1. Introduction

In the last few decades, the applications of underwater robotic vehicles (URVs) [

1] have experienced tremendous growth in industry. Many are used for underwater inspection of sub-sea cables, oil and gas installations, and pipelines. However for search and rescue (SAR) applications involving launch and recovery tasks [

2,

3,

4,

5], an autonomous underwater vehicle (AUV) has become useful due to more reliance on sensor technology [

6], rather than crewed workboats, remotely-operated vehicle (ROV), and expensive on-site labour. However, human intervention is often required for the initial launching and recovery operation in the event of high sea state [

7,

8] and in limited visibility at night. Most AUVs can home into dedicated stationary docking stations; the majority of the docking hoops for recovery purposes do not possess all of the required hardware and software or perhaps even the manoeuvrability to dock the AUV. Instead, an AUV with a docking system designed into the ROV manned by a surface ship becomes an alternative solution due to its robustness via hard-wire links and human-in-the-loop control during the initial launching and unforeseen faults [

9] during recovery.

In order to accomplish the recovery task successfully, we need to build a functional engineering prototype to demonstrate its feasibility to use a docking system to autonomously align the docking hoop to the path of the AUV. However, the modelling of an open-frame ROV can be quite challenging in terms of the accuracy of the model, time and costs spent in test facility. The hydrodynamic parameters and underwater behaviour of the ROV are identified using a lab-based experimental test approach such as towing tank, planar motion mechanism (PMM), marine dynamic test facility, pulley system [

10], free-decaying experiment [

11,

12] and free-decaying method using springs [

13]. In addition, these test methods, including a system identification (SI) method using adaptive and least square-based estimation to estimate the parameters of the ROV [

14,

15,

16] were performed. However, these methods involved extensive sea trials, time, and costs for a mature vehicle design instead of a design that is in the prototype stage.

With the current computer technology, the computational fluid dynamic (CFD) technology has been widely used for URV [

17,

18,

19,

20,

21,

22]. The CFD simulation have been successful in simulating the streamlined underwater vehicles such as an AUV but not on a ROV. This is mainly due to the availability of empirical formulae for these streamlined bodies for the AUV. Although, there is no actual error stated in those papers published in literature, approximately 30% error could be inherent for such simulation. Hence, the prediction of the hydrodynamic parameters of the ROV is still difficult due to the complexity of its geometry.

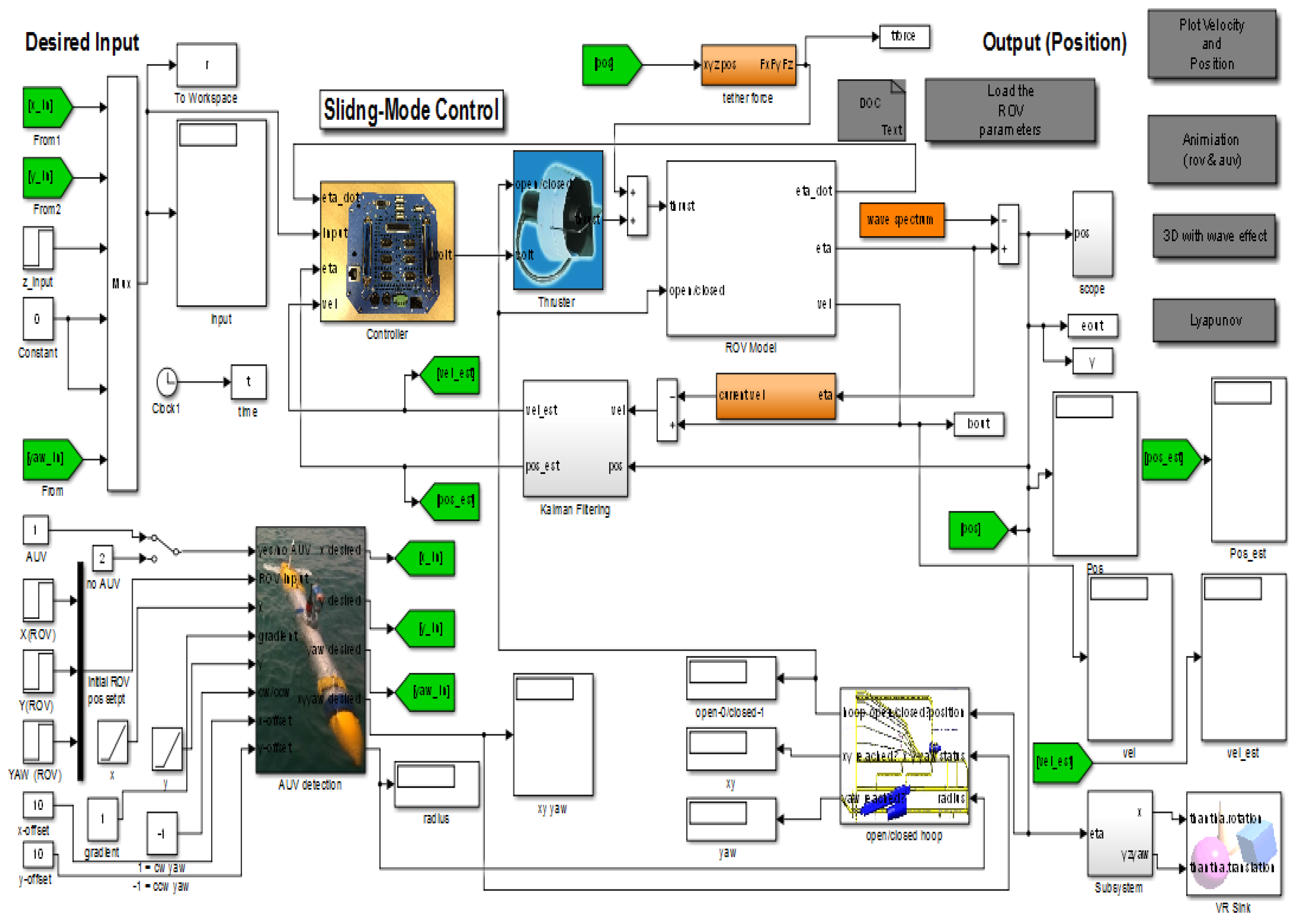

In order to circumvent the problems due to model uncertainty and test constraints, this paper presents the applications of numerical modelling using CFD software, Simulink™ toolboxes for sliding-mode controller design, and a Python-based GUI platform to the final test of AUVDH control. The proposed robust simulation-to-design process helps to overcome the model uncertainty due to the model accuracy and the uncertain external disturbances. Instead of having an exact model of high accuracy [

23,

24], a sufficient simulated model is reasonable for most control purposes. The proposed sliding-mode design will be simulated and implemented on an actual AUVDH.

The paper is organized as follows. The ROV modelling is shown in

Section 2. It is followed by the AUVDH simulation platform and graphical user interface (GUI) design for testing in

Section 3 and

Section 4, respectively. Results and discussion are shown in

Section 5. Lastly,

Section 6 concludes the paper.

2. ROV Model

Modelling dynamic equations of the ROV is usually the first step before the computer simulation. In this section, the basic design of the ROV is described followed by the ROV modelling and simulation. The parameters of the ROV are tabulated in

Table 1. The ROV tasks include launch and recovery of the AUV. The ROV has six thruster inputs for six degrees of freedoms (DOFs) (

i.e., surge, sway, heave, roll, pitch, and yaw velocity) with a high degree of cross-coupling between them. There is also a suite of sensors for position and velocity measurements, namely Inertial Measurement Unit (IMU), depth sensors, and DVL (Doppler Velocity Log). Prior to ROV modelling, the following assumptions are made. There are, namely:

The ROV is a rigid body and is fully submerged once in water;

Water is assumed to be ideal fluid that is incompressible, inviscid, and irrotational;

The ROV is slow moving for operation such as pipeline inspection;

The Earth-fixed frame of reference is inertial;

The tether dynamics attached to the ROV is modelled as 3D Boundary Value Problems (BVP) [

25] with end force estimation at the ROV’s centre of gravity (CG). The end point coordinate coincides with the CG of the ROV. The tether is designed to be neutrally buoyant and to operate with sufficient slack (or remain less taut) so that minimal disturbance loads are transmitted to the vehicle;

Sea current and waves are modelled as disturbances to the ROV.

Table 1.

Linear (KL) and quadratic damping (KQ) coefficients of ROV in surge, sway, heave, and yaw [

26].

Table 1.

Linear (KL) and quadratic damping (KQ) coefficients of ROV in surge, sway, heave, and yaw [26].

| Direction | Surge | Sway | Heave | Yaw |

|---|

| Parameter | KL | KQ | KL | KQ | KL | KQ | KL | KQ |

| STAR CCM+ | 3.221 | 105.3 | 3.291 | 139.6 | 5.682 | 273.8 | 0 | 6.079 |

The ROV model is conventionally represented by a six DOF, nonlinear set of first order differential equations of motion, which may be integrated numerically to yield vehicle linear and angular velocities, given suitable initial conditions. The vehicle is considered as a six DOF free body in space with mass and inertia, being acted on by numerous forces. Two reference frames [

1] are used to describe the vehicles states, one being inertial frame (or Earth-fixed frame), one being local body-fixed frame with its origin coincident with the vehicle’s centre of gravity, and the three principle axes in the vehicle’s surge, sway, and heave directions. For marine vehicles, the six DOF are conventionally defined by the following vectors (by Society of Naval Architects and Marine Engineers):

: position and orientation (Euler angles) in inertia frame;

: linear and angular velocities in body-fixed frame;

: forces and moments acting on the vehicle in body-fixed frame.

The external force and moment vector τ includes the hydrodynamic forces and moments due to damping and inertial of surrounding fluid known as added mass, and restoring force and moment. The mathematical model of an underwater vehicle can be expressed, with respect to a local body-fixed reference frame, by nonlinear equations of motion in matrix form [

1]:

where

is the body-fixed velocity vector,

is the Earth-fixed vector,

is the inertia matrix for rigid body and added mass, respectively,

is the gravitational and buoyancy vector,

is the Coriolis and centripetal matrix for a rigid body and added mass, respectively,

is the linear and quadratic damping matrix respectively. The input force and moment vector

relates the thrust output vector

with the thruster configuration matrix

,

is the dynamics of each thruster that converts the input voltage command

into thrust to propel the vehicle.

is the Euler transformation matrix which brings the inertia frame into alignment with the body-fixed frame:

and

The transformation is singular for . However, for the ROV, this problem does not exist because the vehicle is neither designed nor required to pitch anywhere near instantaneously.

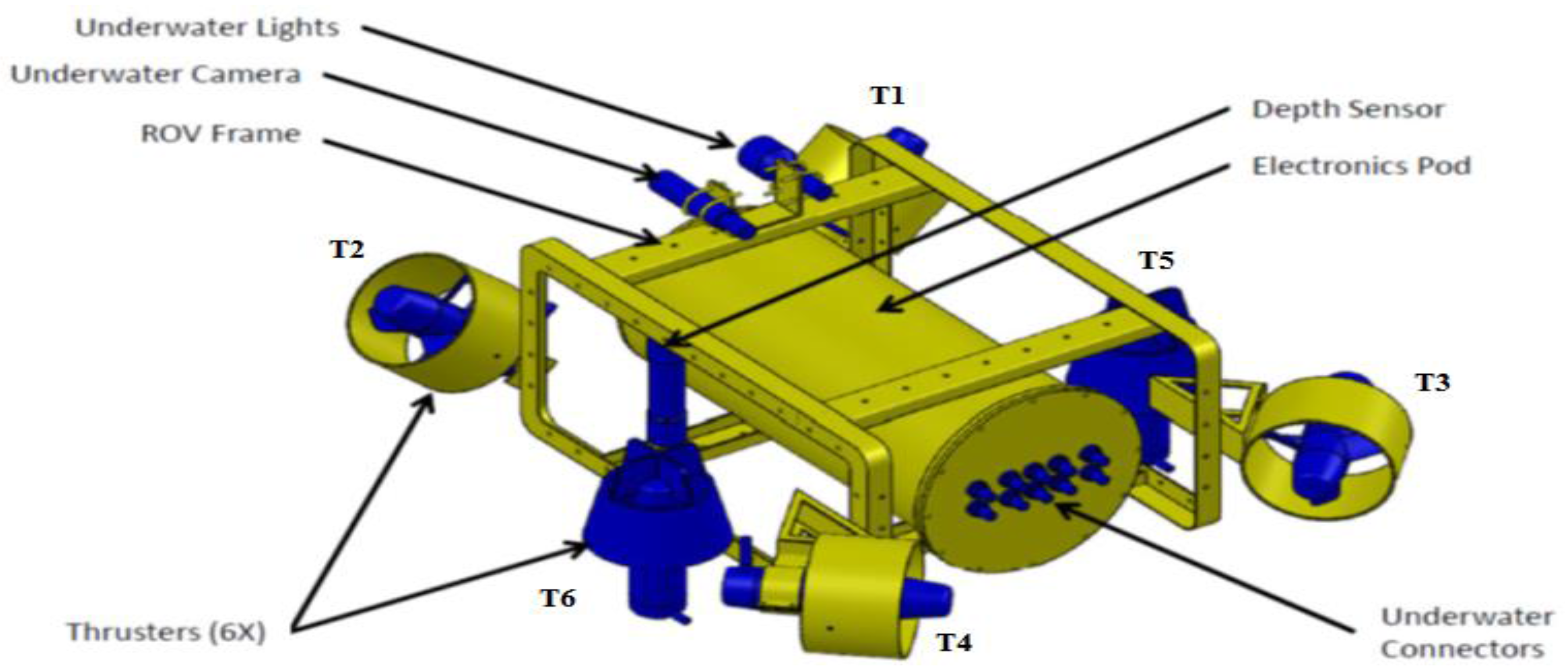

The position of the thruster on the ROV (as seen in

Figure 1) is defined by the thrusters’ configuration matrix, T. As mentioned in the nonlinear ROV dynamic equation, the left hand-side of the equations refers to the input forces and moments to the ROV model. These input forces and moments are determined based on the summation of the force and moment equations in the six DOFs. The force and moments for the open-hoop configuration are as follows.

where

are the minimum and maximum thrust output by each thruster and

is the force and moment vector generated. Here

α (=45°) is the orientation angle for T3 and T4 while

β (=45°) is the orientation angle for T1 and T2. Similar equations can be established for the closed-hoop configuration.

Figure 1.

Six thruster locations on AUVDH platform [

27].

Figure 1.

Six thruster locations on AUVDH platform [

27].

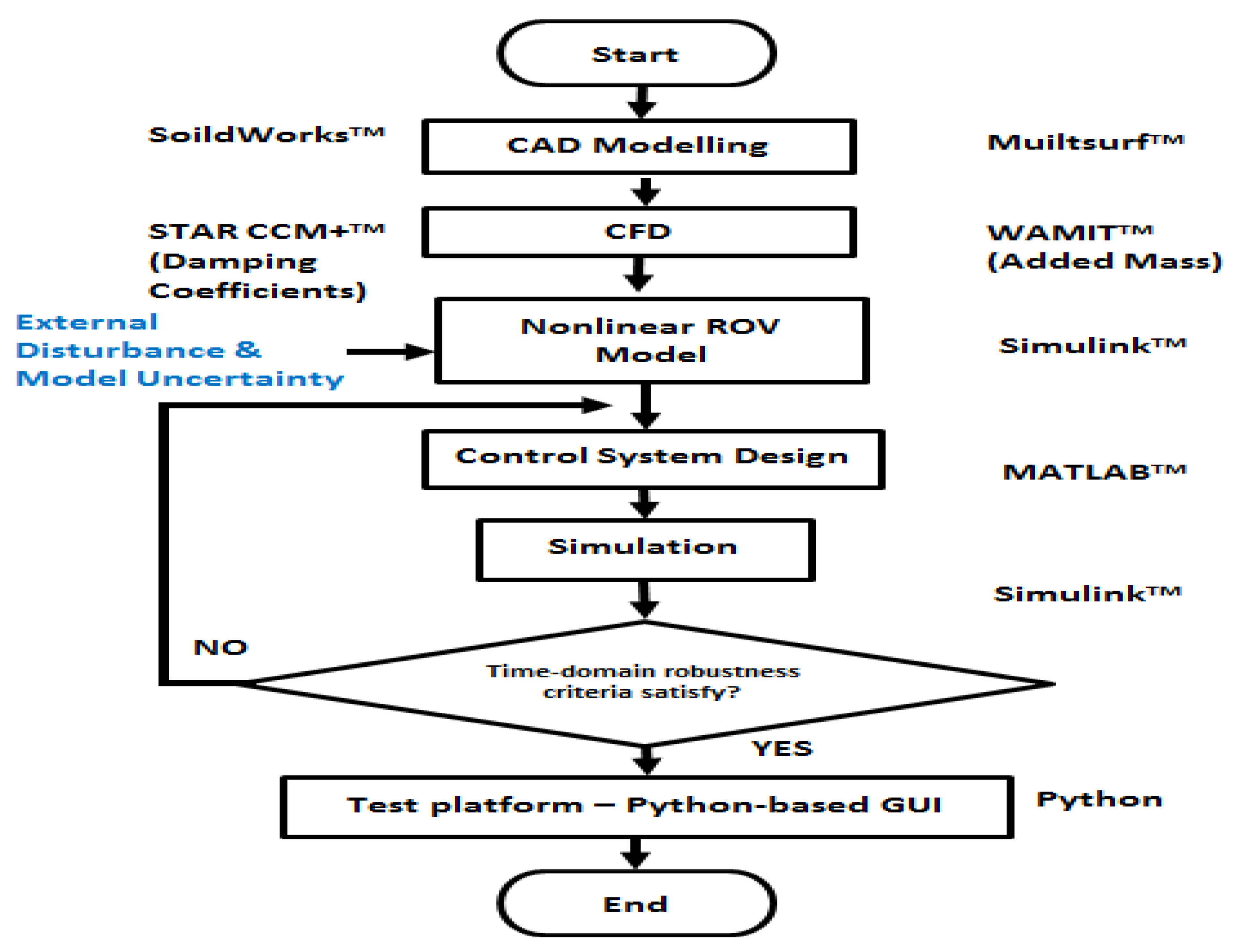

In the proposed hydrodynamics modelling approach,

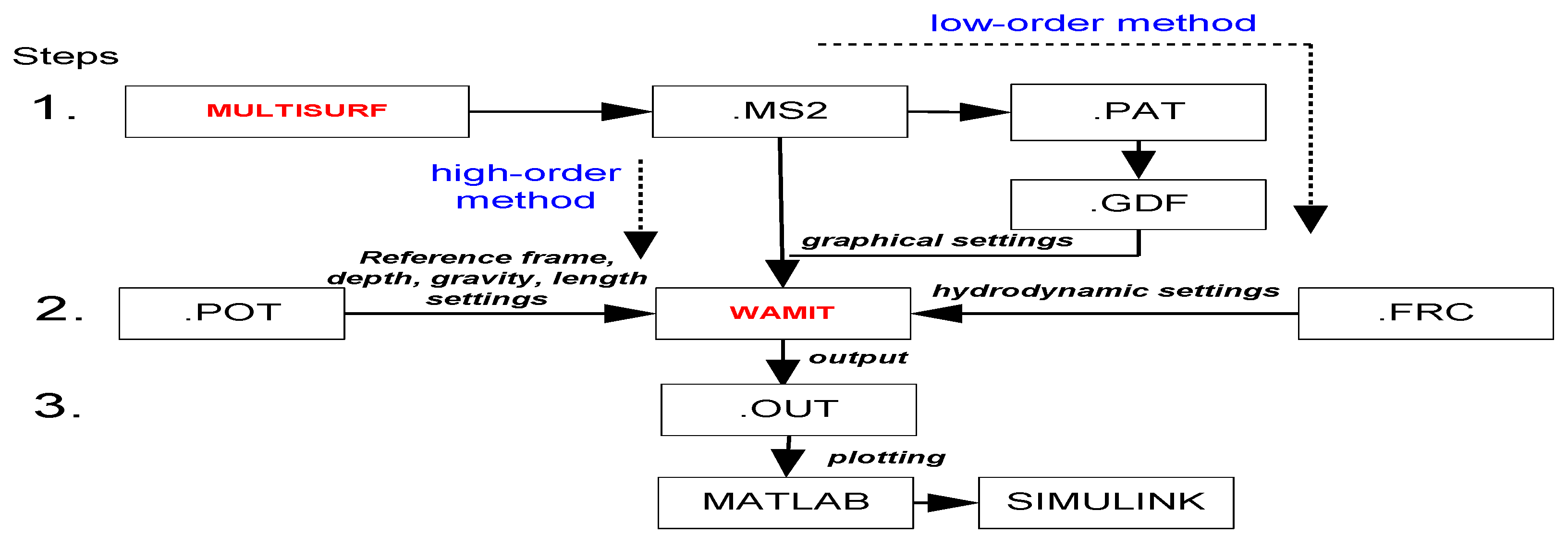

Figure 2 shows the overall approach from numerical modelling to control system design. The computer-aided model of a ROV created using SolidWorks™ and MultiSurf™ is used by computational fluid dynamic (CFD) software such as STAR-CCM+™ and WAMIT™, respectively. As a result, hydrodynamic parameters such as damping and added mass coefficients will be determined for the nonlinear ROV model. For more realistic modelling, the model will be subjected to its inherent model uncertainty due to the numerical computational error and external disturbances. To overcome the model and external disturbance uncertainty, a proposed control system design using sliding-mode based design is applied. The termination of the simulation will depend on satisfying the time-domain criteria and the number of iterations.

Figure 2.

Overall flow chart of AUVDH modelling to control system design.

Figure 2.

Overall flow chart of AUVDH modelling to control system design.

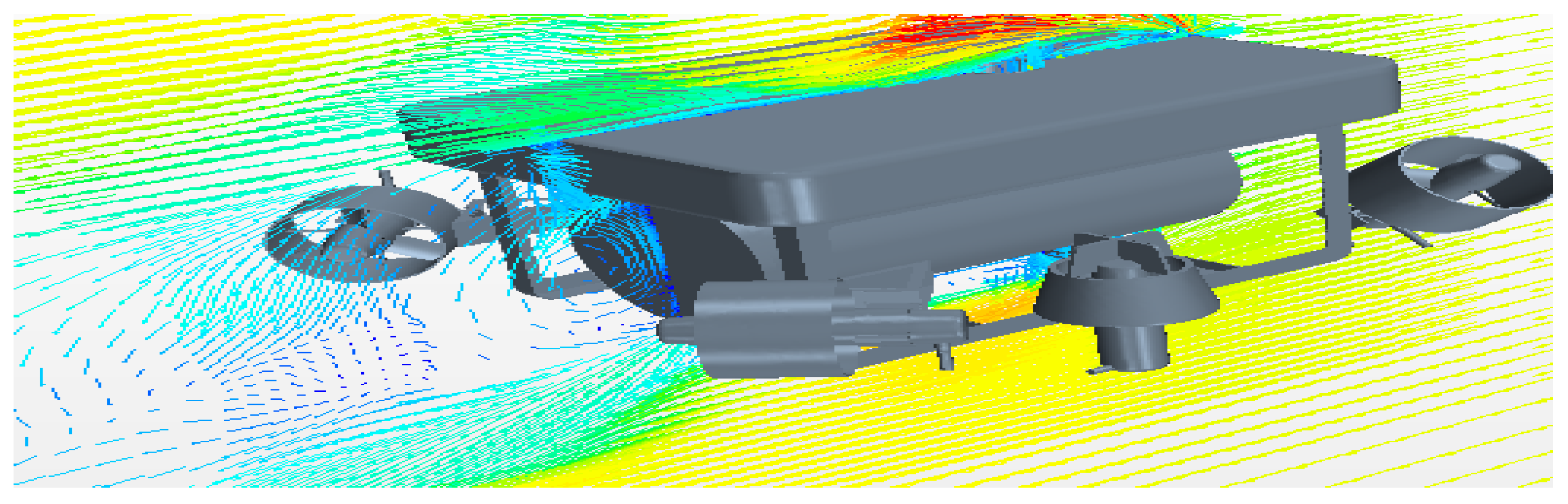

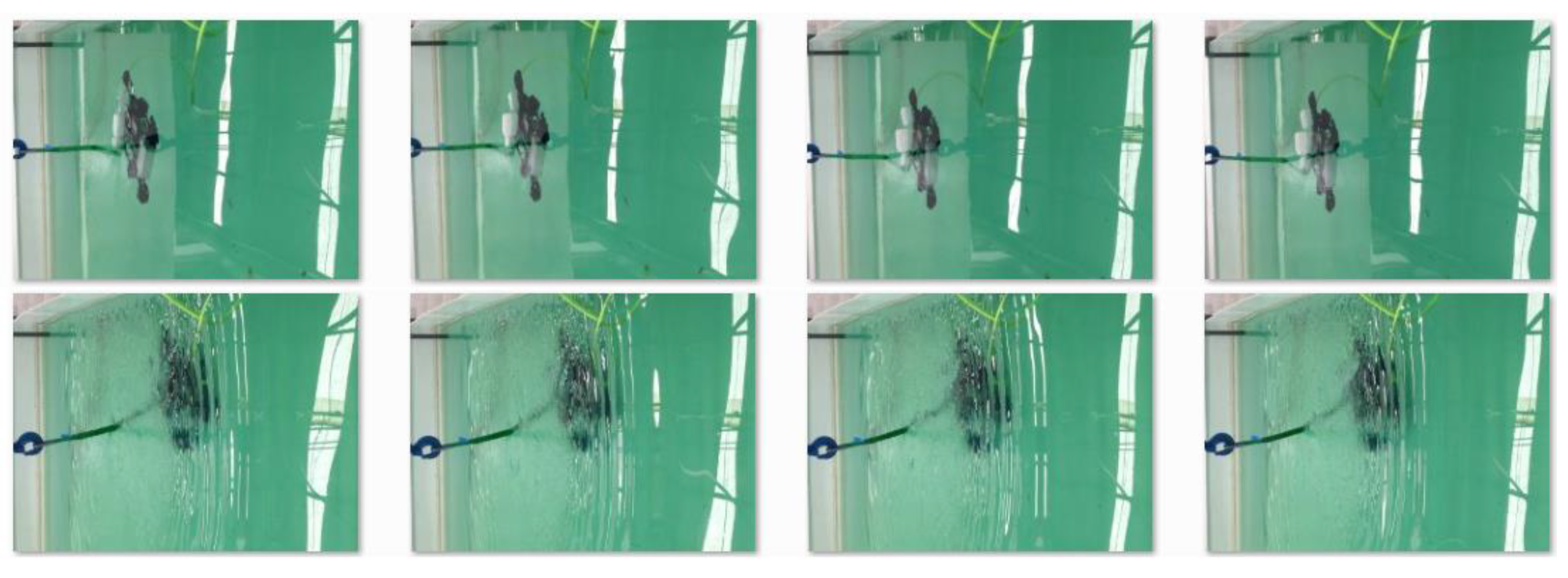

Figure 3 shows the geometrical model of the ROV. The major components of the ROV such as floater, pod, frame and thrusters, are modelled to ensure the flow characteristic is similar to the actual design. As

Figure 3 depicted, the ROV is actuated by six thrusters in six DOFs (namely: surge, sway, heave, roll, pitch, and yaw). The docking hoop for docking the AUV is not included in the model. The rigid-body mass and inertia properties with respect to the centre of gravity of the ROV, are determined using the CAD software. The vehicle has a weight of 135 kg, volume of 0.05 m

3, and surface area of 4.75 m

2. Hence, the rigid-body ROV mass inertia can be written as:

The overall damping effect of ROV is described as a sum of linear damping, drag and the vortex shedding (nonlinear damping). The ROV is designed to be self-stabilizable in pitch and roll motion. The viscous effect of the flow causes the non-linear force and moment under a small pitch angle condition to be negligible. The linear coefficients are adequate to represent the force and moments due to the inviscid part of the flow when ROV is operating at a slow speed (less than 2 m/s) [

1] and small pitching angle.

Figure 3.

Vector plot at centre plane of AUVDH at 0.5 m/s [

26].

Figure 3.

Vector plot at centre plane of AUVDH at 0.5 m/s [

26].

Thus, the ROV hydrodynamic damping matrix

D is simplified due to ROV working at a speed approximately equal to 0.5 m/s (angular speed of 0.3 rad/s). The off-diagonal elements in the damping matrix

D(

v) are small compared to those diagonal elements on the underwater vehicle. Therefore, this hydrodynamic damping matrix becomes:

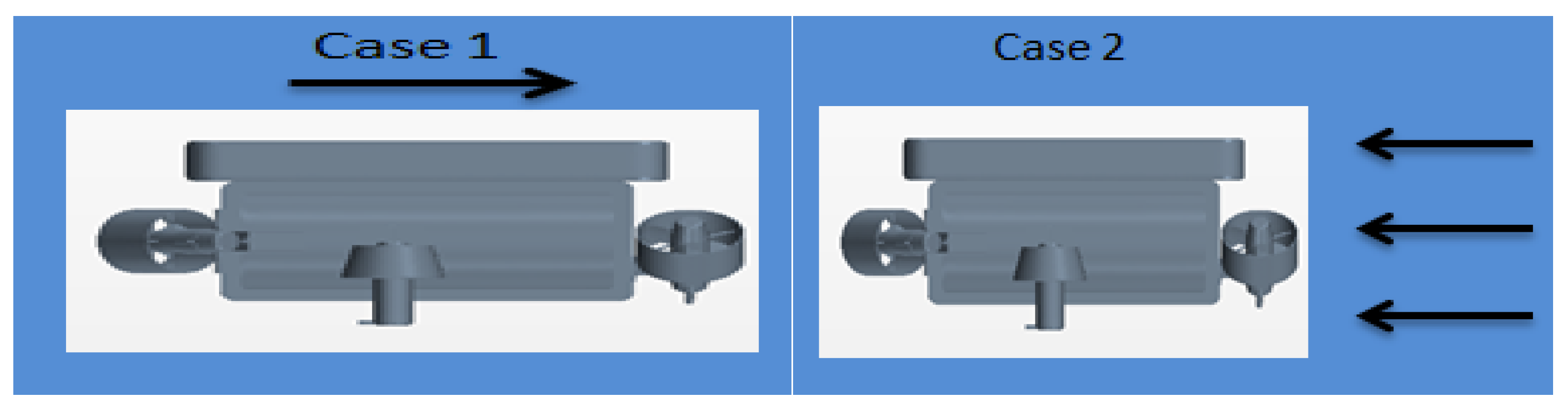

. As shown in

Figure 4, Case 1 shows the real situation where the ROV moves forward at a certain speed in a static fluid domain. However in CFD simulation, the ROV was made static and the flow is at opposite direction (Case 2) due to the drag force depends only on the relative motion between the fluid and the vehicle. Hence, it helps to simplify the modelling of the ROV boundary conditions and meshing.

Figure 4.

Flow on CFD models for AUVDH [

26].

Figure 4.

Flow on CFD models for AUVDH [

26].

A turbulence model with unsteady three-dimensional flow was built for the Reynolds number flow condition greater than 1.0 × 10

6. The Shear-Stress-Transport (SST) model was used in CFD software STAR CCM+. The flow in fluid domain is expected to be turbulent and isothermal. The fluid properties of water remain unchanged throughout the simulation process. The temperature is fixed at 20 degree Celsius and the water is modelled as an incompressible fluid. It is impractical to set the fluid domain to be infinitely large to analyse damping force acting on ROV in CFD or in towed tank tests. The suggest dimension is around 10 to 20 times larger than the dimension of the ROV (see

Figure 5) to ensure the accuracy [

11] of the actual flow domain around the ROV.

Figure 5.

Meshing for flow domain around AUVDH [

26].

Figure 5.

Meshing for flow domain around AUVDH [

26].

Table 1 shows the drag coefficient of ROV in the three principle motions. The flow in domain was simulated at different speeds using STAR CCM+. It also shows the drag moment

versus angular velocity in yaw direction.

With that, the linear and quadratic hydrodynamic damping matrix for ROV is written as:

In summary, the results show that surge motion has the lowest damping while the heave motion has the largest drag force. The values of linear damping coefficients are less than the quadratic terms due to its velocity square term. This may be due to the interaction of the thrusters that was not included in the CFD model.

The hydrodynamic added coefficients of the AUVDH are analysed and presented. The added mass and inertia are independent of the wave circular frequency for a fully submerged vehicle. The added mass coefficients matrix for a ROV can be written as follow:

where

is the added mass along

X-axis due to an acceleration

in

X-direction,

is the added mass along

X-axis due to an acceleration

in

Y-direction, and so forth.

On the other hand, the corresponding added Coriolis and centripetal matrix is represented.

where

The surface-based computer aided design (CAD) software MultiSurf™ is used to model the geometry of the AUVDH. According to the WAMIT™ manual [

28], MultiSurf™ was designed to operate with WAMIT™. It is able to export the necessary file for WAMIT™ applications. The panel surfaces of the AUVDH geometry is shown in

Figure 6. As observed, only half of the ROV is modelled due to the symmetry of the vehicle in XZ-plane. This greatly reduces the complexity of the added mass matrix and computation time required by WAMIT™. Since the AUVDH consists of multi-component, these components were drawn simultaneously in MultiSurf™. The mesh of the AUVDH were created using MultiSurf™ and WAMIT™ to compute the added mass matrix.

Figure 6.

Finite surface panels generation using MultiSurf™ on AUVDH [

26].

Figure 6.

Finite surface panels generation using MultiSurf™ on AUVDH [

26].

The geometry file created by MultiSurf™ was imported to WAMIT™. The low-order panel method was used. The output file created using WAMIT™ can be imported into MATLAB™ for analysis.

Figure 7 illustrates the procedure of using MATLAB™ to analyse the hydrodynamic added mass.

Figure 7.

Program flowchart to determine added mass coefficients for AUVDH [

26].

Figure 7.

Program flowchart to determine added mass coefficients for AUVDH [

26].

Before using the WAMIT™ to test the AUVDH, a study of the empirical results of a 2-m diameter sphere to verify the program setup and parameters was used. The theoretical added mass of a sphere is

for the three translational motions; surge, sway, and heave. The added mass of the sphere can be written as

through normalizing the mass against density.

Table 2 shows the low-order method results of the sphere.

Table 2.

Low-order method for sphere [

26].

Table 2.

Low-order method for sphere [26].

| Panel Number | Numerical Results | Theoretical Results |

|---|

| | Surge | Sway | Heave | Surge | Sway | Heave |

|---|

| 256 | 2.085167 | 2.085168 | 2.073719 | 2.0944 | 2.0944 | 2.0944 |

| 512 | 2.084073 | 2.084074 | 2.087820 | | | |

| 1024 | 2.083766 | 2.083768 | 2.091414 | | | |

| Errors | | | | −0.5% | −0.5% | −0.1% |

As seen in

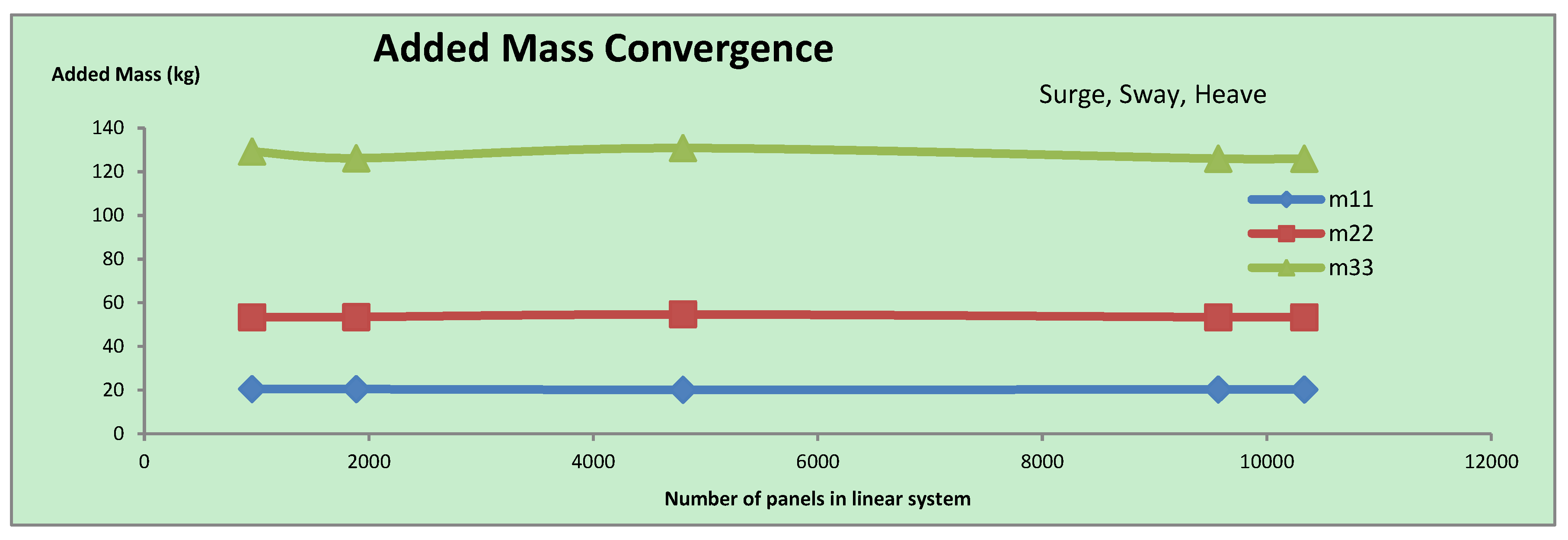

Table 2, the numerical results obtained from WAMIT™ low-order method have a small difference compared with the theoretical results. The above case study identifies the input parameters settings that are suitable and accurate to compute the added mass coefficient of the AUVDH. The AUVDH was then modelled using MultiSurf™ and imported into the WAMIT™ to solve the problem using the low-order panel method. Only the main components of the AUVDH are drawn to reduce the complexity of the geometry. The convergence tests of the added mass of the AUVDH against various panel numbers are shown in

Figure 8 and

Figure 9. As observed from the convergence tests, the added mass results achieved desired value of around 3000 to 4000 panels.

Figure 8.

Convergence plot for surge, sway, and heave [

26].

Figure 8.

Convergence plot for surge, sway, and heave [

26].

Figure 9.

Convergence plot for roll, pitch, and yaw [

26].

Figure 9.

Convergence plot for roll, pitch, and yaw [

26].

The off-diagonal terms in the added mass are smaller as compared to the diagonal components for most of underwater vehicle with approximately three planes of symmetry in the added mass matrix. The off-diagonal components [

1] are usually neglected for a slow-speed operating underwater vehicle. The added mass matrix obtained by MATLAB™ can be further simplified.

The added mass matrix

of the AUVDH must be positive. The following relations are observed from the matrix:

. A smaller added mass in the surge direction,

i.e.,

m11 has been observed. It is due to the AUVDH has the smallest projection area in the surge direction. The corresponding Coriolis and centripetal added mass matrix from Equation (12) can be written as:

In summary, the added mass coefficients of the AUVDH were computed by WAMIT™ using both potential flow and panel method theory. The added mass in surge motion is around 20 kg; in sway motion is 53 kg; in heave motion is 126 kg. As shown in

Figure 8 and

Figure 9, different added mass results with the various numbers of panels are presented were compared. The added mass results tend to converge near to 10,000 panels. By observing the numerical results based on the surface area and shape of the AUVDH, it shows a good relationship with the respectively hydrodynamic parameters. Hence, the AUVDH model is adequate for subsequent control system design.

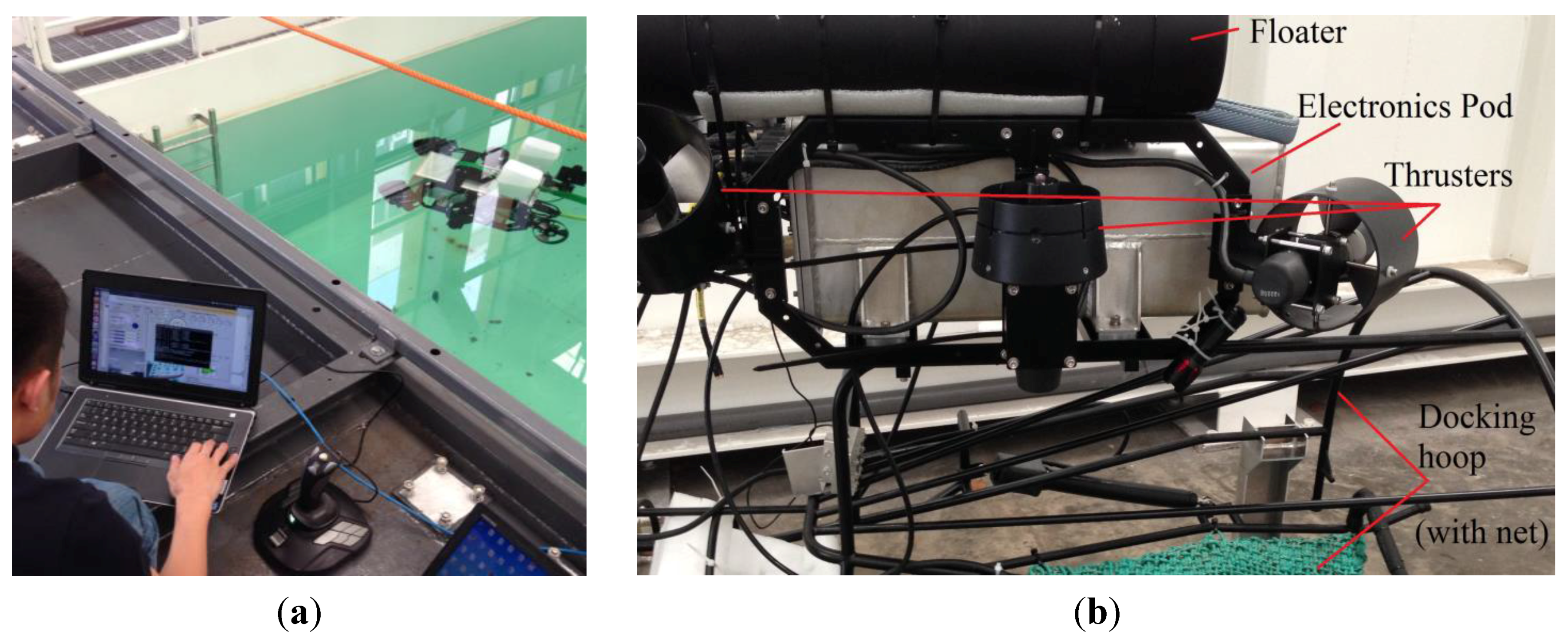

4. AUVDH GUI Test Platform

A graphical user interface (GUI) is seen as an essential requirement for enhanced operator dexterity. Tele-presence systems have been investigated as a means of realizing highly dexterous and intuitive systems for AUVDH. The AUVDH GUI control system panel consists of two primary functions: send control commands to control the thrusters manually and automatically; and display sensors and thrusters’ status in real-time. The actual layout of the GUI control panel is shown in

Figure 17.

Figure 17.

AUVDH GUI control panel layout.

Figure 17.

AUVDH GUI control panel layout.

Creating the AUVDH GUI applications on Linux can be performed in different ways. Using the simplest and the most functional programming languages and libraries under the Linux desktop using the Qt library with the Python programming language, called “PyQt”, was chosen. To facilitate the software development, an integrated development environment (IDE) consisting of a source code editor, build automation tools, and a debugger are needed. Since Python and Qt were chosen, the IDE written in Python, and based on the cross platform Qt GUI toolkit, integrating a flexible editor control is highly desired. Thus, the Eric4Python IDE written in Python and based on the Qt GUI was selected. It includes a plugin system, which allows easy extension of the IDE functionality with plugins downloadable from the Internet. In this project, the GUI control panel was designed using PyQt4, Python 2.7, and the Eric4Python IDE as the integrated development environment.

A brief overall view of the software packages used in the project is described. Qt brings flexibility to embedded development, allowing engineers to create high-performing and modern user-interfaces and applications with built-in productivity-enhancing tools for fast, easy, fully-integrated embedded device application development. The pre-configured embedded development environment, pre-built Qt optimized software stack for immediate deployment to ATHENA III embedded board allows users to get running, and have a working embedded project prototype. The QtGui module contains the graphical components and related classes. These include for example buttons, windows, status bars, toolbars, sliders, bitmaps, colours and fonts. The module enables seamless integration of the Qt GUI library and the OpenGL library. The QtSql module provides classes for working with databases. There are six function modules for the AUVDH GUI. They are namely, control mode, switch control of docking hoop, network connection, thruster readout, and video image display.