Characterization and Photovoltaic Properties of BiFeO3 Thin Films

Abstract

:1. Introduction

2. Materials and Methods

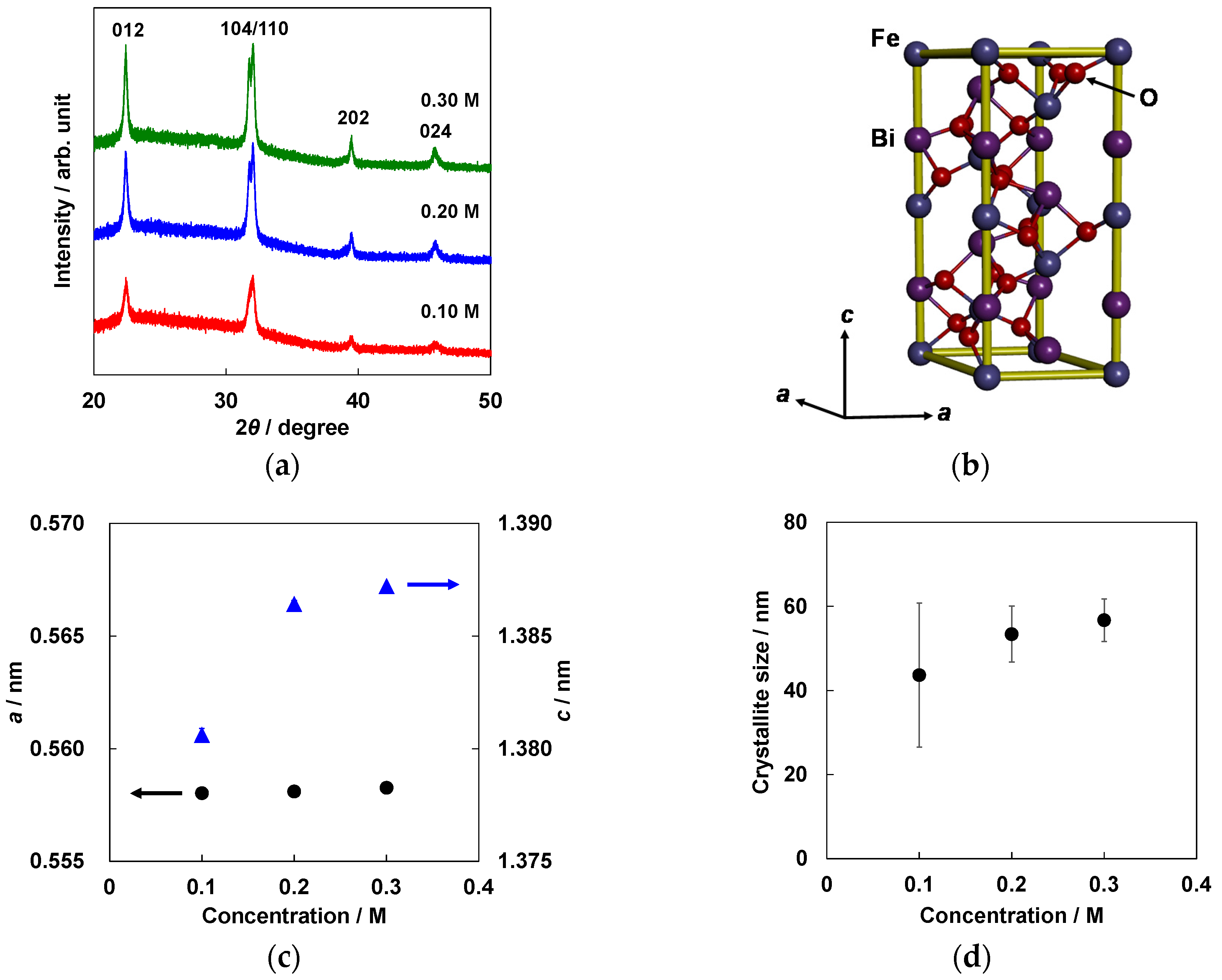

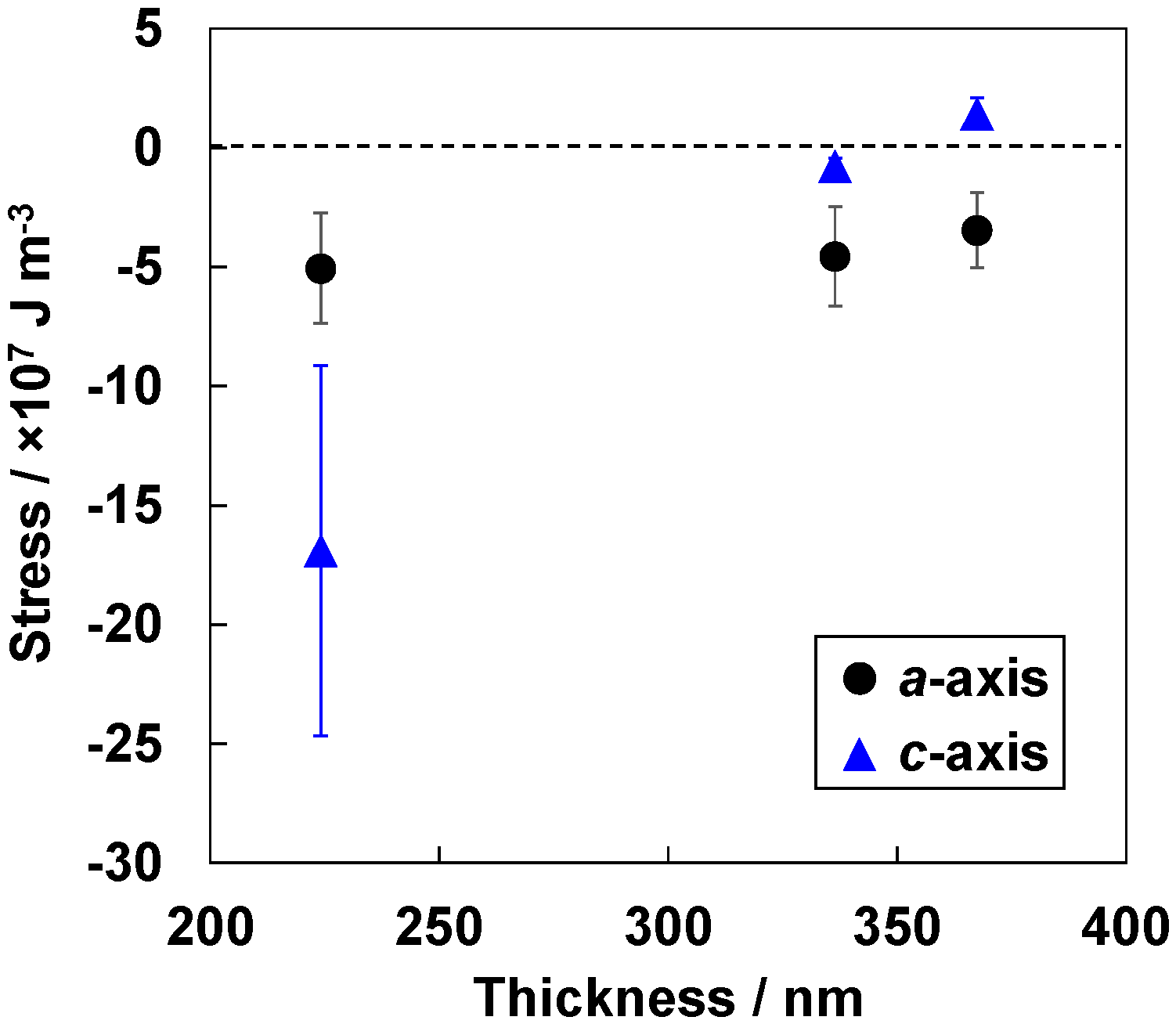

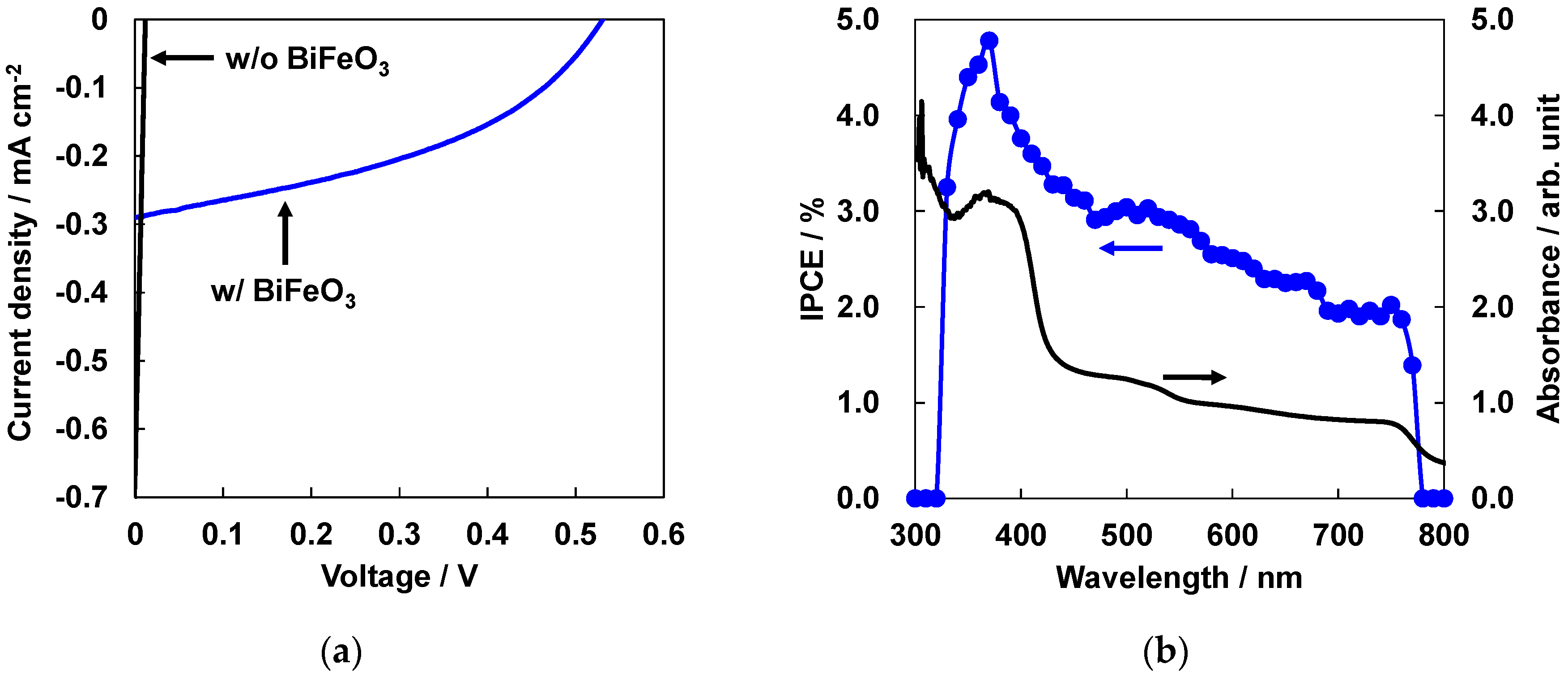

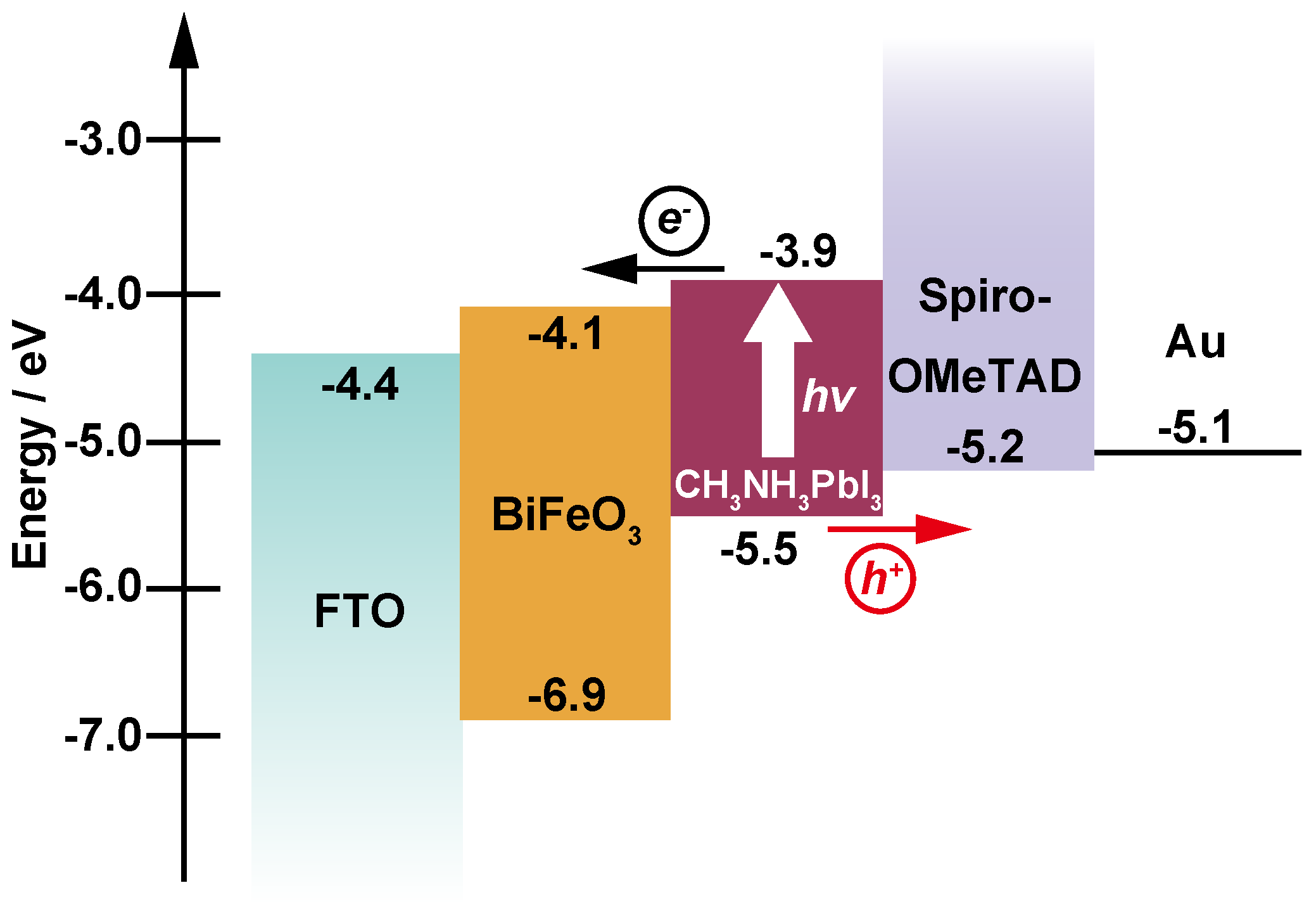

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kumar, M.M.; Palkar, V.R.; Srinivas, K.; Suryanarayana, S.V. Ferroelectricity in a pure BiFeO3 ceramic. Appl. Phys. Lett. 2000, 76, 2764–2766. [Google Scholar] [CrossRef]

- Wang, J.; Neaton, J.B.; Zheng, H.; Nagarajan, V.; Ogale, S.B.; Liu, B.; Viehland, D.; Vaithyanathan, V.; Schlom, D.G.; Waghmare, U.V.; et al. Epitaxial BiFeO3 multiferroic thin film heterostructures. Science 2003, 299, 1719–2722. [Google Scholar] [CrossRef] [PubMed]

- Zhao, T.; Scholl, A.; Zavaliche, F.; Lee, K.; Barry, M.; Doran, A.; Cruz, M.P.; Chu, Y.H.; Ederer, C.; Spaldin, N.A.; et al. Electrical control of antiferromagnetic domains in multiferroic BiFeO3 films at room temperature. Nat. Mater. 2006, 5, 823–829. [Google Scholar] [CrossRef] [PubMed]

- Allibe, J.; Fusil, S.; Bouzehouane, F.; Daumont, C.; Sando, D.; Jacquet, E.; Deranlot, C.; Bibes, M.; Barthèlèmy, A. Room temperature electrical manipulation of giant magnetoresistance in spin valves exchange-biased with BiFeO3. Nano Lett. 2012, 12, 1141–1145. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Zhuge, F.; Zhu, X.; Yin, K.; Wang, J.; Liu, Y.; He, C.; Chen, B.; Li, R.-W. Nonvolatile resistive switching in metal/La-doped BiFeO3/Pt sandwiches. Nanotechnology 2010, 21, 425202. [Google Scholar] [CrossRef] [PubMed]

- Choi, T.; Lee, S.; Choi, Y.J.; Kiryukhin, V.; Cheong, S.-W. Switchable ferroelectric diode and photovoltaic effect in BiFeO3. Science 2009, 324, 63–66. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, A.; Khan, G.G.; Chaudhuri, A.; Das, A.; Mandal, K. Multifunctional BiFeO3/TiO2 nano-heterostructure: Photo-ferroelectricity, rectifying transport, and nonvolatile resistive switching property. Appl. Phys. Lett. 2016, 108, 033112. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, F. Photovoltaic effect of BiFeO3/poly(3-hexylthiophene) heterojunction. Phys. Status Solidi RRL 2011, 5, 367–369. [Google Scholar] [CrossRef]

- Zhao, P.; Bian, L.; Wang, L.; Xu, J.; Chang, A. Enhanced open voltage of BiFeO3 polycrystalline film by surface modification of organolead halide perovskite. Appl. Phys. Lett. 2014, 105, 013901. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, W.; Xu, X.; Wang, Y.; Yuan, G.; Wang, Y.; Liu, Z. The enhanced photocurrent of epitaxial BiFeO3 film at 130 °C. J. Appl. Phys. 2016, 119, 044102. [Google Scholar] [CrossRef]

- Chakrabartty, J.; Nechache, R.; Harnagea, C.; Li, S.; Rosei, F. Enhanced photovoltaic properties in bilayer BiFeO3/Bi-Mn-O thin films. Nanotechnology 2016, 27, 215402. [Google Scholar] [CrossRef] [PubMed]

- Kojima, A.; Teshima, K.; Shirai, Y.; Miyasaka, T. Organometal Halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc. 2009, 131, 6050–6051. [Google Scholar] [CrossRef] [PubMed]

- Im, J.-H.; Lee, C.-R.; Lee, J.-W.; Park, S.-W.; Park, N.-G. 6.5% efficient perovskite quantum-dot-sensitized solar cell. Nanoscele 2011, 3, 4088–4093. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-S.; Lee, C.-R.; Im, J.-H.; Lee, K.-B.; Moehl, T.; Marchioro, A.; Moon, S.-J.; Humphry-Baker, R.; Yum, J.-H.; Moser, J.E.; et al. Lead iodide perovskite sensitized all-solid-state submicron thin film mesoscopic solar cell with efficiency exceeding 9%. Sci. Rep. 2012, 2, 591. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-S.; Lee, L.-W.; Yantara, N.; Boix, P.P.; Kulkarni, S.A.; Mhaisalkar, S.; Grätzel, M.; Park, N.-G. High efficiency solid-state sensitized solar cell-based on submicrometer rutile TiO2 nanorods and CH3NH3PbI3 perovskite sensitizer. Nano Lett. 2013, 13, 2412–2417. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Chen, Q.; Li, G.; Luo, S.; Song, T.-B.; Duan, H.-S.; Hong, Z.; You, J.; Liu, Y.; Yang, Y. Interface engineering of highly efficient perovskite solar cells. Science 2014, 345, 542–546. [Google Scholar] [CrossRef] [PubMed]

- Jeon, N.J.; Noh, J.H.; Yang, W.S.; Kim, Y.C.; Ryu, S.; Seo, J.; Seok, S.I. Compositional engineering of perovskite materials for high-performance solar cells. Nature 2015, 517, 476–480. [Google Scholar] [CrossRef] [PubMed]

- Bi, D.; Yi, C.; Luo, J.; Décoppet, J.-D.; Zhang, F.; Zakeeruddin, S.M.; Li, X.; Hagfeldt, A.; Grätzel, M. Polymer-templated nucleation and crystal growth of perovskite films for solar cells with efficiency greater than 21%. Nat. Energy 2016, 1, 16142. [Google Scholar] [CrossRef]

- Chart of Best Research-Cell Efficiencies provided by National Renewable Energy Laboratory. Available online: http://www.nrel.gov/pv/assets/images/efficiency_chart.jpg (accessed on 2 December 2016).

- Wang, Y.; Jiang, Q.-H.; He, H.-C.; Nan, C.-W. Multiferroic BiFeO3 thin films prepared via a simple sol-gel method. Appl. Phys. Lett. 2006, 88, 142503. [Google Scholar] [CrossRef]

- Wu, F.; Guo, Y.; Zhang, Y.; Duan, H.; Li, H.; Liu, H. Enhanced photovoltaic performance in polycrystalline BiFeO3 thin film/ZnO nanorod heterojunctions. J. Phys. Chem. C 2014, 118, 15200–15206. [Google Scholar] [CrossRef]

- Noh, J.H.; Im, S.H.; Heo, J.H.; Mandal, T.N.; Seok, S.I. Chemical management for colorful, efficient, and stable inorganic-organic hybrid nanostructured solar cells. Nano Lett. 2013, 13, 1764–1769. [Google Scholar] [CrossRef] [PubMed]

- Shirahata, Y.; Suzuki, A.; Oku, T. Fabrication and characterization of bismuth ferrite as an electron transport layer in perovskite photovoltaic devices. J. Ceram. Soc. Jpn. 2016, 124, 602–605. [Google Scholar] [CrossRef]

- Oku, T.; Zushi, M.; Imanishi, Y.; Suzuki, A.; Suzuki, K. Microstructures and photovoltaic properties of perovskite-type CH3NH3PbI3 compounds. Appl. Phys. Express 2014, 7, 121601. [Google Scholar] [CrossRef]

- Zushi, M.; Suzuki, A.; Akiyama, T.; Oku, T. Fabrication and characterization of TiO2/CH3NH3PbI3-based photovoltaic devices. Chem. Lett. 2014, 43, 916–918. [Google Scholar] [CrossRef]

- Suzuki, A.; Okada, H.; Oku, T. Fabrication and characterization of CH3NH3PbI3−x−yBrxCly perovskite solar cells. Energies 2016, 9, 346. [Google Scholar] [CrossRef]

- Oku, T.; Suzuki, K.; Suzuki, A. Effects of chlorine addition to perovskite-type CH3NH3PbI3 photovoltaic devices. J. Ceram. Soc. Jpn. 2016, 124, 234–238. [Google Scholar] [CrossRef]

- Oku, T.; Ohishi, Y.; Suzuki, A. Effects of antimony addition to perovskite-type CH3NH3PbI3 photovoltaic devices. Chem. Lett. 2016, 45, 134–136. [Google Scholar] [CrossRef]

- Ohishi, Y.; Oku, T.; Suzuki, A. Fabrication and characterization of perovskite-based CH3NH3Pb1-xGexI3, CH3NH3Pb1-xTlxI3 and CH3NH3Pb1-xInxI3 photovoltaic devices. AIP Conf. Proc. 2016, 1709, 020020. [Google Scholar]

- Shi, D.; Qin, X.; Li, Y.; He, Y.; Zhong, C.; Pan, J.; Dong, H.; Xu, W.; Li, T.; Hu, W.; Brédas, J.-L.; Bakr, O.M. Spiro-OMeTAD single crystals: Remarkably enhanced charge-carrier transport via mesoscale ordering. Sci. Adv. 2016, 2, e1501491. [Google Scholar] [CrossRef] [PubMed]

- Kubel, H.; Schmid, H. Structure of a ferroelectric and ferroelastic monodomain crystal of the perovskite BiFeO3. Acta Cryst. 1990, B46, 698–702. [Google Scholar] [CrossRef]

- Tang, X.; Dai, J.; Zhu, X.; Yin, L.; Ang, Y.; Song, W.; Yang, Z.; Sun, Y.; Zhang, R. Individual-layer thickness effects on the preferred c-axis-oriented BiFeO3 films by chemical solution deposition. J. Am. Ceram. Soc. 2010, 93, 1682–1687. [Google Scholar]

- Polomska, M.; Kaczmarek, W.; Pająk, Z. Electric and magnetic properties of (Bi1−xLax)FeO3 solid solutions. Phys. Stat. Solidi (a) 1974, 23, 567–574. [Google Scholar] [CrossRef]

- Inorganic Material Database of National Institute for Materials Science. Available online: http://crystdb.nims.go.jp/index_en.html (accessed on 2 December 2016).

- Gao, F.; Chen, X.; Yin, K.; Dong, S.; Ren, Z.; Yuan, F.; Yu, T.; Zou, Z.; Liu, J.-M. Visible-light photocatalytic properties of weak magnetic BiFeO3 nanoparticles. Adv. Mater. 2007, 19, 2889–2892. [Google Scholar] [CrossRef]

- Keskin, V.; Gupta, A.; Szulczewski, G. Solution processed TiO2/BiFeO3/poly(3-hexylthiophene) solar cells. Mater. Lett. 2015, 159, 305–308. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Z.; Zeng, J.; Yan, J.; Shi, D.; Liu, H. Photovoltaic effects in polarized polycrystalline BiFeO3 films. J. Electron. Mater. 2015, 44, 4207–4212. [Google Scholar] [CrossRef]

- Xu, X.; Lin, Y.-H.; Li, P.; Shu, L.; Nan, C.-W. Synthesis and photocatalytic behaviors of high surface area BiFeO3 thin films. J. Am. Ceram. Soc. 2011, 94, 2296–2299. [Google Scholar] [CrossRef]

- Sen, P.; Dey, A.; Mukhopadhyay, A.K.; Bandyopadhyay, S.K.; Himanshu, A.K. Nano indentation behaviour of nano BiFeO3. Ceram. Int. 2012, 38, 1347–1352. [Google Scholar] [CrossRef]

- Zhao, X.; Park, N.-G. Stability issues on perovskite solar cells. Photonics 2015, 2, 1139–1151. [Google Scholar] [CrossRef]

- Scharber, M.C.; Mühlbacher, D.; Koppe, M.; Denk, P.; Waldauf, C.; Heeger, A.J.; Brabec, C. Design rules for donors in bulk-heterojunction solar cells—Towards 10 % energy-conversion efficiency. Adv. Mater. 2006, 18, 789–794. [Google Scholar] [CrossRef]

- Kim, H.D.; Ohkita, H.; Benten, H.; Ito, S. Photovoltaic performance of Perovskite Solar Cells with Different Grain Sizes. Adv. Mater. 2016, 28, 917–922. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shirahata, Y.; Oku, T. Characterization and Photovoltaic Properties of BiFeO3 Thin Films. Coatings 2016, 6, 68. https://doi.org/10.3390/coatings6040068

Shirahata Y, Oku T. Characterization and Photovoltaic Properties of BiFeO3 Thin Films. Coatings. 2016; 6(4):68. https://doi.org/10.3390/coatings6040068

Chicago/Turabian StyleShirahata, Yasuhiro, and Takeo Oku. 2016. "Characterization and Photovoltaic Properties of BiFeO3 Thin Films" Coatings 6, no. 4: 68. https://doi.org/10.3390/coatings6040068