Tribological Behavior of Spark Plasma Sintered Aluminum-Graphene Composites at Room and Elevated Temperatures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Powder Preparation

2.2. Spark Plasma Sintering (SPS)

2.3. Microstructural Characterization

2.4. Tribologial Tests

3. Results and Discussion

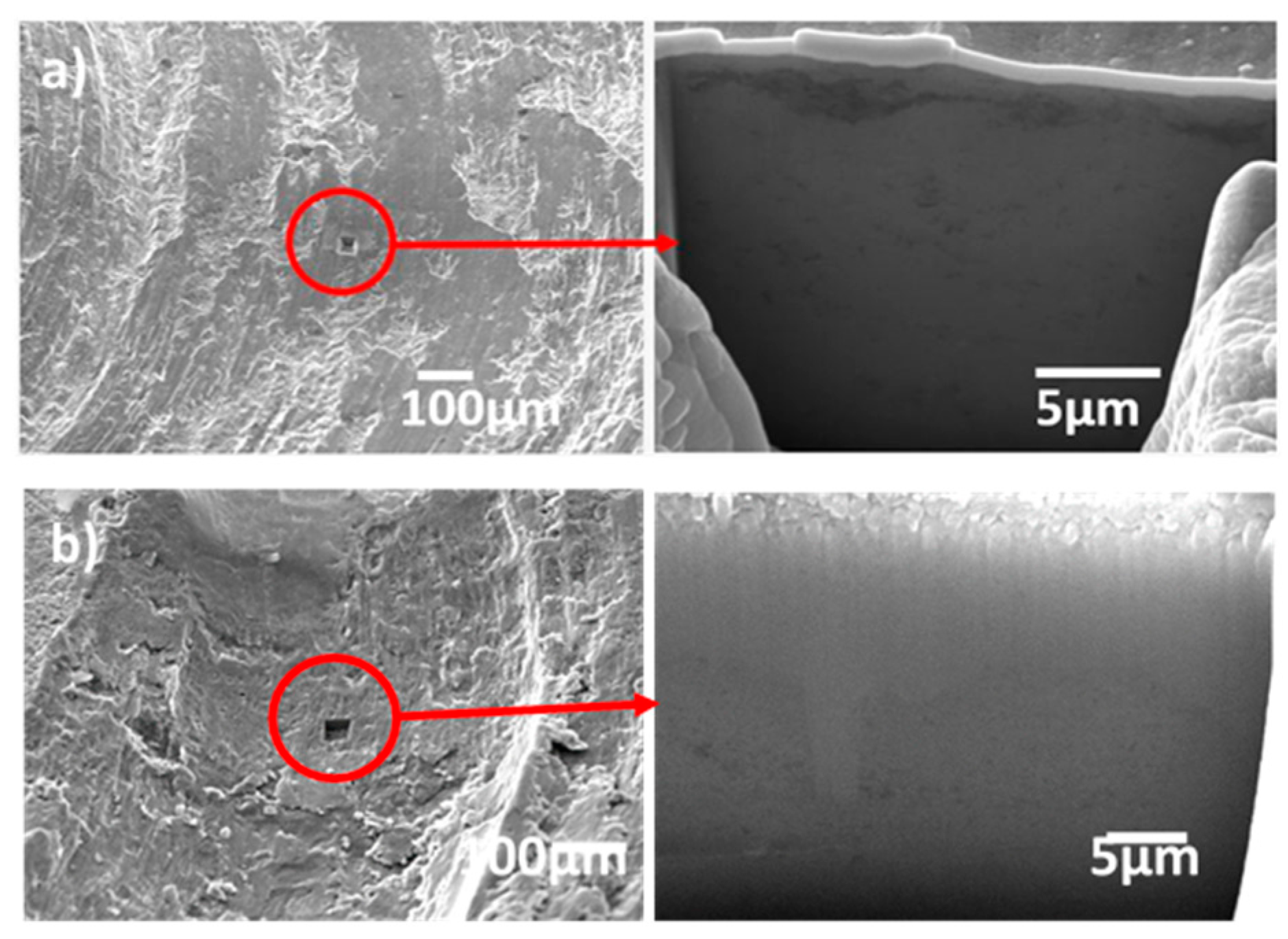

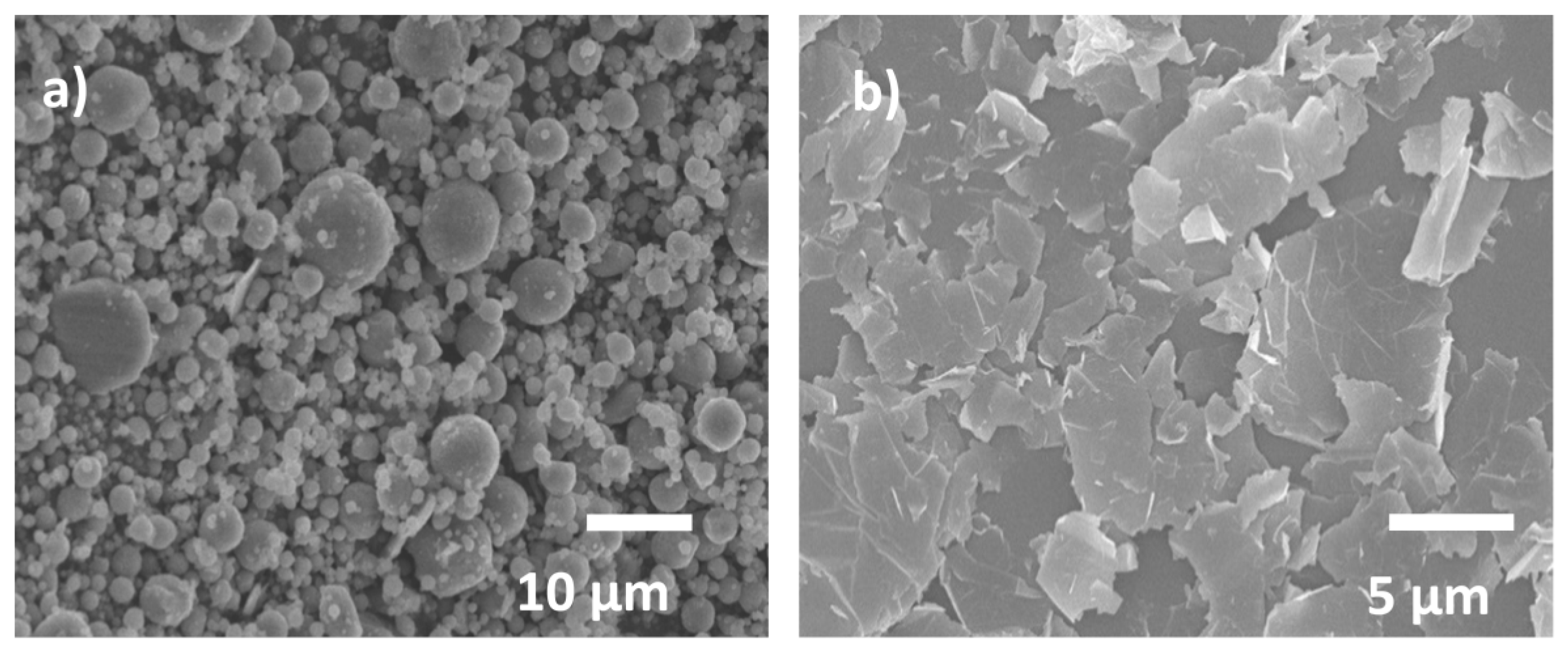

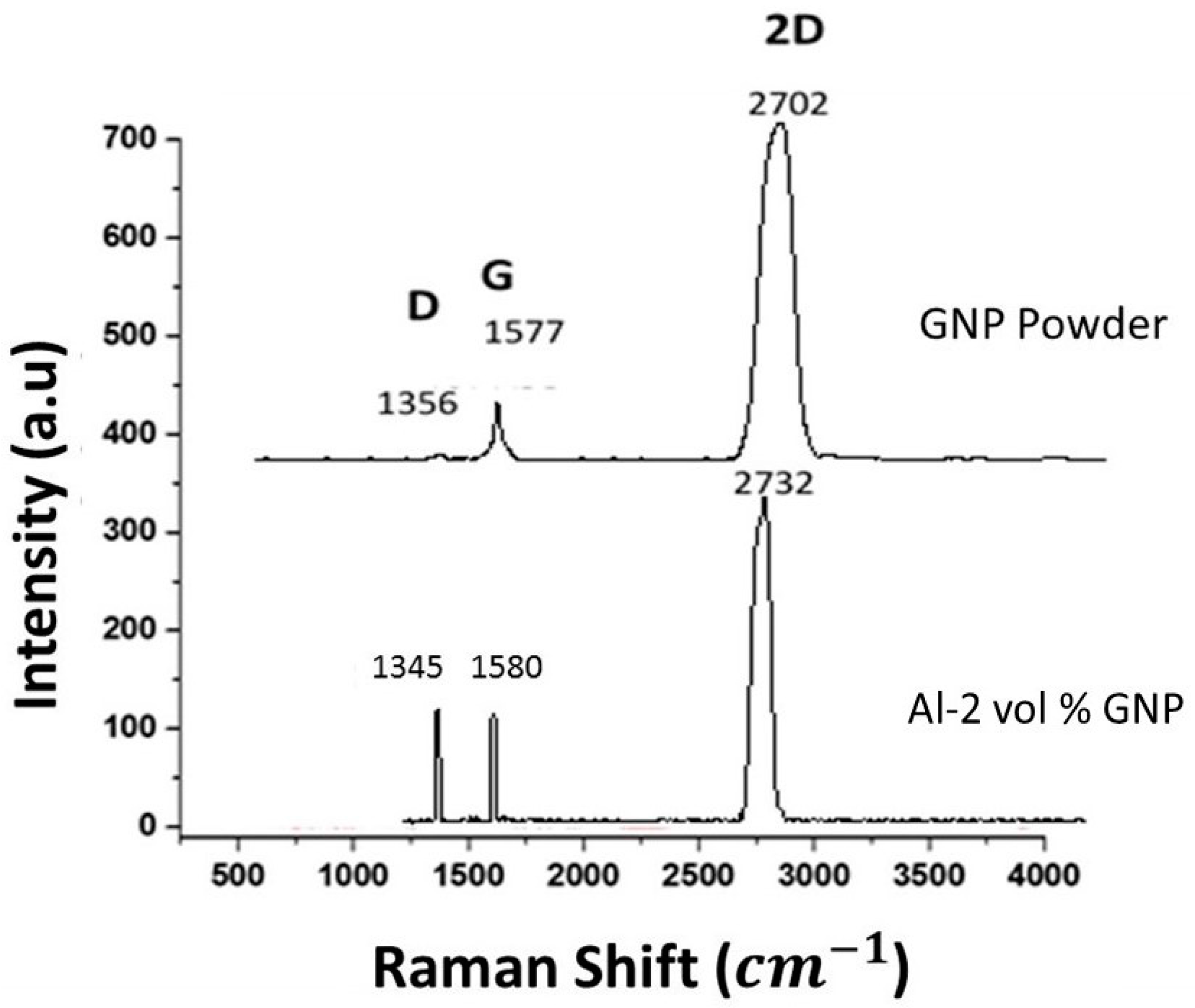

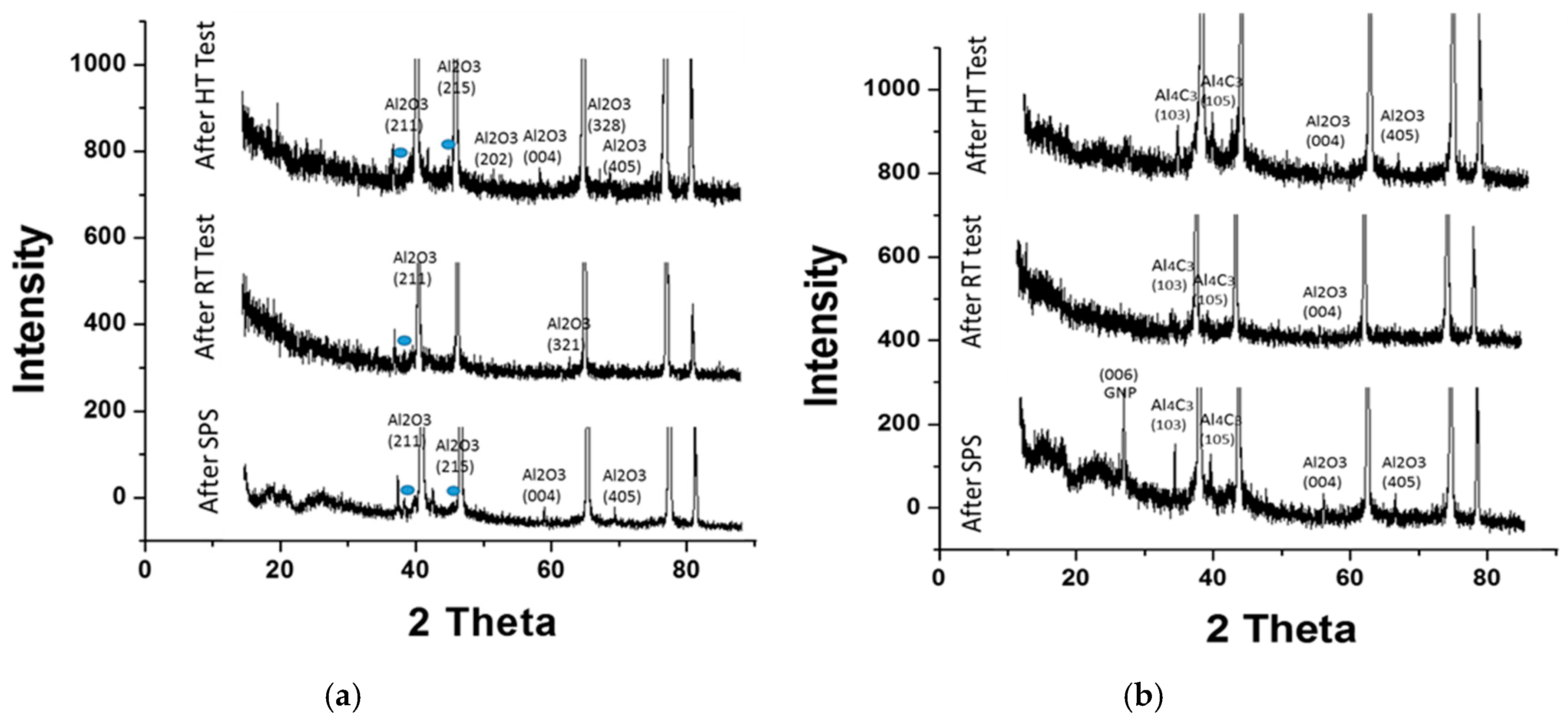

3.1. Microstructure and Phases

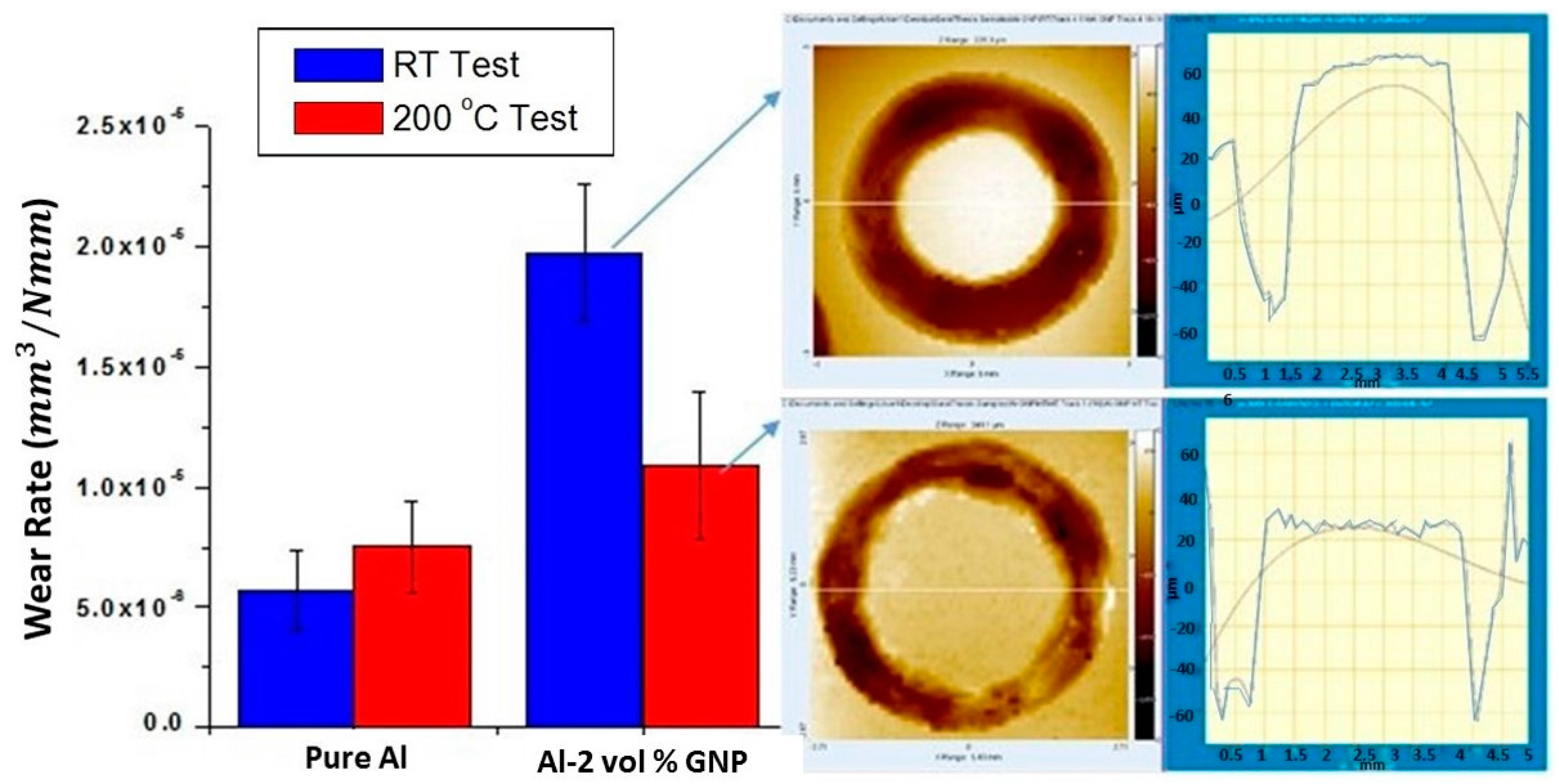

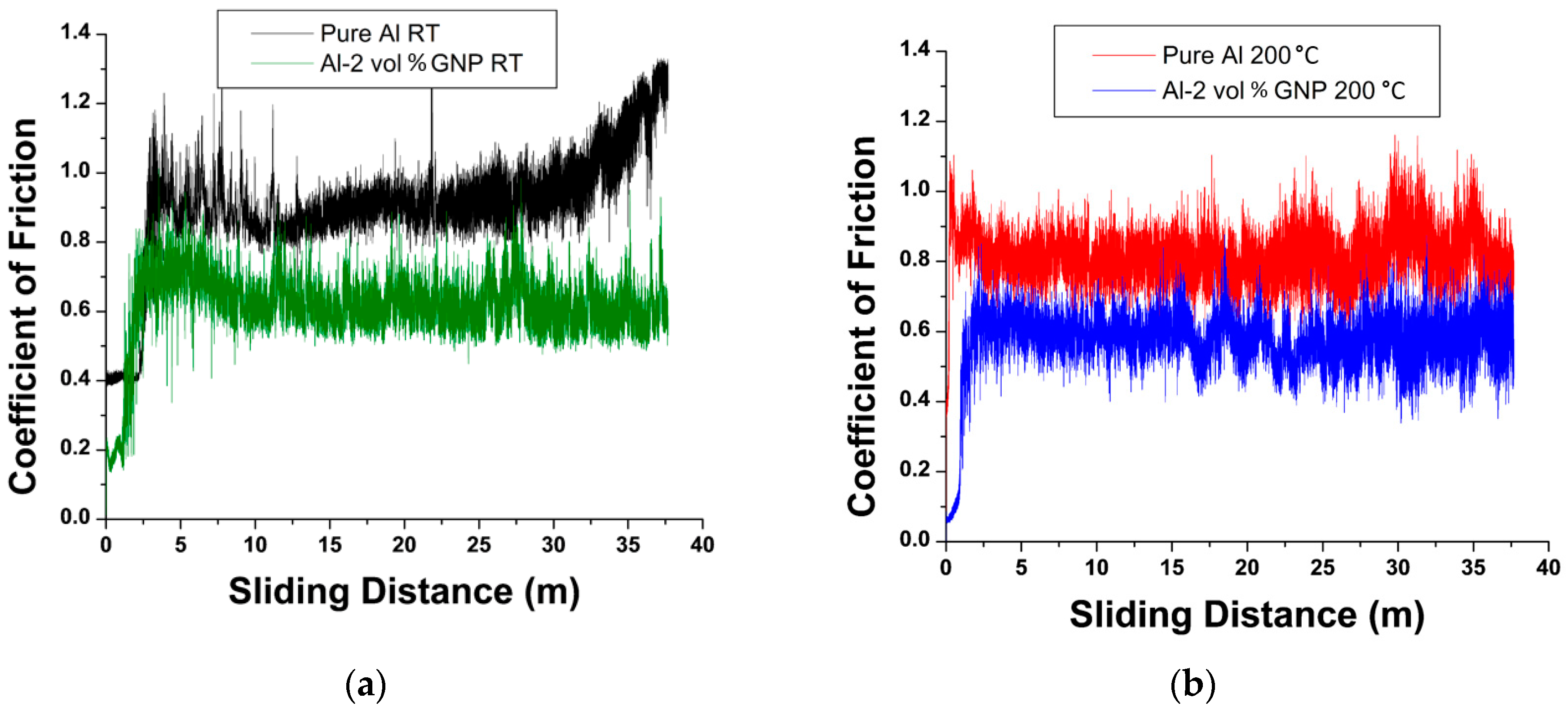

3.2. Wear Rate and Coefficient of Friction

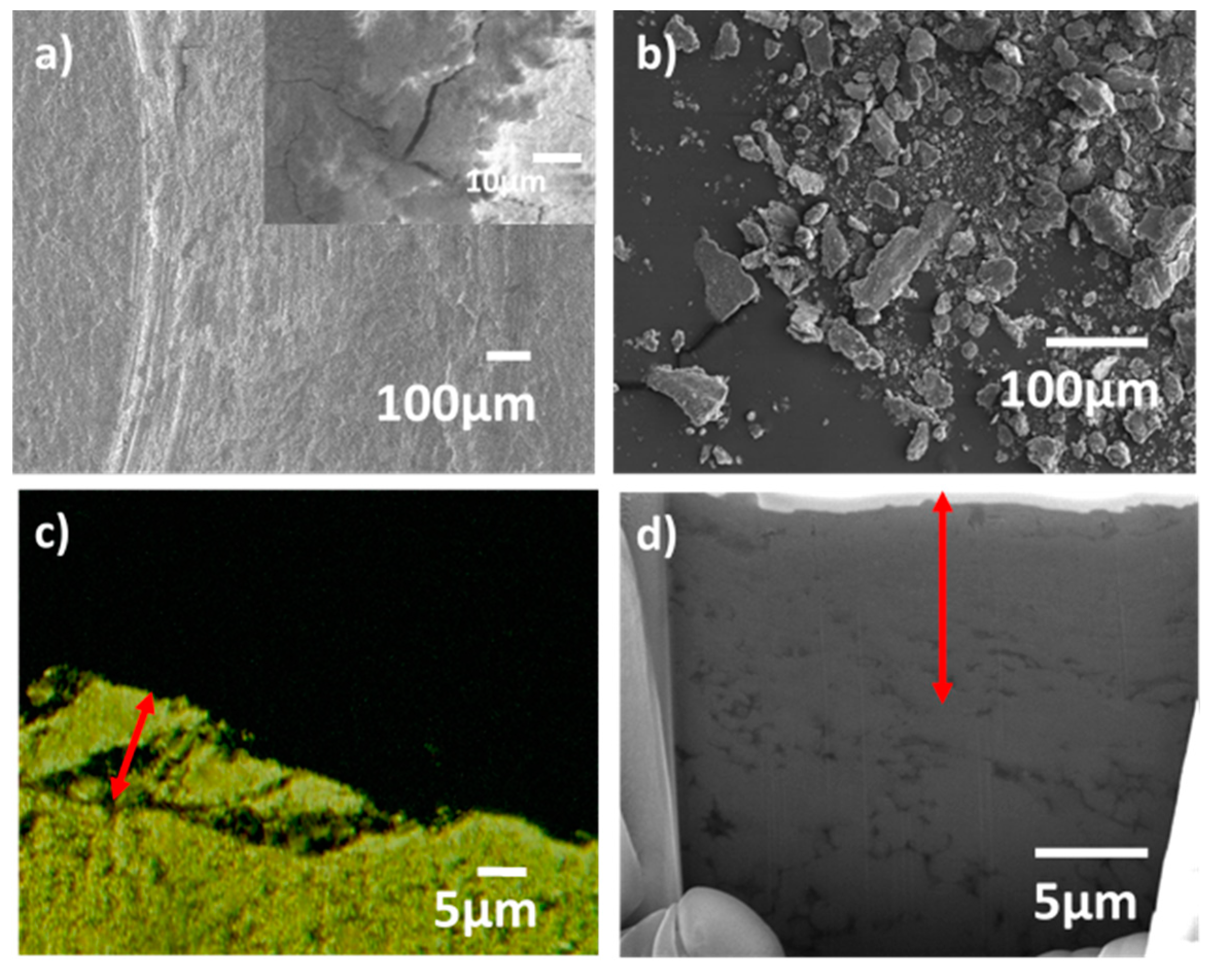

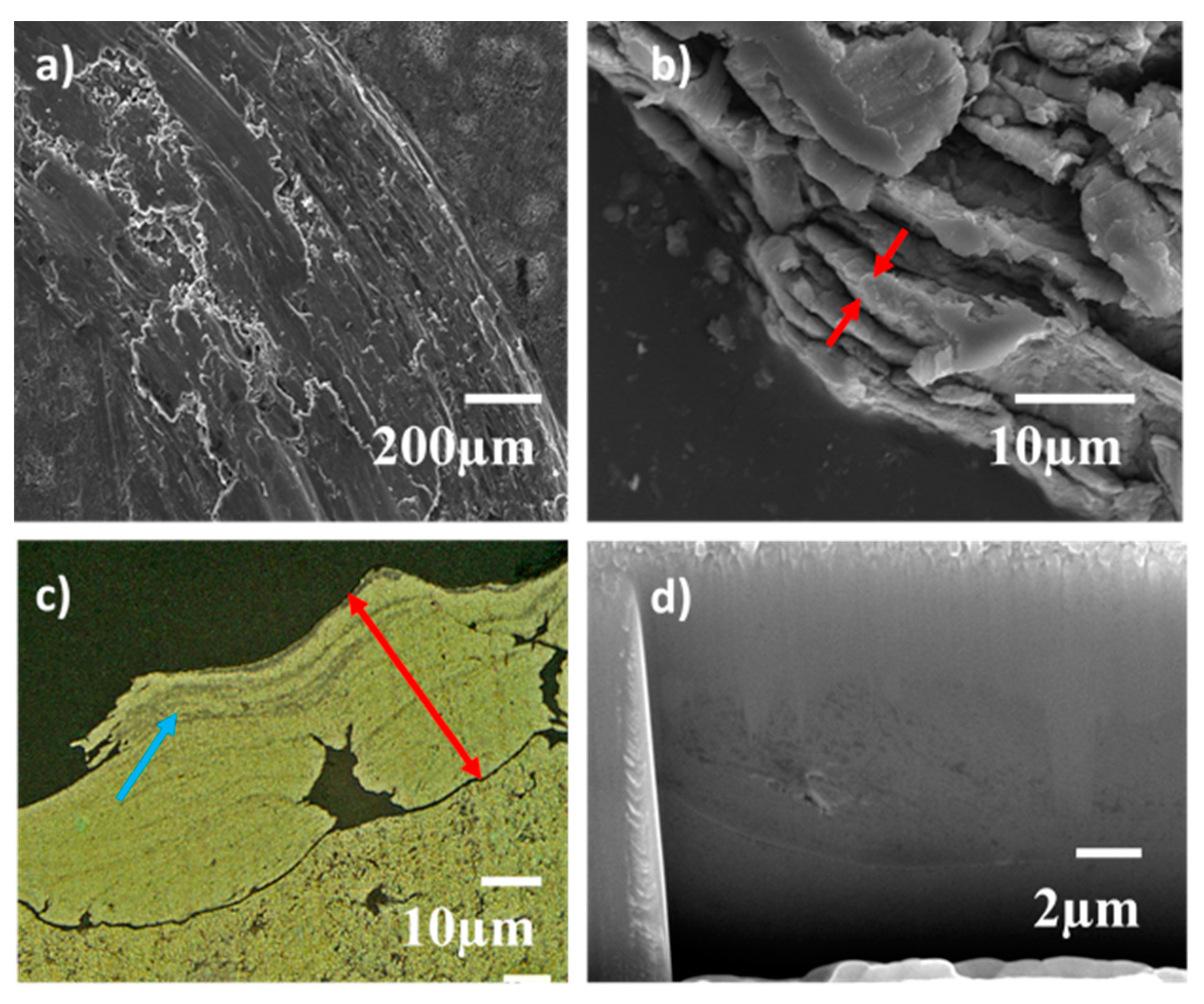

3.3. Wear Mechanism at Room Temperature

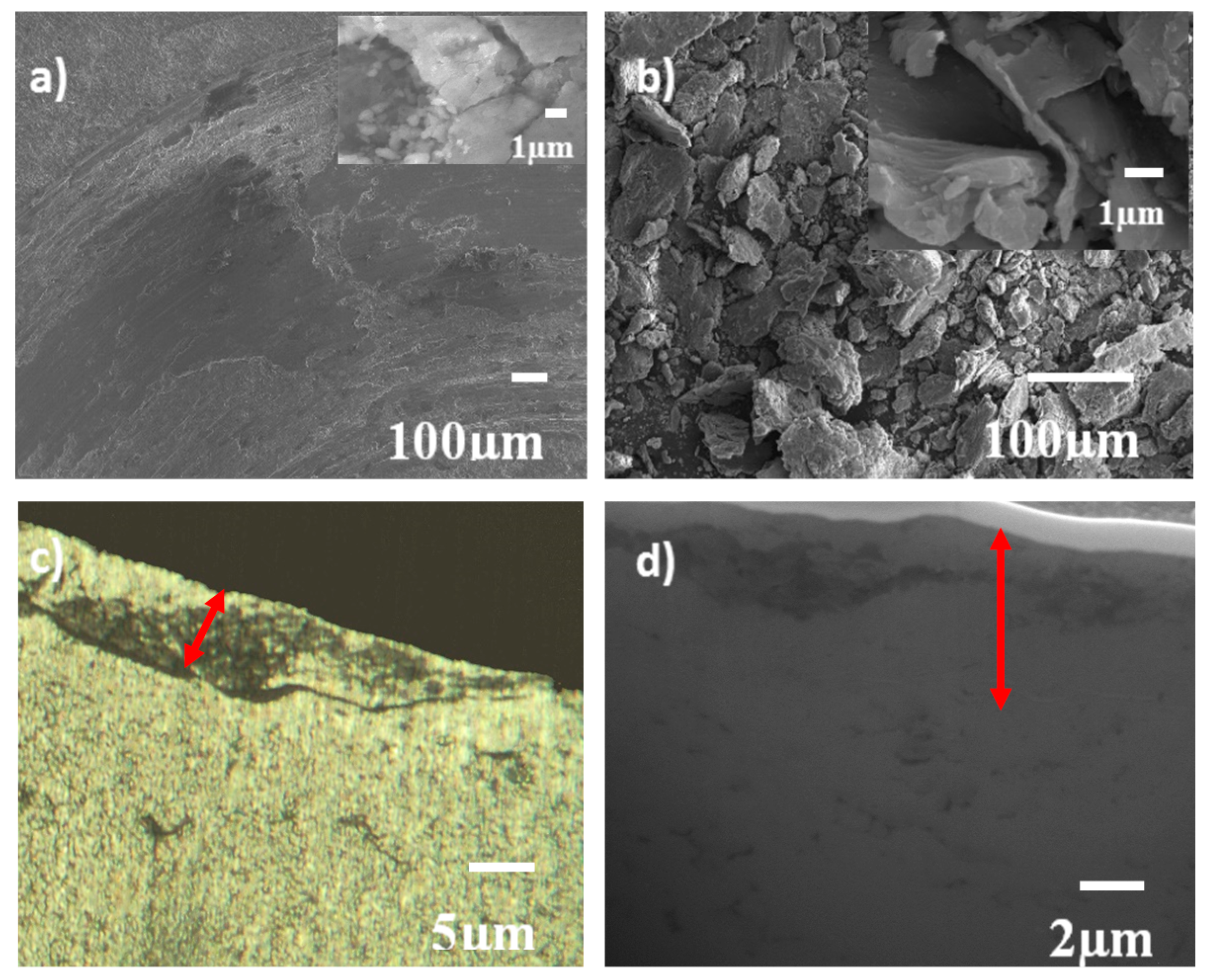

3.4. Wear Mechanisms at 200 °C

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Holmberg, K.; Andersson, P.; Erdemir, Ali. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Evans, C. Strategy for energy conservation through tribology. Amer. Soc. Mech. Engrs. 1977, 6, 170–172. [Google Scholar] [CrossRef]

- Blau, P.J. Fifty years of research on the wear of metals. Tribol. Int. 1997, 30, 321–331. [Google Scholar] [CrossRef]

- Jirang, C.U.I.; Roven, H.J. Recycling of automotive aluminum. Trans. Nonferrous Met. Soc. China 2010, 20, 2057–2063. [Google Scholar]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminum alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Cole, G.S.; Sherman, A.M. Lightweight materials for automotive applications. Mater. Charact. 1995, 1, 3–9. [Google Scholar] [CrossRef]

- Hu, Y.-Z.; Ma, T.-B. Tribology of nanostructured surfaces. In Comprehensive Nanoscience and Technology, 1st ed.; Academic Press: Cambridge, MA, USA, 2011; pp. 383–418. [Google Scholar]

- Menezes, P.; Nosonovsky, M.; Ingole, S.P.; Kailas, S.V.; Lovell, M.R. Tribology for Scientists and Engineers: From Basics to Advanced Concepts; Springer: Berlin, Germany, 2013. [Google Scholar]

- Whitener, K.E.; Sheehan, P.E. Graphene synthesis. Diam. Relat. Mater. 2014, 46, 25–34. [Google Scholar] [CrossRef]

- Filleter, T.; McChesney, J.L.; Bostwick, A.; Rotenberg, E.; Emtsev, K.V.; Seyller, T.; Horn, K.; Bennewitz, R. Friction and dissipation in epitaxial graphene films. Phys. Rev. Lett. 2009, 102, 086102. [Google Scholar] [CrossRef] [PubMed]

- Bastwros, M.; Kim, G.-Y.; Zhu, C.; Zhang, K.; Wang, S.; Tang, X.; Wang, X. Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Composites 2014, 60, 111–118. [Google Scholar] [CrossRef]

- Zhai, W.; Shi, X.; Wang, M.; Xu, Z.; Yao, J.; Song, S.; Wang, Y. Grain refinement: A mechanism for graphene nanoplatelets to reduction friction and wear of Ni3Al matrix self-lubricating composites. Wear 2014, 310, 33–40. [Google Scholar] [CrossRef]

- Porwal, H.; Tatarko, P.; Saggar, R.; Grasso, S.; Manid, M.K.; Dlouhý, I.; Dusza, J.; Reece, M.J. Tribological properties of silica-graphene nano-platelet composites. Ceram. Int. 2014, 40, 12067–12074. [Google Scholar] [CrossRef]

- Das, A.; Harimkar, S.P. Effect of graphene nanoplate and silicon carbide nanoparticle reinforcement on mechanical and tribological properties of spark plasma sintered magnesium matrix composites. J. Mater. Sci. Technol. 2014, 30, 1059–1070. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Composites 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Bartolucci, S.F.; Paras, J.; Rafiee, M.A.; Rafiee, J.; Lee, S.; Kapoor, D.; Koratkar, N. Graphene–aluminum nanocomposites. Mater. Sci. Eng. A 2011, 528, 7933–7937. [Google Scholar] [CrossRef]

- Pu, J.; Wan, S.; Zhao, W.; Mo, Y.; Zhang, X.; Wang, L.; Xue, Q. Preparation and tribological study of functionalized graphene nanocomposite ultrathin lubrication films on si substrates. J. Phys. Chem. C 2011, 115, 13275–13284. [Google Scholar] [CrossRef]

- Tabandeh-Khorshid, M.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Tribological performance of self-lubricating aluminum matrix nanocomposites: Role of graphene nanoplatelets. Int. J. Eng. Sci. Technol. 2016, 19, 463–469. [Google Scholar] [CrossRef]

- Nieto, A.; Bisht, A.; Zhang, C.; Lahiri, D.; Agarwal, A. Graphene reinforced metal and ceramic composites—A Review. Int. Mater. Rev. 2016. [Google Scholar] [CrossRef]

- Priest, M.; Taylor, C.M. Automobile engine tribology—approaching the surface. Wear 2000, 241, 193–203. [Google Scholar] [CrossRef]

- Priest, M.; Dowson, D.; Taylor, C.M. Predictive wear modelling of lubricated piston rings in a diesel engine. Wear 1999, 231, 89–101. [Google Scholar] [CrossRef]

- Donnet, C.; Erdemir, A. Historical developments and new trends in tribological and solid lubricant coatings. Surf. Coat. Technol. 2004, 180–181, 76–84. [Google Scholar] [CrossRef]

- Sandoz-Rosado, E.J. The Tribological Behavior of Graphene and Its Role as a Protective Coating. Ph.D. Thesis, Columbia University, New York, NY, USA, 2013. [Google Scholar]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 8, 981–988. [Google Scholar] [CrossRef]

- Deuis, R.L.; Subramanian, C.; Yellup, J.M. Dry sliding wear of aluminum composites-A review. Compos. Sci. Technol. 1997, 57, 415–435. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W.; Stachowiak, G. Experimental Methods in Tribology; (Tribology Series) Elsevier: Amsterdam, Netherlands, 2004. [Google Scholar]

- Ratoi, M.; Niste, V.B.; Walker, J.; Zekonyte, J. Mechanism of action of WS2 lubricant nanoadditives in high preassure contacts. Tribol. Lett. 2013, 52, 81–91. [Google Scholar] [CrossRef]

- Iwai, Y.; Yoneda, H.; Honda, T. Sliding wear behavior of Sic whisker-reinforced aluminum composite. Wear 1995, 181–183, 594–602. [Google Scholar] [CrossRef]

- Kuo, W.-S.; Tai, N.-H.; Chang, T.-W. Deformation and fracture in graphene nanosheets. Composites 2013, 51, 56–61. [Google Scholar] [CrossRef]

- Nieto, A.; Kumar, A.; Lahiri, D.; Zhang, C.; Seal, S.; Agarwal, A. Oxidation behavior of graphene nanoplatelets reinforced tantalum carbide composites in high temperature plasma flow. Carbon 2014, 67, 398–408. [Google Scholar] [CrossRef]

| Sample | Wear Rate*-RT | Wear Rate*-200 °C | COF-RT | COF-200 °C |

|---|---|---|---|---|

| Pure Al | 5.7 ± 1.6 | 7.5 ± 1.9 | 0.87 ± 0.04 | 0.82 ± 0.03 |

| Al-2 vol % GNP | 19 ± 0.2 | 11 ± 0.3 | 0.79 ± 0.09 | 0.69 ± 0.10 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rengifo, S.; Zhang, C.; Harimkar, S.; Boesl, B.; Agarwal, A. Tribological Behavior of Spark Plasma Sintered Aluminum-Graphene Composites at Room and Elevated Temperatures. Technologies 2017, 5, 4. https://doi.org/10.3390/technologies5010004

Rengifo S, Zhang C, Harimkar S, Boesl B, Agarwal A. Tribological Behavior of Spark Plasma Sintered Aluminum-Graphene Composites at Room and Elevated Temperatures. Technologies. 2017; 5(1):4. https://doi.org/10.3390/technologies5010004

Chicago/Turabian StyleRengifo, Sara, Cheng Zhang, Sandip Harimkar, Benjamin Boesl, and Arvind Agarwal. 2017. "Tribological Behavior of Spark Plasma Sintered Aluminum-Graphene Composites at Room and Elevated Temperatures" Technologies 5, no. 1: 4. https://doi.org/10.3390/technologies5010004