Oleylamine-Mediated Hydrothermal Growth of Millimeter-Long Cu Nanowires and Their Electrocatalytic Activity for Reduction of Nitrate

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

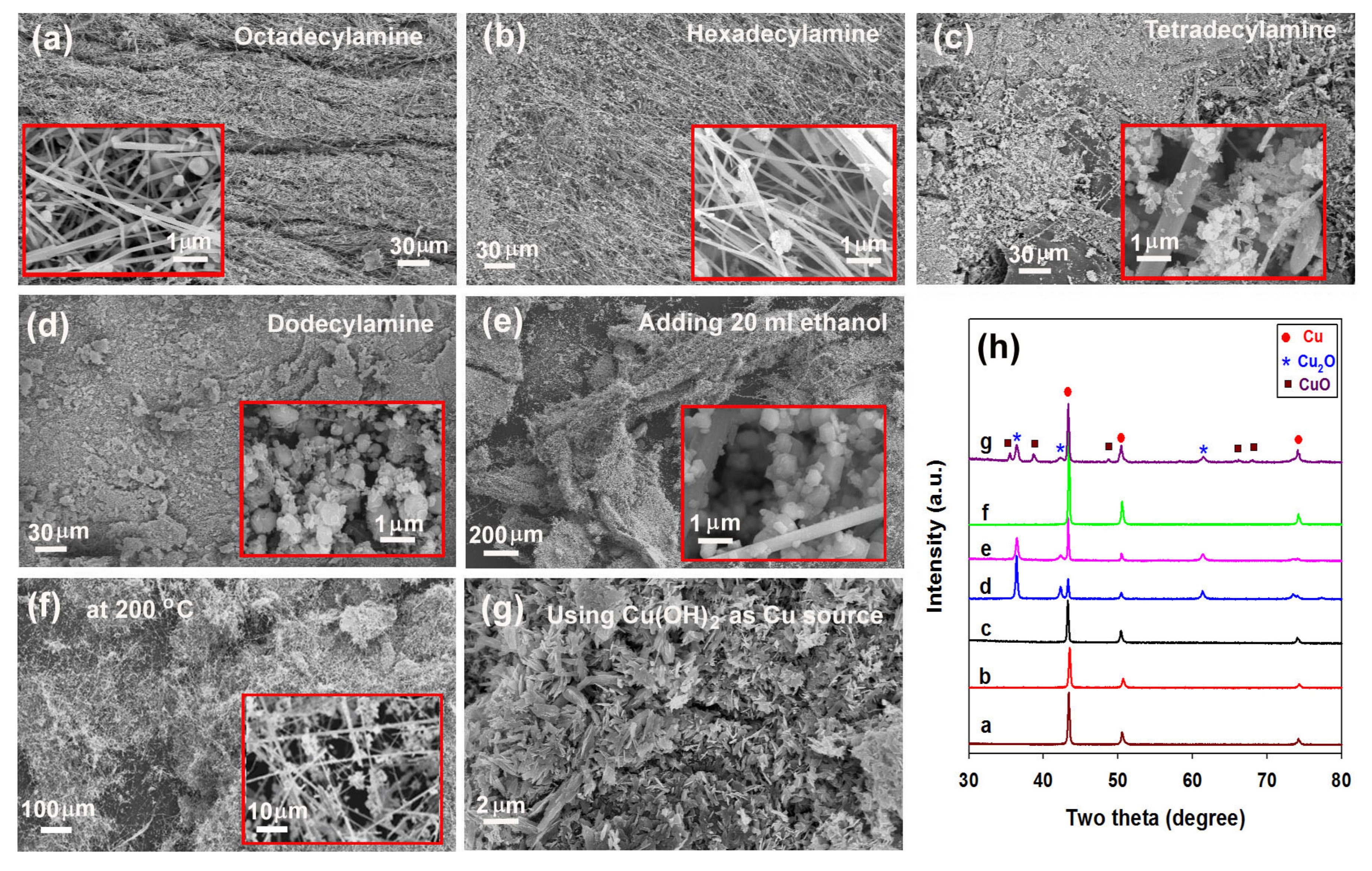

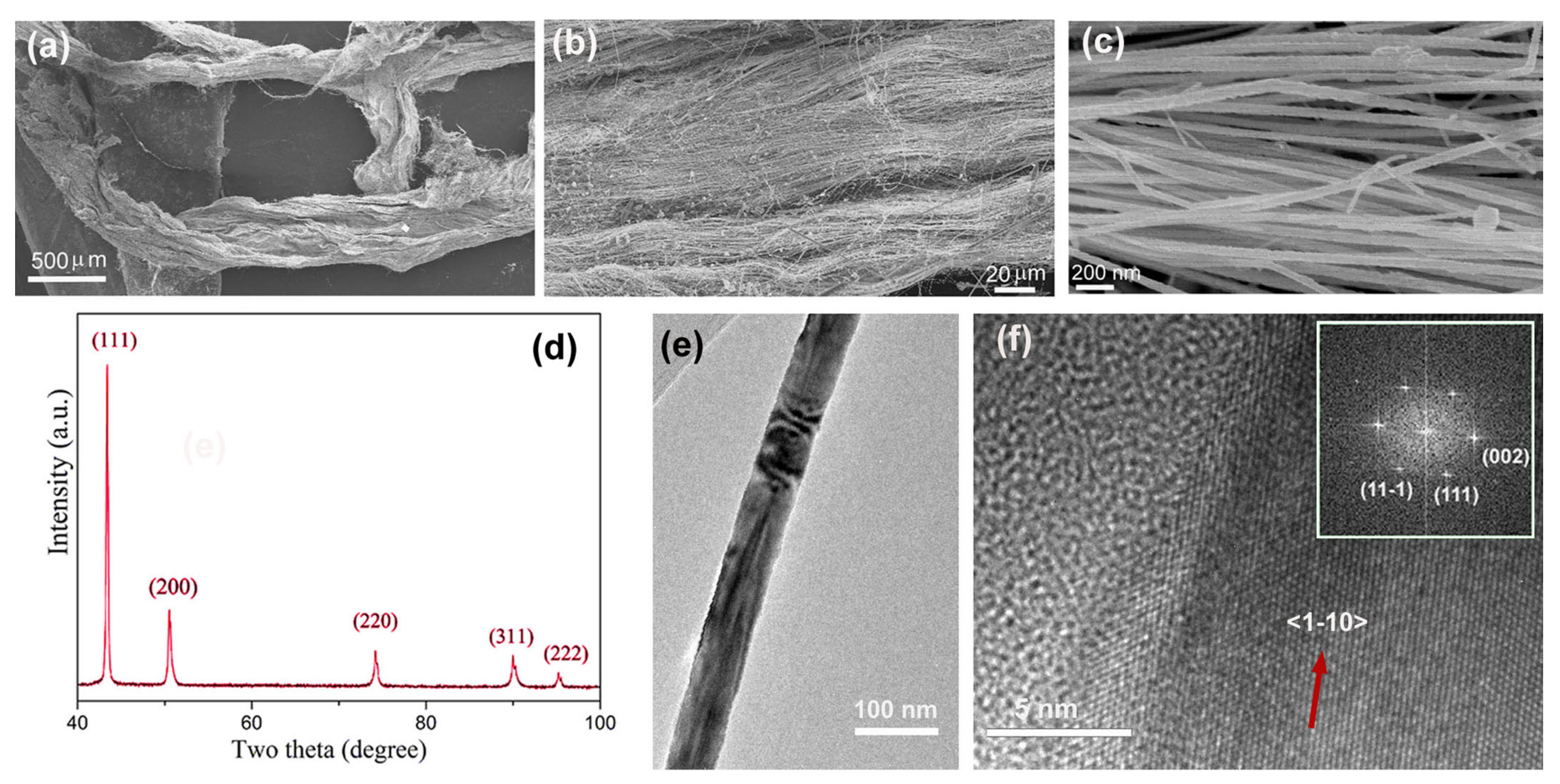

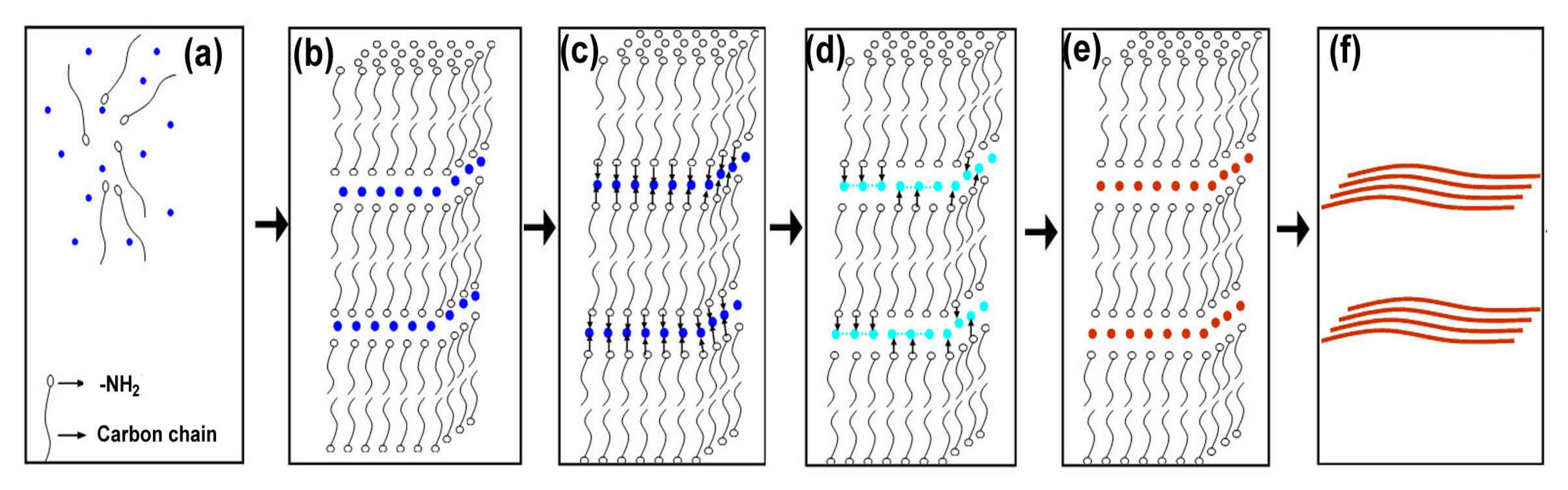

3.1. Oleylamine-Mediated Hydrothermal Growth of Cu Nanowires

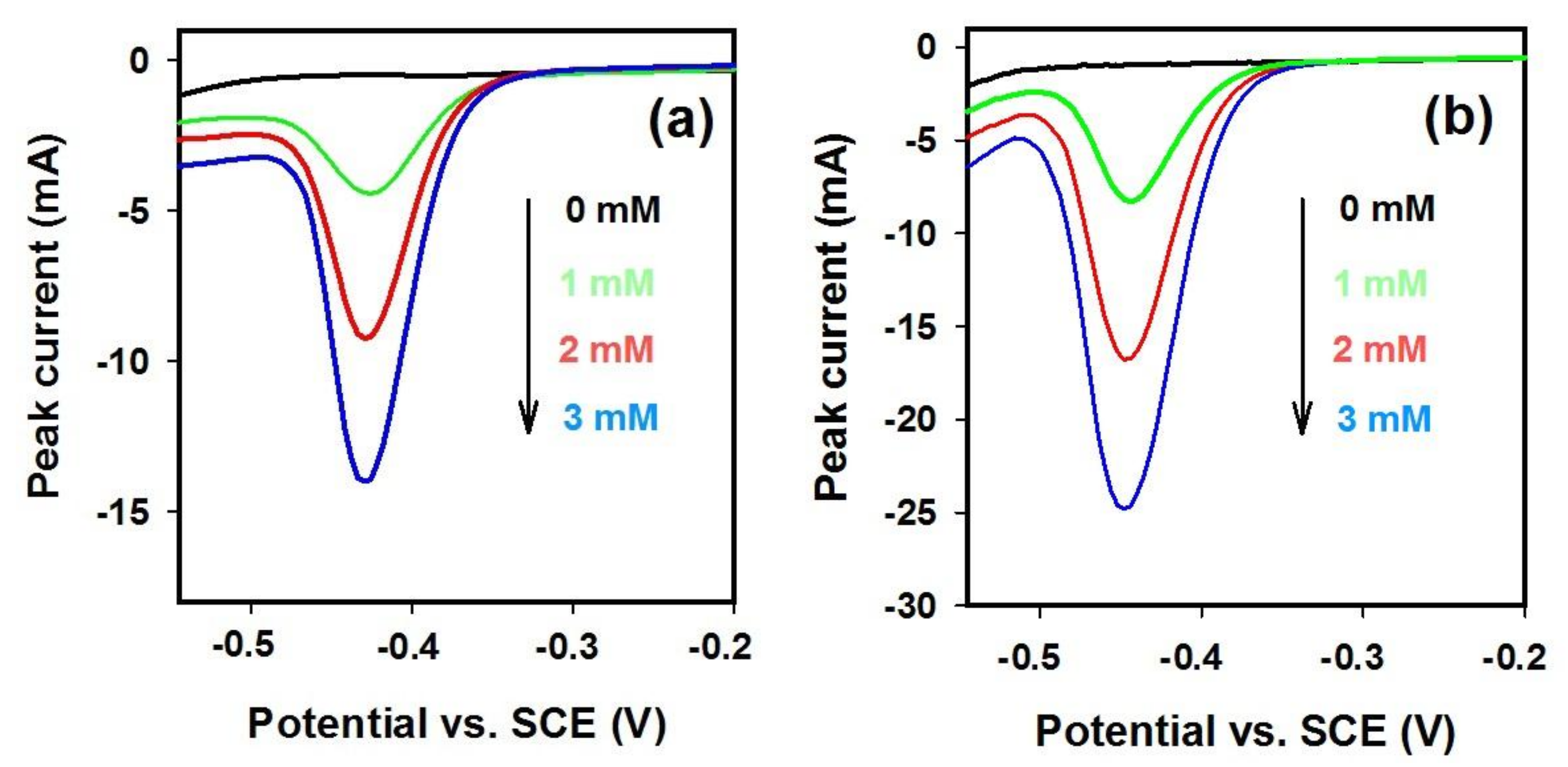

3.2. Self-Supported CuNW Electrodes and Their Electrocatalytic Activity for Nitrate Reduction

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rathmell, A.R.; Bergin, S.M.; Hua, Y.L.; Li, Z.Y.; Wiley, B.J. The growth mechanism of copper nanowires and their properties in flexible, transparent conducting films. Adv. Mater. 2010, 22, 3558–3563. [Google Scholar] [CrossRef] [PubMed]

- Rathmell, A.R.; Wiley, B.J. The synthesis and coating of long, thin copper nanowires to make flexible, transparent conducting films on plastic substrates. Adv. Mater. 2011, 23, 4798–4803. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.Q.; Wang, R.R.; Wen, M.C.; Weng, D.; Cui, X.; Sun, J.; Li, H.X.; Lu, Y.F. Synthesis of ultralong copper nanowires for high-performance transparent electrodes. J. Am. Chem. Soc. 2012, 134, 14283–14286. [Google Scholar] [CrossRef] [PubMed]

- Ye, S.R.; Rathmell, A.R.; Stewart, I.E.; Ha, Y.C.; Wilson, A.R.; Chen, Z.F.; Wiley, B.J. A rapid synthesis of high aspect ratio copper nanowires for high-performance transparent conducting films. Chem. Commun. 2014, 50, 2562–2564. [Google Scholar] [CrossRef] [PubMed]

- Im, H.G.; Jung, S.H.; Jin, J.; Lee, D.; Lee, J.; Lee, D.; Lee, J.Y.; Kim, I.D.; Bae, B.S. Flexible transparent conducting hybrid film using a surface-embedded copper nanowire network: A highly oxidation-resistant copper nanowire electrode for flexible optoelectronics. ACS Nano 2014, 8, 10973–10979. [Google Scholar] [CrossRef] [PubMed]

- Mayousse, C.; Celle, C.; Carella, A.; Simonato, J.P. Synthesis and purification of long copper nanowires. Application to high performance flexible transparent electrodes with and without PEDOT:PSS. Nano Res. 2014, 7, 315–324. [Google Scholar] [CrossRef]

- Li, S.J.; Chen, Y.Y.; Huang, L.J.; Pan, D.C. Large-scale synthesis of well-dispersed copper nanowires in an electric pressure cooker and their application in transparent and conductive networks. Inorg. Chem. 2014, 53, 4440–4444. [Google Scholar] [CrossRef] [PubMed]

- Hwang, C.; An, J.; Chol, B.D.; Kim, K.; Jung, S.W.; Baeg, K.J.; Kim, M.G.; Ok, K.M.; Hong, J. Controlled aqueous synthesis of ultra-long copper nanowires for stretchable transparent conducting electrode. J. Mater. Chem. C 2016, 4, 1441–1447. [Google Scholar] [CrossRef]

- Guo, H.Z.; Lin, N.; Chen, Y.Z.; Wang, Z.W.; Xie, Q.S.; Zheng, T.C.; Gao, N.; Li, S.P.; Kang, J.Y.; Cai, D.J.; et al. Copper nanowires as fully transparent conductive electrodes. Sci. Rep. 2013, 3. [Google Scholar] [CrossRef] [PubMed]

- Cui, F.; Yu, Y.; Dou, L.T.; Sun, J.W.; Yang, Q.; Schildknecht, C.; Schierle-Arndt, K.; Yang, P.D. Synthesis of ultrathin copper nanowires using tris(trimethylsilyl)silane for high-performance and low-haze transparent conductors. Nano Lett. 2015, 15, 7610–7615. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.F.; Rathmell, A.R.; Ye, S.R.; Wilson, A.R.; Wiley, B.J. Optically transparent water oxidation catalysts based on copper nanowires. Angew. Chem. Int. Ed. 2013, 52, 13708–13711. [Google Scholar] [CrossRef] [PubMed]

- Raciti, D.; Livi, K.J.; Wang, C. Highly dense Cu nanowires for low-overpotential CO2 reduction. Nano Lett. 2015, 15, 6829–6835. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.H.; Zheng, Y.F.; Liu, Z.J. Nanowire-based Cu electrode as electrochemical sensor for detection of nitrate in water. Sens. Actuator B Chem. 2016, 232, 336–344. [Google Scholar] [CrossRef]

- Bergin, S.M.; Chen, Y.H.; Rathmell, A.R.; Charbonneau, P.; Li, Z.Y.; Wiley, B.J. The effect of nanowire length and diameter on the properties of transparent, conducting nanowire films. Nanoscale 2012, 4, 1996–2004. [Google Scholar] [CrossRef] [PubMed]

- Venkadesh, A.; Radhakrishnan, S.; Mathiyarasu, J. Eco-friendly synthesis and morphology-dependent superior electrocatalytic properties of CuS nanostructures. Electrochim. Acta 2017, 246, 544–552. [Google Scholar] [CrossRef]

- Radhakrishnan, S.; Kim, H.Y.; Kim, B.S. A novel CuS microflower superstructure based sensitive and selective nonenzymatic glucose detection. Sens. Actuators B Chem. 2016, 233, 93–99. [Google Scholar] [CrossRef]

- Radhakrishnan, S.; Kim, H.Y.; Kim, B.S. Expeditious and eco-friendly fabrication of highly uniform microflower superstructures and their applications in highly durable methanol oxidation and high-performance supercapacitors. J. Mater. Chem. A 2016, 4, 12253–12262. [Google Scholar] [CrossRef]

- Li, J.; Guo, Z.; Liu, J.H.; Huang, X.J. Copper nanowires array: Controllable construction and tunable wettability. J. Phys. Chem. C 2011, 115, 16934–16940. [Google Scholar] [CrossRef]

- Mohl, M.; Pusztai, P.; Kukovecz, A.; Konya, Z.; Kukkola, J.; Kordas, K.; Vajtai, R.; Ajayan, P.M. Low-temperature large-scale synthesis and electrical testing of ultralong copper nanowires. Langmuir 2010, 26, 16496–16502. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.X.; Zhang, Y.; Li, Y.P.; Yan, Z.F. Soft Synthesis of single-crystal copper nanowires of various scales. New J. Chem. 2012, 36, 130–138. [Google Scholar] [CrossRef]

- Chang, Y.; Lye, M.L.; Zeng, H.C. Large-scale synthesis of high-quality ultralong copper nanowires. Langmuir 2005, 21, 3746–3748. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Jin, S. The solution growth of copper nanowires and nanotubes is driven by screw dislocations. Nano Lett. 2012, 12, 234–239. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.F.; Liang, J.H.; Chen, Y.Y.; Liu, Z.J. Economical and green synthesis of Cu nanowires and their use as catalyst for selective hydrogenation of cinnamaldehyde. RSC Adv. 2014, 4, 41683–41689. [Google Scholar] [CrossRef]

- Liu, Z.J.; Chen, Y.Y.; Hu, J.G.; Zheng, Y.F. Synthesis and growth mechanism of Cu nanowires in the presence of different linear alkyl diamines. Sci. Adv. Mater. 2014, 6, 327–335. [Google Scholar] [CrossRef]

- Jin, M.S.; He, G.N.; Zhang, H.; Zeng, J.; Xie, Z.X.; Xia, Y.N. Shape-controlled synthesis of copper nanocrystals in an aqueous solution with glucose as a reducing agent and hexadecylamine as a capping agent. Angew. Chem. Int. Ed. 2011, 50, 10560–10564. [Google Scholar] [CrossRef] [PubMed]

- Ye, E.Y.; Zhang, S.Y.; Liu, S.H.; Han, M.Y. Disproportionation for growing copper nanowires and their controlled self-assembly facilitated by ligand exchange. Chem. Eur. J. 2011, 17, 3074–3077. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.W.; Bando, Y. A novel method for preparing copper nanorods and nanowires. Adv. Mater. 2003, 15, 303–305. [Google Scholar] [CrossRef]

- Wang, P.I.; Zhao, Y.P.; Wang, G.C.; Lu, T.M. Novel growth mechanism of single crystalline Cu nanorods by electron beam irradiation. Nanotechnology 2004, 15, 218–222. [Google Scholar] [CrossRef]

- Zhang, J.H.; Sun, J.L.; Liu, W.; Shi, S.; Sun, H.S.; Guo, J.H. Synthesis of copper nanowires under a direct current electric field. Nanotechnology 2005, 16, 2030–2032. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Li, H.; Chen, L.Q.; Huang, X.J. Obtaining ultra-long copper nanowires via a hydrothermal process. Sci. Technol. Adv. Mater. 2005, 6, 761–765. [Google Scholar] [CrossRef]

- Mourdikoudis, S.; Liz-Marzan, L.M. Oleylamine in nanoparticle synthesis. Chem. Mater. 2013, 25, 1465–1476. [Google Scholar] [CrossRef]

- Huo, Z.Y.; Tsung, C.K.; Huang, W.Y.; Zhang, X.F.; Yang, P.D. Sub-two nanometer single crystal Au nanowires. Nano Lett. 2008, 8, 2041–2044. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.M.; Tuan, H.Y.; Korgel, B.A.; Xia, Y.N. Facile synthesis of gold nanoparticles with narrow size distribution by using AuCl or AuBr as the precursor. Chem. Eur. J. 2008, 14, 1584–1591. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.M.; Yavuz, M.S.; Tuan, H.Y.; Korgel, B.A.; Xia, Y.N. Ultrathin gold nanowires can be obtained by reducing polymeric strands of oleylamine AuCl complexes formed via aurophilic interaction. J. Am. Chem. Soc. 2008, 130, 8900–8901. [Google Scholar] [CrossRef] [PubMed]

- Dima, G.E.; De Vooys, A.C.A.; Koper, M.T.M. Electrocatalytic reduction of nitrate at low concentration on coinage and transition-metal electrodes in acid solutions. J. Electroanal. Chem. 2003, 554, 15–23. [Google Scholar] [CrossRef]

- Bouzek, K.; Paidar, M.; Sadílkova, A.; Bergmann, H. Electrochemical Reduction of Nitrate in Weakly Alkaline Solutions. J. Appl. Electrochem. 2001, 31, 1185–1193. [Google Scholar] [CrossRef]

- Yang, J.; Sebastian, P.; Duca, M.; Hoogenboom, T.; Koper, M.T.M. pH dependence of the electroreduction of nitrate on Rh and Pt polycrystalline electrodes. Chem. Commun. 2014, 50, 2148–2151. [Google Scholar] [CrossRef] [PubMed]

- Amertharaj, S.; Hasnat, M.A.; Mohamed, N. Electroreduction of nitrate ions at a platinum-copper electrode in an alkaline medium: Influence of sodium inositol phytate. Electrochim. Acta 2014, 136, 557–564. [Google Scholar] [CrossRef]

- Ding, J.; Li, W.; Zhao, Q.L.; Wang, K.; Zheng, Z.; Gao, Y.Z. Electroreduction of nitrate in water: Role of cathode and cell configuration. Chem. Eng. J. 2015, 271, 252–259. [Google Scholar] [CrossRef]

- Pletcher, D.; Poorabedi, Z. The reduction of nitrate at a copper in aqueous acid. Electrochim. Acta 1979, 24, 1253–1256. [Google Scholar] [CrossRef]

| Method | Cu Source | Solvent | Reducing Agent | Other Organics Added | Reaction Temperature and Duration | Length of CuNWs | Refs. |

|---|---|---|---|---|---|---|---|

| Hydrothermal reduction | CuCl2 | water | glucose | hexadecylamine | 120°C for 2 h | several microns | [13] |

| CuCl2 | water | glucose | hexadecylamine | 120°C for 12 h | tens of microns | [5] | |

| Cu(NO3)2 | water | ethylene glycol | polyvinyl pyrrolidone | 160°C for 24 h | tens of microns | [20] | |

| CuCl2 | water | octadecylamine | - | 165°C for 140 h | hundreds of microns | [6] | |

| CuCl2 | water | glucose | ethanol, oleic acid, and oleylamine | 116 °C for 2–12 h | tens of microns | [7] | |

| Aqueous solution reduction | Cu(NO3)2 | water | hydrazine | ethylenediamine | 40–80 °C for 25 min–15 h | tens of microns | [1,2,4,21,22] |

| Cu(OH)2 | water | hydrazine | ethylenediamine | 70 °C for 1 h | tens of microns | [23] | |

| Cu(NO3)2 | water | hydrazine | propanediamine | 80 °C for 1 h | tens of microns | [24] | |

| CuCl2 | water | glucose | hexadecylamine | 100 °C for 6 h | hundreds of microns | [25] | |

| CuCl2 | water–alcohol | L-ascorbic acid | oleylamine | 55–85 °C for 12 h | hundreds of microns | [8] | |

| Non-aqueous synthesis | CuCl | oleylamine | via disproportionation reaction | - | 200 °C 30 min | tens of microns | [26] |

| CuCl2 | oleylamine | in the presence of catalytic Ni2+ | - | 175 °C for 10 h | tens of microns | [9] | |

| Cu(acac)2 | hexadecylamine | in the presence of catalytic Pt | cetyltriamoninum bromide | 180 °C for 10 h | hundreds of microns | [3] | |

| CuCl2 | oleylamine | tris(trimethylsilyl)silane | oleic acid | 165 °C for 10 h | tens of microns | [10] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Chen, N.; Wang, C.; Zhang, X.; Liu, Z. Oleylamine-Mediated Hydrothermal Growth of Millimeter-Long Cu Nanowires and Their Electrocatalytic Activity for Reduction of Nitrate. Nanomaterials 2018, 8, 192. https://doi.org/10.3390/nano8040192

Zheng Y, Chen N, Wang C, Zhang X, Liu Z. Oleylamine-Mediated Hydrothermal Growth of Millimeter-Long Cu Nanowires and Their Electrocatalytic Activity for Reduction of Nitrate. Nanomaterials. 2018; 8(4):192. https://doi.org/10.3390/nano8040192

Chicago/Turabian StyleZheng, Yifan, Nana Chen, Chunxiao Wang, Xiaoping Zhang, and Zongjian Liu. 2018. "Oleylamine-Mediated Hydrothermal Growth of Millimeter-Long Cu Nanowires and Their Electrocatalytic Activity for Reduction of Nitrate" Nanomaterials 8, no. 4: 192. https://doi.org/10.3390/nano8040192