An Investigation of Carbon-Doping-Induced Current Collapse in GaN-on-Si High Electron Mobility Transistors

Abstract

:1. Introduction

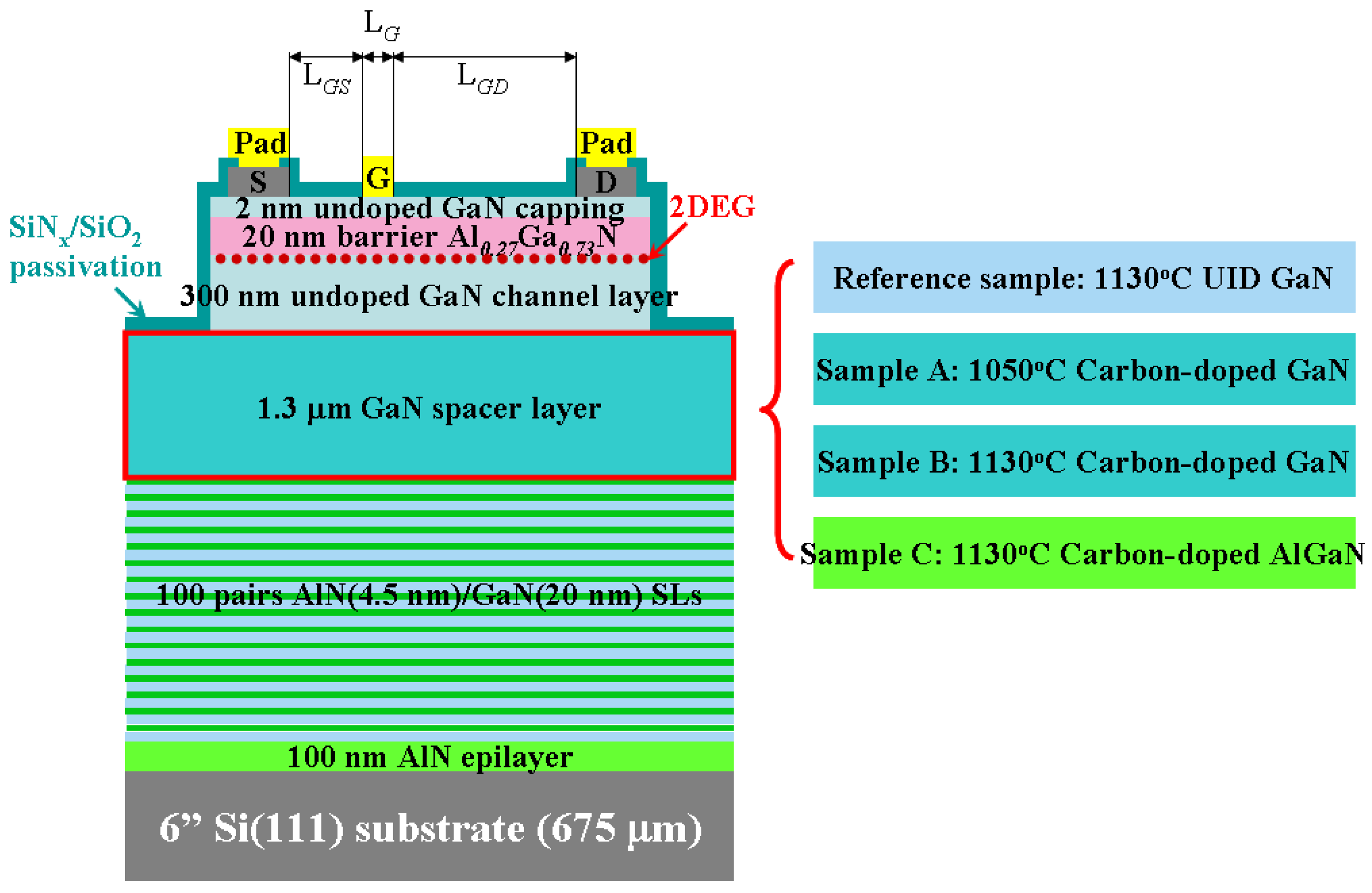

2. Experimental Section

3. Results and Discussion

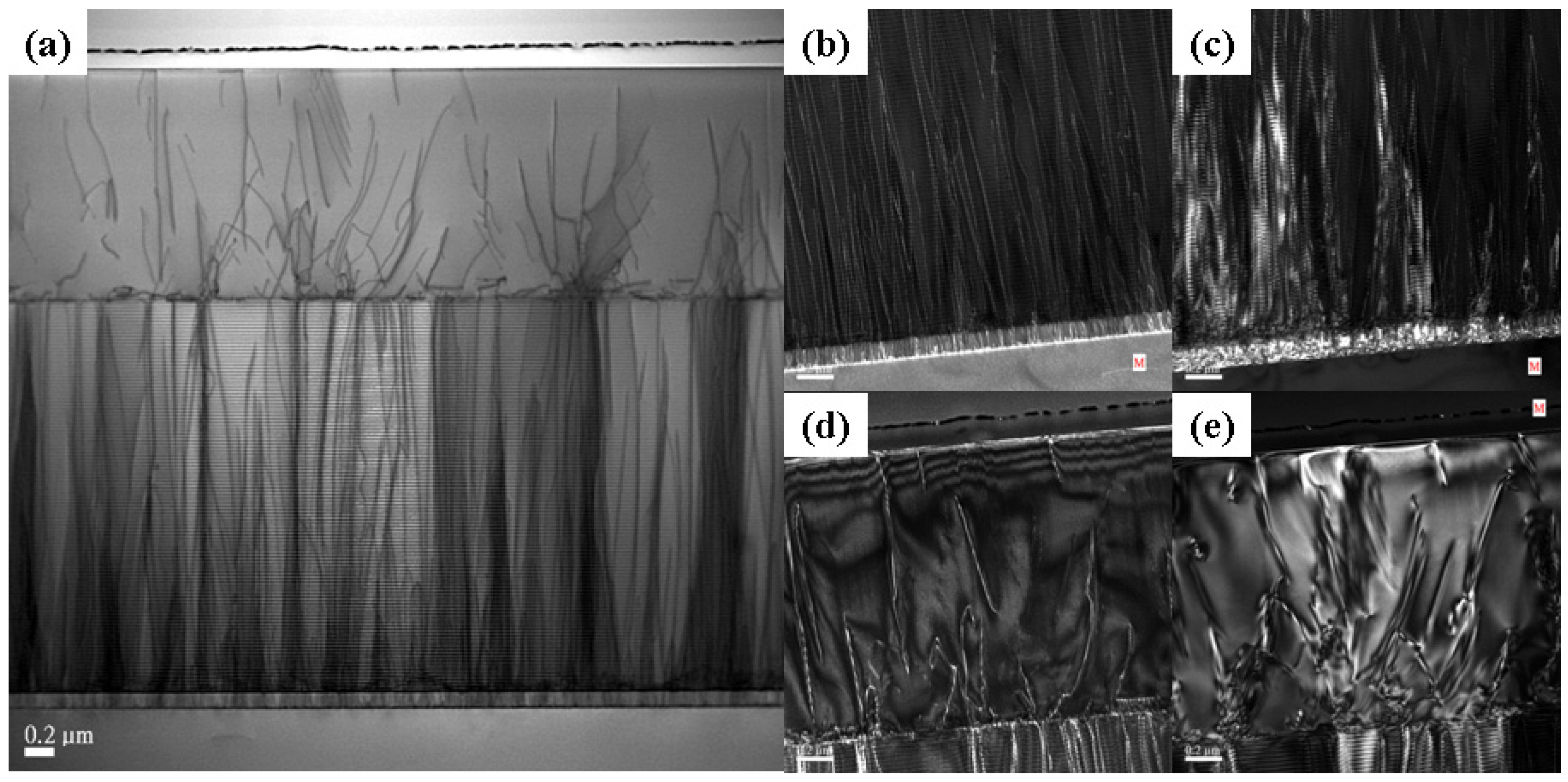

3.1. Strained SLs Buffer Layer of GaN-on-Si Epitaxy

3.2. Carbon-Doping Activities in GaN Spacer Layer

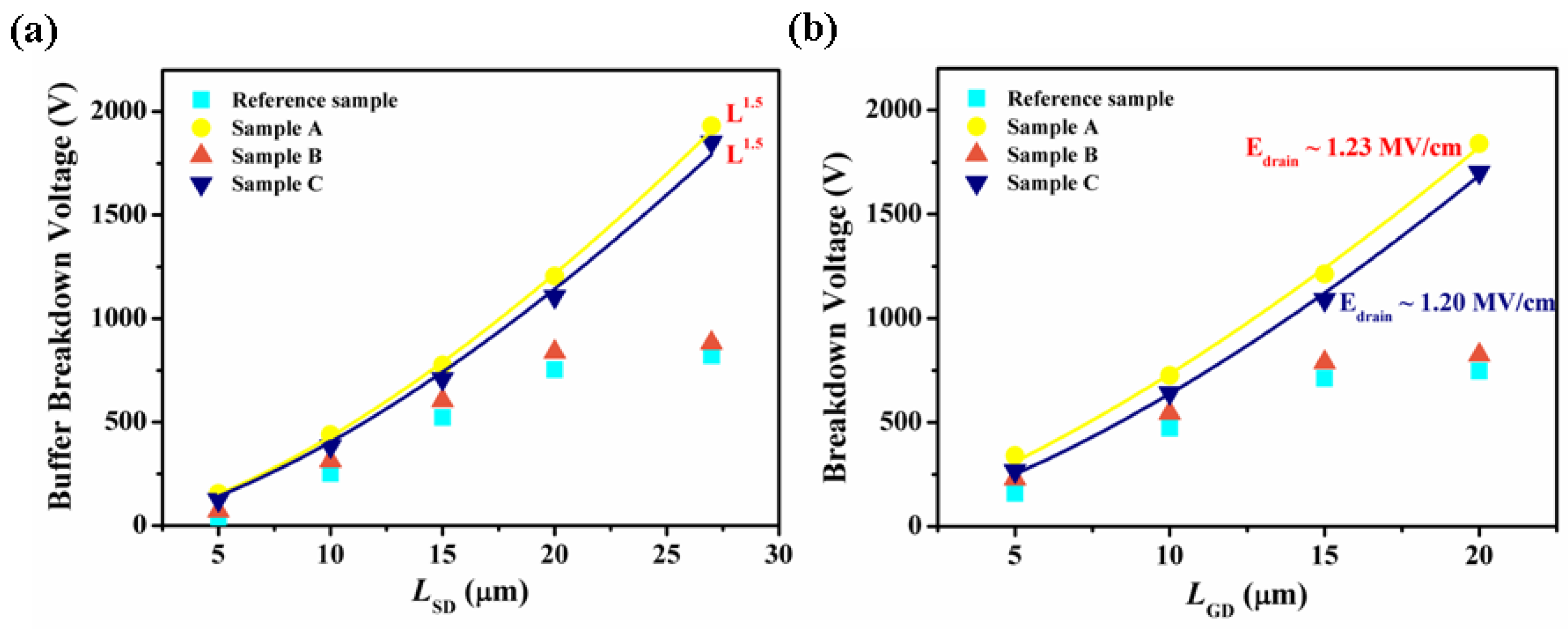

3.3. Breakdown Voltage Discussion

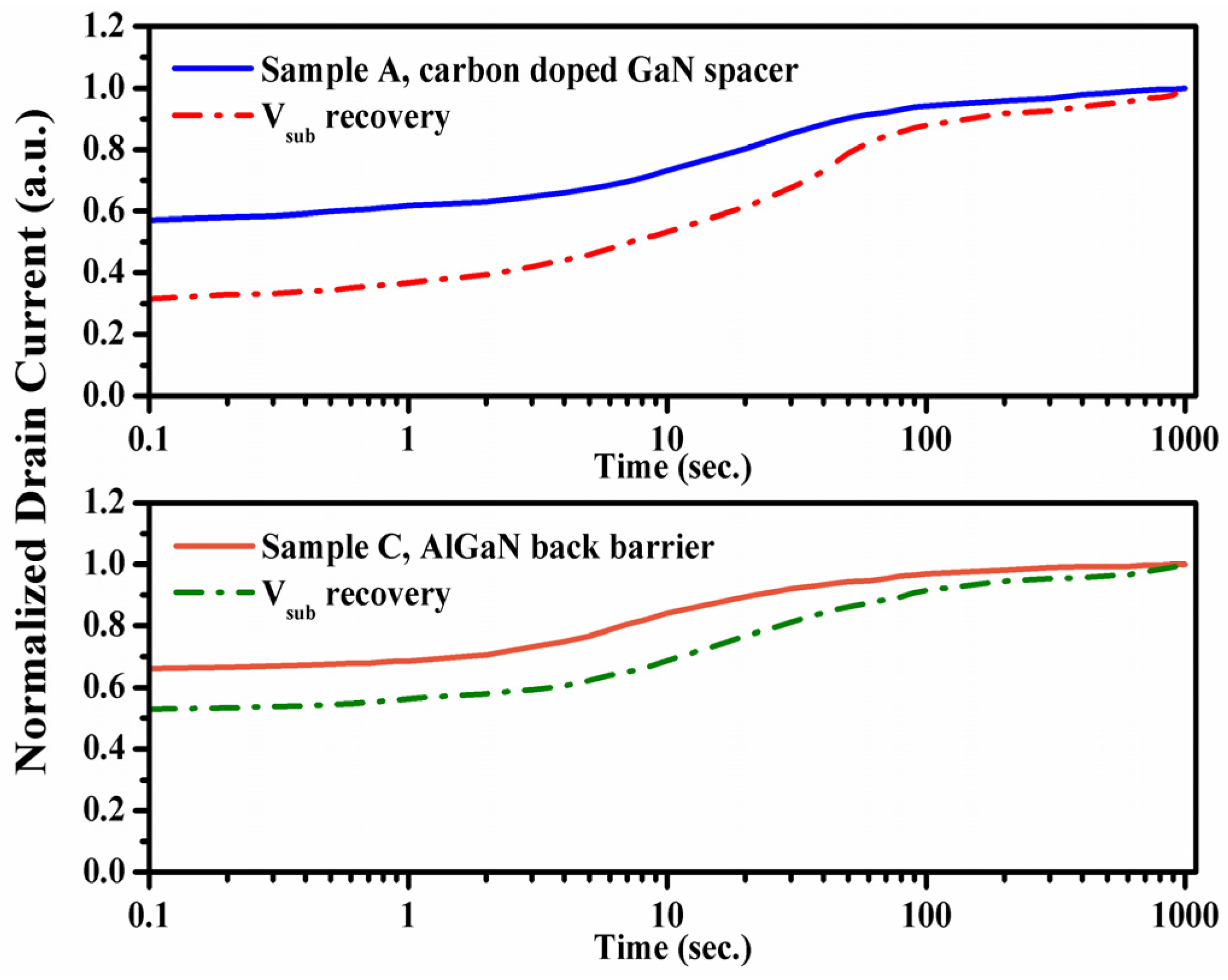

3.4. HEMT Electrical Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mitova, R.; Ghosh, R.; Mhaskar, U.; Klikic, D.; Wang, M.X.; Dentella, A. Investigations of 600-V GaN HEMT and GaN Diode for Power Converter Applications. IEEE Trans. Power Electron. 2014, 29, 2441–2452. [Google Scholar] [CrossRef]

- Lu, B.; Palacios, T. High Breakdown (>1500 V) AlGaN/GaN HEMTs by Substrate-Transfer Technology. IEEE Electron. Dev. Lett. 2010, 31, 951–953. [Google Scholar] [CrossRef]

- Seager, C.H.; Wright, A.F.; Yu, J.; Götz, W. Role of carbon in GaN. J. Appl. Phys. 2002, 92, 6553–6560. [Google Scholar] [CrossRef]

- Shan, Q.F.; Meyaard, D.S.; Dai, Q.; Cho, J.; Schubert, E.F.; Son, J.K.; Sone, C. Transport-mechanism analysis of the reverse leakage current in GaInN light-emitting diodes. Appl. Phys. Lett. 2011, 99, 253506. [Google Scholar] [CrossRef]

- Selvaraj, S.L.; Watanabe, A.; Wakejima, A.; Egawa, T. 1.4-kV Breakdown Voltage for AlGaN/GaN High-Electron-Mobility Transistors on Silicon Substrate. IEEE Electron. Dev. Lett. 2012, 33, 1375–1377. [Google Scholar] [CrossRef]

- Srivastava, P.; Das, J.; Visalli, D.; Hove, M.V.; Malinowski, P.E.; Marcon, D.; Lenci, S.; Geens, K.; Cheng, K.; Leys, M.; et al. Record Breakdown Voltage (2200 V) of GaN DHFETs on Si With 2-μm Buffer Thickness by Local Substrate Removal. IEEE Electron. Dev. Lett. 2011, 32, 30–32. [Google Scholar] [CrossRef]

- Jiang, Q.; Liu, C.; Lu, Y.; Chen, K.J. Mechanism of PEALD-grown AlN passivation for AlGaN/GaN HEMTs: Compensation of interface traps by polarization charges. IEEE Electron. Dev. Lett. 2013, 34, 357–359. [Google Scholar] [CrossRef]

- Treidel, E.B.; Brunner, F.; Hilt, O.; Cho, E.; Würfl, J.; Tränkle, G. AlGaN/GaN/GaN:C Back-Barrier HFETs with Breakdown Voltage of Over 1 kV and Low Ron × A. IEEE Trans. Electron. Dev. 2010, 57, 3050–3058. [Google Scholar] [CrossRef]

- Xuan, R.; Kuo, W.H.; Hu, C.W.; Lin, S.F.; Chen, J.F. Enhancing threshold voltage of AlGaN/GaN high electron mobility transistors by nano rod structure: From depletion mode to enhancement mode. Appl. Phys. Lett. 2012, 101, 112105. [Google Scholar] [CrossRef]

- Koleske, D.D.; Wickenden, A.E.; Henry, R.L.; Twigg, M.E. Influence of MOVPE growth conditions on carbon and silicon concentrations in GaN. J. Cryst. Growth 2002, 242, 55–69. [Google Scholar] [CrossRef]

- Poblenz, C.; Waltereit, P.; Rajan, S.; Heikman, S.; Mishra, U.K.; Speck, J.S. Effect of carbon doping on buffer leakage in AlGaN/GaN high electron mobility transistors. J. Vac. Sci. Technol. B 2004, 22, 1145–1149. [Google Scholar] [CrossRef]

- Zhou, C.; Jiang, Q.; Huang, S.; Chen, K.J. Vertical Leakage/Breakdown Mechanisms in AlGaN/GaN-on-Si Devices. IEEE Electron. Dev. Lett. 2012, 33, 1132–1134. [Google Scholar] [CrossRef]

- Fang, Z.Q.; Claflin, B.; Look, D.C.; Green, D.S.; Vetury, R. Deep traps in AlGaN/GaN heterostructures studied by deep level transient spectroscopy: Effect of carbon concentration in GaN buffer layers. J. Appl. Phys. 2010, 108, 063706. [Google Scholar] [CrossRef]

- Selvaraj, J.; Selvaraj, S.L.; Egawa, T. Effect of GaN Buffer Layer Growth Pressure on the Device Characteristics of AlGaN/GaN High-Electron-Mobility Transistors on Si. Jpn. J. Appl. Phys. 2009, 48, 121002. [Google Scholar] [CrossRef]

- Uren, M.J.; Möreke, J.; Martin, K. Buffer Design to Minimize Current Collapse in GaN/AlGaN HFETs. IEEE Trans. Electron. Dev. 2012, 59, 3327–3333. [Google Scholar] [CrossRef]

- Uren, M.J.; Nash, K.J.; Balmer, R.S.; Martin, T.; Morvan, E.; Caillas, N.; Delage, S.L.; Ducatteau, D.; Grimbert, B.; de Jaeger, J.C. Punchthrough in short-channel AlGaN/GaN HFETs. IEEE Trans. Electron. Dev. 2006, 53, 395–398. [Google Scholar] [CrossRef]

- Zhang, L.; Lester, L.F.; Baca, A.G.; Shul, R.J.; Chang, P.C.; Willison, C.G.; Mishra, U.K.; Denbaars, S.P.; Zolper, J.C. Epitaxially-grown GaN junction field effect transistors. IEEE Trans. Electron. Dev. 2000, 47, 507–511. [Google Scholar] [CrossRef]

- Heying, B.; Wu, X.H.; Keller, S.; Li, Y.; Kapolnek, D.; Keller, B.P. Role of threading dislocation structure on the X-ray diffraction peak widths in epitaxial GaN films. Appl. Phys. Lett. 1996, 68, 643–645. [Google Scholar] [CrossRef]

- Ishida, M.; Ueda, T.; Ueda, D. GaN on Si Technologies for Power Switching Devices. IEEE Trans. Electron Dev. 2013, 60, 3053–3059. [Google Scholar] [CrossRef]

- Kim, D.S.; Won, C.H.; Kang, H.S.; Kim, Y.J.; Kim, Y.T.; Kang, I.M.; Lee, J.H. Growth and characterization of semiinsulating carbon-doped/undoped GaN multiple-layer buffer. Semicond. Sci. Technol. 2015, 30, 035010. [Google Scholar] [CrossRef]

- Green, D.S.; Mishra, U.K.; Speck, J.S. Carbon doping of GaN with CBr4 in radio-frequency plasma-assisted molecular beam epitaxy. J. Appl. Phys. 2004, 95, 8456–8462. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Y.; Zhu, J.; Lau, K.M.; Chen, K.J. AlGaN/GaN/InGaN/GaN DH-HEMTs with an InGaN Notch for Enhanced Carrier Confinement. IEEE Electron. Dev. Lett. 2006, 27, 10–12. [Google Scholar]

- Lampert, M.A. Simplified theory of space-charge-limited currents in an insulator with traps. Phys. Rev. 1956, 103, 1648–1656. [Google Scholar] [CrossRef]

- Lee, H.S.; Piedra, D.; Sun, M.; Gao, X.; Guo, S.; Palacios, T. 3000-V 4.3-mΩ·cm2 InAlN/GaN MOSHEMTs with AlGaN Back Barrier. IEEE Electron. Dev. Lett. 2012, 33, 982–984. [Google Scholar] [CrossRef]

- Kim, H.; Tilak, V.; Green, B.M.; Smart, J.A.; Schaff, W.J.; Shealy, J.R.; Eastman, L.F. Reliability evaluation of high power AlGaN/GaN HEMTs on SiC substrate. Phys. Stat. Sol. 2001, 188, 203–206. [Google Scholar] [CrossRef]

- Joh, J.; del Alamo, J.A. Impact of electrical degradation on trapping characteristics of GaN high electron mobility transistors. IEDM Tech. Dig. 2008, 1–4. [Google Scholar]

- Vetury, R.; Zhang, N.Q.; Keller, S.; Mishra, U.K. The impact of surface states on the DC and RF characteristics of AlGaN/GaN HFETs. IEEE Trans. Electron Dev. 2001, 48, 560–566. [Google Scholar] [CrossRef]

- Joh, J.; del Alamo, J.A. A Current-Transient Methodology for Trap Analysis for GaN High Electron Mobility Transistors. IEEE Trans. Electron. Dev. 2011, 58, 132–140. [Google Scholar] [CrossRef]

- Uren, M.J.; Silvestri, M.; Cäsar, M.; Hurkx, G.A.M.; Croon, J.A.; Šonský, J.; Kuball, M. Intentionally Carbon-Doped AlGaN/GaN HEMTs: Necessity for Vertical Leakage Paths. IEEE Electron. Dev. Lett. 2014, 35, 327–329. [Google Scholar] [CrossRef]

- Wolter, M.; Marso, M.; Javorka, P.; Bernát, J.; Carius, R.; Lüth, H.; Kordoš, P. Investigation of traps in AlGaN/GaN HEMTs on silicon substrate. Phys. Stat. Sol. 2003, 0, 2360–2363. [Google Scholar] [CrossRef]

- Tirado, J.M.; Sanchez-Rojas, J.L.; Izpura, J.I. Simulation of surface state effects in the transient response of AlGaN/GaN HEMT and GaN MESFET devices. Semicond. Sci. Technol. 2006, 21, 1150–1159. [Google Scholar] [CrossRef]

| Layer | Growth Temperature (°C) | Pressure (Torr) | Growth Rate (µm/h) | |

|---|---|---|---|---|

| AlN cladding layer | 1050 | 75 | 0.8 | |

| AlN/GaN SLs | 1150 | 100 | 2.4 | |

| Reference sample | Unintentionally doped GaN spacer layer | 1130 | 100 | 7.0 |

| Sample A | Carbon-doped GaN spacer layer | 1050 | 100 | 7.5 |

| Sample B | Carbon-doped GaN spacer layer | 1130 | 100 | 6.8 |

| Sample C | Al0.3Ga0.7N back barrier layer | 1130 | 100 | 2.0 |

| GaN channel layer | 1130 | 680 | 6.5 | |

| Al0.27Ga0.73N barrier layer | 1130 | 100 | 0.5 |

| Sample | Spacer Layer | Growth Temperature (°C) | Sheet Resistance (Ω/sq) | 2DEG Concentration (× 1013 cm−2) | Carbon-Doping Concentration (cm−3) | XRD fwhm (arc sec) | |

|---|---|---|---|---|---|---|---|

| (002) | (102) | ||||||

| Reference sample | Unintentionally doped GaN spacer layer | 1130 | 414.2 ± 10.7 | 1.16 ± 0.02 | 5×1017 | 736 | 910 |

| Sample A | Carbon-doped GaN spacer layer | 1050 | 414.2 ± 10.7 | 1.16 ± 0.02 | 2×1019 | 929 | 1130 |

| Sample B | Carbon-doped GaN spacer layer | 1130 | 414.2 ± 10.7 | 1.16 ± 0.02 | 1×1018 | 767 | 943 |

| Sample C | Carbon-doped Al0.3Ga0.7N back barrier layer | 1130 | 447.4 ± 8.7 | 1.07 ± 0.02 | 2×1018 | 818 | 1188 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tzou, A.-J.; Hsieh, D.-H.; Chen, S.-H.; Liao, Y.-K.; Li, Z.-Y.; Chang, C.-Y.; Kuo, H.-C. An Investigation of Carbon-Doping-Induced Current Collapse in GaN-on-Si High Electron Mobility Transistors. Electronics 2016, 5, 28. https://doi.org/10.3390/electronics5020028

Tzou A-J, Hsieh D-H, Chen S-H, Liao Y-K, Li Z-Y, Chang C-Y, Kuo H-C. An Investigation of Carbon-Doping-Induced Current Collapse in GaN-on-Si High Electron Mobility Transistors. Electronics. 2016; 5(2):28. https://doi.org/10.3390/electronics5020028

Chicago/Turabian StyleTzou, An-Jye, Dan-Hua Hsieh, Szu-Hung Chen, Yu-Kuang Liao, Zhen-Yu Li, Chun-Yen Chang, and Hao-Chung Kuo. 2016. "An Investigation of Carbon-Doping-Induced Current Collapse in GaN-on-Si High Electron Mobility Transistors" Electronics 5, no. 2: 28. https://doi.org/10.3390/electronics5020028