Flexural Behavior of Hybrid PVA Fiber and AR-Glass Textile Reinforced Geopolymer Composites

Abstract

:1. Introduction

2. Experimental Program, Materials, and Methods

3. Results and Discussion

3.1. Compressive Strengths

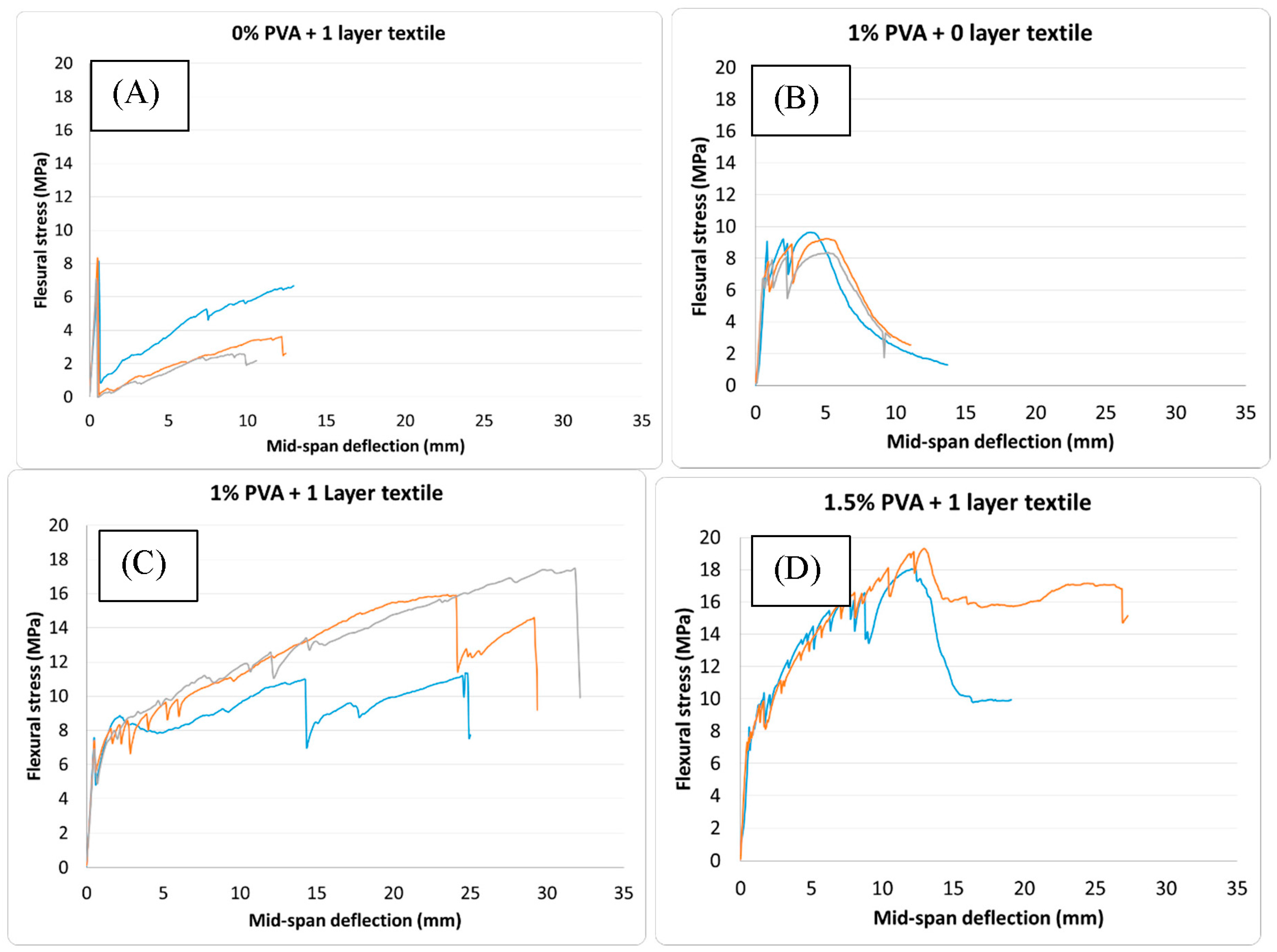

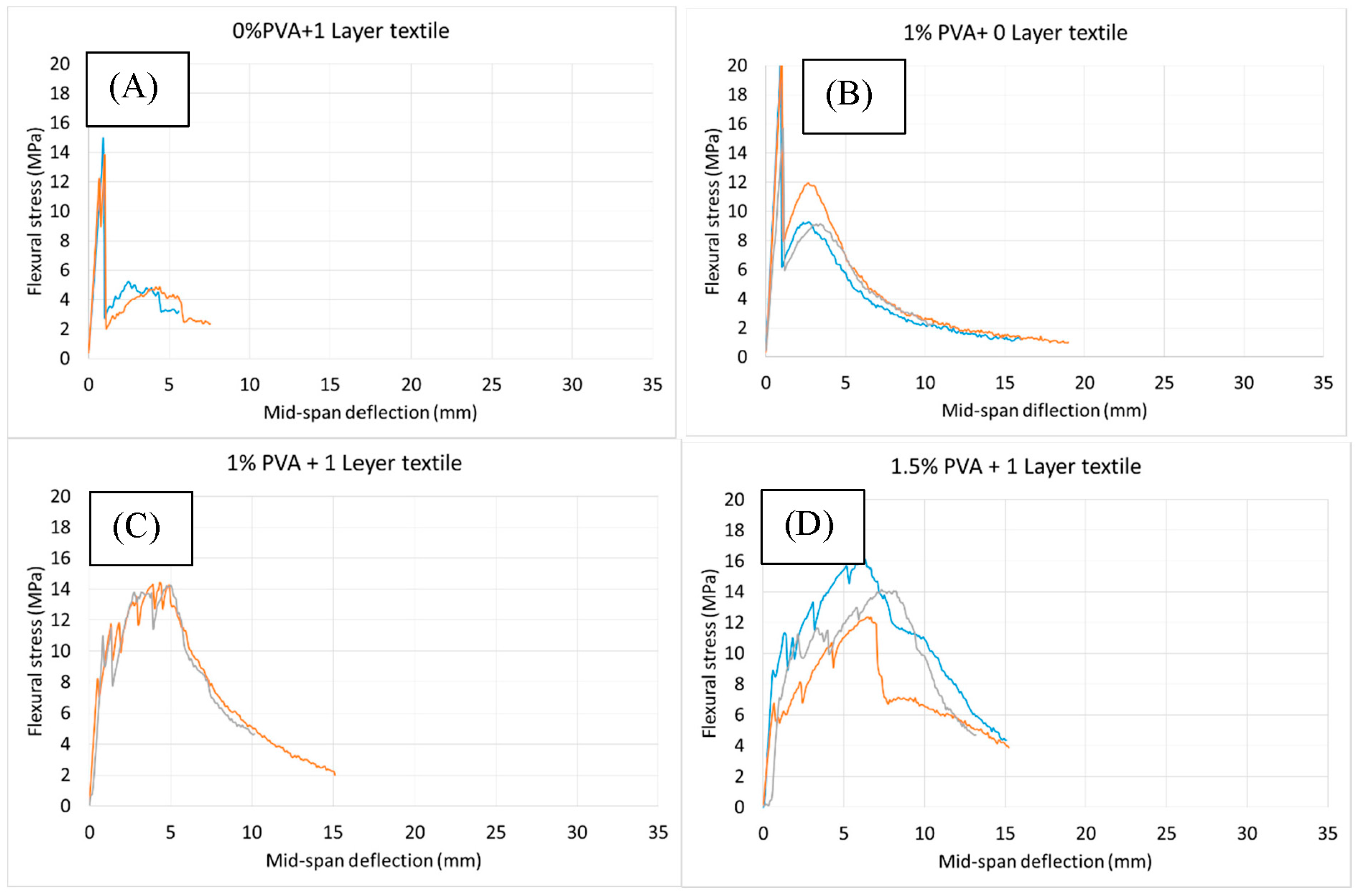

3.2. Flexural Behavior of TRG and TRC Composites

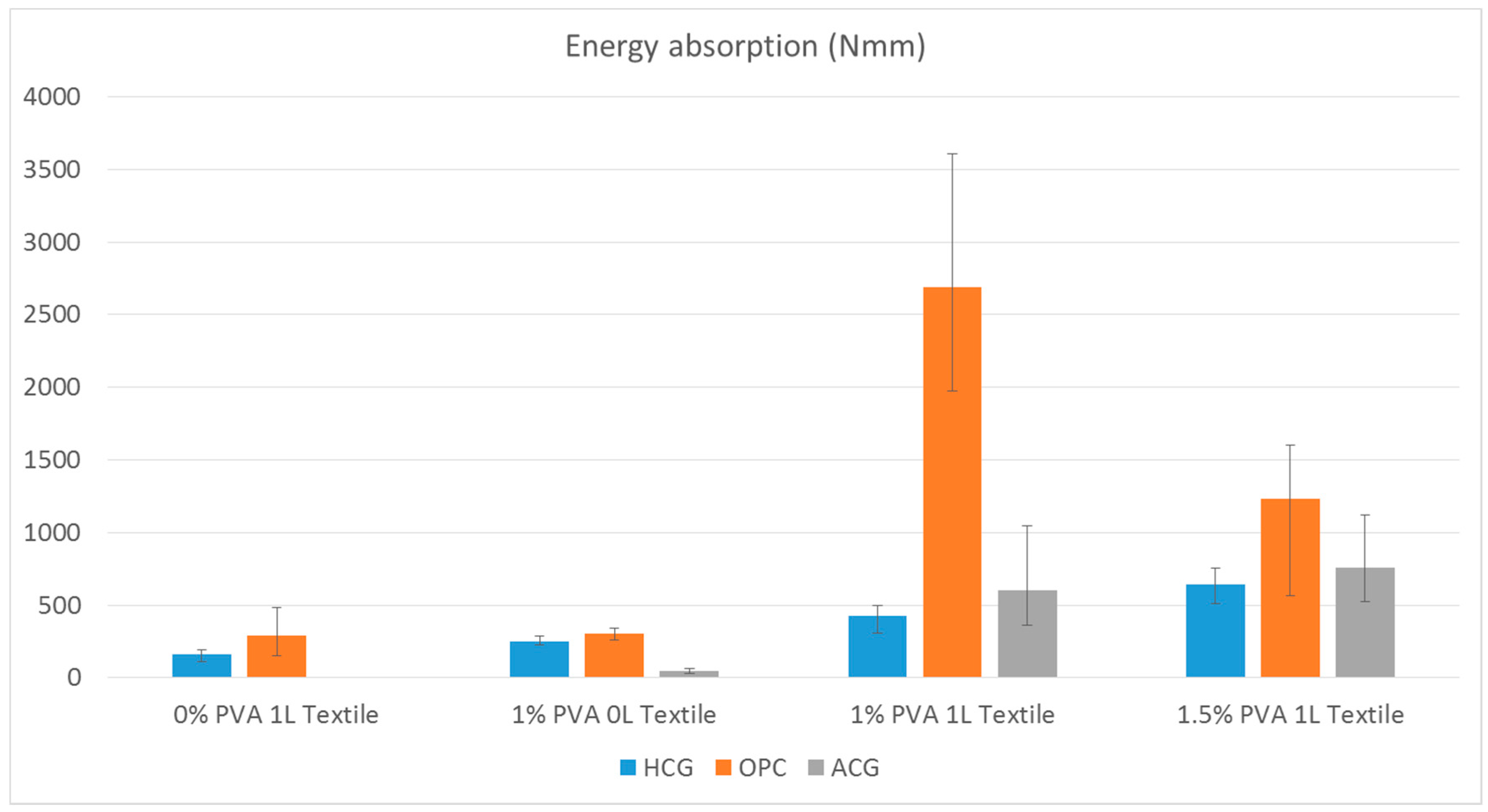

3.3. Energy Absorption Capacity

4. Conclusions

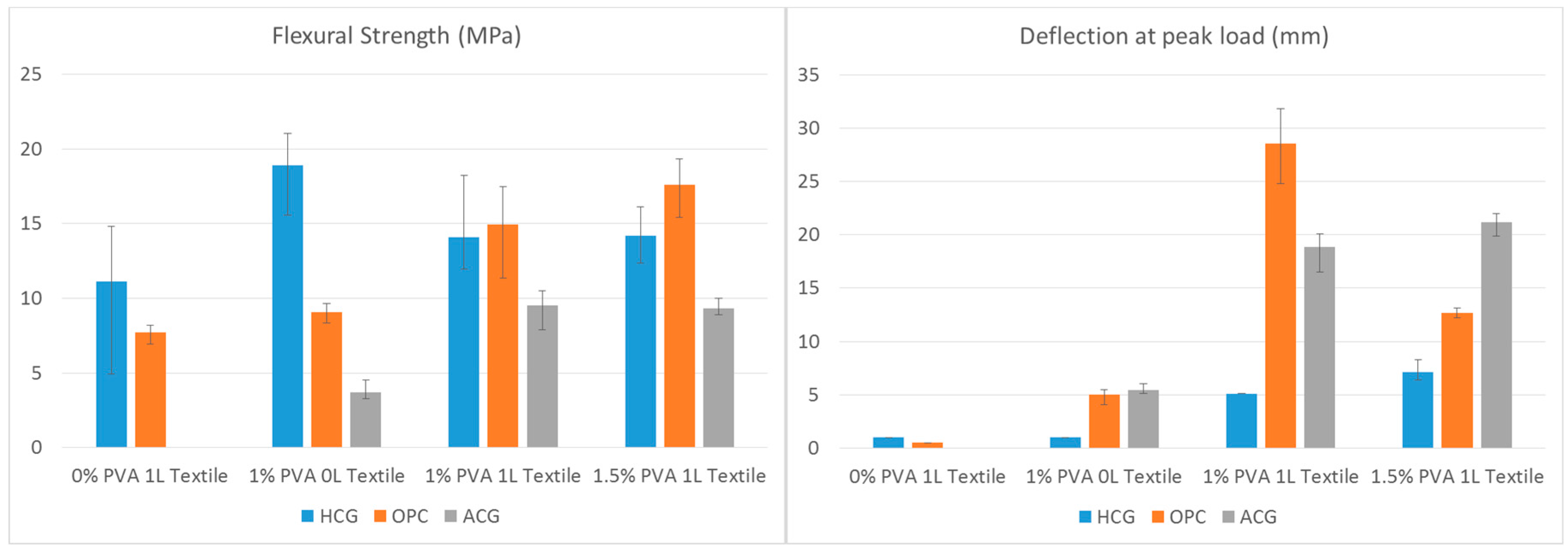

- Flexural stress and deflection behavior of heat cured AR glass TRG is very similar to its cement based TRC counterpart, with flexural strength of former is higher than the latter.

- The addition of PVA fiber in TRGs yielded the deflection hardening behavior. The flexural strength of heat cured hybrid PVA fiber–AR glass fiber TRG is higher than its ambient cured counterpart TRG. However, in the case of deflection at peak load, the opposite phenomenon is observed.

- The increase in PVA fibers from 1% to 1.5% is not affected the flexural strength of both TRGs, however, the deflection at peak load is increased in both TRGs.

- The addition of PVA fiber significantly improved the energy absorption capacity during deflection, hardening up to peak load in both TRGs and TRC. However, in TRC, the energy absorption capacity is significantly decreased due to the increase in PVA fiber from 1% to 1.5%, which is not observed in both TRGs.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, V.C.; Wu, H.C.; Maalej, M.; Mishra, D.K.; Hashida, T. Tensile behavior of engineered cementitious composites with random discontinuous steel fibres. J. Am. Ceram. Soc. 1996, 79, 74–78. [Google Scholar] [CrossRef]

- Naaman, A.E.; Reinhardt, H.W. Characterization of high performance fiber reinforced cement composites. In Proceedings of the Second International RILEM Workshop, Ann Arbor, MI, USA, June 1995; pp. 1–24. [Google Scholar]

- Ahmed, S.F.U.; Maalej, M.; Paramasivam, P. Flexural responses of hybrid steel–polyethylene fibre reinforced cement composites containing high volume fly ash. J. Constr. Build. Mater. 2006, 21, 1088–1097. [Google Scholar] [CrossRef]

- Ahmed, S.F.U.; Maalej, M. Tensile strain hardening behaviour of hybrid steel-polyethylene fibre reinforced cementitious composites. J. Constr. Build. Mater. 2009, 23, 96–106. [Google Scholar] [CrossRef]

- Ahmed, S.F.U.; Mihashi, H. A review on durability properties of strain hardening fibre reinforced cementitious composites. Cem. Concr. Compos. 2007, 29, 365–376. [Google Scholar] [CrossRef]

- Naaman, A.E. Ferrocement and Laminated Cementitious Composites; Techno Press 3000: Ann Arbor, MI, USA, 2000; ISBN 0-9674939-0-0. [Google Scholar]

- Nervi, P.L. Ferrocement: Its Characteristics and Potentialities; Library Translation No. 60; Cement and Concrete Association: London, UK, 1956. [Google Scholar]

- Mansur, M.A.; Ong, K.C.G. (Eds.) Ferro-7: Proceedings of the “Seventh International Symposium on Ferrocement and Thin Reinforced Cement Composites”; National University of Singapore: Singapore, 2001. [Google Scholar]

- Naaman, A.E.; Chandrangsu, K. Bending behavior of laminated cementitious composites reinforced with FRP meshes. In ACI Symposium on High Performance Fiber-Reinforced Concrete Thin Sheet Product, 97–116; Peled, A., Shah, S.P., Banthia, N., Eds.; ACI SP 190; American Concrete Institute: Farmington Hills, MI, USA, 2000. [Google Scholar]

- Williams, B.; Kodur, V.R.; Green, M.F.; Bisby, L.A. Fire endurance of FRP- strengthened concrete T-beams. ACI Struct. J. 2008, 105, 60–67. [Google Scholar]

- Hawileh, R.A.L.; Naser, M.L.; Zaidan, W.L.; Rasheed, H.A. Modeling of insulated CFRP-strengthened reinforced concrete T-beam exposed to fire. Eng. Struct. 2009, 31, 3072–3079. [Google Scholar] [CrossRef]

- Naser, M.; Hawileh, R.; Rasheed, H. Performance of RC T-Beams externally strengthened with CFRP laminates under elevated temperatures. J. Struct. Fire Eng. 2014, 5, 1–24. [Google Scholar] [CrossRef]

- Bisby, L.A. Fire Behaviour of Fibre-Reinforced Polymer (FRP) Reinforced or Confined Concrete; Queen’s University: Kingston, ON, USA, 2003; p. 2520. [Google Scholar]

- Gamage, J.; Al-Mahaidi, R.; Wong, M. Bond characteristics of CFRP plated concrete members under elevated temperatures. Compos. Struct. 2006, 75, 199–205. [Google Scholar] [CrossRef]

- Alaee, F.J.; Karihaloo, B.L. Retrofitting of reinforced concrete beams with CARDIFRC. J. Compos. Constr. 2003, 7, 174–186. [Google Scholar] [CrossRef]

- Buyukozturk, O.; Haering, B. Failure behaviour of precracked concrete beams with FRP. J. Compos. Constr. 1998, 2, 138–144. [Google Scholar] [CrossRef]

- Butler, M.; Mechtcherine, V.; Hempel, S. Experimental investigations on the durability of fibre matrix interfaces in textile reinforced concrete. Cem. Concr. Compos. 2009, 31, 221–231. [Google Scholar] [CrossRef]

- Mechtcherine, V. Novel cement based composites for the strengthening and repair of concrete structures. Constr. Build. Mater. 2013, 41, 365–373. [Google Scholar] [CrossRef]

- Barhum, R.; Mechtcherine, V. Effect of short, dispersed glass and carbon fibres on the behaviour of textile reinforced concrete under tensile loading. Eng. Fract. Mech. 2012, 92, 56–71. [Google Scholar] [CrossRef]

- Barhum, R.; Mechtcherine, V. Influence of short dispersed and short integral glass fibres on the mechanical behaviour of textile reinforced concrete. Mater. Struct. 2013, 46, 557–572. [Google Scholar] [CrossRef]

- Raoof, S.M.; Koutas, L.N.; Bourns, D.A. Bond between textile-reinforced mortar (TRM) and concrete substrates: Experimental investigation. Compos. Part B Eng. 2016, 98, 350–361. [Google Scholar] [CrossRef]

- Tetta, Z.C.; Koutas, L.N.; Bourns, D.A. Textile-reinforced mortar (TRM) versus fiber-reinforced polymers (FRP) in shear strengthening of concrete beams. Compos. Part B Eng. 2015, 77, 338–348. [Google Scholar] [CrossRef]

- Papanicolaou, C.G.; Papantoniou, I.C. Mechanical behaviour of textile reinforced concrete (TRC)/concrete composite elements. J. Adv. Concr. Technol. 2010, 8, 35–47. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data. 2017. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Tamburini, S.; Natali, M.; Garbin, E.; Panizza, M.; Favaro, M.; Valluzzi, M.R. Geopolymer matrix for fibre reinforced composites aimed at strengthening masonry structures. Constr. Build. Mater. 2017, 141, 542–552. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Ferone, C.; Colangelo, F.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Use of geopolymers for composite external reinforcement of RC members. Compos. Part B Eng. 2013, 45, 1667–1676. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, Y.; Zhu, H.; Hua, S.; Chen, Y. Preparation and mechanical properties of polypropylene fibre reinforced calcined kaolin fly ash based geopolymer. J. Cent. South Univ. Technol. 2009, 16, 49–52. [Google Scholar] [CrossRef]

- Khan, M.Z.N.; Shaikh, F.U.A.; Hao, Y.; Hao, H. Synthesis of high strength ambient cured geopolymer composite by using low calcium fly ash. Constr. Build. Mater. 2016, 125, 809–820. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Shaikh, F.U.A. Tensile strain hardening behaviour of PVA fibre reinforced engineered geopolymer composites. J. Mater. Civil Eng. 2015, 27, 04015001. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Deflection hardening behaviour of short fibre reinforced fly ash based geo-polymer composites. Mater. Des. 2013, 50, 674–680. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E. High ductile behaviour of a polyethylene fibre reinforced one-part geopolymer composite: A micromechanical based investigation. Arch. Civil Mech. Eng. 2017, 17, 555–563. [Google Scholar] [CrossRef]

| Types of Composites | PVA Fiber (vol.%) | AR Glass Textile | Mix Ratio (by wt.%) | ||||

|---|---|---|---|---|---|---|---|

| Fly Ash | Slag | OPC | Alkali Activators | Water | |||

| TRC | 1.0 | - | - | - | 1 | - | 0.4 |

| - | 1 layer | - | - | 1 | - | 0.4 | |

| 1.0 | 1 layer | - | - | 1 | - | 0.4 | |

| 1.5 | 1 layer | - | - | 1 | - | 0.4 | |

| Heat cured TRG | 1.0 | - | 1 | - | - | 0.4 | - |

| - | 1 layer | 1 | - | - | 0.4 | - | |

| 1.0 | 1 layer | 1 | - | - | 0.4 | - | |

| 1.5 | 1 layer | 1 | - | - | 0.4 | - | |

| Ambient cured TRG | 1.0 | - | 0.9 | 0.1 | - | 0.4 | - |

| - | 1 layer | 0.9 | 0.1 | - | 0.4 | - | |

| 1.0 | 1 layer | 0.9 | 0.1 | - | 0.4 | - | |

| 1.5 | 1 layer | 0.9 | 0.1 | - | 0.4 | - | |

| Compounds | SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | K2O | MgO | P2O5 | SO3 | TiO2 | MnO | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fly ash | 51.11 | 25.56 | 12.48 | 4.3 | 0.77 | 0.7 | 1.45 | 0.885 | 0.24 | 1.32 | 0.15 | 0.57 |

| Slag | 32.50 | 13.56 | 0.85 | 41.2 | 0.27 | 0.35 | 5.10 | 0.03 | 3.2 | 0.49 | 0.25 | 1.11 |

| Types of Fiber | Length (mm) | Diameter (mm) | Modulus of Elasticity (MPa) | Fiber Strength (MPa) | Density (gm/cm3) | Elongation (%) |

|---|---|---|---|---|---|---|

| PVA | 8 | 0.04 | 40,000 | 1600 | 1.3 | 6 |

| Product Data: | |

| Form: | Glass fiber grid with alkali resistant SBR coating |

| Fiber type: | E-glass fiber |

| Fiber construction: | Fiber orientation 0/90° (bi-directional) |

| Technical data: | |

| Fiber density: | 2.6 g/m2 |

| Finishing: | Soft SBR Coating |

| Stitch spacing: | 16.2 × 14.2 mm (center to center distance) |

| Mechanical properties | |

| Tensile strength: | 2600 MPa (measured on roving) |

| Tensile e-modulus: | >80,000 MPa |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shaikh, F.U.A.; Patel, A. Flexural Behavior of Hybrid PVA Fiber and AR-Glass Textile Reinforced Geopolymer Composites. Fibers 2018, 6, 2. https://doi.org/10.3390/fib6010002

Shaikh FUA, Patel A. Flexural Behavior of Hybrid PVA Fiber and AR-Glass Textile Reinforced Geopolymer Composites. Fibers. 2018; 6(1):2. https://doi.org/10.3390/fib6010002

Chicago/Turabian StyleShaikh, Faiz Uddin Ahmed, and Aditya Patel. 2018. "Flexural Behavior of Hybrid PVA Fiber and AR-Glass Textile Reinforced Geopolymer Composites" Fibers 6, no. 1: 2. https://doi.org/10.3390/fib6010002