The following sections will detail the rationale behind the coating development and potential uses, including curing processes, the optimization of formulations, coating procedures, characterization of formed coatings, and long-term stability testing. The thirteen formulas disclosed are provided as examples from the development process which led to the primary systems (10–13) which are discussed at a greater length below.

3.2. Chemical Characterization

Chemical analysis was carried out using ATR-FTIR and TGA to probe the curing. A representative ATR-FTIR was taken for the solution and spray coated glass surfaces of formula 10 to observe changes occurring during the curing process at time = 0 and after 1 week (

Figure 1). The solution spectra primarily show the presence and loss of methanol and isopropanol by the O–H stretching at 3300 cm

−1, C–H peaks at 2900 cm

−1, C–O stretching at 1085 cm

−1, and C–O stretching 1033 cm

−1, and O–H Bending at 950 cm

−1 which are mostly absent from the cured sample. Additionally, the absence of 1° amine and alcohol peaks in the final product suggests the reactivity of the secondary epoxy and amine process occurred; however partial products may still be present in the system. S–H peaks are absent around 2600 cm

−1 or C=C–H peaks around 3000 cm

−1 in the coated spectra, suggesting minimal amounts of vinyl remain in the system, supporting that the thiol-ene reaction reaches completeness. Furthermore, the peaks at 1012 and 875 cm

−1 in the cured spectra indicate the presence of a combination consisting of Si–O, C–O, and Si–O–C bonds which would be expected of alkoxysilanes and partially reacted species, supporting the occurrence of the tertiary sol-gel reaction expected to take place over a more extended time period.

These findings are supported through a timelapse ATR-FTIR of formula 11, from 1 min post cure (T

3) until the surface was hard to the touch (T

35). Within the first 5 min, there is a loss of the O–H stretching at 3400 cm

−1; and over time the Si–O band at ~1100 cm

−1 gets stronger, suggesting the formation of Si–O–Si bonds (

Figure S1). After 209 days passed, peaks were still observed around 3300 cm

−1, 2930 cm

−1, and 1010 cm

−1 with notable peaks at 1590 cm

−1 and 1410 cm

−1 suggesting the presence of amine and O–H groups in a sample of formula 11 (

Figure S2). Once monument 1 (formula 11) reached 365 days of field testing, a small section of the head stone coating was removed by a razor blade and analyzed with ATR-FTIR (

Figure S3). This spectrum shows similar peaks as those seen previously, however the indication of an amine peak at 1590 has shifted to 1650 cm

−1. FTIR of formula 12 at 1 day and 178 days after application on a glass slide, and of a 282-day old outdoor sample all exhibit similar peaks as those mentioned above; however, an additional amine peak is observed around 1650 cm

−1 in these samples (

Figures S4–S6). This suggest the presence of different amines as indicated to be likely in

Scheme 1. Lastly, spectra were obtained for formula 13 (

Figure S7) which shows the presence of thiol at 2600 cm

−1 in addition to the peaks seen above.

Siloxane formation is further supported through TGA analysis (

Figures S8–S13). When allowed to fully cure prior to analysis (2 weeks), these coatings remain stable with a T

d5% of 308 °C, 275 °C, and 262 °C for formulas 10, 11, and 12, respectively, which is within the anticipated range for siloxane network stability. After time elapsed some samples exhibited slightly lower stabilities with shifts in their Td

5% values to 254 °C (formula 11 at 209 days), 263 °C (formula 12 at 178 days), and 230 °C (formula 12 with 282 days of environmental exposure). All three samples show an indication of moisture by a slow decline in mass up to 100 °C with the outdoor sample showing the largest decrease in this region at 2% of the sample, and a T

d7% of 260 °C supporting this theory. Each of these samples indicate proper formation of Si–O–Si bonds and relatively constant thermal stabilities over time.

Elemental weight percentages were obtained using a Keyence Laser-based Elemental Analyzer EA-300 series. The laser-induced break down spectroscopy is performed under ambient atmosphere and can’t measure nitrogen, preventing confirmation of amine presence. Despite this the analysis gives reasonable weight percentages for formulas 11, 12, and 13 when considering the relative amounts of elements in each system without solvent and the small sample area (10 μm diameter) (

Table S1).

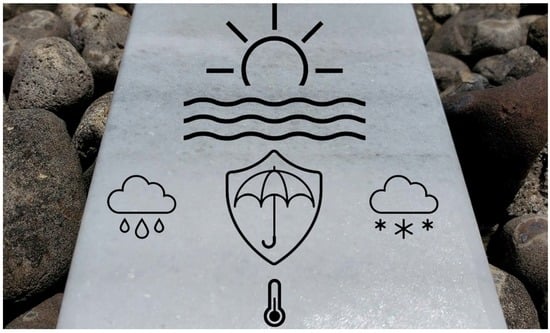

3.3. Formulation

Formulations were developed with several end-of-life goals in mind: (1) The solution is made in a single container as a no-mix system, (2) the final formulations have a pot life exceeding one year, (3) the solution can be applied as a spray-on coating, and (4) they have potential recyclability. Each of these goals have been achieved to different extents with pot lives of some coatings even achieving a year or more of dark stability.

Over 100 different formulations were developed, and all designs fell within the ranges of the components given in

Table 1; however, one series resulted in a desirable set of model systems which will be addressed as formulas 1–13. These solutions are named in the order of their development and were used for the analysis of the properties detailed in this article (

Table 2). Formulations were designed with rapid curing in mind and adjustments to how quickly the coating dries can be made by using longer chain alcohols for the carrier solvent, lengthening the time it takes for the network to settle/arrange on the surface. The developed systems may be applied through spraying, dipping, or wiping, but they were intentionally designed with pressurized pump-spray systems in mind for outdoor use. The intended use for monument preservation led to most of the testing being focused on sprayed-and-dipped applications utilizing marble/granite samples.

Initial design began with a series of solutions containing various ratios of components with relatively low solvent percentages (10%–15%) and octamethylcyclotetrasiloxane (D4) as a non-reactive diluent to improve surface leveling. These were designed to investigate the effects of altering the ratios of components pertaining to the different curing methods. This was achieved by systematically increasing one set of components while decreasing another over a range of volume percentages and repeating the process for multiple combinations of adjustments (i.e., increasing thiol-ene/lowering adhesion, increasing adhesion/decreasing fluorocarbon). The resulting coatings were inspected for their hydrophobicity; systems which did not delaminate after initial curing were chosen for further exploration, including formula 1.

The next set of solutions were designed to investigate adjustments using formula 1 as a basis. From these samples it was decided to remove D4 as the system was intended for spray application and this component added unnecessary cost and health risk to the end-user. While adhesion was successful in these D4-free systems, delamination was still occurring during the secondary and tertiary curing processes days later, and thus a series of solutions were designed to see the effects of increasing the solvent ratio from <15% to 25%, 50%, and 70%. From these dilutions the delamination occurring upon hardening was resolved, suggesting earlier systems were too thick. These thinner samples were coated on glass to offer an even surface to compare static contact angles (see physical characterization). Formula 2 was found to have the highest contact angle from the diluted solutions when inspected on glass and became the new base formulation to build on.

When designing the various formulations, increased hydrophobicity and ensured long-term survival to water exposure were tested. Included in these tests were the implantation of different vinyl-containing compounds as crosslinkers, the potential for an increased reaction rate through the addition of acetic acid to the solution, as well as modifications to the surface by way of nanoparticle formations [

38], both of which were unsuccessful. Then the best samples were chosen from all previous formulations based on contact angles, adhesion, and removability of permanent marker ink. Of these variations, it was deemed an unnecessary expense to implement nanoparticles, addition of acetic acid lowered the contact angle slightly, and most alternative crosslinkers delaminated. From these results, formula 3 (

Table 2) was chosen for further testing due to its optimal performance. However, delamination was still observed in this system during the long-term exposure testing (see physical characterization) where it was submersed in water for 24 h.

To resolve the delamination issues, several sets of this formula were investigated with varying coating thicknesses, UV exposure times, alternative solvents, annealing, and the addition of tetrabutylammonium fluoride (TBAF) as a co-catalyst aid in the sol-gel process. From these tests it was determined that coating thicknesses (~ 2–10 µm) resulting from applying approximately 1.2 mL of solution on an 8.5 cm × 10 cm marble surface (1 mL for 70.8 cm2) eliminated delamination from curing and submersion testing. The new application parameters resulted in formula 4, where the ratios remained relatively the same as formula 3. Samples which implemented TBAF for the sol-gel process had delamination and flaking issues upon curing, and thus were not pursued. Additionally, these tests showed that increasing the cure time and annealing at 45 °C for 24 h resulted in an increase in static contact angles over formula 3 which had 2 min of UV exposure and cured at room temperature. While increasing hydrophobicity/contact angles was a main priority, annealing and elongated cure times were not used during batch sampling indoors, but showed promise for future outdoor applications. Ethanol was used as the carrier solvent for formula 5 and, while it had similar graffiti resistance and contact angles, it delaminated after water submersion testing where system 4 survived water, acid rain, and base solution submersion testing and both utilized similar application parameters.

After water sourced delamination was resolved through the success seen in formula 4, development focused on the effects of coating method and surface preparation to enhance overall adhesion. Results suggested that application method (spray, wipe, or dip coated) had little alteration on the resulting coating, however when comparing stone pretreated with water, vinegar (5%), or 0.11 M Nitric Acid, an improved contact angle was seen in the latter. The collective findings at this point suggested the use of a thinner coating is necessary overall and nitric acid prepped surfaces (mimicking acid rain exposure) are ideal for indoor stone applications.

Further investigation looked at the additive effect of the fluorocarbon species through formulas 6 and 7 which confirmed its role in hydrophobicity. Minimal amounts of triethoxy(1H,1H,2H,2H-nonafluorohexyl) silane were used due to the purchase cost, but removing it completely resulted in a decreased contact angle of 92.6° in formula 6. Testing showed that increasing the amount used resulted in an increase from 97.1° (~3%) to 101.5° (~10%) in the observed contact angle between formulas 4 and 7, however, to explore ratios higher than this range was deemed an unnecessary cost. Similarly, a set of samples were made without the thiol-ene components according to the same conditions. The same samples delaminated, suggesting the thiol most likely relieves tension in the alkoxysilane network.

In an effort to increase the overall hydrophobicity and reaction rate, a photo acid generator (diphenyliodonium hexafluorophosphate) was added in small amounts and the effects on contact angle were compared through formulas 8 and 9. When used in high concentrations, as with formula 8, the system was non-impressionable within 9 min and lower amounts maintained the previously achieved 30-min surface hardness. Ultimately, small amounts of the photo acid generator (PAG) were utilized, as adding too much decreased the observed contact angle, where a higher concentration in formula 8, and lower amount in formula 9 showed a sizeable difference (95.9° vs. 101.5°). These systems were used in the initial outdoor testing, but the solvent in the first samples of each evaporated before curing could be achieved. In response, the formulas were diluted with isopropanol where a diluted formula 8 is still in the field on a smaller marble sample at 371 days, as of this writing. Variations of formula 9 were made using isopropanol as the sole solvent (formula 10) and mixed with methanol (formula 11). Both systems were used for various properties testing to explore the effects of altering the solvent.

The mixed solution 11 was used in the first upscale application on a granite headstone (monument 1), which remains unaffected after 371 days of outdoor exposure at this time. Two more systems were designed which used an alternative fluorocarbon, (tridecafluoro-1,1,2,2-tetrahydrooctyl) triethoxysilane, which is longer and cheaper. The first (system 12) uses the isopropanol dilution and has comparative characteristics to formula 11. Alternatively, formula 13 was designed to lengthen the working time of the solution and used a dilution of butanol to increase the time it takes to achieve non-impressionability from 30 min, with the aforementioned systems, to between 68 and 97 min depending upon the application method and thickness. Collectively, formulae 6–13 have shown success in application and testing, while the ideal systems for monument preservation are formulas 11–13 depending on the user’s needs for cost and working time. Formulas 11 and 12 were utilized for the majority of the detailed characterization and properties testing described below due to their initial results and large batch quantities since many tests required large amounts of coating to perform (i.e., dip coating for oxidation testing).

3.5. Physical Characterization

Surface inspection was performed through SEM images to investigate how the coating adheres to the various substrates and its general appearance/coverage. Initial pictures focused on marble samples coated with formula 11. In both the 50× and 300× images, there is a drastic difference in the surface once the solution settled into the grooves of the calcite (marble), giving a much smoother appearance (

Figure 2). Coated regions have a lower resolution since the electron beam interacts with the transparent coating, resulting in a dark, semi-opaque appearance of features which becomes more intense the thicker the coating is. There is evidence of micron-sized protrusions in the 1000×, coated image, suggesting a thin, secondary application may be necessary to protect the rough stone. The abrasive removal of the top layer of stone using sandpaper is evident through the tracts seen in

Figure 2C, and the transition from the raw to the protected surface is easily distinguished. Due to air pockets trapped under the coating, imaging a thicker surface resulted in fissures forming in these areas upon exposure to high vacuum, which is seen in all porous or rough surfaces imaged and is verified through imaging of a smooth substrate detailed later.

Later in the development process, a piece of the coated monument 1 (formula 11) was chiseled out of lettering after 331 days, the extrusion inside of the R in “FORCE” (detailed below and shown in

Figures S28 and S29). This was used to take SEM images of the same coating after long-term weathering to confirm the presence of and stability of the coating on granite (quartz and feldspar) surfaces. As seen in

Figure S14, the coating has formed a complete layer notable by the observed smoothness and continuous color which includes confirmed regions. Like what is observed in the other stones coated with formula 11, areas where the coating formed an air pocket due to the porous nature of stone resulted in a fissure after exposure to the high vacuum, serving as a verification of its presence after 331 days. Once monument 1 achieved 365 days of field testing, another extrusion was removed from the R in “AIR” in a similar process. The SEM images of this sample show similar confirmations as the sample taken at 331 days supporting its durability up to and exceeding one year (

Figure 3).

Images of the raw glass surface show spotting from oils, while the surface coated with formula 11 has minimal distinctions. Glass microscope slides have no surface depressions that air could be trapped in, eliminating the presence of fissures seen in the stone micrographs. A region of the surface which had encased debris and formed a defect was chosen as the remainder of the area was featureless, and both sides are smooth by nature (

Figure S15). The raw glass appears dirtier despite both sides being cleaned with dry air prior to imaging.

An example stainless steel sample (histology blade) was inspected by SEM after being dip-coated with formula 12, which includes an ultra-fine edge less than one micron thick (

Figure 4 and

Figure S16). A slight bevel is visible on the coated surface where the system closely encases the hone, but the overall edge remains well defined. Small indentations are evident in the final magnification; however, there is no evidence of any system defects, and the entirety of the blade edge remains smoother than the uncoated example. This suggests that this system may be used to cover acute angles on the microscopic scale.

Lastly, the surface interaction of a nitrile glove and wipe-on coating was investigated. Detailed imaging shows how the formula 11 coating covers and fills in many depressions on the surface (

Figure S17). At 1000× magnification, a depression in the surface illustrates how thin plates are formed through this application method. While the entire surface is not covered, this may offer additional protection against chemicals that traditionally penetrate nitrile gloves, since the coating exhibited no changes when exposed to some of these reagents detailed below such as THF or DCM.

Examples of coating thickness were analyzed for sprayed and dipped samples. An initial investigation of surface topography and coating thickness was carried out with a Keyence 3D Laser Confocal Microscope and formula 1 applied to stone and steel substrates. Topography mapping of the uncoated and coated sides of a single stone specimen shows a more subtle and consistent surface across the region, which indicates settling of the coating within the depressions of the surface (

Figure S18). Coating deposition on a brick surface supports this idea as the solution appears to coat the surface, filling in many imperfections, and getting absorbed into the substrate (

Figure S19). Film thickness was assessed using a piece of stainless steel and measuring the distance between the upper and lower scanned surfaces, giving an estimated thickness measurement of 13.19 µm (

Figure 5). Next, ten measurements were taken for Formulas 11 and 12 applied to glass slides and used to calculate the average thickness (

Table S2). Sprayed samples had an average thickness of 2.76 µm (11) and 10.28 µm (12) while the dip-coated sample had a thickness of 1.35 µm (12), suggesting that this is the ideal application method for a thinner coating. Both measurement methods suggest a similar thickness, however formula 11 is notably thinner even when sprayed, due to the higher ratio of methanol used.

Coating stability was investigated through submersion tests detailed in the methods section. Starting with formula 4, the systems using methanol as a solvent showed no changes in the surface when submerged in water (pH 6.5), synthetic acid rain (pH 4.3), and a sodium hydroxide (pH 12) solution for 24 h each. Prior to formula 4, delamination was observed with water exposure. Chemical resistance was observed in formulas 8–12 when pieces of cured coating were also exposed to small amounts of THF, hexanes, DCM, ethanol, isopropanol, 0.1 M nitric acid, 0.1 M sodium hydroxide, and acetone with no change in sample size, shape, color, or condition. This stability against acetone is an improvement upon many single cure epoxy coatings which it’s known to remove. When exposed to a siloxane depolymerization solution containing a fluoride catalyst [

42] for four weeks, partial degradation was observed in a sample of formula 10, but the solid was still partially intact, likely due to the thiol-ene and epoxy/amine cross-linking (

Figure S20). The overall chemical inertness is most likely due to a combination of the fluoropolymer and the orthogonal reactions which are susceptible to different chemicals and may shield each other when bound together in a network.

All coatings containing some quantity of fluorocarbon offered graffiti resistant surfaces. Both Sharpie permanent marker and Rust-o-leum outdoor paint can be removed from coated surfaces using a dry Kim-wipe and light force, leaving the coated surface unscathed (

Figures S21 and S22, Gif S1, Videos S1 and S2). Ease of removal is correlated with the presence of the perfluoroalkyl silanes which may repel the solvent in the marker and prevent proper adhesion of the paint to the surface. This has a wide range of implications and is highly beneficial if the coating is used on monuments that are subject to vandalism.

Hydrophobicity was built into this system’s design mainly to prevent water sitting on surfaces of outdoor structures from soaking into them. This was assessed through the measurement of static contact angles. As mentioned above, the implementation of fluorocarbons increased the overall hydrophobicity observed and was integrated into the system for this reason. The range of contact angles observed in the different variations of all formulas explored was larger than the ideal model system and its lineage (1–13) of formation shown in

Table 4; however, all coatings improved upon the contact angles observed on the raw substrates. Coatings on marble had a range between 92.2° and 101.6° with many ideal samples measuring between 96° and 101° throughout the development of the model system. To reduce any effects of surface roughness, some samples were tested on glass microscope slides to ensure consistent comparisons. When applied to glass a maximum contact angle of 105.5° and a minimum of 101.4° were found. The final coatings (11–13) were tested on several different substrates to ascertain their effectiveness on other materials. These results are reasonable when considering formula 12 and 13 which contain ~7% (post cure) of the perfluoroalkyl silane to the pure loading (100% post cure) of the same fluorosilane on marble, glass, and wood which showed static contact angles of 155°, 114°, and 133°, respectively [

51]. A 93% reduction in the amount of this compound still yielded 101°, 101°, and 131° on similar substrates. While hydrophobicity is ideal, using high loads of fluorocompounds reduces the overall applicability of the network, especially when there are no adhesive or crosslinking integrations in the system.

Brick and steel were investigated as they are used in monument construction and have similar environmental erosion issues like stone. Since bricks are porous, contact angles were taken before, post-cure, and several days after for coating formulas 11 and 12. The non-coated surface completely absorbs water droplets within 30 s (

Gif S2). For the first brick formula 11, two days post-cure, it exhibited a contact angle of 103.9° after water sat 10 min on the surface, and at 39 days outdoor, it measured at 94.4° after the coating had worked its way further into the brick (

Figure S23, Gif S3). A second brick was coated and inspected four days post-cure, where the contact angle was measured after 10 min had elapsed from deposition and achieved 129.1°, an extremely high angle compared to our other substrates (

Figure S23, Gif S4). Stainless steel also showed drastic differences in hydrophobicity after dip-coating with formula 12. The uncoated samples had initial contact angles of 53.5° (1) and 58.8° (S1) on the raw surface, but once coated, measured at 103.5° (2) and 103.7° (S2) in

Figure 6 and

Figure S24. This indicated that the coating was highly effective at increasing the hydrophobicity of steel surfaces and may add further protection such as oxidative resistance (see below). Nitrile gloves were also investigated by accident to see if additional hydrophobicity could be imparted. Solutions 11 and 12 were wiped onto the surface, and once hardened, the surface was pulled taught. Contact angles were estimated due to the elastic nature of the substrate, where the raw surfaces were ~88.1°, and the coated samples were appraised around 88.8° (formula 11) and 93.4° (formula 12). While the difference in contact angles was not astounding, water droplets ran off the surface easier than the uncoated glove, which indicates this system has potential for use on vinyl surfaces. The effects of adding the coating to wood was investigated as many historical buildings use it as their main construction material. When comparing both raw and formula 12 coated blocks, water begins absorbing into the wood and within 30 s the droplet has a static contact angle under 50° while after 10 min has elapsed the coated sample still repels the water with a contact angle of 131.7° (

Video S3). Similar effects were seen with the brick samples, suggesting that porous substrates absorb the solution, enhancing the hydrophobicity of the system.

Surface assessment was carried out to investigate the hardness and abrasion resistance of the coating. Pencil hardness tests were conducted with samples on various surfaces (marble, glass, steel), achieving a hardness of 9H (~0.5 GPa) on each for every sample assessed after 2 days cured, the highest rating with this method [

52]. Both marble and glass microscope slides also exhibited a pencil hardness of 9H, however the graphite was difficult to remove from the stone, still visible on the glass, but easily removed from the coated samples. The final coatings surface is relatively hard compared to other coatings systems such as Axalta’s epoxy coating (6H) [

53] and an alkoxysilane coating utilizing the same epoxy component as included here (8H) [

54]. Abrasion resistance was quantified using a combination of sandpaper and sandblasting techniques and measuring the mass lost from each marble sample. Initial tests with small, coated stone (marble) pieces (average of 3.5 cm × 4 cm) had a maximum mass loss of 3 mg after both smooth (400 grit) and then rough (220 grit) sandpapers (with 1.43 kPa applied force). After exposure to both sandpaper trials, two larger samples (average 8.5 cm × 10 cm) exhibited a total mass loss of 4 mg and 7 mg after 100 rub cycles each. Overall, with a direct abrasive force, the change in surfaces may be considered minimal (207.768 g to 207.764 g for formula 8 and 197.445 g to 197.438 g for formula 9). Marring on these stone samples was observable with a microscope but not the naked eye; however, it is evident when repeated on a transparent coated glass slide. Next, the same samples were sandblasted for thirty seconds at 45 psi, and lost 15 mg and 5 mg, respectively, and damage was visibly evident (

Figure 7). This was reinforced by a loss in surface hydrophobicity in the second sample, formula 9, which dropped from 101.5° to 80.3° after sandblasting, suggesting a significant loss of coating (

Figure S25). This suggests that while the coating system is rigid and provides some resistance to minor abrasion, it may not be ideal for protecting surfaces in dry, sandy environments that undergo frequent sandstorms without recoating.

Stainless steel samples were put through oxidative stress using a rusting solution (water, vinegar, and sodium chloride). After dip coating, samples were sprayed or submerged (see methods), and both raw and coated surfaces were observed. When sprayed, the solution quickly rusted the raw surface while the coated surface was adequately protected; this is seen in

Figure 8, where the top half of the sample was left raw and the lower was coated with formula 12. This suggests that the coating system adequately prevents oxidation when exposed periodically through salt spray (

Figure S26). A second rusting test was conducted by submerging a stainless-steel post which was dip-coated directly into the rusting solution (

Figure S27). The second image shows the formation of bubbles on the coating surface, but not the raw material after one day. Once 14 days had passed, significant oxidation had occurred on the uncoated surface, but the coated section only had minor rusting and discoloration, indicating the process had been slowed. Monument preservation includes the reduction of oxidation on a variety of surfaces, the coating system demonstrates promise in this regard, especially when the substrate will remain terrestrial.

Water staining or build up can also be a detriment to coated surfaces, leading to discoloration and calcification over time. Resistance to ion adhesion was tested by partially coating glass slides with formula 12 and using a concentrated synthetic hard water solution with sodium, calcium, and magnesium. Rapid heating resulted in the formation of hard residue on the coated surface, and a dry Kimwipe was used to attempt the removal of it (

Gif S5). Using the same force, the calcification easily wipes off the coated surface, but adheres while crumbling apart on the raw surface. The resulting build-up was soft when the same experiment was conducted but dried through slow heating. A dry Kimwipe was used to remove the spots on the uncoated side (

Gif S6) and coated side (

Gif S7). While the build-up was quickly removed, there was smudging on both sides, which was readily wiped off the coating and remained on the glass. These results suggest that this coating system offers hard water resistance and helps prevent hard water build-up.

Environmental stability was the final physical characterization investigated. Initial testing was performed indoors to test general thermal stability when exposed to varying circumstances. For both methods, heating and cooling, exposure to high (45 °C) and low (−19 °C) temperatures had no noticeable effect on surface appearance, survivability in submersion tests, and a negligible effect on post-exposure contact angles (± 3°). As previously mentioned, submersion tests were also conducted using a synthetic acid rain solution with a pH of 4.3 to mimic outdoor weather phenomena, and there was no effect on the system.

Long-term stability tests were conducted on a flat rooftop, providing a secure outdoor environment (5 story building in Bowling Green, OH) with limited access to reduce the artificial influence. Daily weather and atmospheric conditions have been recorded since the start of these tests, and samples were inspected periodically to ensure continued success and note any unusual events which may affect testing (see weather log in

Supplementary Materials). To gauge the optimal conditions for coating applications, the UV Index was recorded and monitored. This approximates the UV exposure a particular area is forecasted to receive [(mW/m

2/s)/25 mW]. Successful samples were applied during the summer, and early fall with a UV index exceeding 7.2 (~180 mW/m

2/s), compared to the higher power 200 W UVA Lamp used indoors which measures 18.7 mW/cm

2 of power output per second at the used distance. When coated during peak exposure times at a UV Index exceeding 7.2 and a temperature over 21 °C, the sample surface is non-impressionable within 30 min of application as intended. Samples coated at lower UV index ratings and then exposed to higher amounts within two hours saw issues with splitting. This was believed to occur from post hardening thiol-ene reactivity causing stress in the network, which has brought about the suggestion of application with a minimum index of 7 (125 mW/m

2/s). The longest-lived sample/marble slab has been in place for 371 days and used a diluted variation of formula 8 (

Figure 9). Until around 250 days, it had shown no change to the surface, but as seen in

Figure 9D, it has begun to lose the glossy appearance it had; however, the coating is still partially intact and noticeable by touch due to its leathery texture but has lost some hydrophobicity with water droplets spreading on contact.

For upscaling, a granite headstone was cleaned and sanded to remove any existing protective surfaces and then coated using a pressurized pump sprayer which yielded a slightly thicker but even finish (

Gif S8). This monument has been in field testing for 371 days and has experienced various environmental conditions including sun, rain, wind, and snow with no notable surface changes. This may be attributed to the hydrophobicity of the surface and good adhesion of the coating, with smaller-scale samples applied in the same manner exhibiting a contact angle of 100.1° on stone and 105.5° on glass (

Table 4—Formula 11). Before application, the headstone had a dull gray appearance after being sanded and washed (A), and after application, the surface of the stone became more vivid, enhancing the natural colors of the stone (B), as seen in

Figure S28. This change in appearance, accompanied by an increase in the reflectivity of the sun and leathery texture, has continued to indicate the presence and durability of this coating (

Figures S28 and S29) in addition to the verification by SEM imaging after 331 days (

Figure S14) and at 365 days (

Figure 2). A closer look at the edge and etching details emphasizes the difference between the uncoated and protected surfaces as well as the sharpness of detail in the coated surface (

Figure 10). Comparing images of the monument before coating and after 365 days had elapsed (

Figure S28A and Figure S29) using the CIE76 [

50] color difference equation supports the theory that the enhanced detail is from the original stone, and not a defacement. The findings suggest that there is no visible difference between the surface colors on the macroscopic scale with a ΔE*ab = 1, which indicates alterations are not observable to the naked eye, a requirement for preservation coatings (

Figure S30, Formula S1). Two more monuments were coated using formula 12, however these were excluded from stability testing since the first was damaged during nearby construction and the other had partially delaminated due to poor application conditions (wind) causing a thicker coat. Both samples have remained in place for 357 days to gain other data from long-term weathering on this system (ATR-FTIR and TGA). A similar initial enhancement of the surface color is also seen in the two brick samples previously mentioned, but over time this wetted appearance tends to fade (

Figures S31 and S32).