphous particles have very high hardness, strength and large elastic strain limit);

- (iii)

- Enhanced dislocation density: increase in the dislocation density due to thermal mismatch. The difference in the coefficients of thermal expansion (CTE) between the matrix and reinforcing glassy particles can cause residual plastic strain in the matrix around the particles, resulting in enhanced dislocation density strengthening effect, and (iv) solid-solution strengthening.

4. Summary

- Rapid sintering techniques are more efficient to produce high performing composites, as these methods can (i) prevent devitrification of the reinforcement and (ii) eliminate undesired interfacial reactions. High frequency induction sintering, bidirectional microwave sintering and spark plasma sintering are the rapid sintering methods used to synthesize these composites.

- Amorphous/metallic glass particles effectively bear the load transferred by the matrix due to their inherent high strength. The Hall–Petch effect, Orowon strengthening, solid solution strengthening and enhanced dislocation density due to thermal mismatch are the matrix strengthening mechanisms brought forth by amorphous/metallic glass particle reinforcement.

- Amorphous metallic glass particles are promising as reinforcement materials for light metal matrices, by the incorporation of which composites with superior performance can be realized. It is noteworthy that the discussed composites processing methods have their own unique advantages; and the metallic glass reinforced light metal composites produced by these methods can effectively replace conventional ceramic reinforced light metal composites.

Author Contributions

Conflicts of Interest

References

- Mortensen, A.; Llorca, J. Metal Matrix Composites. Ann. Rev. Mater. Res. 2010, 40, 243–270. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Alanemea, K.K.; Chown, L.H. Aluminum Matrix Hybrid Composites: A Review of Reinforcement Philosophies; Mechanical, Corrosion and Tribological Characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef]

- Gupta, M.; Sharon, N.M.L. Magnesium, Magnesium Alloys, and Magnesium Composites; John Wiley & Sons: Singapore, 2011. [Google Scholar]

- Huang, L.; Geng, L. Discontinuously Reinforced Titanium Matrix Composites: Microstructure, Design and Property Optimization; Springer: Singapore, 2017. [Google Scholar]

- Bakshi, S.R.; Lahiri, D.; Agarwal, A. Carbon nanotube reinforced metal matrix composites—A review. Int. Mater. Rev. 2010, 55, 41–64. [Google Scholar] [CrossRef]

- Hassan, S.F.; Gupta, M. Development of ductile magnesium composite materials using titanium as reinforcement. J. Alloys Compd. 2002, 345, 246–251. [Google Scholar] [CrossRef]

- Wong, W.L.E.; Gupta, M. Enhancing thermal stability, modulus and ductility of magnesium using molybdenum as reinforcement. Adv. Eng. Mater. 2005, 7, 250–256. [Google Scholar] [CrossRef]

- Shanthi, M.; Jayaramanavar, P.; Vyas, V.; Seenivasan, D.V.S.; Gupta, M. Effect of niobium particulate addition on the microstructure and mechanical properties of pure magnesium. J. Alloys Compd. 2012, 513, 202–207. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Loh, Z.; Sankaranarayanan, S.; Hamouda, A.M.S.; Gupta, M. Microstructure and Mechanical Properties of Mg-5Nb Metal-Metal Composite Reinforced with Nano SiC Ceramic Particles. Metals 2012, 2, 178–194. [Google Scholar]

- Tian, L.; Russell, A.; Riedemann, T.; Mueller, S.; Anderson, I. A deformation-processed Al-matrix/Ca-nanofilamentary composite with low density, high strength, and high conductivity. Mater. Sci. Eng. A 2017, 690, 348–354. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Monteiro, W.A. (Ed.) Light Metal Alloys Applications; InTech Open: London, UK, 2014. [Google Scholar]

- Janaki Ram, G.D.; Robinson, C.; Yang, Y.; Stucker, B.E. Use of ultrasonic consolidation for fabrication of multi-material structures. Rapid Prototyp. J. 2007, 13, 226–235. [Google Scholar] [CrossRef]

- Chen, M.A. Brief Overview of Bulk Metallic Glasses. Nat. Pub. Group Asia Mater. 2011, 3, 82–90. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Inoue, A. Bulk Metallic Glasses; CRC Press, Taylor-Francis Group: Boca Raton, FL, USA, 2011. [Google Scholar]

- Basu, J.; Ranganathan, S. Bulk Metallic Glasses: A New Class of Engineering Materials. Sadhana 2003, 28, 783–798. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Gupta, M. Metallic Amorphous Alloy Reinforcements in Light Metal Matrices; Springer Briefs in Materials; Springer: New York, NY, USA, 2015. [Google Scholar]

- Lee, M.; Kim, J.-H.; Park, J.; Kim, J.; Kim, W.; Kim, D. Fabrication of Ni-Nb-Ta metallic glass reinforced Al-based alloy matrix composites by infiltration casting process. Scr. Mater. 2004, 50, 1367–1371. [Google Scholar] [CrossRef]

- Scudino, S.; Ali, F.; Surreddi, K.; Prashanth, K.G.; Sakaliyska, M.; Eckert, J. Al-based metal matrix composites reinforced with nanocrystalline Al-Ti-Ni particles. J. Phys. Conf. Ser. 2010, 240, IOP1–IOP4. [Google Scholar] [CrossRef]

- Scudino, S.; Liu, G.; Prashanth, K.; Bartusch, B.; Surreddi, K.; Murty, B.; Eckert, J. Mechanical properties of Al-based metal matrix composites reinforced with Zr-based glassy particles produced by powder metallurgy. Acta Mater. 2009, 57, 2029–2039. [Google Scholar] [CrossRef]

- Yu, P.; Kim, K.B.; Das, J.; Baier, F.; Xu, W.; Eckert, J. Fabrication and mechanical properties of Ni–Nb metallic glass particle-reinforced Al-based metal matrix composite. Scr. Mater. 2006, 54, 1445–1450. [Google Scholar] [CrossRef]

- Khalil, K.A.; Almajid, A.A. Effect of high-frequency induction heat sintering conditions on the microstructure and mechanical properties of nanostructured magnesium/hydroxyapatite nanocomposites. Mater. Des. 2012, 36, 58–68. [Google Scholar] [CrossRef]

- Gupta, M.; Eugene, W.W.L. Microwaves and Metals; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Tun, K.S.; Gupta, M. Development of magnesium/(yttria+nickel) hybrid nanocomposites using hybrid microwave sintering: Microstructure and tensile properties. J. Alloys Compd. 2009, 487, 76–82. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials-development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Weglowski, M.S.; Pietras, A. Friction stir processing-Analysis of the process. Arch. Metall. Mater. 2011, 56, 779–788. [Google Scholar] [CrossRef]

- Mahoney, M.W.; Lynch, S.P. Friction-Stir Processing; Report; Rockwell Sci. Company LLC: Thousand Oaks, CA, USA, 2016. [Google Scholar]

- Saheb, N.; Iqbal, Z.; Khalil, A.; Hakeem, A.S.; Al Aqeeli, N.; Al-Qutub, T.L.A.; Kirchner, R. Spark Plasma Sintering of Metals and Metal Matrix Nanocomposites: A Review. J. Nanomater. 2012, 2012, 983470. [Google Scholar] [CrossRef]

- Dudina, D.V.; Georgarakis, K.; Li, Y.; Aljerf, M.; LeMoulec, A.; Yavari, A.R.; Inoue, A. A magnesium alloy matrix composite reinforced with metallic glass. Compos. Sci. Technol. 2009, 69, 2734–2736. [Google Scholar] [CrossRef]

- Dudina, D.V.; Georgarakis, K.; Aljerf, M.; Li, Y.; Braccini, M.; Yavari, A.R.; Inoue, A. Cu-based metallic glass particle additions to significantly improve overall compressive properties of an Al alloy. Compos. Part A 2010, 41, 1551–1557. [Google Scholar] [CrossRef]

- Aljerf, M.; Georgarakis, K.; Louzguine-Luzgin, D.; Mulec, A.L.; Inoue, A.; Yavari, A.R. Strong and light metal matrix composites with metallic glass particulate reinforcement. Mater. Sci. Eng. A 2012, 532, 325–330. [Google Scholar] [CrossRef]

- Li, S.; Xie, G.Q.; Louzguine-Luzgin, D.V.; Sato, M.; Inoue, A. Microwave-Induced Sintering of Cu-Based Metallic Glass Matrix Composites in a Single-Mode 915-MHz Applicator. Metall. Mater. Trans. A 2011, 42, 1463–1467. [Google Scholar] [CrossRef]

- Li, S.; Louzguine-Luzgin, D.V.; Xie, G.; Sato, M.; Inoue, A. Development of novel metallic glass/polymer composite materials by microwave heating in a separated H-field. Mater. Lett. 2010, 64, 235–238. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Gupta, S.; Sankaranarayanan, S.; Sahu, S.; Gupta, M. Structural and mechanical properties of Ni60Nb40 amorphous alloy particle reinforced Al-based composites produced by microwave assisted rapid sintering. Mater. Sci. Eng. A 2013, 581, 119–127. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Sahu, S.; Sankaranarayanan, S.; Gupta, S.; Gupta, M. Development of novel Mg-Ni60Nb40 amorphous particle reinforced composites with enhanced hardness and compressive response. Mater. Des. 2014, 53, 849–855. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Hemanth Shankar, V.; Jayalakshmi, S.; Bau, N.Q.; Gupta, M. Development of high performance magnesium composites using Ni50Ti50 metallic glass reinforcement and microwave sintering approach. J. Alloys Compd. 2015, 627, 192–199. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Agrawal, N.; Jayalakshmi, S.; Bau, N.Q.; Gupta, M. Synthesis and characterization of novel magnesium materials containing copper-titanium based (Cu50Ti50) amorphous alloy particles. Magnesium Technology. In Proceedings of the TMS Annual Meeting, Orlando, FL, USA, 15–19 March 2015. [Google Scholar]

- Bau, N.Q.; Nai, M.L.S.; Sankaranarayanan, S.; Jayalakshmi, S.; Wong, W.L.E.; Gupta, M. Microstructure and damping characteristics of Mg and its composites containing metastable Al85Ti15 particle. J Compos. Mater. 2016, 50, 2565–2573. [Google Scholar]

- Nafar Dastgerdi, J.; Marquis, G.; Sankaranarayanan, S.; Gupta, M. Fatigue crack growth behavior of amorphous particulate reinforced composites. Compos. Struct. 2016, 15, 782–790. [Google Scholar] [CrossRef]

- Khoramkhorshid, S.; Alizadeh, M.; Taghvaei, A.H.; Scudino, S. Microstructure and mechanical properties of Al-based metal matrix composites reinforced with Al84Gd6Ni7Co3 glassy particles produced by accumulative roll bonding. Mater. Des. 2016, 90, 137–144. [Google Scholar] [CrossRef]

- Anghelus, A.; Avettand-Fènoël, M.N.; Cordier, C.; Taillard, R. Microstructural evolution of aluminum/Al-Ni–Sm glass forming alloy laminates obtained by controlled accumulative roll bonding. J. Alloys Compd. 2015, 631, 209–218. [Google Scholar] [CrossRef]

- Fujii, H.; Sun, Y.F.; Inada, K.; Ji, Y.S.; Yokoyama, Y.; Kimura, H.; Inoue, A. Fabrication of Fe-Based metallic glass particle reinforced Al-based composite materials by friction stir processing. Mater. Trans. 2011, 52, 1634–1640. [Google Scholar] [CrossRef]

- Wang, Z.; Georgarakis, K.; Nakayama, K.S.; Li, Y.; Tsarkov, A.A.; Xie, G.; Dudina, D.; Louzguine-Luzgin, D.V.; Yavari, A.R. Microstructure and mechanical behavior metallic glass fiber reinforced Al alloy matrix composites. Nat. Sci. Rep. 2016, 6, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Kainer, K.U. Metal Matrix Composites; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Ceschini, L.; Dahle, A.; Gupta, M.; Jarfors, A.; Jayalakshmi, S.; Morri, A.; Rotundo, F.; Toschi, S.; Arvind Singh, R. Aluminum and Magnesium Metal Matrix Nanocomposites; Springer: Singapore, 2016. [Google Scholar]

- Arsenault, R.J.; Shi, N. Dislocation generation due to differences between the coefficients of thermal expansion. Mater. Sci. Eng. 1986, 81, 75–87. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect. Mater. Sci. Eng. A 2012, 531, 112–118. [Google Scholar] [CrossRef]

- So, K.P.; Liu, X.; Kushima, A.; Park, J.G.; Kim, H.S.; Ogata, S.; Lee, Y.H.; Li, J. Ton-scale metal–carbon nanotube composite: The mechanism of strengthening while retaining tensile ductility. Extreme Mech. Lett. 2016, 8, 245–250. [Google Scholar] [CrossRef]

- Tian, L.; Russell, A.; Anderson, I. A dislocation-based, strain-gradient-plasticity strengthening model for deformation processed metal-metal composites. J. Mater. Sci. 2014, 49, 2787–2794. [Google Scholar] [CrossRef]

- Rupert, T.J.; Trenkle, J.C.; Schuh, C.S. Solid solution strengthening Enhanced solid solution effects on the strength of nanocrystalline alloys. Acta Mater. 2011, 59, 1619–1631. [Google Scholar] [CrossRef]

| No. | Material | Normalized Strength (Strength Ratio) | Processing Method and Remarks |

|---|---|---|---|

| 1 | Al-Si-Mg + 20% Ni-Nb-Ta | 1.3 | Squeeze Infiltration [18] |

| 2 | Pure Al + 40% Ni-Nb | 1.15 | Blend-Compact-Sinter [21] (High Volume Fraction) |

| 3 | Al + 40% Zr-Ti-Nb-Cu-Ni-Al Al + 60% Zr-Ti-Nb-Cu-Ni-Al | 1.2 2.0 | Blend-Compact-Sinter [20] (High Volume Fractions) |

| 4 | Mg + 15% Zr-Nb-Cu-Ni-Al | 2.27 | High Frequency Induction Sintering [29] |

| 5 | Al-Mg + 15% Cu-Zr-Ti | 2.8 | High Frequency Induction Sintering [30] |

| 6 | Al 6061 + 15% [(Fe-Co)-B-Si]-Nb | 3.5 | High Frequency Induction Sintering [31] |

| 7 | Pure Al + 25% Ni-Nb | 1.9 | Bidirectional Microwave Sintering [34] |

| 8 | Pure Mg + 5% Ni-Nb | 1.85 | Bidirectional Microwave Sintering [35] |

| 9 | Pure Mg + 20% Ni-Ti | 1.8 | Bidirectional Microwave Sintering [36] |

| 10 | Al7075 + 15% Zr-Cu-Ni-Al | 2.17 | Spark Plasma Sintering [43] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jayalakshmi, S.; Singh, R.A.; Gupta, M. Metallic Glasses as Potential Reinforcements in Al and Mg Matrices: A Review. Technologies 2018, 6, 40. https://doi.org/10.3390/technologies6020040

Jayalakshmi S, Singh RA, Gupta M. Metallic Glasses as Potential Reinforcements in Al and Mg Matrices: A Review. Technologies. 2018; 6(2):40. https://doi.org/10.3390/technologies6020040

Chicago/Turabian StyleJayalakshmi, S., R. Arvind Singh, and Manoj Gupta. 2018. "Metallic Glasses as Potential Reinforcements in Al and Mg Matrices: A Review" Technologies 6, no. 2: 40. https://doi.org/10.3390/technologies6020040