1. Introduction

Road traffic noise is a widespread problem, especially in the densely-populated cities of Europe. Exposure to high levels of (traffic) noise can lead to health problems, such as stress, sleep disturbance and even heart diseases. In a publication by the World Health Organization (WHO) in 2011 [

1], it was estimated that over one million healthy years of life are lost to ill health, disability or early death related to traffic noise in the western part of Europe alone. Sleep disturbance and annoyance, mostly related to road traffic noise, embody the main burden of environmental noise.

The European Commission is well aware of this problem, and the reduction of road noise is one of its higher priorities. As a consequence of the European Noise Directive 2002/49/EC, all EU member states have been forced to not only analyze the situation by producing noise maps, but also to act against the problems by drafting noise action plans. The Environment, Nature and Energy Department (LNE) of the Flemish government drafted such a noise action plan for road noise, which was approved by the Flemish administration in July 2010 [

2]. One of the measures to be taken included the mission for the Flemish Agency for Roads and Traffic (AWV), in cooperation with the Belgian Road Research Centre (BRRC), to expand its knowledge on low noise pavements by studying existing national and international research and by constructing low noise test sections. By the end of 2011, the regional road N19 Turnhout-Kasterlee in Belgium was selected as the location for the construction of the test sections. The concept of this trial was to monitor the acoustical and mechanical performance of different Thin noise-reducing Asphalt Layers (TAL), compared to two reference test sections, in order to evaluate the possibility of including TAL in the Flemish road surface policy in a later stage. Further details on this trial are given in

Section 2.1.

A thorough report stating the health effects, social costs and traffic noise reduction options is given in [

3], commissioned by T&E, the European Federation for Transport and Environment. It is clear that measures at the source are the most cost effective and that the greatest reduction potential is coming from technical measures to reduce noise emissions from vehicles, tires and road surfaces.

Many international studies on low noise pavements have been performed, including thin layers in, e.g., [

4,

5], Double-layer Porous Asphalt Concrete (DPAC [

6]), rubberized asphalt in [

7,

8] and Poro-Elastic Road Surfaces (PERS, in, e.g., [

9]). A good overview of all of the different types of noise-reducing surfaces can be found in [

10], including SMA, TAL, porous asphalt, ultrathin surfacing, cement concrete, rubberized asphalt and poro-elastic road surfaces. The expected lifetime is also given, which shows the difference in expected mechanical lifetime for SMA-like TAL or porous-type TAL. This does not include the acoustical lifetime, which can be defined as the time needed to become louder than the reference of the same age (related to acoustic ageing).

Various European research projects have been initiated in the past on low noise pavements, e.g., SILVIA (Sustainable Road Surfaces for Traffic Noise Control [

11]), SILENCE (Towards the sound of SILENCE in European cities [

12]) and OPTHINAL (Optimization of Thin Asphalt Layers [

13]), all projects in which BRRC was involved. More recently, a project specifically on poro-elastic road surfaces called PERSUADE was coordinated by BRRC (Poro-Elastic Road SUrface: an innovation to Avoid Damages to the Environment [

14]).

Low noise road surfaces can be obtained by influencing one or more of the following surface characteristics, as already stated by [

15] in 1987: texture [

16], absorption [

17], which can remove the so-called horn effect [

18], and mechanical stiffness [

19,

20]. In this paper, the focus is on TAL with an optimized texture and only a limited influence of absorption (except for Test Sections 2 and 3, which have a larger percentage of accessible voids compared to the other TAL).

When monitoring the acoustical quality of low noise surfaces, especially the air and pavement temperature have a large impact on the measurement results. The temperature correction is calculated using a reference air temperature of 20 °C, as shown in Equation (1):

where

LA,max is the A-weighted maximum pass-by level,

T is the air temperature in degree Celsius and

a is the so-called temperature correction coefficient in dB(A)/°C. A similar equation can be established for the temperature correction of CPX measurements.

Different studies have examined this temperature effect related to the air temperature, but with varying results, as shown below:

A semi-generic temperature correction coefficient of −0.06 dB(A)/°C as proposed by [

21];

For dense asphalt mixtures, −0.10 dB(A)/°C, and for porous asphalt mixtures, −0.06 dB(A)/°C [

22];

A generic temperature correction coefficient of −0.10 dB(A)/°C was used for all road surfaces in [

23];

For dense asphalt mixtures, −0.10 dB(A)/°C, and for porous asphalt mixtures, −0.05 dB(A)/°C [

24].

It is clear that this issue still remains unsolved at the moment, but that it can influence the actual results and conclusions. In this paper, the correction coefficients proposed by [

24] are used.

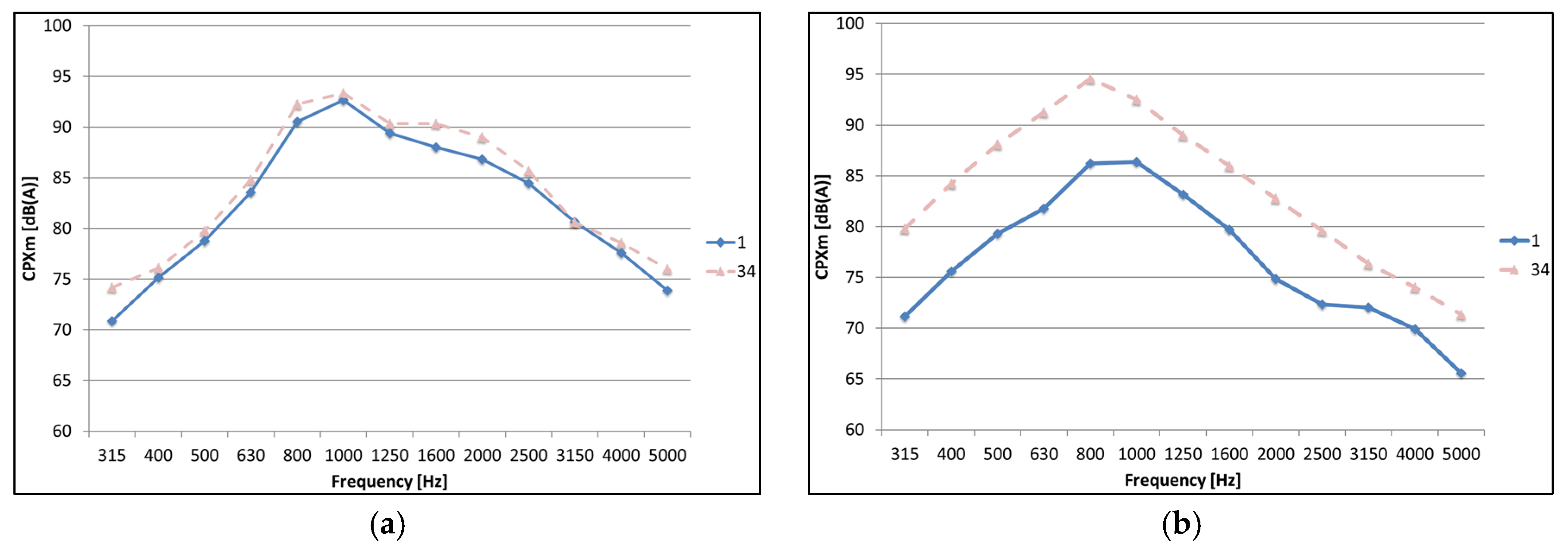

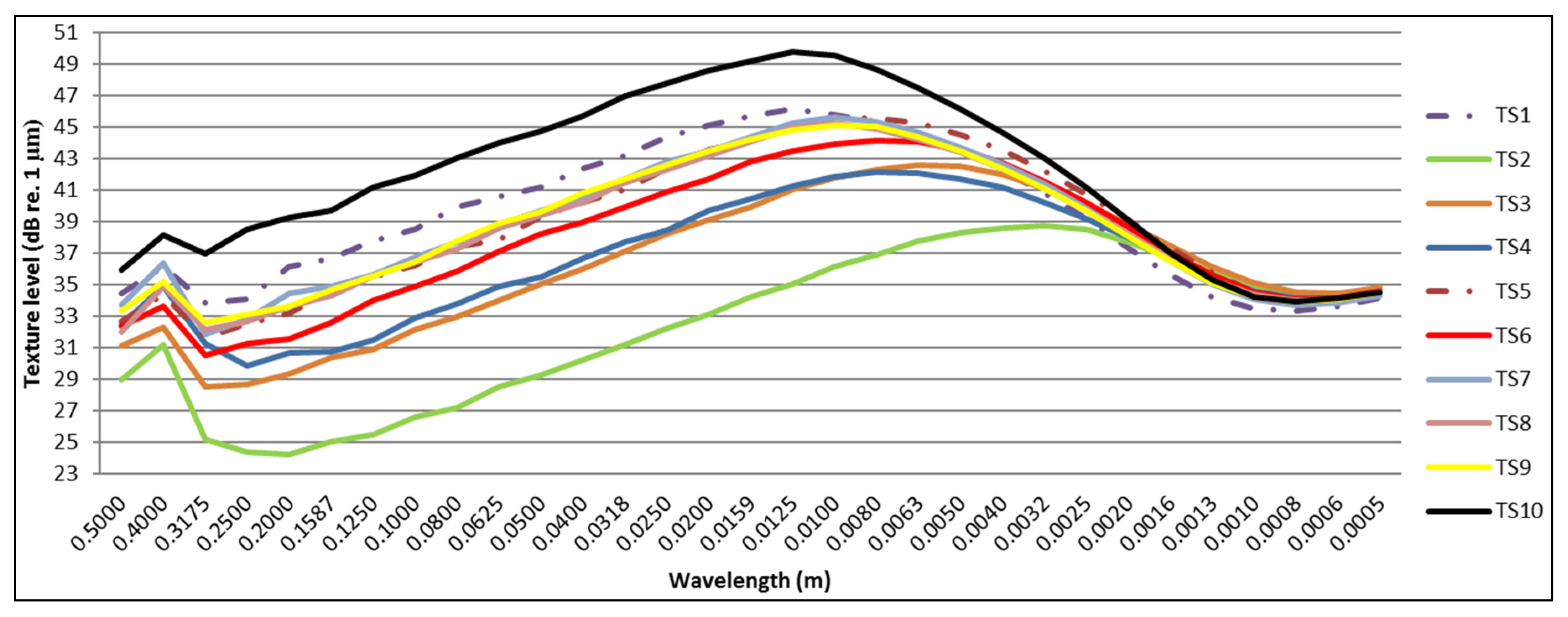

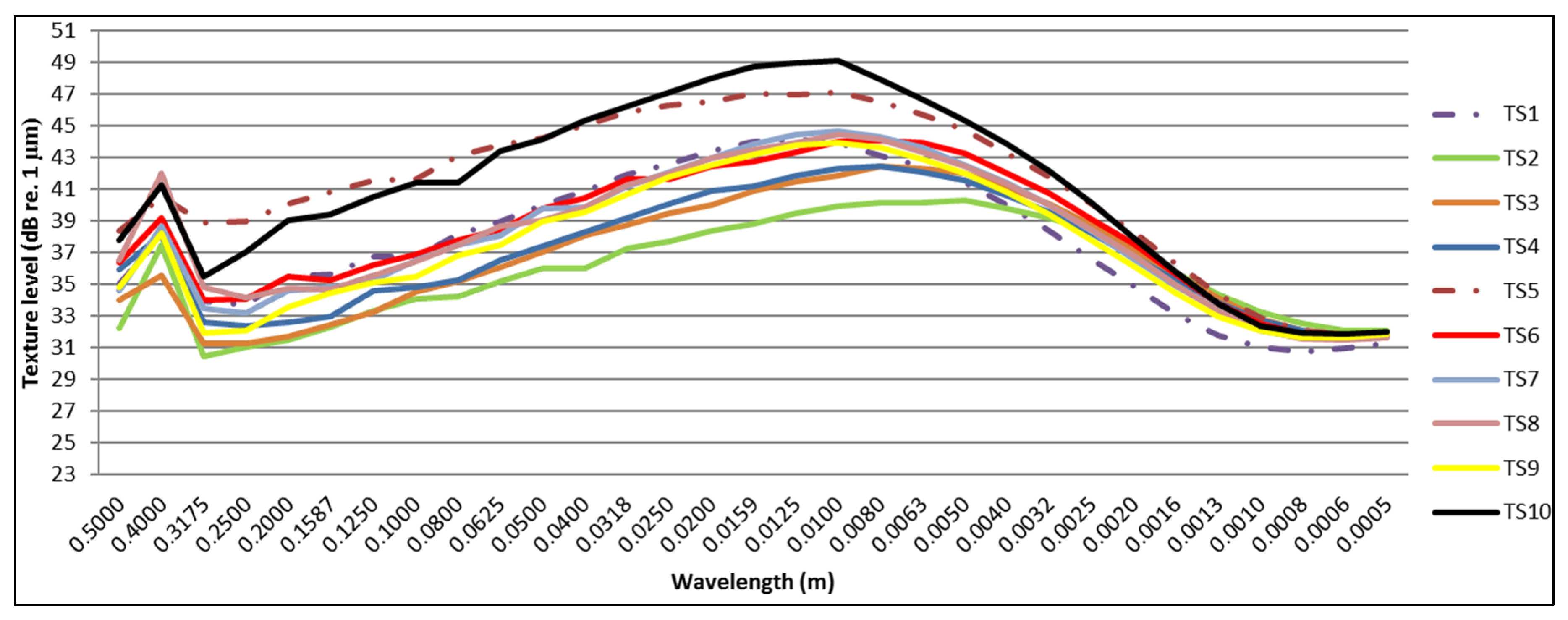

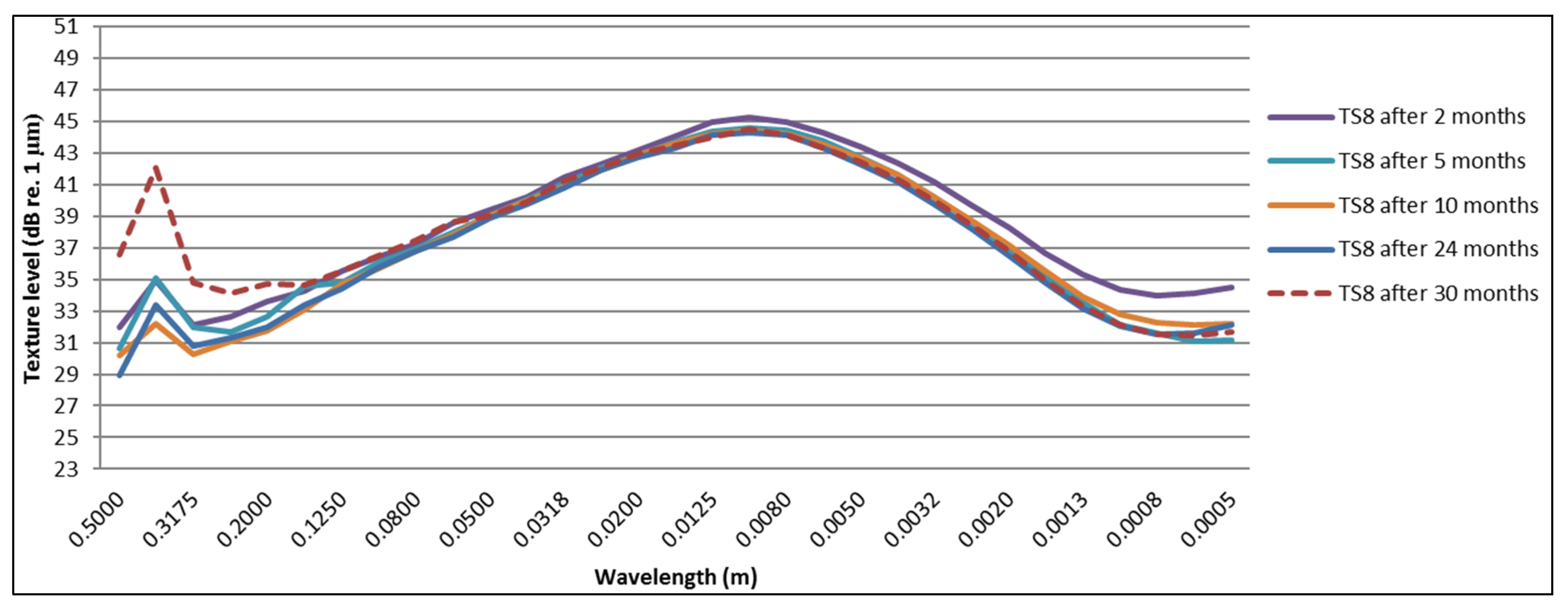

Section 2 of this paper starts with a description of the test sections, followed by an overview of all of the test methods that were used in this study. Next, the acoustical quality is investigated in detail in

Section 3, including the results of repeated SPB, CPX and texture measurement campaigns up to 34 months after construction. A discussion of all of the measurement results is included in

Section 4. Finally, some conclusions are given in

Section 5.

5. Conclusions

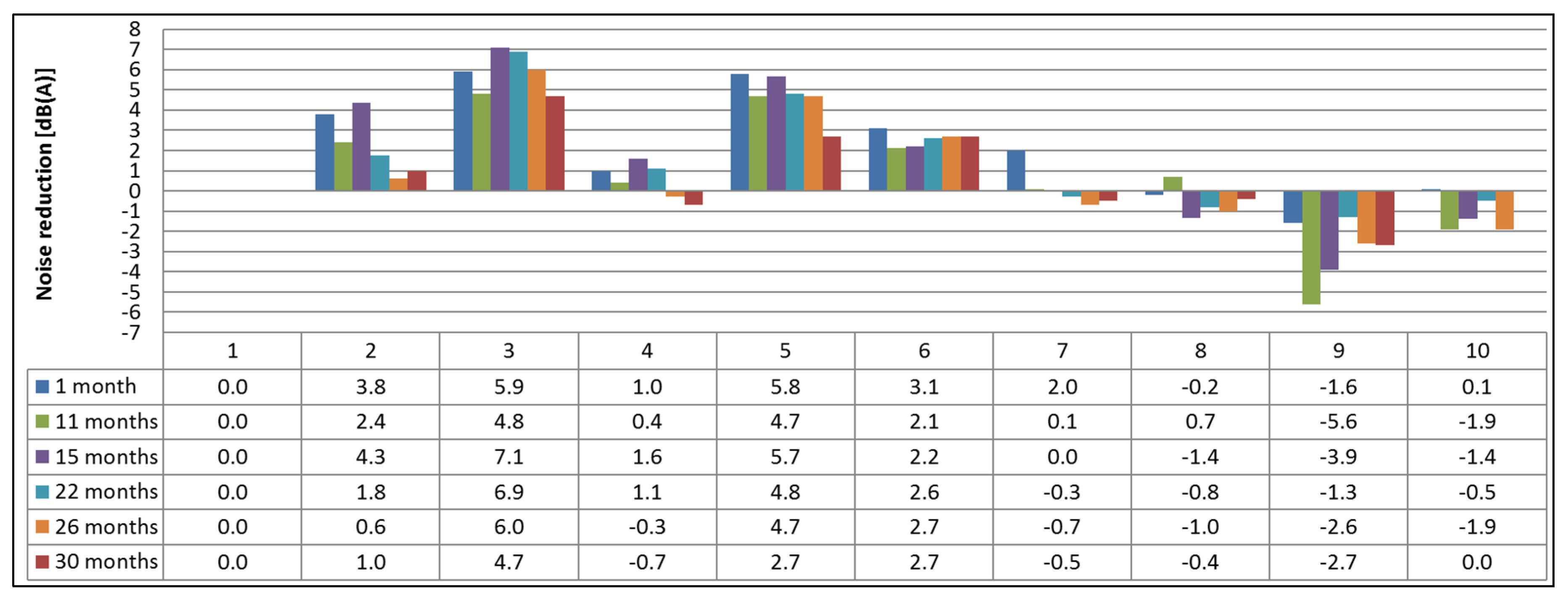

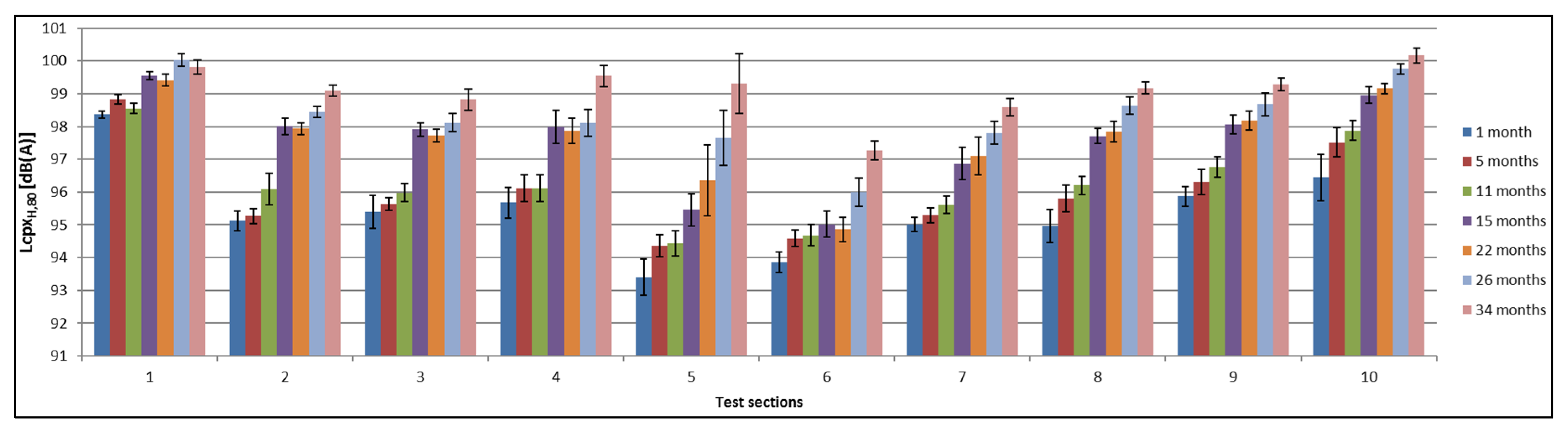

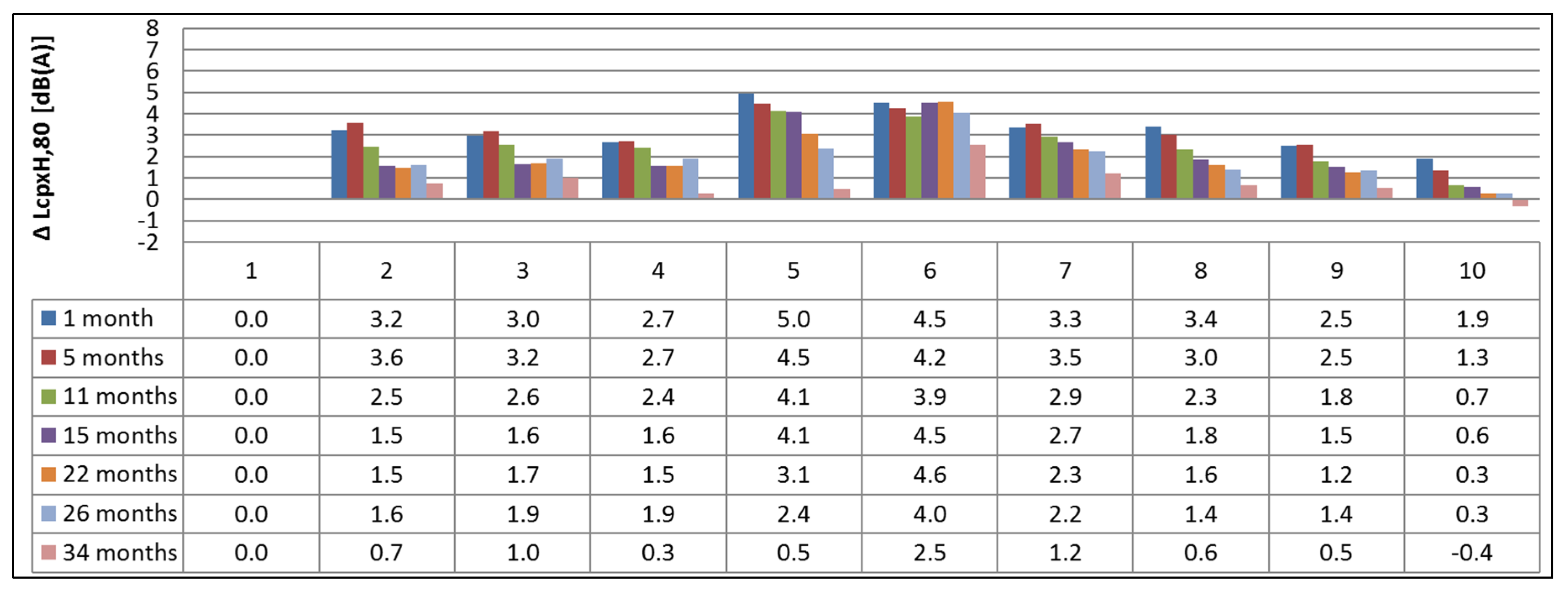

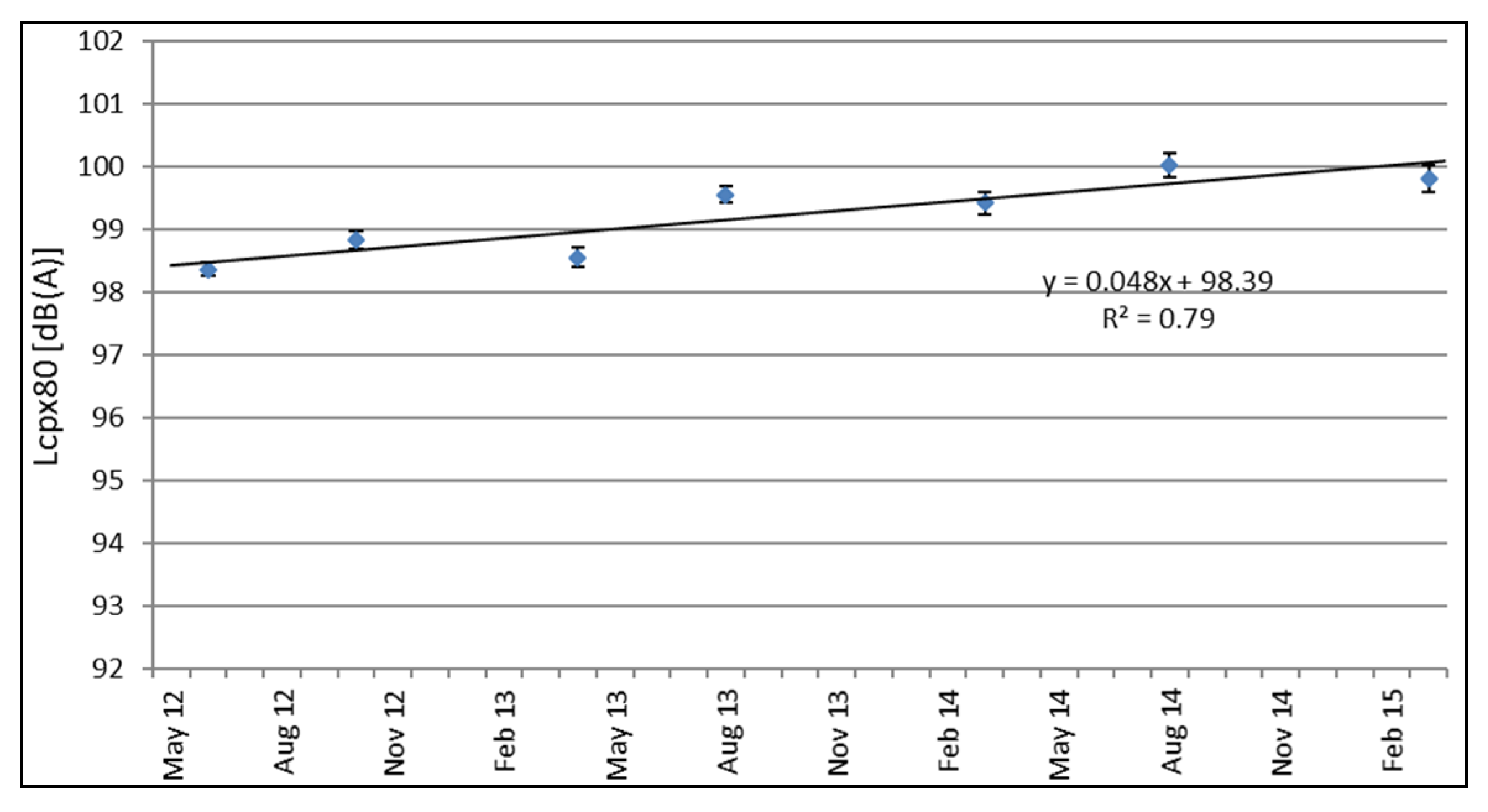

The first experience with TAL in Belgium can be considered only partly successful. A high initial noise reduction was found for a number of TAL one month after construction. The SPB results show lower initial noise reductions compared to the CPX results. As the acoustic ageing effect on the SPB results is lower than for the CPX results, the noise reduction after 2.5–3 years is considerably higher (up to 4.7 dB(A) using SPB and only 1.3 dB(A) and 2.5 dB(A) using CPX for cars and truck tires respectively). Assuming a linear relationship, the acoustic ageing effect on the noise reduction is assessed for both SPB and CPX. The TAL layers show a noise increase of 0.02–0.14 dB(A) per month based on the SPB measurements. The ageing effect is much larger for the CPX measurements with 0.05–0.20 dB(A) per month. All of these results are larger than expected when compared to previous international research.

The overall noise increase is clearly linked with raveling, which is determined through visual inspections and repeated texture measurements. A higher sensitivity to raveling was found in the laboratory for the TAL of Test Sections 2 and 3 [

25], which can easily be explained by the composition of the mixtures (aggregate grading and bitumen content) and the higher void content. Thin layers are therefore not applicable at places like urban road crossings or others where (heavy) vehicles exert high shear forces on the surface layer. The results indicate that it is difficult to realize an excellent noise reduction and durability at the same time.

Extra care should be taken during construction, as thin layers have a higher sensitivity to weather conditions during paving. Heavy rainfall during the construction of Test Sections 2 and 3 and problems with spraying of the tack coat might have increased raveling or even debonding of the base course. Fast cooling of the thin layers means that there is a smaller time window to achieve the desired density and compaction degree.