Durability Analysis and Experimental Validation of Environmental Barrier Coating (EBC) Performance Using Combined Digital Image Correlation and NDE

Abstract

:1. Introduction

2. Experimental Procedure

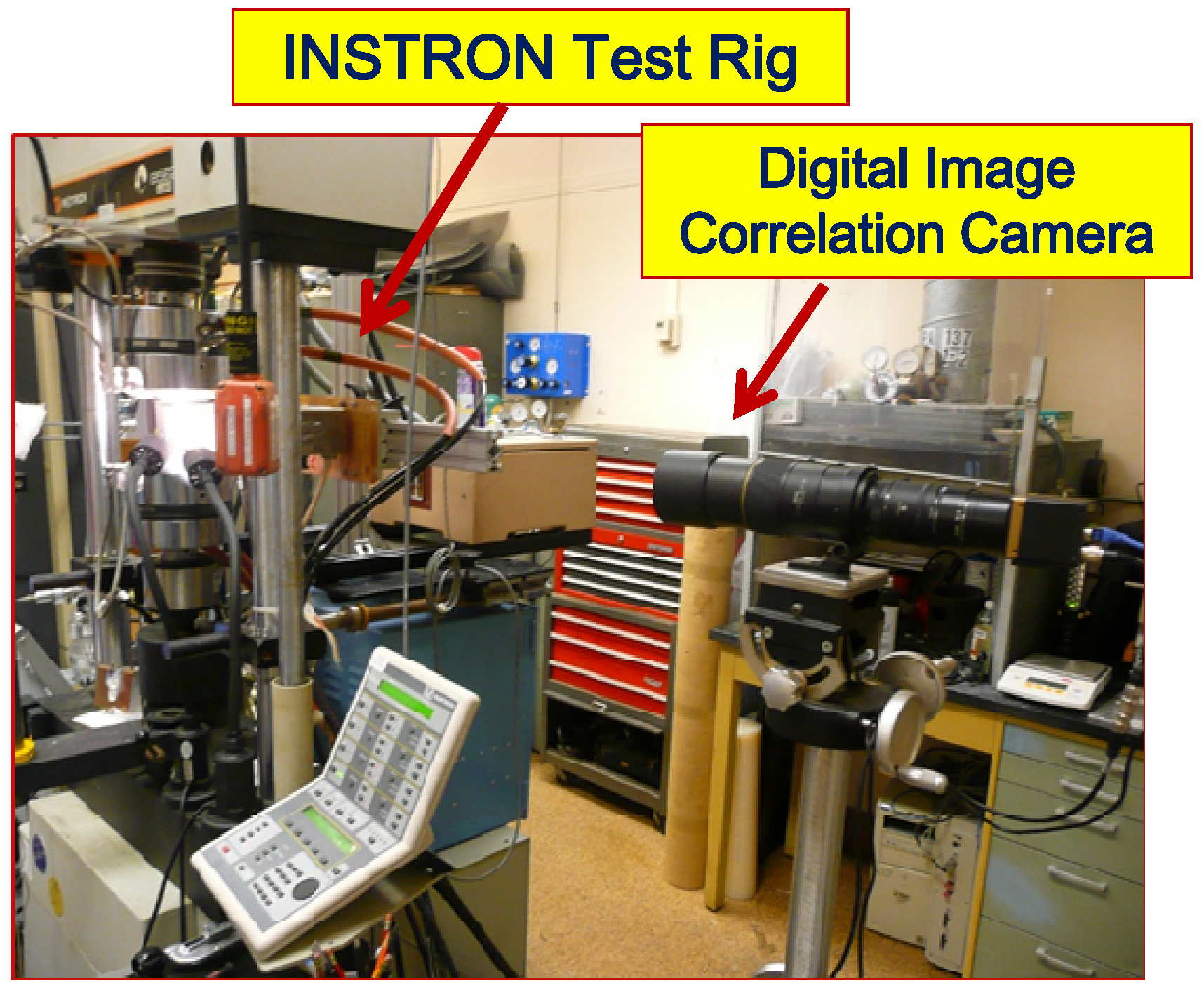

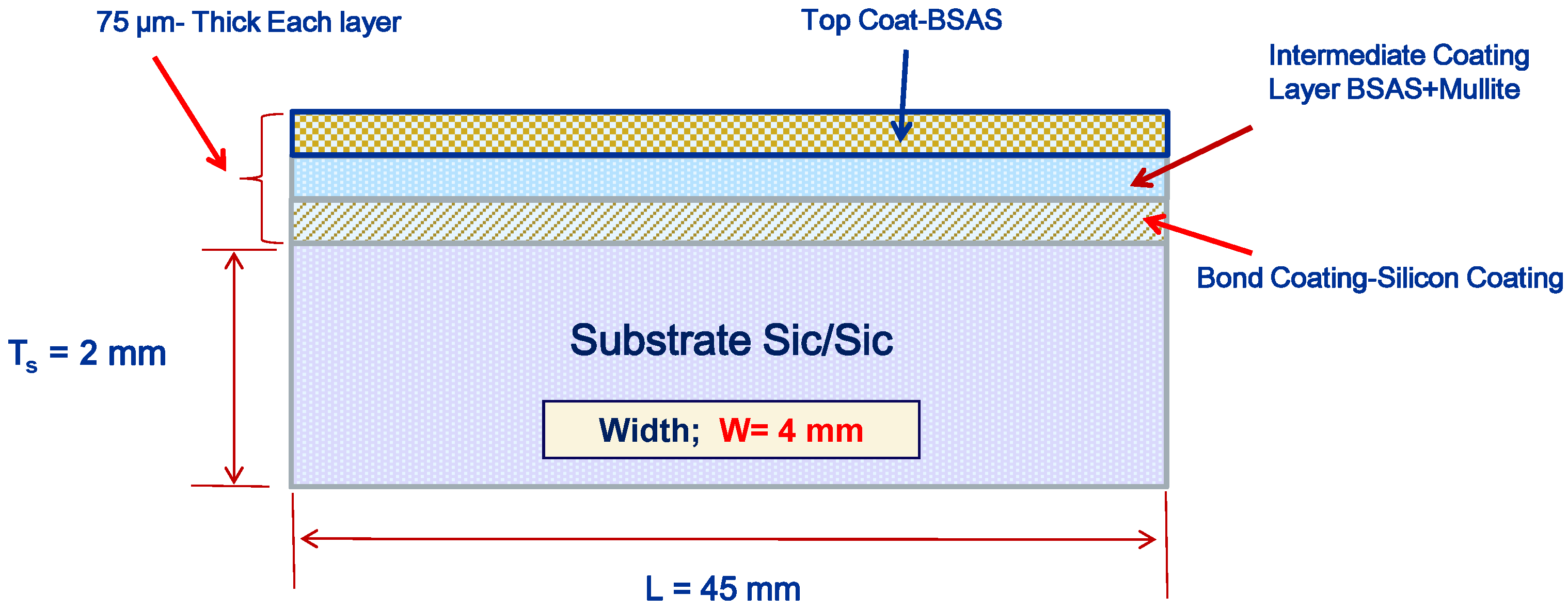

2.1. Experimental Setup and Specimen Description

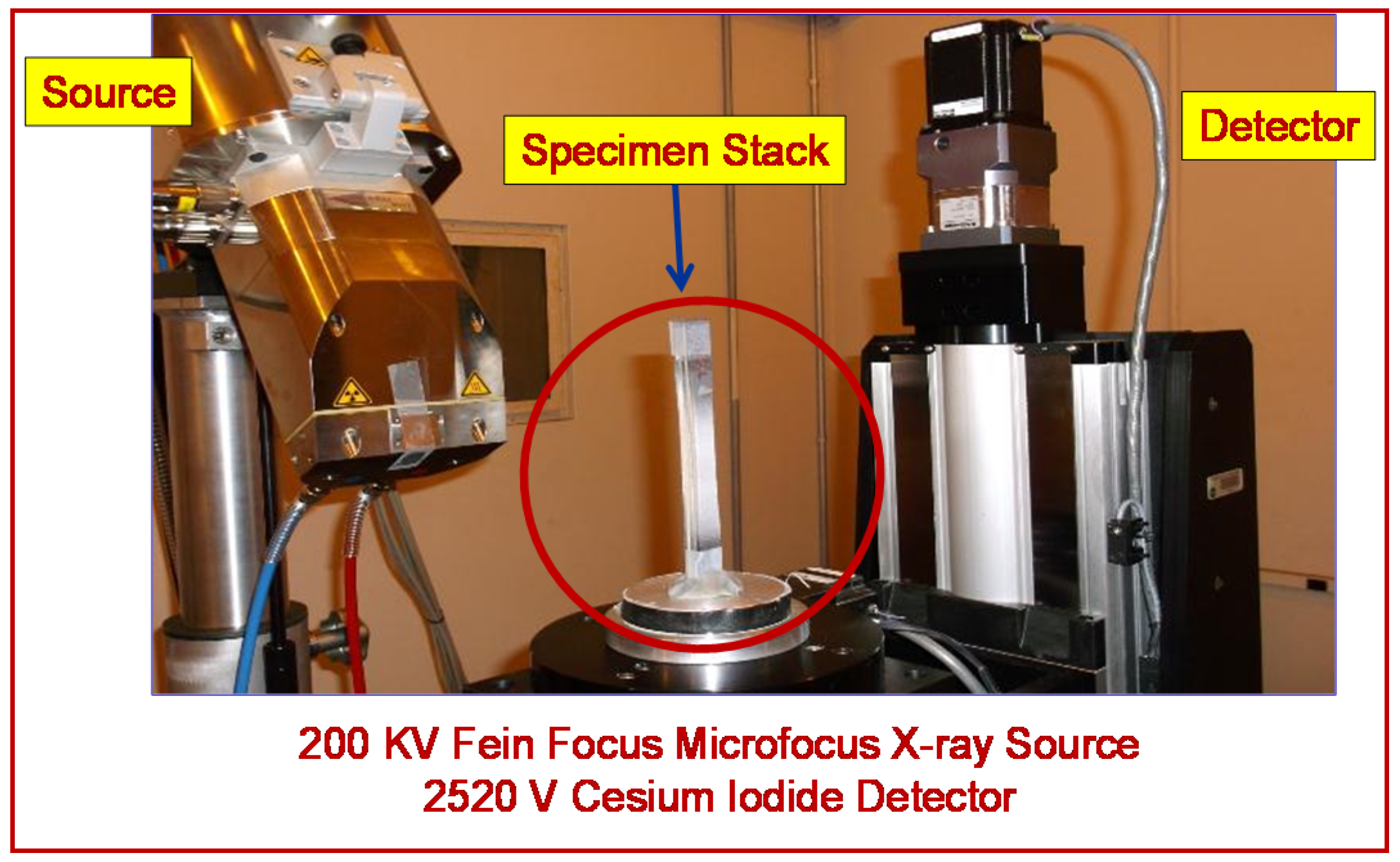

2.2. Nondestructive Evaluation (NDE) Equipment Facility

2.3. Digital Image Correlation

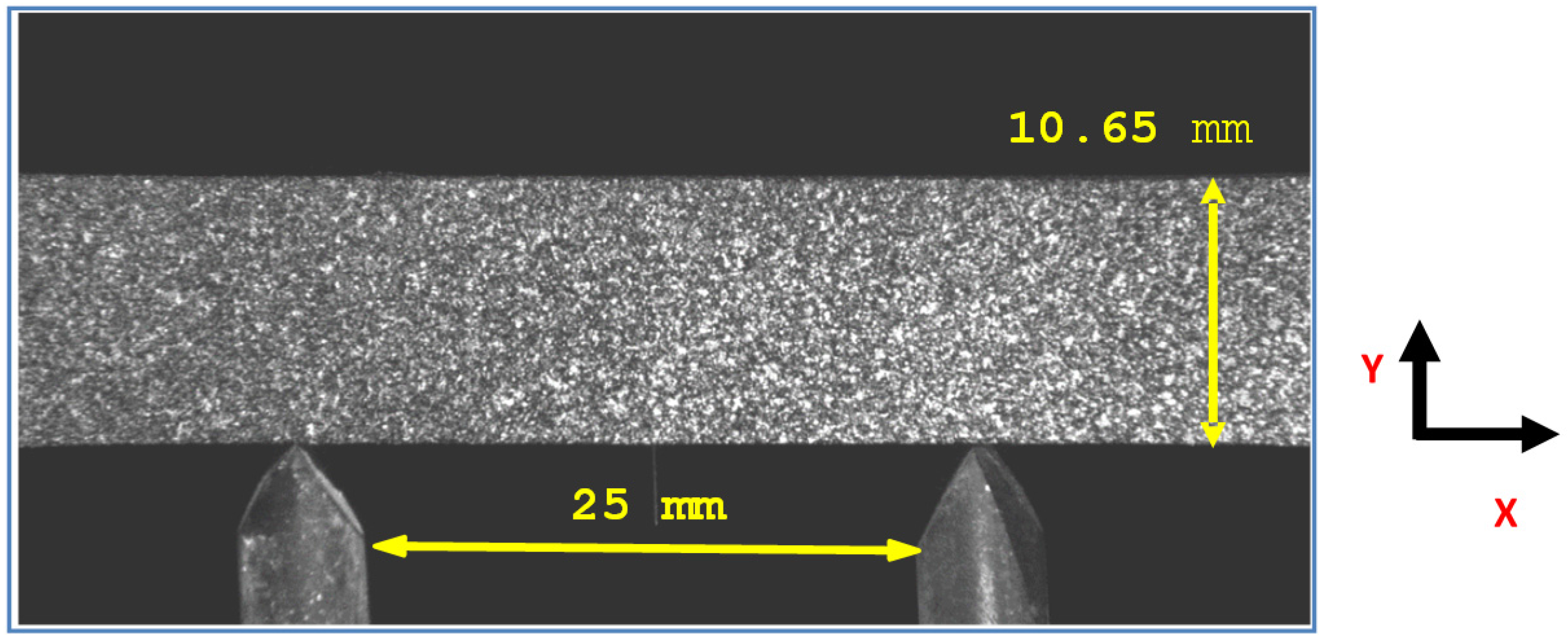

DIC Test Configuration

3. Results and Discussion

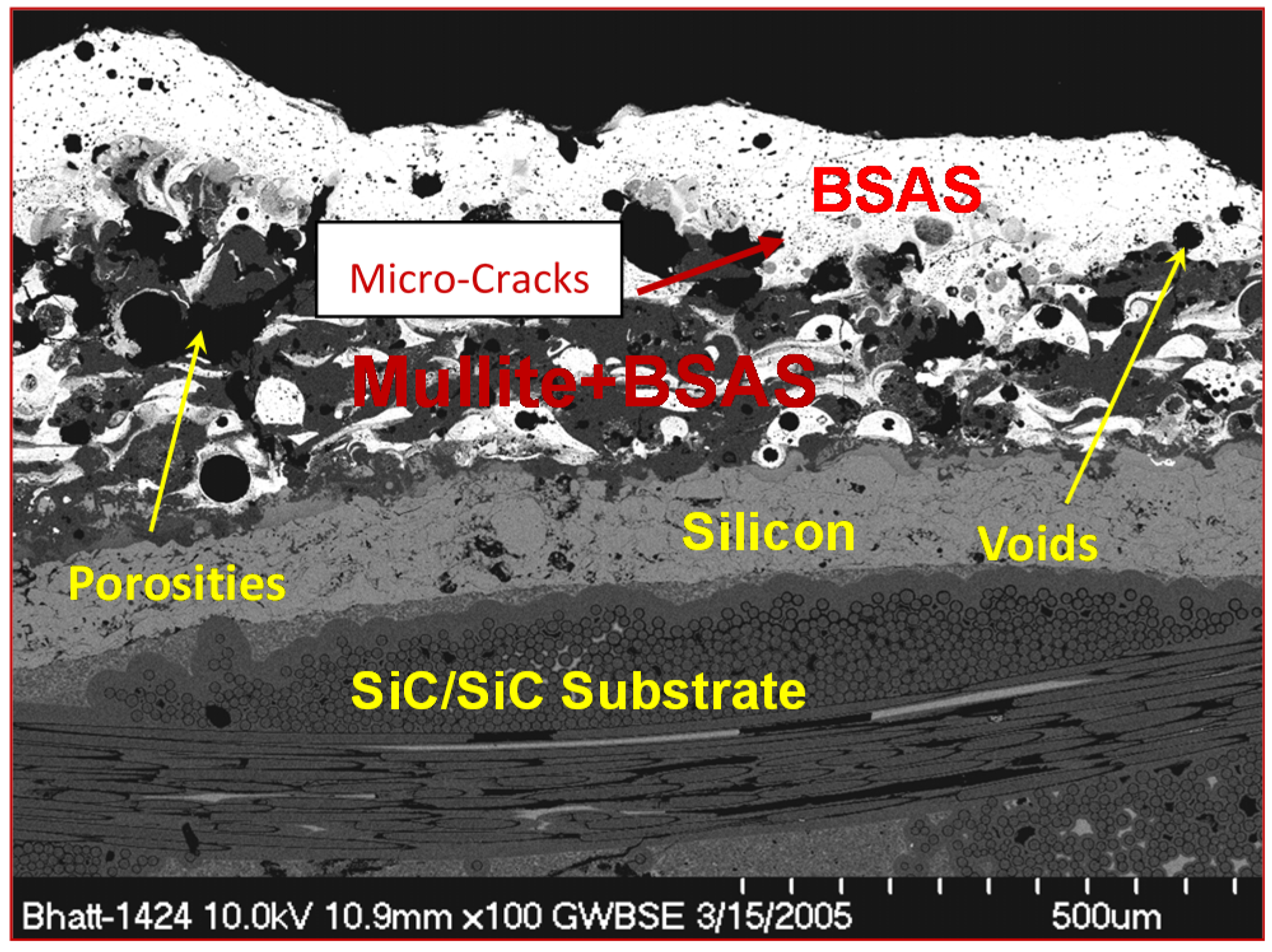

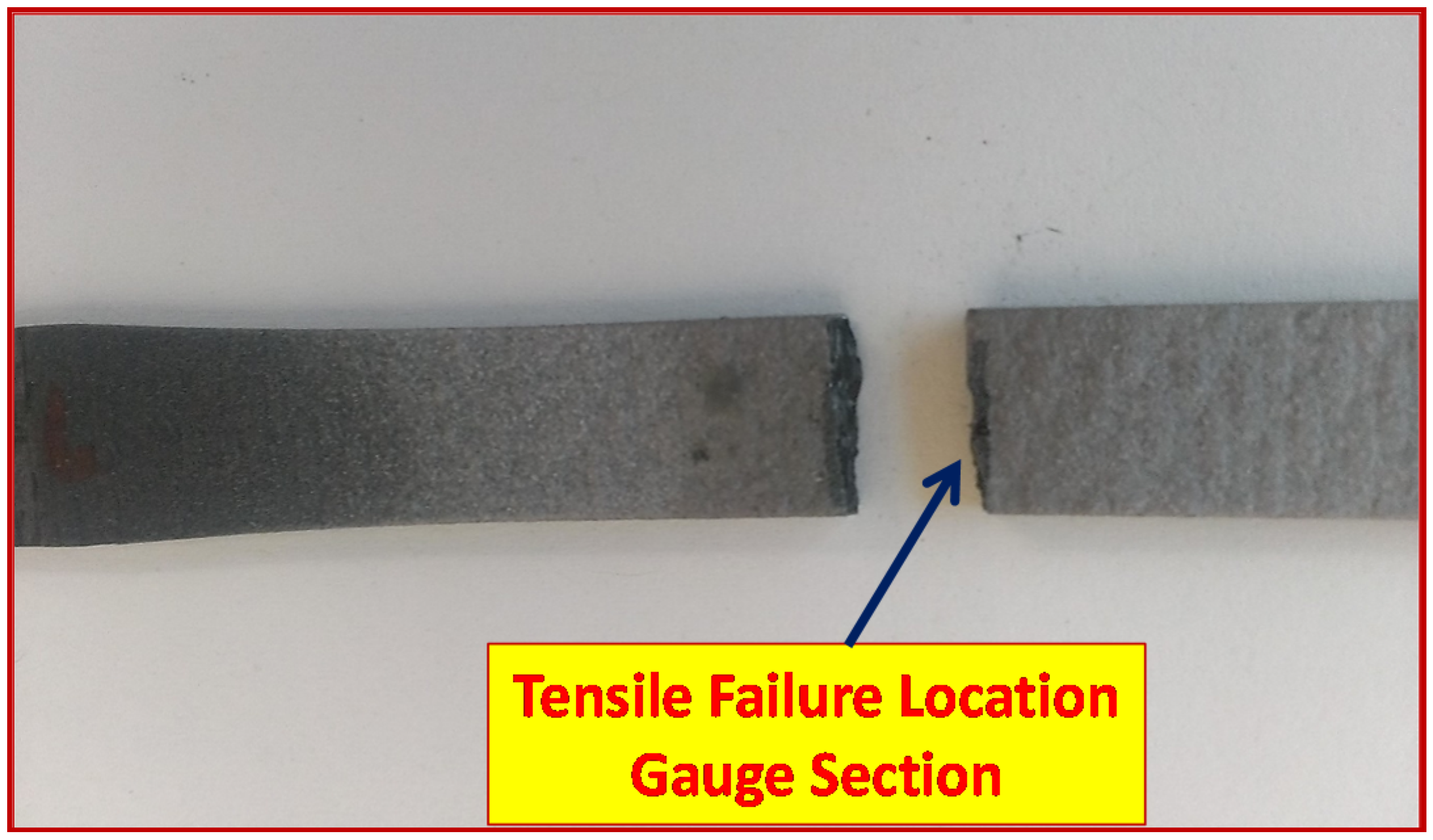

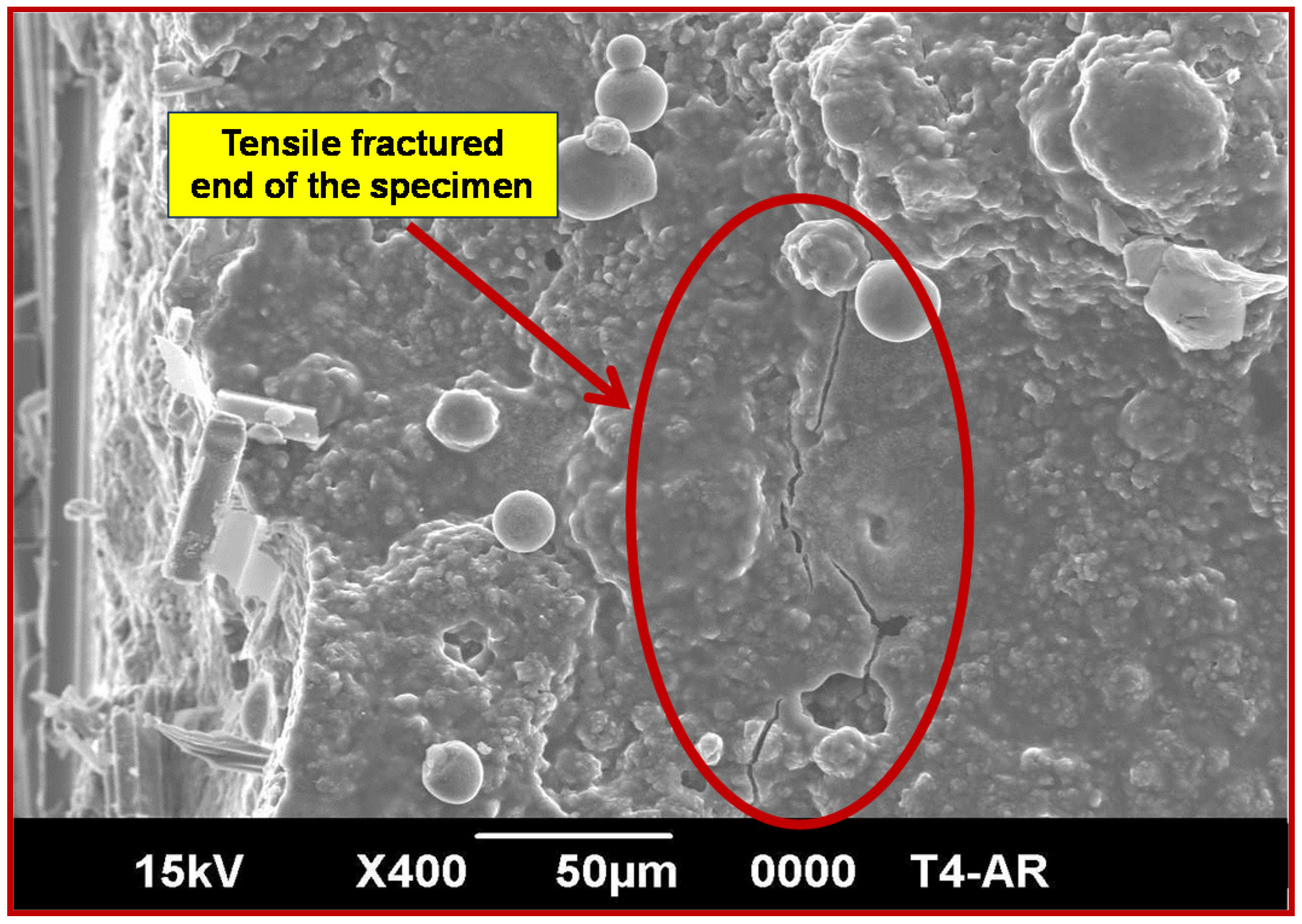

3.1. EBC Coated Dog-Bone Specimen and EBC Microstructure

3.2. NDE Results—Optical and CT Scan

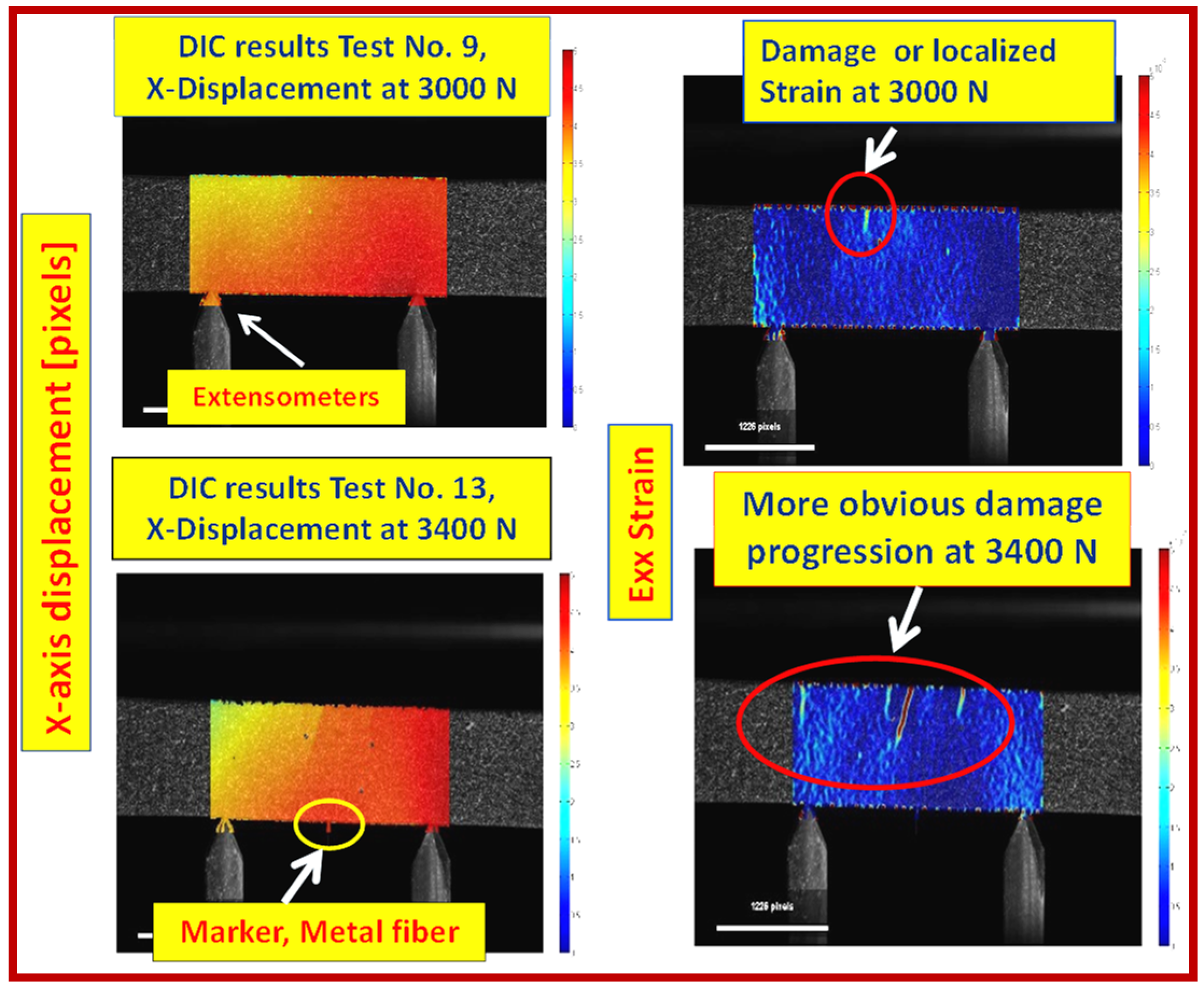

3.3. DIC Observations

4. Durability Modeling

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jorgensen, P.J.; Wadsworth, M.E.; Cutler, I.B. Oxidation of silicon carbide. J. Am. Ceram. Soc. 1959, 42, 613–616. [Google Scholar] [CrossRef]

- Smialek, J.L.; Robinson, R.C.; Opila, E.J.; Fox, D.S.; Jacobson, N.S. SiC and Si3N4 recession due to SiO2 scale volatility under combustor conditions. Adv. Compos. Mater. 1999, 8, 33–45. [Google Scholar] [CrossRef]

- Lee, K.N.; Fox, D.S.; Robinson, R.C.; Bansal, N.P. Environmental Barrier Coatings for Silicon-Based Ceramics. In High Temperature Ceramic Matrix Composites; Krenkel, W., Naslain, R., Schneider, H., Eds.; Wiley-Vch: Weinheim, Germany, 2001. [Google Scholar]

- Lee, K.N.; Fox, D.S.; Bansal, N.P. Rare Earth Environmental Barrier Coatings for SiC/SiC Composites and Si3N4 Ceramics. J. Eur. Ceram. Soc. 2005, 25, 1705–1715. [Google Scholar] [CrossRef]

- Zhu, D.M.; Bansal, N.P.; Miller, R.A. Thermal conductivity and stability of HfO2-Y2O3 and La2Zr2O7 evaluated for 1650 °C. In Proceedings of the 105th Annual Meeting and Exposition of the American Ceramic Society, Nashville, TN, USA, 27–30 April 2003.

- Lee, K.N. Current status of environmental barrier coatings for Si-based ceramics. Surf. Coat. Technol. 2000, 133, 1–7. [Google Scholar] [CrossRef]

- Abdul-Aziz, A.; Adam, C.; Wroblewski, R.T.; Bhatt, M.H.; Jaskowiak, D.G.; Richard, W.R. Assessment of NDE methods for detecting cracks and damage in environmental barrier coated CMC tested under tension. In Proceedings of SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 8 March 2015.

- Harder, B.J.; Faber, K.T. Transformation kinetics in plasma-sprayed barium-and strontium-doped aluminosilicate (BSAS). Scr. Mater. 2010, 62, 282–285. [Google Scholar] [CrossRef]

- Aparicio, M.; Duran, A. Yttrium silicate coatings for oxidation protection of carbon–silicon carbide composites. J. Am. Ceram. Soc. 2000, 83, 135–1355. [Google Scholar] [CrossRef]

- Evans, A.G.; Hutchinson, J.W. On the mechanics of delamination and spalling in compressed films. Int. J. Solids Struct. 1984, 20, 455–466. [Google Scholar] [CrossRef]

- Lee, K.N. Key durability issues with mullite-based environmental barrier coatings for Si-based ceramics. J. Eng. Gas Turbine Power 2000, 122, 632–636. [Google Scholar] [CrossRef]

- Thouless, M.D. Cracking and delamination of coatings. J. Vac. Sci. Technol. 1991, 9, 2510–2515. [Google Scholar] [CrossRef]

- Kim, C.; Heo, Y.S.; Kim, T.W.; Lee, K.S. Fabrication and characterization of zirconia thermal barrier coatings by spray drying and atmospheric plasma spraying. J. Korean Ceram. Soc. 2013, 50, 326–332. [Google Scholar] [CrossRef]

- Feng, F.J.; Lee, D.H.; Park, J.Y.; Lee, K.S. Characterization of sintered silicates for environmental barrier coating materials. J. Ceram. Proc. Res. 2016, 17, 11–16. [Google Scholar]

- Lau, S.K.; Calandra, S.J.; Ohnsorg, R.W. Process for making silicon carbide reinforced silicon carbide composite. US 5840221 A, 2 December 1996. [Google Scholar]

- PerkinElmer Medical Imaging; Perkin Elmer, Inc.: Santa Clara, CA, USA.

- Baid, H.; Christoph, S.; Himadri, S.; Ajit, M. Dispersion of Lamb waves in a honeycomb composite sandwich panel. Ultrasonics 2015, 56, 409–416. [Google Scholar] [CrossRef] [PubMed]

- Roode, M.V.; Bhattacharya, A.M.; Ferber, M.K.; Abdi, F. Creep Resistance and water vapor degradation of SiC/SiC ceramic matrix composite gas turbine hot section components. In Proceedings of ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010.

- Schreier, H.; Orteu, J.-J.; Sutton, M.A. Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications; Springer-Verlag: Boston, MA, USA, 2009. [Google Scholar]

- Morscher, G.N.; DiCarlo, J.A.; Kaiser, J.D.; Yum, H.M. Effects of Fiber Architecture on Matrix Cracking for Melt-Infiltrated SiC/SiC Composites. Int. J. Appl. Ceram. Technol. 2010, 7, 276–290. [Google Scholar] [CrossRef]

- McCormick, N.; Lord, J. Digital image correlation. Mater. Today 2010, 13, 52–54. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdul-Aziz, A.; Wroblewski, A.C. Durability Analysis and Experimental Validation of Environmental Barrier Coating (EBC) Performance Using Combined Digital Image Correlation and NDE. Coatings 2016, 6, 70. https://doi.org/10.3390/coatings6040070

Abdul-Aziz A, Wroblewski AC. Durability Analysis and Experimental Validation of Environmental Barrier Coating (EBC) Performance Using Combined Digital Image Correlation and NDE. Coatings. 2016; 6(4):70. https://doi.org/10.3390/coatings6040070

Chicago/Turabian StyleAbdul-Aziz, Ali, and Adam C. Wroblewski. 2016. "Durability Analysis and Experimental Validation of Environmental Barrier Coating (EBC) Performance Using Combined Digital Image Correlation and NDE" Coatings 6, no. 4: 70. https://doi.org/10.3390/coatings6040070