Experimental and Analytical Modeling of GFRP Strengthened Grouted Mortarless Masonry Prisms

Abstract

:1. Introduction

2. Experimental Research

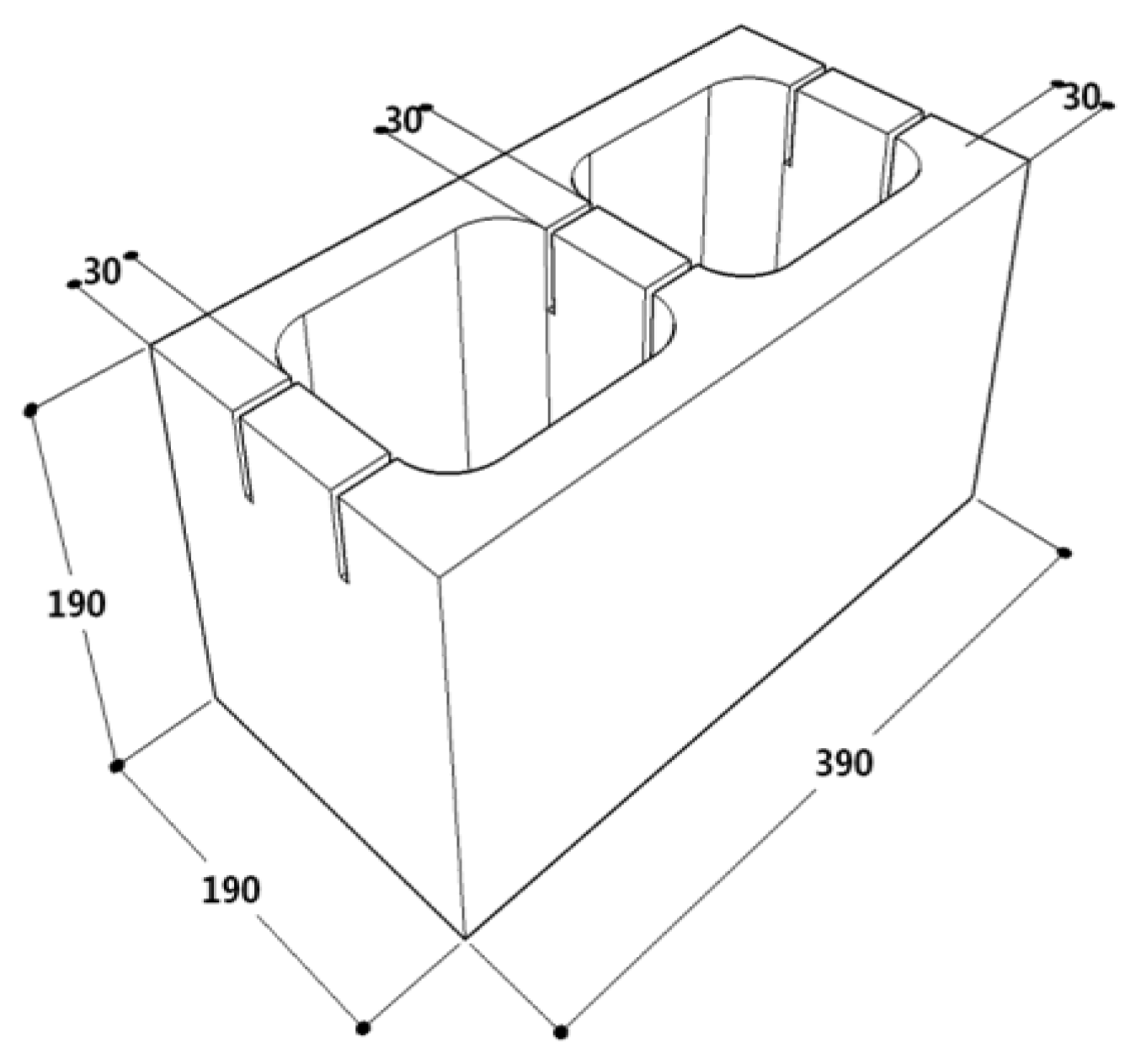

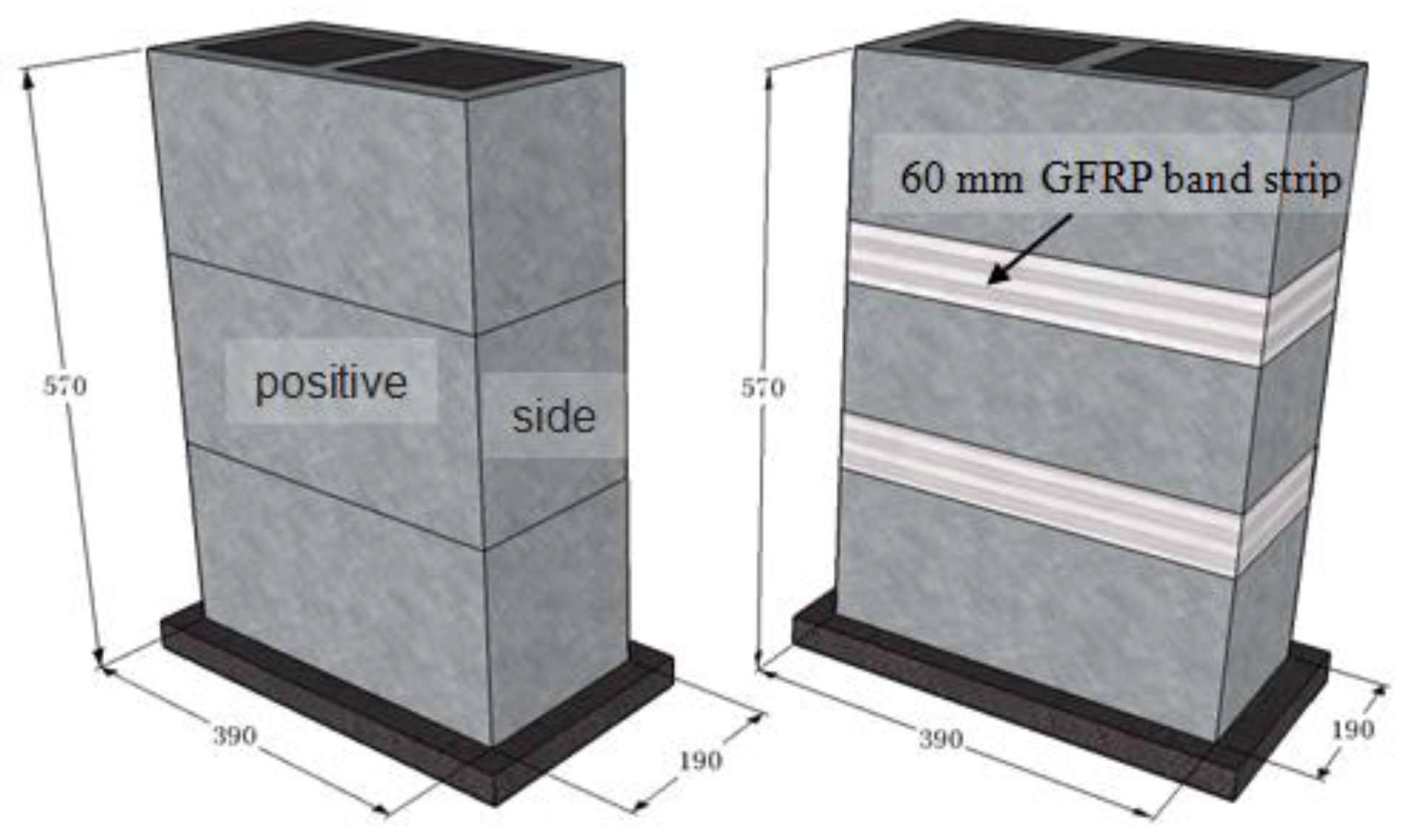

2.1. Material and Specimen Fabrication

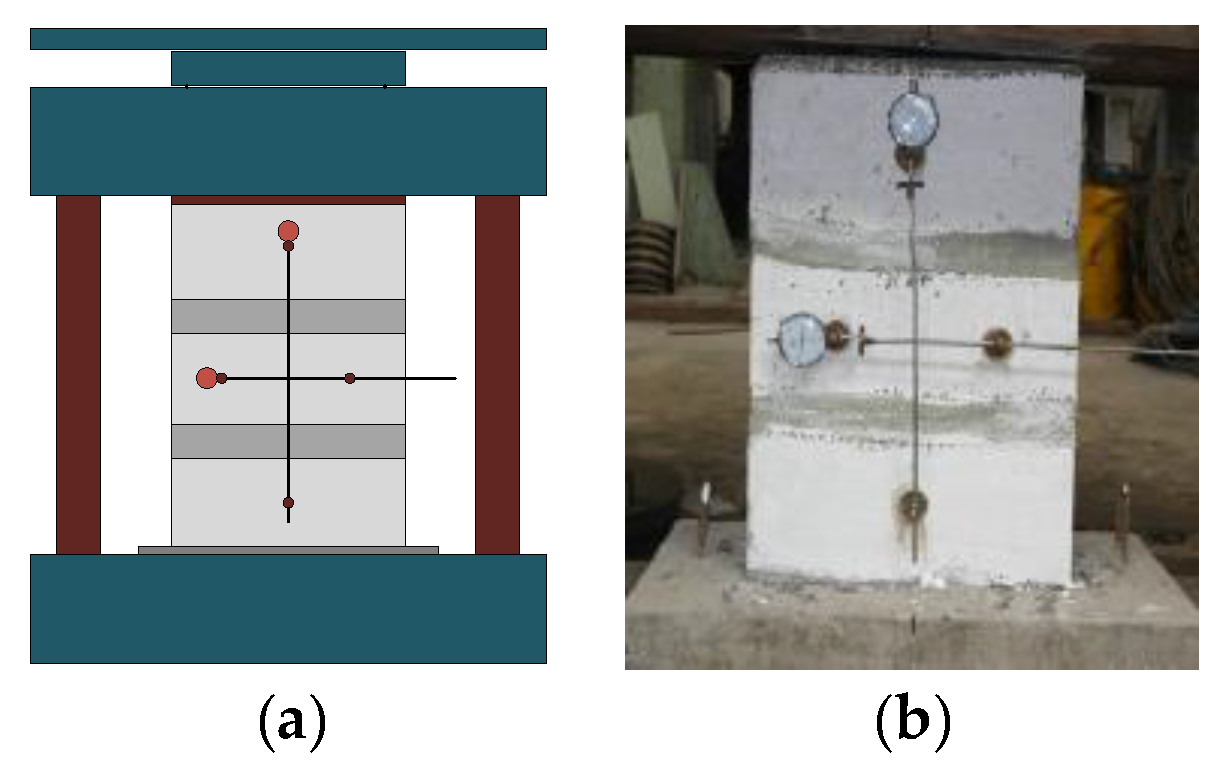

2.2. Test Setup and Method

3. Results and Discussion

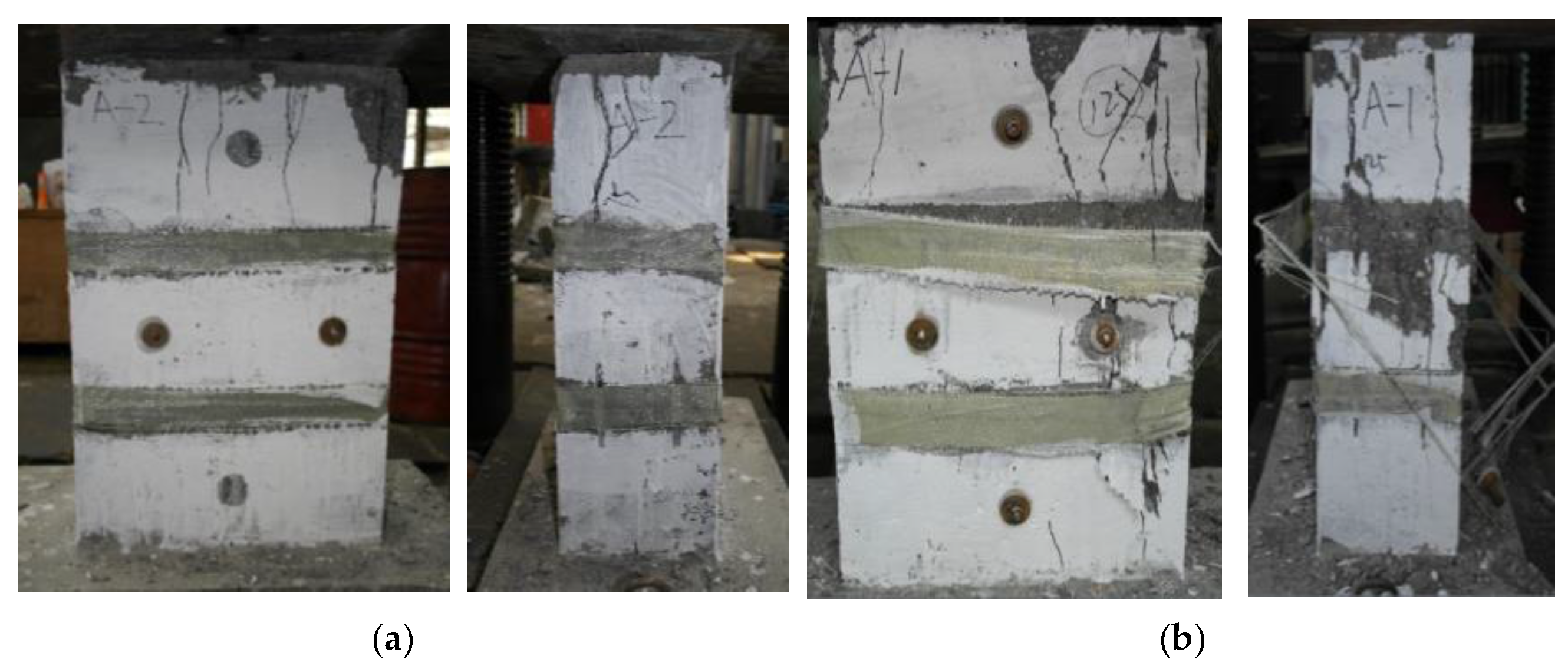

3.1. Failure Modes

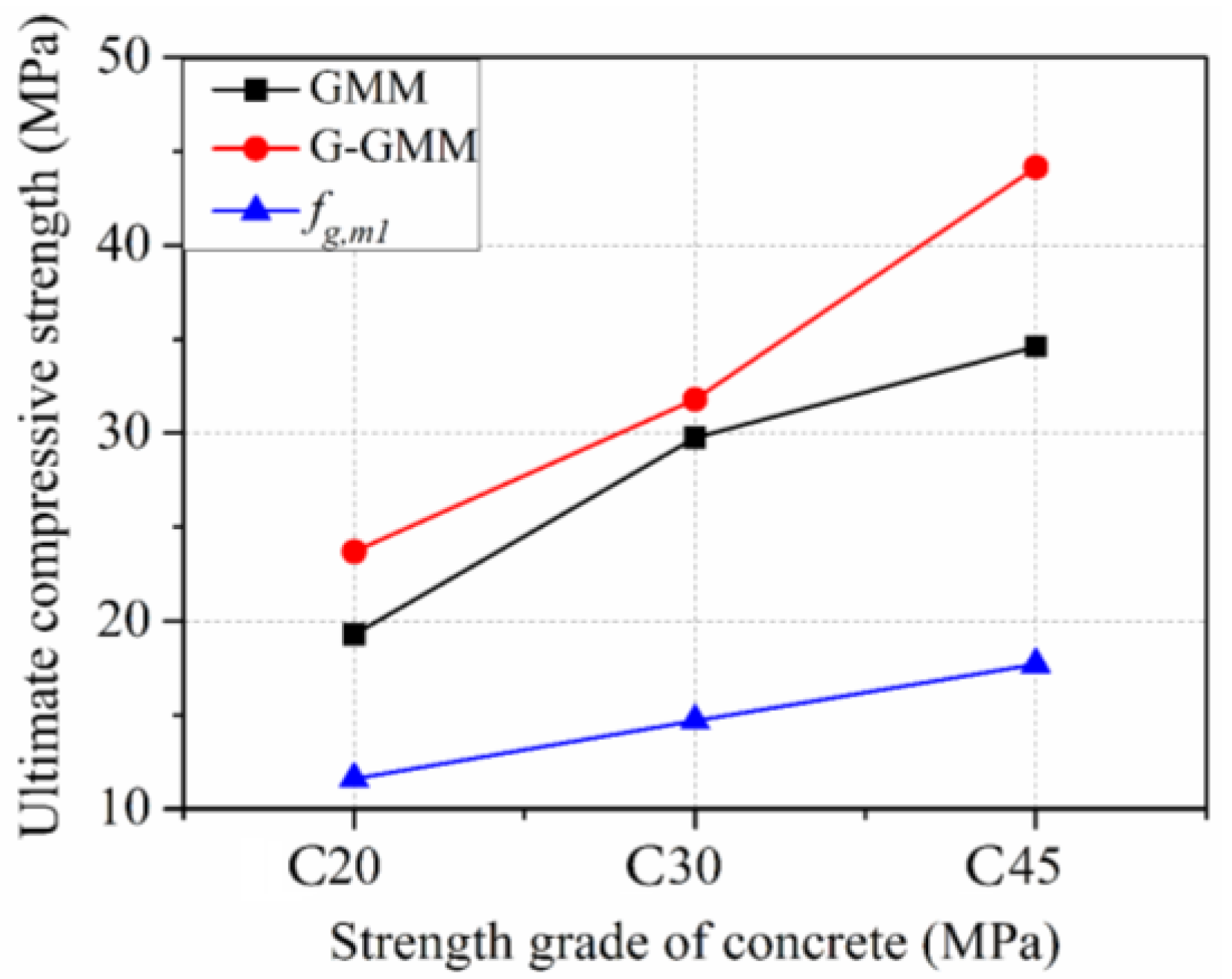

3.2. Tested Results and Analysis

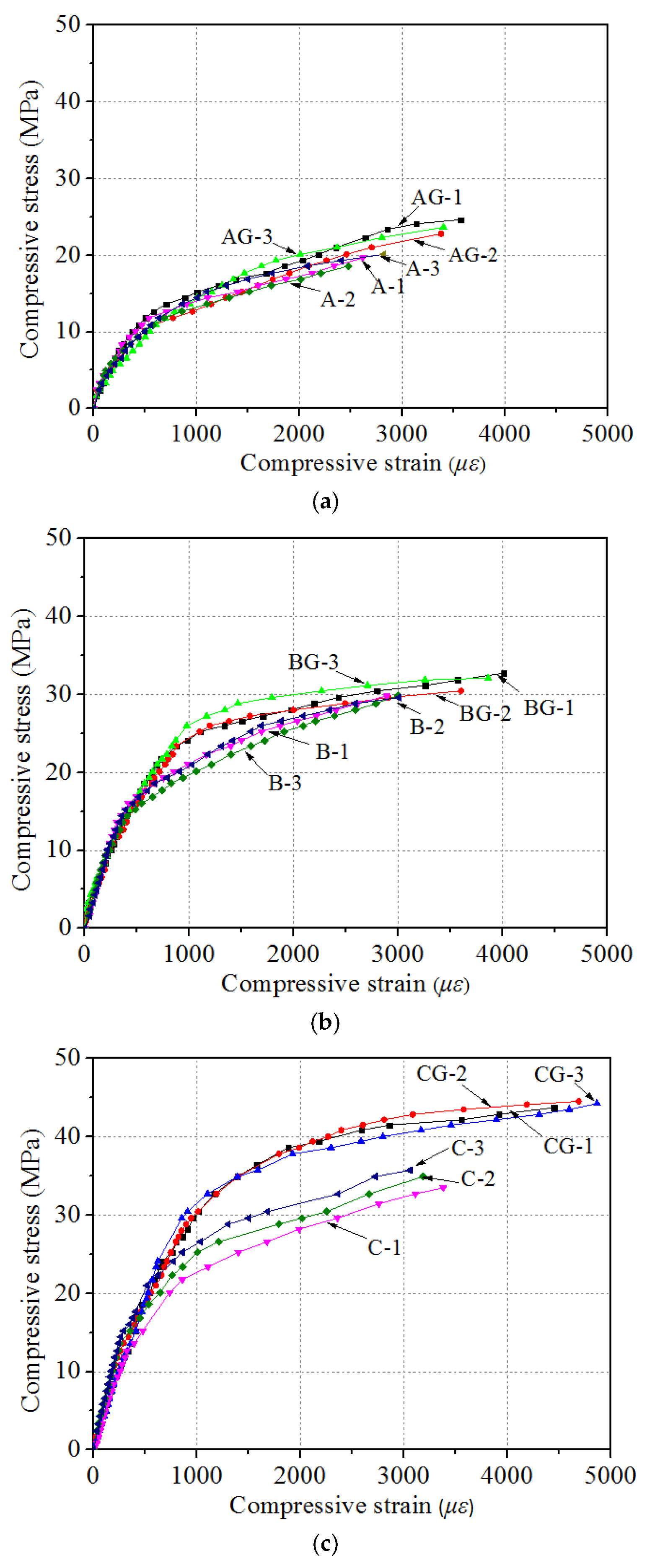

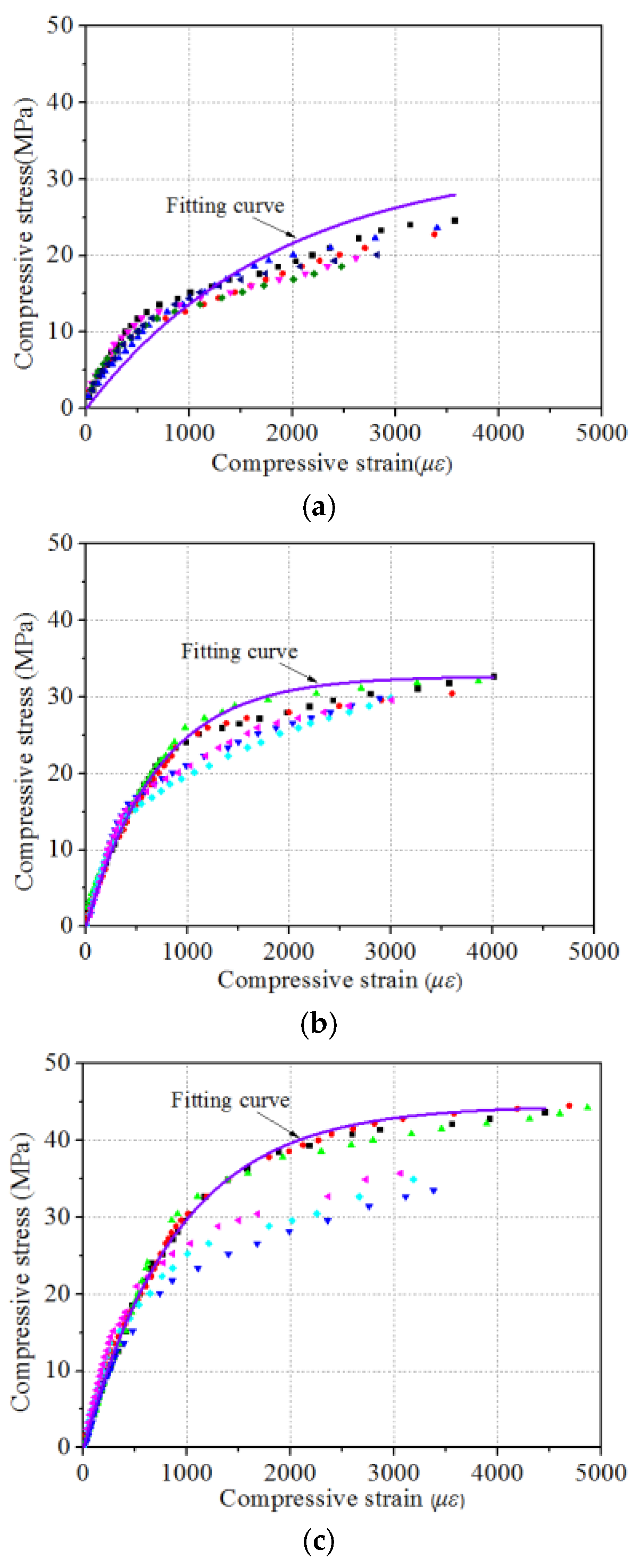

3.3. Axial Compressive Stress–Strain Behavior

3.4. Confinement Mechanism of GFRP Strengthened Mortarless Masonry

3.5. Effective Restraint Area of GFRP Strengthened Masonry

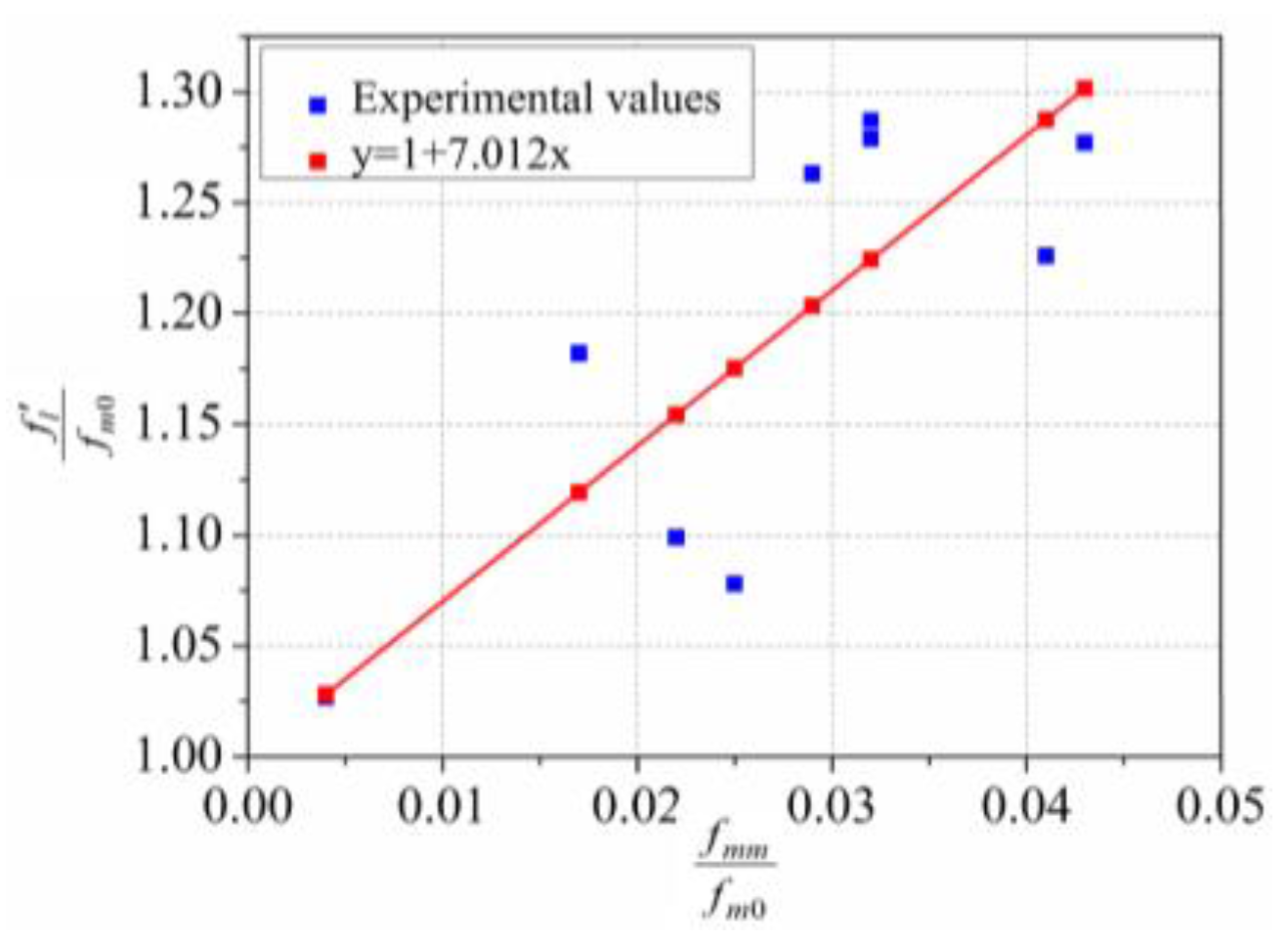

3.6. Carrying Capacity of GFRP Strengthened Masonry

4. Conclusions

- Like the FRP-confined concrete, the GFRP confinement has improved the initial cracking load and ultimate carrying capacity of grouted mortarless masonry, which indicated that the GFRP confinement has restrained the crack development of masonry efficiently and increased the ultimate strain to improve the ductility of masonry system.

- The strength of grouted concrete has a parabolic influence on the ultimate carrying capacity of plain masonry strength but a positive effect on the ultimate carrying capacity of GFRP strengthened masonry. Unstrengthened masonry with different strengths of grouted concrete performed the same failure mode and stress–strain behaviour.

- The general compressive behaviour of GFRP strengthened grouted mortarless masonry was bilinear with an initial PSEUDO-elastic stage and an elastic-linear stage, while the slopes of the second stage at the stress–strain curves exhibit the trend of degression.

- The mechanism properties of GFRP strengthened grouted mortarless masonry was analyzed by homogenization according to FRP-confined concrete, which indicated that the stress concentration phenomenon existing at the corner of the masonry caused GFRP jackets to rupture mostly at the corner of masonry.

- One compressive stress–strain model was developed for the GFRP strengthened grouted mortarless masonry, which performed well to predict the experimental results.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Huang, L.; Liao, L.; Yan, L.B.; Yi, H. Compressive strength of double H concrete block Masonry prisms. J. Mater. Civ. Eng. 2014, 50. [Google Scholar] [CrossRef]

- Ghobarah, A.; Galal, K. Out-of-plane strengthening of unreinforced masonry walls with openings. J. Compos. Constr. 2004, 8, 298–305. [Google Scholar] [CrossRef]

- Safiee, N.A.; Jaafar, M.S.; Alwathaf, A.H.; Noorzaei, J.; Abdulkadir, M.R. Structural behavior of mortarless interlocking load bearing hollow block wall panel under out-of-plane loading. Adv. Struct. Eng. 2011, 14, 1185–1196. [Google Scholar] [CrossRef]

- Waleed, A.; Thanoon, A.H.; Alwathaf, J.N.; Jaafar, S.; Abdulkadir, R. Nonlinear finite element analysis of grouted and ungrouted hollow interlocking mortarless block masonry system. Eng. Struct. 2008, 30, 1560–1572. [Google Scholar]

- Rekik, A.; Allaoui, S.; Gasser, A.; Blond, A.; Andreev, K.; Sinnema, S. Experiments and nonlinear homogenization sustaining mean-field theories for refractory mortarless masonry: The classical secant procedure and its improved variants. Eur. J. Mech. A/Solids 2015, 49, 67–81. [Google Scholar] [CrossRef]

- Waleed, A.; Thanoon, A.H.; Alwathaf, J.N.; Jaafar, S.; Abdulkadirc, R. Finite element analysis of interlocking mortarless hollow block masonry prism. Comput. Struct. 2008, 86, 520–528. [Google Scholar]

- Jaafar, S.; Waleed, A.; Thanoon, A.H.; Alwathaf, J.N.; Abdulkadir, R.; Ali, A.A. Strength correlation between individual block, prism and basic wall panel for load bearing interlocking mortarless hollow block masonry. Constr. Build. Mater. 2006, 20, 492–498. [Google Scholar] [CrossRef]

- Chaimoon, K.; Atttard, M.M. Experimental and numerical investigation of masonry under three-point bending. Eng. Struct. 2009, 31, 103–112. [Google Scholar] [CrossRef]

- Micelli, F.; De Lorenzis, L.; La Tegola, A. FRP-confined masonry columns under axial loads: analytical model andexperimental results. Masonry Int. J. 2004, 17, 95–108. [Google Scholar]

- Yin, P.; Huang, L.; Yan, L.B.; Zhu, D. Compressive behavior of concrete confined by CFRP and transverse spiral reinforcement. Part A: Experimental study. Mater. Struct. 2016, 49, 1001–1011. [Google Scholar] [CrossRef]

- Huang, L.; Sun, X.X.; Yan, L.B.; Zhu, D. Compressive behavior of concrete confined with GFRP tubes and steel spirals. Polymers 2015, 7, 851–875. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.B.; Kasal, B. Behavior of glass and carbon FRP tube encased recycled aggregate concrete with recycled clay brick aggregate. Compos. Struct. 2016, 155, 245–254. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.B.; Ma, G. Compressive behavior of CFFT with inner steel wire mesh. Compos. Struct. 2015, 133, 322–330. [Google Scholar] [CrossRef]

- Huang, L.; Gao, C.; Yan, L.B.; Kasal, B. Confinement models of GFRP-confined concrete: Statistical analysis andunified stress–strain models. J. Reinf. Plast. Compos. 2016, 35, 867–891. [Google Scholar] [CrossRef]

- Huang, L.; Gao, C.; Yan, L.B.; Kasal, B.; Ma, G. Reliability assessment of confinement models of carbon fiber reinforced polymer-confined concrete. J. Reinf. Plast. Compos. 2016, 35, 996–1026. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. On energy absorption capacity, flexural and dynamic properties of flax/epoxy composite tubes. Fiber. Poly. 2014, 15, 1270–1277. [Google Scholar] [CrossRef]

- Yan, L.B. Plain concrete cylinders and beams externally strengthened with natural flax fabric reinforced epoxy composites. Mater. Struct. 2016, 49, 2083–2095. [Google Scholar] [CrossRef]

- Micelli, F.; Di Ludovico, M.; Balsamo, A.; Manfredi, G. Mechanical behaviour of FRP-confined masonry by testing of full-scale columns. Mater. Struct. 2014, 47, 2081–2100. [Google Scholar] [CrossRef]

- Aiello, M.; Micelli, F.; Valente, L. FRP confinement of square masonry columns. J. Compos. Constr. 2014, 13, 148–158. [Google Scholar] [CrossRef]

- Basilio, I.; Fedele, R.; Lourenço, P.B.; Milani, G. Assessment of curved FRP-reinforced masonry prisms: Experiments and modeling. Constr. Build. Mater. 2014, 51, 492–505. [Google Scholar] [CrossRef]

- Fossetti, M.; Minafo, G. Comparative experimental analysis on the compressive behaviour of masonry columns strengthened by FRP, BFRCM or steel wires. Composites Part B 2017, 112, 112–124. [Google Scholar] [CrossRef]

- Malena, M.; Focacci, F.; Carloni, C.; de Felice, G. The effect of the shape of the cohesive material law on the stress transfer at the FRP-masonry interface. Composites Part B 2014, 110, 368–380. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, D.; Sheng, Y.; Garrity, S.W.; Xu, L.H. Numerical modelling of FRP-reinforced masonry walls under in-plane seismic loading. Constr. Build. Mater. 2017, 134, 649–663. [Google Scholar] [CrossRef]

- Sadek, H.; Lissel, S. Seismic performance of masonry walls with GFRP and Geogrid Bed joint reinforcement. Constr. Build. Mater. 2013, 41, 977–989. [Google Scholar] [CrossRef]

- Krevaikas, T.D.; Triantafillou, T.C. Masonry confinement with fiber-reinforced polymers. J. Compos. Constr. 2014, 9, 128–135. [Google Scholar] [CrossRef]

- Freddi, F.; Sacco, E. Debonding process of masonry element strengthened with FRP. Procedia Eng. 2015, 109, 27–34. [Google Scholar] [CrossRef]

- Carloni, C.; Focacci, F. FRP-masonry interfacial debonding: An energy balance approach to determine the influence of the mortar joints. Eur. J. Mech. A/Solids 2016, 55, 122–133. [Google Scholar] [CrossRef]

- Carrara, P.; Freddi, F. Statistical assessment of a design formula for the debonding resistance of FRP reinforcements externally glued on masonry units. Composites Part B 2014, 66, 65–82. [Google Scholar] [CrossRef]

- Grande, E.; Milani, G. Modeling of FRP-strengthened curved masonry specimens and proposal of a simple design formula. Compos. Struct. 2016, 158, 281–290. [Google Scholar] [CrossRef]

- Ministry of Development of the People’s Republic of China. Code for Design of Masonry Structures. GB50003-2011; China Planning Press: Beijing, China, 2011.

- Ministry of Development of the People’s Republic of China. Standard for Test Method of Mechanical Properties on Ordinary Concrete; GB/T 50081-2002; China Planning Press: Beijing, China, 2002.

- Ministry of Development of the People’s Republic of China. Standard for Test Method of Basic Mechanical Properties of Masonry; GB/T 50129-2011; China Planning Press: Beijing, China, 2011.

- Zeng, X.M.; Yang, W.J.; Shi, C.X. Study of consititution relationship model for compressive masonry. Build. Sci. Res. Sichuan 2001, 27, 8–10. [Google Scholar]

- Liu, T.; Feng, W.; Zhan, Z.M.; Wei, G.F. A study on the compressive performance of rectangular concrete columns confined with CFRP sheets. China Civ. Eng. J. 2006, 39, 41–47. [Google Scholar]

- ACI 440.2R-08. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- Toutanji, H.A. Stress-strain characteristics of concrete columns externally confined with advanced fiber composite sheets. ACI Mater. J. 1999, 96, 397–404. [Google Scholar]

- Saafi, M.; Toutanji, H.A.; Li, Z. Behavior of concrete columns confined with fiber-reinforced polymer tubes. ACI Mater. J. 1999, 96, 500–509. [Google Scholar]

- Zhao, T.; Xie, J.; Liu, M.G.; Dai, Z.Q. Research on new method of improving properties of high strength concrete by using continuous carbon fiber sheet. Ind. Const. 2001, 31, 42–44. [Google Scholar]

- Lam, L.; Teng, J.G. Compressive strength of FRP-confined concrete in rectangular columns. In Proceedings of the International Conference on FRP Composites in Civil Engineering, Hong Kong, China, 12–15 December 2001; Volume 1, pp. 335–343. [Google Scholar]

- Richart, F.E.; Brandtzæg, A.; Brown, R.L. A Study of the Failure of Concrete under Combined Compressive Stresses; Technical Report; University of Illinois at Urbana Champaign College of Engineering Experiment Station: Champaign, IL, USA, 1928. [Google Scholar]

| Nominal Thickness (mm) | Tensile Strength (MPa) | Modulus of Elasticity (GPa) | The Volume Fractions | Weight Density (g/m2) | Ultimate Elongation (%) | Fiber Direction |

|---|---|---|---|---|---|---|

| 0.436 | 660 | 83 | 29.5% | 414 | 4.3 | Uni- directional |

| Resin Type | Density (g/cm3) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Thermal Expansion Coefficient (10−6/°C) | Solidification Shrinkage (%) |

|---|---|---|---|---|---|

| Epoxy | 1.2–1.3 | 35–130 | 1.75–4.1 | 40 | 1–5 |

| Specimen | Grouted Concrete Standard Strength (MPa) | Grouted Concrete Tested Strength (MPa) | Strengthened |

|---|---|---|---|

| AG-1,2,3 | C20 | 23.9 | GFRP |

| A-1,2,3 | C20 | 23.9 | – |

| BG-1,2,3 | C30 | 34.7 | GFRP |

| B-1,2,3 | C30 | 34.7 | – |

| CG-1,2,3 | C45 | 45.0 | GFRP |

| C-1,2,3 | C45 | 45.0 | – |

| Group | Sample | Grout | (MPa) | (MPa) | (MPa) | Ncr/Nu | Failure Mode | |

|---|---|---|---|---|---|---|---|---|

| Type | fcu,m (MPa) | |||||||

| G. 1 | AG-1 | GN1 | 23.9 | 19.66 | 24.63 | 11.6 | 0.80 | Z |

| AG-2 | GN2 | 23.9 | 17.37 | 22.79 | 0.76 | X | ||

| AG-3 | GN3 | 23.9 | 18.11 | 23.64 | 0.77 | X | ||

| Average | – | 23.9 | 18.38 | 23.69 | 0.78 | — | ||

| A-1 | GN1 | 23.9 | 12.51 | 19.65 | 0.64 | Y | ||

| A-2 | GN2 | 23.9 | 12.23 | 18.08 | 0.68 | Y | ||

| A-3 | GN3 | 23.9 | 12.66 | 20.11 | 0.63 | Y | ||

| Average | – | 23.9 | 12.47 | 19.28 | 0.65 | — | ||

| G. 2 | BG-1 | GN1 | 34.7 | 19.23 | 32.71 | 14.7 | 0.59 | Z |

| BG-2 | GN2 | 34.7 | 18.87 | 30.57 | 0.62 | Y | ||

| BG-3 | GN3 | 34.7 | 19.10 | 32.09 | 0.60 | Z | ||

| Average | – | 34.7 | 19.06 | 31.79 | 0.60 | — | ||

| B-1 | GN1 | 34.7 | 16.13 | 29.81 | 0.54 | Y | ||

| B-2 | GN2 | 34.7 | 16.29 | 29.87 | 0.55 | Y | ||

| B-3 | GN3 | 34.7 | 16.05 | 29.60 | 0.54 | Y | ||

| Average | – | 34.7 | 16.15 | 29.76 | 0.54 | — | ||

| G. 3 | CG-1 | GN1 | 45.0 | 23.08 | 43.70 | 17.7 | 0.53 | X |

| CG-2 | GN2 | 45.0 | 25.24 | 44.53 | 0.57 | Z | ||

| CG-3 | GN3 | 45.0 | 23.75 | 44.24 | 0.54 | Z | ||

| Average | – | 45.0 | 24.02 | 44.16 | 0.54 | — | ||

| C-1 | GN1 | 45.0 | 14.82 | 33.41 | 0.44 | Y | ||

| C-2 | GN2 | 45.0 | 14.47 | 34.67 | 0.42 | Y | ||

| C-3 | GN3 | 45.0 | 15.21 | 35.72 | 0.43 | Y | ||

| Average | – | 45.0 | 14.83 | 34.60 | 0.43 | — | ||

| Sample | (MPa) | (MPa) | (MPa) | / | / |

|---|---|---|---|---|---|

| AG-1 | 19.28 | 24.63 | 0.829 | 0.043 | 1.277 |

| AG-2 | 19.28 | 22.79 | 0.330 | 0.017 | 1.182 |

| AG-3 | 19.28 | 23.64 | 0.792 | 0.041 | 1.226 |

| BG-1 | 29.76 | 32.71 | 0.659 | 0.022 | 1.099 |

| BG-2 | 29.76 | 30.57 | 0.132 | 0.004 | 1.027 |

| BG-3 | 29.76 | 32.09 | 0.734 | 0.025 | 1.078 |

| CG-1 | 34.60 | 43.70 | 1.020 | 0.029 | 1.263 |

| CG-2 | 34.60 | 44.53 | 1.103 | 0.032 | 1.287 |

| CG-3 | 34.60 | 44.24 | 1.108 | 0.032 | 1.279 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Gao, C.; Yan, L.; Li, X.; Ma, G.; Wang, T. Experimental and Analytical Modeling of GFRP Strengthened Grouted Mortarless Masonry Prisms. Fibers 2017, 5, 18. https://doi.org/10.3390/fib5020018

Huang L, Gao C, Yan L, Li X, Ma G, Wang T. Experimental and Analytical Modeling of GFRP Strengthened Grouted Mortarless Masonry Prisms. Fibers. 2017; 5(2):18. https://doi.org/10.3390/fib5020018

Chicago/Turabian StyleHuang, Liang, Chang Gao, Libo Yan, Xiaoxi Li, Gao Ma, and Tianfeng Wang. 2017. "Experimental and Analytical Modeling of GFRP Strengthened Grouted Mortarless Masonry Prisms" Fibers 5, no. 2: 18. https://doi.org/10.3390/fib5020018