Fatigue and Healing Properties of Low Environmental Impact Rubberized Bitumen for Asphalt Pavement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Design

3. Results and Discussion

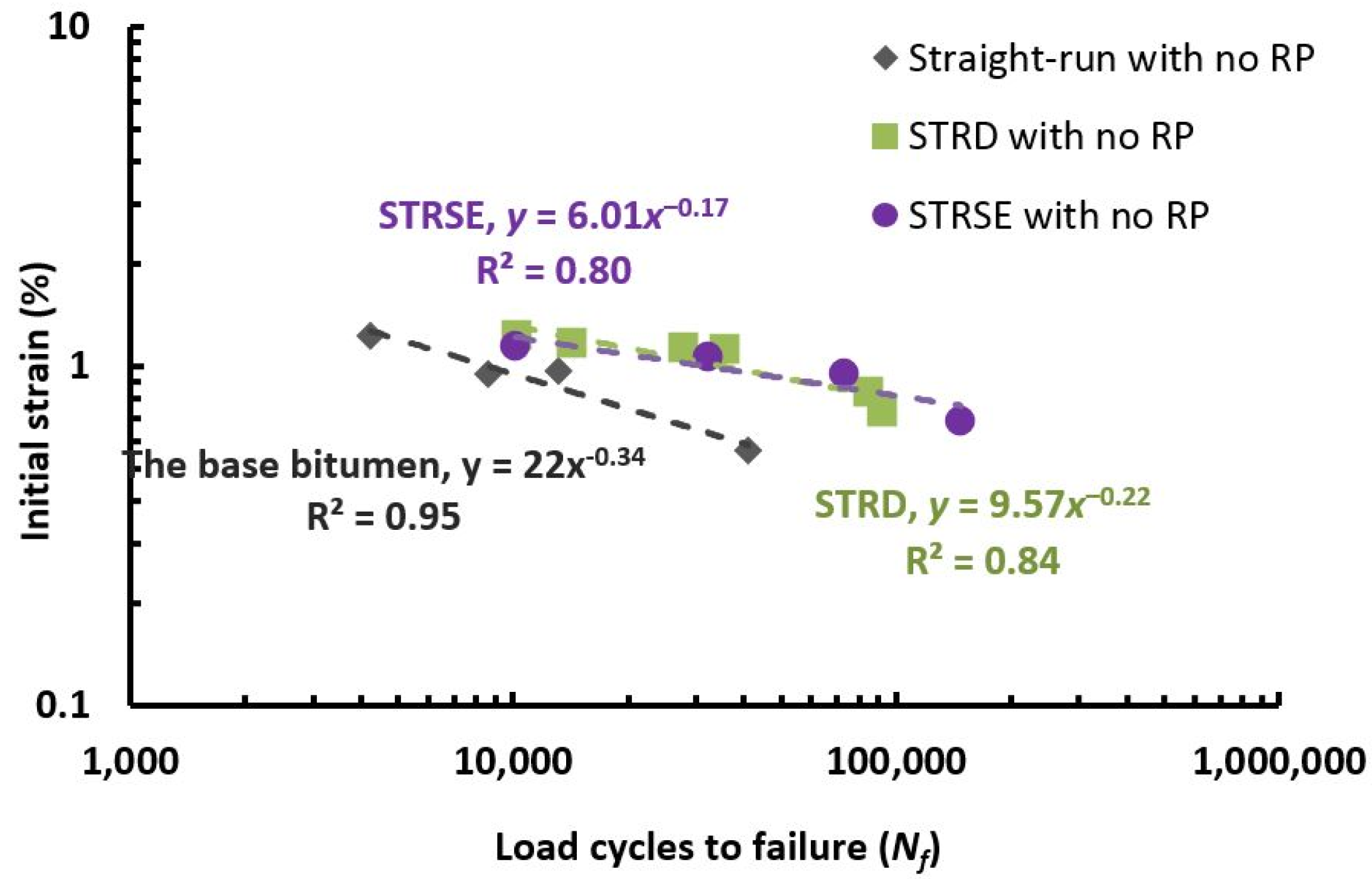

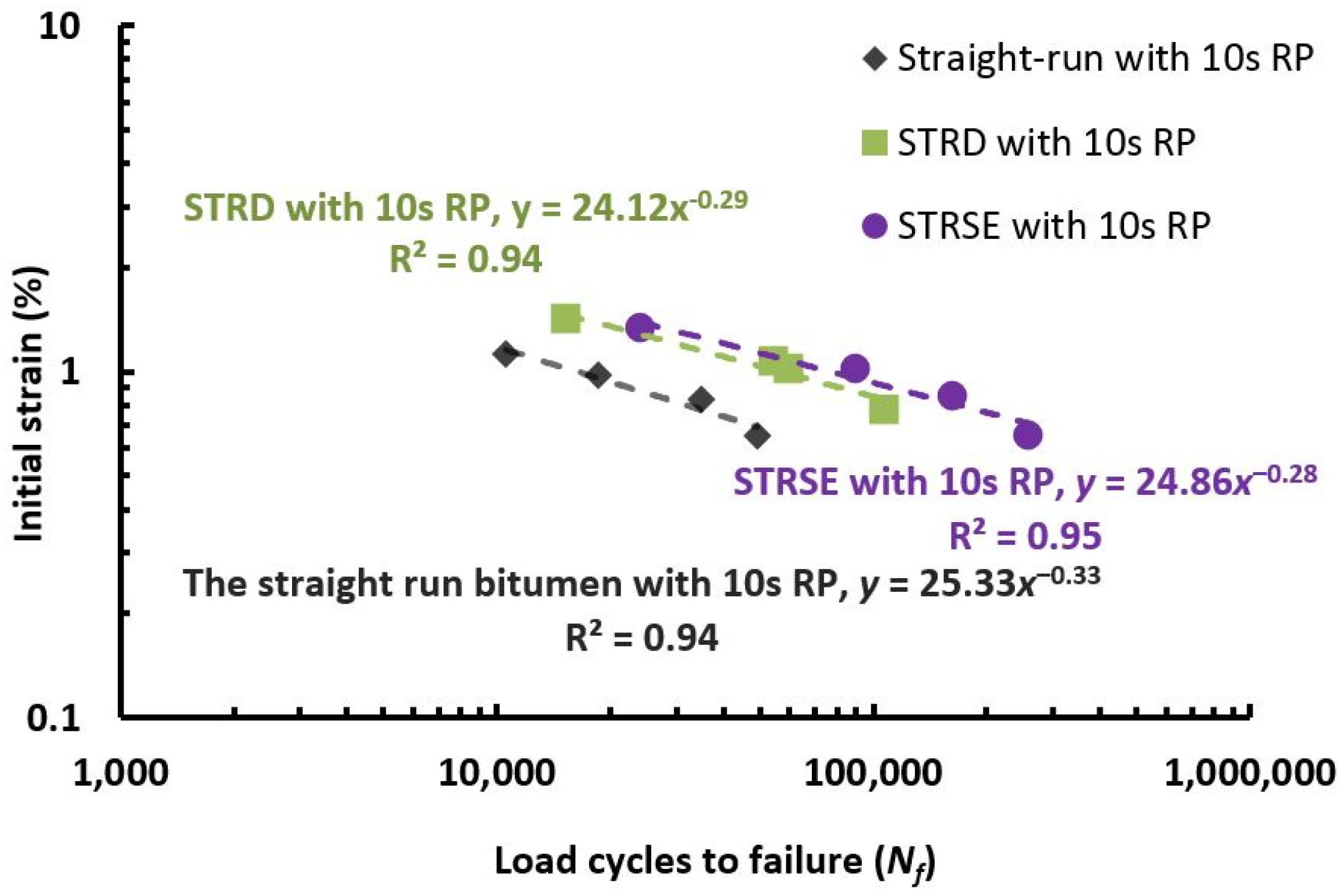

3.1. Traditional Fatigue Analysis

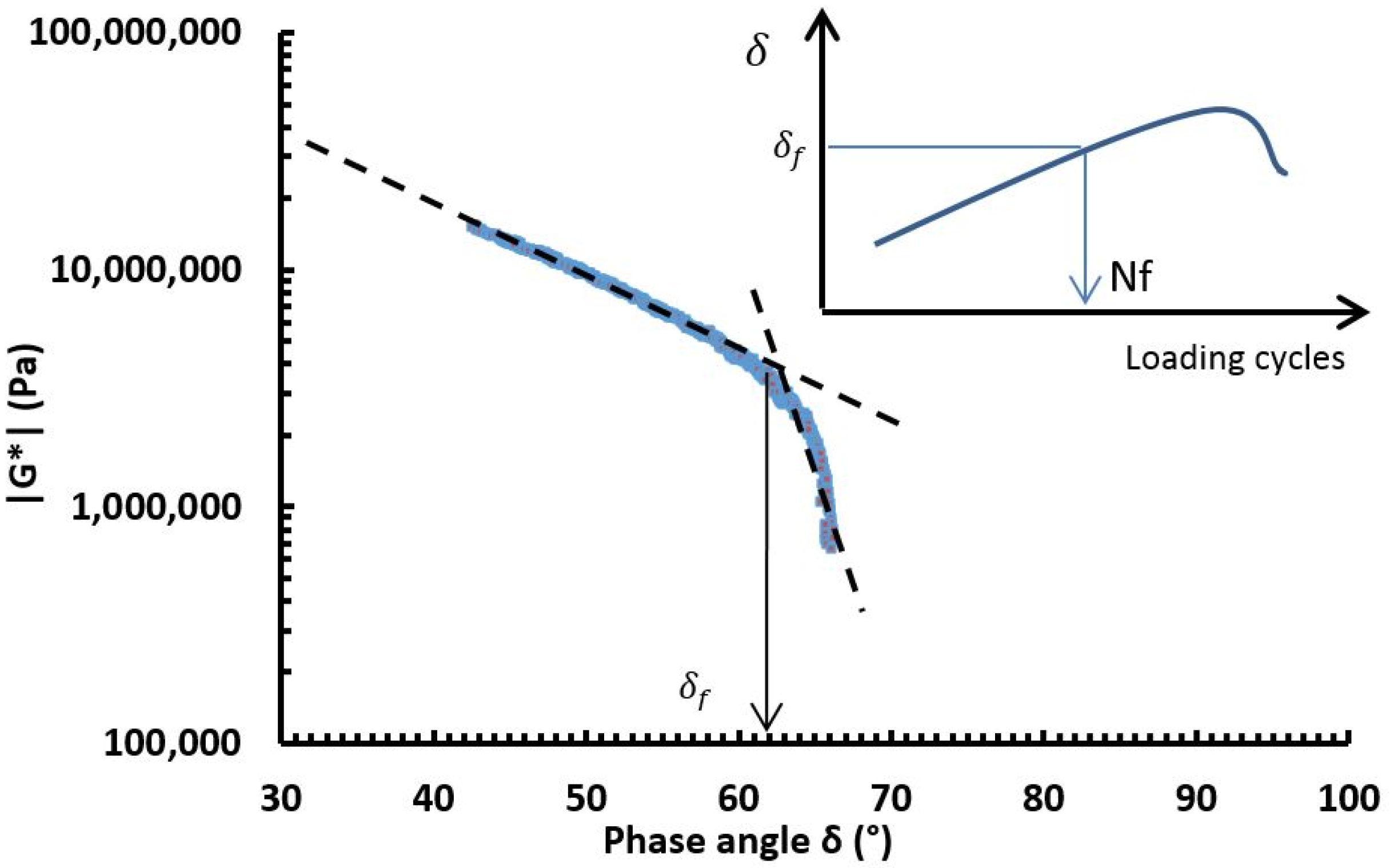

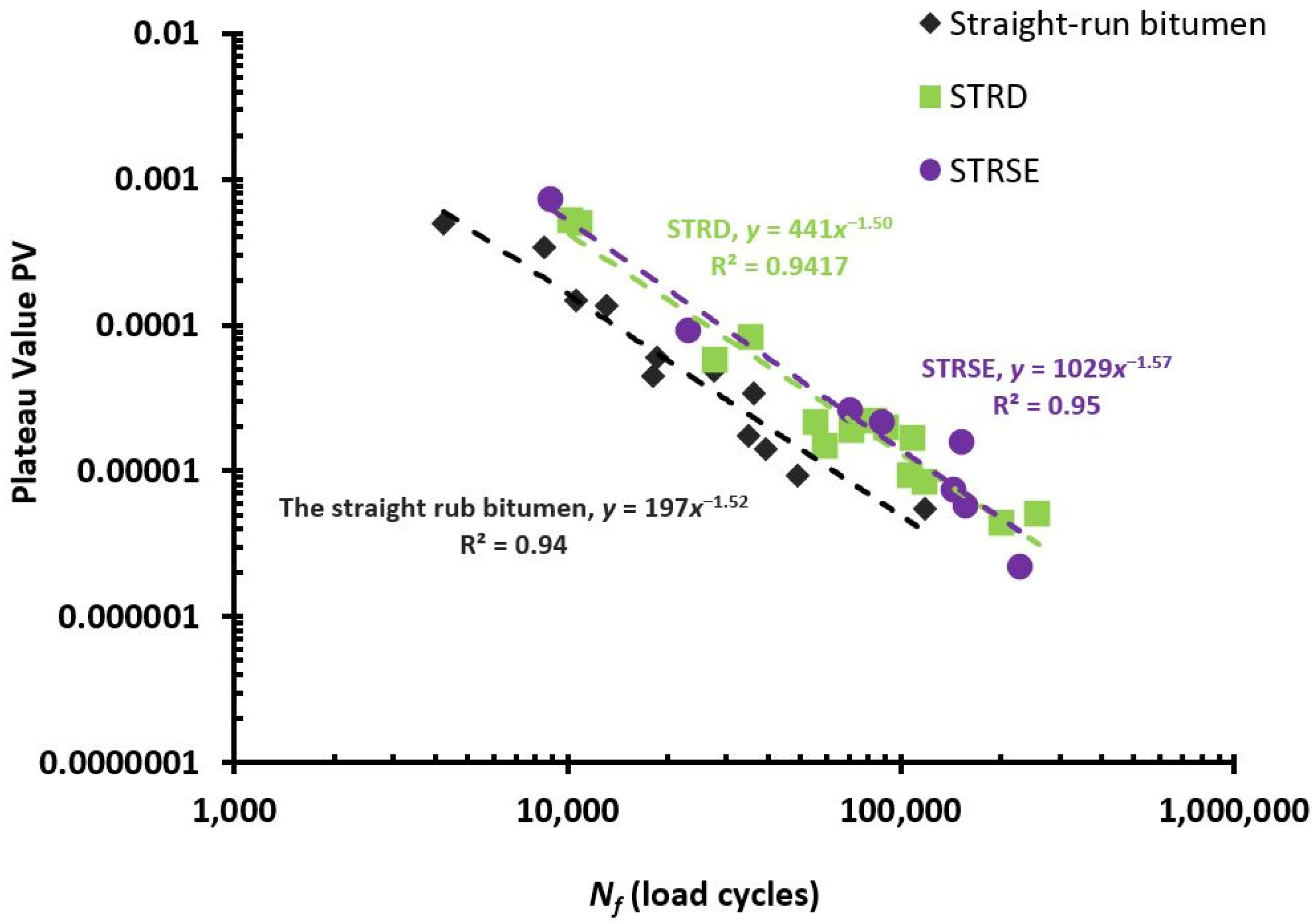

3.2. The Dissipated Energy Approach

3.3. Quantifying Healing Properties

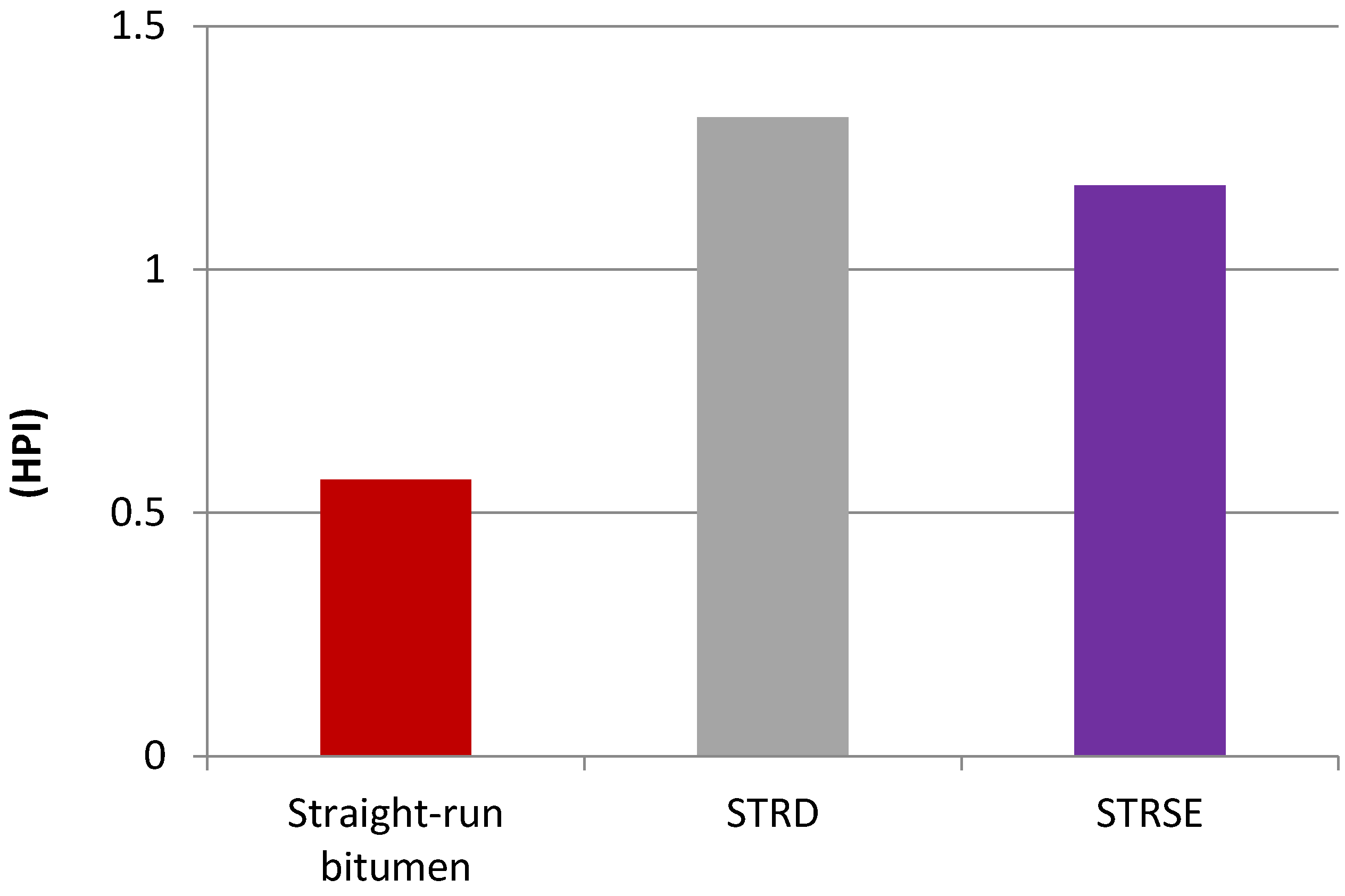

4. Conclusions

- Using pre-treated RTRs can significantly reduce the High Temperature Viscosity of the binders and this could help lowering manufacturing and compaction temperatures.

- The RTR-MBs manufactured by pre-treated recycled rubbers showed superior fatigue and healing properties over the straight-run bitumen based on both energy and classical fatigue approaches.

- The healing capability of binders was successfully quantified by the proposed HPI. The index is based on quantifying the relative change in PV multiply by the relative increase in fatigue life when a 10 s rest period is introduced.

- The inclusion of rest periods has a significant effect on extending the fatigue life of binders.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Subhy, A.; Lo Presti, D.; Airey, G. Rubberised bitumen manufacturing assisted by rheological measurements. Road Mater. Pavement Des. 2016, 17, 290–310. [Google Scholar] [CrossRef]

- Subhy, A.; Lo Presti, D.; Airey, G. An investigation on using pre-treated tyre rubber as a replacement of synthetic polymers for bitumen modification. Road Mater. Pavement Des. 2015, 16, 245–264. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled tyre rubber modified bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Zhou, F.; Mogawer, W.; Li, H.; Andriescu, A.; Copeland, A. Evaluation of fatigue tests for characterizing asphalt binders. J. Mater. Civ. Eng. 2012, 25, 610–617. [Google Scholar] [CrossRef]

- Bahia, H.U.; Hanson, D.; Zeng, M.; Zhai, H.; Khatri, M.; Anderson, R. Characterization of Modified Asphalt Binders in Superpave Mix Design; Transportation Research Board: Washington, DC, USA, 2001. [Google Scholar]

- Tsai, B.-W.; Monismith, C.; Dunning, M.; Gibson, N.; D’Angelo, J.; Leahy, R.; King, G.; Christensen, D.; Anderson, D.; Davis, R. Influence of asphalt binder properties on the fatigue performance of asphalt concrete pavements. J. Assoc. Asph. Paving Technol. 2005, 74, 733–790. [Google Scholar]

- Planche, J.-P.; Anderson, D.; Gauthier, G.; Le Hir, Y.M.; Martin, D. Evaluation of fatigue properties of bituminous binders. Mater. Struct. 2004, 37, 356–359. [Google Scholar] [CrossRef]

- Chen, J.-S.; Tsai, C.-J. How good are linear viscoelastic properties of asphalt binder to predict rutting and fatigue cracking? J. Mater. Eng. Perform. 1999, 8, 443–449. [Google Scholar] [CrossRef]

- Johnson, C.M.; Bahia, H.U.; Wen, H. Evaluation of Strain-Controlled Asphalt Binder Fatigue Testing in the Dynamic Shear Rheometer, 4th ed.; Int. Siiv Congress: Palermo, Italy, 2007. [Google Scholar]

- Shen, S.; Airey, G.D.; Carpenter, S.H.; Huang, H. A dissipated energy approach to fatigue evaluation. Road Mater. Pavement Des. 2006, 7, 47–69. [Google Scholar] [CrossRef]

- Pronk, A.; Hopman, P. Energy Dissipation: The Leading Factor of Fatigue; Thomas Telford Publishing: London, UK, 1991. [Google Scholar]

- Van Dijk, W.; Visser, W. Energy Approach to Fatigue for Pavement Design. In Proceedings of the Association of Asphalt Paving Technologists, San Antonio, TX, USA, 21–23 February 1977. [Google Scholar]

- Ghuzlan, K.A.; Carpenter, S.H. Energy-derived, damage-based failure criterion for fatigue testing. Transp. Res. Rec. J. Transp. Res. Board 2000, 1723, 141–149. [Google Scholar] [CrossRef]

- Williams, D.; Little, D.; Lytton, R.; Kim, Y.; Kim, Y. Microdamage Healing in Asphalt and Asphalt Concrete, Volume II: Laboratory and Field Testing to Assess and Evaluate Microdamage and Microdamage Healing; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2001.

- Little, D.N.; Lytton, R.L.; Chairl, B.; Williams, D.; Texas, A. An analysis of the mechanism of microdamage healing based on the application of micromechanics first principles of fracture and healing. Assoc. Asph. Paving Technol. 1998, 68, 501–542. [Google Scholar]

- Kim, Y.-R.; Little, D.; Lytton, R. Fatigue and healing characterization of asphalt mixtures. J. Mater. Civ. Eng. 2003, 15, 75–83. [Google Scholar] [CrossRef]

- Shen, S.; Chiu, H.-M.; Huang, H. Characterization of fatigue and healing in asphalt binders. J. Mater. Civ. Eng. 2010, 22, 846–852. [Google Scholar] [CrossRef]

- Glover, C.J.; Davison, R.R.; Bullin, J.A.; Estakhri, C.K.; Williamson, S.A.; Billiter, T.C.; Chipps, J.F.; Chun, J.S.; Juristyarini, P.; Leicht, S.E. A Comprehensive Laboratory and Field Study of High-Cure Crumb-Rubber Modified Asphalt Materials; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2000.

- Rodríguez-Alloza, A.M.; Gallego, J.; Pérez, I. Study of the effect of four warm mix asphalt additives on bitumen modified with 15% crumb rubber. Constr. Build. Mater. 2013, 43, 300–308. [Google Scholar] [CrossRef]

- Akisetty, C.K.; Lee, S.-J.; Amirkhanian, S.N. Effects of compaction temperature on volumetric properties of rubberized mixes containing warm-mix additives. J. Mater. Civ. Eng. 2009, 21, 409–415. [Google Scholar] [CrossRef]

- Zanzotto, L.; Kennepohl, G.J. Development of rubber and asphalt binders by depolymerization and devulcanization of scrap tires in asphalt. Transp. Res. Rec. J. Transp. Res. Board 1996, 1530, 51–58. [Google Scholar] [CrossRef]

- Akisetty, C.; Xiao, F.; Gandhi, T.; Amirkhanian, S. Estimating correlations between rheological and engineering properties of rubberized asphalt concrete mixtures containing warm mix asphalt additive. Constr. Build. Mater. 2011, 25, 950–956. [Google Scholar] [CrossRef]

- Billiter, T.; Davison, R.; Glover, C.; Bullin, J. Production of asphalt-rubber binders by high-cure conditions. Transp. Res. Rec. J. Transp. Res. Board 1997, 1586, 50–56. [Google Scholar] [CrossRef]

- Attia, M.; Abdelrahman, M. Enhancing the performance of crumb rubber-modified binders through varying the interaction conditions. Int. J. Pavement Eng. 2009, 10, 423–434. [Google Scholar] [CrossRef]

- Anderson, D.A.; Hir, Y.M.L.; Marasteanu, M.O.; Planche, J.-P.; Martin, D.; Gauthier, G. Evaluation of fatigue criteria for asphalt binders. Transp. Res. Rec. J. Transp. Res. Board 2001, 1766, 48–56. [Google Scholar] [CrossRef]

- Di Benedetto, H.; De La Roche, C.; Baaj, H.; Pronk, A.; Lundström, R. Fatigue of bituminous mixtures. Mater. Struct. 2004, 37, 202–216. [Google Scholar] [CrossRef]

- Tapsoba, N.; Sauzéat, C.; Benedetto, H.D. Analysis of fatigue test for bituminous mixtures. J. Mater. Civ. Eng. 2012, 25, 701–710. [Google Scholar] [CrossRef]

- Lundstrom, R.; Di Benedetto, H.; Isacsson, U. Influence of asphalt mixture stiffness on fatigue failure. J. Mater. Civ. Eng. 2004, 16, 516–525. [Google Scholar] [CrossRef]

- Carpenter, S.H.; Shen, S. Dissipated energy approach to study hot-mix asphalt healing in fatigue. Transp. Res. Rec. J. Transp. Res. Board 2006, 1970, 178–185. [Google Scholar] [CrossRef]

- Shen, S.; Carpenter, S.H. Application of the dissipated energy concept in fatigue endurance limit testing. Transp. Res. Rec. J. Transp. Res. Board 2005, 1929, 165–173. [Google Scholar] [CrossRef]

- Shen, S.; Carpenter, S.H. Dissipated Energy Concepts for HMA Performance: Fatigue and Healing; University of Illinois: Bloomington-Normal, IL, USA, 2007. [Google Scholar]

- Pais, J.C.; Pereira, P.A.; Minhoto, M.J.; Fontes, L.; Kumar, D.; Silva, B. Application of plateau value to predict fatigue life. In Proceedings of the 2nd Workshop on Four-point Bending, University of Minho, Guimarães, Portugal, 24–25 September 2009. [Google Scholar]

- Bhasin, A.; Castelo Branco, V.T.; Masad, E.; Little, D.N. Quantitative comParison of energy methods to characterize fatigue in asphalt materials. J. Mater. Civ. Eng. 2009, 21, 83–92. [Google Scholar] [CrossRef]

- Boudabbous, M.; Millien, A.; Petit, C.; Neji, J. Shear test to evaluate the fatigue of asphalt materials. Road Mater. Pavement Des. 2013, 14, 86–104. [Google Scholar] [CrossRef]

| Ageing States | Index | Straight-Run Binder | STRD | STRSE |

|---|---|---|---|---|

| Unaged binder | Penetration @ 25 °C, 0.1 mm | 200 | – | – |

| Softening point °C | 37.0 | – | – | |

| Rotational viscosity, mPa·s @ 180 °C | 25 | 560 | 355 | |

| Asphaltenes content | 4.2% | – | – | |

| |G*|/sinδ @ 60 °C & 1.59 Hz, kPa | 0.615 | 6.053 | 12.13 | |

| RTFOT or TFOT * aged residue | |G*|/sinδ @ 60 °C & 1.59 Hz, kPa | 1.256 | 12.05 | 25.86 |

| RTFOT or TFOT * + PAV aged residue | |G*|·sinδ @ 10 °C & 1.59 Hz, kPa | 5650 | 3680 | 4734 |

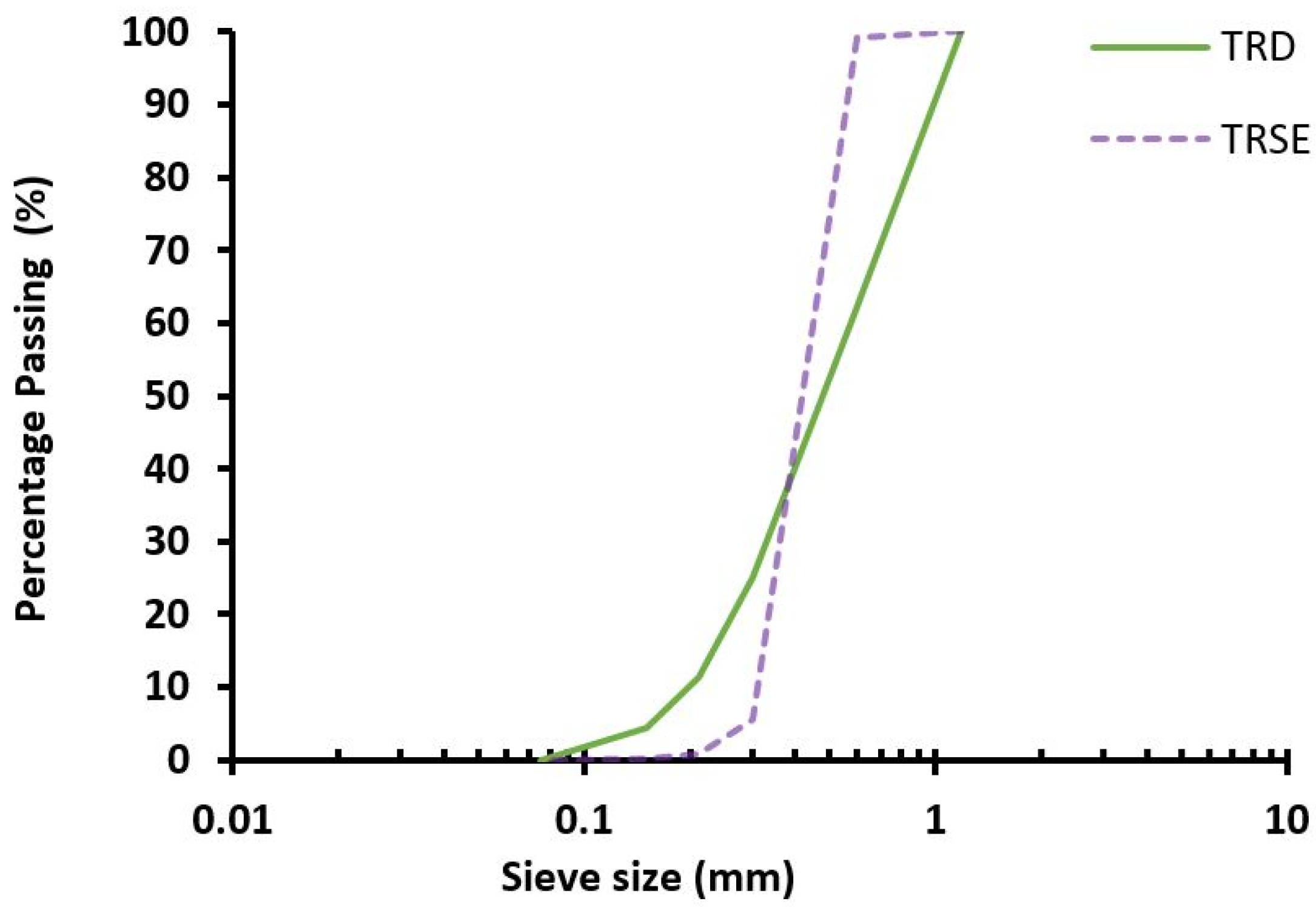

| No. | Material Description | Code |

|---|---|---|

| 1 | Neat bitumen Pen 160/220 | Straight run bitumen |

| 2 | Rubberised bitumen manufactured using 84.75% of neat bitumen Pen 160/220 with 15.25% of TRD crumb rubber | STRD |

| 3 | Rubberised bitumen manufactured using 84.75% of neat bitumen Pen 160/220 with 15.25% of TRSE crumb rubber | STRSE |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subhy, A.; Lo Presti, D. Fatigue and Healing Properties of Low Environmental Impact Rubberized Bitumen for Asphalt Pavement. Coatings 2017, 7, 66. https://doi.org/10.3390/coatings7050066

Subhy A, Lo Presti D. Fatigue and Healing Properties of Low Environmental Impact Rubberized Bitumen for Asphalt Pavement. Coatings. 2017; 7(5):66. https://doi.org/10.3390/coatings7050066

Chicago/Turabian StyleSubhy, Ayad, and Davide Lo Presti. 2017. "Fatigue and Healing Properties of Low Environmental Impact Rubberized Bitumen for Asphalt Pavement" Coatings 7, no. 5: 66. https://doi.org/10.3390/coatings7050066