Uncertainty Analysis of the Temperature–Resistance Relationship of Temperature Sensing Fabric

Abstract

:1. Introduction

2. Materials and Methods

2.1. Statistical Parameters Associated with the Temperature-Resistance Data

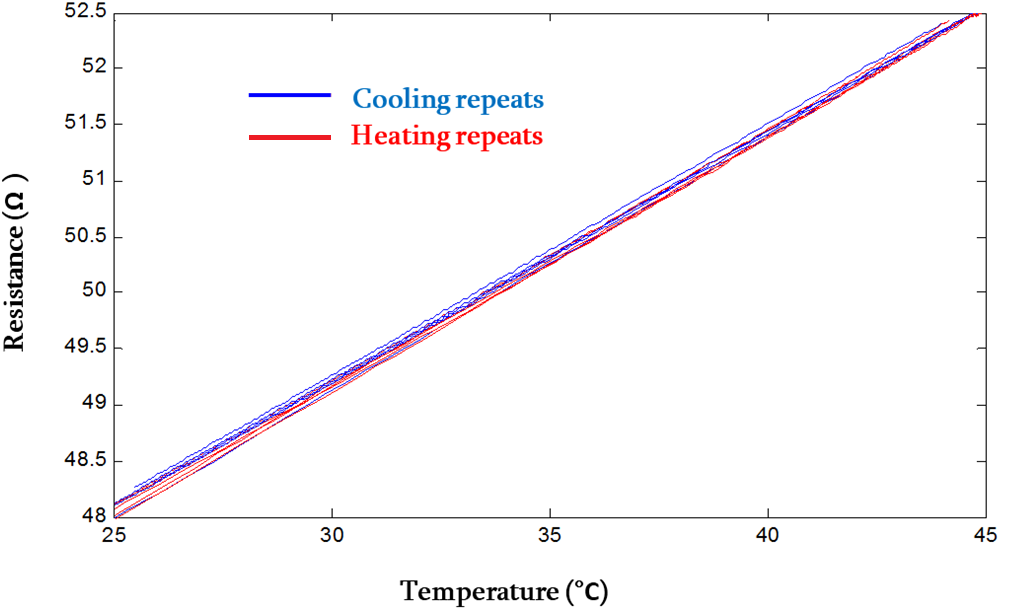

2.2. Comparison of Heating and Cooling Experiments (Single Test Repeat)

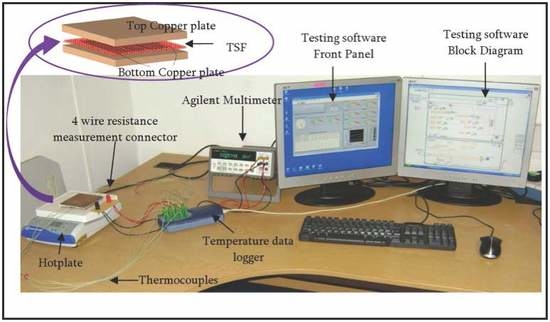

2.2.1. Testing Procedure

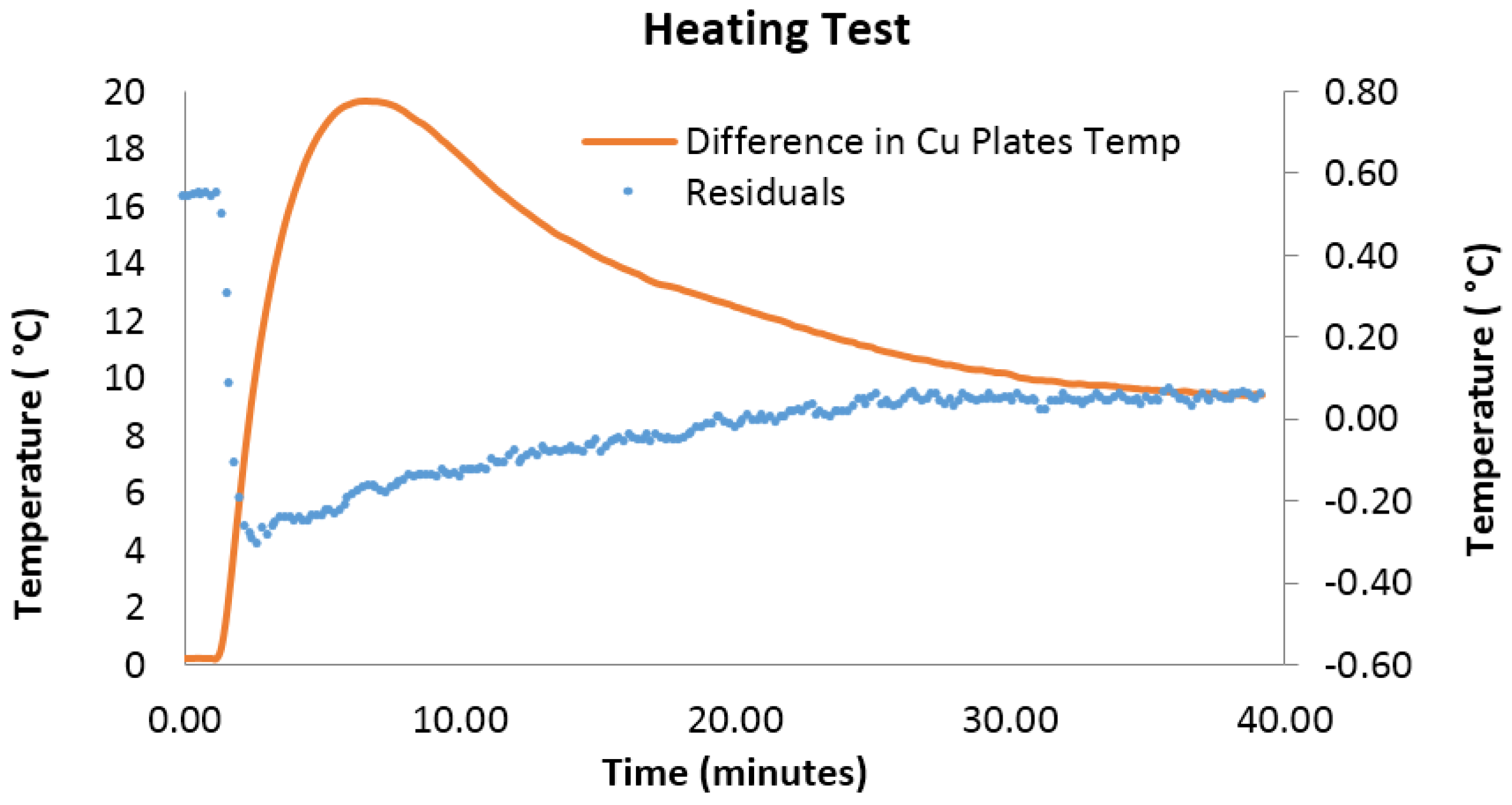

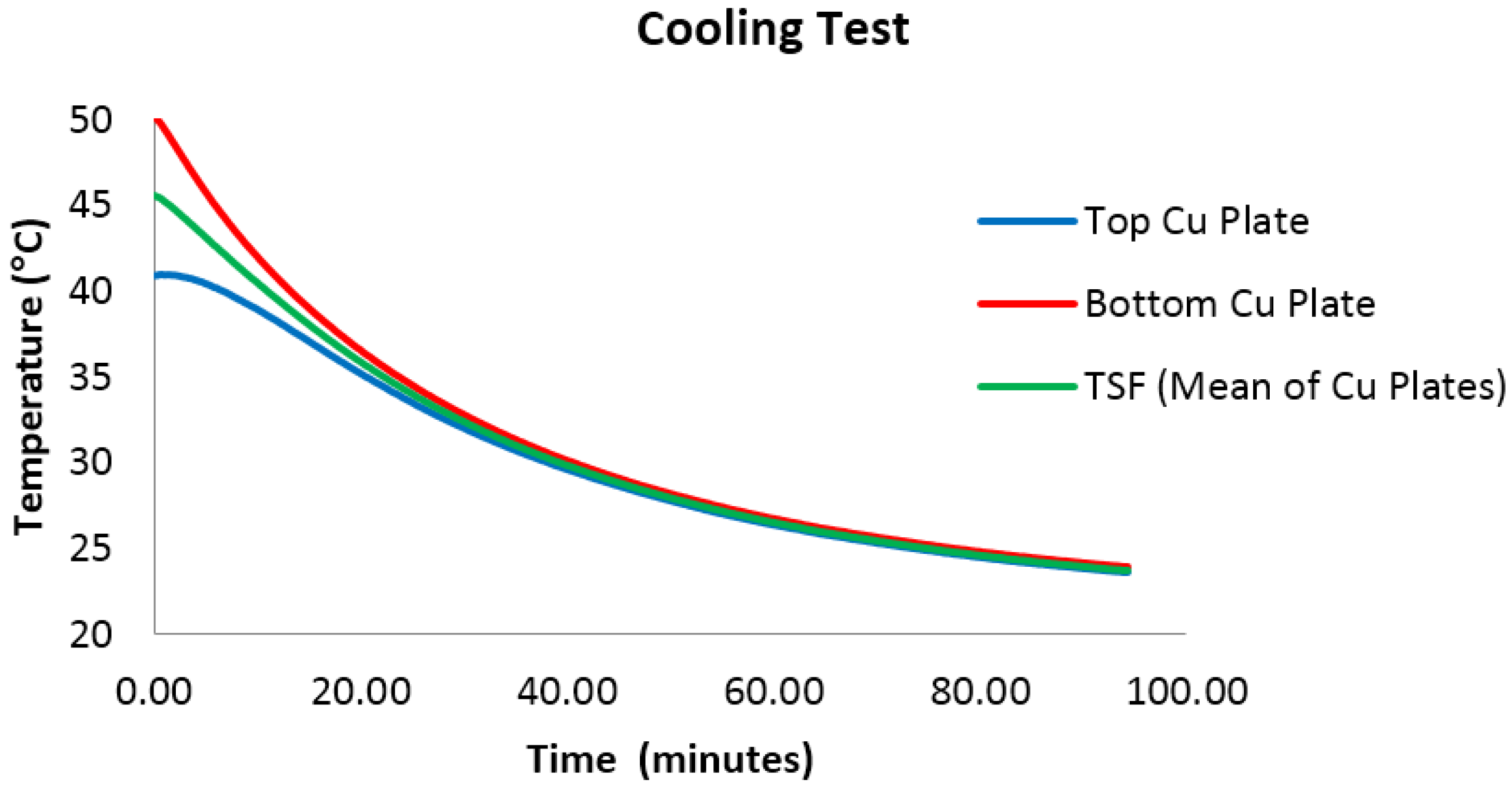

2.3. Temperature Profiles

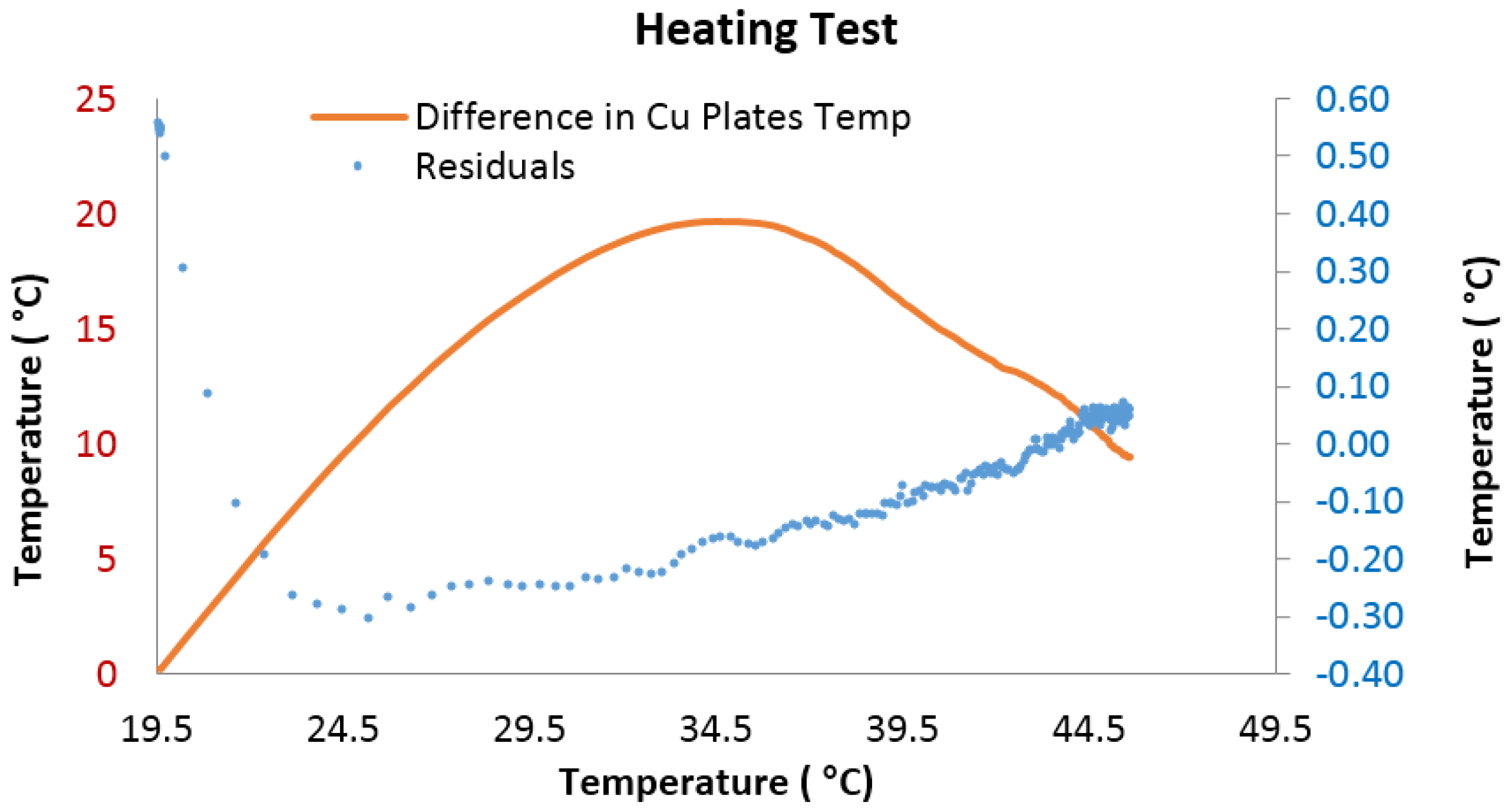

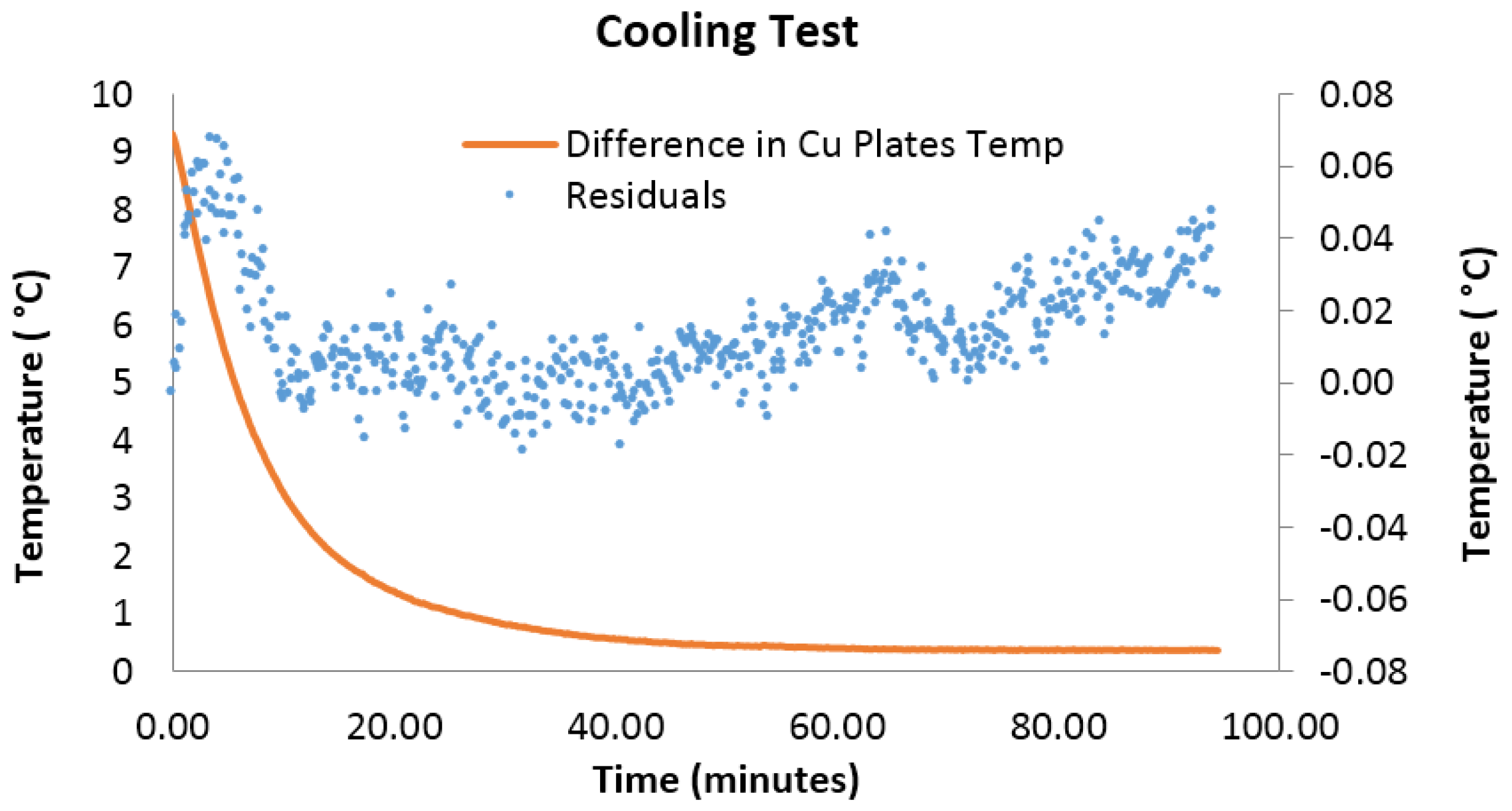

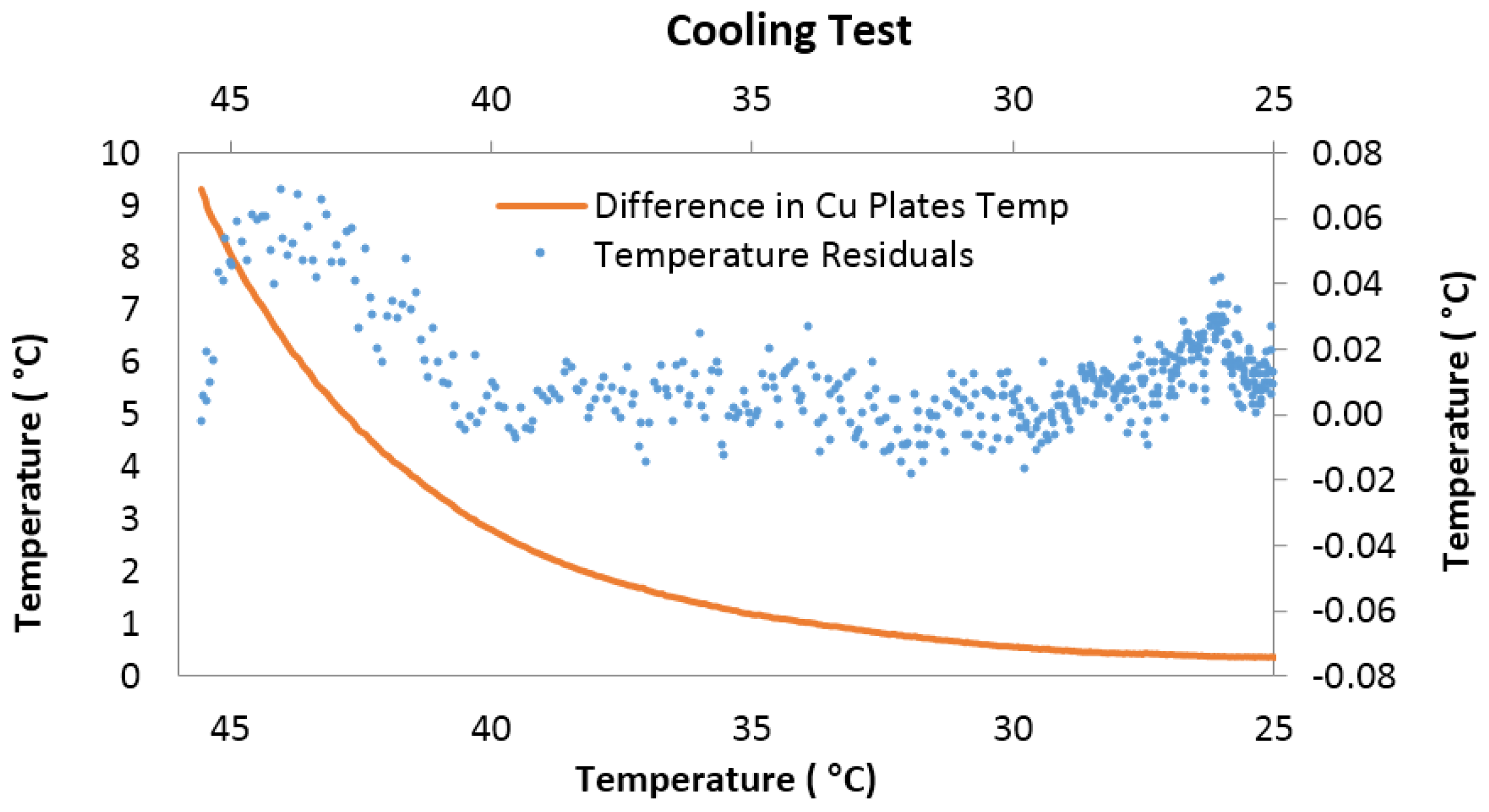

2.3.1. Residuals

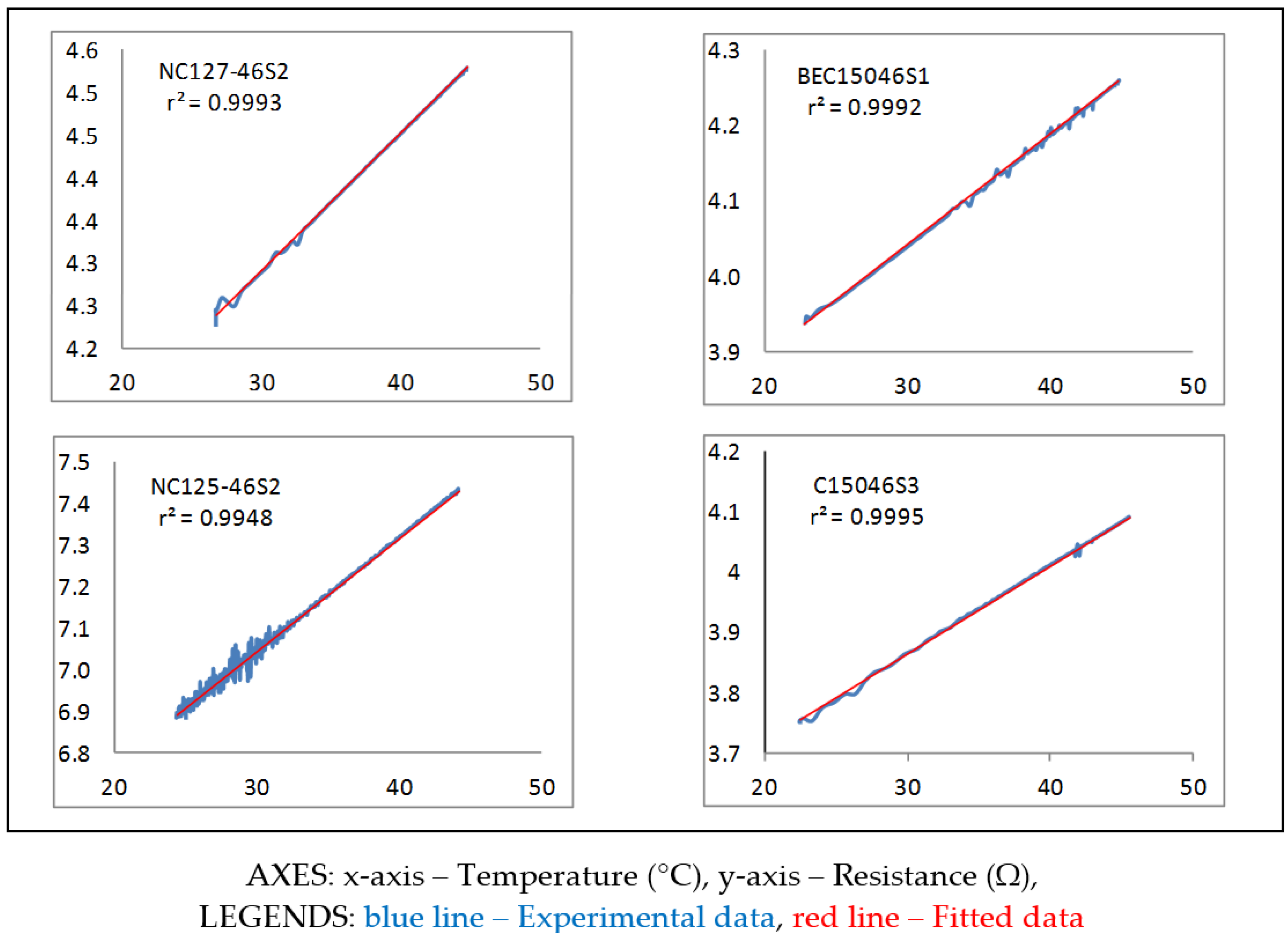

2.4. Temperature–Resistance Curves

2.5. Regression Uncertainty

3. Results and Discussion

3.1. Effect of Temperature Profile

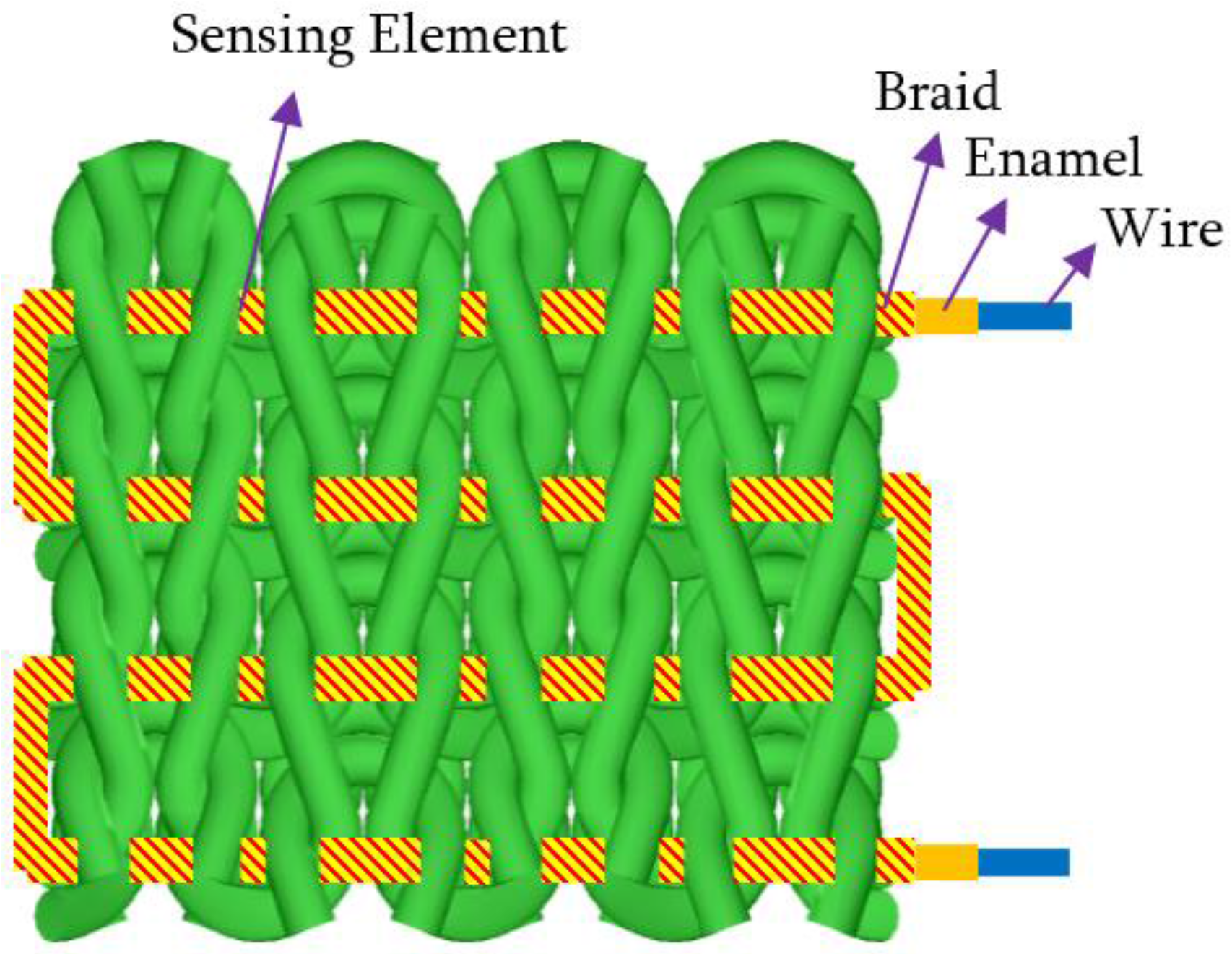

3.2. Effect of Sensing Element

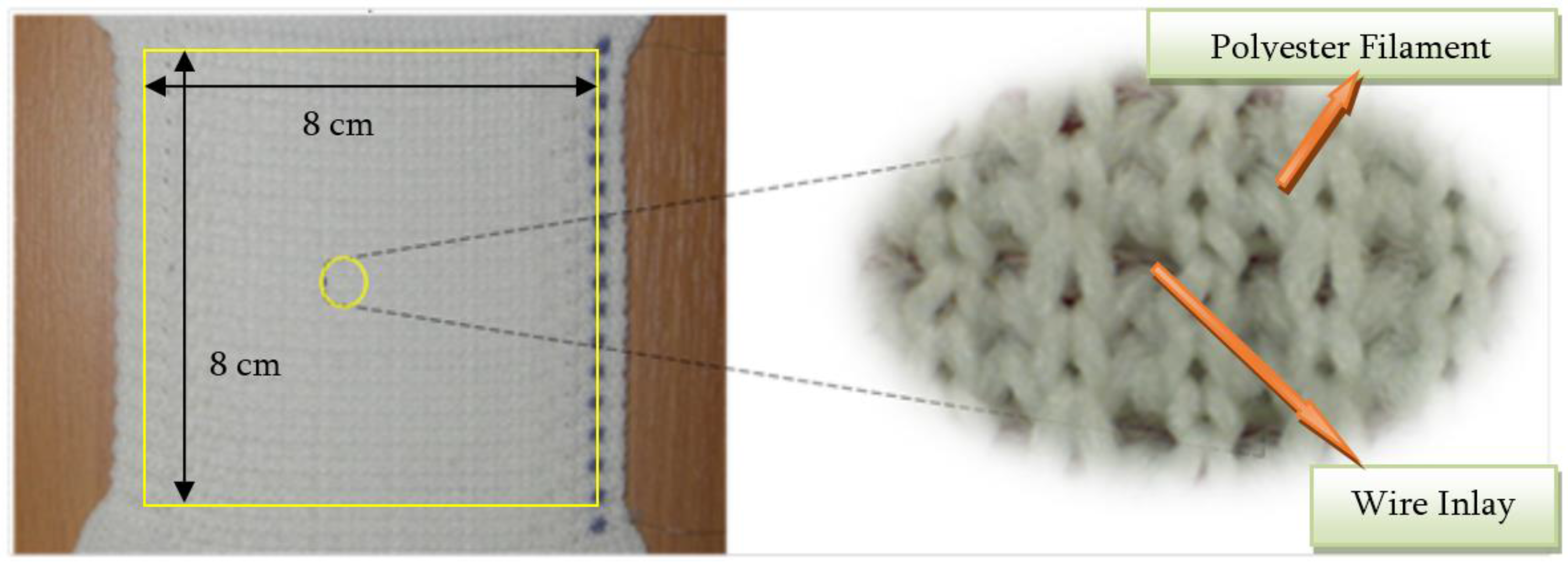

3.3. Effect of Inlay Density

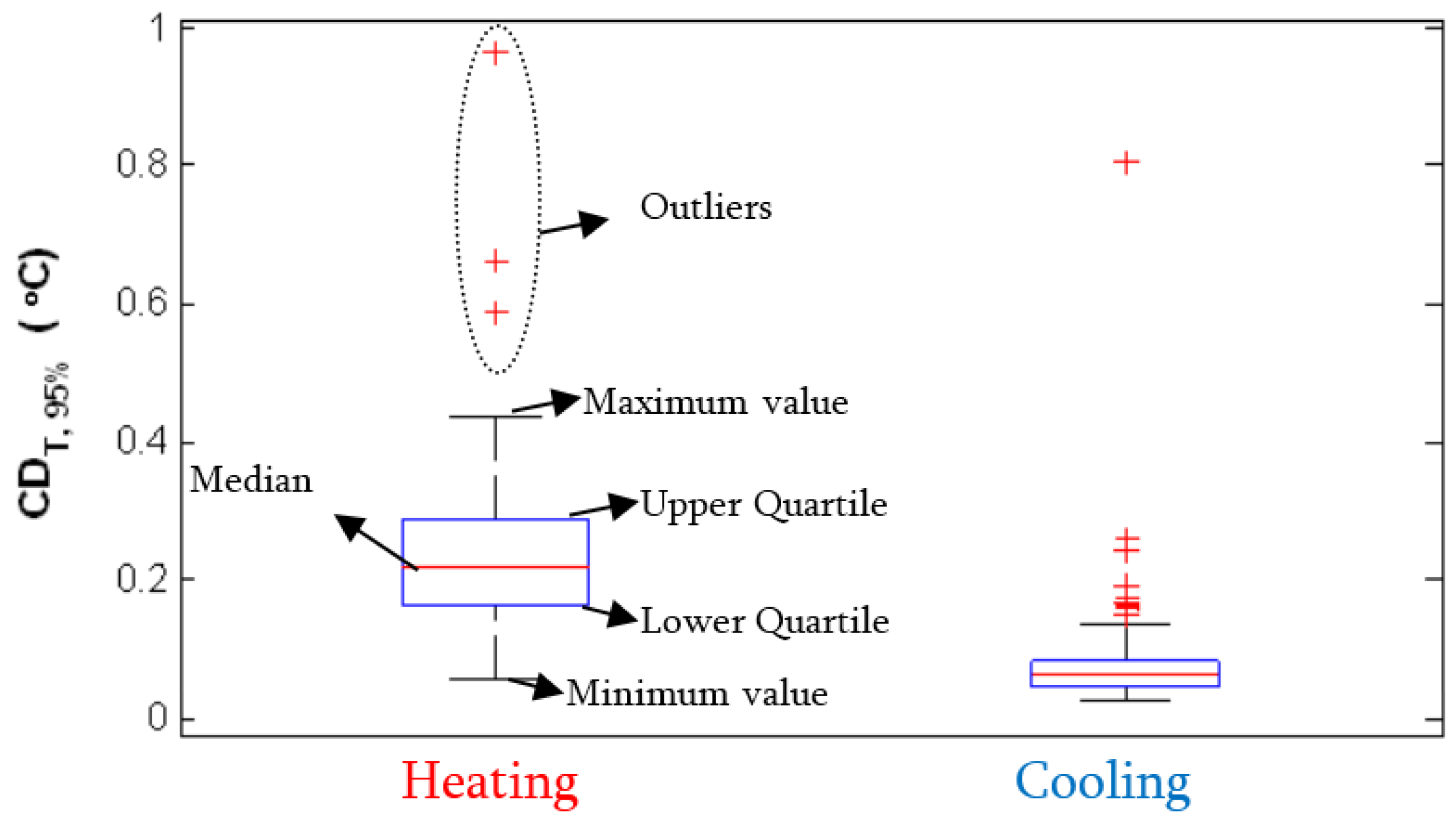

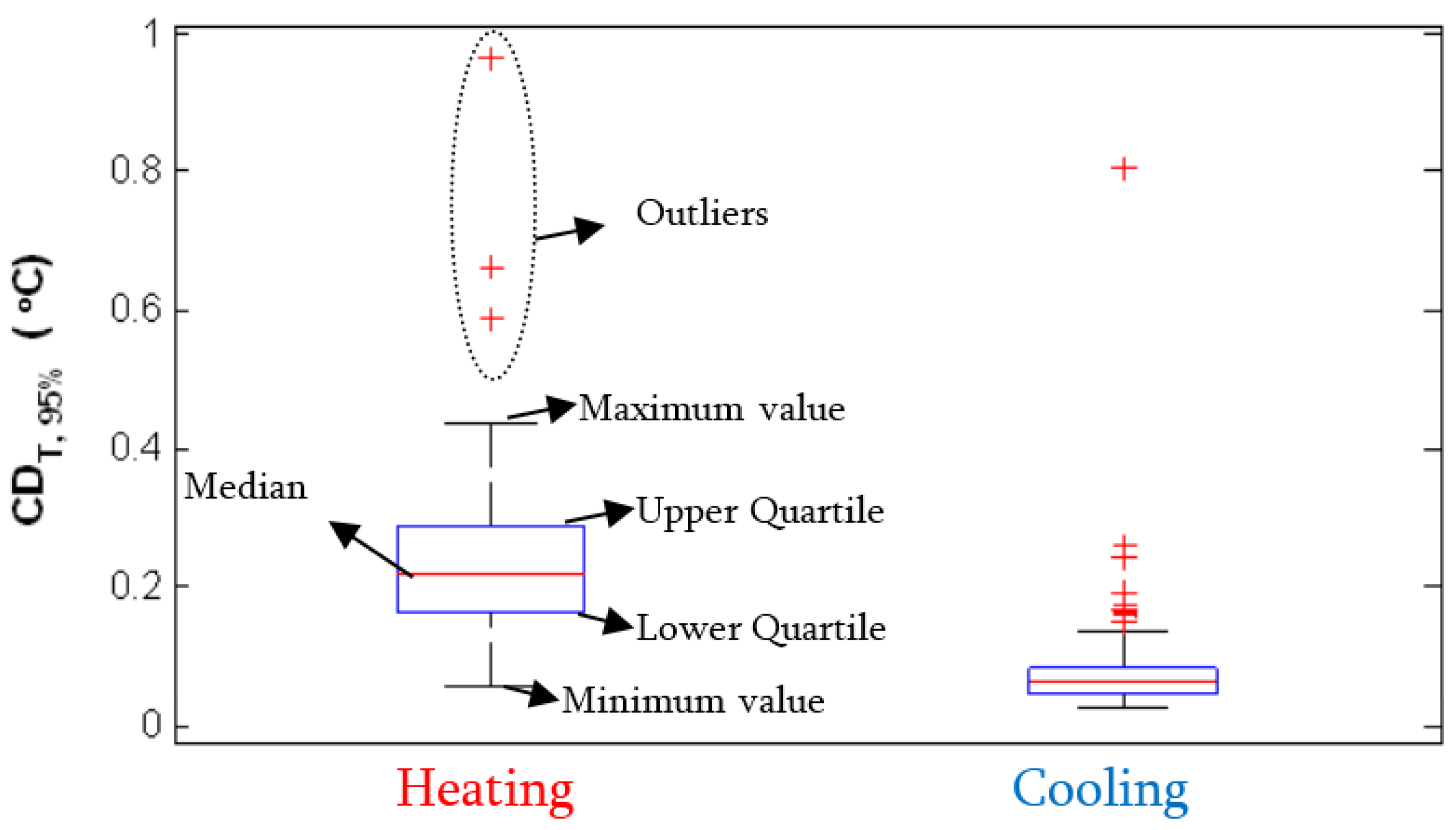

3.4. Repeatability Uncertainty

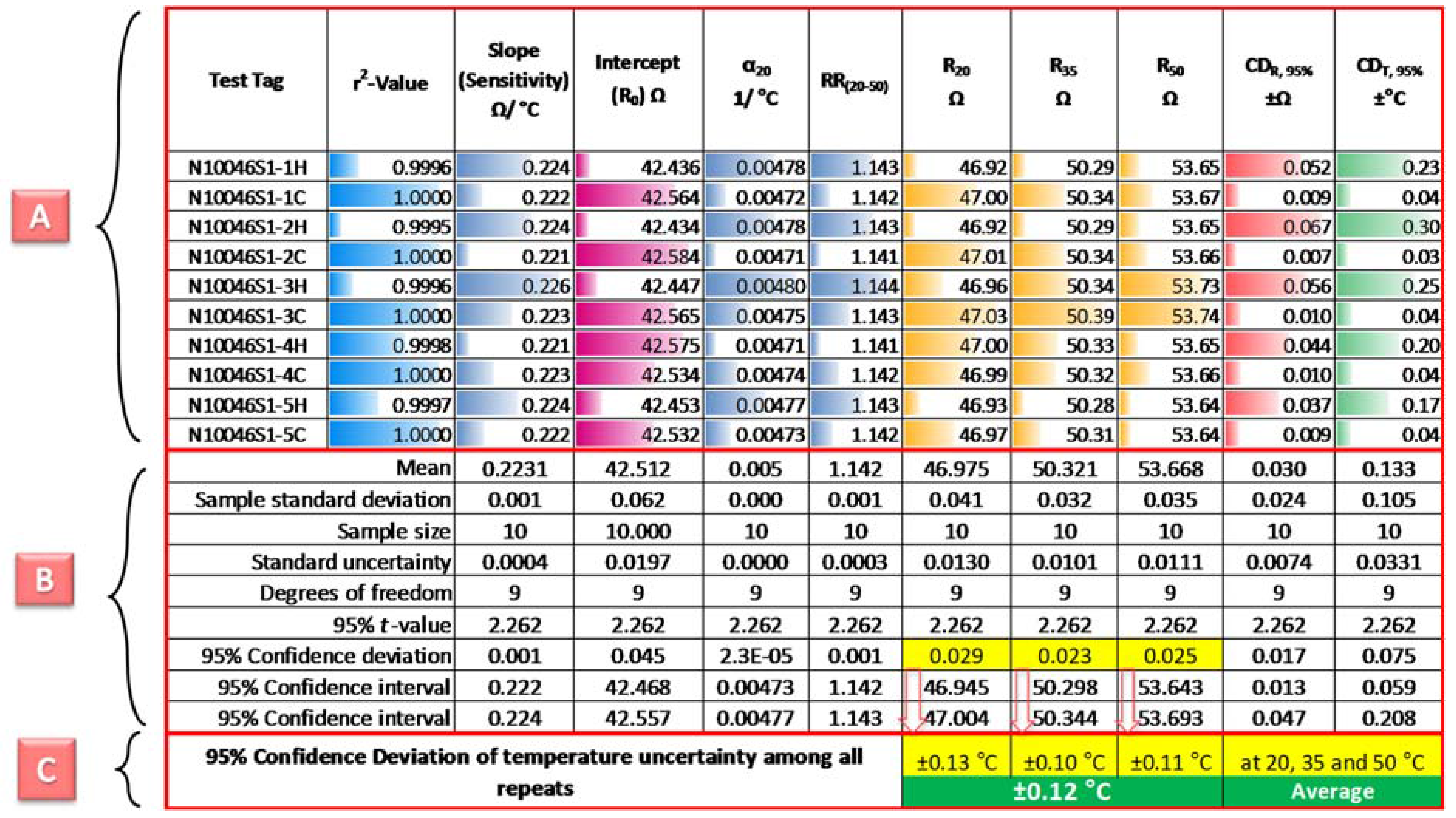

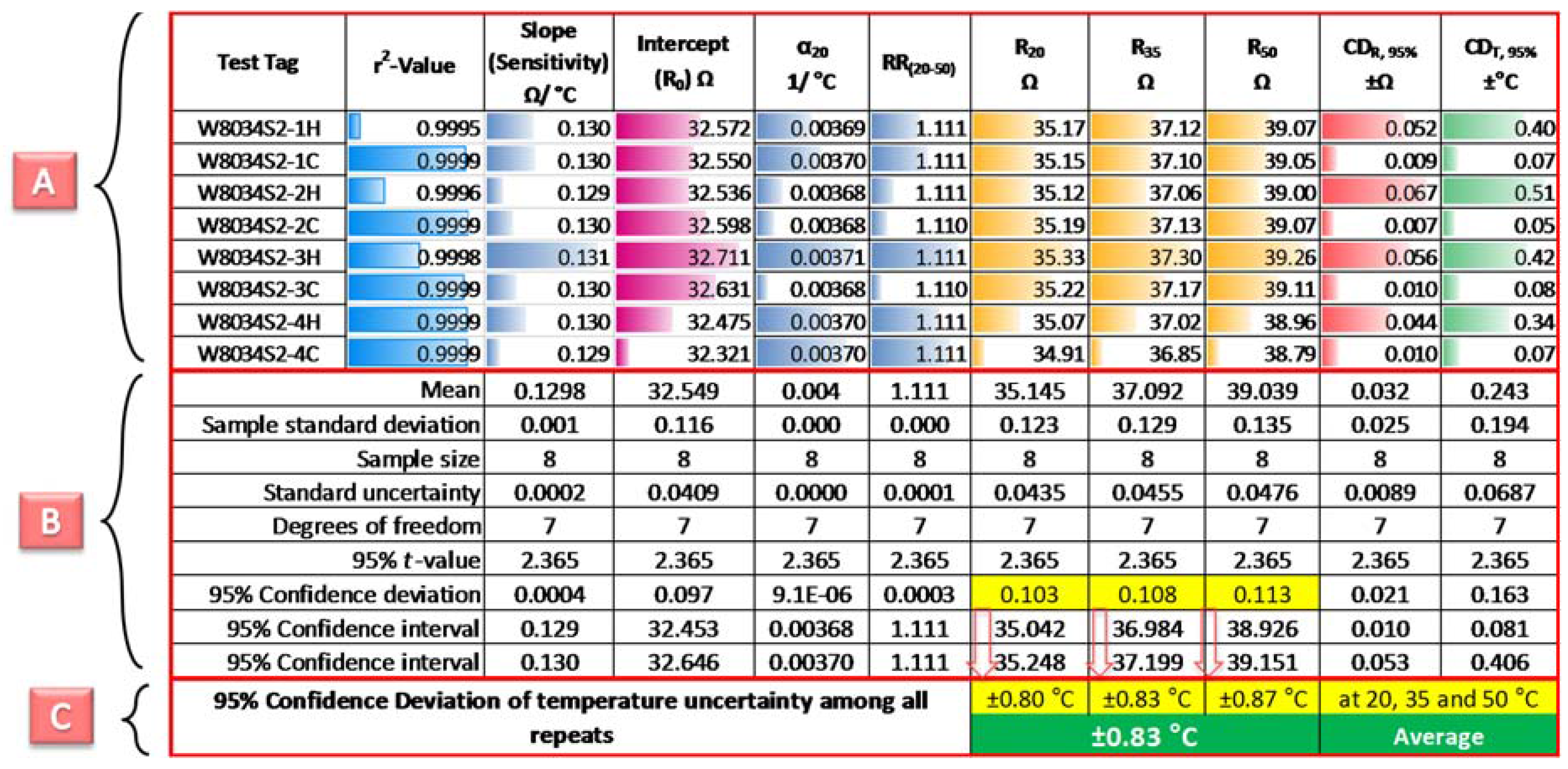

3.4.1. Analysis Criteria

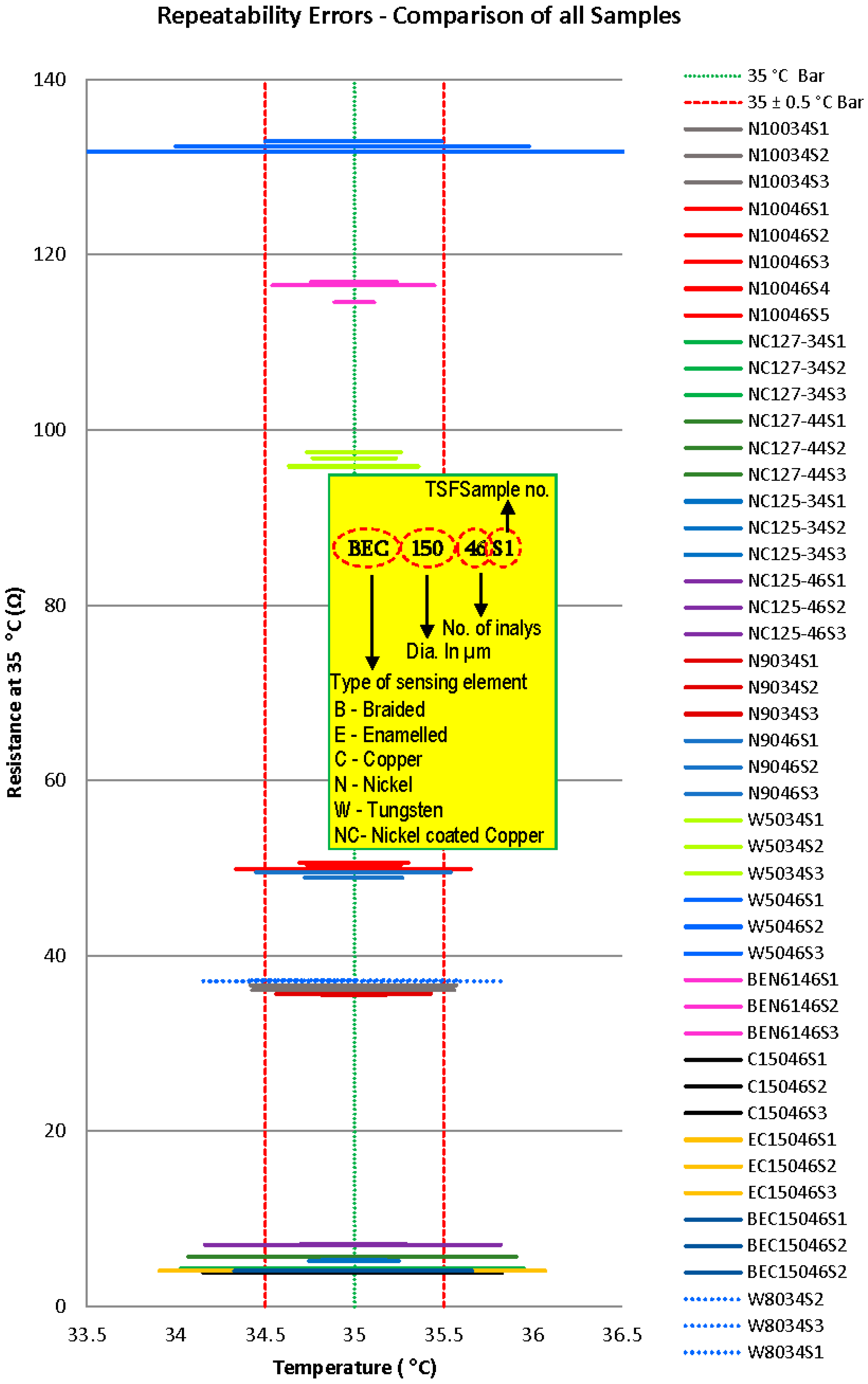

3.5. Comparison among All Temperature Sensing Fabric (TSF) Samples

3.6. Average Temperature-Resistance (TR) Equation

- By considering only the three data points (i.e., the mean resistance values at 20, 35, and 50 °C);

- By considering all data points (i.e., all resistance values at 20, 35, and 50 °C);

- By considering the mean of “slope” and “intercept” of all experimental repeats.

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Funnell, R.; Koutoukidis, G.; Lawrence, K. Chapter 21—Vital Signs. In Tabbner’s Nursing Care: Theory and Practice; Churchill Livingstone: Sydney, Australia, 2009; pp. 251–274. [Google Scholar]

- Parsons, K. Human thermal physiology and thermoregulation. In Human Thermal Environments; Taylor & Francis: London, UK, 2003; pp. 31–48. [Google Scholar]

- Jardine, D.S. Heat illness and heat stroke. Pediatr. Rev. 2007, 28, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Ring, E.F.J. Progress in the measurement of human body temperature. IEEE Eng. Med. Biol. Mag. 1998, 17, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Husain, M.D.; Kennon, W.R.; Dias, T. Design and fabrication of temperature sensing fabric. J. Ind. Text. 2014, 44, 398–417. [Google Scholar] [CrossRef]

- Husain, M.D.; Kennon, W.R. Preliminary investigations into the development of textile based temperature sensor for healthcare applications. Fibers 2013, 1, 2–10. [Google Scholar] [CrossRef]

- Husain, M.D.; Atalay, O.; Atalay, A.; Kennon, W.R. Development of test rig system for calibration of temperature sensing fabric. Autex Res. J. 2017. Accepted. [Google Scholar]

- Husain, M.D.; Atalay, O.; Kennon, W.R. Effect of strain and humidity on the performance of temperature sensing fabric. Int. J. Text. Sci. 2013, 2, 105–112. [Google Scholar]

- Husain, M.D.; Naqvi, S.; Atalay, O.; Hamdani, S.T.A.; Kennon, R. Measuring human body temperature through temperature sensing fabric. AATCC J. Res. 2016, 3, 1–12. [Google Scholar] [CrossRef]

- Catrysse, M.; Puers, R.; Hertleer, C.; Langenhove, L.V.; Egmond, H.V.; Matthys, D. Towards the integration of textile sensors in a wireless monitoring suit. Sens. Actuators A 2004, 114, 302–311. [Google Scholar] [CrossRef]

- Curone, D.; Dudnik, G.; Loriga, G.; Magenes, G.; Secco, E.L.; Tognetti, A.; Bonfiglio, A. Smart garments for emergency operators: Results of laboratory and field tests. In Proceedings of the 30th Annual International IEEE Conference of Engineering in Medicine and Biology Society (EMBS), Vancouver, BC, Canada, 20–24 August 2008.

- Derchak, P.A.; Ostertag, K.L.; Coyle, M.A. LifeShirt® System as a Monitor of Heat Stress and Dehydration; VivoMetrics, Inc.: Ventura, CA, USA, 2004. [Google Scholar]

- Noury, N.; Dittmar, A.; Corroy, C.; Baghai, R.; Weber, J.L.; Blanc, D.; Klefstat, F.; Blinovska, A.; Vaysse, S.; Comet, B. VTAMN—A smart clothe for ambulatory remote monitoring of physiological parameters and activity. In Proceedings of the 26th Annual International IEEE Conference of Engineering in Medicine and Biology Society (EMBS), San Francisco, CA, USA, 1–4 September 2004.

- Pandian, P.S.; Mohanavelu, K.; Safeer, K.P.; Kotresh, T.M.; Shakunthala, D.T.; Gopal, P.; Padaki, V.C. Smart vest: Wearable multi-parameter remote physiological monitoring system. Med. Eng. Phys. 2008, 30, 466–477. [Google Scholar] [CrossRef] [PubMed]

- Soh, P.J.; Vandenbosch, G.A.E.; Mercuri, M.; Schreurs, D.M.M.-P. Wearable wireless health monitoring: Current developments, challenges, and future trends. IEEE Microw. Mag. 2015, 16, 55–70. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, T.; Li, G.; Li, T.; Inoue, Y. Wearable Sensor Systems for Infants. Sensors 2015, 15, 3721. [Google Scholar] [CrossRef] [PubMed]

- Atalay, A.; Atalay, O.; Husain, M.D.; Fernando, A.; Potluri, P. Piezofilm yarn sensor-integrated knitted fabric for healthcare applications. J. Ind. Text. 2016. [Google Scholar] [CrossRef]

- Atalay, O.; Kennon, W.; Husain, M. Textile-based weft knitted strain sensors: Effect of fabric parameters on sensor properties. Sensors 2013, 13, 11114–11127. [Google Scholar] [CrossRef] [PubMed]

- Atalay, O.; Tuncay, A.; Husain, M.D.; Kennon, W.R. Comparative study of the weft-knitted strain sensors. J. Ind. Text. 2015. [Google Scholar] [CrossRef]

- Ziegler, S.; Frydrysiak, M. Initial research into the structure and working conditions of textile thermocouples. Fibres Text. East. Eur. 2010, 17, 84–88. [Google Scholar]

- Bielska, S.; Sibinski, M.; Lukasik, A. Polymer temperature sensor for textronic applications. Mater. Sci. Eng. B 2009, 165, 50–52. [Google Scholar] [CrossRef]

- De Rossi, D.; Della Santa, A.; Mazzoldi, A. Dressware: Wearable hardware. Mater. Sci. Eng. C 1999, 7, 31–35. [Google Scholar] [CrossRef]

- Locher, I.; Kirstein, T.; Troester, G. Routing methods adapted to e-textiles. In Proceedings of the 37th International Symposium on Microelectronics (IMAPS), Long Beach, CA, USA, 14–18 November 2004.

- Locher, I.; Kirstein, T.; Troester, G. Temperature profile estimation with smart textiles. In Proceedings of the International Conference on Intelligent textiles, Smart clothing, Well-being, and Design, Tampere, Finland, 19–20 September 2005.

- Smartex, S.R.L. Wearable wellness system (WWS). Available online: http://www.smartex.it/index.php/en/products/wearable-wellness-system (accessed on 27 December 2015).

- Mukhopadhyay, S.C. Wearable sensors for human activity monitoring: A review. IEEE Sens. J. 2015, 15, 1321–1330. [Google Scholar] [CrossRef]

- Lina, M.C.; Alison, B.F. Smart fabric sensors and e-textile technologies: A review. Smart Mater. Struct. 2014, 23, 053001. [Google Scholar]

- Lam Po Tang, S. Recent developments in flexible wearable electronics for monitoring applications. Trans. Inst. Meas. Control 2007, 29, 283–300. [Google Scholar] [CrossRef]

- PicoTech. USB TC-08 thermocouple data logger. Available online: http://www.picotech.com/thermocouple.html (accessed on 8 December 2015).

- Agilent Technologies. Agilent 34401A Multimeter—Product Overview. Available online: http://cp.literature.agilent.com/litweb/pdf/5968-0162EN.pdf (accessed on 8 November 2015).

- Bell, S. A Beginner’s Guide to Uncertainty of Measurement; National Physical Laboratory: Teddington, UK, 1999. [Google Scholar]

- Currell, G.; Dowman, A. Chapter 13—Correlation and Regression. In Essential Mathematics and Statistics for Science; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2009; pp. 315–330. [Google Scholar]

| Reference Resistance (Ω) | Sensitivity mΩ/°C | Sensing Elements | Remarks |

|---|---|---|---|

| Low 3–7 | Low 14–27 | NC127: Nickel coated copper of 127 µm dia. | coarse diameter Cu-based sensing elements |

| NC125: Nickel coated copper of 125 µm dia. | |||

| C150: Pure copper of 150 µm dia. | |||

| EC150: Enamelled copper of 150 µm dia. | |||

| BEC150: Braided enamelled copper of 150 µm dia. | |||

| Medium 32–47 | Medium 130–230 | W80: Tungsten of 80 µm dia. | medium diameter Ni and W sensing elements |

| N100: Nickel of 100 µm dia. | |||

| N90: Nickel of 90 µm dia. | |||

| High 91–126 | High 310–550 | W50: Tungsten of 50 µm dia. | fine diameter Ni and W sensing elements |

| BEN61: Braided enamelled nickel of 61 µm dia. |

| Parameters | Abbreviation | Unit | Heating TR Curve | Cooling TR Curve |

|---|---|---|---|---|

| TR Equation | - | |||

| Calibration Equation | - | |||

| Test Duration | - | min | 40 | 95 |

| t-value | - | 1.97 | 1.96 | |

| r-square value | - | 0.999537 | 0.999993 | |

| Temperature Coefficient of Resistivity at 0 °C | 1/°C | 0.0053 | 0.0052 | |

| Temperature Coefficient of Resistivity at 20 °C | 1/°C | 0.0048 | 0.0047 | |

| Resistance Ratio (20–50 °C) | - | 1.143 | 1.141 | |

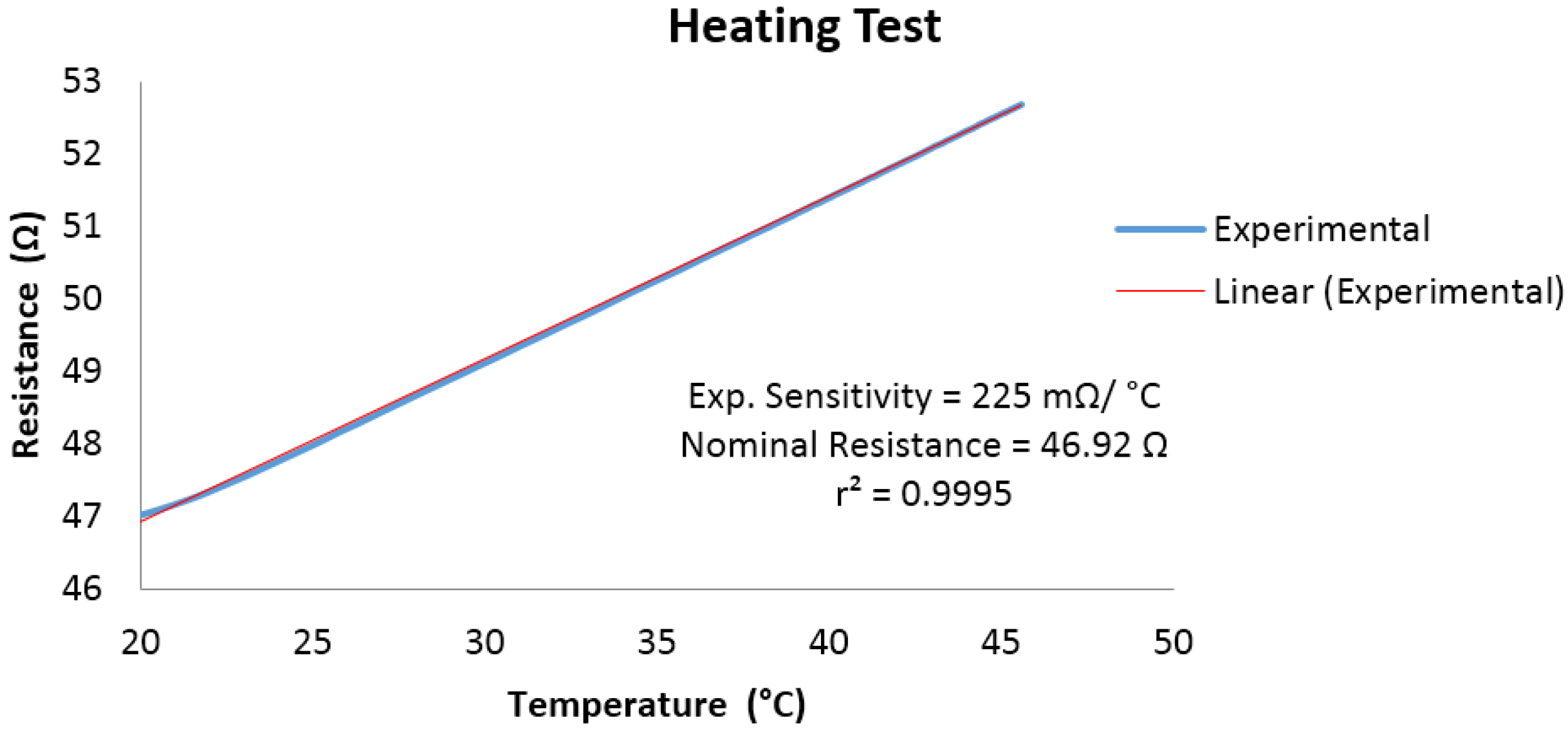

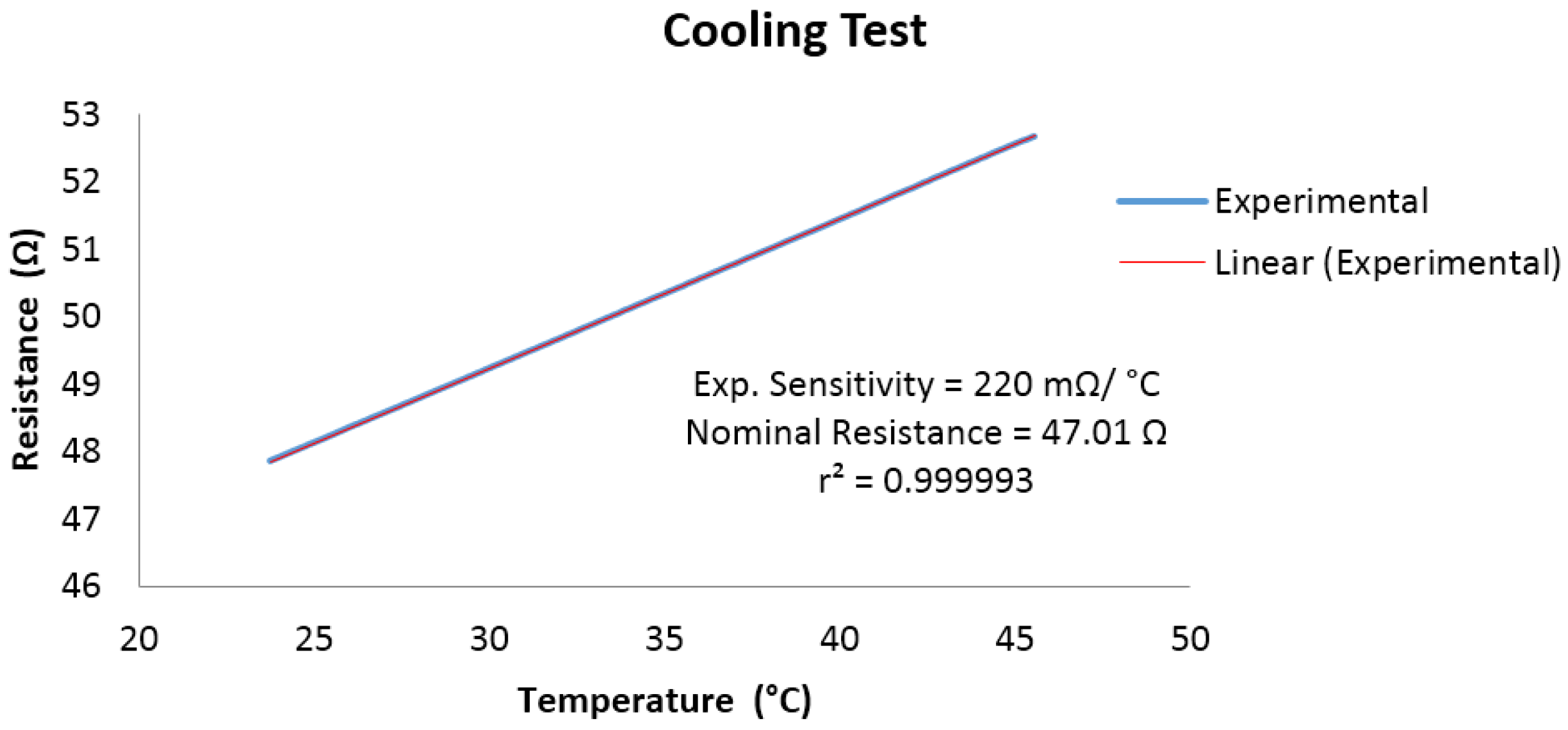

| Slope (Sensitivity) | Ω/°C | 0.225 | 0.220 | |

| Slope Error | Ω/°C | 0.0003 | 0.00002 | |

| 95% Confidence Interval of Slope | Ω/°C | 0.224 ± 0.0006 0.224 ± 0.28% | 0.222 ± 0.00005 0.222 ± 0.02% | |

| Nominal Resistance | Ω | 46.92 | 47.01 | |

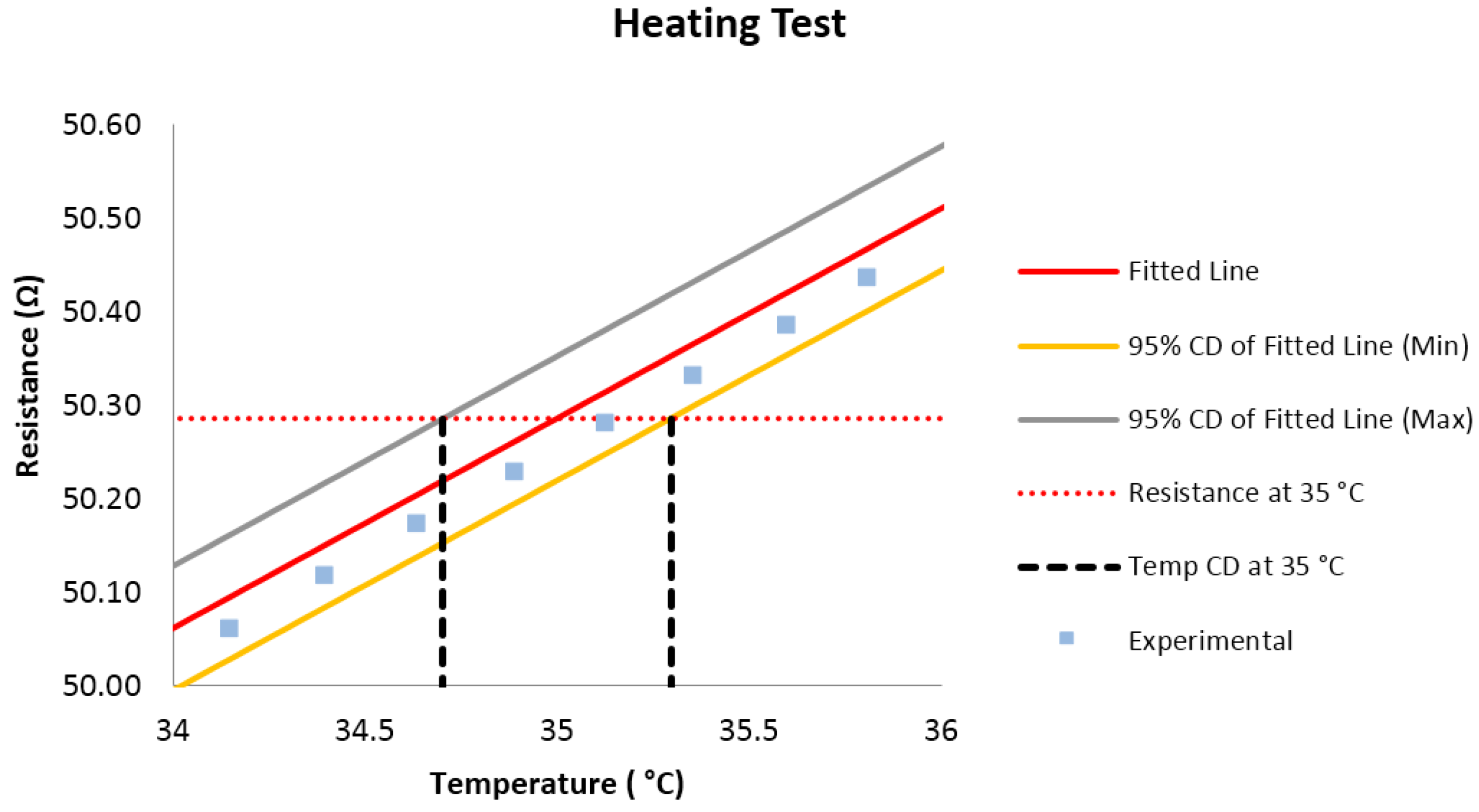

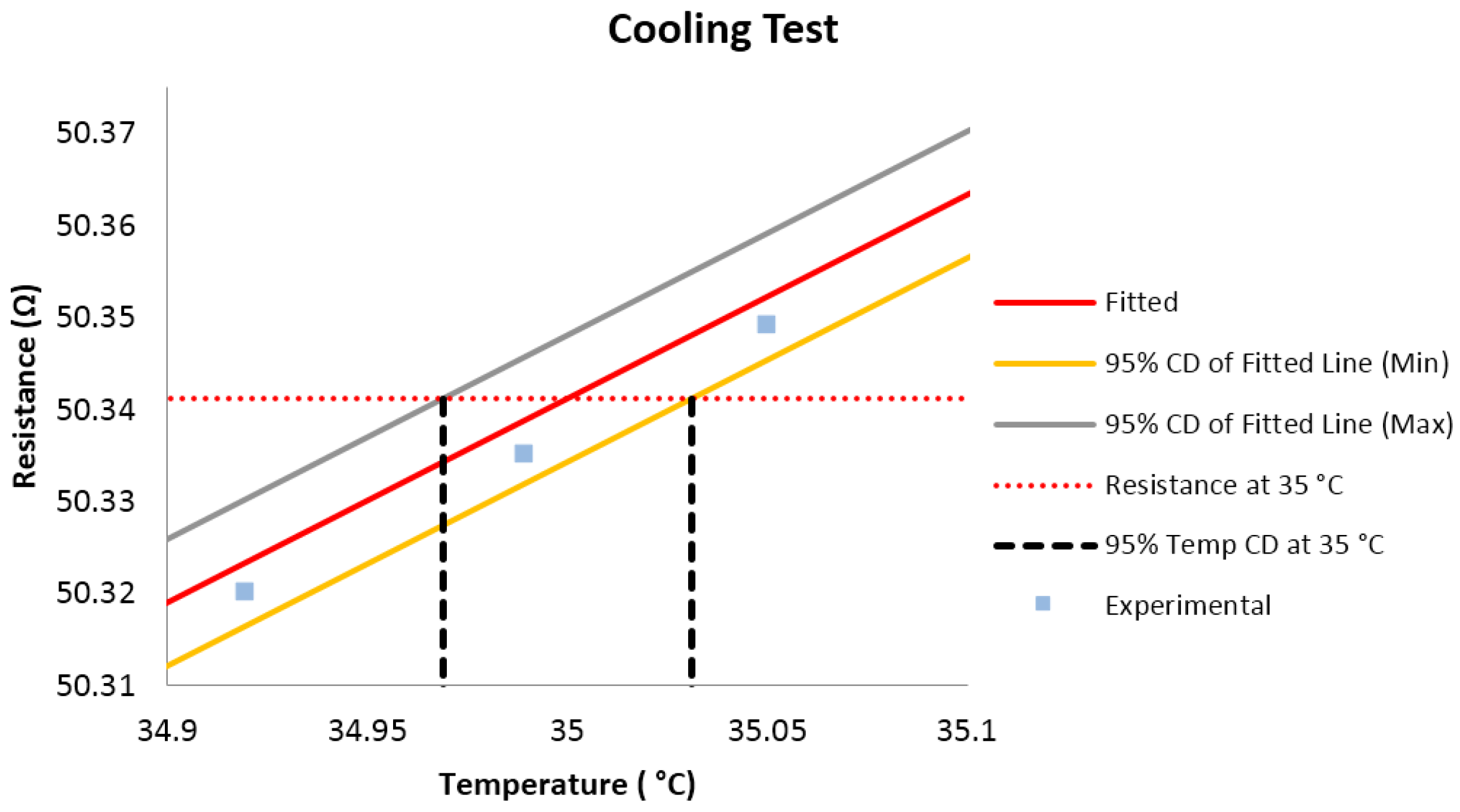

| Resistance at 35 °C | Ω | 50.28 | 50.34 | |

| Intercept (Resistance at 0 °C) | Ω | 42.44 | 42.58 | |

| Intercept Error | Ω | 0.013 | 0.0007 | |

| 95% Confidence Interval of Intercept | Ω | 42.44 ± 0.025 42.44 ± 0.06% | 42.58 ± 0.0015 42.58 ± 0.003% | |

| Standard error in Resistance | Ω | 0.034 | 0.003 | |

| 95% Confidence Interval of Resistance at 35 °C | Ω | 50.28 ± 0.067 50.28 ± 0.13% | 50.34 ± 0.007 50.34 ± 0.014% | |

| 95% Confidence Interval of Temperature at 35 °C | °C | 35 ± 0.30 35 ± 0.8% | 35 ± 0.03 35 ± 0.08% |

| Group Category | Mean Regression Errors (±°C) |

|---|---|

| All repeats | 0.16 |

| All heating repeats | 0.24 |

| All cooling repeats | 0.07 |

| All repeats of 46 inlay TSF | 0.15 |

| All repeats of 34 inlay TSF | 0.17 |

| All heating repeats of 46 inlay TSF | 0.22 |

| All cooling repeats of 46 inlay TSF | 0.07 |

| All heating repeats of 34 inlay TSF | 0.26 |

| All cooling repeats of 34 inlay TSF | 0.07 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Husain, M.D.; Atalay, O.; Atalay, A.; Kennon, R. Uncertainty Analysis of the Temperature–Resistance Relationship of Temperature Sensing Fabric. Fibers 2016, 4, 29. https://doi.org/10.3390/fib4040029

Husain MD, Atalay O, Atalay A, Kennon R. Uncertainty Analysis of the Temperature–Resistance Relationship of Temperature Sensing Fabric. Fibers. 2016; 4(4):29. https://doi.org/10.3390/fib4040029

Chicago/Turabian StyleHusain, Muhammad Dawood, Ozgur Atalay, Asli Atalay, and Richard Kennon. 2016. "Uncertainty Analysis of the Temperature–Resistance Relationship of Temperature Sensing Fabric" Fibers 4, no. 4: 29. https://doi.org/10.3390/fib4040029