Study on the Preparation of a High-Efficiency Carbon Fiber Dissipating Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Coatings

2.3. Performance Testing

2.3.1. Measurement of Thermal Conductivity of the Coating

2.3.2. Measurement of Heat Dissipation of the Coating

2.3.3. Coating Surface Structure Observation

2.3.4. Measurement of Mechanical Properties of Coating

- Hardness: First, the 5 um thickness sample coating was fixed on the horizontal test platform. Then, in conditions in which the lead core was not broken, in degrees, a series of pencils, with hardness of 5 B to 5 H, were pushed 1 cm along the coating at about 45°. Each hard lead core was pushed 5 times. If two or more of the 5 lines were scratched, the pencil mark of the previous hardness was designated as the hardness of the coating.

- Impact resistance: The coated steel plates were placed on the impactor. Then, a heavy cone (1 kg weight) was dropped from a certain height to the center of the coating on the model, and each high impact was tested 3–5 times. If there was not an obvious crack or spalling under the 4 times magnification, the height was further increased until a crack or spalling occurred, and the final height was designated as the impact strength of the coating.

- Temperature resistance: The thermal stability of the coating was analyzed by placing a sample of 10 mg in the sample chamber of the STA449C thermo-gravimetric analysis (TGA), Taiwan National Taiwan University Co., Ltd., Dong Guan, China. The conditions of the test were such that under a nitrogen atmosphere, the heating rate was 10 °C/min, the air velocity 20 mL/min, and the scanning temperature was increased from 100 °C to 700 °C. In the resulting TG curve, the highest temperature resistance of the coating was the temperature at which the weight began to decrease.

- Adhesion: First, the coating was spread on the aluminum plate. Then, A F107 paint film scriber was used to draw a cross grid shape in the model, with an incision until the base material. A hairbrush was used to brush 5 times along the diagonal direction of the lattice cross, after which adhesive tape was used close to the incision and pulled off quickly. The above test was repeated several times, and the level of adhesion of the coating was determined in accordance with the ISO adhesion grade standard under microscope observation.

3. Results and Discussion

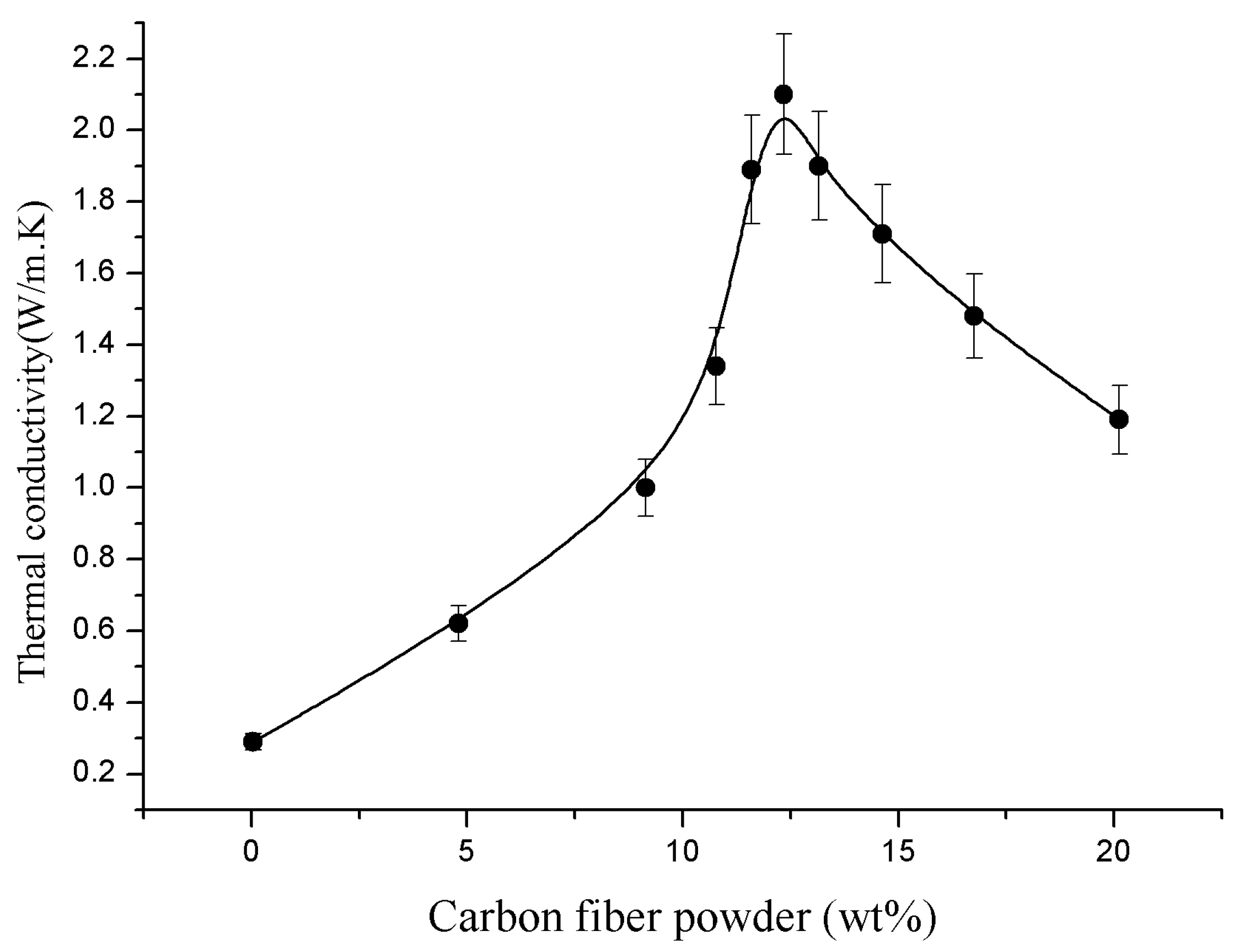

3.1. Effect of CF Mass Fraction on the Thermal Conductivity of Coatings

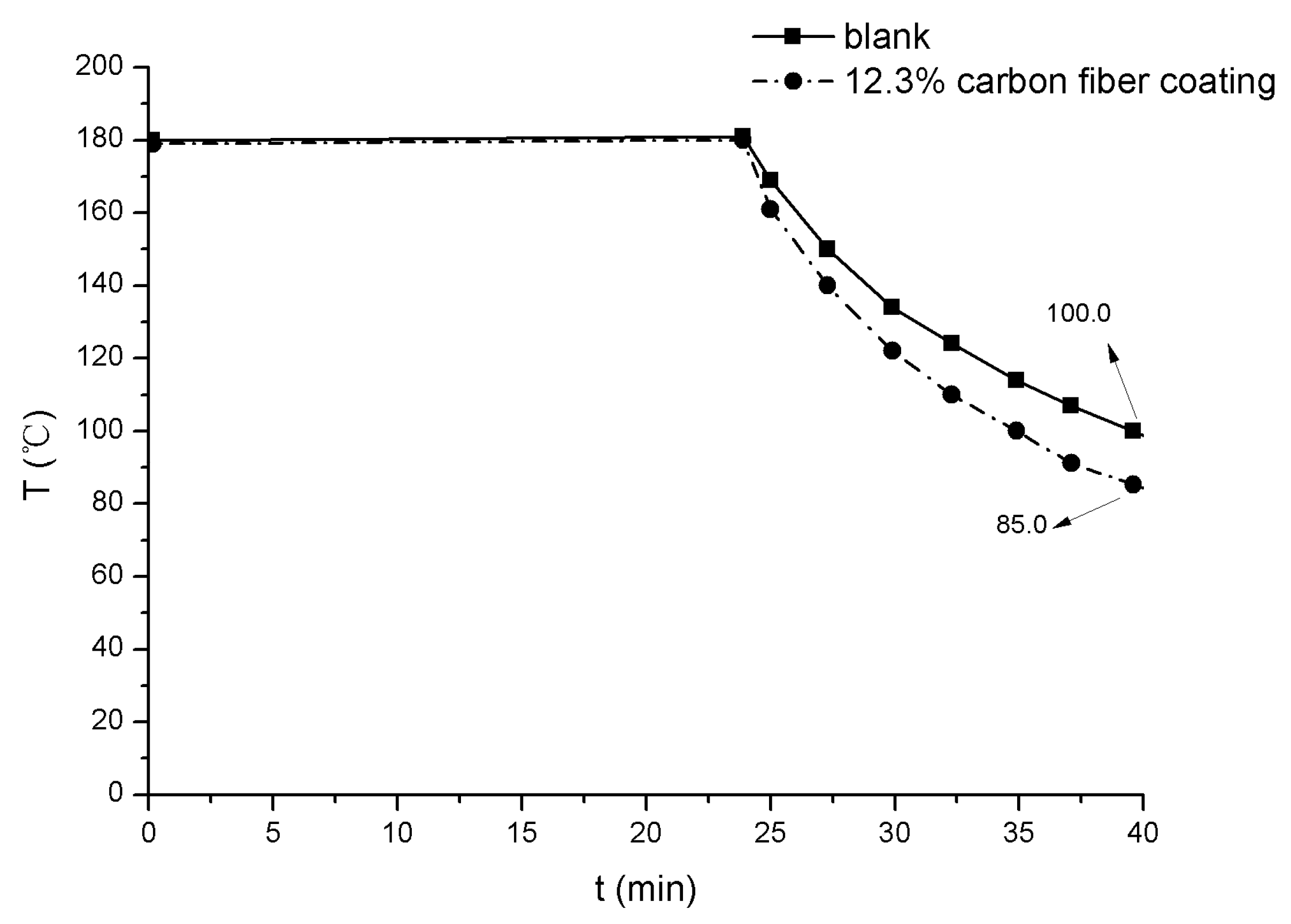

3.2. Effect of CF Mass Fraction on the Cooling Range of the Coating

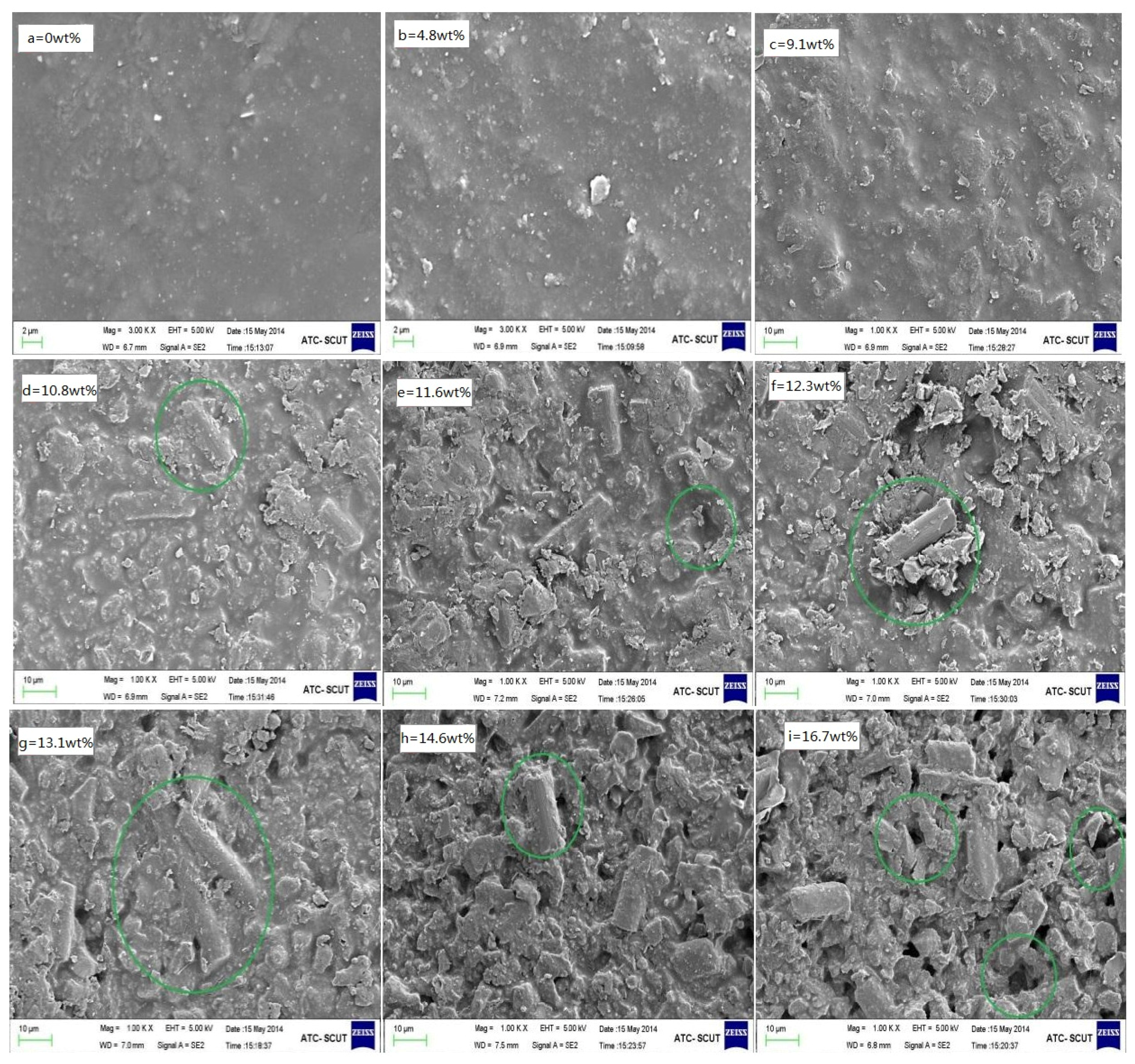

3.3. Analysis of Coating Morphology and Mechanism Analysis

4. Application Performance Testing

4.1. Coating Performance Index

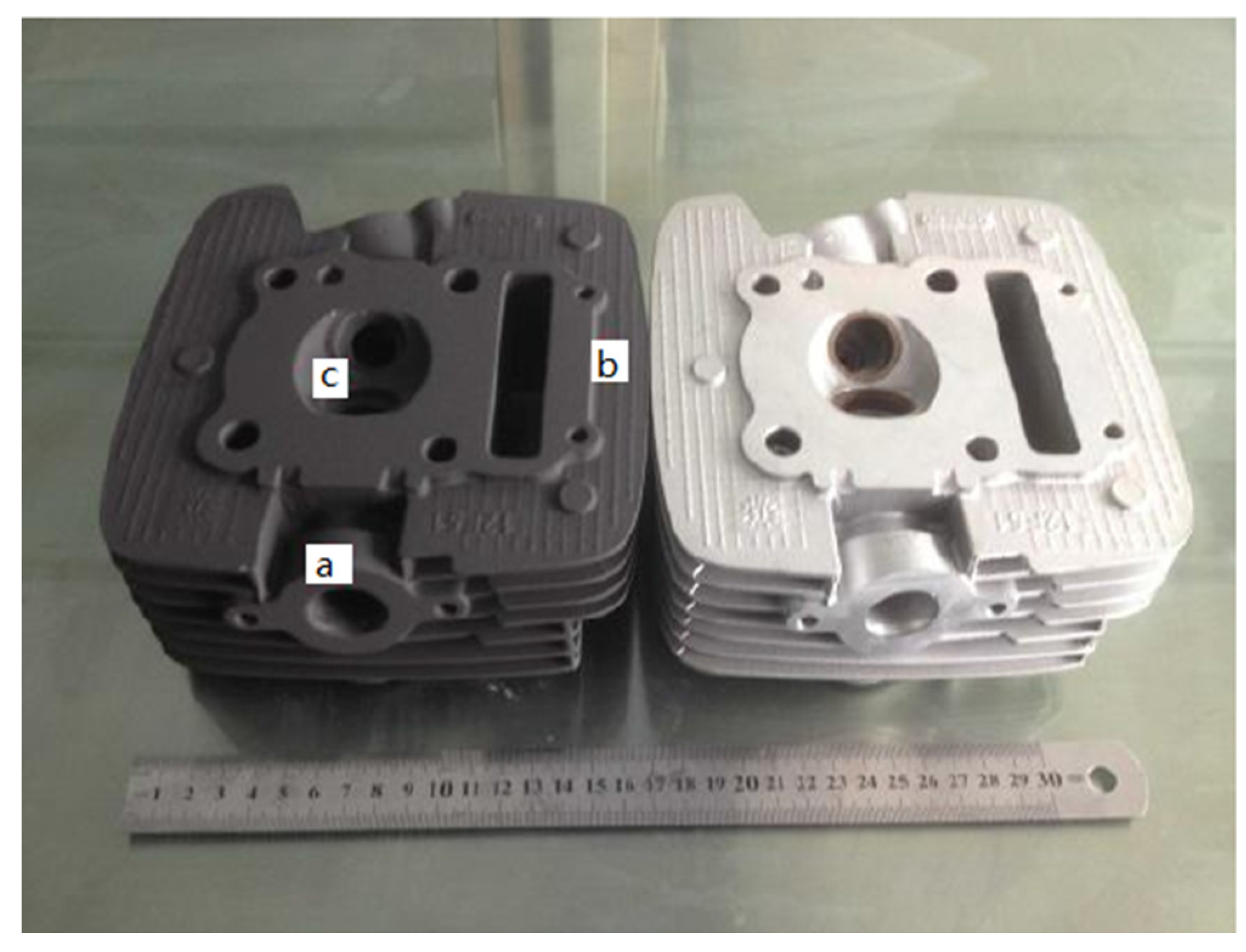

4.2. Application

5. Conclusions

- Single factor experiments indicate: With the increase of CF content, the thermal conductivity and cooling temperature range of the coating tend to increase rapidly and then decrease slowly. When the mass fraction of CF is 12.3 wt %, the coating has the best cooling effect.

- The SEM results of the coating show: With the increase of CF content, a “channel” is formed inside the coating. Due to the continuous overlap between the fillers, the “channel” forms a type of rapid thermal conduction. When the CF content is excessive, the simple random accumulation reduces the orientation of the fibers, and leads to the “channel” being weakened.

- When the CF mass fraction is 12.3 wt %, the thermal conductivity is the highest, and the coating has good weather resistance, high temperature resistance, and good insulation which meet the performance requirements of the coating application.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nie, Y.; Jin, L.; Hang, J.; Zhang, J.; Shi, L. Study on preparation and performance of waterborne nano composite cooling coating. Funct. Mater. 2013, 5, 736–739. [Google Scholar]

- Guo, Y. Research on thermal design of electronic components in printed circuit board. Good Parent Vocat. Educ. Res. 2016, 16, 212. [Google Scholar]

- Tian, F.; Zhang, Y.; Di, L.; Zhang, F. Application research on high density electronic equipment cooling technology. Electron. Package 2014, 14, 1–5. [Google Scholar]

- Li, M. Preparation and Properties of Filled Polyamide 6 Thermal Conductive Composites; Tianjin University: Tianjin, China, 2012. [Google Scholar]

- Srikar, R.; Gambaryan-Roisman, T.; Steffes, C.; Stephan, P.; Tropea, C.; Yarin, A.L. Nanofiber coating of surfaces for intensification of drop or spray impact cooling. Int. J. Heat Mass Transf. 2009, 52, 5814–5826. [Google Scholar] [CrossRef]

- Yang, Q.; Huang, T.; Yang, L. Study on thermal conductive polyester coatings for display devices. Coat. Ind. 2013, 43, 8–11. [Google Scholar]

- Lei, D.; Ma, W.; Zheng, Z.; Wang, S.; Liu, Y. Surface modification of Al2O3 and its application in thermal conductive coating based on epoxy resin. Funct. Mater. 2016, 47, 07225–07228. [Google Scholar]

- Zhang, X.; Li, Z.; Yan, H.; Yang, B.; Fan, H. Study on thermal conductive insulating coatings for printed circuit boards. Insul. Mater. 2015, 48, 24–27. [Google Scholar]

- Li, S.; Peng, C.; Xing, S.; Xiao, J. Research progress on thermal conductivity of carbon fiber reinforced polymer matrix composites. Mater. Rev. A 2012, 26, 79–92. [Google Scholar]

- Yan, D.; Gao, X.; Liu, G.; Chang, Y.; Qiao, G.; Mou, X.; Zhao, B. Research progress of alumina nitride ceramics with high thermal conductivity. Bull. Chin. Ceram. Soc. 2011, 3, 602–606. [Google Scholar]

- Yang, S.; Yang, H.; Chen, F.; Chen, H.; Qu, J. Study on thermal conducting mechanism of PP/AlN composite. Plast. Sci. Technol. 2013, 43, 60–63. [Google Scholar]

- Liang, Y.; Ding, H.; Zhou, H.; Hou, X. Research progress of surface modification of sericite. China Non-Met. Min. Ind. Her. 2013, 1, 5–8. [Google Scholar]

- Ran, S.; Shen, S.; Song, X. Study on ultra-fine grinding and surface modification of sericite and its application. Ind. Miner. Process. 2003, 32, 14–16. [Google Scholar]

- Huo, C.; Liu, X.; Xue, D.; Xu, T. Preparation of novel waterborne acrylic polyurethane coatings. Chin. Coat. 2016, 31, 38–41. [Google Scholar]

- Guo, R. Preparation of Conductive Epoxy Resin Composites; South China University of Technology: Guangzhou, China, 2013. [Google Scholar]

- Sun, X. Study on Preparation and Properties of Graphite/Resin Composites; Hunan University: Changsha, China, 2012. [Google Scholar]

- Yu, W. Study on Preparation and Properties of High Thermal Conductivity Polymer Matrix Composites; Shanghai Jiao Tong University: Shanghai, China, 2012. [Google Scholar]

- Agari, Y.; Ueda, A.; Nagai, S. Thermal conductivities of composites in several types of dispersion systems. J. Appl. Polym. Sci. 1991, 42, 1665–1669. [Google Scholar] [CrossRef]

| Parameter | CF |

|---|---|

| Tensile strength (MPa) | >3500 |

| Density (g/cm3) | 1.75 |

| Filament diameter (μm) | 7 |

| Carbon content (wt %) | >95 |

| Fineness (mesh) | 300 |

| Aspect ratio | 3:1–4:1 |

| Thermal conductivity of fiber direction (W/m·K) | 120 |

| Material | Specifications | Manufacturer | Mass (g) |

|---|---|---|---|

| Silicone-acrylic resin | Solid containing 50 wt %, silicon containing 40 wt % | Sihui Xinda Chemical Industry Co. Ltd., Guangzhou, China | 36 |

| AlN | Modified AlN powder | Qingzhou Zhengda Chemical Co. Ltd., Qingzhou, Shandong, China | 8 |

| Sericite powder | – | Chuzhou Gerui Mining Co. Ltd., Chuzhou, Anhui, China | 13 |

| Silicon dioxide | 200 meshes | Shijiazhuang Gold and Nano Chemical Co. Ltd., Guangzhou, China | 1.5 |

| Amino resin | Solid containing 60% | Nanjing Witten Chemical Technology Co. Ltd., Nanjing, China | 11 |

| Cosolvent (butyl acetate, two acetone alcohol, xylene) | Analysis of pure | Zhongshan Yongsheng Chemical Co. Ltd., Guangzhou, China | 20–35 |

| Additives (BYK-ATU, BYK-355) | – | BYK(Shanghai) Co. Ltd., Shanghai, China | 0.5–2 |

| CF (300 mesh) | Average length: 45 μm | Zibo Xinnuo lubricants Co. Ltd., Zibo, Shandong, China | Variable (gradient) |

| Test | Result |

|---|---|

| Hardness Impact resistance (cm) | H 50 |

| Adhesion | Level 1 |

| Temperature resistance | paint not taken off at 200 °C × 200 h |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Li, X.; Fan, C.; Yao, H.; Chen, X.; Liu, Y. Study on the Preparation of a High-Efficiency Carbon Fiber Dissipating Coating. Coatings 2017, 7, 94. https://doi.org/10.3390/coatings7070094

Li J, Li X, Fan C, Yao H, Chen X, Liu Y. Study on the Preparation of a High-Efficiency Carbon Fiber Dissipating Coating. Coatings. 2017; 7(7):94. https://doi.org/10.3390/coatings7070094

Chicago/Turabian StyleLi, Jing, Xue Li, Chunlei Fan, Huan Yao, Xuyang Chen, and Yeming Liu. 2017. "Study on the Preparation of a High-Efficiency Carbon Fiber Dissipating Coating" Coatings 7, no. 7: 94. https://doi.org/10.3390/coatings7070094