Proposal of a Sustainable Circular Index for Manufacturing Companies

Abstract

:1. Introduction

2. Sustainability

3. Circular Economy

4. Sustainability and Circularity Assessment

5. Proposal of a Sustainable Circular Index

- Phase 1—Selection of sustainability and circularity indicators

- Phase 2—Weighting of indicators

- Phase 3—Normalization

- Phase 4—Aggregation method for Index construction

- Phase 5—Index construction.

5.1. Phase 1—Selection of Sustainability and Circularity Indicators

5.2. Phase 2—Weighting of Indicators

- wz represents the weighting of a particular variable z

- Mz represents the mean rating of a particular variable z

- represents the summation of the mean rating of each set of variables

5.3. Phase 3—Normalization

5.4. Phase 4—Aggregation Method for Index Construction

5.5. Phase 5—Index Construction

5.6. The Sustainable Circular Index

5.7. Discussion on the Selected Methods and Approaches Followed in this Work

6. Managerial Contribution of the Proposed Sustainable Circular Index

7. Conclusions

- Establishing a list of sustainability indicators sorted by TBL dimensions and circularity indicators.

- Generating a weight distribution for the quantitative assessment of dimensions and indicators’ importance, using diverse expert judgment by the Delphi method. This supports the decision-making process relating to sustainability improvement efforts.

- Presenting a guideline for the construction of a Sustainable Circular Index through the description of the framework and the corresponding steps.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ness, D. Sustainable urban infrastructure in China: Towards a Factor 10 improvement in resource productivity through integrated infrastructure systems. Int. J. Sustain. Dev. World Ecol. 2008, 15, 288–301. [Google Scholar] [CrossRef]

- Cole, M.; Rayner, A.J.; Bates, J.M. The environmental Kuznets curve: An empirical analysis. Environ. Dev. Econ. 1997, 2, 401–416. [Google Scholar] [CrossRef]

- Rennings, K.; Ludwig Brockmann, K.; Bergmann, H. Voluntary agreements in environmental protection: Experiences in Germany and future perspectives. Bus. Strategy Environ. 1997, 6, 245–263. [Google Scholar] [CrossRef]

- Yoshida, H.; Shimamura, K.; Aizawa, H. 3R strategies for the establishment of an international sound material-cycle society. J. Mater. Cycles Waste Manag. 2007, 9, 101–111. [Google Scholar] [CrossRef]

- Lazarevic, D.; Valve, H. Narrating expectations for the circular economy: Towards a common and contested European transition. Energy Res. Soc. Sci. 2017. [Google Scholar] [CrossRef]

- Scipioni, A.; Mazzi, A.; Mason, M.; Manzardo, A. The Dashboard of Sustainability to measure the local urban sustainable development: The case study of Padua Municipality. Ecol. Indic. 2009, 9, 364–380. [Google Scholar] [CrossRef]

- Sardain, A.; Tang, C.; Potvin, C. Towards a dashboard of sustainability indicators for Panama: A participatory approach. Ecol. Indic. 2016, 70, 545–556. [Google Scholar] [CrossRef]

- Prescott-Allen, R. The Wellbeing of Nations: A Country-by-Country Index of Quality of Life and the Environment; Island Press: Washington, DC, USA, 2001; ISBN 978-1-55963-831-9. [Google Scholar]

- Global Reporting Initiative Search. Available online: https://www.globalreporting.org/Search/Pages/default.aspx?k=Sustainability%20reporting%20guidelines&s=Website (accessed on 10 September 2017).

- IChemE|Sustainability Special Interest Group|Resources|Sustainability Tools. Available online: http://www.icheme.org/communities/special-interest-groups/sustainability/resources/sustainability%20tools.aspx (accessed on 10 September 2017).

- Searcy, C.; Elkhawas, D. Corporate sustainability ratings: An investigation into how corporations use the Dow Jones Sustainability Index. J. Clean. Prod. 2012, 35, 79–92. [Google Scholar] [CrossRef]

- Sariannidis, N.; Giannarakis, G.; Partalidou, X. The effect of weather on the European stock market: The case of Dow Jones Sustainability Europe Index. Int. J. Soc. Econ. 2016, 43, 943–958. [Google Scholar] [CrossRef]

- Becker, W.; Saisana, M.; Paruolo, P.; Vandecasteele, I. Weights and importance in composite indicators: Closing the gap. Ecol. Indic. 2017, 80, 12–22. [Google Scholar] [CrossRef] [PubMed]

- Abberger, K.; Graff, M.; Siliverstovs, B.; Sturm, J.-E. Using rule-based updating procedures to improve the performance of composite indicators. Econ. Model. 2017. [Google Scholar] [CrossRef]

- United Nations Development Programme. Human Development Report 2001: Making New Technologies Work for Human Development; Oxford University Press: Oxford, UK, 2001; ISBN 978-0-19-521835-0. [Google Scholar]

- Yale Center for Environmental Law and Policy. 2005 Environmental Sustainability Index: Benchmarking National Environmental Stewardship; Yale Center for Environmental Law and Policy: New Haven, CT, USA, 2005. [Google Scholar]

- Atkinson, G. Measuring Corporate Sustainability. J. Environ. Plan. Manag. 2000, 43, 235–252. [Google Scholar] [CrossRef]

- Benn, S.; Dunphy, D.; Griffiths, A. Organizational Change for Corporate Sustainability; Routledge: Oxford, UK, 2014; ISBN 978-1-317-81911-0. [Google Scholar]

- Oskarsson, K.; von Malmborg, F. Integrated management systems as a corporate response to sustainable development. Corp. Soc. Responsib. Environ. Manag. 2005, 12, 121–128. [Google Scholar] [CrossRef]

- Tschopp, D.J. Corporate social responsibility: A comparison between the United States and the European Union. Corp. Soc. Responsib. Environ. Manag. 2005, 12, 55–59. [Google Scholar] [CrossRef]

- Marrewijk, M.; van Hardjono, T.W. European Corporate Sustainability Framework for Managing Complexity and Corporate Transformation. J. Bus. Ethics 2003, 44, 121–132. [Google Scholar] [CrossRef]

- Hopwood, B.; Mellor, M.; O’Brien, G. Sustainable development: Mapping different approaches. Sustain. Dev. 2005. [Google Scholar] [CrossRef]

- Sneddon, C.; Howarth, R.B.; Norgaard, R.B. Sustainable development in a post-Brundtland world. Ecol. Econ. 2006, 57, 253–268. [Google Scholar] [CrossRef]

- Gończ, E.; Skirke, U.; Kleizen, H.; Barber, M. Increasing the rate of sustainable change: A call for a redefinition of the concept and the model for its implementation. J. Clean. Prod. 2007, 15, 525–537. [Google Scholar] [CrossRef]

- Baumgartner, R.J.; Korhonen, J. Strategic thinking for sustainable development. Sustain. Dev. 2010, 18, 71–75. [Google Scholar] [CrossRef]

- Labuschagne, C.; Brent, A.C.; Claasen, S.J. Environmental and social impact considerations for sustainable project life cycle management in the process industry. Corp. Soc. Responsib. Environ. Manag. 2005, 12, 38–54. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. An overview of sustainability assessment methodologies. Ecol. Indic. 2009, 9, 189–212. [Google Scholar] [CrossRef]

- Veleva, V.; Ellenbecker, M. Indicators of sustainable production: A new tool for promoting business sustainability. New Solut. J. Environ. Occup. Health Policy NS 2001, 11, 41–62. [Google Scholar] [CrossRef] [PubMed]

- Salvado, M.F.; Azevedo, S.G.; Matias, J.C.O.; Ferreira, L.M. Proposal of a Sustainability Index for the Automotive Industry. Sustainability 2015, 7, 2113–2144. [Google Scholar] [CrossRef]

- Searcy, C.; Karapetrovic, S.; McCartney, D. Designing sustainable development indicators: Analysis for a case utility. Meas. Bus. Excell. 2005, 9, 33–41. [Google Scholar] [CrossRef]

- Sikdar, S.K. Sustainable development and sustainability metrics. AIChE J. 2003, 49, 1928–1932. [Google Scholar] [CrossRef]

- Johnston, P.; Everard, M.; Santillo, D.; Robèrt, K.-H. Reclaiming the definition of sustainability. Environ. Sci. Pollut. Res. Int. 2007, 14, 60–66. [Google Scholar] [PubMed]

- World Commission on Environment and Development. Our Common Future; Oxford University Press: Oxford, UK, 1990; ISBN 978-0-19-553191-6. [Google Scholar]

- Wang, L. A Methodology of Sustainability Accountability and Management for Industrial Enterprises. Master’s Thesis, The State University of New York at Buffalo, Buffalo, NY, USA, 2005. [Google Scholar]

- Dyllick, T.; Hockerts, K. Beyond the business case for corporate sustainability. Bus. Strategy Environ. 2002, 11, 130–141. [Google Scholar] [CrossRef]

- Schaltegger, S.; Burritt, R.; Petersen, H. An Introduction to Corporate Environmental Management: Striving for Sustainability. Manag. Environ. Qual. Int. J. 2003, 14, 541–542. [Google Scholar] [CrossRef]

- Elkington, J. Accounting for the triple bottom line. Meas. Bus. Excell. 1998, 2, 18–22. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Elkington, J. Towards the Sustainable Corporation: Win-Win-Win Business Strategies for Sustainable Development. Calif. Manage. Rev. 1994, 36, 90–100. [Google Scholar] [CrossRef]

- Gros, D.; Roth, F. The Europe 2020 Strategy: Can It Maintain the EU’s Competitiveness in the World? Center for European Policy Studies: Brussels, Belgium, 2014; ISBN 978-94-6138-124-8. [Google Scholar]

- European Commission. Directorate-General Communication. Europe 2020: Europe’s Growth Strategy: Growing to a Sustainable and Job-Rich Future; Publications Office of the European Union: Luxembourg, 2012; ISBN 978-92-79-23972-4. [Google Scholar]

- Poschen, P. Decent Work, Green Jobs and the Sustainable Economy: Solutions for Climate Change and Sustainable Development; Greenleaf Publishing: Oxford, UK, 2015; ISBN 978-1-78353-447-0. [Google Scholar]

- REMake Greenovate! Europe. Available online: https://www.greenovate-europe.eu/projects/completed/remake (accessed on 10 September 2017).

- Meadows, D.; Meadows, D.L.; Randers, J.; Behrens Ill, W. The Limits to Growth: A Report for the Club of Rome’s Project on the Predicament of Mankind; New American Library: New York, NY, USA, 1974. [Google Scholar]

- Pan, J. The Development Paradigm of Ecological Civilization. In China’s Environmental Governing and Ecological Civilization; China Insights; Springer: Berlin/Heidelberg, Germany, 2016; pp. 29–49. ISBN 978-3-662-47428-0. [Google Scholar]

- Elks, J. Why a Circular Economy Is Key to Sustainable Development (and Why Business Must Lead the Way) Sustainable Brands. Available online: http://www.sustainablebrands.com/news_and_views/next_economy/jennifer_elks/why_circular_economy_key_sustainable_development_why_busin (accessed on 11 September 2017).

- Lacy, P.; Rutqvist, J. The Roots of the Circular Economy. In Waste to Wealth; Palgrave Macmillan: London, UK, 2015; pp. 19–23. ISBN 978-1-349-58040-8. [Google Scholar]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Robert, U.A.; Kneese, A.V. Production, Consumption, and Externalities; Resources for the Future: Washington, DC, USA, 1969. [Google Scholar]

- Gordon, R.B.; Bertram, M.; Graedel, T.E. Metal stocks and sustainability. Proc. Natl. Acad. Sci. USA 2006, 103, 1209–1214. [Google Scholar] [CrossRef] [PubMed]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; Harvester Wheatsheaf: Birmingham, UK, 1990; ISBN 978-0-7450-0202-6. [Google Scholar]

- Bandarage, A. Sustainability and Well-Being: The Middle Path to Environment, Society and the Economy; Springer: New York, NY, USA, 2013; ISBN 978-1-137-30899-3. [Google Scholar]

- Hellstrom, E.; Hamalainen, T.; Lahti, V.-M.; Cook, J.; Jousilahti, J. Towards a Sustainable Well-being Society—From Principles to Applications. Available online: https://media.sitra.fi/2017/02/23221124/Towards_a_Sustainable_Wellbeing_Society_2.pdf. (accessed on 15 September 2017).

- Smol, M.; Kulczycka, J.; Henclik, A.; Gorazda, K.; Wzorek, Z. The possible use of sewage sludge ash (SSA) in the construction industry as a way towards a circular economy. J. Clean. Prod. 2015, 95, 45–54. [Google Scholar] [CrossRef]

- Valipour, M. A comprehensive study on irrigation management in Asia and Oceania. Arch. Agron. Soil Sci. 2015, 61, 1247–1271. [Google Scholar] [CrossRef]

- Aminoff, A.; Valkokari, K.; Antikainen, M.; Kettunen, O. Exploring Disruptive Business Model Innovation for the Circular Economy. In Sustainable Design and Manufacturing 2017; Smart Innovation, Systems and Technologies; Springer: Cham, Switzerland, 2017; pp. 525–536. [Google Scholar]

- Prendeville, S.; Hartung, G.; Purvis, E.; Brass, C.; Hall, A. Makespaces: From Redistributed Manufacturing to a Circular Economy. In Sustainable Design and Manufacturing 2016; Smart Innovation, Systems and Technologies; Springer: Cham, Switzerland, 2016; pp. 577–588. ISBN 978-3-319-32096-0. [Google Scholar]

- Franconi, E.; Bridgeland, B.; Webster, K. A New Dynamic 2- Effective Systems in a Circular Economy; Ellen MacArthur Foundation Publishing: Isle of Wight, UK, 2016; ISBN 978-0-9927784-4-6. [Google Scholar]

- Georgescu-Roegen, N. Inequality, Limits and Growth from a Bioeconomic Viewpoint. Rev. Soc. Econ. 1977, 35, 361–375. [Google Scholar] [CrossRef]

- Daly, H.E.; Townsend, K.N. Valuing the Earth: Economics, Ecology, Ethics; MIT Press: Cambridge, MA, USA, 1996; ISBN 978-0-262-26056-5. [Google Scholar]

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition. Bind 1. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/TCE_Ellen-MacArthur-Foundation_9-Dec-2015.pdf (accessed on 27 September 2017).

- Vanner, R.; Hudson, C.; Bicket, M.; Sirini, W.; Patrick, B.; Paolo, R.; van Dijl, E.; Emma, W.; Mathieu, H.; Adrian, T.; et al. Scoping Study to Identify Potential Circular Economy Actions, Priority Sectors, Material Flows & Value Chains; European Commission, Directorate-General Research & Innovation: Brussels, Belgium, 2014; pp. 1–78. [Google Scholar]

- Jacobs, T.L.; Everett, J.W. Optimal Scheduling of Consecutive Landfill Operations with Recycling. J. Environ. Eng. 1992, 118, 420–429. [Google Scholar] [CrossRef]

- Tanskanen, J.-H.; Reinikainen, A.; Melanen, M. Waste streams, costs and emissions in municipal solid waste management: A case study from Finland. Waste Manag. Res. 1998, 16, 503–513. [Google Scholar] [CrossRef]

- Andreasi, B.S.; Christensen, T.H.; Damgaard, A. Environmental performance of household waste management in Europe—An example of 7 countries. Waste Manag. 2017, 69, 545–557. [Google Scholar] [CrossRef] [PubMed]

- Expósito, A.; Velasco, F. Municipal solid-waste recycling market and the European 2020 Horizon Strategy: A regional efficiency analysis in Spain. J. Clean. Prod. 2018, in press. [Google Scholar] [CrossRef]

- Patermann, C.; Aguilar, A. The origins of the bioeconomy in the European Union. New Biotechnol. 2017. [Google Scholar] [CrossRef] [PubMed]

- Powell-Turner, J.; Antill, P.D.; Fisher, R.E. The United Kingdom Ministry of Defence and the European Union’s electrical and electronic equipment directives. Resour. Policy 2016, 49, 422–432. [Google Scholar] [CrossRef]

- Bahers, J.-B.; Kim, J. Regional approach of waste electrical and electronic equipment (WEEE) management in France. Resour. Conserv. Recycl. 2018, 129, 45–55. [Google Scholar] [CrossRef]

- Parajuly, K.; Wenzel, H. Potential for circular economy in household WEEE management. J. Clean. Prod. 2017, 151, 272–285. [Google Scholar] [CrossRef]

- Welfens, P.; Bleischwitz, R.; Geng, Y. Resource efficiency, circular economy and sustainability dynamics in China and OECD countries. Int. Econ. Econ. Policy 2017, 14, 377–382. [Google Scholar] [CrossRef]

- United Nations. Report of the Commission on Sustainable Development Acting as the Preparatory Committee for the World Summit on Sustainable Development, 4th Session (27 May–7 June 2002); UN: New York, NY, USA, 2001. [Google Scholar]

- Bell, S.; Morse, S. Sustainability Indicators: Measuring the Immeasurable? Earthscan: London, UK, 2008; ISBN 978-1-84407-299-6. [Google Scholar]

- Mitchell, G. Problems and Fundamentals of Sustainable Development Indicators. Sustain. Dev. 1996, 4, 1–11. [Google Scholar] [CrossRef]

- Spangenberg, J.H. Environmental space and the prism of sustainability: Frameworks for indicators measuring sustainable development. Ecol. Indic. 2002, 2, 295–309. [Google Scholar] [CrossRef]

- Dewulf, J.; Van Langenhove, H. Integrating industrial ecology principles into a set of environmental sustainability indicators for technology assessment. Resour. Conserv. Recycl. 2005, 43, 419–432. [Google Scholar] [CrossRef]

- Hallstedt, S.I. Sustainability criteria and sustainability compliance index for decision support in product development. J. Clean. Prod. 2017, 140, 251–266. [Google Scholar] [CrossRef]

- United Nations. Indicators of Sustainable Development: Guidelines and Methodologies; United Nations Publications: New York, NY, USA, 2007; ISBN 978-92-1-104577-2. [Google Scholar]

- Kirchain, R.; Blanpain, B.; Meskers, C.; Olivetti, E.; Apelian, D.; Howarter, J.; Kvithyld, A.; Mishra, B.; Neelameggham, N.; Spangenberger, J. REWAS 2016: Towards Materials Resource Sustainability; Springer: Berlin, Germany, 2016; ISBN 978-3-319-48768-7. [Google Scholar]

- Filho, W.L.; Pociovalisteanu, D.-M.; Al-Amin, A.Q. Sustainable Economic Development: Green Economy and Green Growth; Springer: Berlin, Germany, 2016; ISBN 978-3-319-45081-0. [Google Scholar]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. How to Assess Product Performance in the Circular Economy? Proposed Requirements for the Design of a Circularity Measurement Framework. Recycling 2017, 2, 6. [Google Scholar] [CrossRef]

- Behrens, A.; Taranic, I.; Rizos, V. Resource Efficiency Indicators for Policy-Making. CEPS Working Document No. 415/November 2015. Available online: https://www.ceps.eu/system/files/WD415.pdf. (accessed on 27 September 2017).

- Finkbeiner, M. Special Types of Life Cycle Assessment; Springer: Berlin, Germany, 2016; ISBN 978-94-017-7610-3. [Google Scholar]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring circular economy strategies through index methods: A critical analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; New Society Publishers: Oxford, UK, 1997; ISBN 978-0-86571-392-5. [Google Scholar]

- Moriguchi, Y. Material flow indicators to measure progress toward a sound material-cycle society. J. Mater. Cycles Waste Manag. 2007, 9, 112–120. [Google Scholar] [CrossRef]

- Figge, F.; Hahn, T. Value-oriented impact assessment: The economics of a new approach to impact assessment. J. Environ. Plan. Manag. 2004, 47, 921–941. [Google Scholar] [CrossRef]

- Maio, F.D.; Rem, P.C. A Robust Indicator for Promoting Circular Economy through Recycling. J. Environ. Prot. 2015, 6, 1095. [Google Scholar] [CrossRef]

- Geng, Y.; Sarkis, J.; Ulgiati, S.; Zhang, P. Measuring China’s Circular Economy. Science 2013, 339, 1526–1527. [Google Scholar] [CrossRef] [PubMed]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.C.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Guogang, J.; Jing, C. Research on Evaluation of Circular Economy Development. In Proceedings of the 8th International Conference on Innovation & Management, Kitakyushu, Japan, 30 November–2 December 2011; pp. 153–157. [Google Scholar]

- Pintér, L. International Experience in Establishing Indicators for the Circular Economy and Considerations for China|IISD. Available online: http://www.iisd.org/library/international-experience-establishing-indicators-circular-economy-and-considerations-china (accessed on 11 September 2017).

- Zhijun, F.; Nailing, Y. Putting a circular economy into practice in China. Sustain. Sci. 2007, 2, 95–101. [Google Scholar] [CrossRef]

- Chertow, M.R. INDUSTRIAL SYMBIOSIS: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- National Academy Engineering. Technological Trajectories and the Human Environment; National Academies Press: Washington, DC, USA, 1997; ISBN 978-0-309-05133-0. [Google Scholar]

- Graedel, T.E.; Allenby, B.R. Industrial Ecology; Prentice Hall: Upper Saddle River, NJ, USA, 2003; ISBN 978-0-13-046713-3. [Google Scholar]

- Tromans, S. EC Waste Law—A Complete Mess? J. Environ. Law 2001, 13, 133–156. [Google Scholar] [CrossRef]

- Bisson, K.; Proops, J.L.R. Waste in Ecological Economics; Edward Elgar Publishing: Cheltenham, UK, 2002; ISBN 978-1-84064-648-1. [Google Scholar]

- Gaba, J.M. Solid waste and recycled materials under RCRA: Separating chaff from wheat. Ecol. Law Q. 1989, 16, 623–666. [Google Scholar]

- Ayres, R.U.; Ayres, L.W.; Martinás, K. Exergy, waste accounting, and life-cycle analysis. Energy 1998, 23, 355–363. [Google Scholar] [CrossRef]

- Rosen, M.A.; Dincer, I. On Exergy and Environmental Impact. Int. J. Energy Res. 1997, 21, 643–654. [Google Scholar] [CrossRef]

- Connelly, L.; Koshland, C.P. Exergy and industrial ecology. Part 2: A non-dimensional analysis of means to reduce resource depletion. Exergy Int. J. 2001, 1, 234–255. [Google Scholar] [CrossRef]

- Gaudreau, K.; Fraser, R.A.; Murphy, S. The Tenuous Use of Exergy as a Measure of Resource Value or Waste Impact. Sustainability 2009, 1, 1444–1463. [Google Scholar] [CrossRef]

- Haas, W.; Krausmann, F.; Wiedenhofer, D.; Heinz, M. How Circular is the Global Economy? An Assessment of Material Flows, Waste Production, and Recycling in the European Union and the World in 2005. J. Ind. Ecol. 2015, 19, 765–777. [Google Scholar] [CrossRef]

- Geng, Y.; Fu, J.; Sarkis, J.; Xue, B. Towards a national circular economy indicator system in China: An evaluation and critical analysis. J. Clean. Prod. 2012, 23, 216–224. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Guo-gang, J. Empirical Analysis of Regional Circular Economy Development—Study Based on Jiangsu, Heilongjiang, Qinghai Province. Energy Procedia 2011, 5, 125–129. [Google Scholar] [CrossRef]

- Qing, Y.; Qiongqiong, G.; Mingyue, C. Study and Integrative Evaluation on the development of Circular Economy of Shaanxi Province. Energy Procedia 2011, 5, 1568–1578. [Google Scholar] [CrossRef]

- Zaman, A.U.; Lehmann, S. The zero waste index: A performance measurement tool for waste management systems in a “zero waste city”. J. Clean. Prod. 2013, 50, 123–132. [Google Scholar] [CrossRef]

- Li, R.H.; Su, C.H. Evaluation of the circular economy development level of Chinese chemical enterprises. Procedia Environ. Sci. 2012, 13, 1595–1601. [Google Scholar] [CrossRef]

- Wen, Z.; Meng, X. Quantitative assessment of industrial symbiosis for the promotion of circular economy: A case study of the printed circuit boards industry in China’s Suzhou New District. J. Clean. Prod. 2015, 90, 211–219. [Google Scholar] [CrossRef]

- Scheepens, A.E.; Vogtländer, J.G.; Brezet, J.C. Two life cycle assessment (LCA) based methods to analyse and design complex (regional) circular economy systems. Case: Making water tourism more sustainable. J. Clean. Prod. 2016, 114, 257–268. [Google Scholar] [CrossRef]

- Park, J.Y.; Chertow, M.R. Establishing and testing the “reuse potential” indicator for managing wastes as resources. J. Environ. Manag. 2014, 137, 45–53. [Google Scholar] [CrossRef] [PubMed]

- Marković, A.; Rakočević, S.B. Proceedings of the xiv International Symposium Symorg 2014: New Business Models and Sustainable Competitiveness; FON: Belgrade, Serbia, 2014; ISBN 978-86-7680-295-1. [Google Scholar]

- Wang, Z.; Sarkis, J. Corporate social responsibility governance, outcomes, and financial performance. J. Clean. Prod. 2017, 162, 1607–1616. [Google Scholar] [CrossRef]

- Fet, A.M.; Knudson, H. Implementing Corporate Social Responsibility. In Encyclopedia of Sustainable Technologies; Abraham, M.A., Ed.; Elsevier: Oxford, UK, 2017; pp. 125–130. ISBN 978-0-12-804792-7. [Google Scholar]

- Salzman, J. Methodological Choices Encountered in the Construction of Composite Indices of Economic and Social Well-Being. In Proceedings of the Annual Meeting of the Canadian Economics Association, Ottawa, ON, CA, March 2003. [Google Scholar]

- Yu, L.; Liu, H. Efficient Feature Selection via Analysis of Relevance and Redundancy. J. Mach. Learn. Res. 2004, 5, 1205–1224. [Google Scholar]

- Manly, B.F.J.; Alberto, J.A.N. Multivariate Statistical Methods: A Primer, 4th ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-1-4987-2899-7. [Google Scholar]

- Hair, J.; Anderson, R.; Black, B.; Babin, B. Multivariate Data Analysis; Pearson Education: London, UK, 2016; ISBN 978-0-13-379268-3. [Google Scholar]

- Keeble, J.J.; Topiol, S.; Berkeley, S. Using Indicators to Measure Sustainability Performance at a Corporate and Project Level. J. Bus. Ethics 2003, 44, 149–158. [Google Scholar] [CrossRef]

- Seuring, S.A.; Koplin, J.; Behrens, T.; Schneidewind, U. Sustainability assessment in the German detergent industry: From stakeholder involvement to sustainability indicators. Sustain. Dev. 2003, 11, 199–212. [Google Scholar] [CrossRef]

- Welford, R.J. Editorial: Corporate environmental management, technology and sustainable development: Postmodern perspectives and the need for a critical research agenda. Bus. Strategy Environ. 1998, 7, 1–12. [Google Scholar] [CrossRef]

- Székely, F.; Knirsch, M. Responsible Leadership and Corporate Social Responsibility: Metrics for Sustainable Performance. Eur. Manag. J. 2005, 23, 628–647. [Google Scholar] [CrossRef]

- Chan, A.P.C.; Yung, E.H.K.; Lam, P.T.I.; Tam, C.M.; Cheung, S.O. Application of Delphi method in selection of procurement systems for construction projects. Constr. Manag. Econ. 2001, 19, 699–718. [Google Scholar] [CrossRef]

- Linstone, H.A.; Turoff, M. The Delphi Method: Techniques and Applications; Addison-Wesley Pub. Co., Advanced Book Program: Boston, MA, USA, 1975; ISBN 978-0-201-04294-8. [Google Scholar]

- Rowe, G.; Wright, G. The Delphi technique as a forecasting tool: Issues and analysis. Int. J. Forecast. 1999, 15, 353–375. [Google Scholar] [CrossRef]

- Yeung, J.F.Y.; Chan, A.P.C.; Chan, D.W.M.; Li, L.K. Development of a partnering performance index (PPI) for construction projects in Hong Kong: A Delphi study. Constr. Manag. Econ. 2007, 25, 1219–1237. [Google Scholar] [CrossRef]

- Israel, D. Data Analysis in Business Research: A Step-By-Step Nonparametric Approach; SAGE Publications: New Delhi, India, 2009; ISBN 978-81-321-0093-5. [Google Scholar]

- Nardo, M.; Saisana, M.; Saltelli, A.; Tarantola, S.; Hoffman, A.; Giovannini, E. Handbook on Constructing Composite Indicators; Organisation for Economic Co-operation and Development: Paris, France, 2005. [Google Scholar]

- Rovan, J. Composite Indicators. In International Encyclopedia of Statistical Science; Lovric, M., Ed.; Springer: Berlin/Heidelberg, Geramny, 2011; pp. 275–276. ISBN 978-3-642-0 4897-5. [Google Scholar]

- Zhou, P.; Ang, B.W.; Poh, K.L. Comparing aggregating methods for constructing the composite environmental index: An objective measure. Ecol. Econ. 2006, 59, 305–311. [Google Scholar] [CrossRef]

- Arrow, K.J. Social Choice and Individual Values; Yale University Press: New Haven, CT, USA, 2012; ISBN 978-0-300-18698-7. [Google Scholar]

- Fetscherin, M. The determinants and measurement of a country brand: The country brand strength index. Fac. Publ. 2010. [Google Scholar] [CrossRef]

- Nardo, M.; Saisana, M.; Saltelli, A.; Tarantola, S. Tools for Composite Indicators Buildings; European Commission, Joint Research Centre, 2005. Available online: http://publications.jrc.ec.europa.eu/repository/bitstream/JRC31473/EUR%2021682%20EN.pdf (accessed on 18 September 2017).

- Curwin, J.; Slater, R. Quantitative Methods for Business Decisions; Cengage Learning EMEA: Boston, MA, USA, 2007; ISBN 978-1-84480-574-7. [Google Scholar]

- Farmer, T.A. Testing the Robustness of Multiattribute Utility Theory in an Applied Setting. Decis. Sci. 1987, 18, 178–193. [Google Scholar] [CrossRef]

- Hartman, L.; Painter-Morland, M. Exploring the Global Reporting Initiative Guidelines as a Model for Triple Bottom-Line Reporting. Available online: https://www.researchgate.net/publication/240635956_Exploring_the_Global_Reporting_Initiative_Guidelines_as_a_model_for_triple_bottom-line_reporting (accessed on 27 September 2017).

- Rainey, D.L. Sustainable Business Development: Inventing the Future through Strategy, Innovation, and Leadership; Cambridge University Press: Cambridge, UK, 2010; ISBN 978-1-139-45711-8. [Google Scholar]

- Feil, A.A.; Quevedo, D.M.; de Schreiber, D. An analysis of the sustainability index of micro- and small-sized furniture industries. Clean Technol. Environ. Policy 2017, 19, 1883–1896. [Google Scholar] [CrossRef]

- Latif, H.H.; Gopalakrishnan, B.; Nimbarte, A.; Currie, K. Sustainability index development for manufacturing industry. Sustain. Energy Technol. Assess. 2017. [Google Scholar] [CrossRef]

- Shuaib, M.; Seevers, D.; Zhang, X.; Badurdeen, F.; Rouch, K.E.; Jawahir, I.S. Product Sustainability Index (ProdSI). J. Ind. Ecol. 2014, 18, 491–507. [Google Scholar] [CrossRef]

- Azapagic, A. Developing a framework for sustainable development indicators for the mining and minerals industry. J. Clean. Prod. 2004, 12, 639–662. [Google Scholar] [CrossRef]

- Baumann, H.; Tillman, A.-M. The Hitch Hiker’s Guide to LCA: An Orientation in Life Cycle Assessment Methodology and Application; Professional Publishing House: Los Angeles, CA, USA, 2004; ISBN 978-91-44-02364-9. [Google Scholar]

- Krajnc, D.; Glavič, P. A model for integrated assessment of sustainable development. Resour. Conserv. Recycl. 2005, 43, 189–208. [Google Scholar] [CrossRef]

- Jacobs, R.; Goddard, M. How Do Performance Indicators Add Up? An Examination of Composite Indicators in Public Services; Social Science Research Network: Rochester, NY, USA, 2007. [Google Scholar]

- Harik, R.; Hachem, W.E.; Medini, K.; Bernard, A. Towards a holistic sustainability index for measuring sustainability of manufacturing companies. Int. J. Prod. Res. 2015, 53, 4117–4139. [Google Scholar] [CrossRef]

- Freudenberg, M. Composite Indicators of Country Performance; Organisation for Economic Co-operation and Development: Paris, France, 2003. [Google Scholar]

- Shuaib, N.A.; Mativenga, P.T. Energy demand in mechanical recycling of glass fibre reinforced thermoset plastic composites. J. Clean. Prod. 2016, 120, 198–206. [Google Scholar] [CrossRef]

- Ülengin, B.; Ülengin, F.; Güvenç, Ü. A multidimensional approach to urban quality of life: The case of Istanbul. Eur. J. Oper. Res. 2001, 130, 361–374. [Google Scholar] [CrossRef]

- Lee, Y.-J.; Huang, C.-M. Sustainability index for Taipei. Environ. Impact Assess. Rev. 2007, 27, 505–521. [Google Scholar] [CrossRef]

- Keeney, R.L.; Raiffa, H. Decisions with Multiple Objectives: Preferences and Value Trade-Offs; Cambridge University Press: Cambridge, UK, 1993; ISBN 978-0-521-43883-4. [Google Scholar]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M.; Koh, S.L.; Rosa, P. A comparison of environmental and energetic performance of European countries: A sustainability index. Renew. Sustain. Energy Rev. 2017, 78, 401–413. [Google Scholar] [CrossRef]

- Zhou, L.; Tokos, H.; Krajnc, D.; Yang, Y. Sustainability performance evaluation in industry by composite sustainability index. Clean Technol. Environ. Policy 2012, 14, 789–803. [Google Scholar] [CrossRef]

- Munda, G.; Nardo, M. Constructing Consistent Composite Indicators: The Issue of Weights; European Commission, 2005. Available online: http://publications.jrc.ec.europa.eu/repository/bitstream/JRC32434/EUR%2021834%20EN.pdf (accessed on 16 September 2017).

- Podinovskii, V.V. Criteria importance theory. Math. Soc. Sci. 1994, 27, 237–252. [Google Scholar] [CrossRef]

| Level of Analysis | Reference | Description |

|---|---|---|

| National Level | [88] | Analyzed the adoption of Material flow accounting and analysis (MFA) models for measuring circular material flows. |

| [106] | Proposed a quantitative analysis based on the Economy-Wide MFA (EW-MFA) model to assess the circularity level of the European Union referred to in 2005. | |

| [107] | Discussed benefits and challenges due to the adoption of the so-called ‘Chinese national CE indicator system’, developed by the National Development and Reform Commission (NDRC). | |

| [108] | Consider four categories of indicators, as proposed by the Chinese Ministry of Environmental Protection: material reducing and recycling, economic development, pollution control and administration, and management perspectives. | |

| [60] | Pointed out four main ‘circularity areas’ to be measured at the national level: resource productivity, circular activities, waste generation and energy, and greenhouse gas GHG emissions. | |

| [107] | Discussed benefits and challenges due to the adoption of the so-called ‘Chinese national CE indicator system’, developed by the National Development and Reform Commission (NDRC). | |

| [93,109] | Proposed an index method for assessing the adoption of CE at the regional level. | |

| [110] | Discussed a similar method applied in a Chinese province by adding other categories of indicators, focusing on economic development, environment protection, and pollution reduction. | |

| [111] | Adopted the so-called ‘circular city metabolism’ measured trough a ‘zero-waste index’, based on the circularity of the waste management process in a city to compare the performance of three cities worldwide. | |

| Regional Level | [112] | Proposed a five category index method of economic development, resource exploitation, pollution reduction, ecological efficiency, and developmental potential to assess the circularity level of Chinese chemical enterprises. |

| [113] | Proposed a Resource Productivity (RP) indicator for assessing the CE paradigm level of adoption characterizing the Chinese printed circuit boards industry. | |

| [92] | Proposed a hybrid life cycle assessment (LCA) model combining traditional LCA with an environmental input-output analysis to compare the performances of circular production systems in two process industries (food and chemical). | |

| [114] | Applied the LCA Eco-cost and Value Ratio (EVR) model as a single indicator, integrating effectively the costs, eco-costs, and market value to assess the level of CE adoption in a regional water recreation park. | |

| Company Level | [60] | Proposed an index, called Material Circularity Indicator (MCI), to measure how restorative flows are maximized and linear flows are minimized, considering also the length and intensity of the product’s use. |

| [90] | Proposed the Circular Economy Index (CEI), which is defined as the ratio between the material value obtained from recycled products and the one entering the recycling facility. | |

| [115] | Proposed the Reuse Potential Indicator (RPI), which indicates how much a material is ‘resource-like’ rather than ‘waste-like’, attending to the current available technologies. |

| Dimension of Sustainability | Sustainability Indicators | Source | Unit of Measure |

|---|---|---|---|

| Social G4—LA2 | Number of accidents per year by organization | G4—LA6 Accident rate (TA) | Quantity |

| Loss of productivity by organization i | G4—LA7 | % | |

| Percentage of contracted women by the organization i | G4—LA12 Composition of governance bodies and breakdown of employees per employee category according to gender, age, and other indicators of diversity | % | |

| Percentage of temporary workers by organization i | G4—LA4 | % | |

| Absenteeism rate by organization i | G4—LA6 Type of injury and injury rates, diseases, lost days, absenteeism, and work-related deaths | % | |

| Rotation of workers by organization i | G4—LA1 Total number and rate of new employee hires and employee turnover | Quantity | |

| Percentage of people with special needs by organization i | G4—LA12 | % | |

| Economic | Direct economic value generated and distributed | G4—EC1 (operating costs + salaries and employee benefits + payment to suppliers of capital) | € |

| Research and development expenditures | [123,124,125] | € | |

| Number of persons employed | [126] | Quantity | |

| Environmental | Rate of non-hazardous waste | ISO 14031 | % |

| Rate of hazardous waste | ISO 14031 | % | |

| Amount of water consumed per year in industrial processes | ISO 14031 | m3 | |

| Amount of energy used per year | G4—EN3 Power consumption within the organization ISO 14031 | kW/h |

| Indicator | Characterization | Calculation | Unit of Measure |

|---|---|---|---|

| Input in the production process | Quantity of the inputs that are coming from virgin and recycled materials and reused components. | The amount of virgin material (VM) for each sub-assembly, part, and/or material: V(x) = M(x)(1 − FR(x) − FU(x)), where M(x)—Mass of a product x FR(x)—Fraction of mass of a product’s feedstock x from recycled sources; FU(x)—Fraction of mass of a product’s feedstock x from reused sources The total amount of virgin material: Wo(x) = M(x)(1 − CR(x) − CU(x)), where: CR(x)—Fraction of mass of a product x being collected to go into a recycling process and CU(x)—Fraction of mass of a product x going into component reuse | Quantity |

| Utility during use phase | Lifetime and intensity of the product used compared to an industry average product of similar type. This considers the increased durability of products and also repair/maintenance and shared consumption business models. | Lav.—This is based on the premise that, if the lifetime of a product is doubled, the waste created and the virgin materials used per year by the linear portion of a product’s flow are halved. U/Uav—Reflects the extent to which a product is used to its full capacity. U—Number of functional units achieved during the use of a product. Uav The number of functional units achieved during the use of an industry-average product of similar type. It is expected that, in most cases, either lifetimes or functional units, but not both, will be used to calculate UtilusePhase. If lifetimes are used exclusively, this means assuming that LU/ULav = 1. If functional units are used exclusively, this means assuming U/Uav = 1. | Quantity |

| Efficiency of recycling | Quantifies how efficient are the recycling processes used to produce recycled input and to recycle material after use. | The values of efficiency of the recycling process for a specific material and recycling process will depend on a wide range of factors such as: material(s)—some materials are easier to recycle and will often have higher recycling efficiency; the quantity of material(s) involved; the recycling preparation process—higher efficiency can be expected when product disassembly takes place prior to material recovery; Values for recycling efficiency can be derived from various sources, for example: Reference Documents on Best Available Techniques from the European IPPC Bureau; U. Arena, “LCA of a Plastic Packaging Recycling System”, the International Journal of Life Cycle Assessment, March 2003, Volume 8, Issue 2, pages 92 to 98; P. Shonfield, “LCA of Management Options for Mixed Waste Plastics”, WRAP, 2008. | Percentage |

| Index Dimensions (Iis) | Indicators |

|---|---|

| Ii1 = Social Sustainability | I11—number of accidents per year by company |

| I21—loss of productivity by company j | |

| I31—percentage of contracted women employed by company j | |

| I41—percentage of temporary workers employed by company j | |

| I51—absenteeism rate by company j | |

| I61—rotation of workers by company j | |

| I71—percentage of people with special needs employed by company j | |

| Ii2 = Economic sustainability | I12—direct economic value generated and distributed |

| I22—research and development expenditures | |

| I32—number of persons employed | |

| Ii3 = Environmental sustainability | I13—rate of non-hazardous waste |

| I23—rate of hazardous waste | |

| I33—amount of water consumed per year in industrial processes | |

| I43—amount of energy used per year | |

| Ii4 = Circularity | I14—input in the production process |

| I24—utility during use phase | |

| I34—efficiency of recycling |

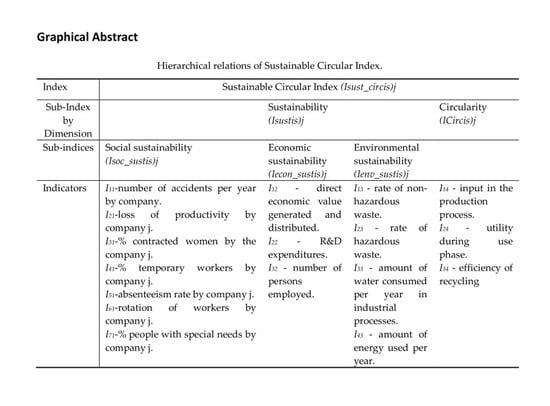

| Index | Sustainable Circular Index (Isust_circis)j | |||

|---|---|---|---|---|

| Sub-Index by Dimension | Sustainability (Isustis)j | Circularity (ICircis)j | ||

| Sub-indices | Social sustainability (Isoc_sustis)j | Economic sustainability (Iecon_sustis)j | Environmental sustainability (Ienv_sustis)j | |

| Indicators | I11—number of accidents per year by company. I21—loss of productivity by company j. I31—percentage of contracted women employed by company j. I41—percentage of temporary workers employed by company j. I51—absenteeism rate by company j. I61—rotation of workers by company j. I71—percentage of people with special needs employed by company j. | I12—direct economic value generated and distributed. I22—research and development expenditures. I32—number of persons employed. | I13—rate of non-hazardous waste. I23—rate of hazardous waste. I33—amount of water consumed per year in industrial processes. I43—amount of energy used per year. | I14—input in the production process. I24—utility during use phase. I34—efficiency of recycling |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azevedo, S.G.; Godina, R.; Matias, J.C.d.O. Proposal of a Sustainable Circular Index for Manufacturing Companies. Resources 2017, 6, 63. https://doi.org/10.3390/resources6040063

Azevedo SG, Godina R, Matias JCdO. Proposal of a Sustainable Circular Index for Manufacturing Companies. Resources. 2017; 6(4):63. https://doi.org/10.3390/resources6040063

Chicago/Turabian StyleAzevedo, Susana Garrido, Radu Godina, and João Carlos de Oliveira Matias. 2017. "Proposal of a Sustainable Circular Index for Manufacturing Companies" Resources 6, no. 4: 63. https://doi.org/10.3390/resources6040063