Influence of Coating Formulation on Its Mechanical Properties and Cracking Resistance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Coatings

2.2. Hardness

2.3. Tensile Test

2.4. Artificial Weathering

3. Results and Discussion

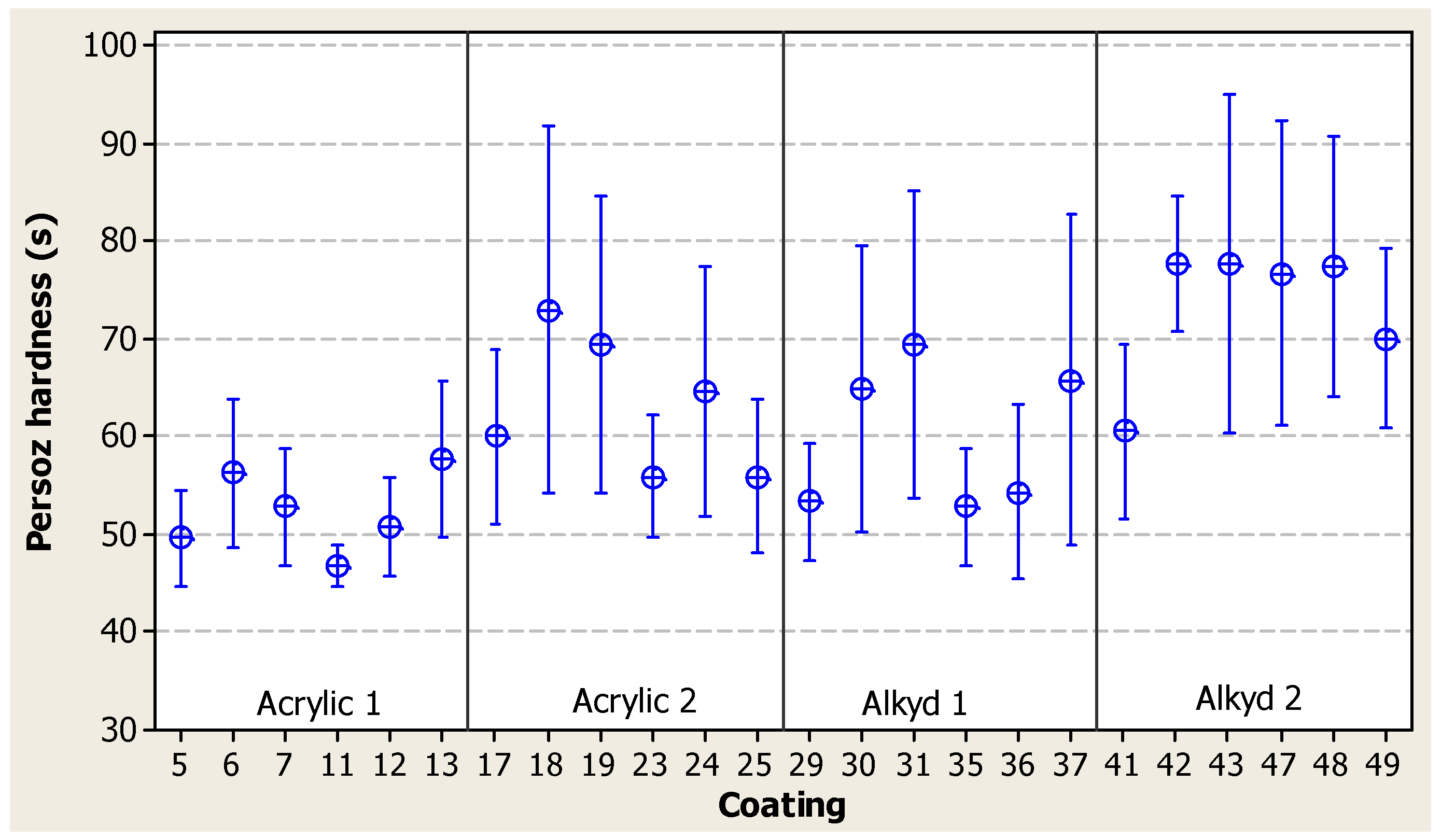

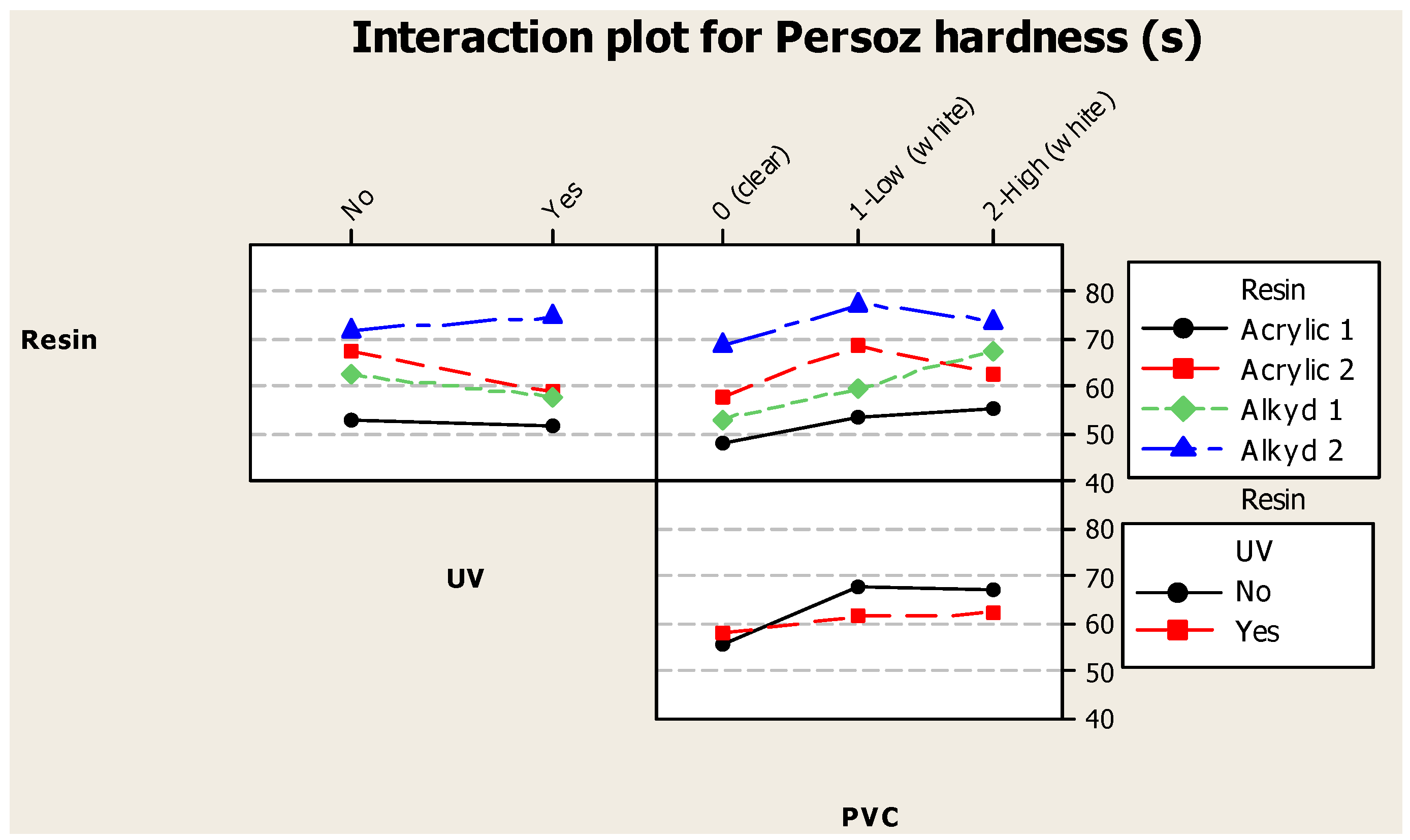

3.1. Hardness before Weathering

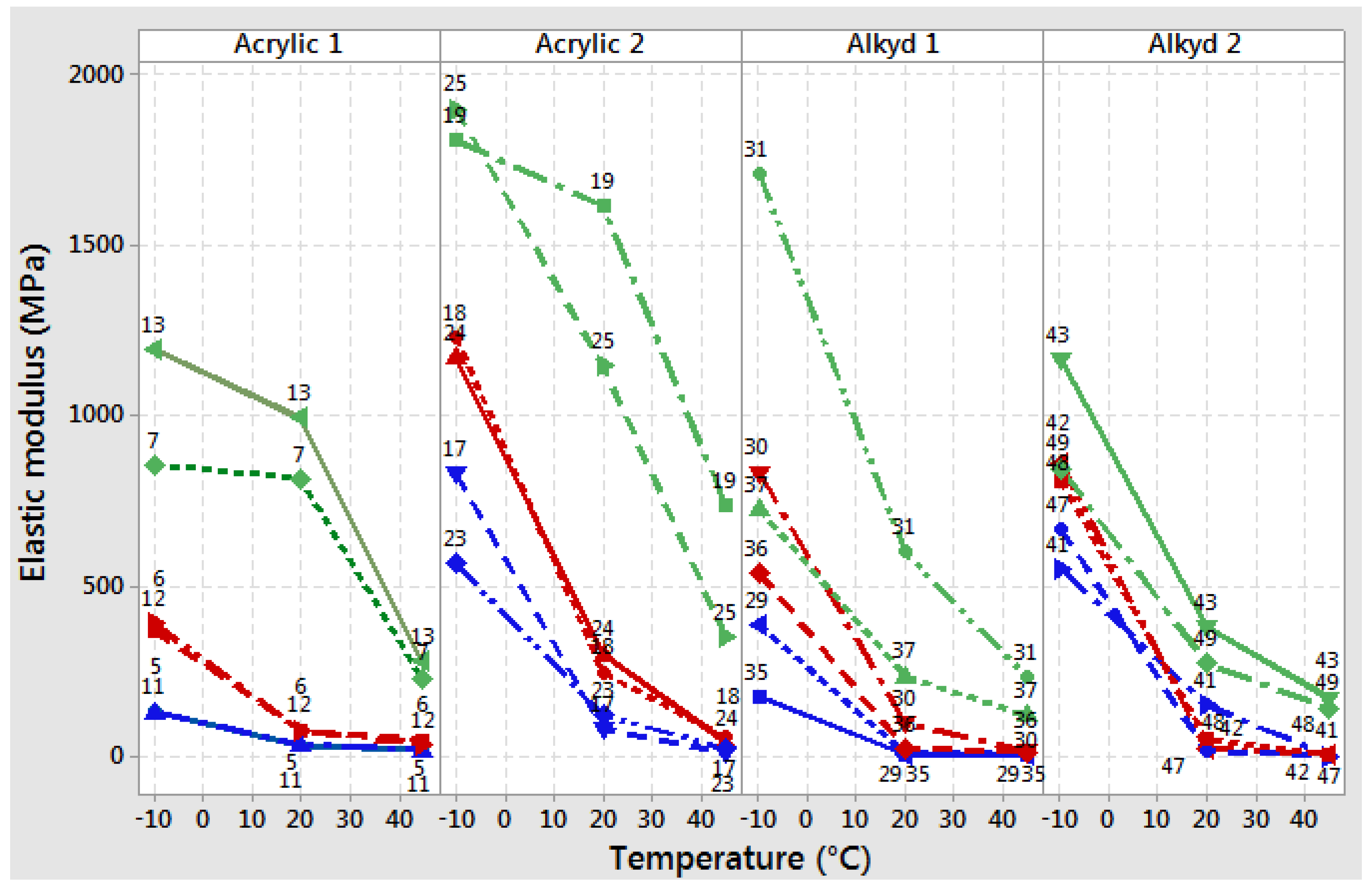

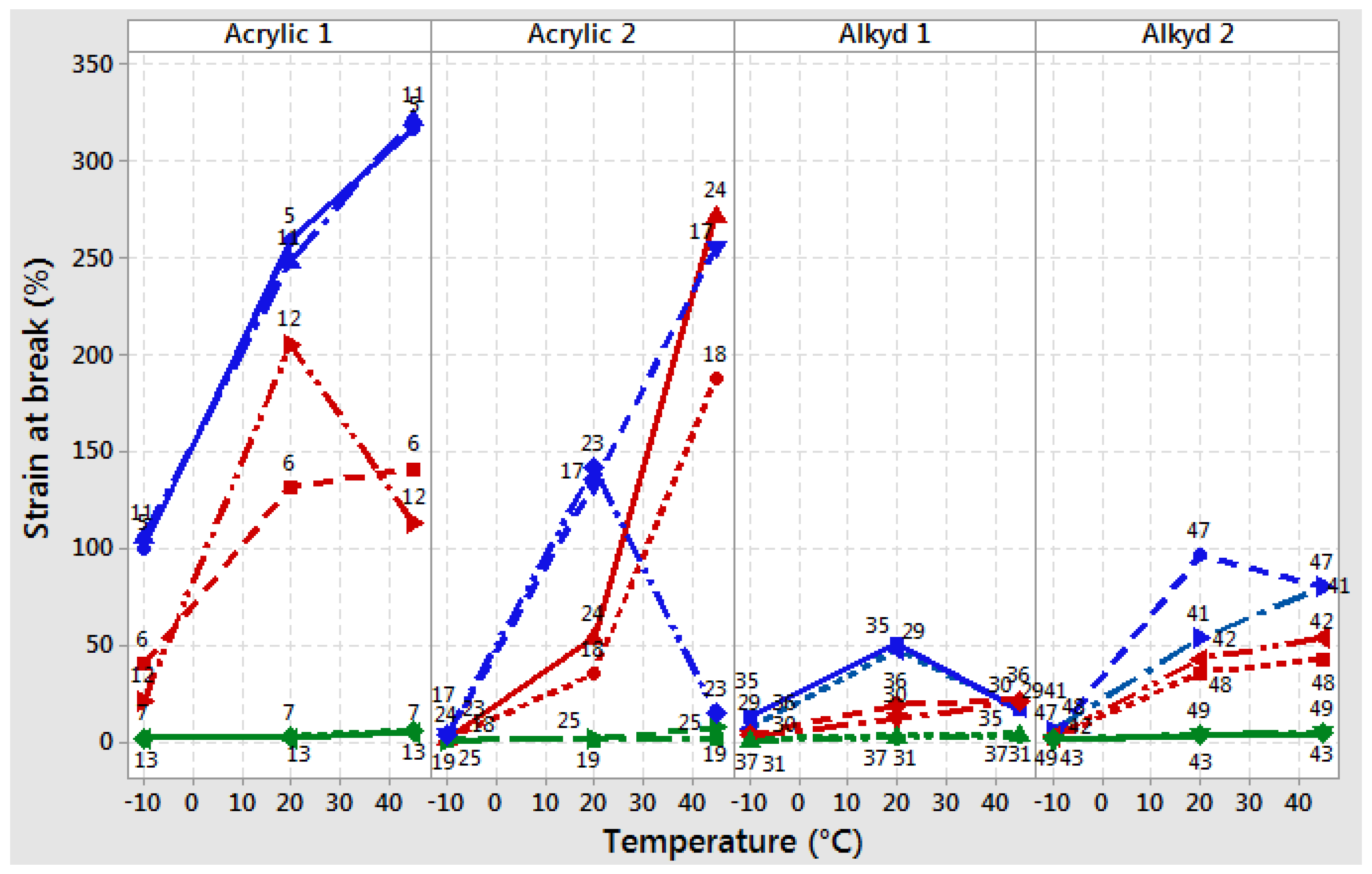

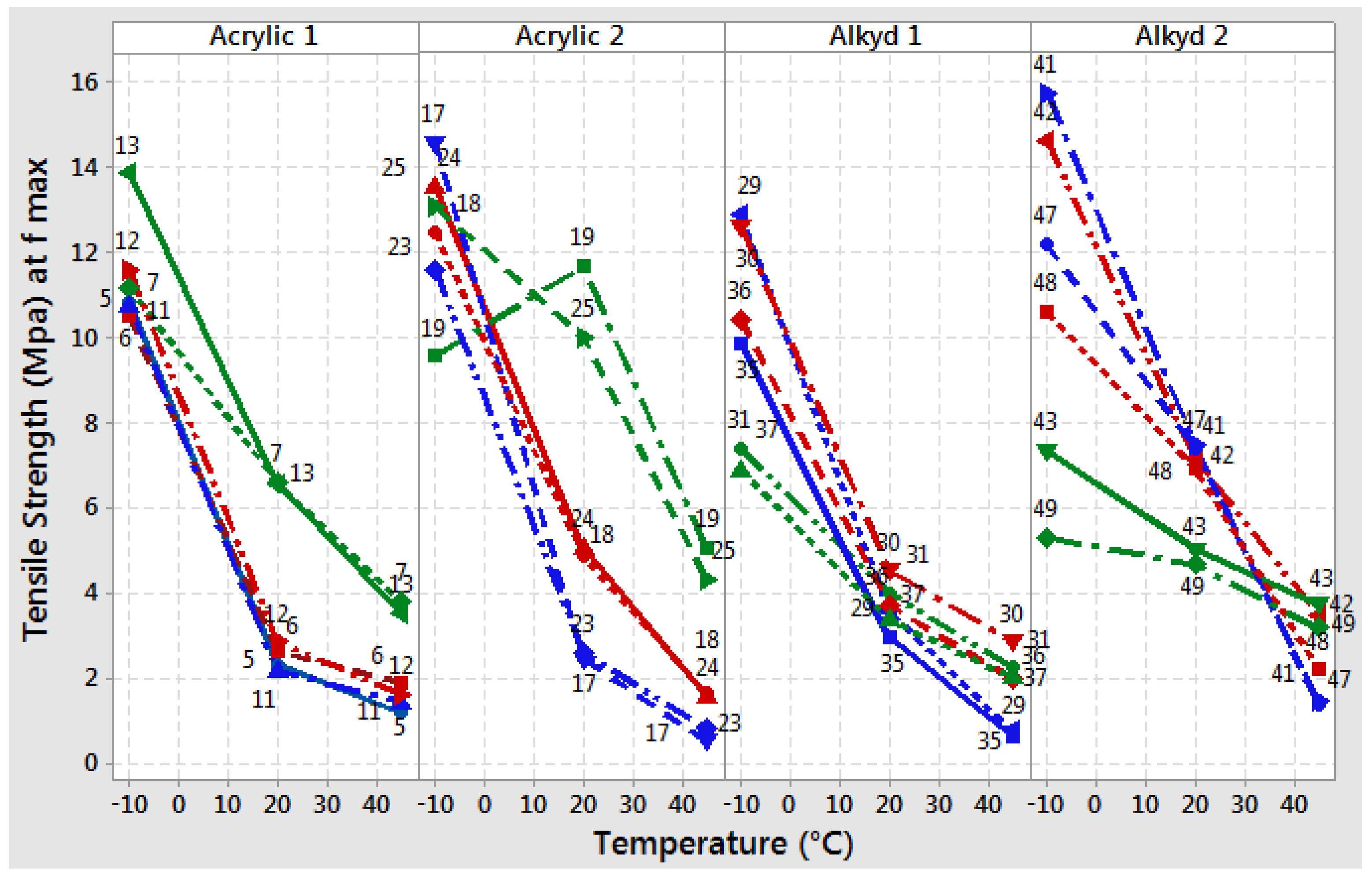

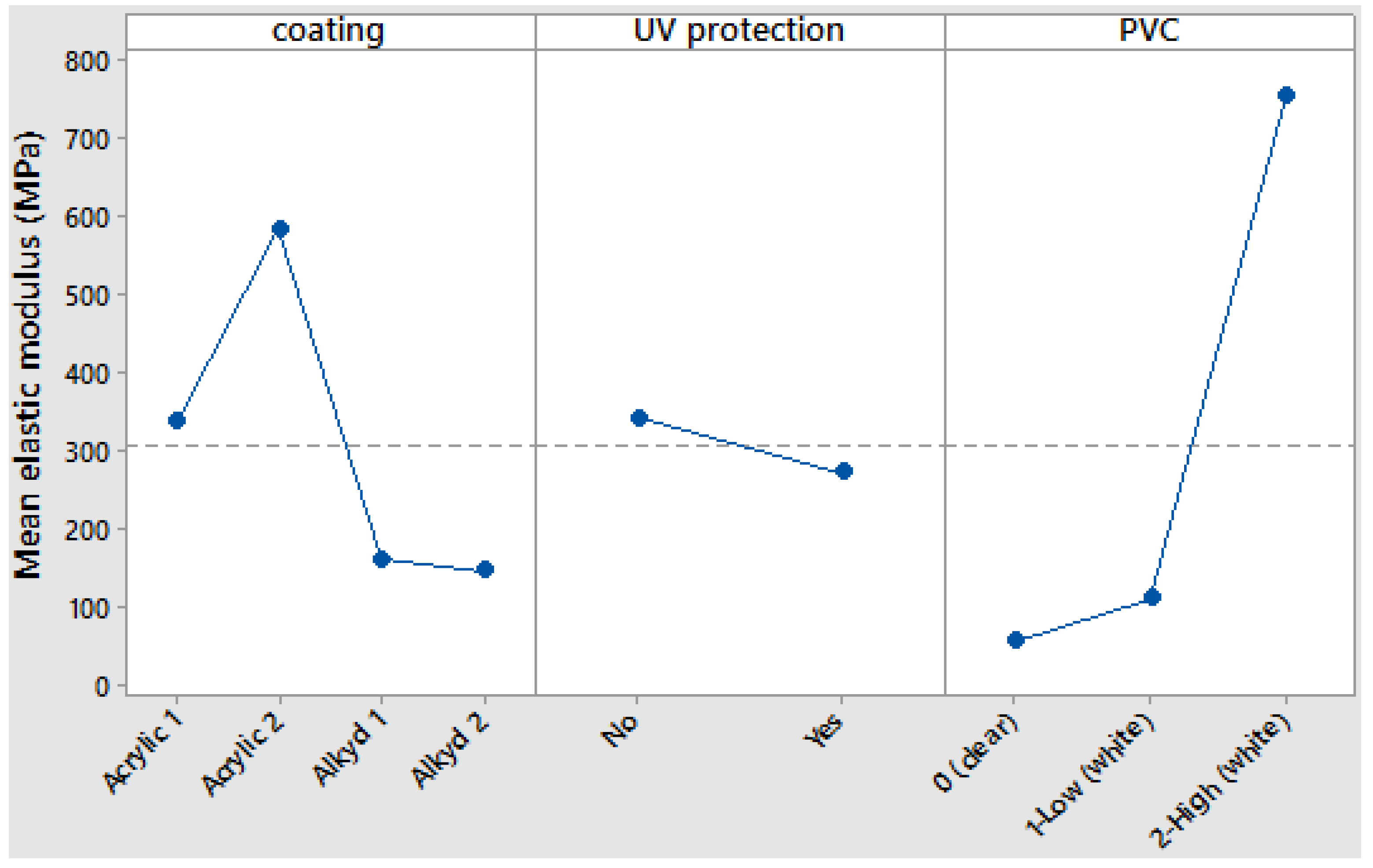

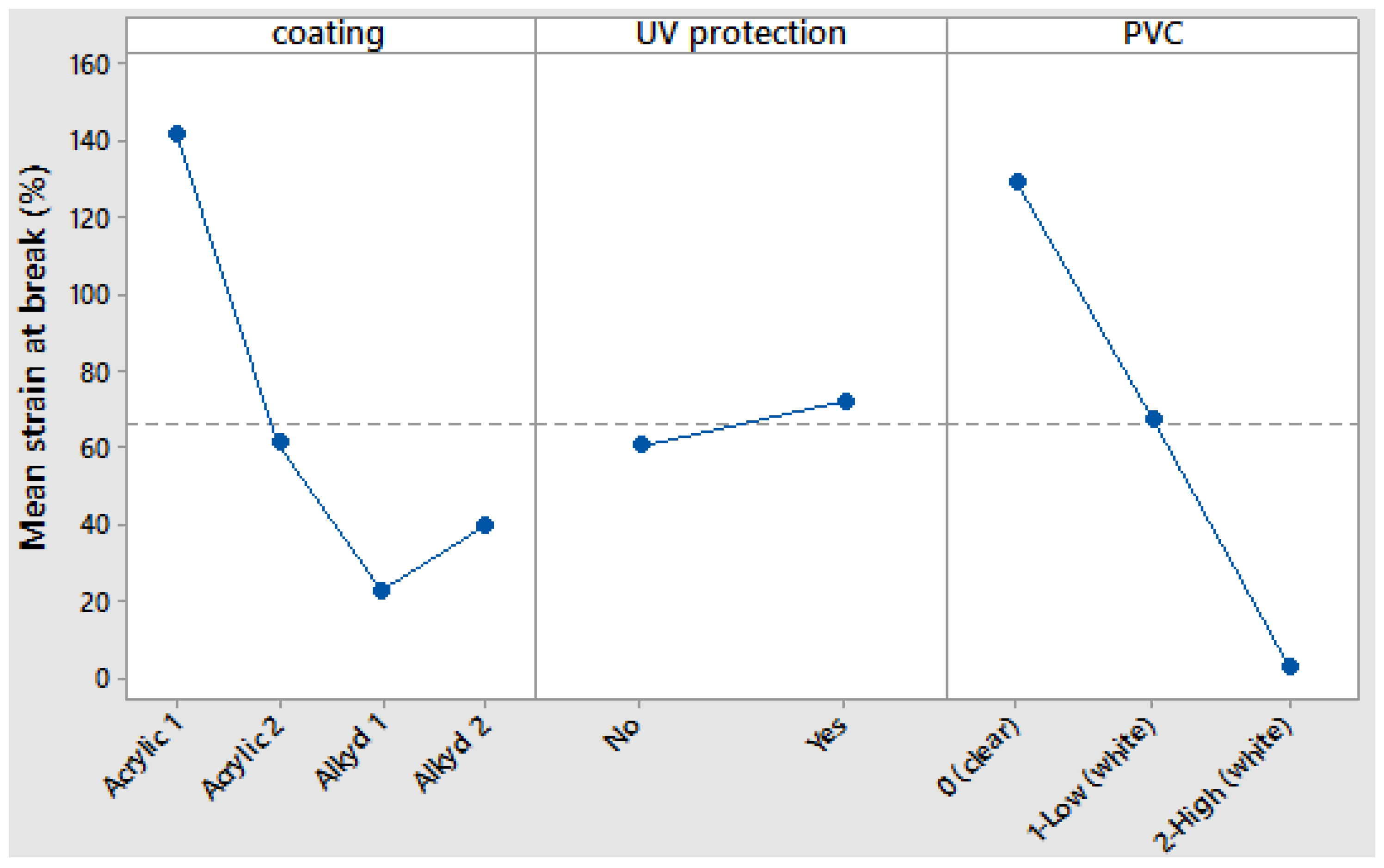

3.2. Tensile Tests

3.3. Cracking and Weathering Resistance

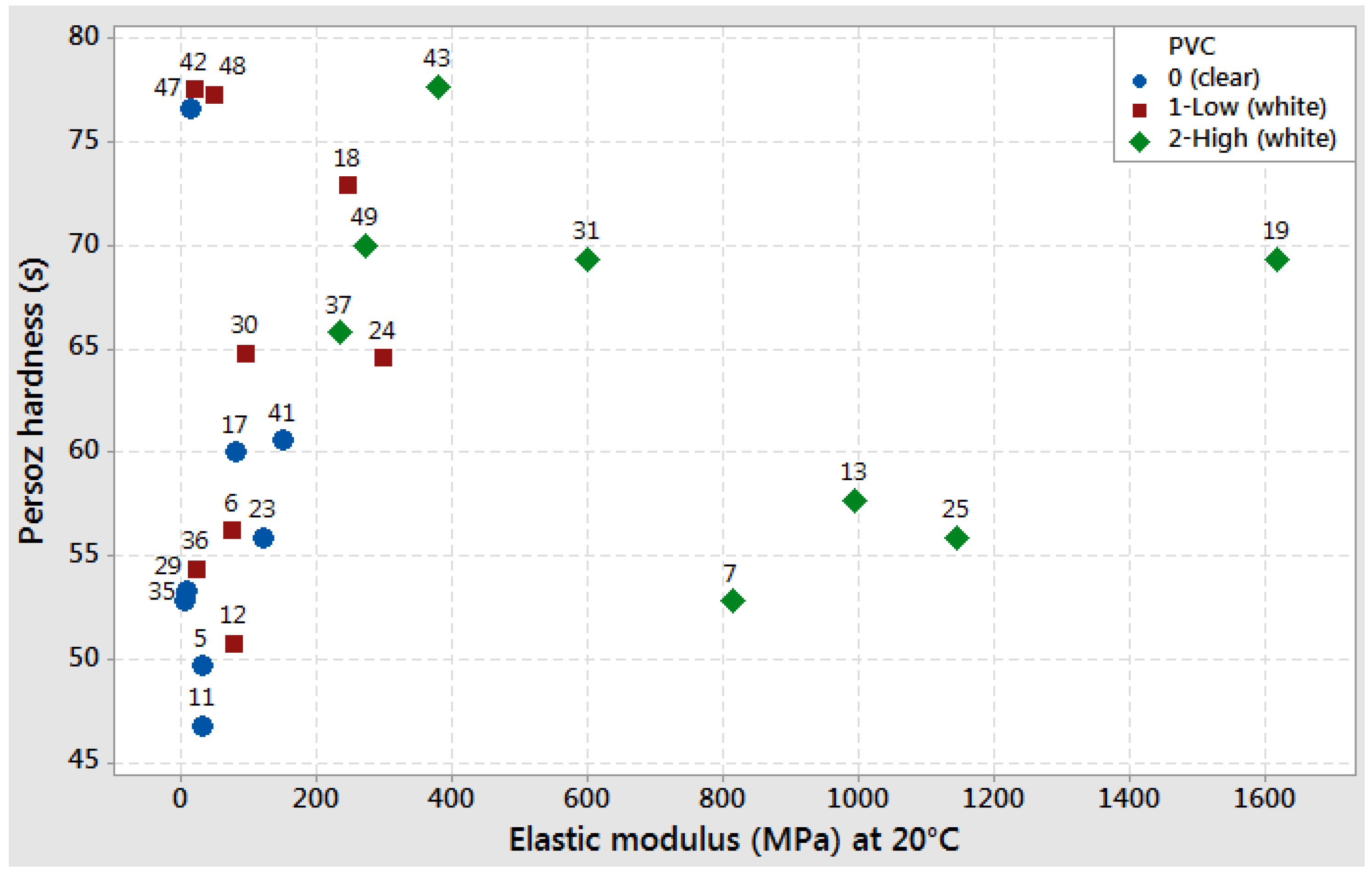

3.4. Relation between Elastic Modulus and Persoz Hardness

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Evans, P.D.; Vollmer, S.; Kim, J.D.W.; Chan, G.; Gibson, S.K. Improving the performance of clear coatings on wood through the aggregation of marginal gains. Coatings 2016, 6, 66. [Google Scholar] [CrossRef]

- Podgorski, L.; Roux, M.L. Wood modification to improve the durability of coatings. Surf. Coat. Int. 1999, 82, 590–596. [Google Scholar] [CrossRef]

- De Meijer, M.; Nienhuis, J. Influence of internal stress and extensibility on the exterior durability of wood coatings. Prog. Org. Coat. 2009, 65, 498–503. [Google Scholar] [CrossRef]

- EN 927-2:2014 Paints and Varnishes—Coating Materials and Coating Systems for Exterior Wood—Part 2: Performance Specification; European Committee for Standardization: Brussels, Belgium, 2014.

- CEN/TC 139/WG2 N872 Technical Specification—Draft Tensile Properties; CEN Technical Committee: Berlin, Germany, 2016.

- Arnold, A. EU–project SERVOWOOD—Improved service life prediction and test capability for wood coatings. In Proceedings of the 7th European Weathering Symposium, Naples, Italy, 16–18 September 2015; Reichert, T., Ed.; GUS: Pfinztal, Germany, 2015; pp. 149–159. [Google Scholar]

- EN 927-6:2014 Paints and Varnishes—Coating Materials and Coating Systems for Exterior Wood—Part 6: Exposure of Wood Coatings to Artificial Weathering Using Fluorescent UV Lamps and Water; European Committee for Standardization: Brussels, Belgium, 2014.

- ISO 4628-4:2016 Paints and Varnishes—Evaluation of Degradation of—Designation of Quantity and Size of Defects, and of Intensity of Uniform Changes in Appearance—Part 4: Assessment of Cracking; International Organization for Standardization: Geneva, Switzerland, January 2016.

- Malassenet, L.; George, B.; Merlin, A.; Podgorski, L. Persoz hardness: A useful property to study performance of exterior wood coatings. Int. Wood Prod. J. 2015, 6, 174–180. [Google Scholar]

- Podgorski, L.; Malassenet, L.; Reynaud, C. Variation in coating hardness during the EN 927-6 weathering test: Influence of pigmentation. In Proceedings of the International Research Group on Wood Protection, 47th Annual Meeting, Lisbon, Portugal, 15–19 May 2016. [Google Scholar]

- Sato, K. Physical significance of the pendulum hardness of coating films. J. Coat. Technol. 1984, 56, 47–57. [Google Scholar]

| Resin | Information/Recommendations on Formulation and Use (from Data Sheets) |

|---|---|

| Acrylic 1 | Dispersion; Good elasticity, especially at low temperature; For highly durable wood coatings |

| Acrylic 2 | High-gloss paints interior/exterior/wood stains |

| Alkyd 1 | Long oil alkyd emulsion; Interior/exterior primers and topcoat; Outdoor durability |

| Alkyd 2 | Alkyd dispersion; Interior/exterior stains and trim paints for wood and metals |

| Resin | UV Protection | PVC | Coating Reference |

|---|---|---|---|

| Acrylic 1 | No | Clear | 05 |

| Low | 06 | ||

| High | 07 | ||

| Yes | Clear | 11 | |

| Low | 12 | ||

| High | 13 | ||

| Acrylic 2 | No | Clear | 17 |

| Low | 18 | ||

| High | 19 | ||

| Yes | Clear | 23 | |

| Low | 24 | ||

| High | 25 | ||

| Alkyd 1 | No | Clear | 29 |

| Low | 30 | ||

| High | 31 | ||

| Yes | Clear | 35 | |

| Low | 36 | ||

| High | 37 | ||

| Alkyd 2 | No | Clear | 41 |

| Low | 42 | ||

| High | 43 | ||

| Yes | Clear | 47 | |

| Low | 48 | ||

| High | 49 |

| Additive | wt % |

|---|---|

| 2-Hydroxyphenyl-s-triazine | 3.0 |

| Amino-ether hindered amine light stabilizer | 1.5 |

| PVC | Pigment and Fillers (wt %) | ||

|---|---|---|---|

| TiO2 | Calcium Carbonate | Talc | |

| Clear | n/a | n/a | n/a |

| Low | 18 | 1.5 | 0.75 |

| High | 18 | 15 | 7.5 |

| Resin | Temperature | ||

|---|---|---|---|

| −10 °C | 20 °C | 45 °C | |

| Acrylic 1 | Ductile | Ductile | Ductile |

| Acrylic 2 | Brittle | Ductile | Ductile |

| Alkyd 1 | Brittle | Ductile | Ductile |

| Alkyd 2 | Brittle | Ductile | Ductile |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Podgorski, L.; De Meijer, M.; Lanvin, J.-D. Influence of Coating Formulation on Its Mechanical Properties and Cracking Resistance. Coatings 2017, 7, 163. https://doi.org/10.3390/coatings7100163

Podgorski L, De Meijer M, Lanvin J-D. Influence of Coating Formulation on Its Mechanical Properties and Cracking Resistance. Coatings. 2017; 7(10):163. https://doi.org/10.3390/coatings7100163

Chicago/Turabian StylePodgorski, Laurence, Mari De Meijer, and Jean-Denis Lanvin. 2017. "Influence of Coating Formulation on Its Mechanical Properties and Cracking Resistance" Coatings 7, no. 10: 163. https://doi.org/10.3390/coatings7100163