1. Introduction

There is a long-standing desire for an exterior clear coating that will maintain wood’s attractive natural appearance and protect it from environmental degradation. However, the performance of clear coatings on wood has been so poor that they are not recommended for the finishing of exterior wood unless regular maintenance is carried out [

1]. For example, the California Redwood Association initiated a large scale testing program of clear coatings in the 1950s [

2]. They tested close to 200 different commercially available clear finishes, of which only a handful were listed as possible candidates for the finishing of redwood (

Sequoia sempervirens (D. Don) Endl.). These “listed” finishes failed within twenty months of outdoor exposure, and the poorer (unlisted) systems failed within 6 to 9 months. Because of these disappointing findings, the California Redwood Association stopped recommending clear finishes for redwood used outdoors. Subsequent testing in several countries have confirmed the poor performance of clear coatings on wood exposed outdoors—most fail within 2 years in temperate climates, and failure within a year is common in tropical climates [

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20].

Clear finishes perform badly in comparison to opaque coatings because the clear-coat transmits light, which leads to photodegradation of the underlying wood and failure of the coating by the loss of adhesion [

21]. Hence, the most obvious way to improve the performance of clear coatings on wood is to photostabilize the wood surface before applying clear coats. Numerous studies using a variety of photostabilizers have confirmed the veracity of such an approach [

11,

12,

15,

17,

18,

19]. Indeed, the best photoprotective systems can easily double the lifetime of clear coatings on wood, but such an increase falls short of what is needed. Hence, it is clear that alternative approaches will be needed if the large market demand for durable clear coatings for wood is ever going to be met. One possible approach is to improve each feature of the wood-clear coating system that influences performance to develop a system with far greater longevity. This approach, known as the aggregation of marginal gains “seeks to translate the additive impact of multiple small improvements into a significant overall gain in performance” [

22]. It is producing remarkable increases in the performance of complex systems, for example, the performance of athletes or outcomes for patients undergoing medical therapies [

23,

24]. Perhaps it could produce similar beneficial effects on the performance of clear coatings on wood? In this paper, we test this hypothesis by focusing on five factors that our review of the literature identified as having significant effects on the durability of clear coatings exposed to the weather [

3]. These factors are wood’s photostability and dimensional stability, moisture ingress via end-grain, coating flexibility and photostability, and coating thickness. Preliminary research was performed to select effective wood pre-treatments and durable clear-coatings. We then tested the performance of the coating systems with good solutions to each of the aforementioned issues. The best coating systems on radiata pine are still performing well after 4 years of outdoor exposure. We conclude that our approach shows promise. Future research will build on the current work by developing solutions to additional factors that influence the performance of exterior clear coatings.

3. Materials and Methods

3.1. Experimental Design and Statistical Analyses

Factorial principles were used to design an experiment that examined the performance of different coating systems on test panels exposed to natural weathering. Red oak (Quercus rubra L.) and radiata pine (Pinus radiata D. Don) panels were cut from four parent wood samples. Panels cut from each parent wood sample were randomly allocated to the four different chemical pre-treatments (including the control treated with water), and the four coatings (4 parent wood samples × 2 species × 4 pre-treatments × 4 coatings = 128 panels in total). This approach provided replication at the higher level (4 blocks), and made it possible to analyze data using analysis of variance (ANOVA) for a randomized block design. All statistical computation including model checking to ensure that data met the assumptions of ANOVA (normality and constant variance) was performed using Genstat (v. 18). Results are presented in graphs and error bars on each graph (least significant difference, LSD) can be used to estimate whether differences between individual means are statistically significant (p < 0.05).

3.2. Wood Panels

Four defect-free, quarter-sawn, radiata pine 2 × 4’s were purchased from an Australian big box store (Bunnings, Tuggeranong, Canberra, Australia), and a similar number of quarter-sawn red oak boards were purchased from a timber merchant (P.J. White, Vancouver, Canada). Quarter-sawn boards were preferred because they are less susceptible to checking and distortion than flat-sawn boards. The parent pine and oak boards were stored in a conditioned environment at 20 ± 1 °C and 65% ± 5% relative humidity (r.h.) for 1 month. Panels of each species measuring 150 mm (length) × 70 mm (width) × 10 mm (thickness) were cut from parent boards using a table saw and planed to a final thickness of 8 mm using a rotary planer. Panels were re-conditioned as above and weighed. Their dimensions were measured with a digital caliper and their air-dry densities were calculated. The number of growth rings visible on the end-grain of the panels were also counted (

Table 2).

3.3. Synthesis and Analysis of Low Molecular Weight PF Resin Photostabilizer

The objective of resin synthesis was to develop a low molecular weight, low formaldehyde/phenol (F/P) molar ratio resin suitable for use as a photostabilizer for wood. Our aim was to develop a resin with a high content of low molecular weight phenolic species (hydroxymethylphenols) that could easily penetrate solid wood and absorb UV radiation. Technical grade 90% P (aq.) or industrial grade 99.7% P (at 60–70 °C), industrial grade 52% F (aq.) (stored at 60–70 °C), industrial grade 50% NaOH (aq.), and tap water were used for the syntheses of the resins. The resins were formulated as: (1) an F/P molar ratio of 1.5–2.0; (2) an NaOH to P molar ratio of 0.10–0.15, and; (3) containing 40%–45% total water. The total formulated amounts of phenol solution and water were added to a heat resistant glass reactor (4 L) equipped with agitation, cooling coils, heating jacket, and automatic temperature control capabilities. The resulting mixture was milky white. The NaOH solution was then added to the reactor over a period of 5 min while the temperature of the resulting clear sodium phenoxide solution was adjusted to 40–50 °C. After the temperature of the sodium phenoxide solution was adjusted to 50 °C (if necessary), the formaldehyde solution was then added to the reactor at a rate of 34–40 g/min. During the initial 5–15 min of the formaldehyde addition, the contents of the reactor were allowed to exotherm to 55–65 °C, after which point the temperature was held at 55–65 °C. After the completion of the formaldehyde addition, the reaction solution was allowed to rise to 75–85 °C at a rate of 1.0–1.5 °C/min. The contents of the reactor were then cooled to 55–65 °C and held at a constant temperature for 2 h. The resulting PF resin was then cooled to 25 °C. The resin was analyzed (post-manufacture) to determine its chemical and physical properties. Viscosity was measured via the Gardner-Holdt method at 25 °C and was converted to and reported in Centistokes (

Table 3). The gel time of the resin was evaluated with 10 g of resin in a glass test tube at 100 °C until gelation occurred. The content of free F was determined by the hydroxylamine HCl titration method. The content of free P was determined by gas chromatography. The non-quantitative phenolic speciation was conducted on a Waters Alliance 2690 HPLC solvent delivery system with Waters 2487 variable UV detector and a Waters C18 column. Physical and chemical specification ranges of the resin are listed in

Table 3. The resin had “infinite” water tolerance properties. Its unreacted phenol content was much higher than its unreacted formaldehyde contents. The resins’ infinite water dilutability characteristics allow for them to be diluted if necessary, in which case the overall unreacted phenol and formaldehyde contents of the resins would be reduced.

HPLC results indicated that the resin contained significant amounts of the following substituted phenols: 13.39% 2-hydroxy methylphenol; 8.82% 4-hydroxy methylphenol; 5.26% 2,6-dihydroxy methylphenol; and 41.55% 2,4-dihydroxy methylphenol, and 2,4,6-trihydroxy methylphenol. PF resin was stored in plastic containers and frozen. The containers were thawed, and the PF was diluted with distilled water and used and/or modified by adding a water soluble HALS, Lignostab® 1198 as required. Four different treatment solutions were prepared: (1) 20% PF resin solution and 2% HALS (PFH 20); (2) 30% PF resin solution and 2% HALS (PFH 30); (3) 30% PF resin solution (PF 30); (4) Distilled water (UNT).

3.4. Treatment and Coating of Red Oak and Radiata Pine Panels

One hundred and twenty eight conditioned and pre-weighed oak and pine panels were vacuum (15 min) and pressure (30 min at 827 kPa) impregnated with the three different PF resin solutions, and water (mentioned above). Treated panels were placed on an inclined rack for 5 min to allow excess PF resin solution to drain from the panels, and were then weighed. They were individually wrapped in thin PVC film and stored for 2 days in a conditioning room at 20 ± 1 °C and 65 ± 5% r.h. The PVC film was removed from the panels and they were air dried in a conditioning room for 5 days. The panels were placed in an oven at 140 °C (1 h), followed by an additional hour of curing in an oven at 160 °C. Panels were removed from the oven, allowed to cool, and were then weighed. Panels were then conditioned for 3 days, scuff-sanded with 220 grit abrasive paper to remove raised grain, and coated with the following four different clear finishes: (1) Flexible water-based acrylic (Akzo Nobel, Malmö, Sweden) with double the normal level of UV stabilizers (the same finish that performed well in the first trial, above); (2) Flexible water-based alkyd (Akzo Nobel, Malmö, Sweden) that performed well in the first trial, above; (3) Water-based spar urethane varnish (C74404 gloss, Old Masters, Orange City, FL, USA); (4) Solvent-based spar varnish (C92304 satin, Old Masters, Orange City, FL, USA). Panels were coated with the different clear finishes using a gravity feed spray gun (Devilbiss EXL-HVLP, 1.8 mm tip size). Coatings were allowed to cure after they were applied to the panels (according to the manufacturers’ instructions), and they were then scuff-sanded with 220 grit abrasive paper. Five coats of each finish were sprayed onto each of the panels, with sanding between coats. The dry thickness (Mils) of acrylic, alkyd, water-based spar urethane, and solvent-based spar varnish on pine were 8.1, 9.9, 5.2, and 8.4, respectively. Comparable coating thickness figures for oak panels were 7.9, 9.2, 5.3, and 7.3, respectively. The back and edges of each coated panel were sealed using a sheet of aluminium foil (90 mm × 174 mm), which was then primed and top-coated with white acrylic enamel paint (Behr Premium Plus 436 Ultrapure satin enamel primer and Behr Premium Plus 9050 Ultrapure exterior satin enamel topcoat, Santa Ana, CA, USA).

3.5. Measurement of Penetration of PF Resin into Wood Panels and Effects of Treatment on Weight Gains and Dimensional Stability of Panels

Thirty pre-weighed red oak and radiata pine panels cut from the same parent boards as those used to prepare panels for the coating trials were treated with the different PF resin solutions or water and weighed, as above. Panels were wrapped in PVC film and stored for two days in a conditioning room, as above. One complete set of treated oak and pine panels (eight in total) were then cross-cut using a small table saw with a 1 mm kerf (Byrnes 4” table saw, Orlando, FL, USA) into two samples of the same size. The remaining panels were air dried and then placed in an oven to cure the PF resin, and weighed, as above. The penetration of PF resin into the panels was assessed by brushing a fresh aqueous solution of ferric chloride (10%

w/w) onto the end-grain that was revealed when treated panels were cross-cut into two samples. The ferric chloride reacted with the uncured PF resin to produce a blue-black colour, which was more intense in areas that contained PF resin. The ends of each of the samples were scanned using a desktop scanner. The resulting images showed complete penetration of PF resin in the panels, but the penetration of the PF resin into the different tissues in the oak and pine panels was not uniform (

Figure 6).

Pine and oak panels containing cured PF resin were weighed and conditioned at 20 ± 1 °C and 65 ± 5% r.h. for 3 days. The weight gain of the panels as a result of treatment was then calculated (

Table 4). The thickness of each panel was measured in four places using a digital caliper. Panels were immersed in water for 72 h and the thickness of each panel was re-measured. The percentage increase in thickness of the PF resin treated panels and water-treated controls was calculated (

Table 4).

3.6. Exposure of Treated and Coated Panels to the Weather and Assessment of Coating Performance

Clear-coated and sealed panels were placed on a weathering rack inclined at 45° to the vertical and exposed outdoors facing south on the campus of UBC on 26 August 2011. The panels were removed from the weathering rack, each year, conditioned for a minimum of one week, and scanned using a desktop scanner. Scanned images were loaded into the image analysis program, Image J. This program was used to assess the area of clear coating affected by defects that could be manually thresholded because they were darker (cracks in the coating and underlying wood; black fungal discolouration associated with cracks in the coating; water damage/marking) or lighter (photo-bleaching) than the coated wood surface. Following assessment of the panels, any damage to the edge seals on the panels was repaired using a two-part marine epoxy adhesive, and the panels were returned to the weathering rack.

4. Results

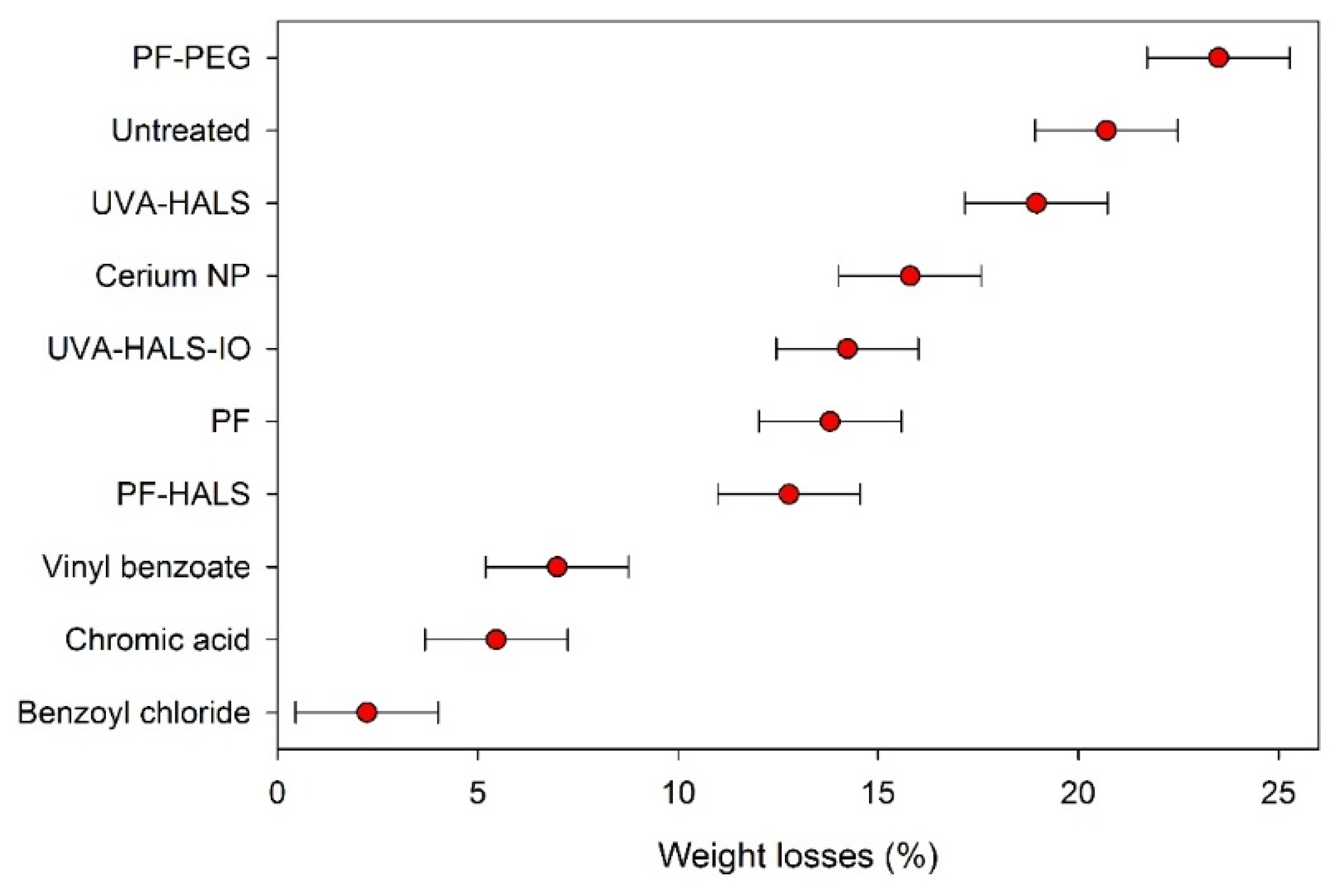

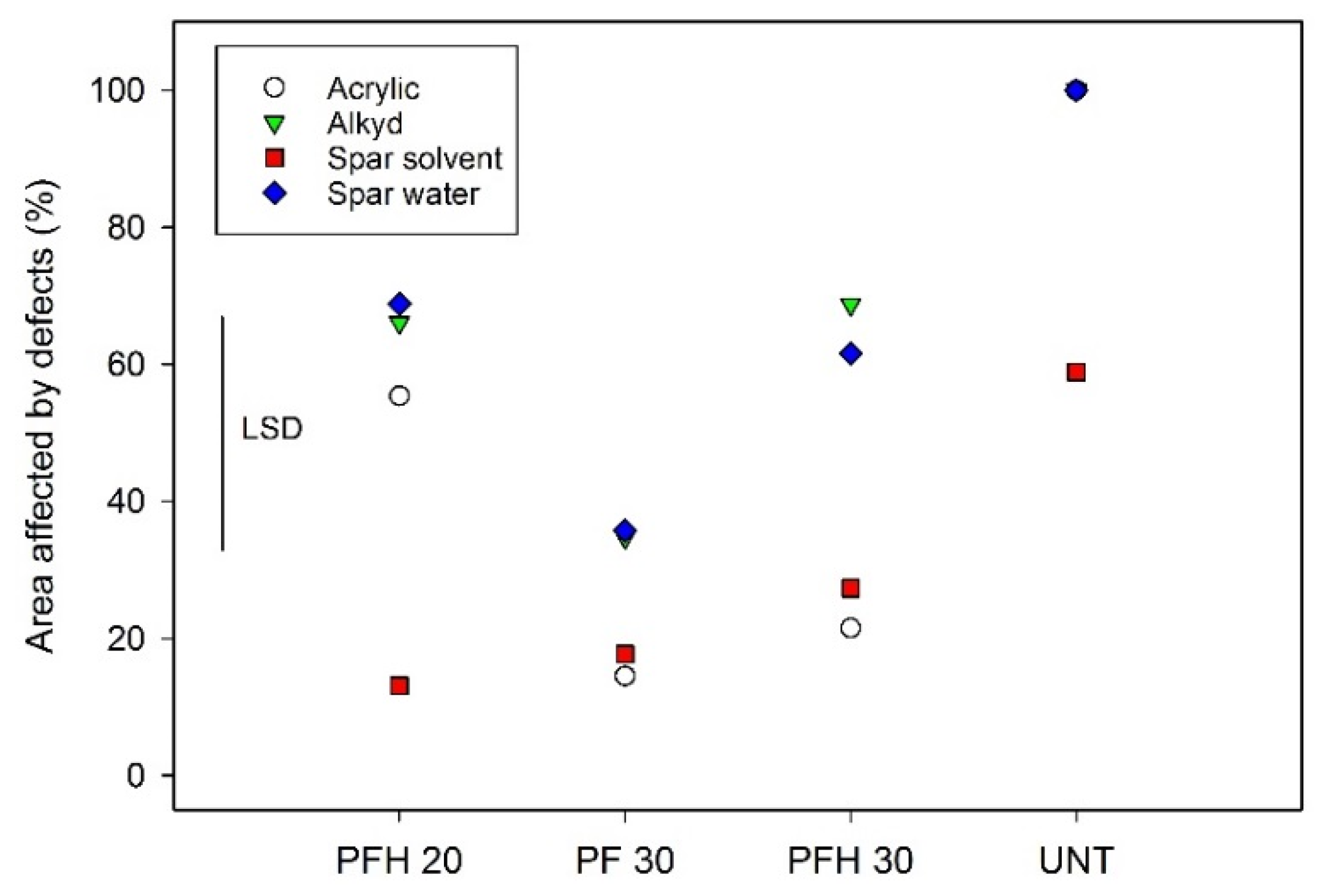

The coatings on radiata pine panels treated with PF resin are still performing very well after 4 years’ exposure, particularly those on panels treated with 30% PF resin or 30% PF and HALS (

Figure 7). The performance of the coatings on radiata pine wood modified with 20% PF resin and HALS after 4 years of exposure to the weather was not as good as those of the coatings on wood modified with 30% PF resin or 30% PFH (

Figure 7), but the difference is not statistically significant (

p > 0.05). There was no statistically significant (

p > 0.05) effect of coating type on the level of defects in radiata pine panels exposed to the weather for 4 years. Similarly, there was no significant (

p = 0.496) interaction of treatment x coating type on the defects present on coatings in panels exposed to the weather for 4 years.

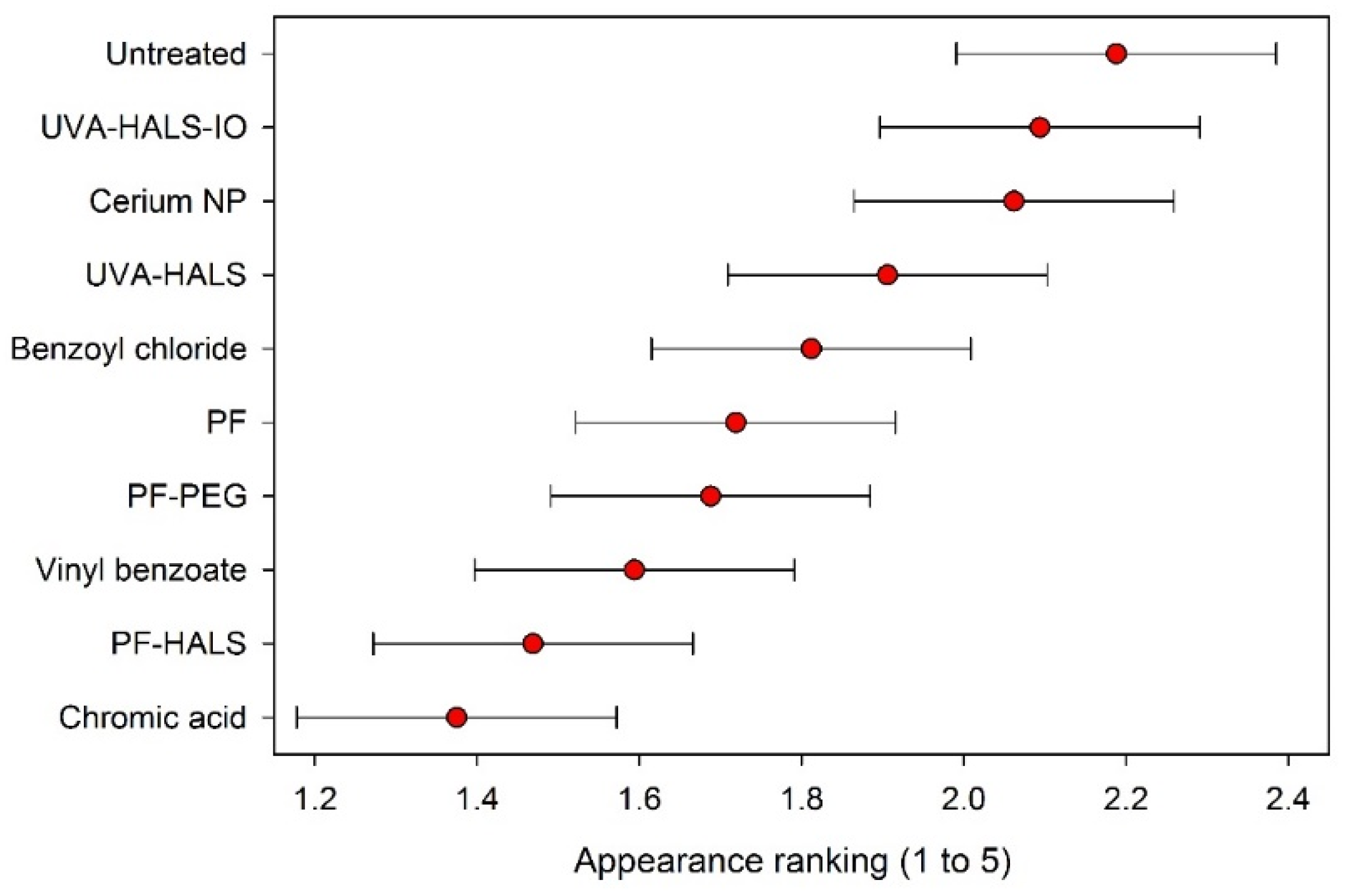

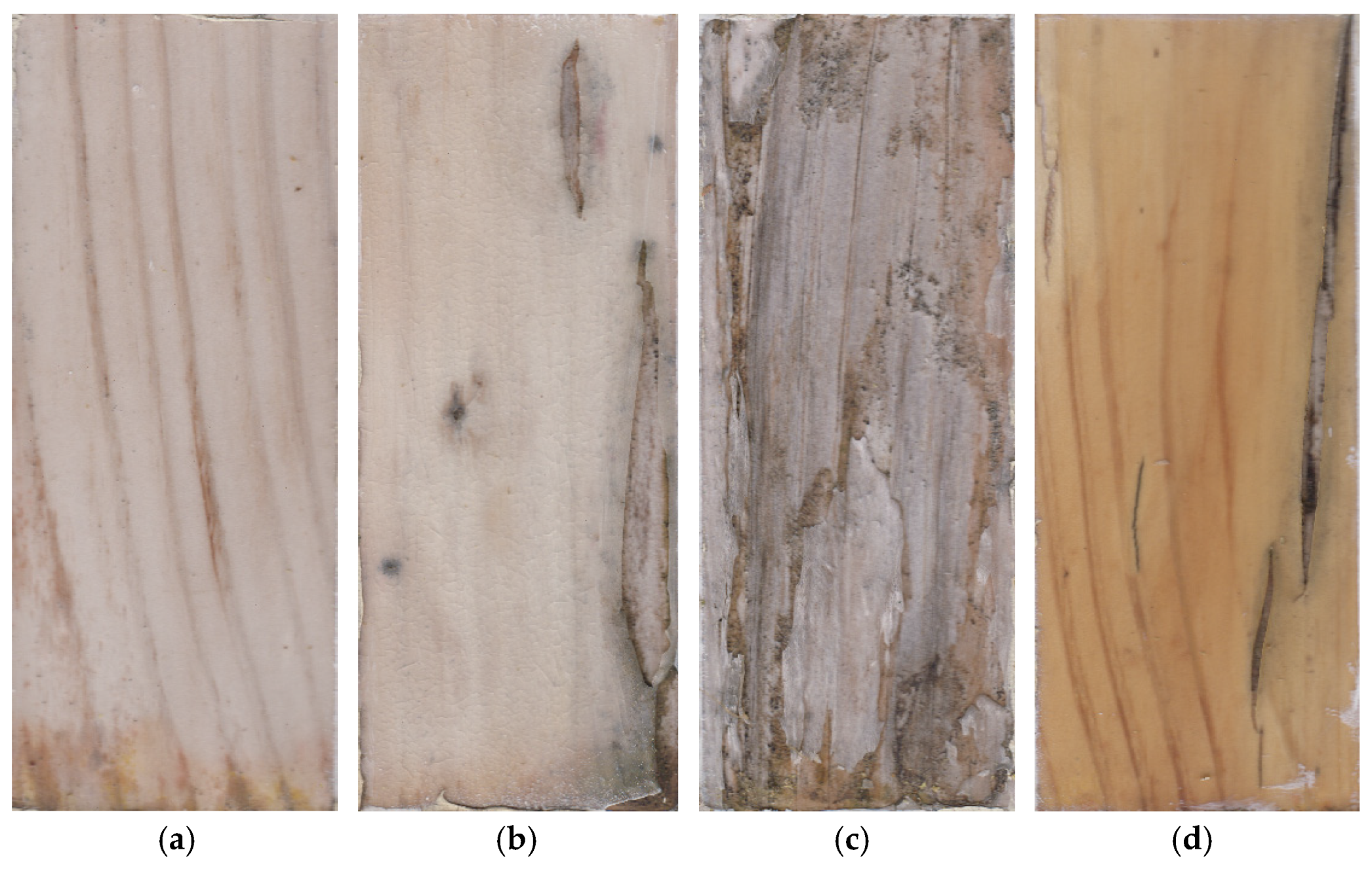

The appearance of the different coatings on PF-resin treated radiata pine panels after 4 years of exterior exposure can be seen in

Figure 8. The panels did not cup and the coatings were free of visible defects, although the dark-brown colour of the PF-modified wood beneath the coatings had lightened during exterior exposure.

In contrast to the performance of the coatings on PF modified pine, the coatings had completely failed on the untreated controls after 2 years of exposure, with the exception of the solvent-based spar varnish, which showed high levels of defects (63%), and had completely failed by the end of the third year of exposure. The mode of failure of the different coatings on untreated pine panels varied. The two spar varnishes invariably cracked, and cracking of the alkyd coating also occurred (

Figure 9). In contrast, the acrylic coating did not crack, but the untreated wood beneath the coating was bleached during exterior exposure (

Figure 9). Bleaching of untreated wood also occurred beneath the alkyd and the water-based spar-urethane, but there was less bleaching of wood beneath the solvent-based spar varnish.

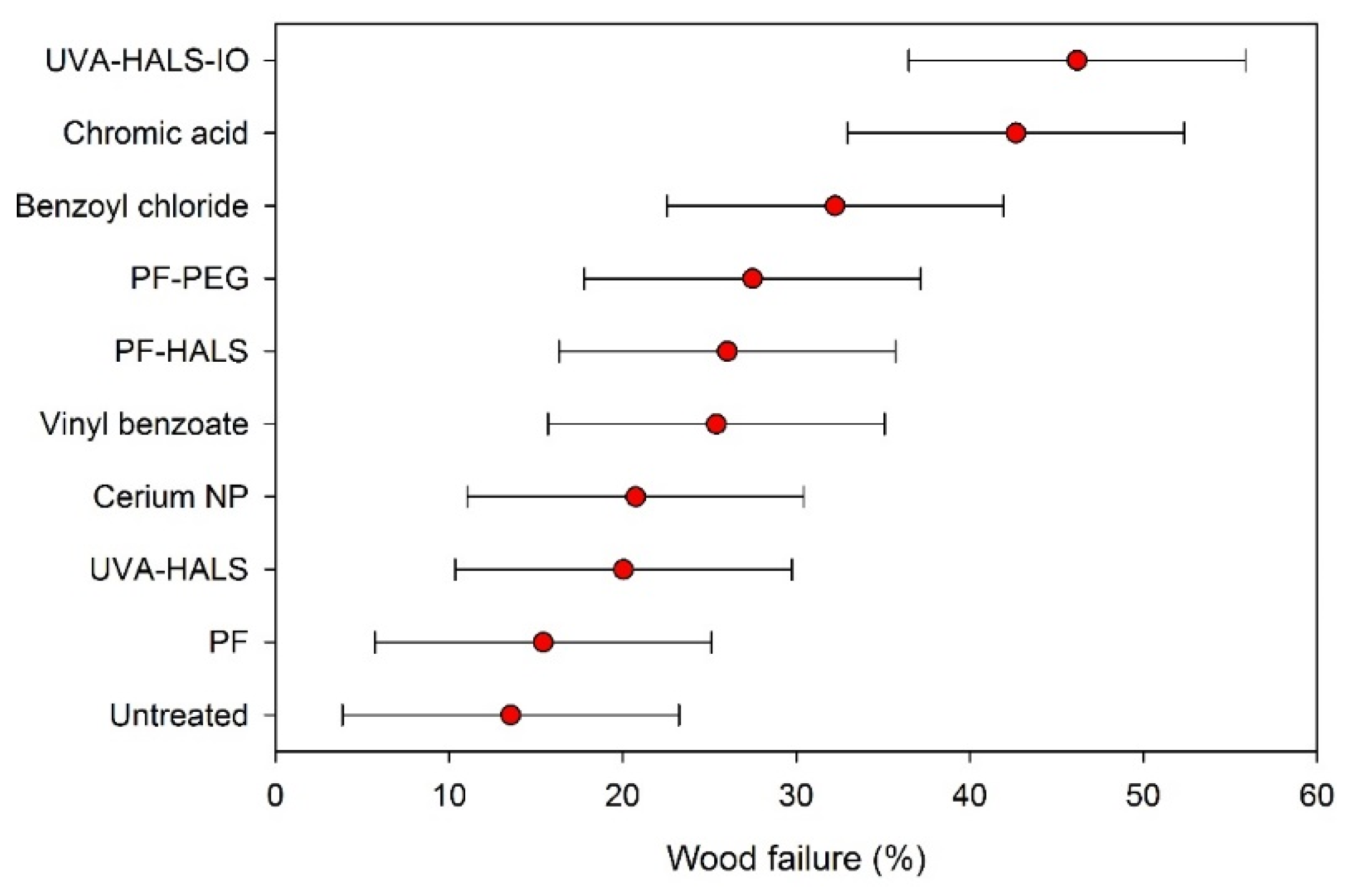

There was very little failure of coatings on oak panels at the end of the first year of exposure, although statistical analysis revealed greater failure of the water-based spar urethane varnish on untreated oak controls than on panels treated with PF resin. This effect was also apparent on oak panels after 2 and 3 years of exposure. Other trends also emerged with longer exposure of oak panels to the weather. After 3 and 4 years’ exposure to the weather, the solvent-based spar varnish was out-performing the other coatings on untreated wood, and wood treated with 20% PF. The solvent-based spar varnish also outperformed the alkyd and water-based spar urethane varnish on wood treated with 30% PF resin and HALS (

Figure 10). However, the performance of the acrylic finish on oak treated with 30% PF or 30% PF-HALS was comparable to that of the solvent-based spar varnish (

Figure 10). The main effects of PF resin “treatment” on coating failure on oak after 4 years’ exposure was statistically significant (

p < 0.001), because failure when averaged across the different coatings was significantly lower on panels pre-treated with 30% PF resin than on panels treated with 20% or 30% PF resin containing HALS. Similarly, the main effect of finish type on the failure of coatings on oak was also highly significant (

p < 0.001), because failure when averaged across the different treated panels was significantly lower on panels coated with the solvent-based spar varnish than on panels finished with the other coatings. There was no significant interaction of treatment x coating type on the defects on coatings in panels exposed to the weather for 4 years.

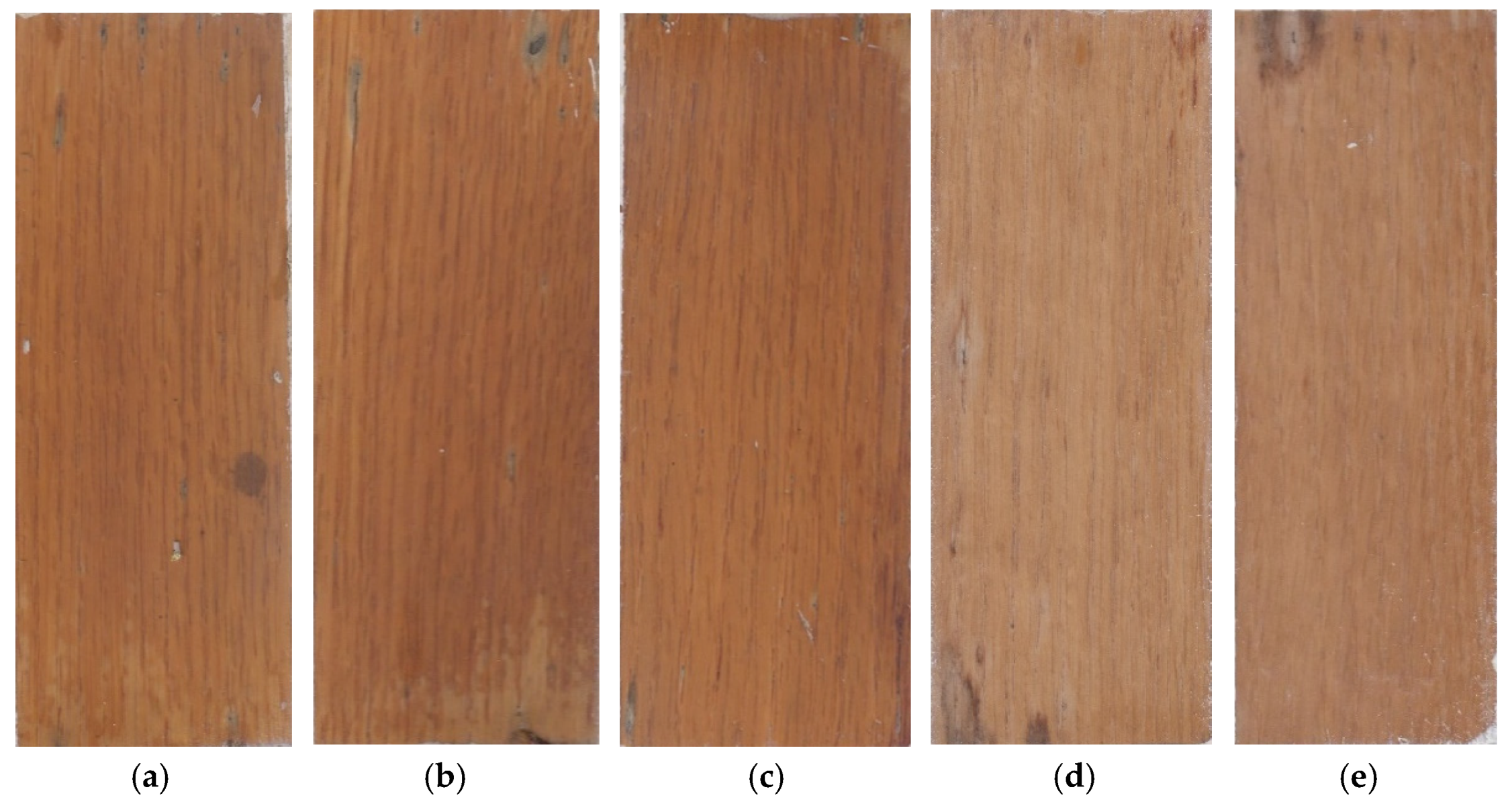

The appearance of the best coating systems on oak panels exposed to the weather for 4 years can be seen in

Figure 11. The appearance of the coatings is not as good as those on radiata pine because there are small defects in the coatings, particularly around the edges of the panels, whereas no such defects were present in the pine panels.

The failure of coatings on oak invariably occurred as a result of the development of pin holes or cracks in the coatings followed by moisture ingress and colonization of the underlying wood by mould fungi. The cracks in the coating developed over large earlywood pores (arrowed top centre-right in

Figure 12b), possibly because the coating was thinner in these areas. A similar mode of failure of a thin acrylic coating over the resin canals in radiata pine panels exposed to the weather for 28 months was noted by Evans and coworkers [

3].

5. Discussion

The excellent performance of the clear coatings on PF modified radiata pine panels is encouraging and supports the approach of trying to improve the performance of clear coatings by optimising different elements of the coating system that contribute to coating longevity. Each element of the coating system appeared to contribute to the longevity of the coatings, and will be discussed in turn.

The first important element of the coating system we considered was the wood substrate. We noted that Black and Mraz [

25] selected stable edge-grain redwood or western red cedar (

Thuja plicata Donn ex D. Don.) in their successful attempt to improve the performance of clear coatings on wood modified with iron, copper, or chromium compounds. We selected radiata pine sapwood for our tests because it is obtained from a sustainable resource that is extensively grown in plantations in the southern hemisphere (Australia, Chile, and New Zealand). Furthermore, “clear” radiata pine wood, free of knots and other defects, is available from plantations in New Zealand [

43]. Radiata pine wood is very permeable, and is the substrate of choice for chemical modification, for example acetylation [

44]. The high permeability of radiata pine wood was an important consideration here because it favoured the bulking of wood with low molecular weight PF resin species, which is known to enhance the dimensional stability of wood [

41]. The enhanced dimensional stability of PF treated radiata pine wood contributed to coating longevity because untreated radiata pine wood cupped, resulting in cracking of the spar varnishes and the alkyd clear coatings, whereas no such failure occurred on PF-treated radiata pine panels. Panels made from red oak were less extensively modified with PF resin than the radiata pine panels (

Table 4), even though red oak is one of the most permeable hardwoods [

45]. Nevertheless, PF modification of oak enhanced the durability of the clear coatings, in part by reducing their tendency to crack.

Modification treatments designed to enhance the dimensional stability of wood generally rely on impregnating wood with aqueous chemicals that bulk cell walls and keep the wood in a swollen condition. Our selection of PF resin in preference to other resins (melamine formaldehyde, furfural alcohol, or dimethylol resins) that are used to modify wood was based on the following characteristics of PFs: (1) low cost; (2) commercial uses for dimensional stabilization of knife handles, flooring, and wood used outdoors [

46,

47]; (3) colour imparted to treated wood [

41]; and (4) results of our preliminary research, which indicated that PF resin can photostabilize wood and enhance the performance of clear coatings [

38,

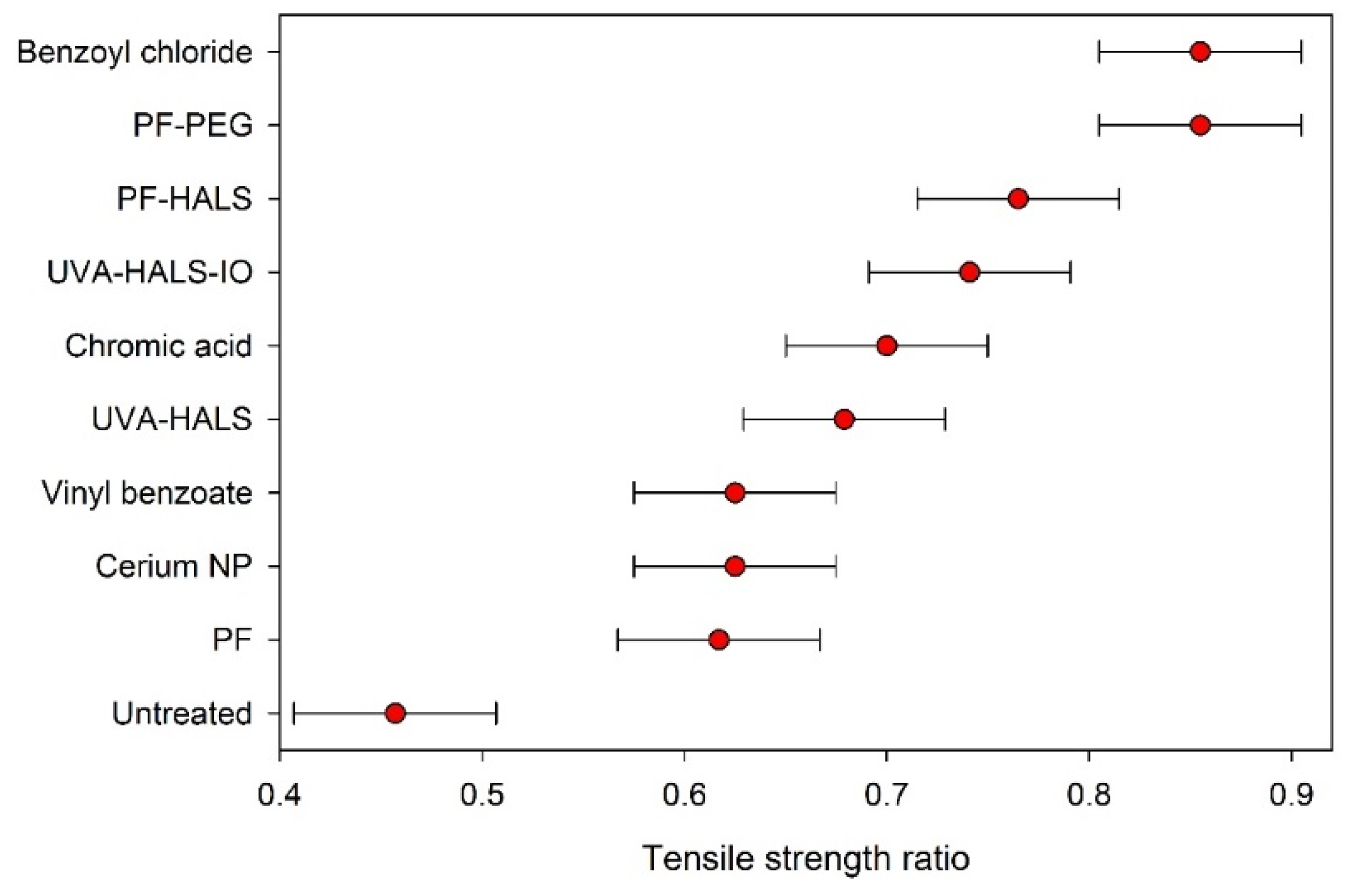

48]. Our preliminary research suggested that the addition of a water-soluble HALS to the PF resin would have beneficial effects on coating longevity (

Figure 5). Coatings performed well on radiata pine modified with 30% PF resin and HALS (

Figure 7), but there was little beneficial effect of the HALS on the performance of coatings on oak modified with 30% PF resin (

Figure 10). Coatings failed more quickly on oak than on radiata pine, possibly because it was less extensively modified with PF resin than radiata pine, and less dimensionally stable (

Table 4). In addition, differences in the surface microstructure of the two species also appear to have contributed to the more rapid failure of coatings on oak, because the failure of coatings on oak was due to cracking of the coating over the large earlywood vessels (pores) at the oak surfaces. Such an effect was more pronounced with the water-based spar urethane, which formed the thinnest coating.

Failure of clear coatings on small panels used to test coatings often occurs as a result of ingress of moisture via faulty edge seals, as our preliminary work showed. Moisture ingress via end grain also leads to the failure of opaque coatings in service [

49]. Moisture ingress into test panels here was restricted by combining an impermeable physical barrier made of thin aluminium foil with an opaque film-forming paint system. The resulting seal wrapped around the edges and ends of the panels. This seal certainly contributed to the longevity of the clear coatings on test panels because when it failed there was associated failure of the adjacent clear coating as a result of moisture ingress. Clear coatings fail on wood in areas where the coating is thinner [

50], and there is evidence for such an effect here, as mentioned above. Hence, the application of thicker coatings in this trial probably enhanced their longevity, although all of the coatings failed rapidly on untreated radiata pine due, in part, to the high permeability and dimensional instability of the substrate. Thus, coating thickness did not significantly influence clear coating performance on untreated pine, in contrast to its positive effect on PF-modified oak.

The selection of coatings, in addition to the wood substrate, pre-treatment, and edge seal was an important consideration in our attempt to create a high-performance clear coating system. There is evidence from the performance of the coatings on oak that the type of coating and film thickness influenced the performance of the coating systems, but there was no difference in the performance of the different coatings on PF modified radiata pine. Differences in coating performance on pine may emerge with further exposure of PF modified panels to the weather. However, the coatings behaved differently on untreated radiata pine. The spar varnishes and the alkyd clear coating cracked on untreated pine panels exposed to the weather, possibly because the coatings lacked the flexibility to accommodate moisture-related shrinkage and swelling of the wood. In contrast, cracking was far less apparent in panels coated with the acrylic finish, suggesting that the weathered acrylic finish was still flexible enough to accommodate the shrinkage and swelling of the untreated wood substrate. Coating flexibility is a key consideration when formulating durable clear finishes for unmodified wood [

51]. It may, however, be less important for substrates such as PF modified wood that are dimensionally stable. For such substrates, other coating properties may be more important; for example, the ability to prevent water from reaching the wood substrate [

52].

The performance of our best coating system already matches the best tested by Ashton in his exposure trials [

42]. The performance of clear coatings developed by Black and Mraz [

25] at the U.S. Forest Products Laboratory was even better than those tested by Ashton [

42]. They were able to extend the lifetime of a UV transparent and durable silicone coating on a stable wood substrate by pre-treating the wood with copper, iron, or chromium compounds, as mentioned above [

25]. Their exposure trials indicated that copper and iron pre-treatments increased clear coating longevity from 2 to 6 years, and the longevity of the coating on chromium modified wood was in excess of 15 years. Our trial will be extended to determine how the current coating systems compare with those developed by Black and Mraz [

25]. Based on the performance of our best systems on radiata pine after 4 years’ exposure, it is possible that they may still be serviceable after 6 years. Additional measures such as filling pores in red oak, incorporating a biocide in the PF resin, and the use of a sacrificial hydrophobic coating on top of the clear-coatings might be able to delay failure of the clear coating systems we developed. Further research would be needed to test this hypothesis, and explore the additive effect of such measures on the overall gain in performance of the clear-coating systems.