Dry Sliding Wear Behavior of Spark Plasma Sintered Fe-Based Bulk Metallic Glass/Graphite Composites

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

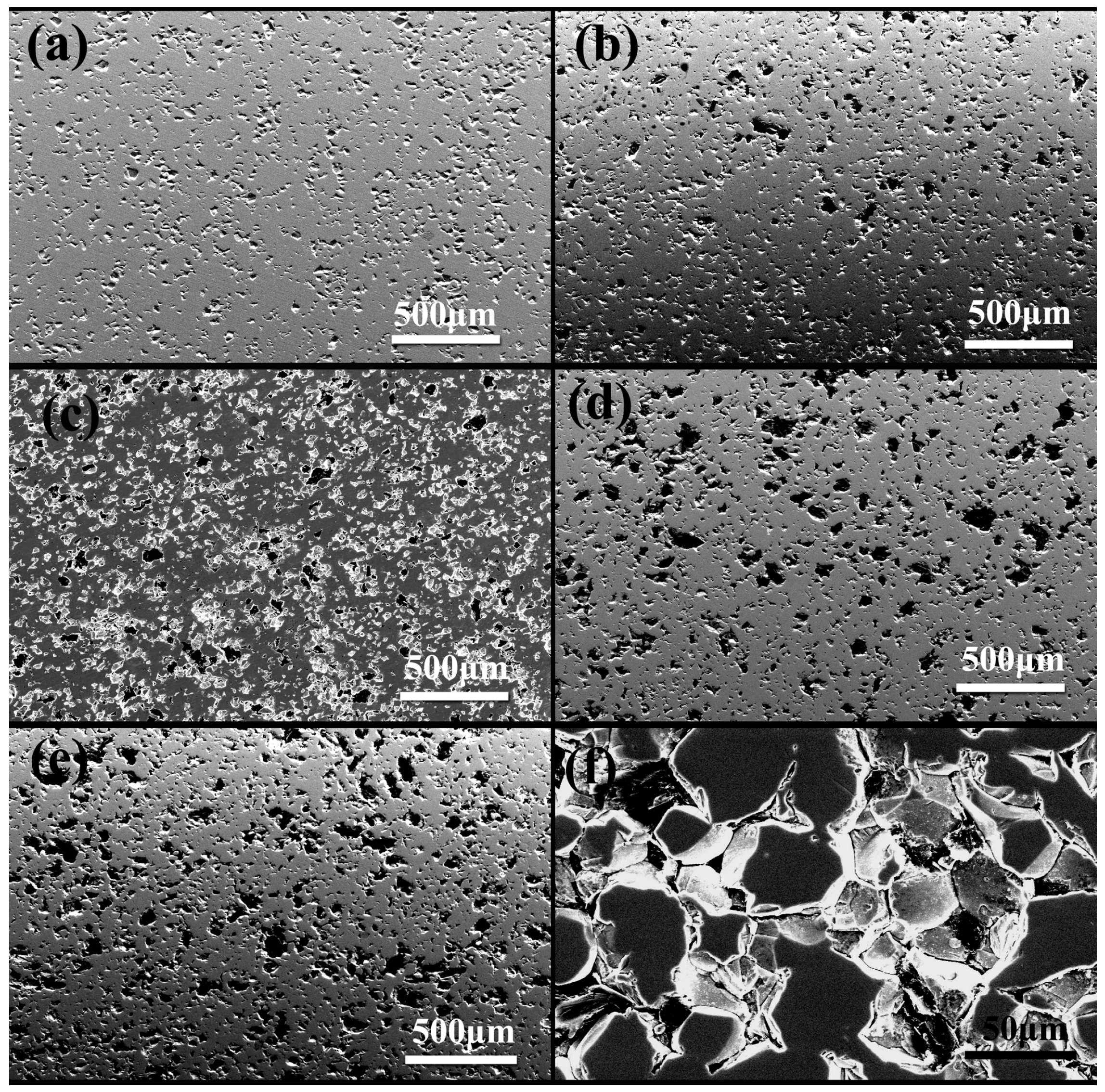

3.1. Microstructure of BMG/Graphite Composite

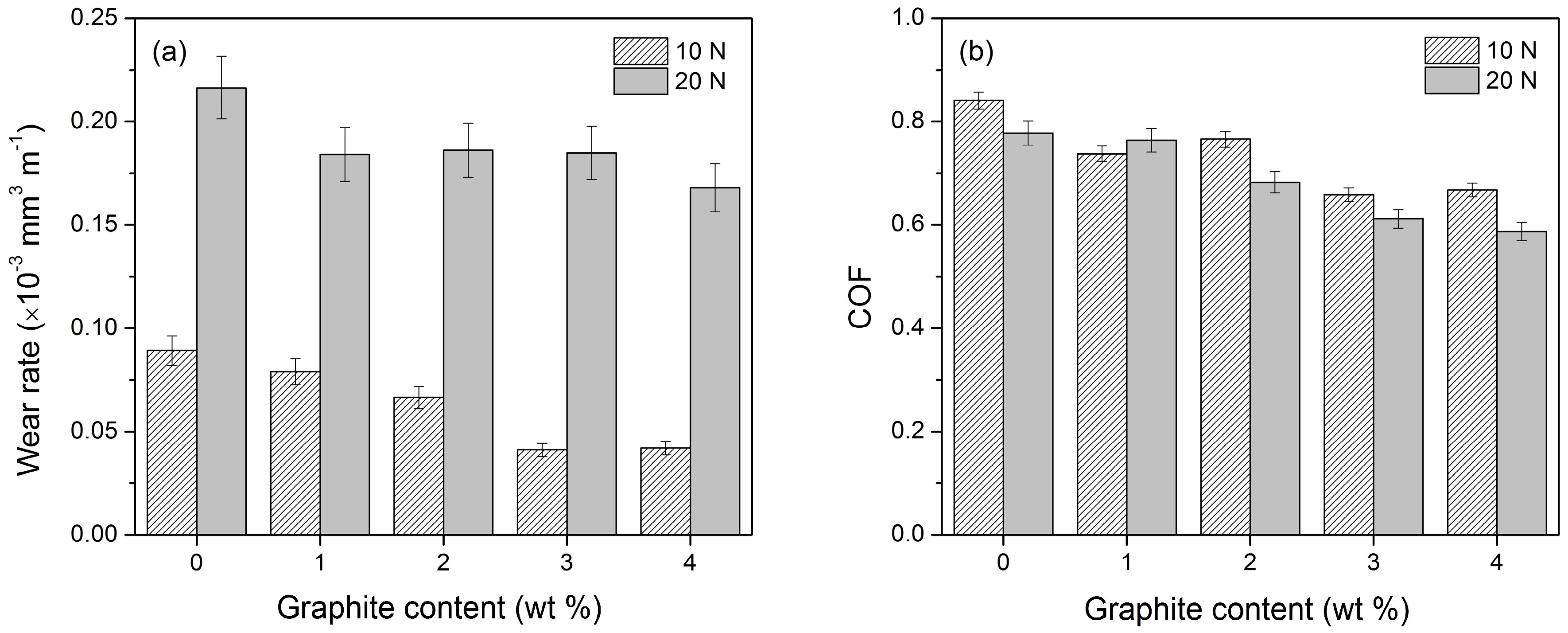

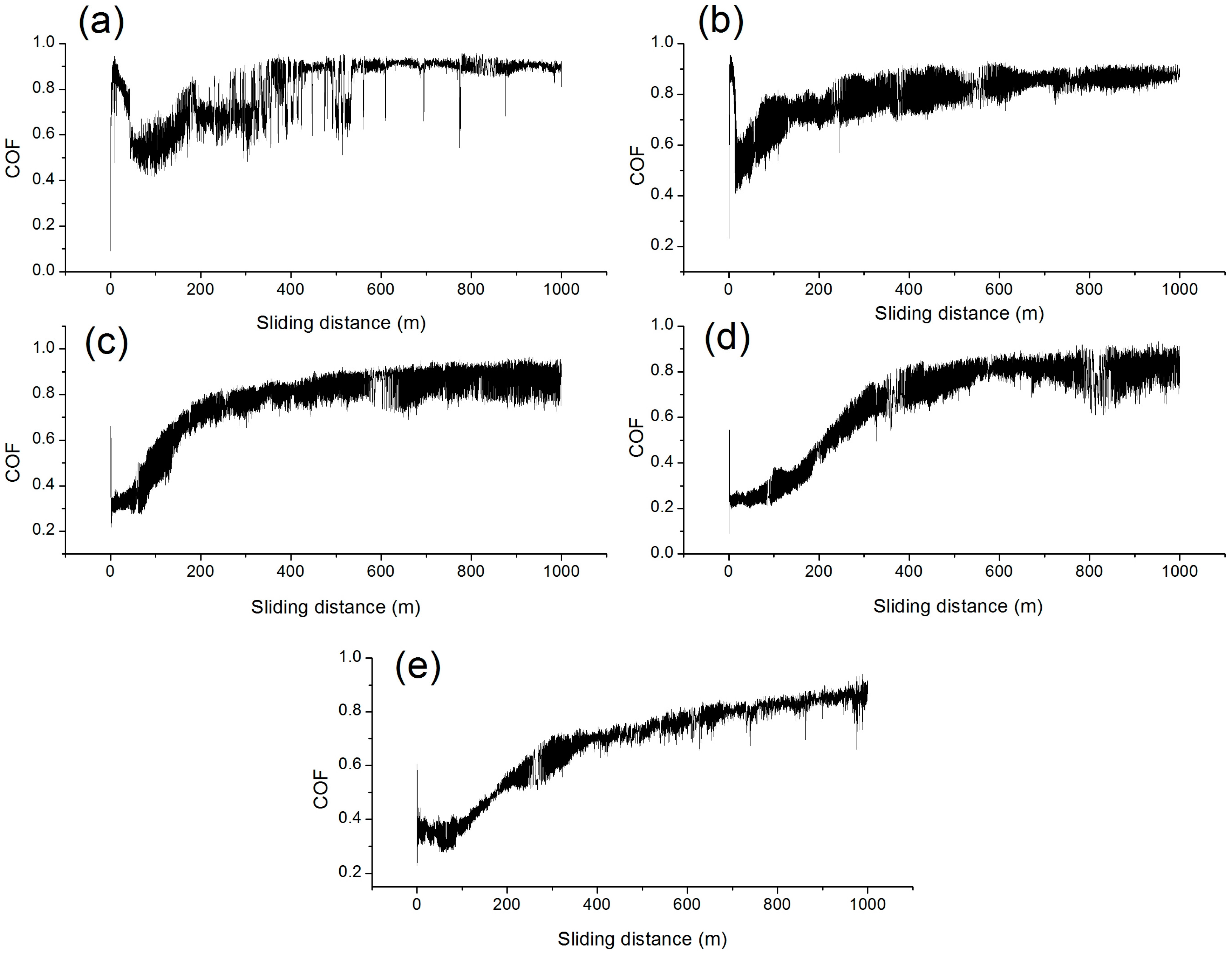

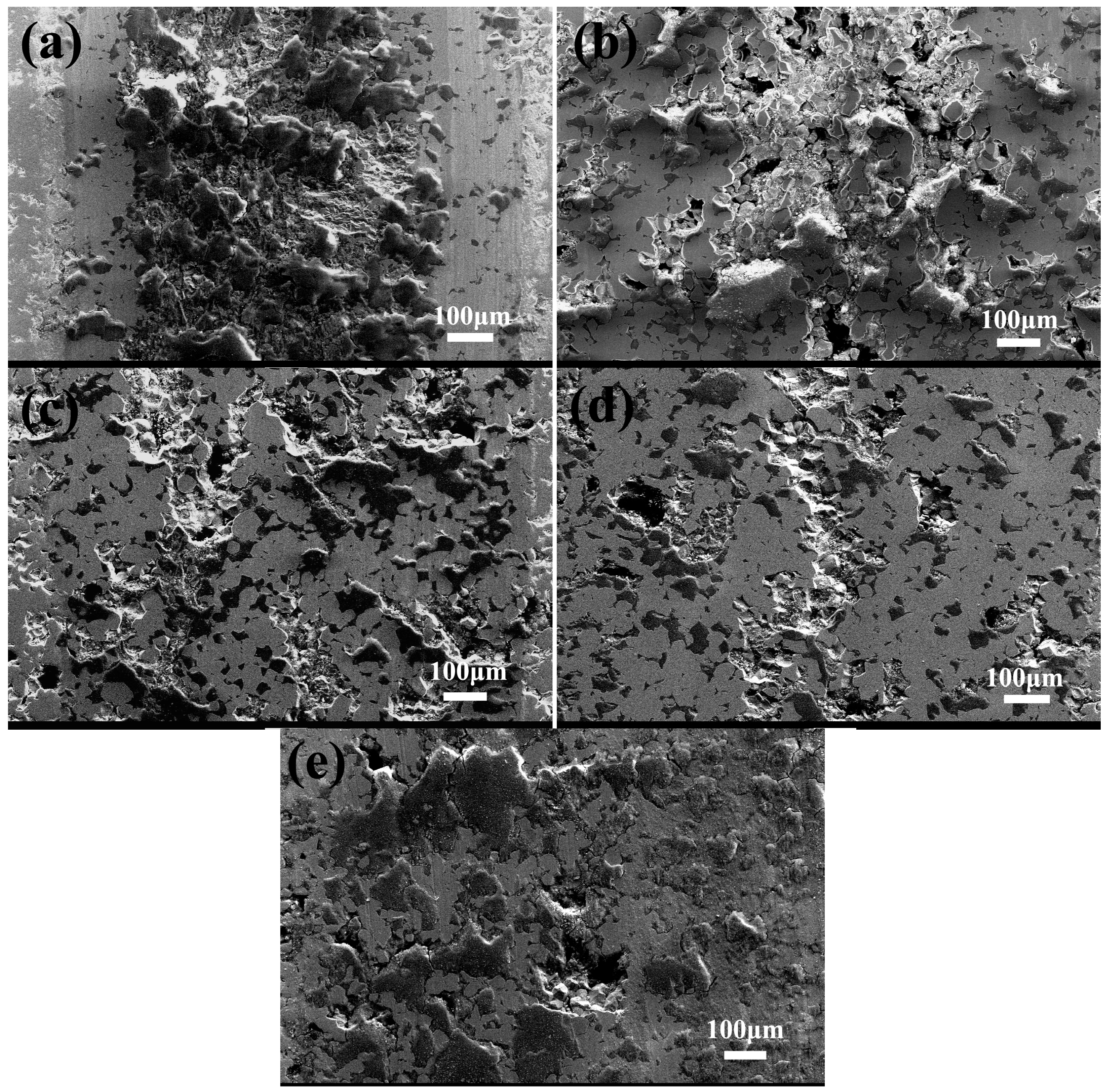

3.2. Hardness and Tribology Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ashby, M.F.; Greer, A.L. Metallic glasses as structural materials. Scripta Mater. 2006, 54, 321–326. [Google Scholar] [CrossRef]

- Schroers, J.; Kumar, G.; Hodges, T.M.; Chan, S.; Kyriakides, T.R. Bulk metallic glasses for biomedical applications. JOM 2009, 61, 21–29. [Google Scholar] [CrossRef]

- Schroers, J.; Pham, Q.; Desai, A. Thermoplastic forming of bulk metallic glass—A technology for mems and microstructure fabrication. J. Microelectromech. Syst. 2007, 16, 240–247. [Google Scholar] [CrossRef]

- Löffler, J.F. Bulk metallic glasses. Intermetallics 2003, 11, 529–540. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B.; Nishiyama, N. Development and applications of late transition metal bulk metallic glasses. In Bulk Metallic Glasses; Miller, M., Liaw, P., Eds.; Springer US: Boston, MA, USA, 2008; pp. 1–25. [Google Scholar]

- Singh, A.; Bakshi, S.R.; Agarwal, A.; Harimkar, S.P. Microstructure and tribological behavior of spark plasma sintered iron-based amorphous coatings. Mater. Sci. Eng. A 2010, 527, 5000–5007. [Google Scholar] [CrossRef]

- Basu, A.; Samant, A.N.; Harimkar, S.P.; Majumdar, J.D.; Manna, I.; Dahotre, N.B. Laser surface coating of Fe–Cr–Mo–Y–B–C bulk metallic glass composition on AISI 4140 steel. Surf. Coat. Technol. 2008, 202, 2623–2631. [Google Scholar] [CrossRef]

- Sahasrabudhe, H.; Bandyopadhyay, A. Laser processing of Fe based bulk amorphous alloy coating on zirconium. Surf. Coat. Technol. 2014, 240, 286–292. [Google Scholar] [CrossRef]

- Prakash, B. Abrasive wear behaviour of Fe, Co and Ni based metallic glasses. Wear 2005, 258, 217–224. [Google Scholar] [CrossRef]

- Greer, A.L.; Rutherford, K.L.; Hutchings, I.M. Wear resistance of amorphous alloys and related materials. Int. Mater. Rev. 2002, 47, 87–112. [Google Scholar] [CrossRef]

- Hodge, A.M.; Nieh, T.G. Evaluating abrasive wear of amorphous alloys using nanoscratch technique. Intermetallics 2004, 12, 741–748. [Google Scholar] [CrossRef]

- Paul, T.; Alavi, S.H.; Biswas, S.; Harimkar, S.P. Microstructure and wear behavior of laser clad multi-layered Fe-based amorphous coatings on steel substrates. Lasers Manuf. Mater. Process. 2015, 2, 231–241. [Google Scholar] [CrossRef]

- Singh, A.; Paital, S.R.; Andapally, A.; Dahotre, N.B.; Harimkar, S.P. Densification behavior and wear response of spark plasma sintered iron-based bulk amorphous alloys. Adv. Eng. Mater. 2012, 14, 400–407. [Google Scholar] [CrossRef]

- Siegrist, M.E.; Amstad, E.D.; Löffler, J.F. Tribological properties of graphite-and ZrC-reinforced bulk metallic glass composites. Intermetallics 2007, 15, 1228–1236. [Google Scholar] [CrossRef]

- Matthews, D.; Ocelik, V.; De Hosson, J.T.M. Tribological and mechanical properties of high power laser surface-treated metallic glasses. Mater. Sci. Eng. A 2007, 471, 155–164. [Google Scholar] [CrossRef]

- Harimkar, S.P.; Paital, S.R.; Wang, G.; Liaw, P.K.; Dahotre, N.B. Periodically laser patterned Fe–B–Si amorphous ribbons: Phase evolution and mechanical behavior. Adv. Eng. Mater. 2011, 13, 955–960. [Google Scholar] [CrossRef]

- Ji, X.; Alavi, S.H.; Harimkar, S.P. High-temperature sliding wear behavior of Zr-based bulk amorphous alloys. JOM 2015, 67, 1578–1584. [Google Scholar] [CrossRef]

- Wang, Y.; Li, G.; Shi, Z.; Liu, M.; Zhang, X.; Liu, Y. Effects of graphite addition on the microstructure and properties of laser cladding Zr–Al–Ni–Cu amorphous coatings. J. Alloys Compd. 2014, 610, 713–717. [Google Scholar] [CrossRef]

- Roy, D.; Singh, S.S.; Basu, B.; Lojkowski, W.; Mitra, R.; Manna, I. Studies on wear behavior of nano-intermetallic reinforced al-base amorphous/nanocrystalline matrix in situ composite. Wear 2009, 266, 1113–1118. [Google Scholar] [CrossRef]

- Gloriant, T. Microhardness and abrasive wear resistance of metallic glasses and nanostructured composite materials. J. Non-Cryst. Solids 2003, 316, 96–103. [Google Scholar] [CrossRef]

- Huang, K.J.; Yan, L.; Wang, C.S.; Xie, C.S.; Zhou, C.R. Wear and corrosion properties of laser cladded Cu47Ti34Zr11Ni8/SiC amorphous composite coatings on AZ91D magnesium alloy. Trans. Nonferrous Met. Soc. China 2010, 20, 1351–1355. [Google Scholar] [CrossRef]

- Yue, T.M.; Su, Y.P. Laser cladding of sic reinforced Zr65Al7.5Ni10Cu17.5amorphous coating on magnesium substrate. Appl. Surf. Sci. 2008, 255, 1692–1698. [Google Scholar] [CrossRef]

- Lu, Z.P.; Liu, C.T.; Thompson, J.R.; Porter, W.D. Structural amorphous steels. Phys. Rev. Lett. 2004, 92, 245503. [Google Scholar] [CrossRef] [PubMed]

- Ponnambalam, V.; Poon, S.J.; Shiflet, G.J. Fe-based bulk metallic glasses with diameter thickness larger than one centimeter. J. Mater. Res. 2004, 19, 1320–1323. [Google Scholar] [CrossRef]

- Graeve, O.A.; Kanakala, R.; Kaufman, L.; Sinha, K.; Wang, E.; Pearson, B.; Rojas-George, G.; Farmer, J.C. Spark plasma sintering of Fe-based structural amorphous metals (SAM) with Y2O3 nanoparticle additions. Mater. Lett. 2008, 62, 2988–2991. [Google Scholar] [CrossRef]

- Harimkar, S.P.; Paital, S.R.; Singh, A.; Aalund, R.; Dahotre, N.B. Microstructure and properties of spark plasma sintered Fe–Cr–Mo–Y–B–C bulk metallic glass. J. Non-Cryst. Solids 2009, 355, 2179–2182. [Google Scholar] [CrossRef]

- Singh, A.; Harimkar, S.P. Spark plasma sintering of in situ and ex situ iron-based amorphous matrix composites. J. Alloys Compd. 2010, 497, 121–126. [Google Scholar] [CrossRef]

- Singh, A.K.; Alavi, S.H.; Paital, S.R.; Dahotre, N.B.; Harimkar, S.P. Structural relaxation and nanocrystallization-induced laser surface hardening of Fe-based bulk amorphous alloys. JOM 2014, 66, 1080–1087. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, X.; Alavi, S.H.; Harimkar, S.P. Dry Sliding Wear Behavior of Spark Plasma Sintered Fe-Based Bulk Metallic Glass/Graphite Composites. Technologies 2016, 4, 27. https://doi.org/10.3390/technologies4030027

Ji X, Alavi SH, Harimkar SP. Dry Sliding Wear Behavior of Spark Plasma Sintered Fe-Based Bulk Metallic Glass/Graphite Composites. Technologies. 2016; 4(3):27. https://doi.org/10.3390/technologies4030027

Chicago/Turabian StyleJi, Xiulin, S. Habib Alavi, and Sandip P. Harimkar. 2016. "Dry Sliding Wear Behavior of Spark Plasma Sintered Fe-Based Bulk Metallic Glass/Graphite Composites" Technologies 4, no. 3: 27. https://doi.org/10.3390/technologies4030027