3.1. Results of the Completely Randomized Design

Because food packaging materials are required to have high strength, the tensile strength was selected as the standard for the completely randomized design test [

28]. The test results are shown in

Table 1. For an increase in the SA content for a fixed CS and CMC contents of 1.0% and 1.5%, respectively, in the casting solution, the thickness of the composite film increased continually, while the tensile strength first increased and then decreased. When the SA content was 1.5%, the maximum tensile strength of 84.19 ± 12.86 MPa was achieved; however, the content had no significant effect on the elongation after fracture of the composite film. The high viscosity and film-forming ability of SA causes the molecules to link closely, decreasing the intermolecular spaces and increasing the tensile strength of the composite film [

29]. The highest tensile strength was observed for an SA content of 1.5%. When the SA content was less than 0.5%, the solution was as transparent as water and had no film-forming ability. When the SA content exceeded 2.0%, SA did not dissolve completely during the solution preparation process, and small air bubbles formed in the solution, which could not be removed, thus preventing the film formation. For comprehensive tensile strength testing, SA contents of 1.0%, 1.5%, and 2.0% were selected for the orthogonal experimental design.

With a change in the CS content of the casting solution from 0.5% to 2.0% (with fixed SA and CMC contents of 1.0% and 1.5%, respectively), the thickness of the composite film continued to increase, while the tensile strength and elongation after fracture changed minimally. Further, as the CS content increased, the tensile strength of the composite film increased slightly at first and then decreased. The maximum tensile strength was the maximum of 61.39 ± 10.07 MPa was achieved with a CS content of 1.5%. For comprehensive tensile strength test, CS contents of 1.0%, 1.5%, and 2.0% were selected for the orthogonal experimental design.

With change in CMC content from 0.5% to 2.0% (with fixed SA and CS contents of 1.0%, respectively), the thickness of the composite film did not change significantly, whereas the tensile strength first increased and then decreased. When the CMC content was 1.0%, the maximum tensile strength of 78.23 ± 11.74 MPa was observed, while the cracking and elongation after fracture showed a fluctuating trend. More specifically, the tensile strength first decreased, then increased, and finally decreased again, with the maximum value reaching 9.56% ± 2.17%. Because of the low CMC content, which was only 15% of the mass of the composite membrane sample, the film thickness did not change significantly with a change in the CMC content. However, Because CMC has an internal sugar ring structure, it has a good skeleton effect as a composite structure, and it can improve the internal structural stability of the composite film, thus increasing the tensile strength and ductility of the composite film [

30]. In order to obtain a composite film that has high tensile strength and good ductility, CMC contents of 0.5%, 1.0%, and 1.5% were selected for the orthogonal experimental design. Although the ductility was good at 2.0% CMC, the tensile strength diminished. Therefore, this value was not used.

In summary, the single factor concentration range of SA, CMC and CS is 0.5%–2.0%. This test is to control the thickness of the film by mass. During the experiment, it was found that when the concentration was less than 0.5%, the composite film formed was very thin due to the too small amount of solute substances in the solution. As it is difficult to maintain the integrity of the film, the composite film is intended for use in food packaging. Thickness is a key parameter in determining film clarity, water permeability and mechanical properties, which increases the film’s ability to improve the mechanical integrity of foods. When the concentration is greater than 2%, when the solution is prepared, the solution reaches saturation, and the solute is difficult to completely dissolve. Therefore, no further experiments were continued. And within the concentration range of this experiment, the performance of the composite membrane showed a trend of increasing first and then less. The effect of concentration changes on the performance of the composite membrane has been well demonstrated. This concentration range is representative [

28].

3.2. Results of Orthogonal Experiment

Based on the results of the completely randomized design test, a comprehensive orthogonal experimental design was carried out using a combination of SA (content: 1.0%, 1.5%, and 2.0%), CS (content: 1.0%, 1.5%, and 2.0%), and CMC (content: 0.5%, 1.0%, and 1.5%). Moreover, the tensile strength, elongation after fracture, and other indices were determined. SA, CS, and CMC were used as the test factors, while the tensile strength, elongation after fracture, water absorption, oil permeability coefficient, moisture permeability coefficient, and transparency were the tested parameters. The orthogonal experimental design factors and parameters are shown in

Table 2.

The results of the orthogonal experimental design were processed and analyzed based on a reference. According to the raw data, a series of the performance indicators of the nine composite membranes are arranged in sequence. The best performance score is 10 points, and the worst is 1 point. The scores of the nine composite membranes were calculated according to the proportions. All performance scores were added to get the total score; according to the factors, the total scores were averaged to obtain K. According to the factors, the scores of a certain performance were added and arranged in sequence, and the degree of the influence of the factors on the performance can be judged [

31]. Because the composite film is intended for food packaging applications, it is required to have high strength and ductility. The higher the tensile strength and the elongation after fracture, the better is the film [

18]. Moreover, since food packaging often comes into contact with water and oils, the lower the water absorption, oil permeability coefficient, and moisture permeability coefficient, the better the composite film. In addition, the film should have high light transmittance so that the packaging contents can be clearly visible [

31,

32].

Table 3 shows the results of the orthogonal experimental design.

Table 4 shows the raw data of the composite film, and

Table 5 shows the grading results for the individual factors. It is evident from

Table 3 that the composite film 3, with the highest score, has the optimal physical performance.

Table 3 also indicates the following primary and secondary relationships between the factors that affect the comprehensive performance of the composite film: B > A > C, which is CS > SA > CMC. When the CS, SA, and CMC contents are varied, the physical attributes of the composite film are mainly affected by CS and SA. The combination that results in the optimal comprehensive performance is A2B2C1, that is, the composite film fabricated with SA, CS, and CMC contents of 1.5%, 1.5%, and 0.5%, respectively.

A, B, and C stand for SA, CS, CMC; 1–9 represent the concentration combination of the composite film; K1, the total score of each factor in its first level; K2, the total score of each factor in its second level; K3, the total score of each factor in its third level; and R, the range score of each factor in its each level.

Based on the data in

Table 5, the primary and secondary relationships between the three factors based on their effects on each indicator were analyzed using a ranking score analysis, and the results are shown in

Table 6.

It is evident that the tensile strength is an important indicator of the cross-sectional tension of the composite film [

28]. All the three test factors affected the tensile strength of the composite film. The central part of the molecular structure contained a large number of hydroxyl groups, which provided the necessary conditions for the formation of intermolecular hydrogen bonds and help increase the intermolecular forces. Both CS and CMC strongly affect the tensile strength of the composite film, while the viscous CS solution caused the molecules to bind more tightly, and CMC, which itself has a stable network structure, increased the tensile strength of the composite film. Bajpai et al. [

18] proposed that as the CS content increases from 0% to 2.0%, the tensile strength of the CS film increases by a factor of three. This is related to strengthening of the cellulose crystals and is associated with the interaction between the polar groups of the CMC and CS chains. The addition of CMC can enhance the tensile strength of the composite film, however, when the CMC content exceeds a certain limit, it reacts to the tensile strength. Atefa et al. [

33] demonstrated that excessive super-hard stiffness and cracks in the film matrix are the main reasons leading to brittleness and reduced tensile strength of the film. However, Hu et al. [

28] believe that some of the weak polymers replace the stronger polymers, thereby weakening the internal network structure of the film, and thus causing a decrease in the tensile strength. In addition, the cross-linking agent, CaCl

2, can increase the tensile strength of the composite film within a certain range. Calcium ions form strong chemical bonds with CMC, but they also continue to concentrate, which can cause the film to have uneven internal structure, which lowers its tensile strength. Contrast, the opposite occurs when SA cross-links with CaCl

2. The SA content affected the tensile strength of the composite film indirectly. Elongation after fracture is an indicator of the composite film’s toughness. An appropriate elongation is essential for improving the packaging adaptability, enhancing its protective quality, and ensuring that no breakage occurs when the packaging is folded. The elongation after fracture of the composite film in this study was mostly influenced by the CS content. CS molecules contain a large number of amino and hydrogen groups, which form strong hydrogen bonds and prevent molecular slip, thereby increasing the tensile strength of the composite film, but reduce its elongation capability [

34]. The elongation after fracture was also influenced by the cross-linking agent, CaCl

2, which destroys the CS and SA hydrogen bonds, thus lowering their crystallinity. The higher the crystallinity, the stronger the intermolecular force, which increases the tensile strength of the material; however, it reduces the properties related to molecular action, such as the elongation rate. The cross-linking agent reduces the tensile strength of the composite film, while increasing its elongation after fracture. This is similar to the conclusions of [

35]. Ebrahimi et al. [

32] believe that glycerin is the most common plasticizer that reduces the intermolecular forces between polymers. This results in a decrease in the tensile strength and an increase in the elongation at break.

The water absorption and moisture permeability coefficients of a film are related to the hydrophilicity of the molecules. Ebrahimi et al. [

32] clearly pointed out that WVP is one of the important indicators to avoid mass transfer between food and the surrounding environment within the membrane. Furthermore, Kanmani et al. [

36] suggested that it is affected by factors such as crystallinity, hydrophobic properties, and film thickness and integrity of the film components. All three precursor molecules of the composite film contain a large number of hydrophilic hydroxyl groups, which significantly increases the permeability coefficients of all substrate combinations, thereby limiting the application of the film to packaging of food with lower water content. SA and CMC are soluble in water, while CS is soluble in dilute acids. Adding a small amount of CMC has minimal effect on water absorption and the moisture permeability coefficient. Because SA has poor water resistance, the SA in the composite film was cross-linked using a CaCl

2 solution, leading to the formation of a gel network structure, which reduced the effect of water on the composite film. However, CS is also strongly affected by water; therefore, without a cross-linking treatment, the problem of high water absorption rate and moisture permeability coefficient of the composite film remains unsolved. Hu et al.’s study [

28] showed that the mixing of CMC and CS led to a significant drop in WVP. This is the formation of hydrogen bonds between CS and CMC, which reduces the characteristics of the hydrophilic polysaccharide matrix. However, due to the added amount of CMC, the hydrophilicity of the composite membrane still exists. During the subsequent application of the composite film for the preservation of perishable fruits, it was discovered that the high moisture absorption and permeability helped absorb the moisture released during the respiration process of fresh fruit and prevented its spoilage. Noshirvani et al. [

16] added cinnamon essential oil to the CS/CMC composite film. Studies indicated that the decrease in the WVP of CS/CMC composite films is due to hydrogen bonding between the biopolymers. The added cinnamon oil plasticizes the polysaccharide network of CS and CMC, and improves the moisture permeability and oxidation resistance of the antimicrobial composite membrane. The composite film can be used for food preservation and improve food safety and quality. Bajpai et al. [

18] proposed that the moisture absorption rate of the composite film is positively related to the content of CMC, while the composite film has strong moisture permeability. This is mainly due to the fact that CMC has a surface hydroxyl group and can easily adsorb water molecules, which renders that the CMC composite membrane hygroscopic. When water vapor enters the membrane matrix, the fluorene group in the cellulose chain does not interact with the invading water molecule owing to the strong internal triple bond interaction, and it exhibits good moisture permeability. This feature is important for preserving the freshness and extending the shelf life of fresh fruits.

The oil permeability of a film is related to the amount of lipophilic groups present in the film. The high oil permeability coefficient of the composite film is partially affected by SA, which contains a large number of lipophilic groups and ether groups. In addition, CS contains lipophilic groups and amino groups. Ebrahimzadeh et al. [

37] proposed that the CMC composite film has good oxygen and lipid barrier properties. This conclusion is similar to that of [

38]. However, owing to the small amount of CMC added to the composite membrane, the effect of CMC on the oil-repellent properties of the composite membrane is not significant. Therefore, the composite film has poor oil resistance that renders it suitable for packaging food that has low oil content. This also implies a decrease in the light transmittance rate of the composite film, which endows the film with an additional anti-oxidative effect [

39]. This is consistent with the idea of Hu et al. [

28] who suggested that transparency is one of the ideal features for food packaging films, and transparent films can see the packaged product. After adding the CMC to the blend film, the CMC may cause optical scattering and refraction, so the composite film transmittance decreases. However, it can shield some ultraviolet rays and prevent the photo-induced deterioration of packaged foods. Bonilla et al. [

40] proposed that, owing to the presence of chitosan, the composite membrane is yellow, which limits the application of composite membranes.

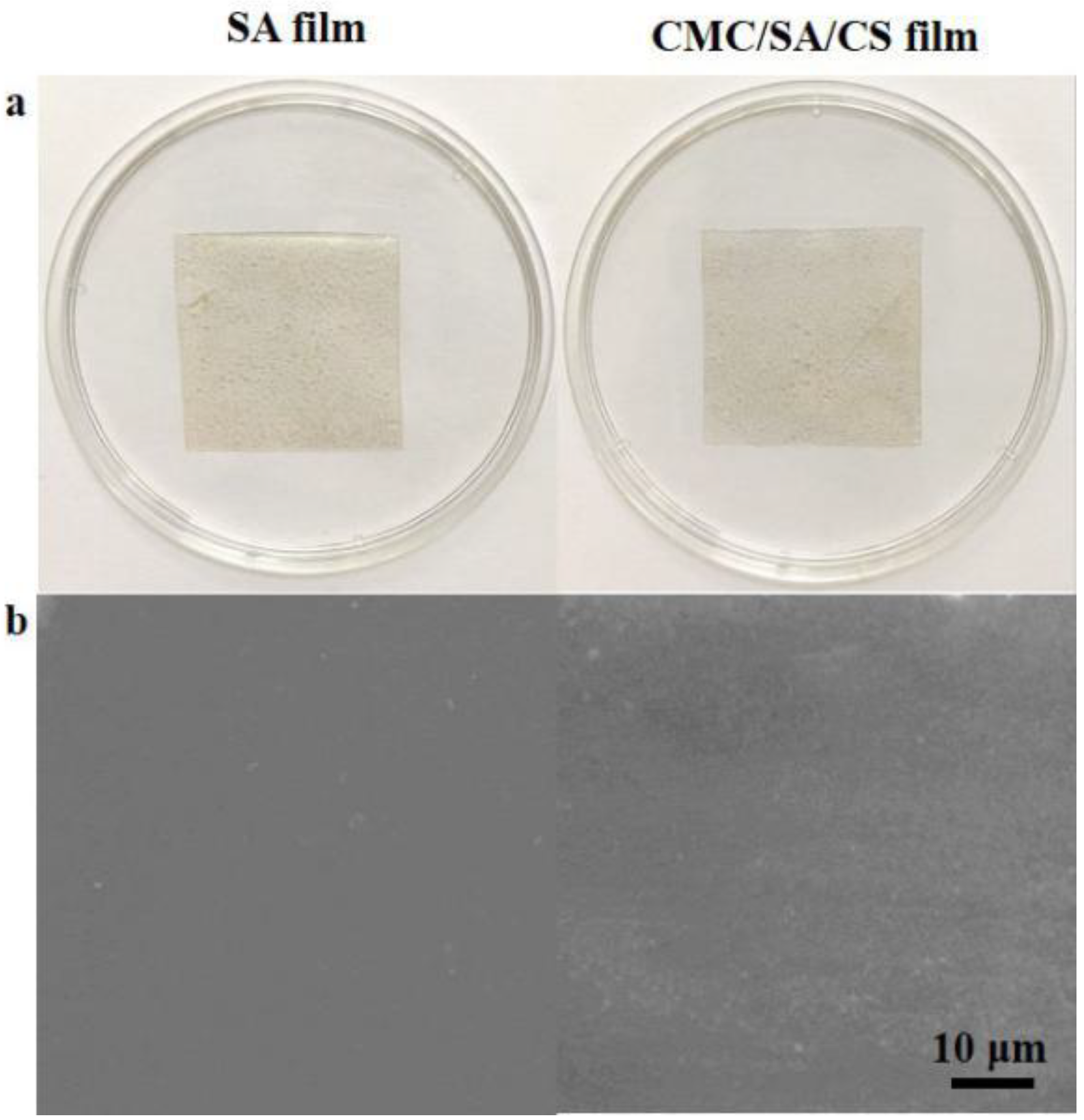

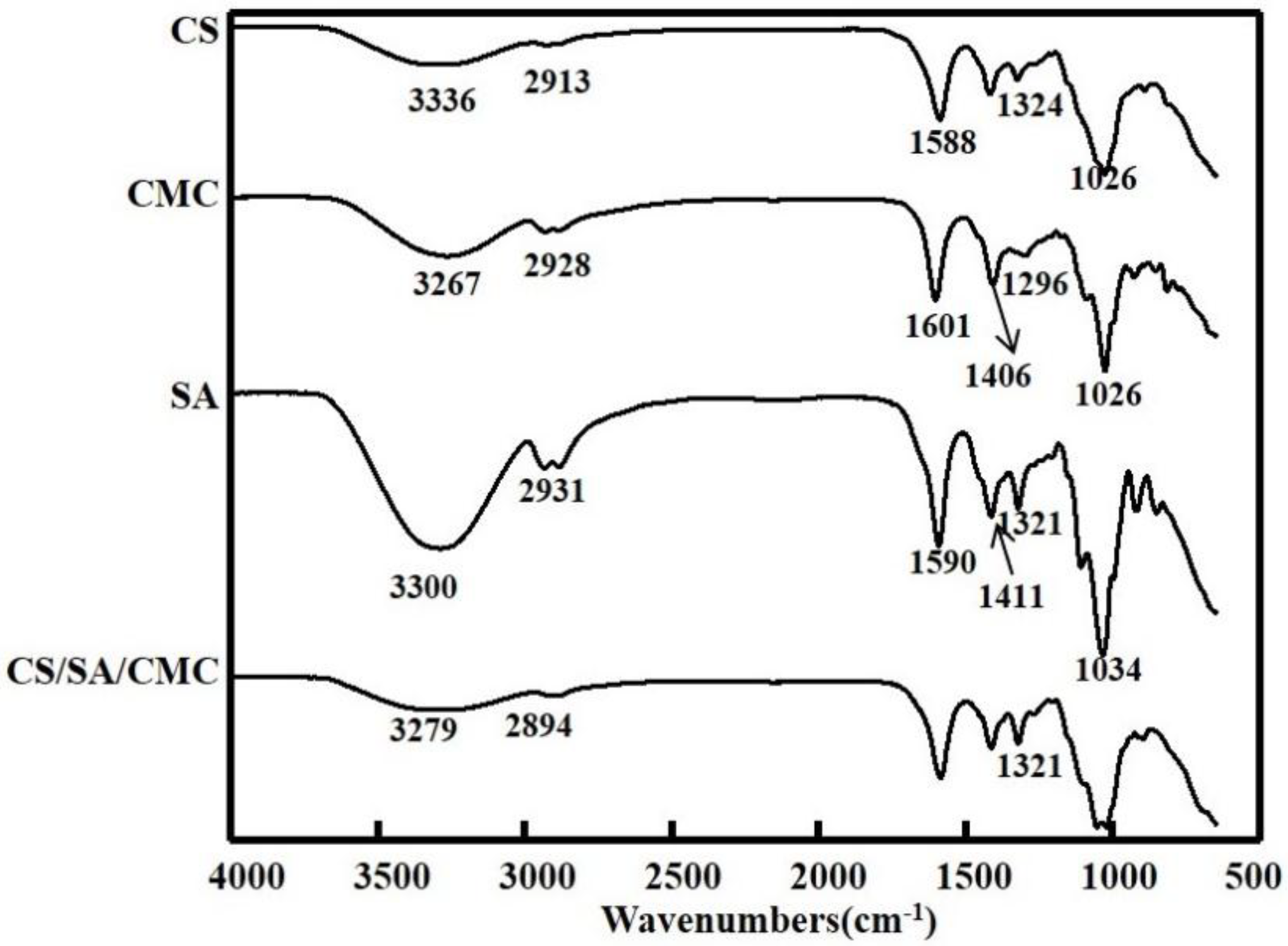

3.4. FTIR Analysis

Figure 2 presents the characteristic FTIR spectra corresponding to CS, SA, CMC, CMC/SA/CS. For the SA film, the bands at approximately 3300 cm

−1 are assigned to the stretching vibrations of the hydroxyl group, respectively [

41]. The band corresponding to asymmetric stretching vibrations of the methylene group occurs at approximately 2931 cm

−1 [

42]. The stretching vibration of the carboxylate anion –COO

− exhibits two characteristic absorption peaks at 1590 and 1411 cm

−1, corresponding to asymmetric and symmetric stretching vibration of the carboxylate group, respectively [

43,

44,

45]. The band at approximately 1034 cm

−1 corresponds to C–O stretching in the acetyl groups present on the SA backbone [

8]. This is similar to the results of Esteghlal et al. [

46]. The characteristic absorption bands of CMC were detected at 1601 cm

−1 and 1406 cm

−1, which were the –COO asymmetric vibration and symmetric vibration absorption peak, respectively [

8]. In the CS spectrum, The strong amino characteristic bands at 1588 cm

−1 and 1324 cm

−1 are assigned to amide I and amide II, respectively [

43,

47].

The spectra of CMC/SA/CS show clear increases in the intensity of the band strength is significantly wider and lower 3279 cm

−1, attributed to the stretching vibration of CMC, SA hydroxyl group and the secondary amide group of CS. This may be due to the formation of hydrogen bonds between CMC, CS, and SA macromolecules. The formation of hydrogen bonds increases the degree of polarization of chemical bonds. Physical cross-linking between the surface –OH of the CMC and the –OH group of the CS molecule also consumes a small amount of –OH groups [

16,

47]. Followed by the C–H stretching vibration peak at 2931 cm

−1, the peak of the composite film almost disappeared, which may be related to the participation of C–H in the Na

+ crosslinking reaction [

47]. Finally, the –COO stretching vibration absorption peak at 1321 cm

−1, the group pattern of the composite film becomes sharp, indicating that the composite film contains SA component, and is related to CS–NH

3+ protonation and hydration [

48,

49]. This is also related to the interaction between CS and CMC molecules [

13]. In summary, the CS/SA/CMC composite film is not a simple physical mixture of ingredients, so it has great research value.

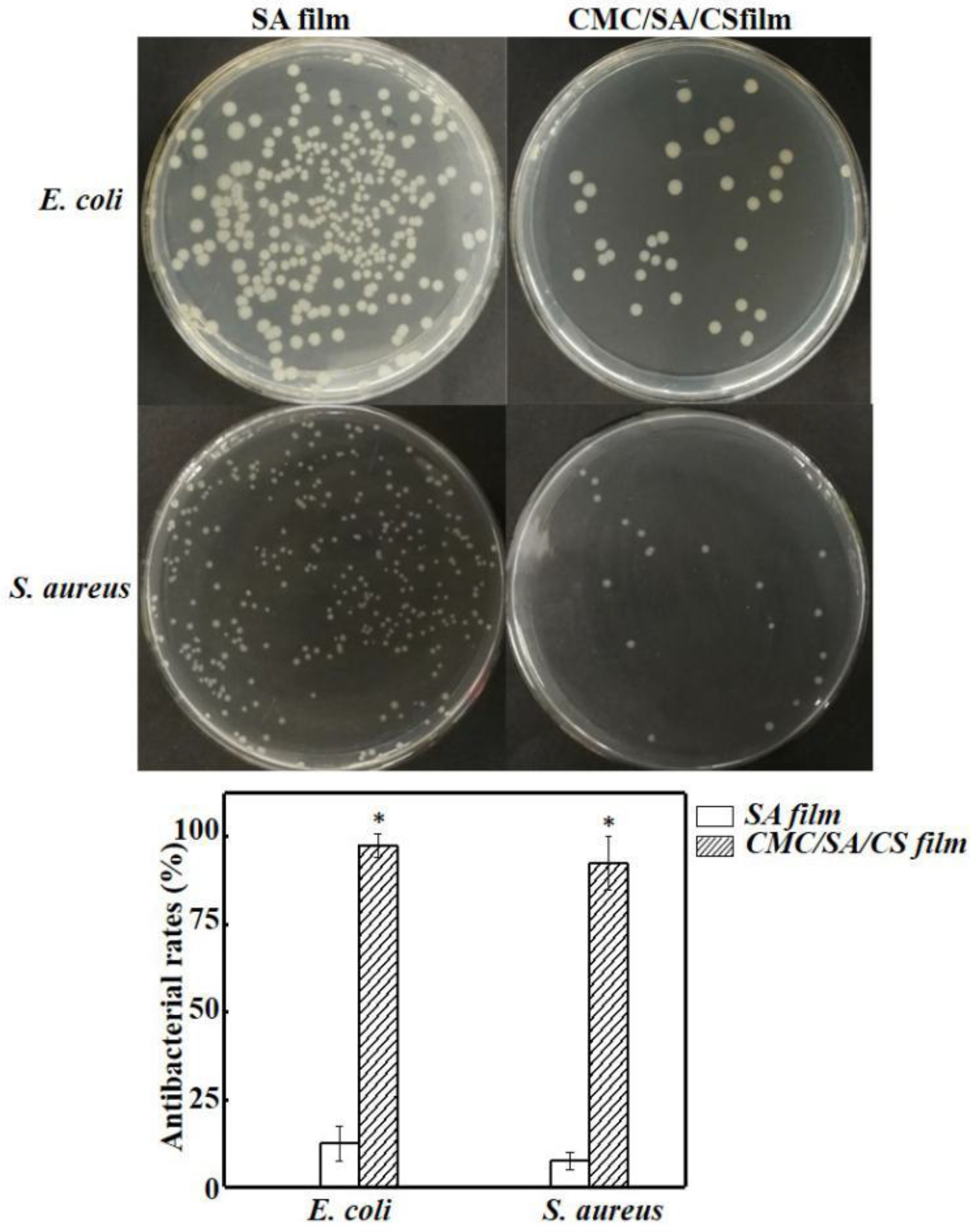

3.5. Analysis of the Antibacterial Activity

In the antibacterial activity test, the SA film was used as the negative control group. The composite films of the experimental groups were prepared using SA, CS, and CMC contents of 1.5%, 1.5%, and 0.5%, respectively, and tested against

E. coli and

S. aureus (

Figure 3). The addition of CMC in the composite film may have an impact on the antibacterial properties, which is similar to that of Hu et al. [

28]. They included CMC in quaternized chitosan (HTCC)-based films to develop antibacterial films for food preservation in order to meet the microbiological safety requirements for food packaging. The incorporation of CMC improved the tensile strength, thermal stability, and water resistance, but increased the oxygen permeability and reduced the antibacterial activity against gram-positive (

S. aureus) and gram-negative (

E. coli) bacteria. Further, the composite film could extend the shelf life of bananas. The antibacterial test results of our study are shown in

Figure 3. The antibacterial rate of the composite film against

E. coli is 95.7% ± 5.4%, while that against

S. aureus is 93.4% ± 4.7%. These results indicate that the CMC/SA/CS composite film has an obvious inhibitory effect on the two bacterial strains.

Figure 3 also reveals that the antibacterial performance of the composite film against

E. coli is better than that against

S. aureus. The same amount of CS exhibited stronger antibacterial performance against

E. coli than against

S. aureus, which is consistent with the conclusions of Ashraf et al. [

50]. Being an organic antibiotic, CS can reduce or prevent bacterial adhesion and biofilm formation. The antibacterial mechanism of CS occurs by the promotion of the separation of microbial cell walls and films and destruction of the cell film by binding with the proteins in it; thus, the film loses its ability to control the incoming and outgoing substances [

51]. Doulabi et al. [

52] also reported the inhibition rate of CMC/SA/CS composite membrane against

S. aureus to be 93.4%. This difference may be related to the concentration of chitosan and the antibacterial properties of CMC to inhibit CS, which further validates the above conclusions.

Liu et al. [

53] tested the antibacterial activity of PVA/CS composite membranes with different CS weight ratios on gram-negative (

E. coli) and gram-positive (

S. aureus) microorganisms. At the mass ratio of the composite membrane of PVA/CS-2.5, the composite membrane showed the best antibacterial effect. The antibacterial rate of PVA/CS membrane against

E. coli and

S. aureus were reported to be 98.8% and 99.16%, respectively. The antibacterial activity of CS against gram-negative bacteria is better than that against gram-positive bacteria, which is contrary to the conclusion of this experiment. This may be attributed to the composition of the composite film and may also vary depending on the preparation method and conditions [

54].

3.6. Film Performance Comparison

As mentioned earlier, SA has good film formation property, but it has strong water solubility, which limits the scope of development. CMC has a good internal network structure, but it cannot form a film by itself, without plasticizers. Chitosan has excellent antibacterial properties, but its membrane mechanical properties are poor. Each of the precursors, SA, CMC, and CS has its own defects, and many researchers have used them in combination to complement each other and expand the role of the field (

Table 7). Such studies are remarkable, but new composite membranes consisting of SA, CMC, and CS are not studied well. Wang et al. [

13] prepared HTCC/CMC composite membrane and found the tensile strength of the HTCC/CMC composite to be significantly higher than that of the pure film. When the mass ratio was 10%, the tensile strength reached a maximum of 28.56 MPa. However, there is a negative relation between the tensile strength and elongation at break; the elongation at break decreases slightly to 2.27%. Those improvements were attributed to the excellent compatibility between HTCC and CMC and strong electrostatic interaction between the molecules. Khazaei et al. [

55] proposed that the elongation at break is closely related to the formation of a stable structure of biological macromolecules through hydrogen bonds or ionic bonds. The tensile strength of the composite film in this study can reach 65.32 ± 14.31 MPa and the elongation at break is 17.85% ± 3.86%, which is far beyond that of the pure HTCC film, pure CMC film, and HTCC/CMC composite film. This is mainly because, with the addition of SA, which has good film formation ability and adhesion, the pores in the composite membrane can be fully filled and the tensile strength and elongation at break of the composite membrane can be improved. Hu et al. also prepared HTCC/CMC composite membranes; with the addition of CMC, the tensile strength of the composite membranes increased from 2.06 to 45.56 MPa and the elongation at break decreased from 246.36% to 8.08% [

56]. Treenate et al. [

57] developed a biomedical hydrogel film using hydroxyethyl acrylate chitosan (HC) and SA. The hydrogel film was reported to have a tensile strength and elongation of 12.1 MPa and 162%, respectively, which fully satisfy the reasonable mechanical properties and sufficient flexibility required during use. Han et al. [

14] also prepared an antibacterial SA/CMC composite membrane. The composite film uses cinnamon essential oil as an antibacterial agent and glycerin as a plasticizer. The tensile strength and elongation at break of the SA/CMC composite film in the control group were reported to be 32.10 MPa and 20.07%, respectively. This may be related to the crystallinity of chitosan and also the amount of CMC added. However, the CMC/SA/CS composite membrane is superior to the CMC/SA membrane in terms of the tensile strength and antibacterial performance, and therefore, it is more promising. Overall, the tensile strength of the CMC/SA/CS composite membrane is better than those of all other previously reported composite membranes.