In recent decades, various procedures for estimating the reliability have been introduced by different organizations. The first of reliability estimation titled TR-1100 was published in 1956 in United States by Rome Air Development Center (RADC). This standard described the failure rate for electronic and computer parts [

52]. After the publication of this standard, MIL-HDBK-217 was published as a handbook and became the most popular one in this field. After that different firms and organizations developed and improve their own reliability handbooks and software. Some of these procedures include:

CNET's reliability prediction method [

56]

Siemens’ SN29500 standard [

57]

British Telecom’s HRD-4 [

58]

In Reference [

59], authors made a comparison between different methods available for estimating the reliability. Today, MIL-HDBK-217 handbook is still used as a reference for reliability estimation. It should be mentioned that MIL-HDBK-217 is a standard applied to military industry so it is very conservative compared to other standards. Moreover, the suitability of this standard compared to other ones has been proved because of its different and more factors which cover all aspects of reliability and influential items [

60]. This handbook uses two methods called parts count and parts stress to estimate the reliability of system components at various stages of design [

47,

61].

Having the stress of electrical components and designed circuits, reliability can be predicted by using parts stress method. The parts count method requires less data, generally including information such as the number of parts, their quality level, and conditions of use. That is why parts stress methods usually yields more accurate results regarding system reliability [

47]. The main difference between the parts stress and parts count methods is in how they calculate the system failure rate.

3.1. Approximate Method

As previously mentioned, there are two extensively used approaches for reliability assessments to calculate failure rates. The first method is parts count which is a simple way to estimate the reliability of a system. When there is no detailed system information, using this method is preferred. This method uses typical operating conditions called reference conditions to predict the failure rate under these conditions. However, it may be assumed that the device is not working under reference conditions, and the actual operating conditions will affect failure rates calculated from the parts count method. Therefore, this method can be considered as an approximate method. In this method, only the number of components is important, and the construction is not involved. Therefore, this method is typically based on quantitative analyses.

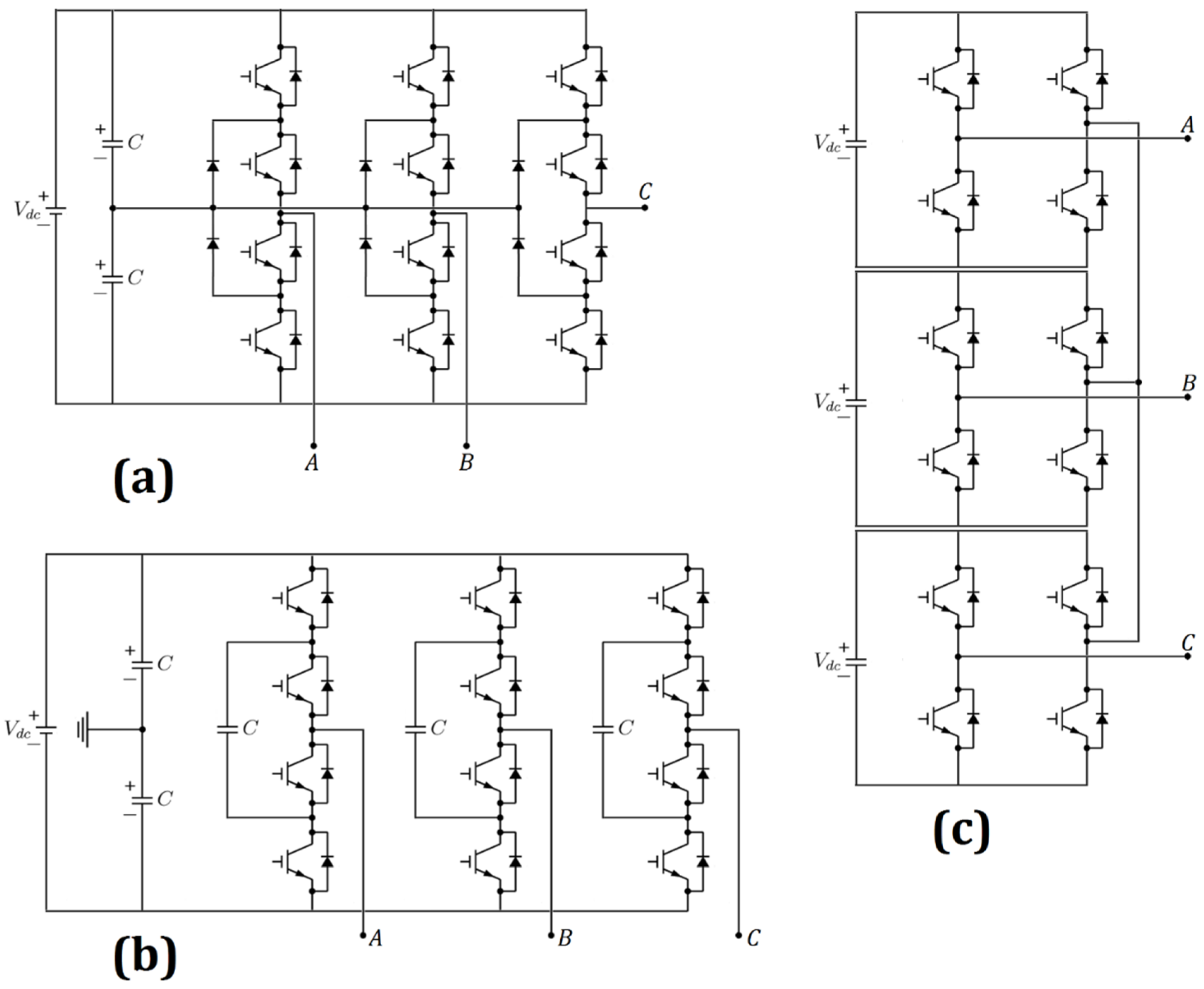

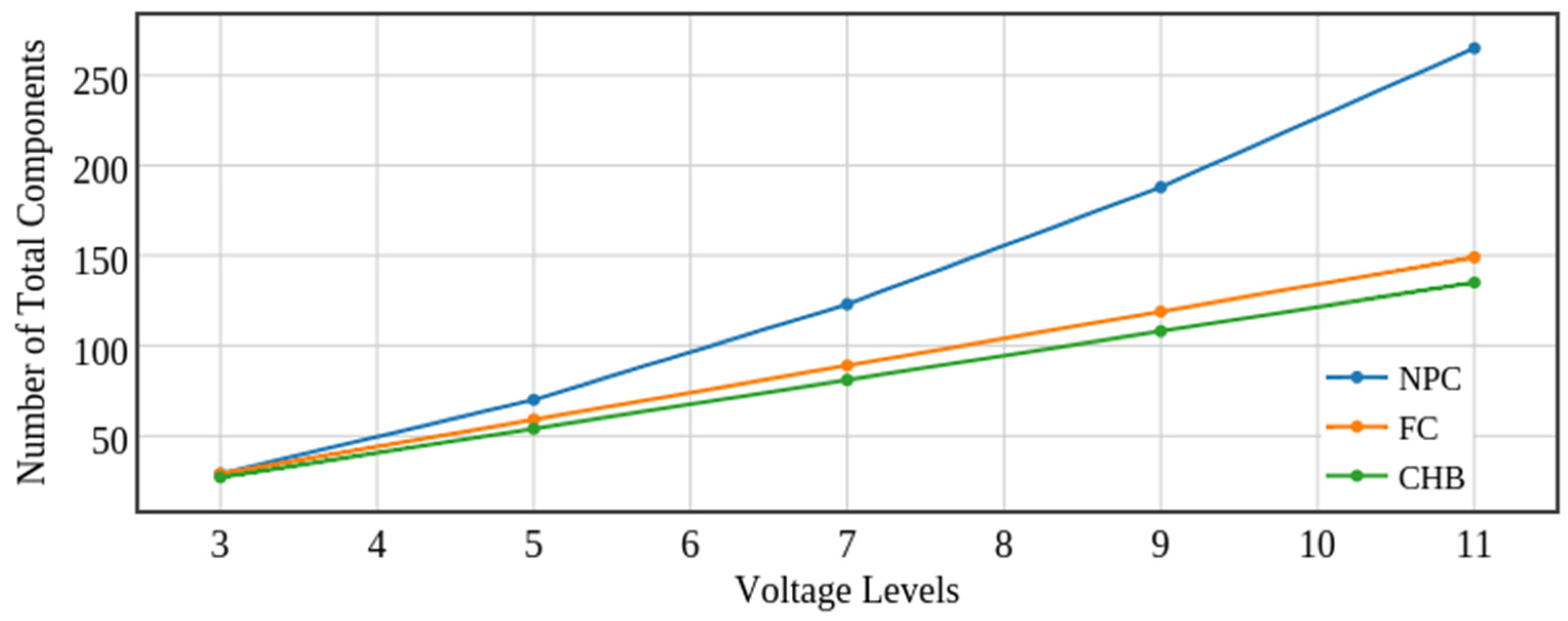

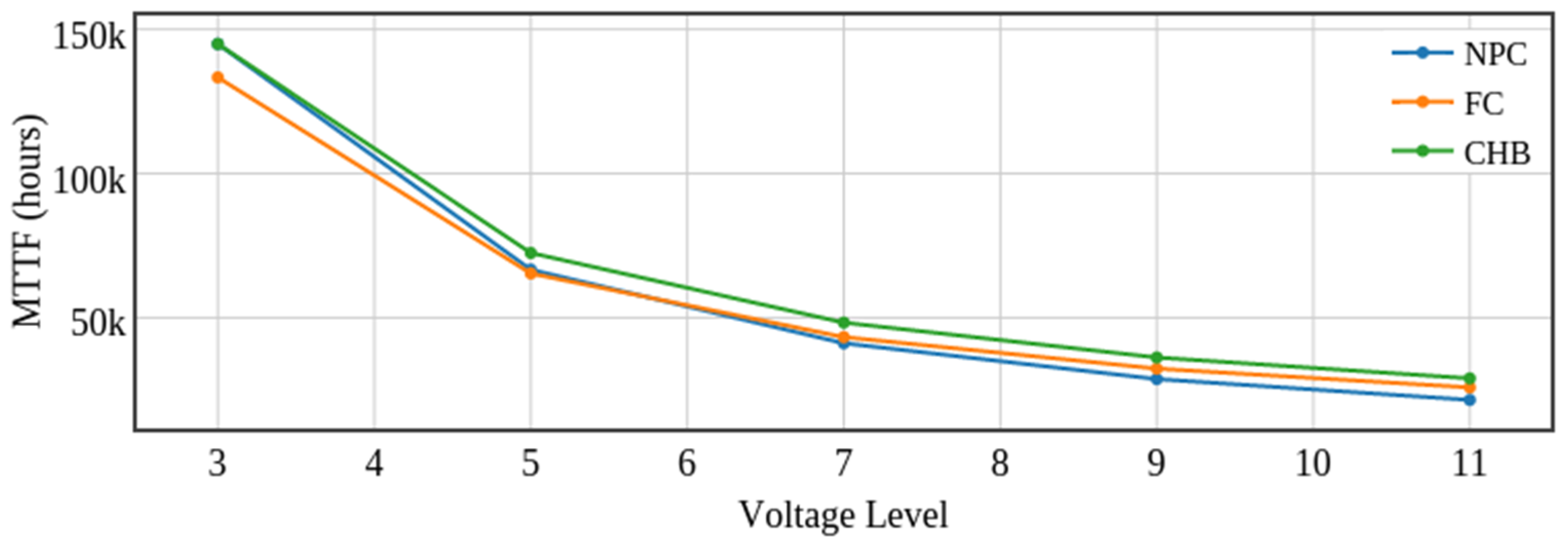

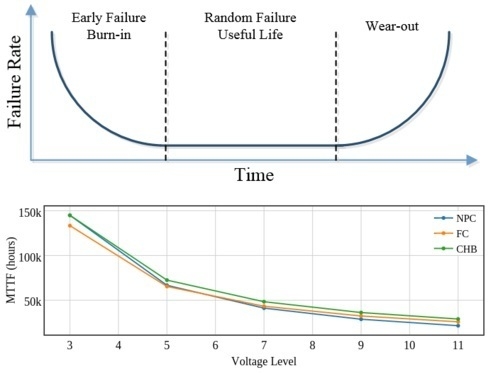

The approximate method used in this paper is similar to the method employed in Reference [

62], which the reliability of three-level NPC and CHB inverter based on FIT has been studied. In that article, the voltage difference between circuit elements in properly compared. In this comparison, NPC has used IGBT’s with medium voltage and CHB has used low voltage. In this comparison, the quantities of components have been the center of focus. The results of that article have shown that in terms of reliability, NPC inverter is 4.5 times better than CHB inverter.

It is obviously clear that one of the factors required for the analysis using this method is the voltage level of investigated inverters. In fact, this method of comparison is the same as parts count method, where failure rates are estimated based on voltage values. In addition, the comparison has been made when inverters were connected to the drive. Therefore it is necessary to make a comparison individually and without drive.

As mentioned above, we should find the voltage level of inverters in the first step. According to the authors of [

62,

63], the NPC, FC, and CHB inverters can be placed in the category of high, high, and low voltage IGBT switches. Based on this method, failure rate of diode has always been determined as 100 FIT, and failure rates of high voltage and low voltage IGBT have been determined as 400 FIT and 100 FIT, respectively. Additionally, failure rate of high voltage capacitor has been determined as 300 FIT and this parameter for low voltage capacitor has been determined as 400 FIT. The whole system failure rate can be determined by multiplying the diode, IGBT, and capacitors failure rate by their quantity, and summing all obtained values.

In general, the failure rate for a device under reference conditions can be expressed by:

where

k is the number of elements with the reference failure rate of

λref (i), and

N is the number of parts.

3.2. Exact Method

The exact method presents a scheme of parts stress method. Unlike the parts count method, parts stress method requires knowledge of the specific part’s stress levels and different operating conditions. In order to assess reliability of a system using this method, the various stresses on each part and accurate environment conditions are needed. These conditions can be shown by different pi factors in the failure rate equations. Number of various parameters in this method leads to a complexity in determining the failure rates, and although increases the accuracy. The total failure rate in the parts stress method can be calculated by summing all failure rates, similar to the parts count method. The following discussions will review the related relations of the exact method.

In MIL-HDBK-217 handbook, the failure rate of circuit components is calculated using an index called the base failure rate. Equation of base failure rate can be shown as below [

64]:

where

A is the scaling factor of failure rate.

NT,

TM, and

P are the shape parameters,

T is the temperature, Δ

T is the difference between maximum allowable temperature with no junction current and the maximum allowable temperature with full rated junction current or power,

S is the stress ratio that can be calculated by the ratio of actual stress to rated stress.

Handbook MIL-HDBK-217 offers a combined approach to predict reliability so that the reliability of each part of the system is determined individually and as a whole. Form of this model is as follows [

65]:

where λ

p is the predicted failure rate, λ

O is the failure rate from operational stresses, λ

e is the failure rate caused by environmental stresses, λ

C is the failure rate caused by temperature cycling stresses, λ

Sj is the failure rate caused by solder joints, λ

i is the failure rate caused by induced stresses, π

O is the operational factor, π

e is the environmental factor, π

C is the cycling factor, and π

Sj is the solder joints factor.

As the thickness of the solder increases, reliability also increases.

Figure 3 shows the effect of solder joint on the reliability of an IGBT module; as can be seen, module lifetime increases with increasing thickness of solder [

32]:

Recent articles about the reliability of electronic components (switches, diodes, capacitors and inductors) have presented specific relationships and equations for failure rate in each of these components. Considering to the components usually used in power electronic circuits, in this paper we express the failure rate for the following elements [

26,

47,

66,

67]:

where λ

b is the base failure rate, which is 0.012 and 0.064 for switch and diode, respectively. Equation (20) must be used to calculate

λb for inductors [

47,

67]:

where

THS is the heat sink temperature or the temperature of the inductor hot spot, which is calculated as follows [

26,

47,

67]:

In Equation (21),

TA is the device ambient operating temperature (in degrees Celsius); ∆

T is also average temperature rise above ambient. The following equation must be used to calculate λ

b for capacitors [

47]:

where

S is the ratio of operating voltage to nominal voltage. In switch and diode failure rates, π

T is the temperature factor and can be calculated as is shown below [

26,

47]:

In Equations (23) and (24),

Tj is the junction temperature and must be obtained by the following equation:

where

TC is the heat sink temperature, θ

jc is the thermal resistance of diode or switch (assumed 0.25 for switch and 1.6 for diode) and

Ploss is the power loss of switch or diode; π

S is the stress factor and is calculated as follows [

47]:

where

VS is the ratio of operating voltage to nominal voltage.

In the capacitor failure rate, π

CV is the capacitor factor which can be obtained by [

47]:

where

C is the capacitance values (in microfarad).

In some articles, π

Q (quality factor) and π

E (environment factor) have been considered to be equal to 1, and consequently have been ignored [

26,

66]. To increase the accuracy, the values of quality factor for semiconductor, inductor and capacitor, can be considered 5.5, 10 and 20 respectively. The value of 1 is considered as environment factor π

E for all components. Application factor

πA, and contact construction factor

πC can be obtained from

Table 1 and

Table 2:

The temperature factor plays a prominent role in the reliability assessment of power electronic devices, and is related to power losses for semiconductors components. Thus, the failure rate depends on the calculation method of power losses in diodes and IGBTs. The used approach in this paper is based upon the determination of conduction and switching losses for each semiconductor component. For this purpose, we used a simulation software to find an accurate value for power losses. Detailed and extensive explanations of the procedure for identifying and determining these power losses can be found in [

68].