Multilayer CVD Diamond Coatings in the Machining of an Al6061-15 Vol % Al2O3 Composite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Al–Al2O3 Composite Workpiece

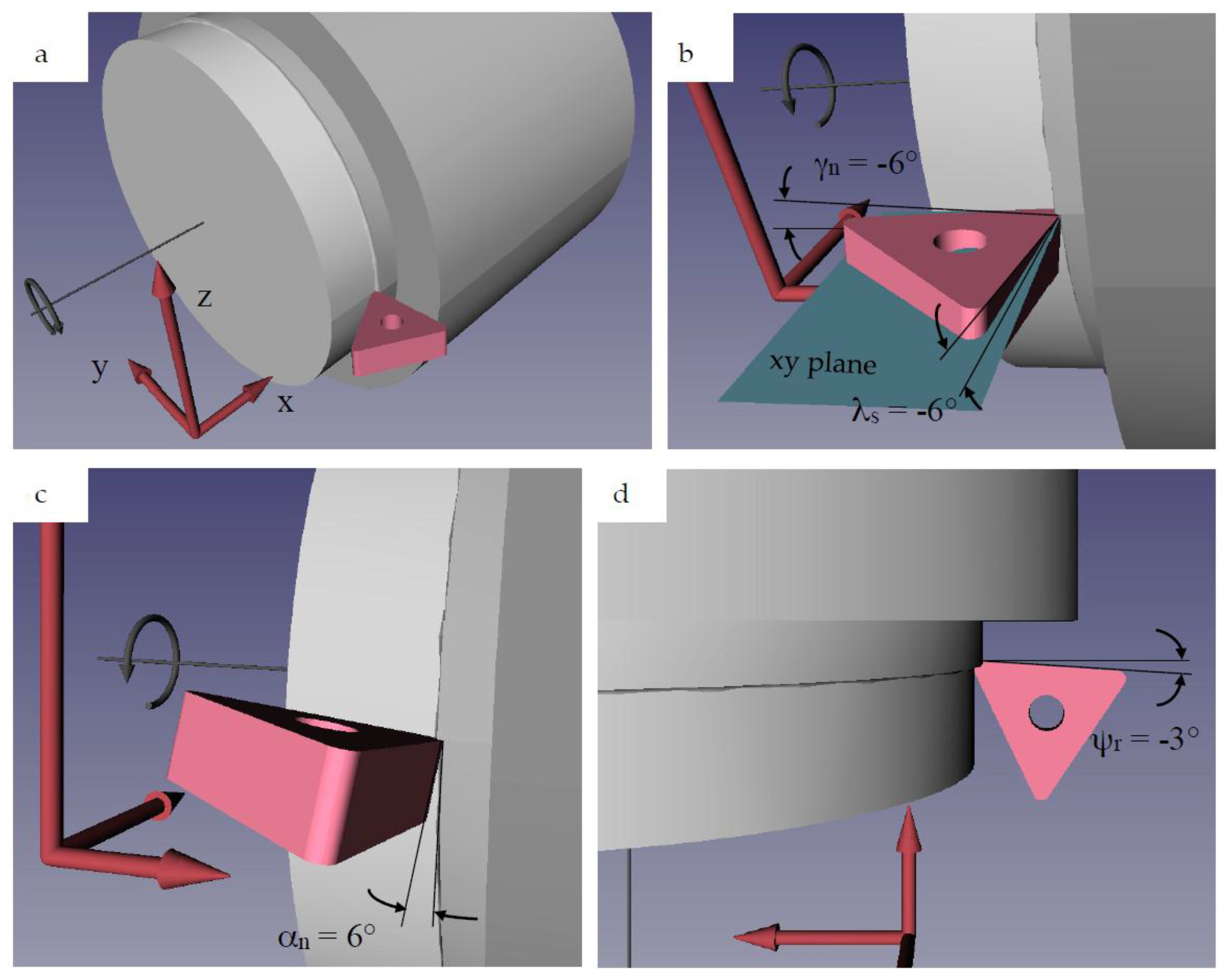

2.2. Cutting Inserts

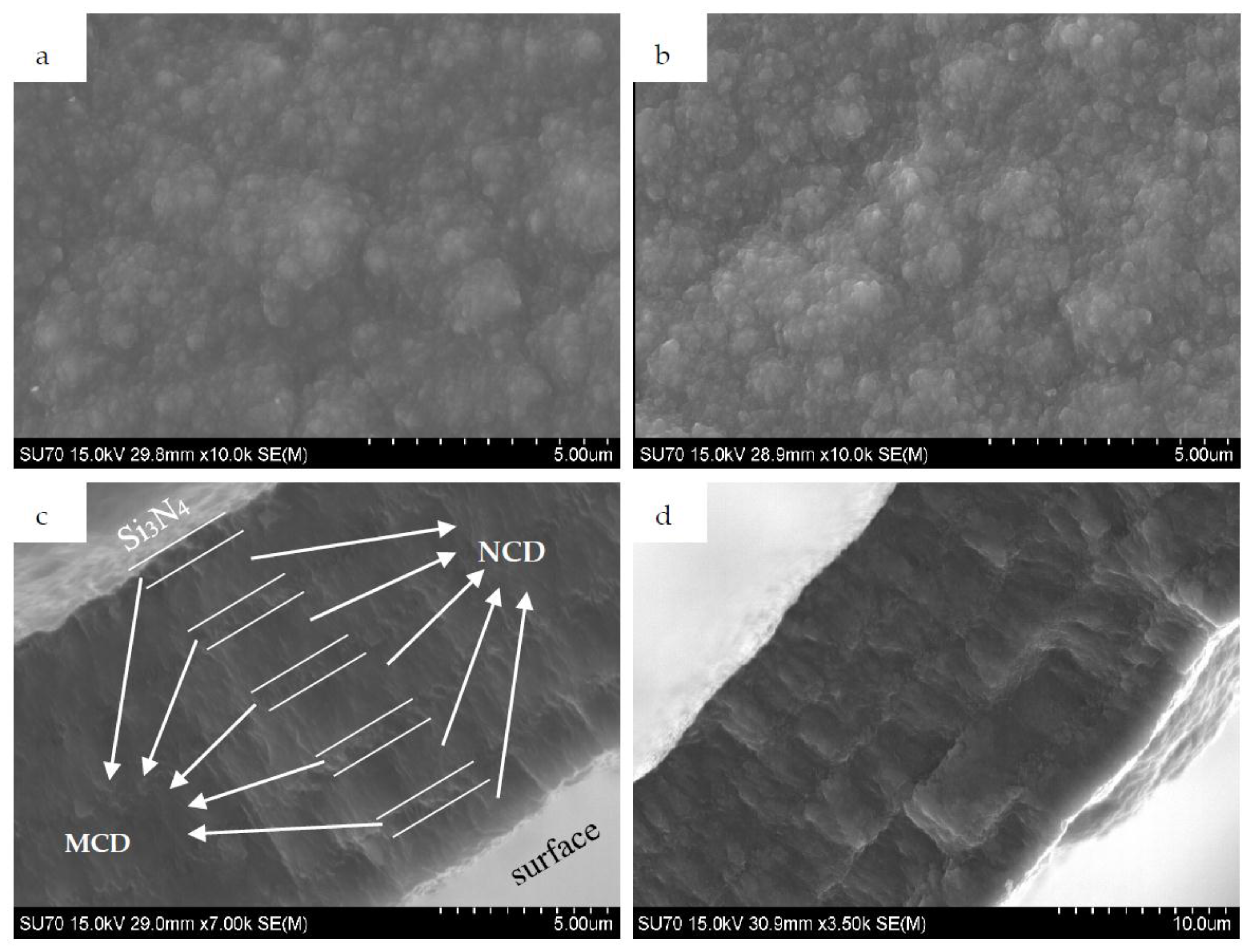

2.3. Diamond Coating

2.4. Dry Turning

3. Results and Discussion

3.1. Multilayer MCD/NCD Coatings

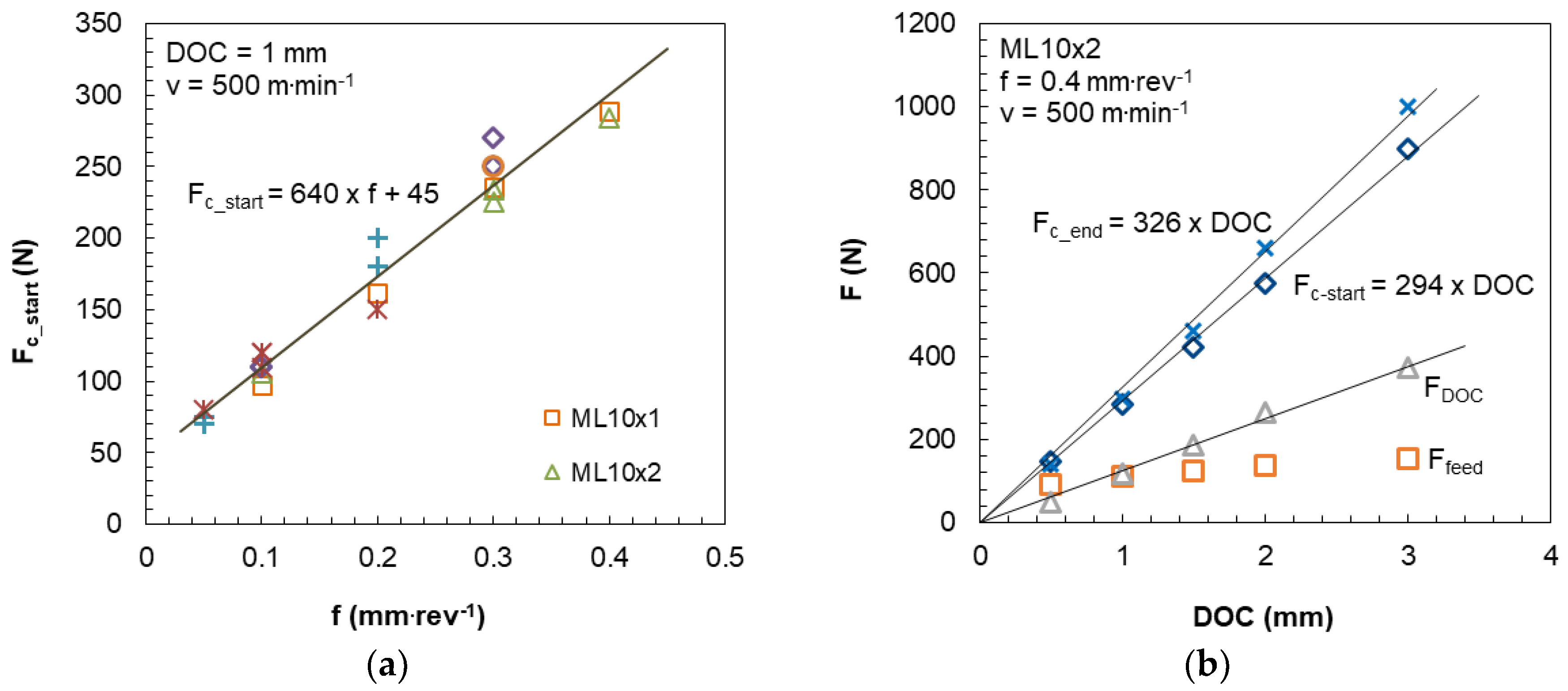

3.2. Machining Performance

3.2.1. ML10x1-12 µm Thick CVD Diamond

3.2.2. ML10x2-24 µm Thick CVD Diamond

3.2.3. ML10x2-Multi-Pass Tests

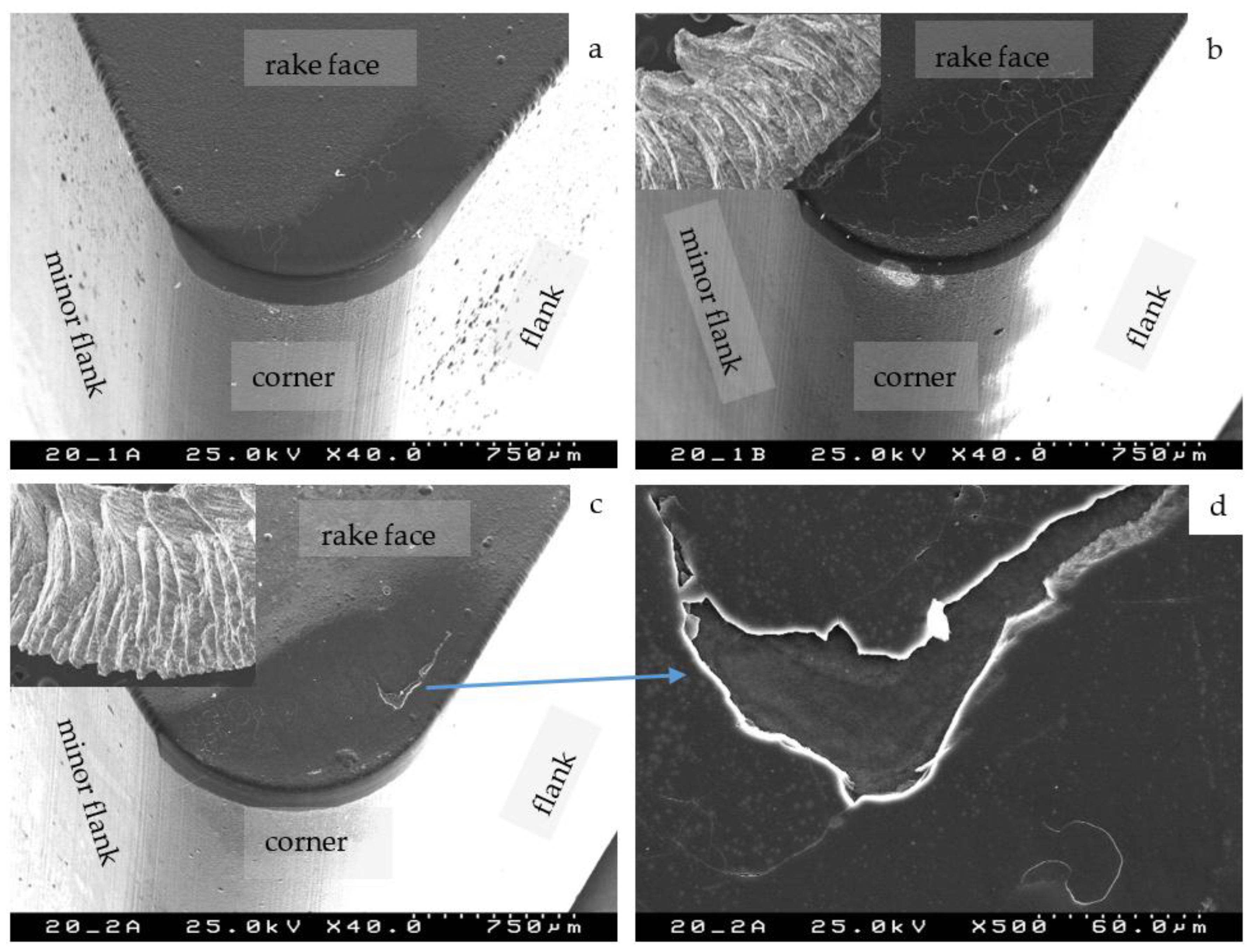

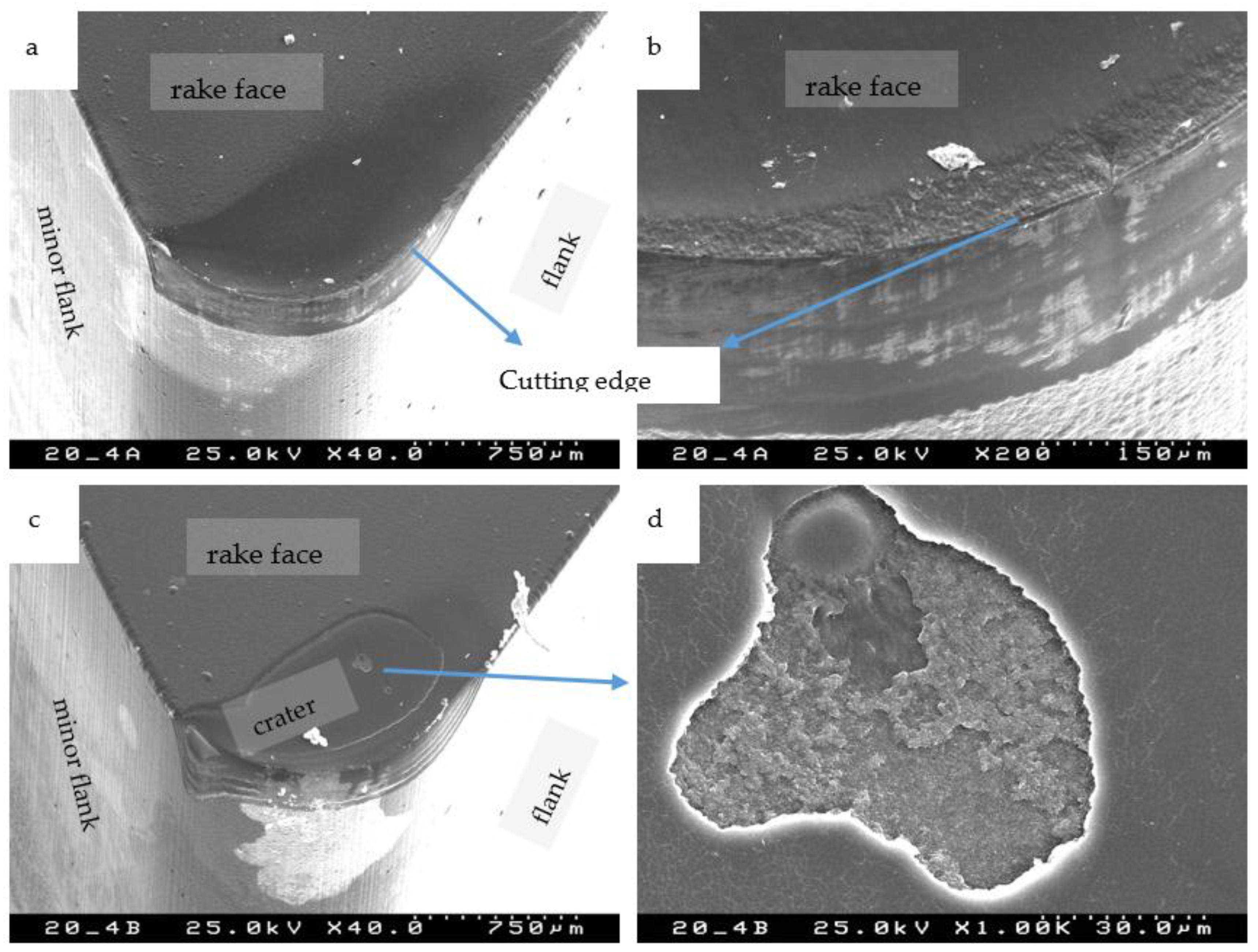

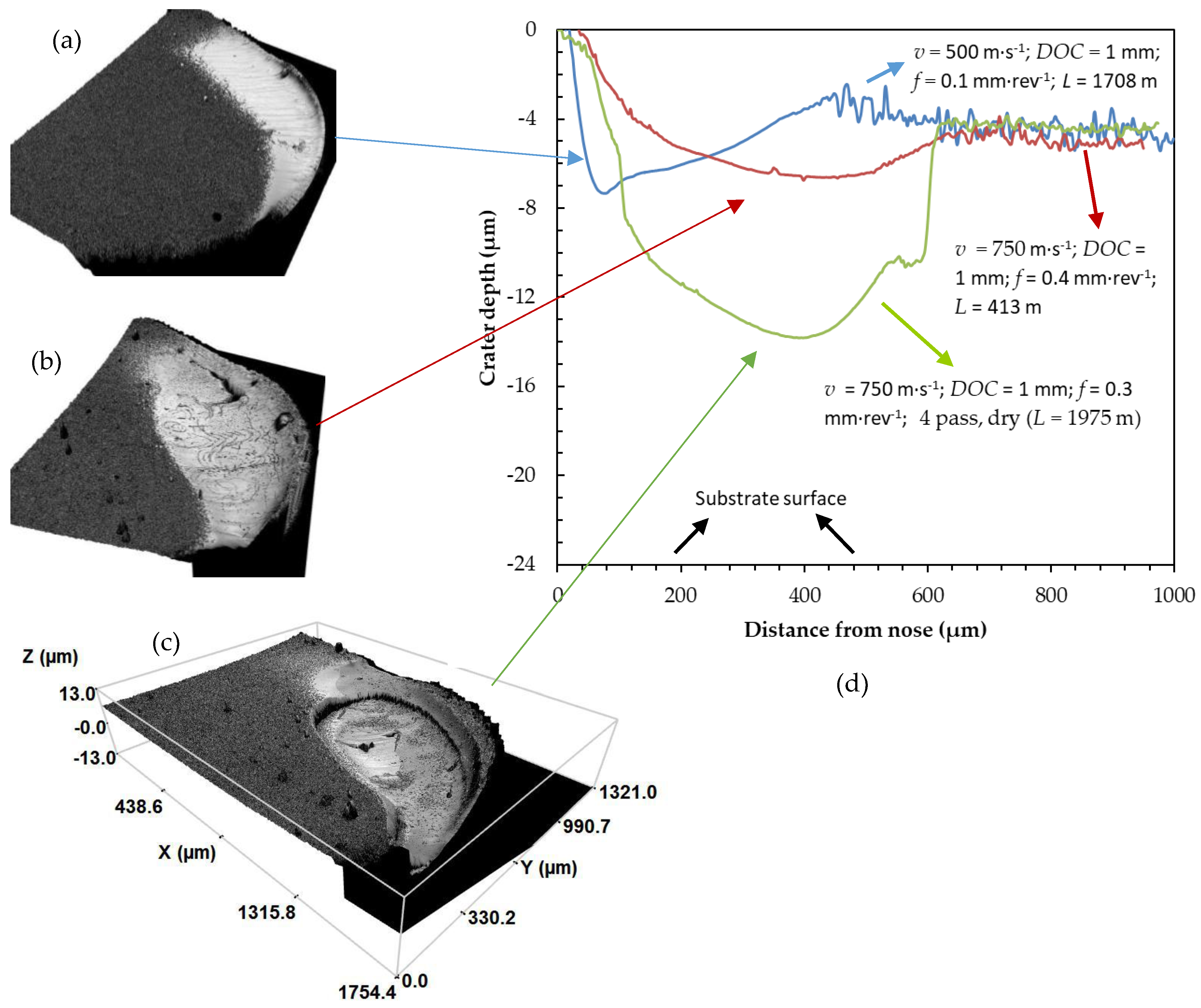

3.2.4. Crater Wear

3.3. Tool Life

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hung, N.P.; Boey, F.Y.C.; Khor, K.A.; Phua, Y.S.; Lee, H.F. Machinability of aluminum alloys reinforced with silicon carbide particulates. J. Mater. Process. Technol. 1996, 56, 966–977. [Google Scholar] [CrossRef]

- Durante, S.; Rutelli, G.; Rabezzana, F. Aluminum-based MMC machining with diamond-coated cutting tools. Surf. Coat. Technol. 1997, 94–95, 632–640. [Google Scholar] [CrossRef]

- El-Gallab, M.; Sklad, M. Machining of Al/SiC particulate metal-matrix composites. Part I: Tool performance. J. Mater. Process. Technol. 1998, 83, 151–158. [Google Scholar] [CrossRef]

- Lin, J.T.; Bhattacharyya, D.; Lane, C. Case Study—Machinability of a silicon carbide reinforced matrix composite aluminium metal. Wear 1995, 181–183, 883–888. [Google Scholar] [CrossRef]

- Vandevelde, T.C.S.; Vandierendonck, K.; van Stappen, M.; Du Mong, W.; Perremans, P. Cutting applications of DLC, hard carbon and diamond films. Surf. Coat. Technol. 1999, 113, 80–85. [Google Scholar] [CrossRef]

- D’Errico, G.E.; Calzavarini, R. Turning of metal matrix composites. J. Mater. Process. Technol. 2001, 119, 257–260. [Google Scholar] [CrossRef]

- Weinert, K.; Buschka, M.; Niehues, J.; Schoberth, A. Spanende Bearbeitung von Bauteilen aus Al-Matrix-Verbundwerkstoffen (Machining of Components of Al Matrix Composites). Materialwiss. Werkstofftech. 2001, 32, 447–461. [Google Scholar] [CrossRef]

- Almeida, F.A.; Oliveira, F.J.; Sousa, M.; Fernandes, A.J.S.; Sacramento, J.; Silva, R.F. Machining hardmetal with CVD diamond direct coated ceramic tools: Effect of tool edge geometry. Diam. Relat. Mater. 2005, 14, 651–656. [Google Scholar] [CrossRef]

- Chou, Y.K.; Liu, J. CVD diamond tool performance in metal matrix composite machining. Surf. Coat. Technol. 2005, 200, 1872–1878. [Google Scholar] [CrossRef]

- Skordaris, G. Temperature-Dependent Fatigue Strength of Diamond Coating-Substrate Interface Quantified via the Shear Failure Stress. J. Mater. Eng. Perform. 2015, 24, 3335–3342. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Skordaris, G.; Bouzakis, E.; Charalampous, P.; Kotsanis, T.; Tasoulas, D.; Kombogiannis, S.; Lemmer, O. Effect of the Interface Fatigue Strength of NCD Coated Hardmetal Inserts on Their Cutting Performance in Milling. Diam. Relat. Mater. 2015, 59, 80–89. [Google Scholar] [CrossRef]

- Skordaris, G.; Bouzakis, K.-D.; Charalampous, P.; Kotsanis, T.; Bouzakis, E.; Lemmer, O. Effect of structure and residual stresses of diamond coated cemented carbide tools on the film adhesion and developed wear mechanisms in milling. CIRP Ann. Manuf. Technol. 2016, 65, 101–104. [Google Scholar] [CrossRef]

- Iuliano, L.; Settineri, L.; Gatto, A. High-speed turning experiments on metal matrix composites. Compos. Part A 1998, 29, 1501–1509. [Google Scholar] [CrossRef]

- Polini, R.; Casadei, F.; D’Antonio, P.; Traversa, E. Dry turning of alumina/aluminum composites with CVD diamond coated Co-cemented tungsten carbide tools. Surf. Coat. Technol. 2003, 166, 127–134. [Google Scholar] [CrossRef] [Green Version]

- Kremer, A.; Devillez, A.; Dominiak, S.; Dudzinski, D.; El Mansori, M. Machinability of Al/SiC particulate metal-matrix composites under dry conditions with CVD diamond-coated carbide tools. Mach. Sci. Technol. 2008, 12, 214–233. [Google Scholar] [CrossRef]

- Qin, F.; Hu, J.; Chou, Y.K.; Thompson, R.G. Delamination wear of nano-diamond coated cutting tools in composite machining. Wear 2009, 267, 991–995. [Google Scholar] [CrossRef]

- Shen, B.; Sun, F.H. The Cutting Performance of Ultra-Smooth Composite Diamond Coated WC-Co Inserts in Dry Turning Al/SiC-MMC. Adv. Mater. Res. 2011, 325, 400–405. [Google Scholar] [CrossRef]

- Salgueiredo, E.; Abreu, C.S.; Amaral, M.; Oliveira, F.J.; Gomes, J.R.; Silva, R.F. Self-mated tribological systems based on multilayer micro/nanocrystalline CVD diamond coatings. Wear 2013, 303, 225–234. [Google Scholar] [CrossRef]

- Salgueiredo, E.; Almeida, F.A.; Amaral, M.; Neto, M.A.; Oliveira, F.J.; Silva, R.F. A multilayer approach for enhancing the erosive wear resistance of CVD diamond coatings. Wear 2013, 297, 1064–1073. [Google Scholar] [CrossRef]

- Abreu, C.S.; Amaral, M.; Oliveira, F.J.; Fernandes, A.J.S.; Gomes, J.R.; Silva, R.F. Enhanced performance of HFCVD nanocrystalline diamond self-mated tribosystems by plasma pretreatments on silicon nitride substrates. Diam. Relat. Mater. 2006, 15, 2024–2028. [Google Scholar] [CrossRef]

- Basic Nomenclature and Definitions for Single—Point Cutting Tools; ANSI B94.50; American National Standard Institute: Washington, DC, USA, 1975.

- Almeida, F.A.; Amaral, M.; Oliveira, F.J.; Fernandes, A.J.S.; Silva, R.F. Nano to micrometric HFCVD diamond adhesion strength to Si3N4. Vacuum 2007, 81, 1443–1447. [Google Scholar] [CrossRef]

- Davim, J.P.; Baptista, A.M. Relationship between cutting force and PCD cutting tool wear in machining silicon carbide reinforced aluminium. J. Mater. Process. Technol. 2000, 103, 417–423. [Google Scholar] [CrossRef]

- Ramesh, M.V.; Lee, W.B.; Cheung, C.F.; Chan, K.C. A parametric analysis of cutting forces in single-point diamond turning of Al6061/SiCp metal matrix composites (MMCs) forces in single-point diamond turning. Mater. Manuf. Processes 2001, 16, 61–78. [Google Scholar] [CrossRef]

- Kamiya, H.; Takahara, T.; Sakurai, Y.; Jimbo, G.; Wada, S. Erosion wear properties of toughened ceramics and composites. In Advanced Materials '93: Ceramics, Powders, Corrosion and Advanced Processing; Elsevier Science: Amsterdam, The Netherlands, 1994; pp. 313–316. [Google Scholar]

- Muthukrishnan, N.; Murugan, M.; Rao, K.P. Machinability issues in turning of Al-SiC (10p) metal matrix composites. Int. J. Adv. Manuf. Technol. 2007, 39, 211–218. [Google Scholar] [CrossRef]

—30 µm CVD diamond coating [9];

—30 µm CVD diamond coating [9];  —hardmetal tool coated with 6 µm CVD diamond [15]; ◯—hardmetal tool coated with 25–30 µm CVD diamond [16]; ✴—PCD tool [23]; (b) Effect of depth of cut in the initial values of cutting force for the ML10x2 inserts and end values of Fc, for fixed feed and speed.

—hardmetal tool coated with 6 µm CVD diamond [15]; ◯—hardmetal tool coated with 25–30 µm CVD diamond [16]; ✴—PCD tool [23]; (b) Effect of depth of cut in the initial values of cutting force for the ML10x2 inserts and end values of Fc, for fixed feed and speed.

—30 µm CVD diamond coating [9];

—30 µm CVD diamond coating [9];  —hardmetal tool coated with 6 µm CVD diamond [15]; ◯—hardmetal tool coated with 25–30 µm CVD diamond [16]; ✴—PCD tool [23]; (b) Effect of depth of cut in the initial values of cutting force for the ML10x2 inserts and end values of Fc, for fixed feed and speed.

—hardmetal tool coated with 6 µm CVD diamond [15]; ◯—hardmetal tool coated with 25–30 µm CVD diamond [16]; ✴—PCD tool [23]; (b) Effect of depth of cut in the initial values of cutting force for the ML10x2 inserts and end values of Fc, for fixed feed and speed.

| Deposition Parameters | MCD | NCD |

|---|---|---|

| Tfilament (°C) | 2255 | 2325 |

| Tsubstrate (°C) | 850 | 750 |

| Filament diameter (mm) | 0.3 | 0.3 |

| W-filament (#) | 8 | 8 |

| CH4/H2 (%) | 2 | 4 |

| Gas flow (mL·min−1) | 1800 | 900 |

| Pressure (mbar) | 75 | 25 |

| Tool Angles and Corner Radius | Value |

|---|---|

| γn, tool normal rake | −6° |

| αn, tool normal clearance | 6° |

| ψr, tool lead angle | −3° |

| κr, tool cutting edge angle | 93° |

| λs, tool cutting edge inclination | −6° |

| εr, tool included angle | 60° |

| βn, normal wedge angle | 90° |

| rε, corner radius (mm) | 0.8 |

| Insert | v (m·min−1) | f (mm·rev−1) | DOC (mm) | L (m) | t (s) | n (rpm) |

|---|---|---|---|---|---|---|

| ML10x1 | 250 | 0.1 | 1 | 1812 | 435 | 391 |

| 250 | 0.4 | 1 | 460 | 110 | 387 | |

| 500 | 0.1 | 1 | 2021 | 243 | 705 | |

| 500 | 0.2 | 1 | 993 | 119 | 717 | |

| 500 | 0.3 | 1 | 653 | 78 | 732 | |

| 500 | 0.4 | 1 | 485 | 58 | 735 | |

| 750 | 0.1 | 1 | 1879 | 150 | 1133 | |

| 750 | 0.4 | 1 | 479 | 38 | 1113 | |

| 1000 | 0.1 | 1 | 2001 | 120 | 1424 | |

| 1000 | 0.4 | 1 | 474 | 28 | 1497 | |

| ML10x2 | 500 | 0.1 | 1 | 1708 | 205 | 819 |

| 500 | 0.3 * | 1 | 1975 | 237 | 938 | |

| 500 | 0.3 ** | 1 | 1878 | 225 | 985 | |

| 500 | 0.4 | 0.5 | 411 | 49 | 849 | |

| 500 | 0.4 | 1 | 422 | 51 | 828 | |

| 500 | 0.4 | 1.5 | 404 | 48 | 862 | |

| 500 | 0.4 | 2.0 | 388 | 47 | 896 | |

| 500 | 0.4 | 3.0 | 375 | 45 | 927 | |

| 750 | 0.4 | 1 | 413 | 33 | 1267 | |

| 1000 | 0.4 | 1 | 418 | 25 | 1672 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shabani, M.; Sacramento, J.; Oliveira, F.J.; Silva, R.F. Multilayer CVD Diamond Coatings in the Machining of an Al6061-15 Vol % Al2O3 Composite. Coatings 2017, 7, 165. https://doi.org/10.3390/coatings7100165

Shabani M, Sacramento J, Oliveira FJ, Silva RF. Multilayer CVD Diamond Coatings in the Machining of an Al6061-15 Vol % Al2O3 Composite. Coatings. 2017; 7(10):165. https://doi.org/10.3390/coatings7100165

Chicago/Turabian StyleShabani, Mohammadmehdi, Joaquim Sacramento, Filipe J. Oliveira, and Rui F. Silva. 2017. "Multilayer CVD Diamond Coatings in the Machining of an Al6061-15 Vol % Al2O3 Composite" Coatings 7, no. 10: 165. https://doi.org/10.3390/coatings7100165