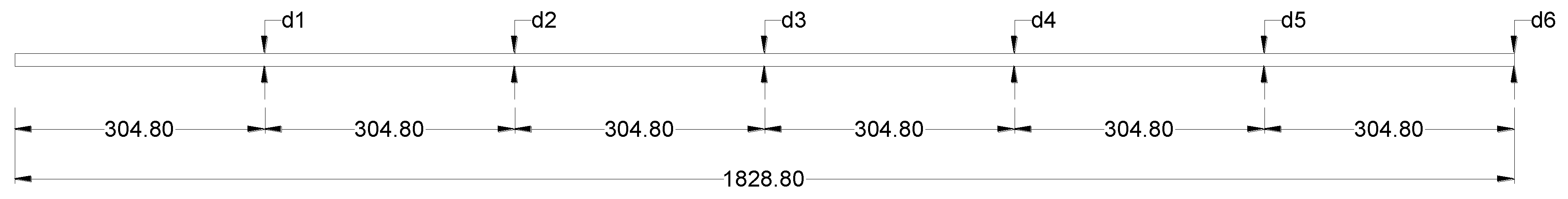

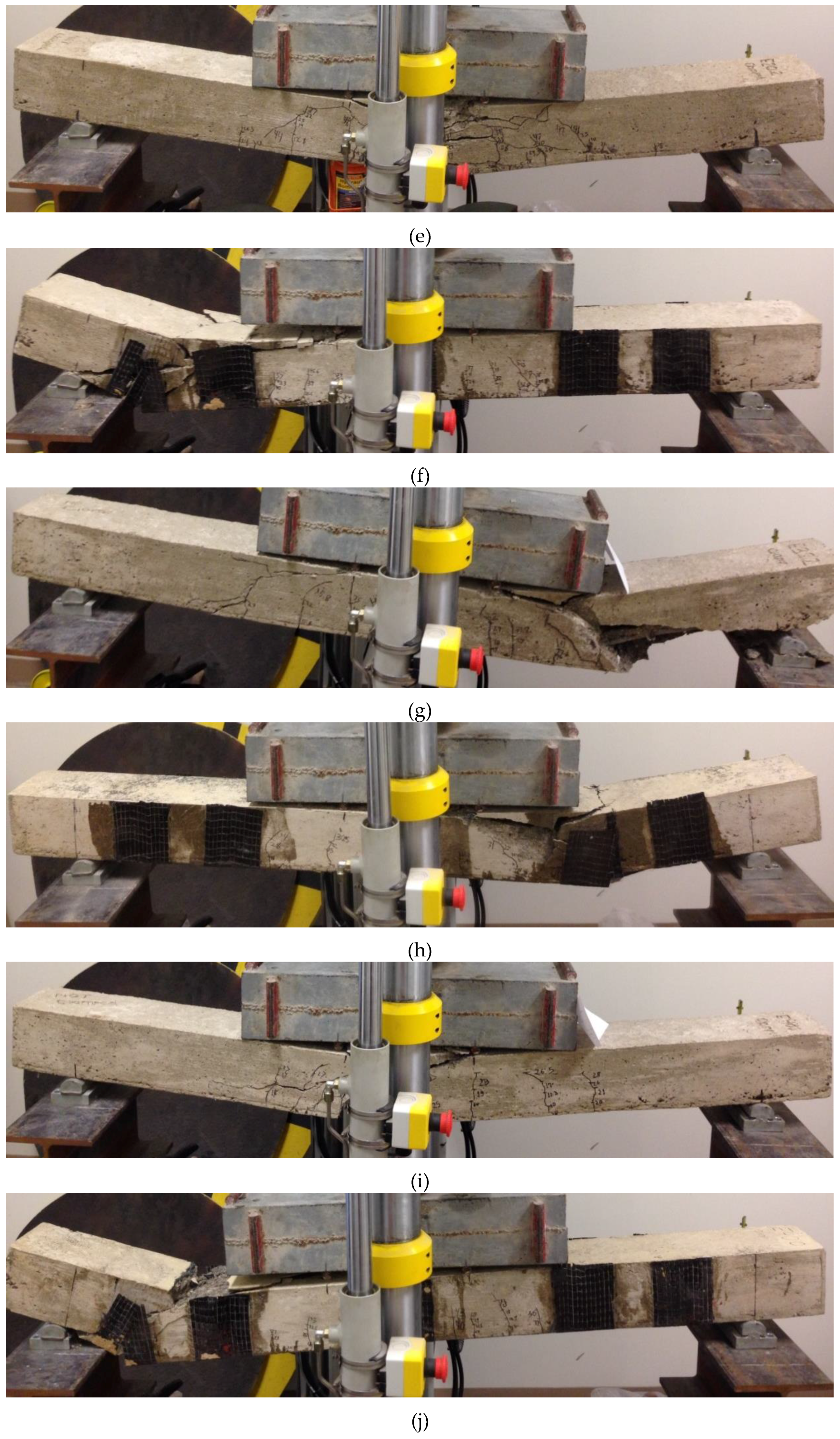

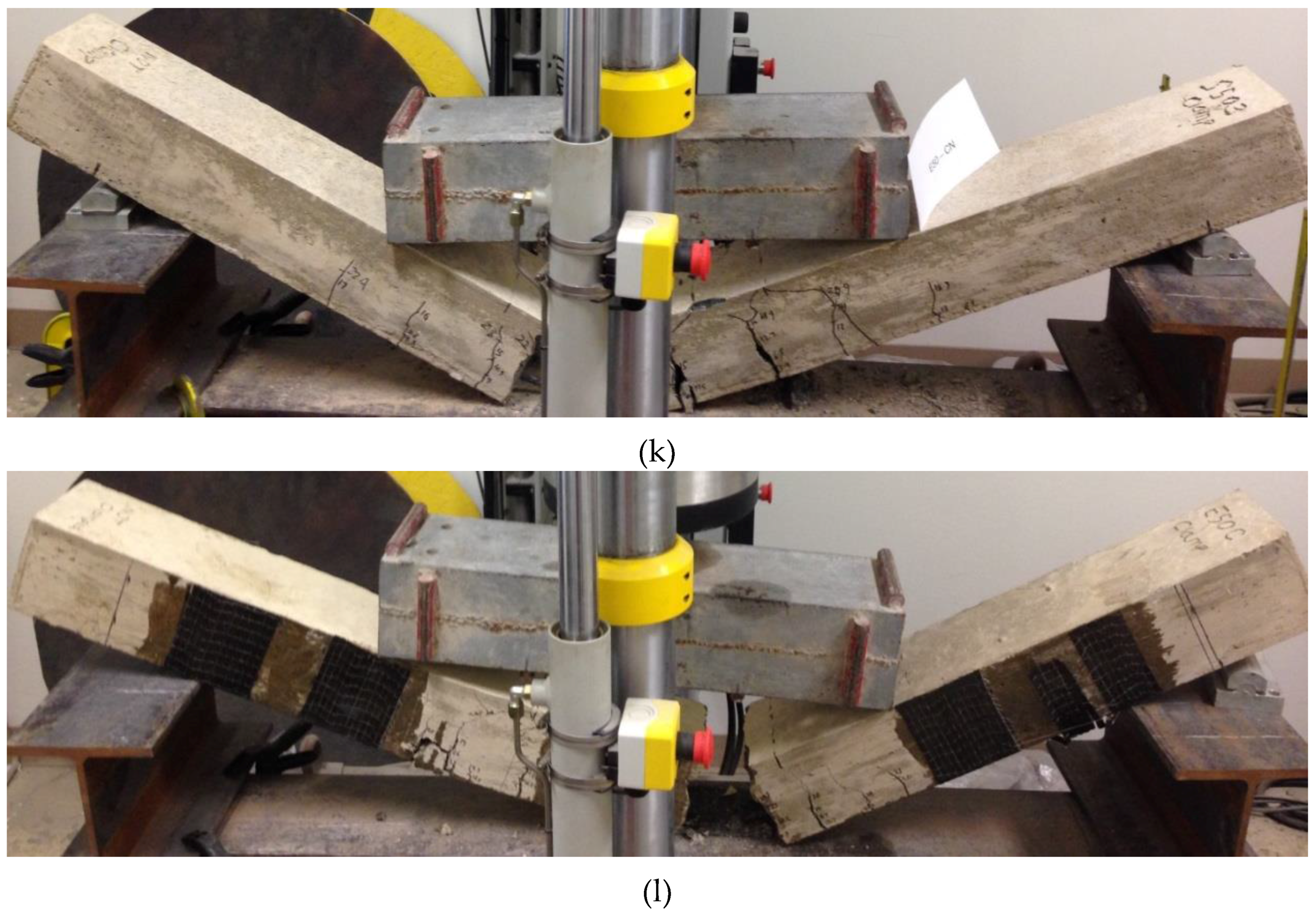

Figure 17.

Failure of all tested beams. (a) CB–CN; (b) CB–CR; (c) E 10–CN; (d) E 10–CR; (e) E 20–CN; (f) E 20–CR; (g) E 32–CN; (h) E 32–CR; (i) E 40–CN; (j) E 40–CR; (k) E 50–CN; (l) E 50–CR.

3.3.1. Failure Mode of Beams

All of the tested beams experienced extensive flexural cracks close to mid-span before failure. Failure of each beam is described as follows:

For CB–CN (Control Beam), the first crack appeared at 9.9 kN in the middle of the beam. The next crack appeared to the right of the first crack at 28 kN. The third crack appeared to the left of the original crack at 32 kN. A splitting crack occurred at the very end of the test at approximately 55 kN close to the clamped side, where rebars were clamped during the corrosion process. Note that beam CB–CN did not have any corrosion problem. Failure was initiated by flexural cracks.

For CB–CR, which is only reinforced with U-wraps (U). It had its first crack appear at 8.6 kN. At 28 kN a little bit of a popping sound, indicating debonding of CFRP, was heard in the middle U. At 48 kN some popping was heard in the second U from the clamped side. There were a number of flexural cracks close to the mid-span and propagated towards the top. At 54 kN more snapping noise was heard in the middle U and at 58 kN the beginning of a hairline splitting crack started from the loading point on the clamped side and propagated downward. Subsequently, the second U on the clamped side debonded. Then the splitting crack propagated from that loading point down to the support and both of the first U on the clamped side and the second U on the unclamped side debonded. There was also crushing of the concrete in the top. Failure was in initiated by flexural cracks.

For E 10–CN, The beam showed its first crack at 7 kN. Extensive flexural cracking took place close to the mid-span. At 42 kN, a splitting crack started to propagate on the clamped side between the second and third stirrups. At 44 kN the beam failed due to the splitting crack and crushing of the top concrete. Failure was in initiated by flexural cracks.

For E 10–CR, the beam first cracked at 4.9 kN. It showed extensive flexural cracking close to the mid-span. At 24.7 kN, a little popping noise was heard from the second U on the unclamped side, indicating debonding of CFRP. At 30 kN a puff of dirt came from the bottom sheet from under the middle U. At 43.kN, a little popping noise was heard from the second U on the clamped side. At 50.5 kN, a splitting crack appeared, originating from near the support on the unclamped side. Subsequently, there was crushing of the concrete on the top of the beam, debonding of both of the first U and the second U on the unclamped side, which partially debonded. There were also signs of debonding of the second U on the clamped side after the splitting crack took place. Failure was in shear.

For E 20–CN, the beam had its first crack at 2.5 kN in the concrete cover. More cracks were developed in the cover. There was extensive cracking close to the midspan of the beam. At 44 kN, a splitting crack started close to the left loading point on the unclamped side of the beam. There was another splitting crack on the other side. Both of the splitting cracks propagated close to the mid-span. The beam later failed due to a flexural crack that propagated at the mid-span and crushing of the top concrete, which is a different mode of failure from the other tested beams. Failure was in flexure.

For E 20–CR, The beam first cracked at 7 kN. Extensive flexural cracking took place close to the mid-span. At 28 kN, popping noise was heard from the bottom close to the second U on the unclamped side, indicating debonding of CFRP. Some dust escaped the bottom sheet at 33 kN from close to the midspan. Popping noise was heard from the middle U at 40 kN. The bottom sheet debonded near the mid-span at 44 kN. A stronger popping noise was heard at 47 kN. At 61 kN, a snapping noise was heard. At 62 kN, a splitting crack appeared close to the support on the unclamped side. The first and second U on the unclamped side debonded and there was crushing of the concrete in the top of the beam. Failure was in shear.

For E 32–CN, the beam had its first crack at 9 kN. Extensive flexural cracking occurred close to the mid-span. Some of the cracks extended all of the way to the top of the concrete. At 36 kN, a splitting crack started from the loading point on the unclamped side and propagated down near the support on the unclamped side. Later, as that crack propagated, a similar crack propagated on the clamped side. There was also crushing of the top concrete. Failure was in initiated by flexural cracks.

For E 32–CR, the beam showed its first crack at 10.2 kN. It had a number of flexural cracks close to the mid-span. At 14 kN, popping noise was heard from bottom close to the middle U, indicating debonding of CFRP. At 16 kN, popping noise was heard from the second U on the unclamped side and at 19 kN dust was seen escaping from under the second U on the clamped side. At 27 kN, a snapping noise was heard from the bottom of the unclamped side and at 30 kN, the middle U debonded. At 36 kN a hairline splitting crack was propagating close to the clamped side. At 38 kN, the second U on the clamped side debonded. Later, the splitting crack became more pronounced while the first U on the clamped side debonded and the top concrete crushed. Failure was in initiated by flexural cracks.

For E 40–CN, the beam showed its first crack at 9 kN. There were extensive flexural cracks close to the mid-span of the beam. Some of the cracks extended to the top of the beam. At 28 kN, a hairline splitting crack developed from under the loading point close to the clamped side and propagated downward. At 30 kN, another hairline splitting crack developed on the other side. At 33 kN, failure took place due to the splitting crack on the unclamped side. There was also crushing of concrete in the top. Failure was in flexure.

For E 40–CR, the beam showed its first crack at 2.5 kN. There were extensive flexural cracks close to the mid-span of the beam. Noise indicating debonding in the FRP was first heard at 42 kN in the middle of the beam. A splitting crack occurred close to the unclamped side of the beam at 47 kN. Slight crushing of top concrete also took place. There were signs of debonding in the bottom sheet; however, there were no signs of fracture. Failure was in initiated by flexural cracks.

For E 50–CN, the beam showed its first crack at 5.9 kN. There were extensive flexural cracks close to the mid-span of the beam. Most of the cracks extended to the top of the beam. At 23 kN, a loud noise was heard close to the mid-span, then the beam splitted into two halves at 25 kN. It was found that both of the two rebars have fractured. Failure took place due to the fracture of the two rebars and crushing of concrete. Failure was in flexure.

For E 50–CR, the beam first cracked at 8.5 kN. Popping sound was first noted at 10 kN. Extensive flexural cracking occurred close to the mid-span of the beam. The popping sound occurred more frequently at 27 kN and at 31 kN. Subsequently, the bottom sheet and the U sheets located at the mid-span and the support on the clamped end ruptured at 31 kN and the load dropped to 25 kN. Flexural failure occurred resulting in the beam to split into two halves. The rebars also ruptured and top concrete crushed. Failure was in flexure.

It seems that the CFRP repairs held up the failure process, which is confirmed with the load-deflection curves as discussed below.

3.3.2. Load-Deflection Relationships

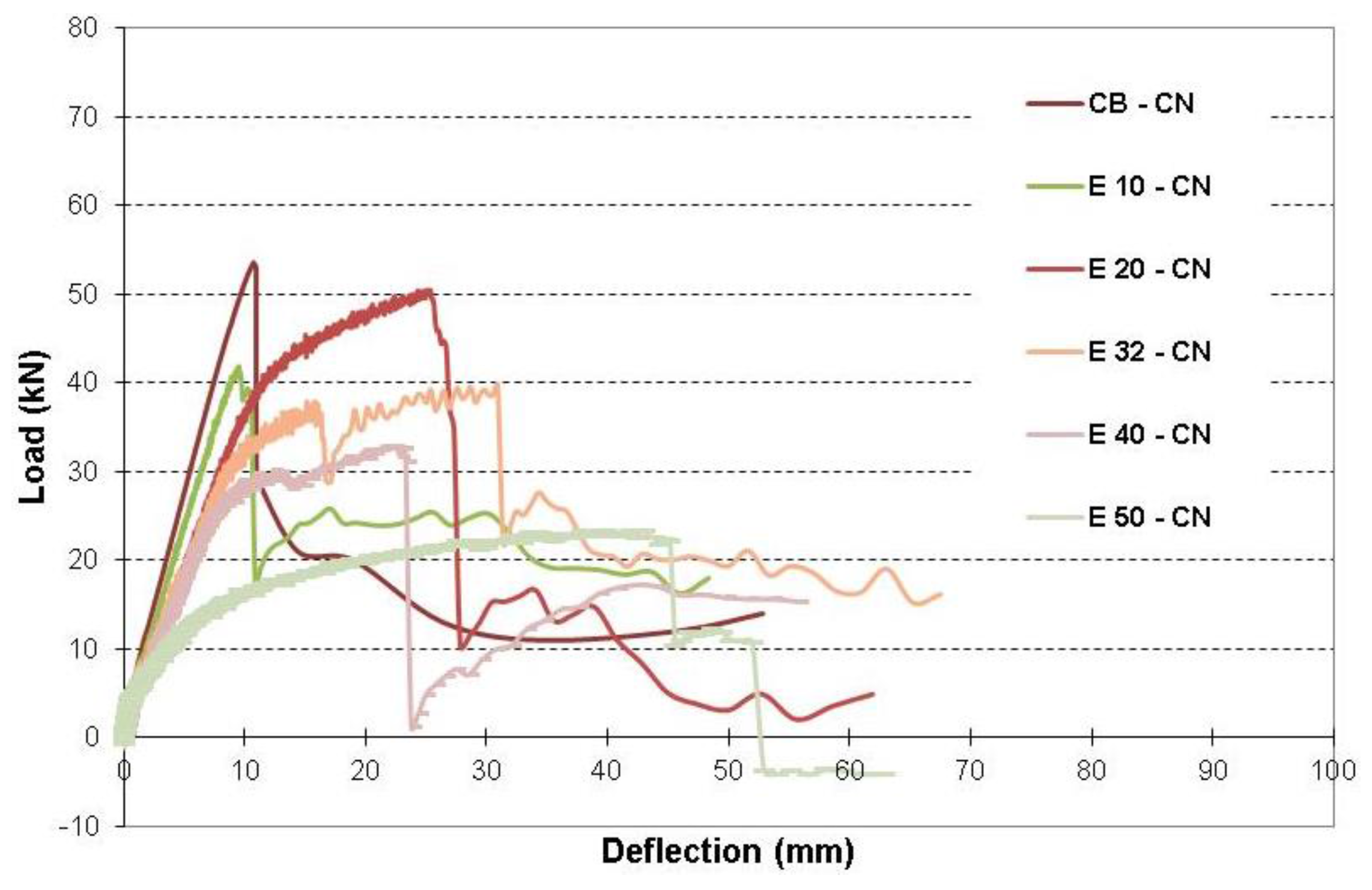

From comparing load-deflection relationships of beams CB–CN, E 10–CN, E 20–CN, E 32–CN, E 40–CN, and E 50–CN (

Figure 18), it can be determined that as the level of corrosion increased, the beam became less stiff. As the corrosion level increased, beams became more ductile except for beam with 40% corrosion as it showed similar stiffness to that with 32% corrosion, but it showed less ductility. Overall, it can be concluded that the cracking load did not changed significantly due to corrosion. It can also be concluded that load capacity decreased as the level of corrosion became higher (

Table 7). For example, the beam with 40% corrosion level lost about 39% of its carrying capacity while the one with 50% corrosion level lost about 56% of its carrying capacity when they were compared to CB-CN. Thus, the relationship between the corrosion level and the loss in load carrying capacity of RC members seem not linear.

Figure 18.

Load-Deflection relationships for all beams without repair.

Figure 18.

Load-Deflection relationships for all beams without repair.

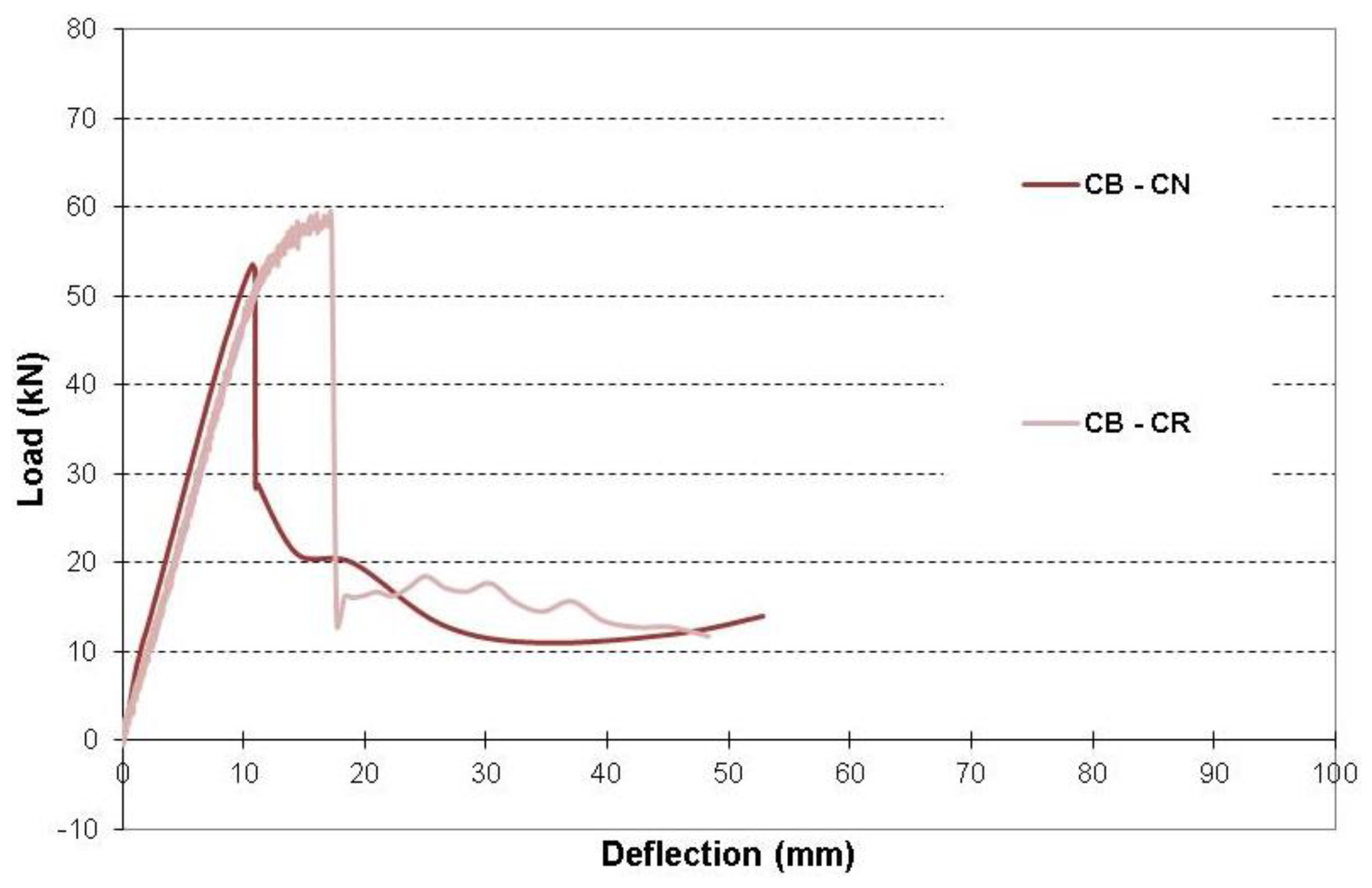

Figure 19 presents a comparison between load-deflection relationships of non-repaired and repaired beams, CB-CN and CB-CR. It is clear that adding only U-Wraps to the CB-CN (control beam) improved its load capacity and ductility. Progressive debonding and then rupture of some of the U-wraps led to the yielding point on the load-deflection curve. As load increased, the beam completely failed. It can also be observed that both CB-CN and CB-CR had similar reserve load capacity after failure.

Figure 19.

Load-Deflection relationships of control beams without and with repair.

Figure 19.

Load-Deflection relationships of control beams without and with repair.

Table 7.

Effect of corrosion level on load capacity.

Table 7.

Effect of corrosion level on load capacity.

| Beam | Load Capacity (kN) | % of Change from CB–CN | % of Change from CB–CR | % of Change from E10–CN | % of Change from E20–CN | % of Change from E32–CN | % of Change from E40–CN | % of Change from E50–CN |

|---|

| CB–CN | 53.59 | – | −9.99 | – | – | – | – | – |

| CB–CR | 59.54 | 11.09 | – | – | – | – | – | – |

| E10–CN | 41.87 | −21.87 | −29.67 | | – | – | – | – |

| E10–CR | 50.94 | −4.96 | −14.45 | 21.64 | – | – | – | – |

| E20–CN | 50.49 | −5.78 | −15.19 | – | – | – | – | – |

| E20–CR | 64.00 | 19.41 | 7.49 | – | 26.74 | – | – | – |

| E32–CN | 36.73 | −31.46 | −38.30 | – | – | – | – | – |

| E32–CR | 38.81 | −27.58 | −34.81 | – | – | 5.67 | – | – |

| E40–CN | 32.90 | −38.61 | −44.74 | – | – | – | – | – |

| E40–CR | 45.82 | −14.50 | −23.04 | – | – | – | 39.27 | – |

| E50–CN | 23.35 | −56.44 | −60.79 | – | – | – | – | – |

| E50–CR | 45.81 | −14.52 | −23.06 | – | – | – | – | 96.21 |

Figure 20 presents a comparison between load-deflection relationships of the control beam (CB–CN), E 10–CN, and E 10–CR. Due to 10% corrosion level in rebars, the beam lost about 22% of its load carrying capacity, but when repaired with both CFRP sheet and U-wraps, it recovered about 17% of its load carrying capacity.

Figure 20.

Effect of 10% corrosion level on load-deflection relationship.

Figure 20.

Effect of 10% corrosion level on load-deflection relationship.

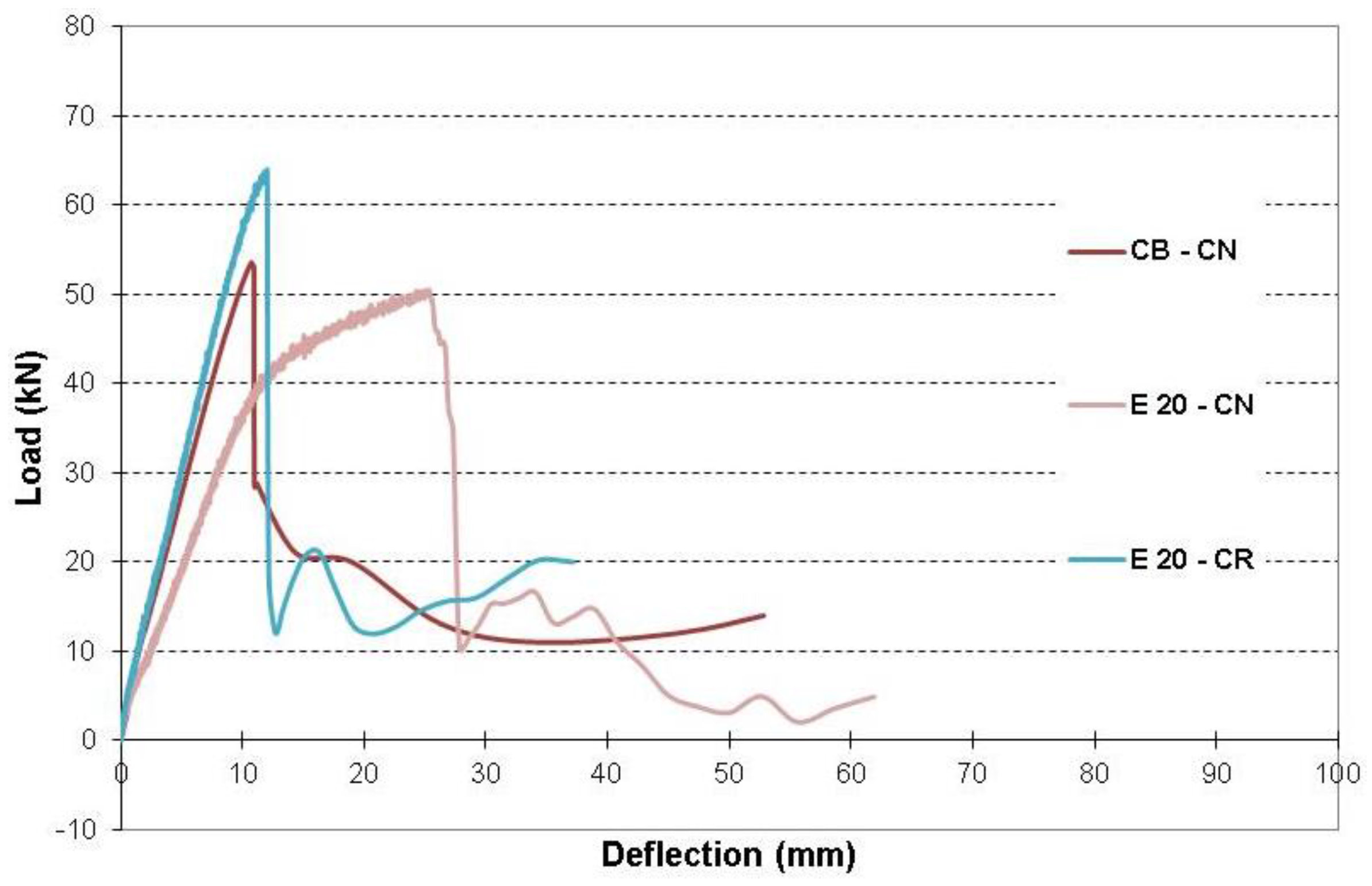

Figure 21 presents a comparison between load-deflection relationships of the control beam (CB–CN), E 20–CN, and E 20–CR. Due to 20% corrosion level in rebars, the beam lost about 6% of its load carrying capacity, but when repaired with both CFRP sheet and U-wraps, it had about 19% higher load capacity than the control beam. This can be attributed to the fact that E 20–CN experienced different mode of failure than E 10–CN. It should be also noted that E 20–CN had smaller stiffness than the control beam and was more ductile, but when repaired it had a similar stiffness to the control beam and became less ductile.

Figure 21.

Effect of 20% corrosion level on load-deflection relationship.

Figure 21.

Effect of 20% corrosion level on load-deflection relationship.

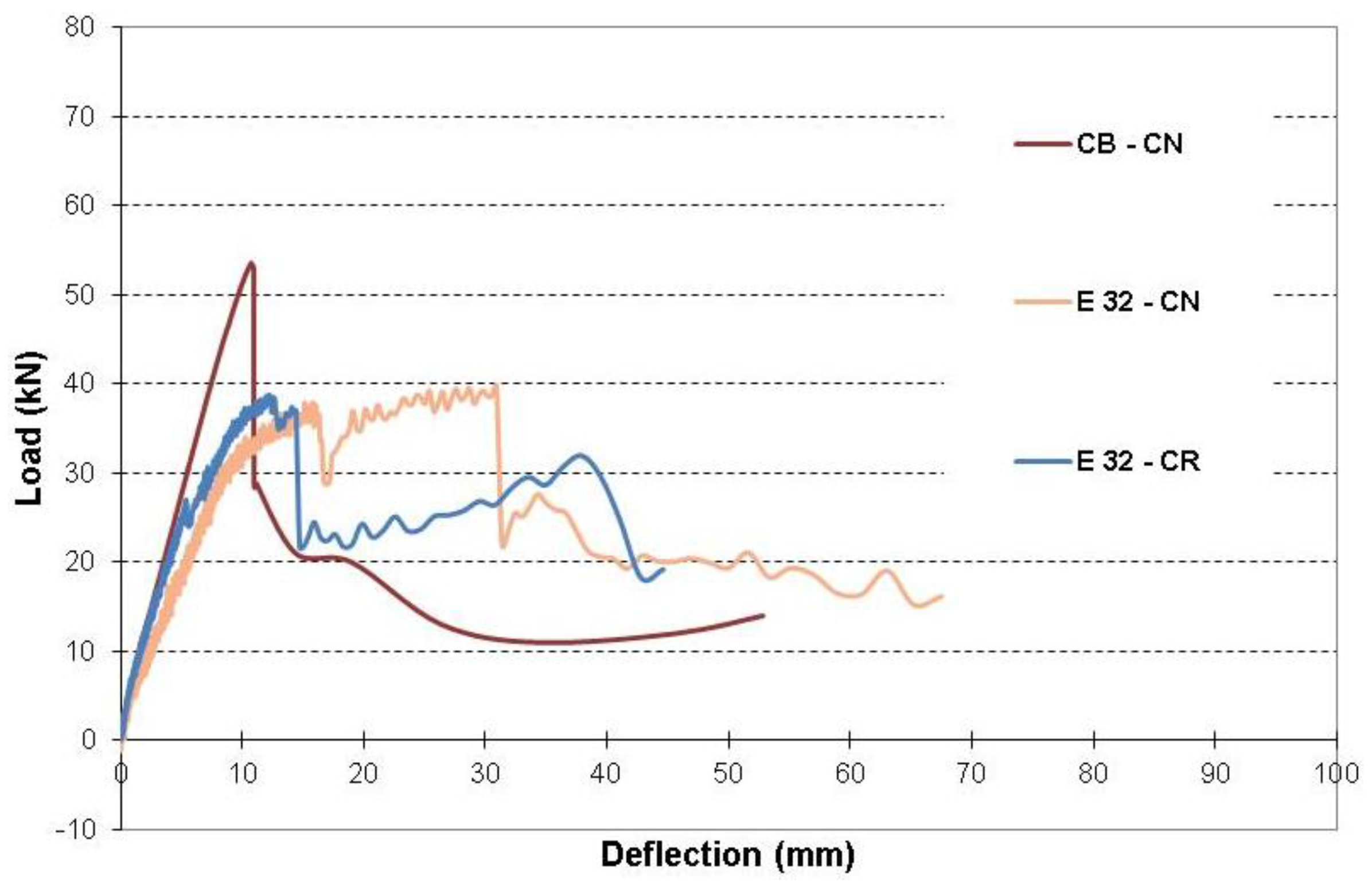

Figure 22 presents a comparison between load-deflection relationships of the control beam (CB–CN), E 32–CN, and E 32–CR. Due to 32% corrosion level in rebars, the beam lost about 32% of its load carrying capacity, but when repaired with both CFRP sheet and U-wraps, it only recovered about 4% of its load carrying capacity. This little improvement can be owing to the early signs of debonding in CFRP, which adversely affected the capacity of the repaired beam. Both beams with 32% corrosion level had smaller stiffness than their counterpart control beam and were more ductile. However, E 32–CR became stiffer and less ductile than E 32–CN.

Figure 22.

Effect of 32% corrosion level on load-deflection relationship.

Figure 22.

Effect of 32% corrosion level on load-deflection relationship.

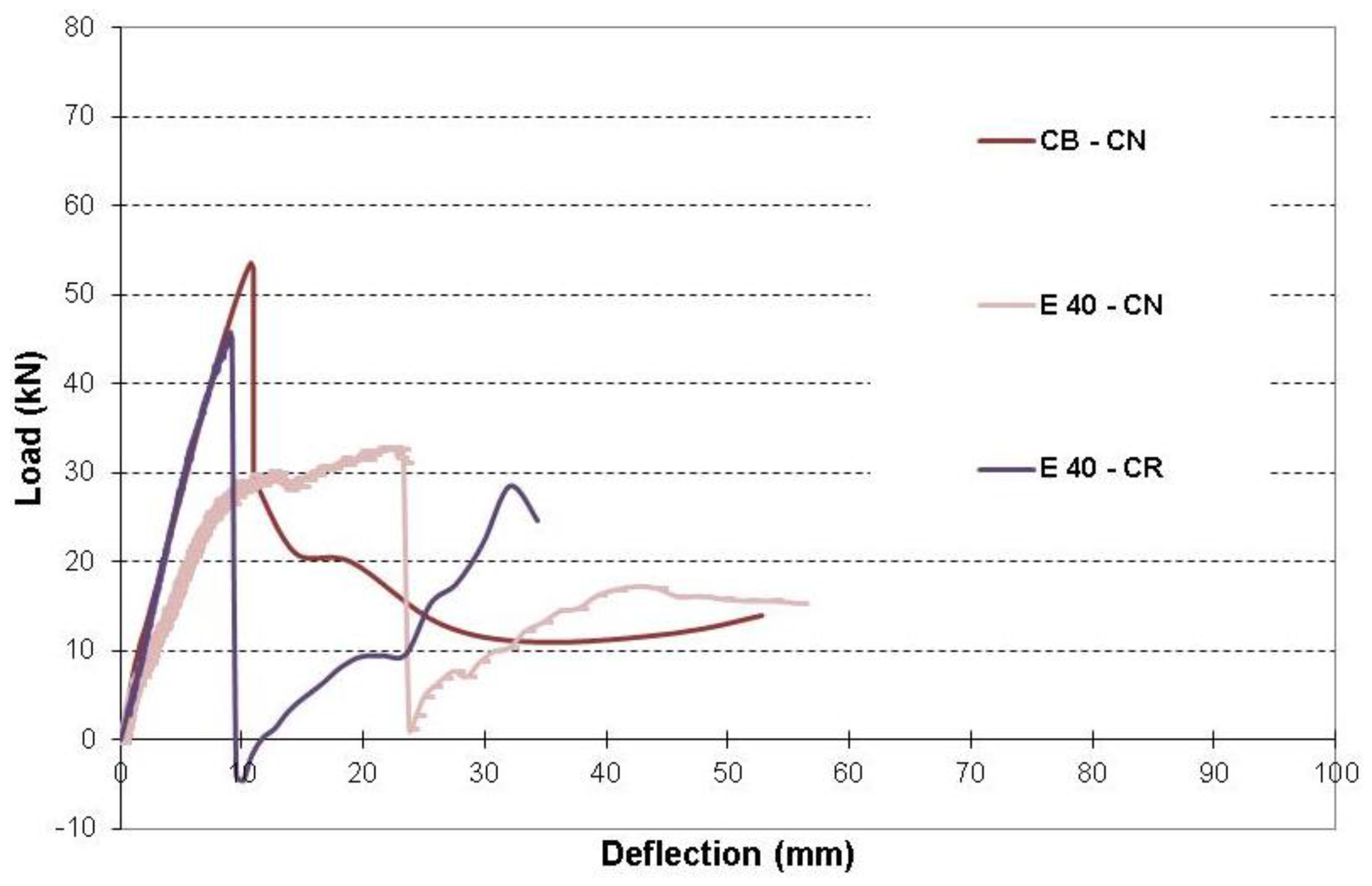

Figure 23 presents a comparison between load-deflection relationships of the control beam (CB–CN), E 40–CN, and E 40–CR. Due to 40% corrosion level in rebars, the beam lost about 39% of its load carrying capacity, but when repaired with both CFRP sheet and U-wraps, it recovered about 24% of its load carrying capacity. Beams with 40% corrosion level had smaller stiffness and experienced more ductility than their counterpart control beam, but when repaired, it had stiffness close to the control beam and became even less ductile than the control beam.

Figure 23.

Effect of 40% corrosion level on load-deflection relationship.

Figure 23.

Effect of 40% corrosion level on load-deflection relationship.

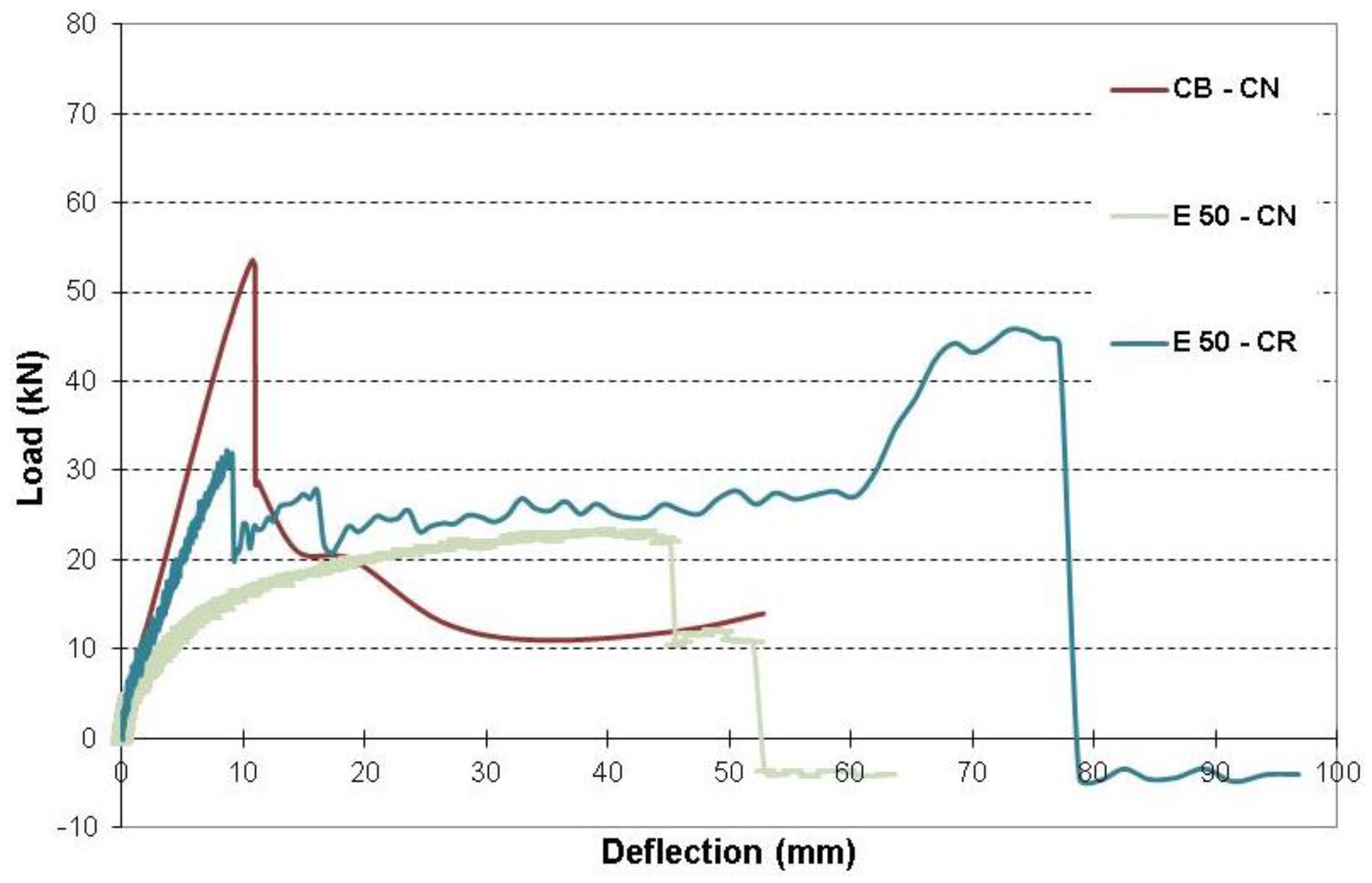

Figure 24 presents a comparison between load-deflection relationships of the control beam (CB–CN), E 50–CN, and E 50–CR. Due to 50% corrosion level in rebars, there was a drastic loss in capacity. The beam lost about 56% of its load carrying capacity, but when repaired with both CFRP sheet and U-wraps, it recovered about 42% of its load carrying capacity. Both beams with 50% corrosion level exhibited ductile performance as rebars fully yielded, formed nicking, and then ruptured. Furthermore, E 50–CR had load-deflection curve similar to the stress-strain diagram of the steel. E 50–CR experienced drop in capacity before the load levels out due to debonding and rupture of some of CFRP. E 50–CN had smaller stiffness and experienced more ductility than their counterpart control beam, but when repaired, it had larger stiffness yet smaller than that of the control beam and became more ductile than the control beam.

Figure 24.

Effect of 50% corrosion level on load-deflection relationship.

Figure 24.

Effect of 50% corrosion level on load-deflection relationship.