Optimization Method for Developing Spectral Controlling Cosmetics: Application for Thermal Barrier Cosmetic

Abstract

:1. Introduction

2. Materials and Methods

2.1. Complex Refractive Index

2.2. Radiative Properties of Single Particles

2.3. Radiative Properties of a Particle Cloud

2.3.1. Independent Scattering

2.3.2. Dependent Scattering

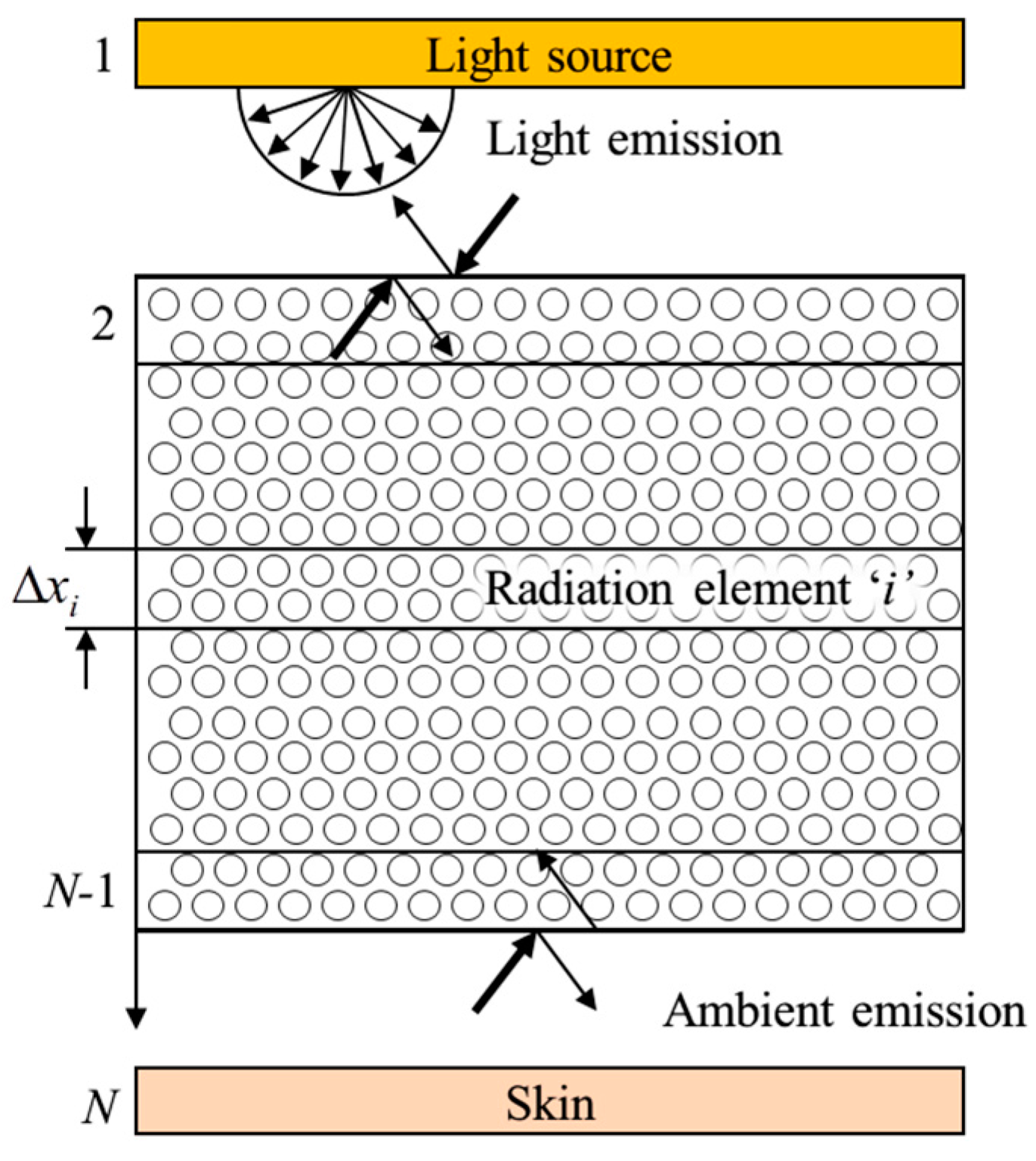

2.4. Radiative Transfer Analysis

2.5. Evaluation Parameter

3. Results and Discussion

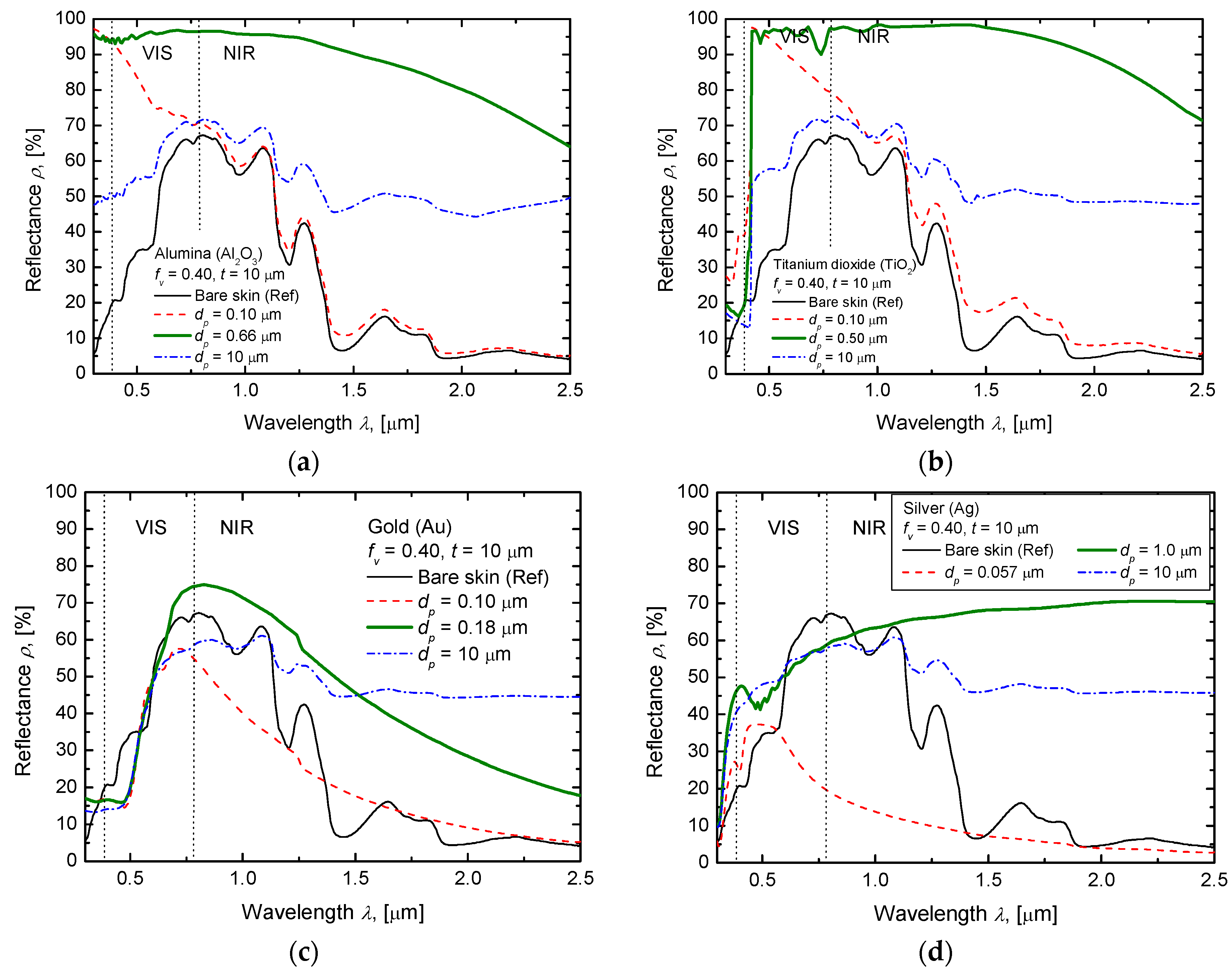

3.1. Spectral Reflectance

3.2. Evaluation Parameter

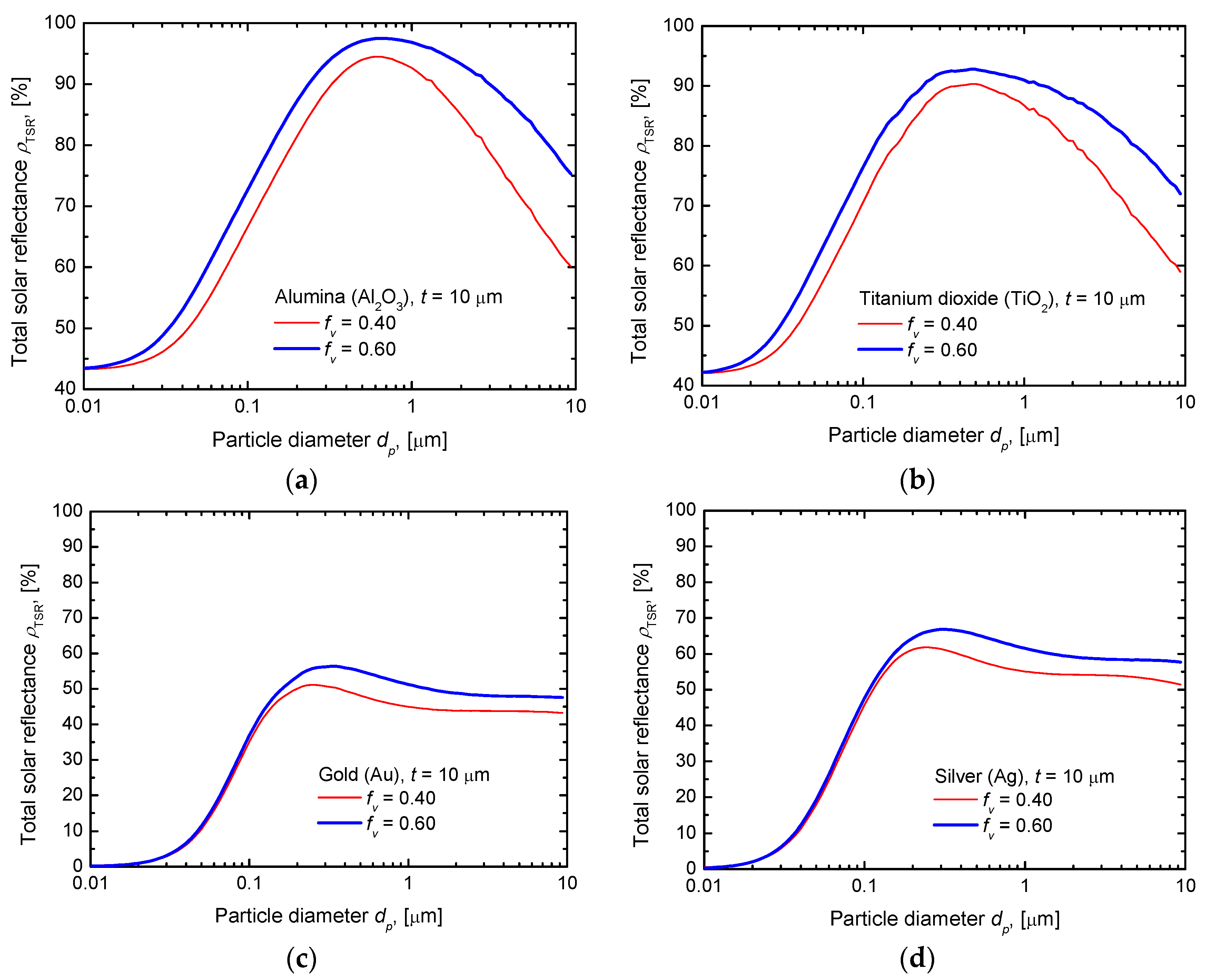

3.2.1. Total Solar Reflectance

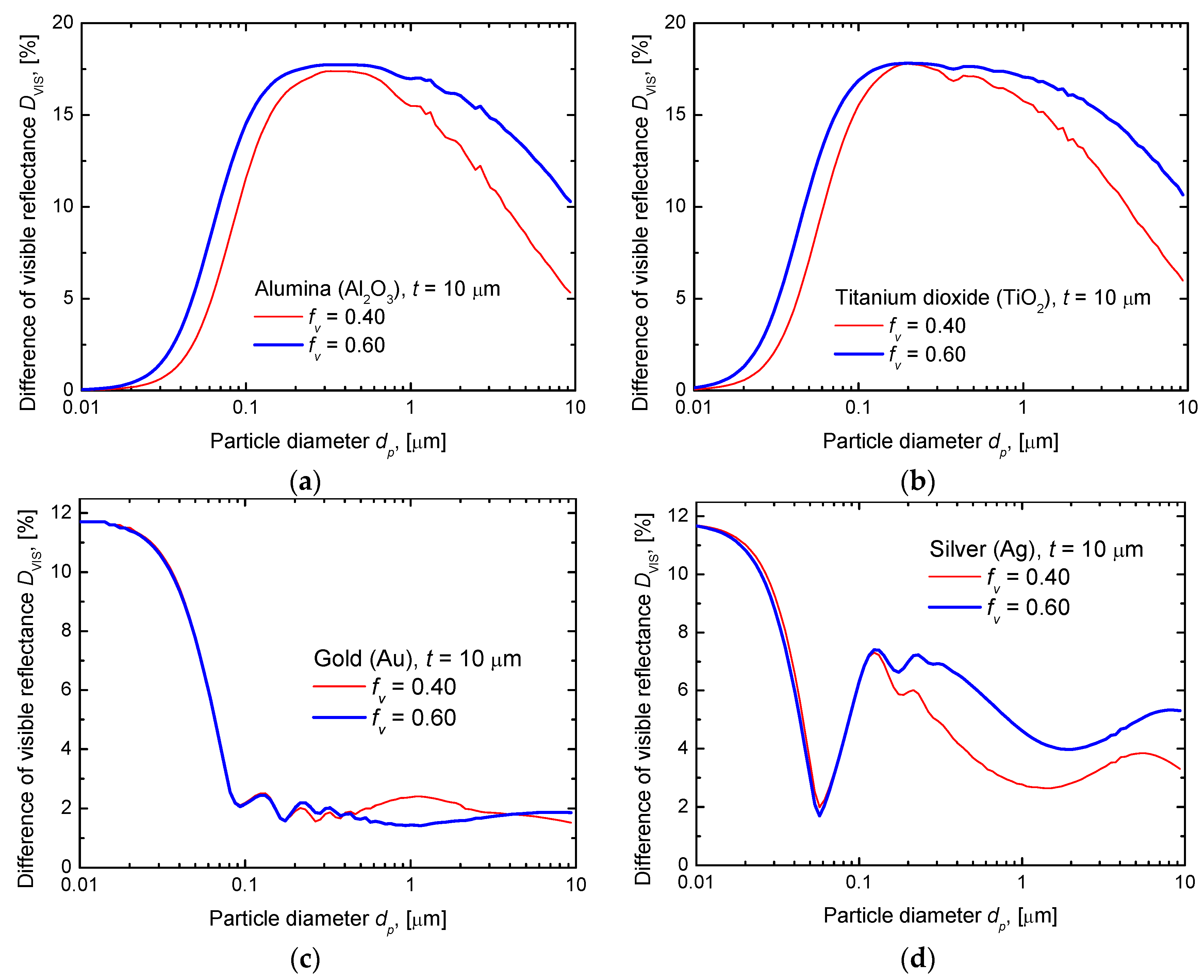

3.2.2. Difference of Visible Reflectance

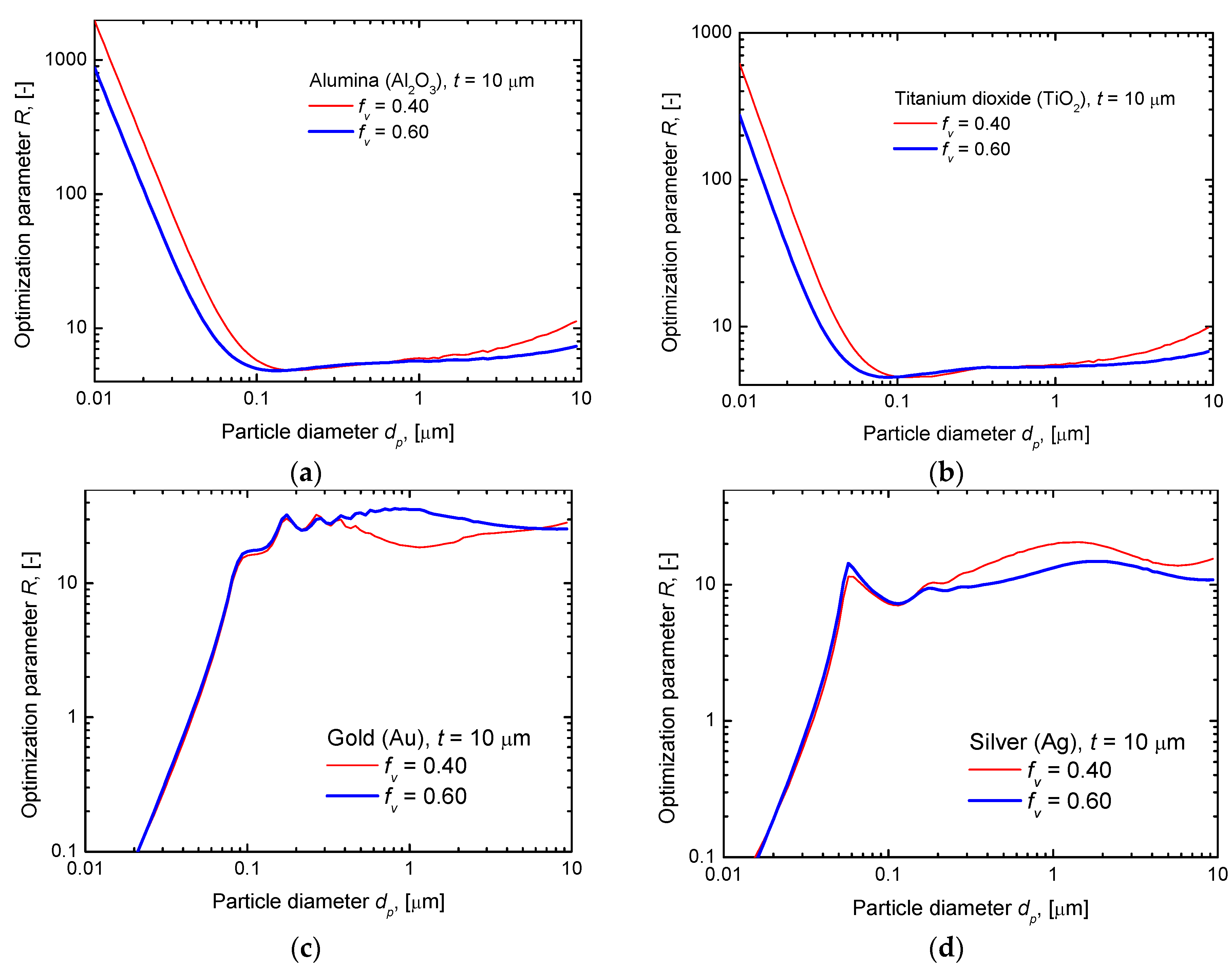

3.2.3. Optimization Parameter

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- ASTM G 173-03 Standard Tables for Reference Solar Spectral Irradiances: Direct Normal and Hemispherical on 37° Tilted Surface; ASTM International: West Conshohocken, PA, USA, 2012.

- Diffey, B.; Robson, J. A new substrate to measure sunscreen protection factors throughout the ultraviolet spectrum. J. Soc. Cosmet. Chem. 1989, 40, 127–133. [Google Scholar]

- Shaath, N.A. On the theory of ultraviolet absorption by sunscreen chemicals. J. Soc. Cosmet. Chem. 1987, 82, 193–198. [Google Scholar]

- Popov, A.P.; Priezzhev, A.V.; Lademann, J.; Myllylä, R. Alteration of skin light-scattering and absorption properties by application of sunscreen nanoparticles: A Monte Carlo study. J. Quant. Spectrosc. Radiat. Transf. 2011, 112, 1891–1897. [Google Scholar] [CrossRef]

- Luke, S.M.; Vukusic, P. An introduction to biomimetic photonic design. Europhys. News 2011, 42, 20–23. [Google Scholar] [CrossRef] [Green Version]

- Yamada, J.; Kawamura, A.; Miura, Y.; Takata, S.; Ogawa, K. Study on radiation transfer in human skin for cosmetics. J. Quant. Spectrosc. Radiat. Transf. 2005, 93, 219–230. [Google Scholar] [CrossRef]

- Nakamura, K.; Ogawa, T.; Takata, S.; Yamada, J. Numerical model for optical characteristics of the human skin surface. Therm. Sci. Eng. 2015, 23, 61–69. (In Japanese) [Google Scholar]

- Gonome, H.; Baneshi, M.; Okajima, J.; Komiya, A.; Maruyama, S. Controlling the radiative properties of cool black-color coatings pigmented with CuO submicron particles. J. Quant. Spectrosc. Radiat. Transf. 2014, 132, 90–98. [Google Scholar] [CrossRef]

- Gonome, H.; Baneshi, M.; Okajima, J.; Komiya, A.; Yamada, N.; Maruyama, S. Control of thermal barrier performance by optimized nanoparticle size and experimental evaluation using a solar simulator. J. Quant. Spectrosc. Radiat. Transf. 2014, 149, 81–89. [Google Scholar] [CrossRef]

- Álvarez-Docio, C.M.; Reinosa, J.J.; del Campo, A.; Fernández, J.F. 2D particles forming a nanostructured shell: A step forward cool NIR reflectivity for CoAl2O4 pigments. Dyes Pigments 2017, 137, 1–11. [Google Scholar] [CrossRef]

- Mie, G. Beiträge zur Optik trüber Medien, speziell kolloidaler Metallösungen. Annalen der Physik 1908, 330, 377–445. [Google Scholar] [CrossRef] [Green Version]

- Palik, E.D. Handbook of Optical Constants of Solids, 1st ed.; Academic Press: Cambridge, MA, USA, 1998. [Google Scholar]

- Modest, M.F. Radiative Heat Transfer, 2nd ed.; Academic Press: Cambridge, MA, USA, 2003. [Google Scholar]

- Drolen, B.L.; Tien, C.L. Independent and dependent scattering in packed-sphere systems. J. Thermophys. Heat Transf. 1987, 1, 63–68. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Kruth, J.P. Modelling of radiation transfer in metallic powders at laser treatment. Inter. J. Heat Mass Transf. 2005, 48, 3423–3434. [Google Scholar] [CrossRef]

- Singh, B.P.; Kaviany, M. Modelling radiative heat transfer in packed beds. Int.J. Heat Mass Transf. 1992, 35, 1397–1405. [Google Scholar] [CrossRef]

- Maruyama, S.; Aihara, T. Radiation heat transfer of arbitrary three-dimensional absorbing, emitting and scattering media and specular and diffuse surfaces. J. Heat Transf. 1997, 119, 129–136. [Google Scholar] [CrossRef]

- Reinosa, J.J.; Docio, C.M.Á.; Ramírez, V.Z.; Lozano, J.F.F. Hierarchical nano ZnO-micro TiO2 composites: High UV protection yield lowering photodegradation in sunscreens. Ceram. Int. 2018, 44, 2827–2834. [Google Scholar] [CrossRef]

- Baneshi, M.; Gonome, H.; Komiya, A.; Maruyama, S. The effect of particles size distribution on aesthetic and thermal performances of polydisperse TiO2 pigmented coatings: Comparison between numerical and experimental results. J. Quant. Spectrosc. Radiat. Transf. 2012, 113, 594–606. [Google Scholar] [CrossRef]

- Bird, R.E.; Riordan, C. Simple solar spectral model for direct and diffuse irradiance on horizontal and tilted planes at the earth’s surface for cloudless atmospheres. J. Clim. Appl. Meteorolo. 1986, 25, 87–97. [Google Scholar] [CrossRef]

- Cooksey, C.C.; Allen, W.D. Reflectance measurements of human skin from the ultraviolet to the shortwave infrared (250 nm to 2500 nm). In Proceedings of the SPIE Defense, Security, and Sensing, Baltimore, MD, USA, 29 April–3 May 2013; p. 87340N. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonome, H.; Yamada, J. Optimization Method for Developing Spectral Controlling Cosmetics: Application for Thermal Barrier Cosmetic. Coatings 2018, 8, 286. https://doi.org/10.3390/coatings8080286

Gonome H, Yamada J. Optimization Method for Developing Spectral Controlling Cosmetics: Application for Thermal Barrier Cosmetic. Coatings. 2018; 8(8):286. https://doi.org/10.3390/coatings8080286

Chicago/Turabian StyleGonome, Hiroki, and Jun Yamada. 2018. "Optimization Method for Developing Spectral Controlling Cosmetics: Application for Thermal Barrier Cosmetic" Coatings 8, no. 8: 286. https://doi.org/10.3390/coatings8080286