Performance Testing of Suspension Plasma Sprayed Thermal Barrier Coatings Produced with Varied Suspension Parameters

Abstract

:1. Introduction

2. Experimental

2.1. Coating Production

2.1.1. Suspensions

| Suspension | Solids Loading | Particle D50 (nm) | Suspension Density (g/cc) | Deposition Rate (µm/pass) | Coating Thickness (µm) |

|---|---|---|---|---|---|

| T1 | 25% | 45 nm | 1.003 | 3.4 | 344 |

| T2 | 33% | 200 nm | 1.104 | 5.3 | 531 |

| T3 | 25% | 200 nm | 1.029 | 3.6 | 362 |

| T4 | 17% | 200 nm | 0.941 | 2.2 | 221 |

| T5 | 25% | 500 nm | 1.031 | 3.8 | 378 |

| C1 | 25% | 400 nm | 1.049 | 3.7 | 374 |

| C2 | 25% | 45 nm | 1.242 | 4.8 | 484 |

2.1.2. Suspension Atomization Parameters

2.1.3. SPS Sample Production

2.2. Porosity Measurement

2.3. Thermo-Cyclic Fatigue Testing

2.4. Thermal Diffusivity Analysis

3. Results

3.1. Mercury Porosimetry

3.2. Microstructure Analysis

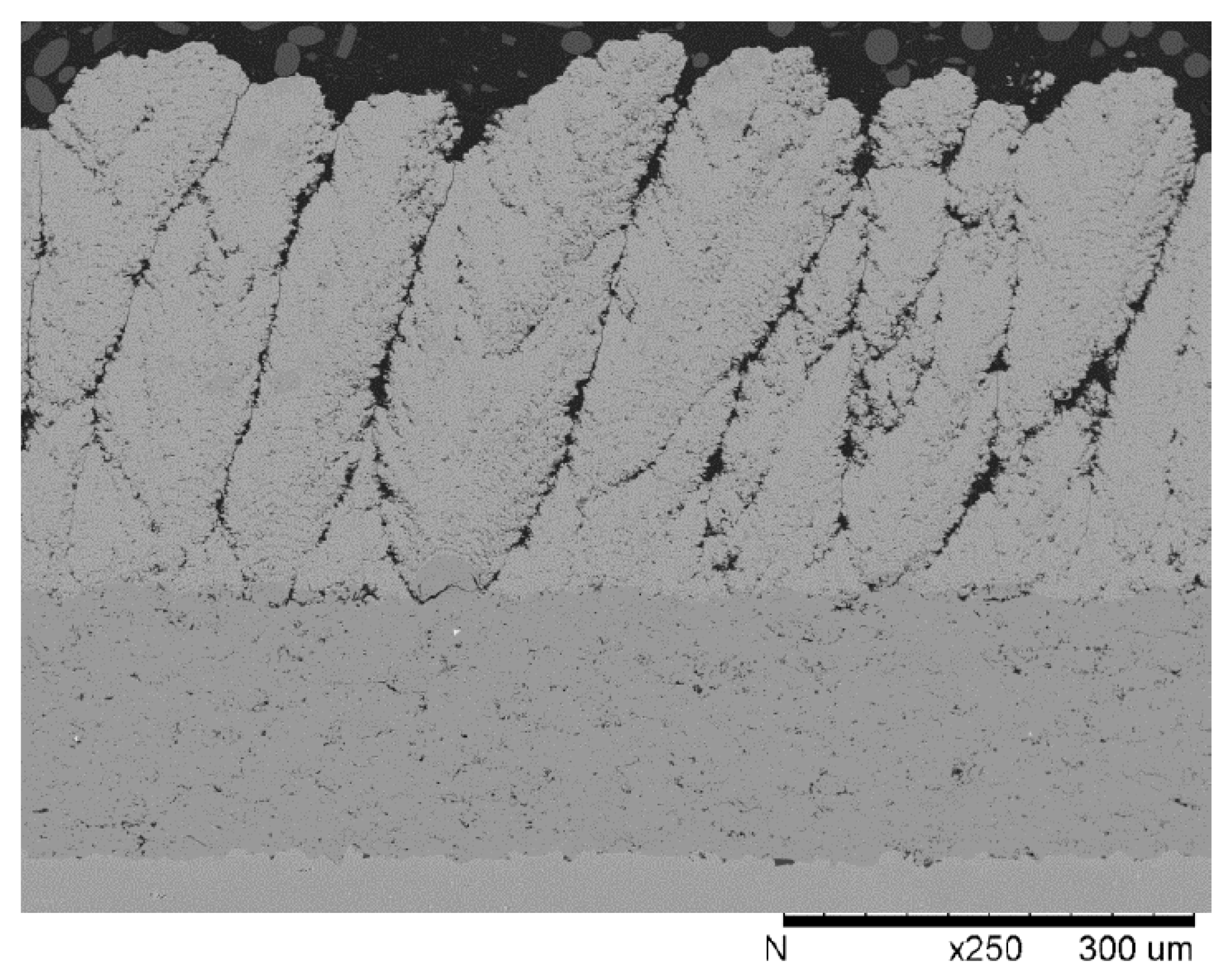

3.2.1. Influence of Solids Loading

- (1)

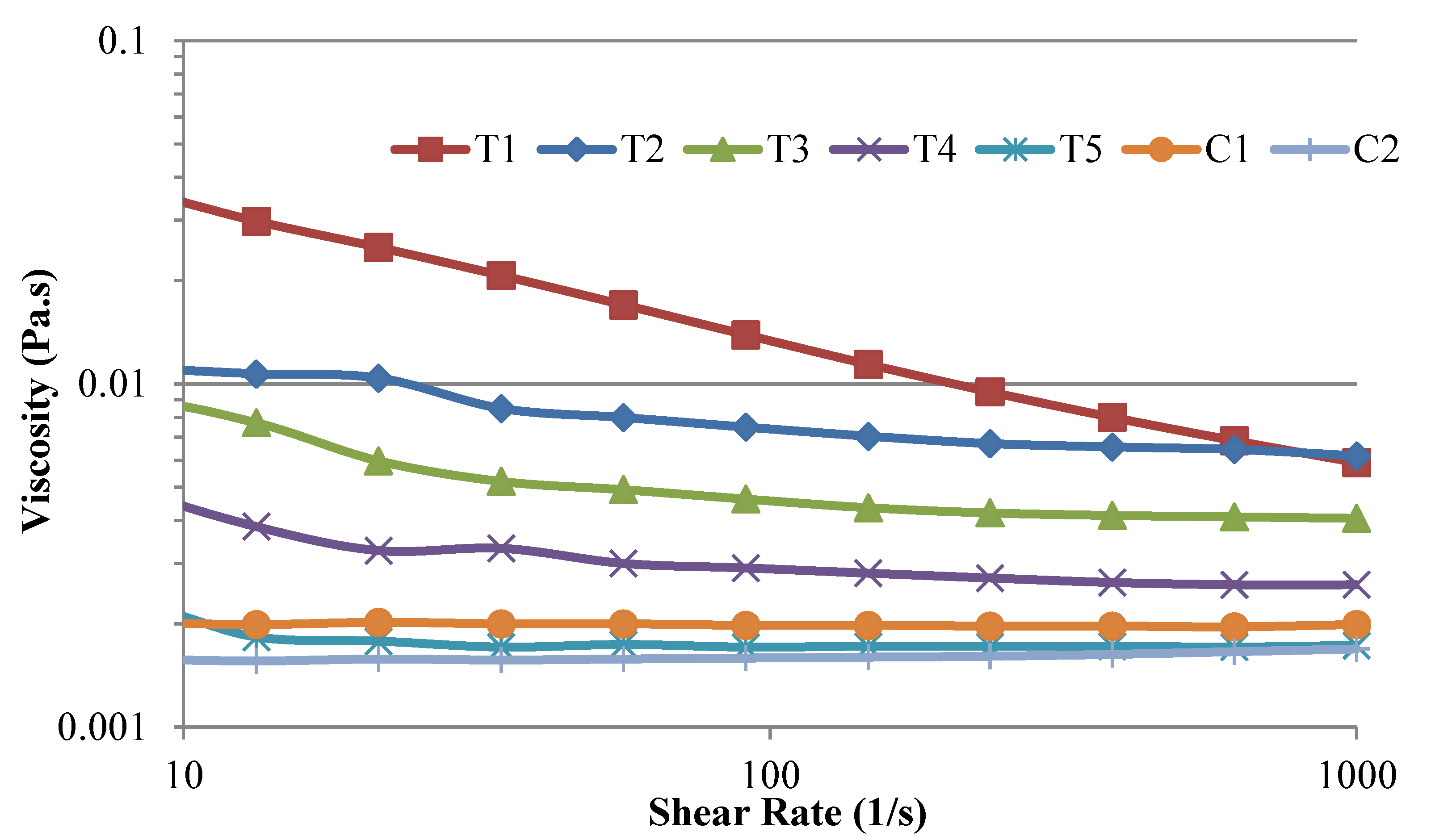

- Reducing the suspension solids loading reduces the suspension viscosity as shown in Figure 2 for the 200 nm suspensions. The reduced viscosity will allow easier atomization and increase the production of the smallest suspension droplets during fragmentation according to Rampon et al. [11] and predicted by Equation (2).

- (2)

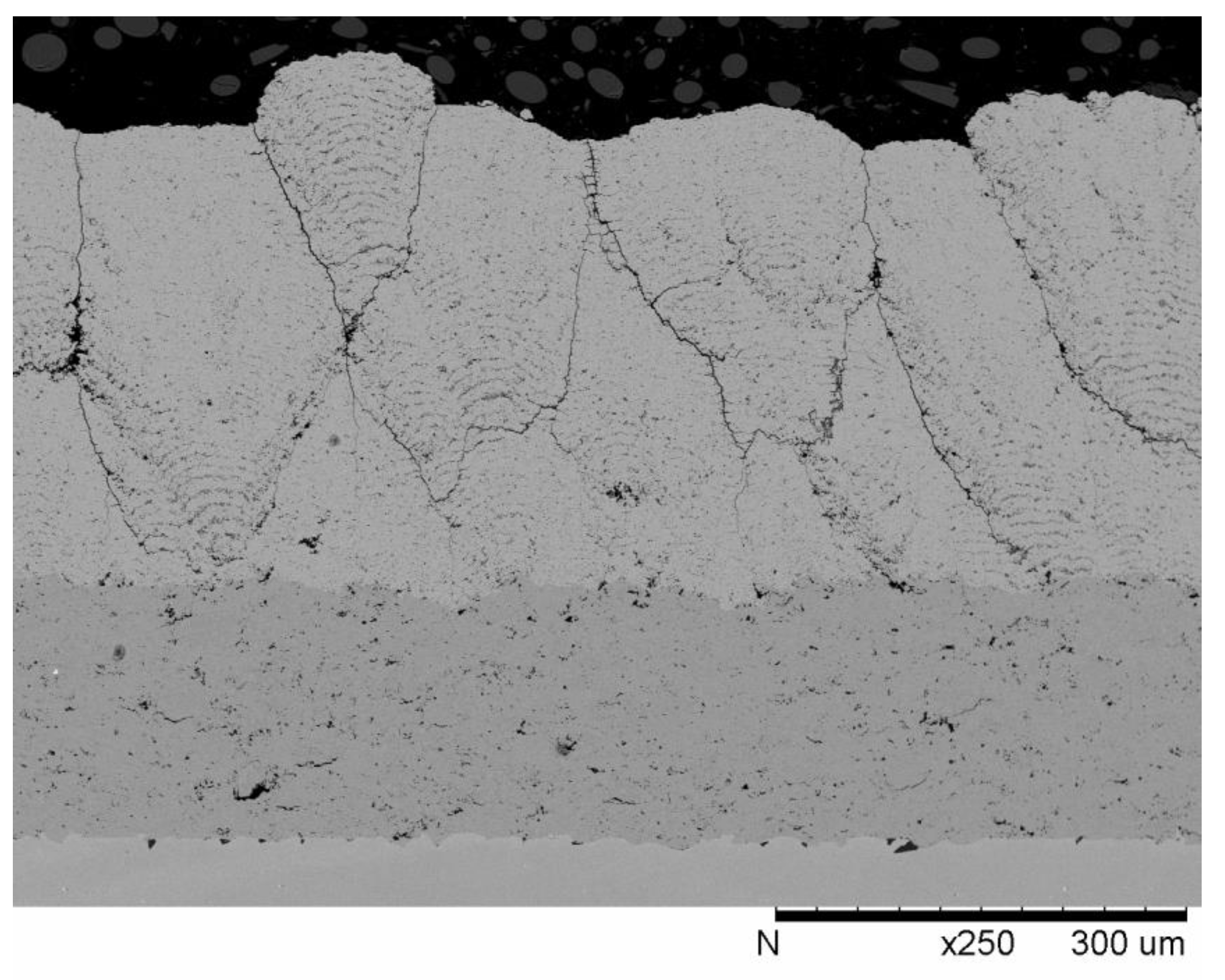

- As a secondary effect, increasing the powder solids load within a suspension increases the mass of powder contained within each suspension droplet produced during the fragmentation process. A larger suspension droplet will also contain more powder particles, leading to a larger YSZ particle after solvent evaporation and subsequent melting of the ceramic.

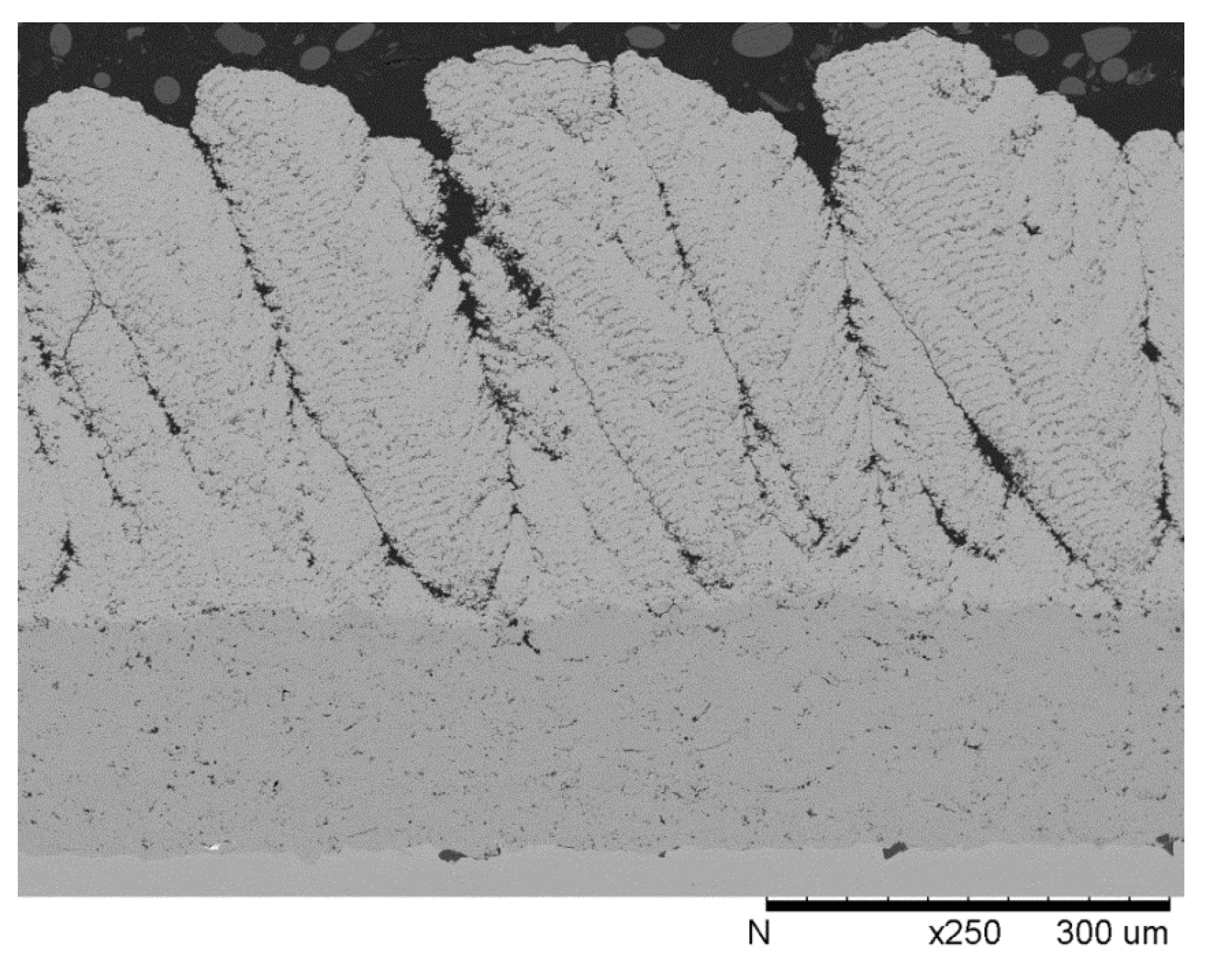

3.2.2. Comparison of Sub-Micron Suspensions

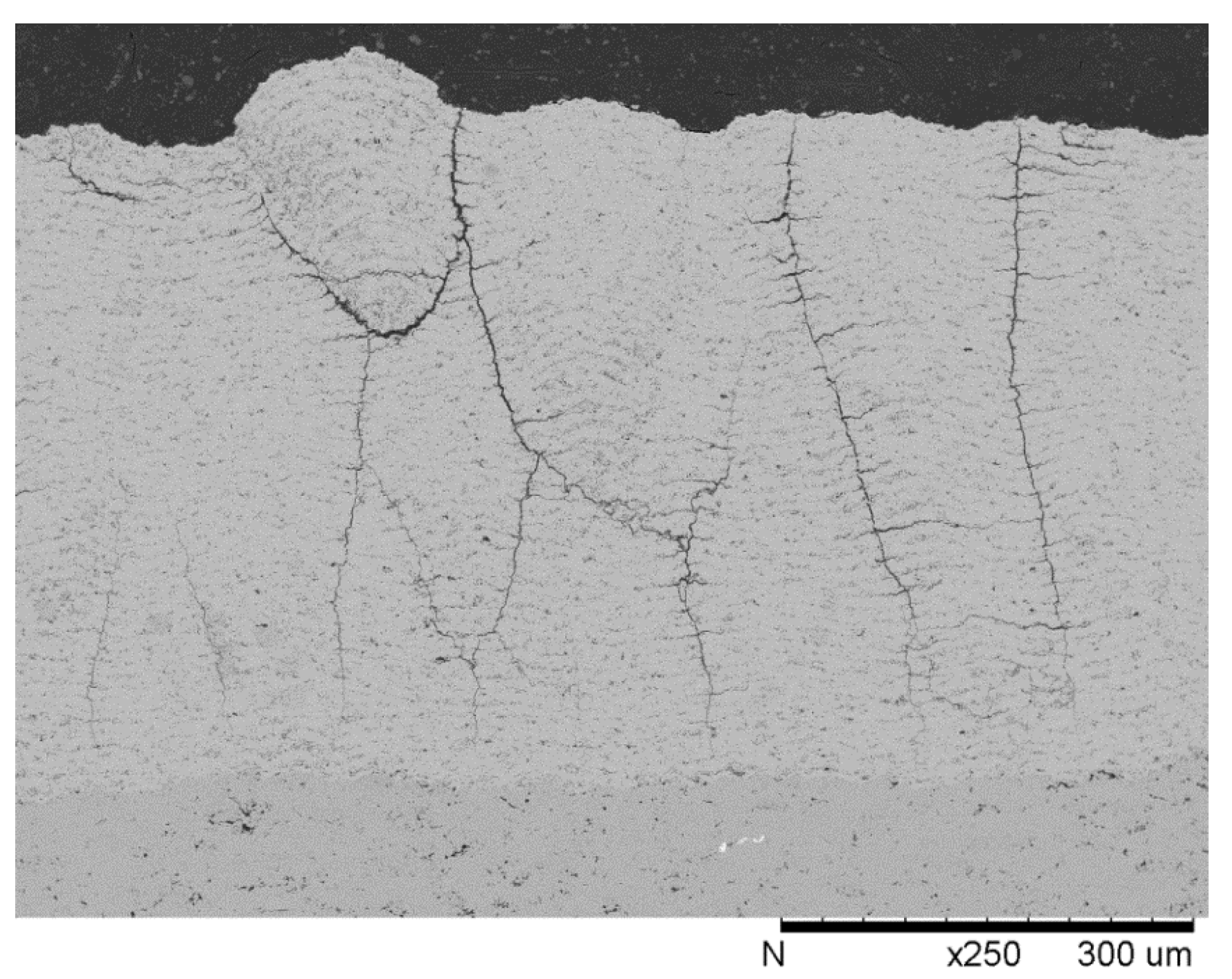

3.2.3. Influence of Suspension Solvent

3.3. Thermal Conductivity Results

- (1)

- The C1 coating was formed from YSZ powder with 14 wt % yttria, whereas all other suspensions contained YSZ powder with 8 wt % yttria. The incorporation of yttrium atoms into the zirconia lattice requires the generation of oxygen vacancies. These point defects produce scattering of the lattice waves (phonons) that transport the thermal energy through the coating [20,21,22]. Thus, compared to the other samples, the 75% increase in yttria within the C1 samples should have reduced the thermal diffusivity of these coatings.

- (2)

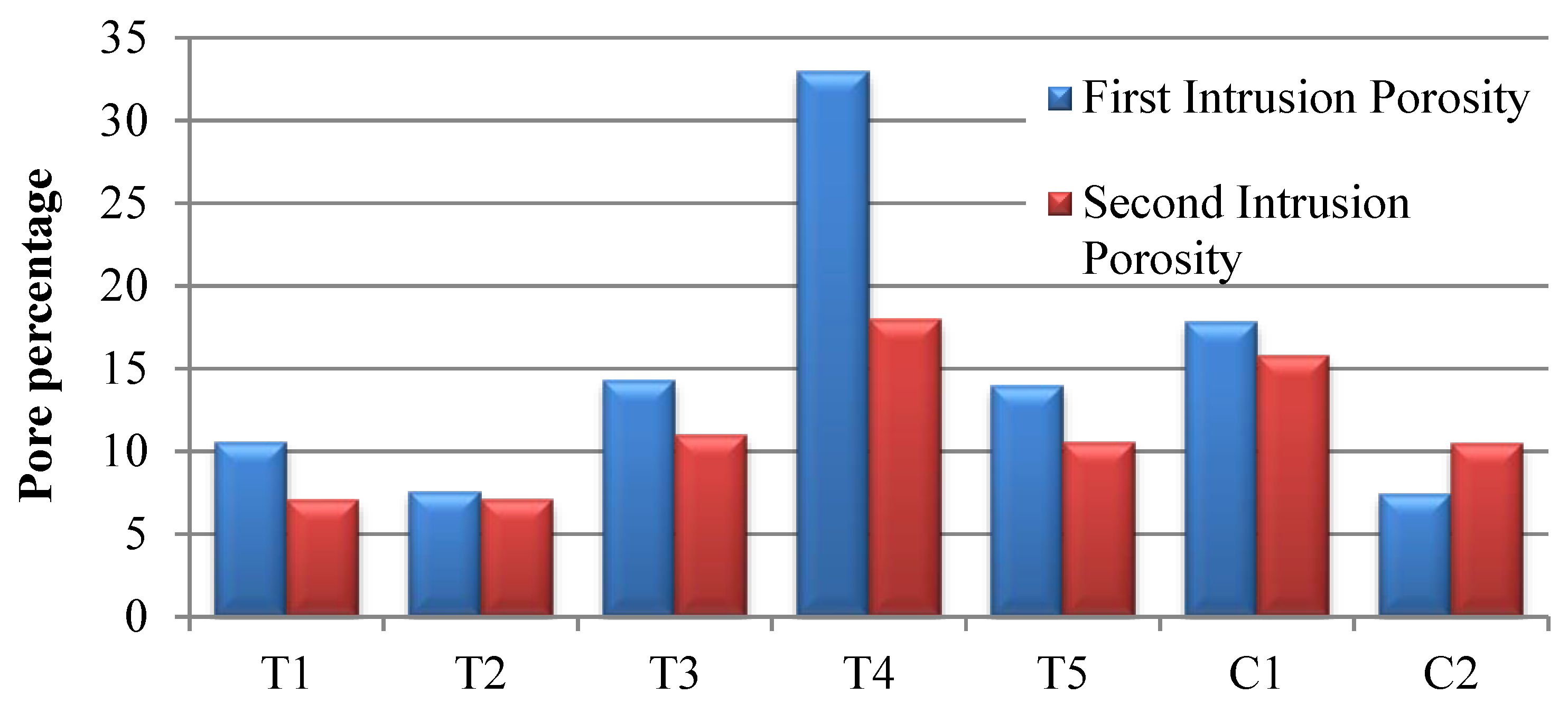

- Additionally, interactions between phonons and pore boundaries can disrupt phonons transport through the coating. Hence, the porosity that most effectively reduces thermal diffusivity is that with the most area oriented perpendicular to the direction of heat transfer [23]. Therefore, higher porosity level in the form of IPBs within the C1 coating, and which ran roughly perpendicular to the primary heat transfer direction, will have increased the effectiveness of the porosity within this coating at reducing thermal conductivity.

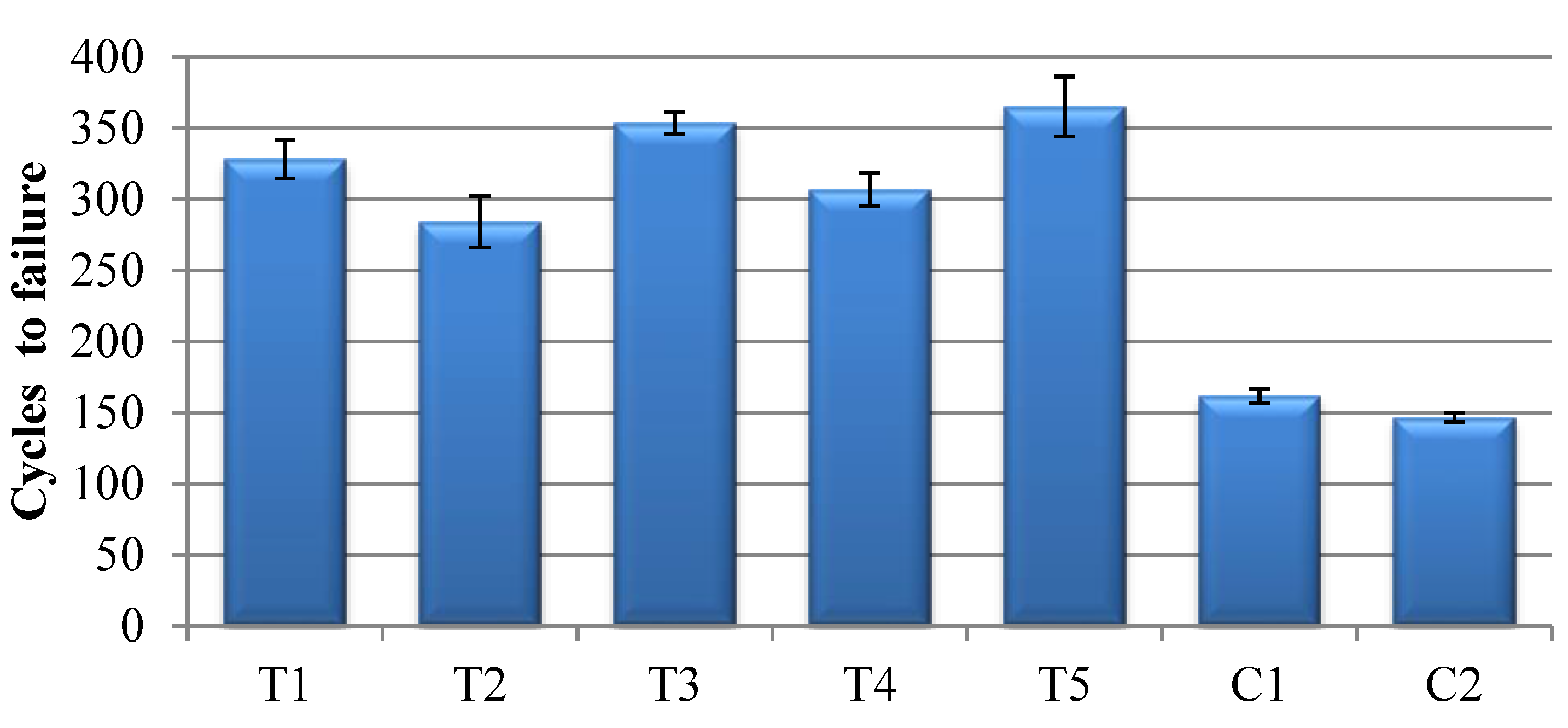

3.4. Thermo-Cyclic Fatigue

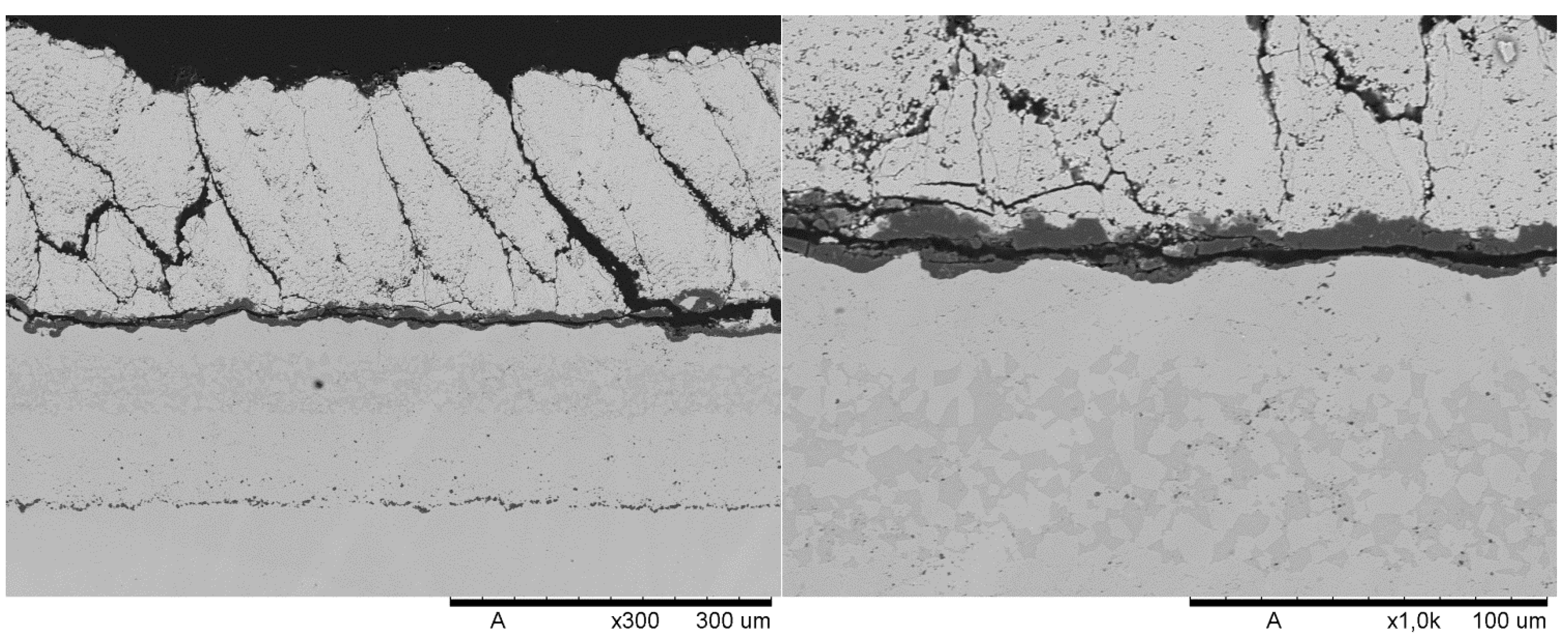

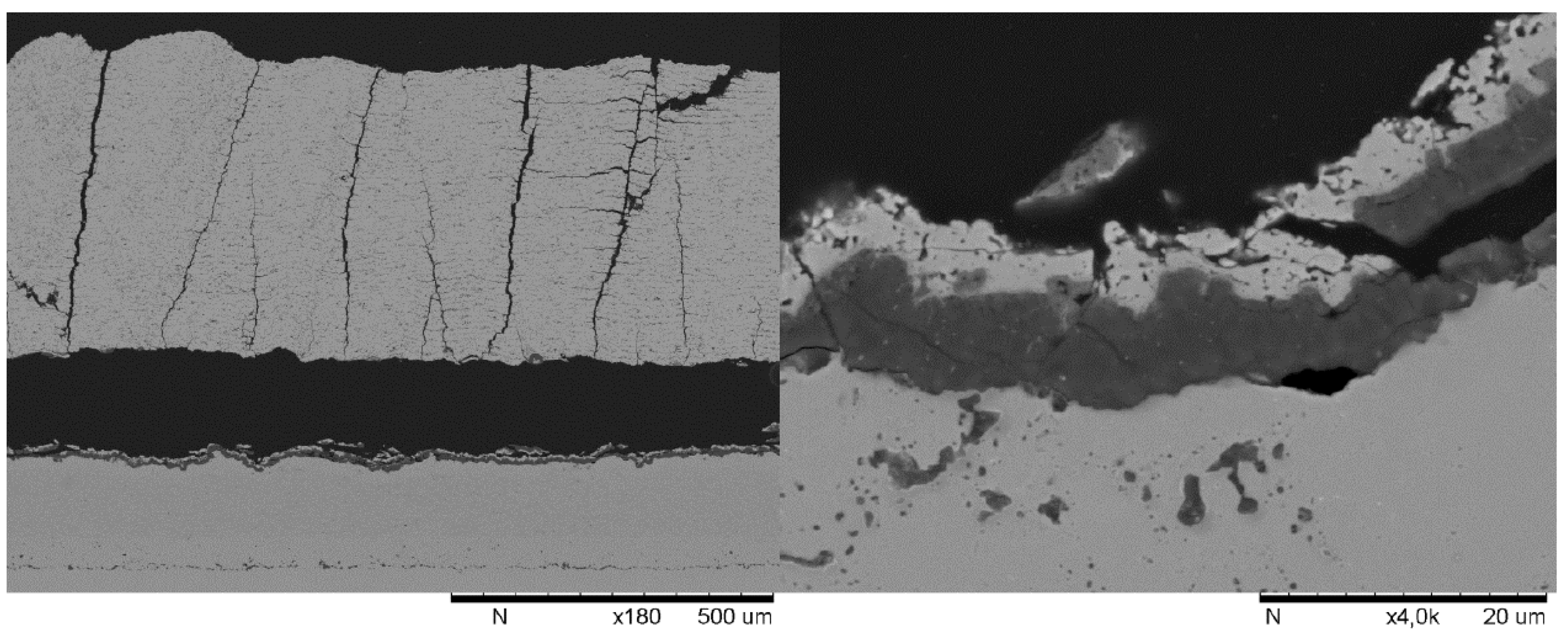

3.5. Failure Microstructures

4. Conclusions

- For ethanol-based suspensions, the tendency for columnar microstructure formation increases with reducing suspension viscosity due to stronger atomization of the suspension and resultant smaller particles in the plasma plume. Additionally, increasing suspension viscosity increased the coating thermal conductivity and tended to reduce the thermo-cyclic fatigue lifetimes.

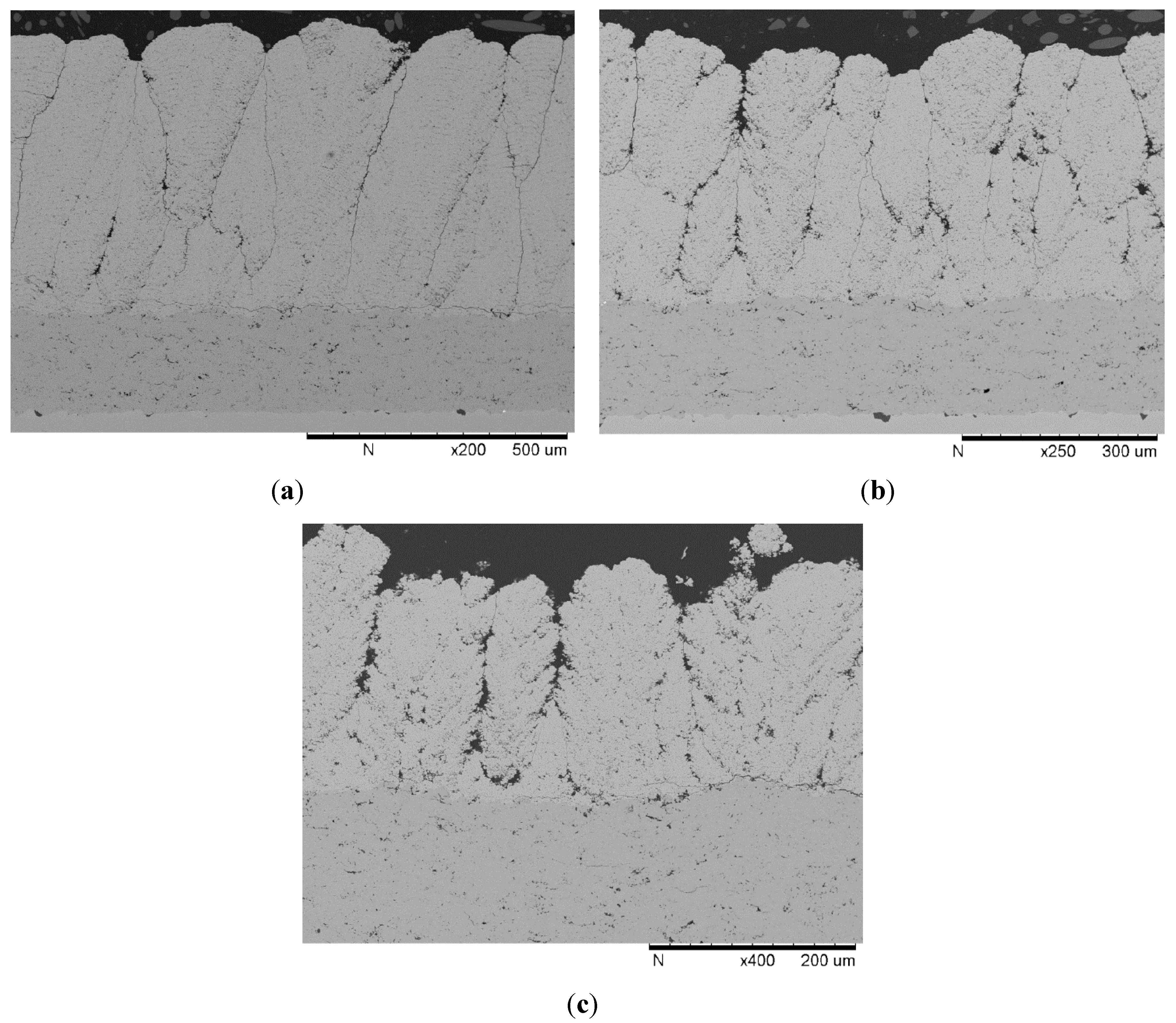

- Changing the suspension solvent from ethanol to water produced a shift in the coating microstructure morphology from columnar to vertically-cracked. Higher suspension surface tension; due to moving from ethanol to water as a solvent, has the tendency to dramatically increase atomized droplet size and therefore transitions deposition to a more APS-like coating. This change also increased the coating thermal conductivity by roughly 3% and decreased the thermo-cyclic fatigue life by 54%.

- Median powder particle size in suspension has only an indirect impact on the size of the depositing droplets and consequently the coating deposition type. It is clear that the simple metric of powder size in suspension is not sufficient to help define parameters for suspension plasma spray coating.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Killinger, A.; Gadow, R.; Mauer, G.; Guignard, A.; Vaßen, R.; Stöver, D. Review of new developments in suspension and solution precursor thermal spray processes. J. Therm. Spray Technol. 2011, 20, 677–695. [Google Scholar] [CrossRef]

- Bacciochini, A.; Ilavsky, J.; Montavon, G.; Denoirjean, A.; Ben-ettouil, F.; Valette, S.; Fauchais, P.; Wittmann-teneze, K. Quantification of void network architectures of suspension plasma-sprayed (SPS) yttria-stabilized zirconia (YSZ) coatings using ultra-small-angle X-ray scattering (USAXS). Mater. Sci. Eng. A 2010, 528, 91–102. [Google Scholar] [CrossRef]

- Feuerstein, A.; Knapp, J.; Taylor, T.; Ashary, A.; Bolcavage, A.; Hitchman, N. Technical and economical aspects of current thermal barrier coating systems for gas turbine engines by thermal spray and EB-PVD: A review. J. Therm. Spray Technol. 2008, 17, 199–213. [Google Scholar] [CrossRef]

- Berghaus, J.O.; Bouaricha, S.; Legoux, J.-G.; Moreau, C.; Chráska, T. Suspension plasma spraying of nano-ceramics using and axial injection torch. In Proceedings of the International Thermal Spray Conference, Basel, Switzerland, 2–4 May 2005.

- Fauchais, P.; Vardelle, M.; Goutier, S.; Vardelle, A. Key challenges and opportunities in suspension and solution plasma spraying. Plasma Chem. Plasma Process. 2015, 35, 511–525. [Google Scholar] [CrossRef]

- VanEvery, K.; Krane, M.; Trice, R.; Wang, H.; Porter, W.; Besser, M.; Sordelet, D.; Ilavsky, J.; Almer, J. Column formation in suspension plasma-sprayed coatings and resultant thermal properties. J. Therm. Spray Technol. 2011, 20, 817–828. [Google Scholar] [CrossRef]

- Fazilleau, J.; Delbos, C.; Rat, V.; Coudert, J.F.; Fauchais, P.; Pateyron, B. Phenomena involved in suspension plasma spraying part 1: Suspension injection and behavior. Plasma Chem. Plasma Process. 2006, 26, 371–391. [Google Scholar] [CrossRef]

- Fauchais, P.; Rat, V.; Coudert, J.-F.; Etchart-Salas, R.; Montavon, G. Operating parameters for suspension and solution plasma-spray coatings. Surf. Coat. Technol. 2008, 202, 4309–4317. [Google Scholar] [CrossRef]

- Pawlowski, L. Suspension and solution thermal spray coatings. Surf. Coat. Technol. 2009, 203, 2807–2829. [Google Scholar] [CrossRef]

- Wolfe, H.E.; Anderson, W.H. Kenetics, Mechanism, and Resultant Droplet Sizes of the Aerodynamic Breakup of Liquid Drops. Aerojet General Corporation Research and Development Department: Downey, CA, USA, 1964. [Google Scholar]

- Rampon, R.; Marchand, O.; Filiatre, C.; Bertrand, G. Influence of suspension characteristics on coatings microstructure obtained by suspension plasma spraying. Surf. Coat. Technol. 2008, 202, 4337–4342. [Google Scholar] [CrossRef]

- Curry, N.; VanEvery, K.; Snyder, T.; Markocsan, N. Thermal conductivity analysis and lifetime testing of suspension plasma-sprayed thermal barrier coatings. Coatings 2014, 4, 630–650. [Google Scholar] [CrossRef]

- Curry, N.; Tang, Z.; Markocsan, N.; Nylén, P. Influence of bond coat surface roughness on the structure of axial suspension plasma spray thermal barrier coatings—Thermal and lifetime performance. Surf. Coat. Technol. 2015, 268, 15–23. [Google Scholar] [CrossRef]

- Gong, K.; VanEvery, H.; Wang, R.W. Trice, Microstructure and thermal properties of inflight rare-earth doped thermal barriers prepared by suspension plasma spray. J. Eur. Ceram. Soc. 2014, 34, 1243–53. [Google Scholar] [CrossRef]

- Taylor, R.E. Thermal conductivity determinations of thermal barrier coatings. Mater. Sci. Eng. A 1998, 245, 160–167. [Google Scholar] [CrossRef]

- Curry, N.; Markocsan, N.; Östergren, L.; Li, X.-H.; Dorfman, M. Evaluation of the lifetime and thermal conductivity of dysprosia-stabilized thermal barrier coating systems. J. Therm. Spray Technol. 2013, 22, 864–872. [Google Scholar] [CrossRef]

- Curry, N.; Donoghue, J. Evolution of thermal conductivity of dysprosia stabilised thermal barrier coating systems during heat treatment. Surf. Coat. Technol. 2012, 209, 38–43. [Google Scholar] [CrossRef]

- ISO 10545-3:1995 Ceramic Tiles Part 3: Determination of Water Absorption, Apparent Porosity, Apparent Relative Density and Bulk Density; International Organization for Standardization: Geneva, Switzerland, 2010.

- Pateyron, B.; Calve, N.; Pawlowski, L. Influence of water and ethanol on transport properties of the jets used in suspension plasma spraying. Surf. Coat. Technol. 2013, 220, 257–260. [Google Scholar] [CrossRef]

- Nicholls, J.R.; Lawson, K.J.; Johnstone, A.; Rickerby, D.S. Methods to reduce the thermal conductivity of EB-PVD TBCs. Surf. Coat. Technol. 2002, 151–152, 383–391. [Google Scholar] [CrossRef]

- Schelling, P.K.; Phillpot, S.R. Mechanism of thermal transport in zirconia and yttria-stabilized zirconia by molecular-dynamics simulation. J. Am. Ceram. Soc. 2001, 84, 2997–3007. [Google Scholar] [CrossRef]

- Klemens, P.G. Theory of Thermal Conduction in Thin Ceramic Films. Int. J. Thermophys. 2001, 22, 265–275. [Google Scholar] [CrossRef]

- Bjorneklett, A.; Haukeland, L.; Wigren, J.; Kristiansen, H. Effective medium theory and the thermal conductivity of plasma-sprayed ceramic coatings. J. Mater. Sci. 1994, 29, 4043–4050. [Google Scholar] [CrossRef]

- Curry, N.; Markocsan, N.; Li, X.-H.; Tricoire, A.; Dorfman, M. Next generation thermal barrier coatings for the gas turbine industry. J. Therm. Spray Technol. 2010, 20, 108–115. [Google Scholar] [CrossRef]

- Hille, T.S.; Nijdam, T.J.; Suiker, A.S.J.; Turteltaub, S.; Sloof, W.G. Damage growth triggered by interface irregularities in thermal Barrier Coatings. Acta Mater. 2009, 57, 2624–2630. [Google Scholar] [CrossRef]

- Hille, T.S.; Turteltaub, S.; Suiker, A.S.J. Oxide growth and damage evolution in thermal barrier coatings. Eng. Fract. Mech. 2011, 78, 2139–2152. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Curry, N.; VanEvery, K.; Snyder, T.; Susnjar, J.; Bjorklund, S. Performance Testing of Suspension Plasma Sprayed Thermal Barrier Coatings Produced with Varied Suspension Parameters. Coatings 2015, 5, 338-356. https://doi.org/10.3390/coatings5030338

Curry N, VanEvery K, Snyder T, Susnjar J, Bjorklund S. Performance Testing of Suspension Plasma Sprayed Thermal Barrier Coatings Produced with Varied Suspension Parameters. Coatings. 2015; 5(3):338-356. https://doi.org/10.3390/coatings5030338

Chicago/Turabian StyleCurry, Nicholas, Kent VanEvery, Todd Snyder, Johann Susnjar, and Stefan Bjorklund. 2015. "Performance Testing of Suspension Plasma Sprayed Thermal Barrier Coatings Produced with Varied Suspension Parameters" Coatings 5, no. 3: 338-356. https://doi.org/10.3390/coatings5030338