Nanoporous Structure Formation on the Surface of InSb by Ion Beam Irradiation

Abstract

:1. Introduction

2. Experimental Procedure

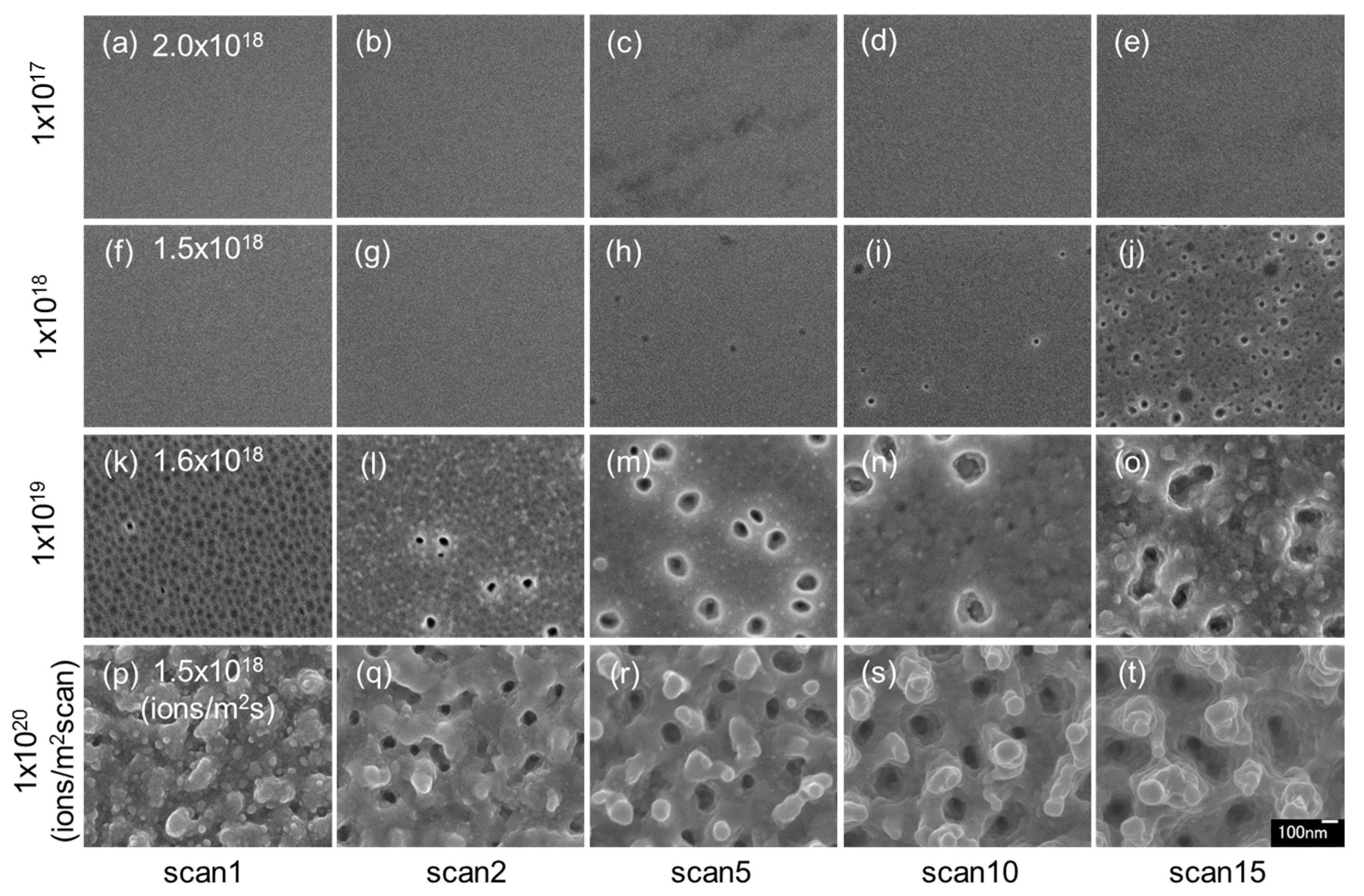

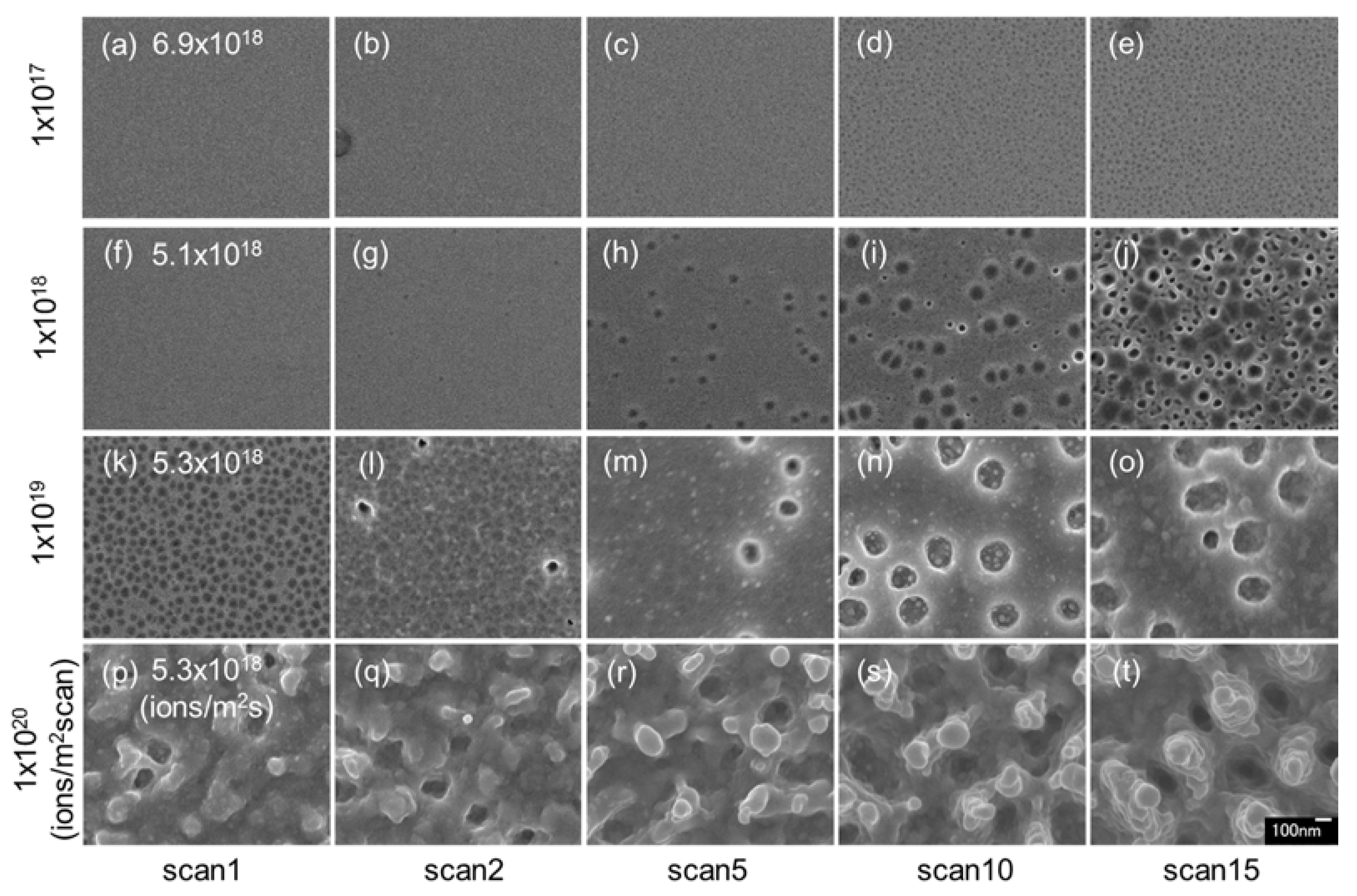

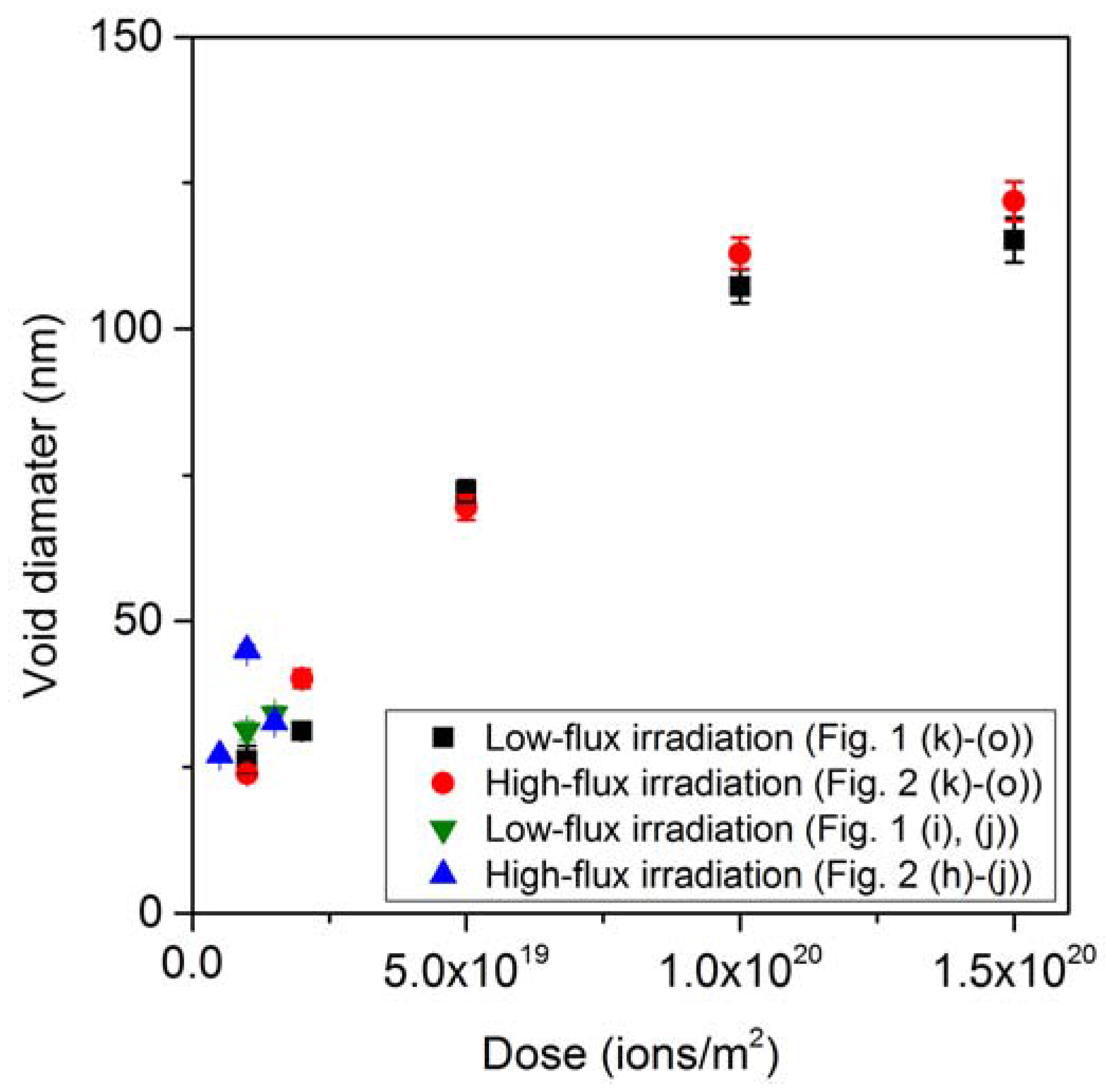

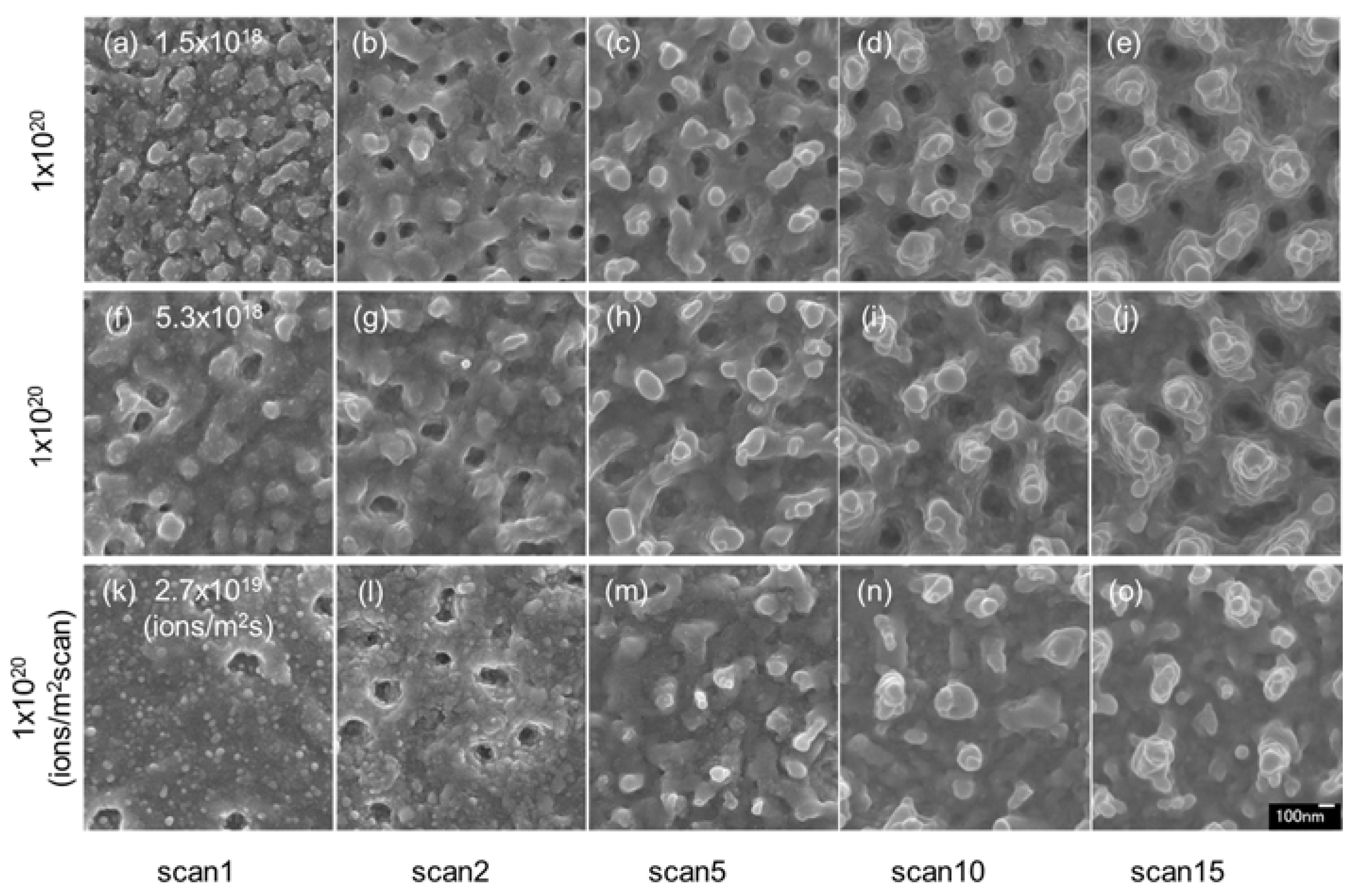

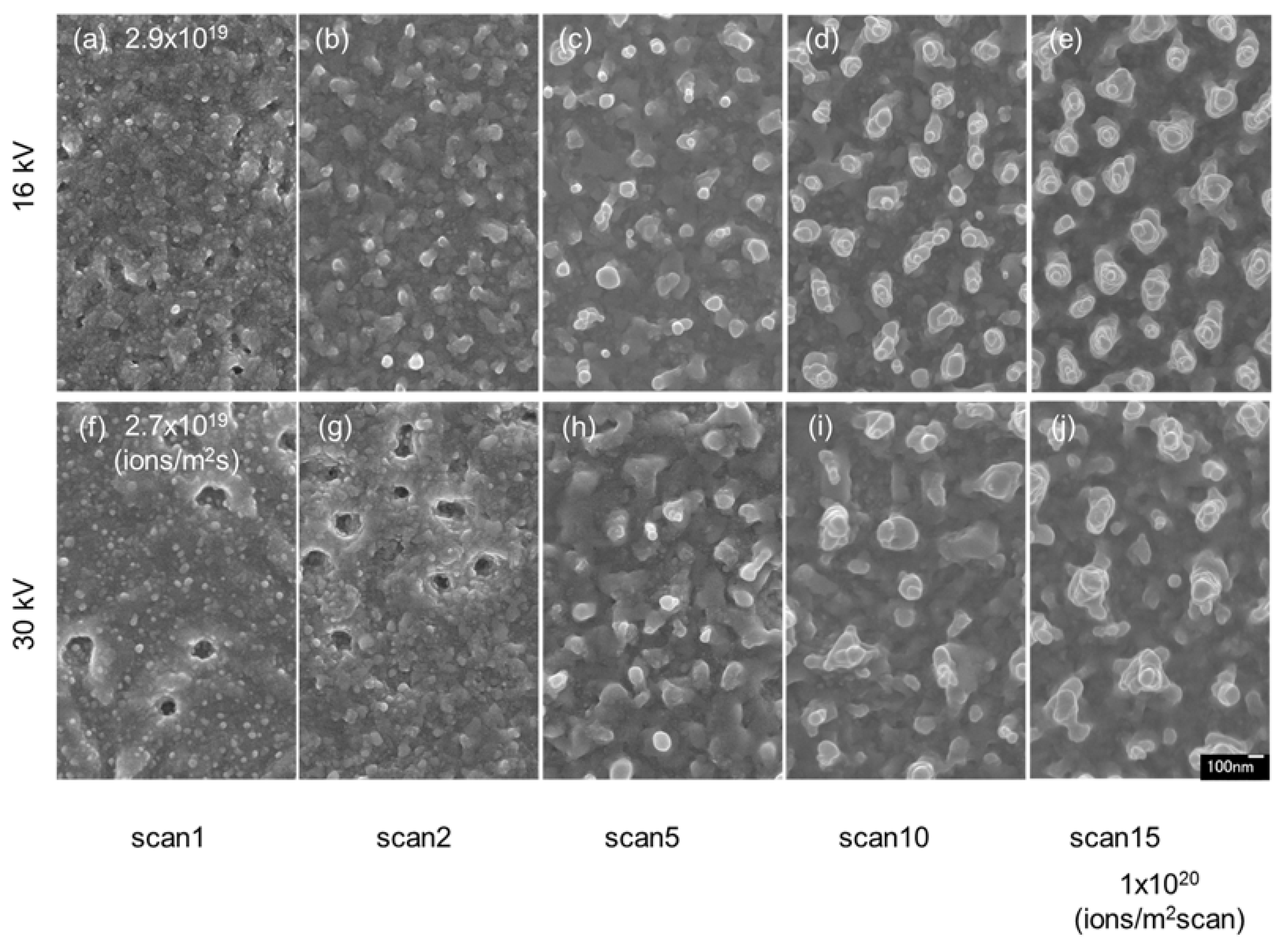

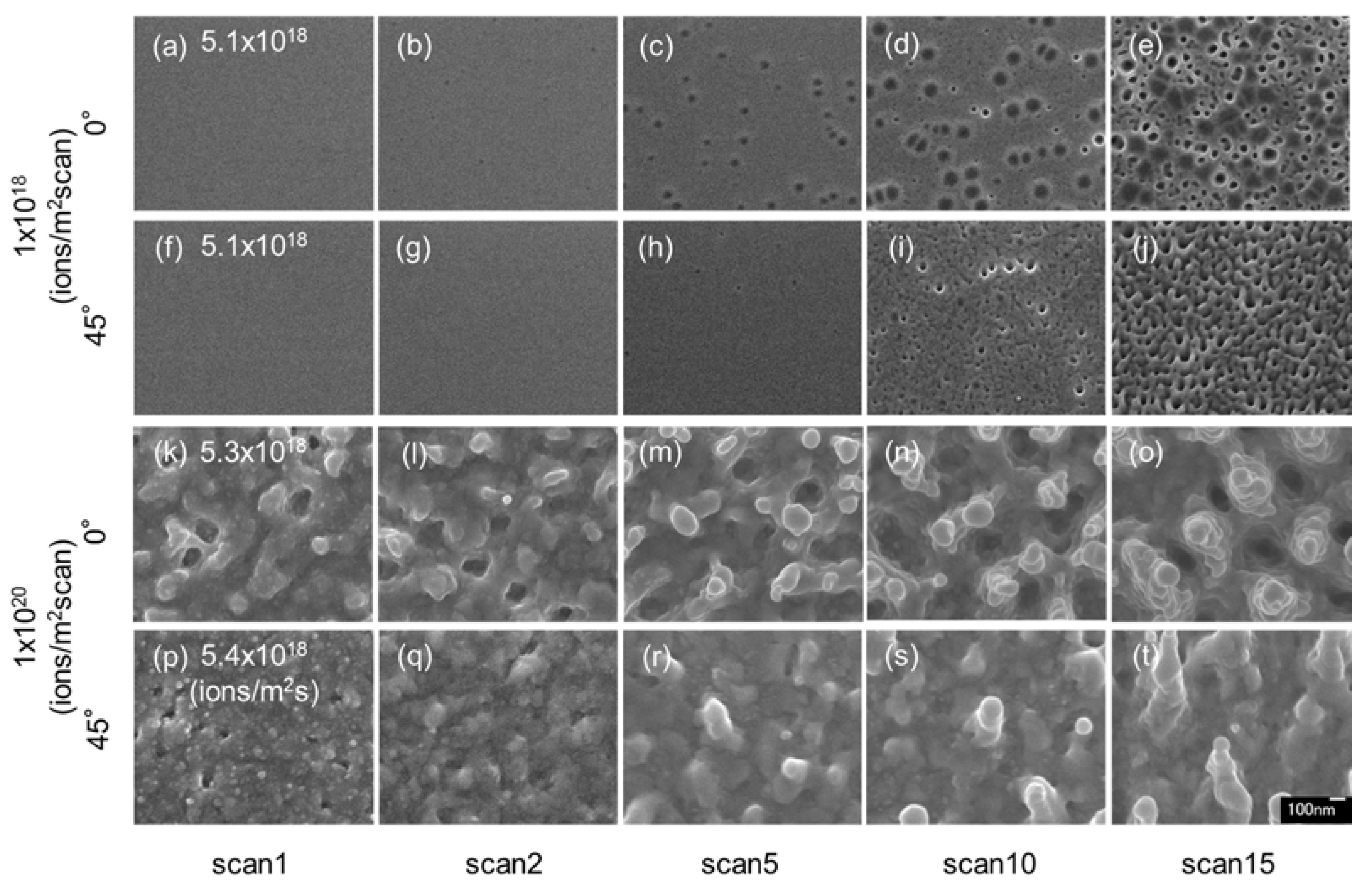

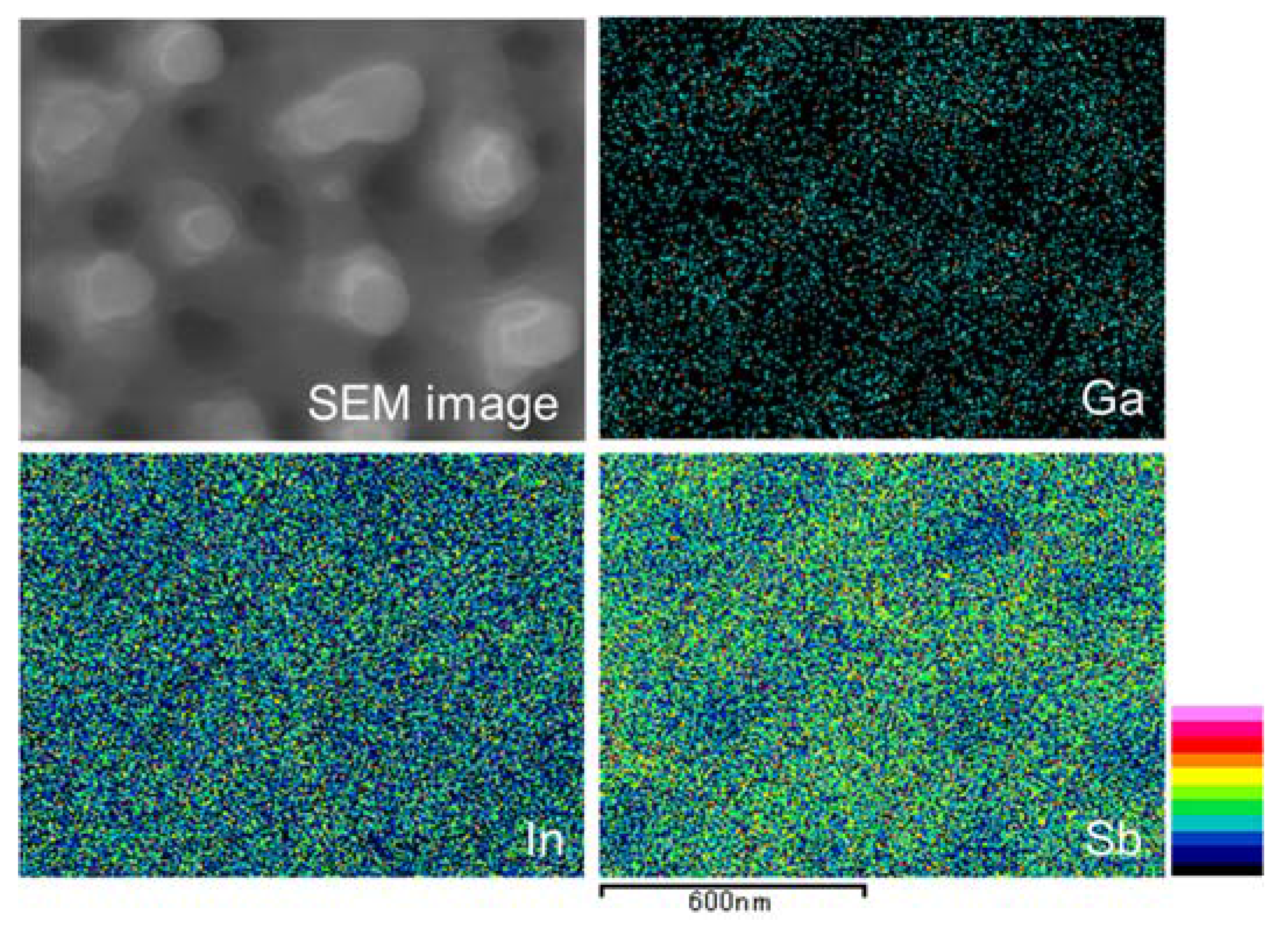

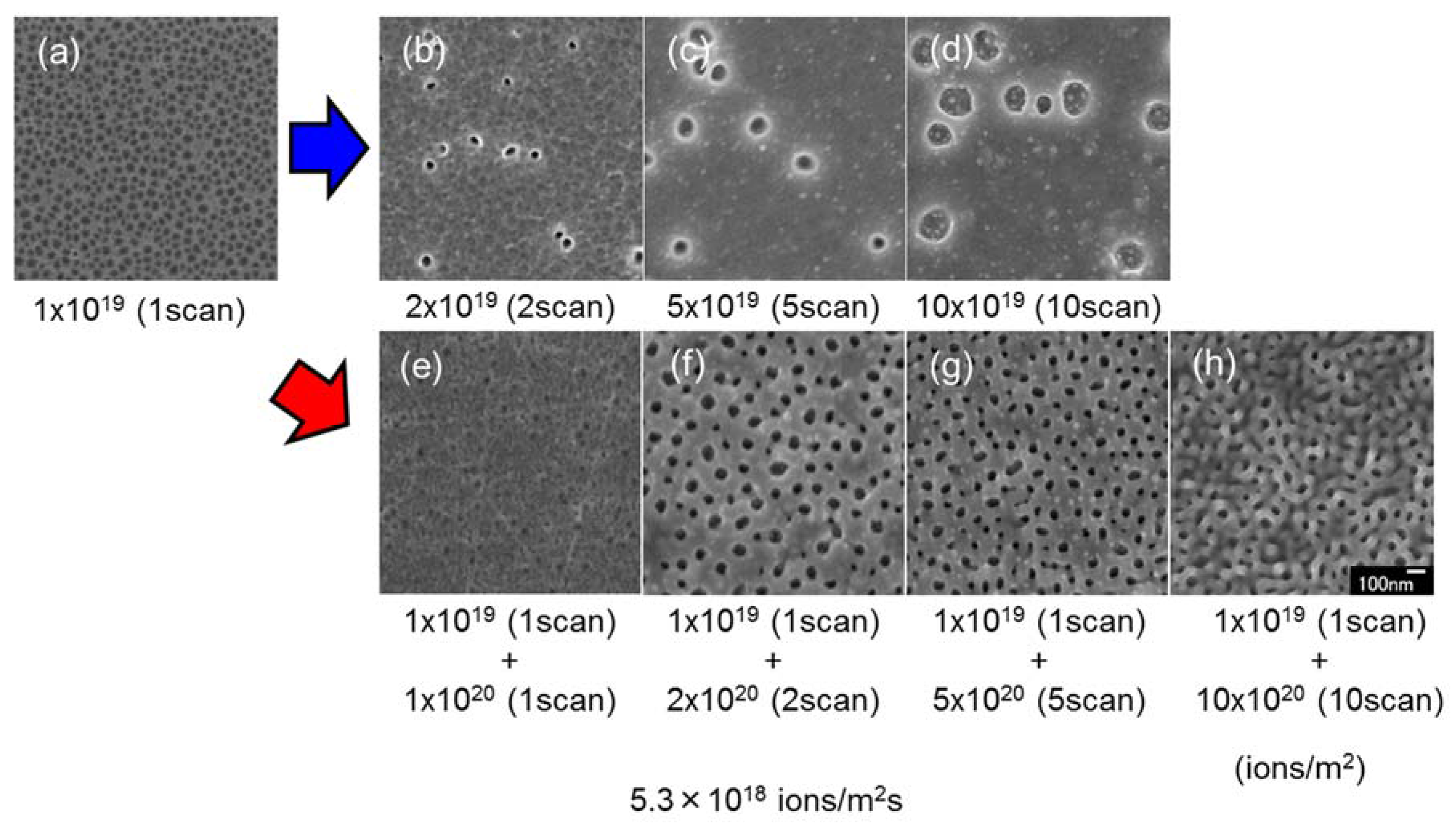

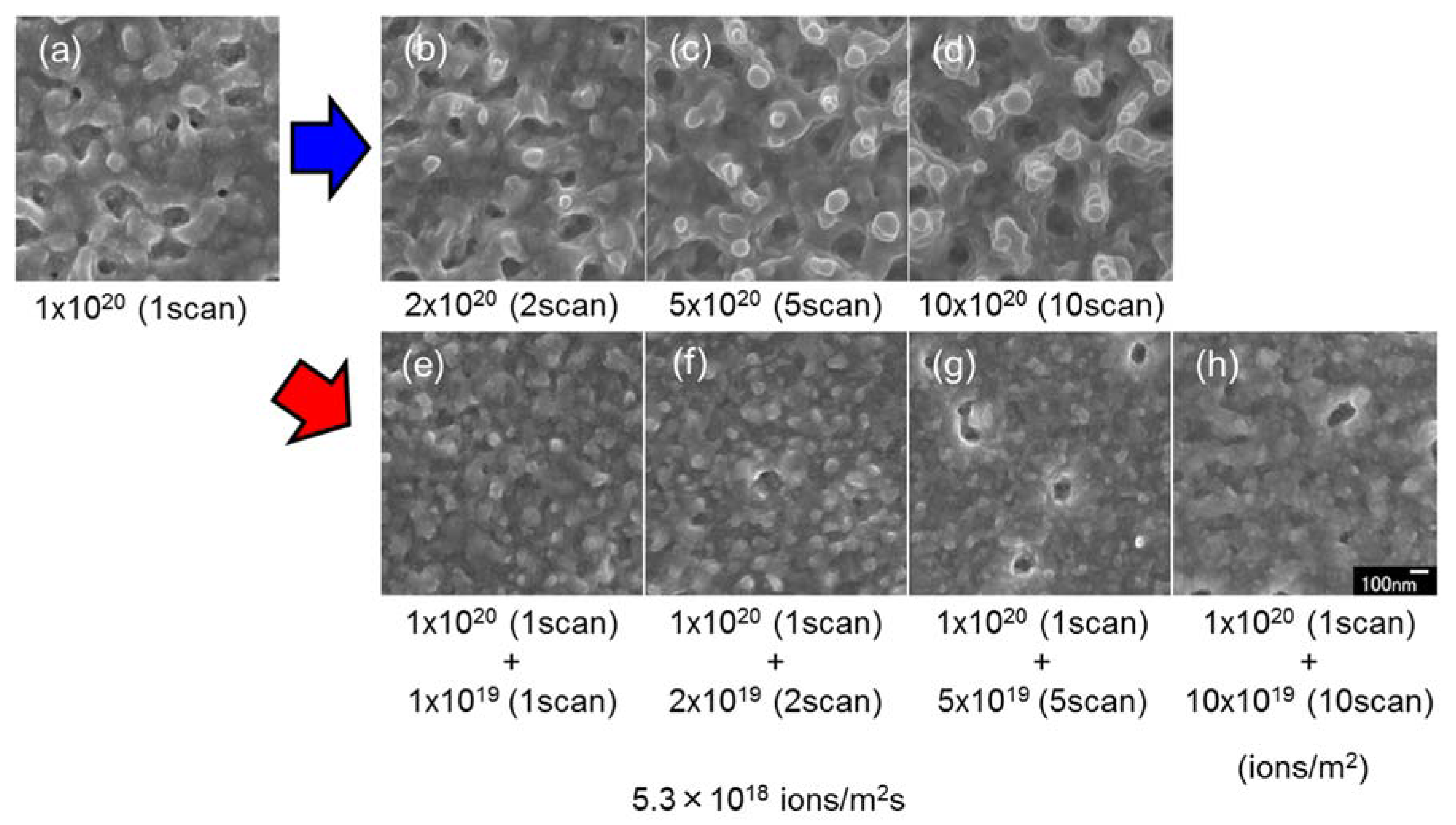

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kleitman, D.; Yearian, H.J. Radiation-Induced Expansion of Semiconductors. Phys. Rev. 1957, 108, 901. [Google Scholar] [CrossRef]

- Destefanis, G.L.; Gailliard, J.P. Very efficient void formation in ion implanted InSb. Appl. Phys. Lett. 1980, 36, 40–42. [Google Scholar] [CrossRef]

- Gnaser, H.; Kallmayer, C.; Oechsner, H. Focused-ion-beam implantation of Ga in elemental and compound semiconductors. J. Vac. Sci. Tech. B 1995, 13, 19–26. [Google Scholar] [CrossRef]

- Kluth, S.M.; Llewellyn, D.; Ridgway, M.C. Irradiation fluence dependent microstructural evolution of porous InSb. Nucl. Instrum. Methods B 2006, 242, 640–642. [Google Scholar] [CrossRef]

- Perez-Bergqu, A.G.; Li, K.; Zhang, Y.; Wang, L.M. Ion irradiation-induced bimodal surface morphology changes in InSb. Nanotechnology 2010, 21, 325602. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.H.; Goldman, R.S. Mechanisms of nanorod growth on focused-ion-beam-irradiated semiconductor surfaces: Role of redeposition. Appl. Phys. Lett. 2012, 100, 053103. [Google Scholar] [CrossRef]

- Kang, M.; Wu, J.H.; Ye, W.; Jiang, Y.; Robb, E.A.; Chen, C.; Goldman, R.S. Mechanisms of nanorod growth on focused-ion-beam-irradiated semiconductor surfaces: Role of redeposition. Appl. Phys. Lett. 2014, 104, 052103. [Google Scholar] [CrossRef]

- Datta, D.P.; Garg, S.K.; Satpati, B.; Sahoo, P.K.; Kanjilal, A.; Dhara, S.; Kanjilal, D.; Som, T. 60 keV Ar+-ion induced modification of microstructural, compositional, and vibrational properties of InSb. J. Appl. Phys. 2014, 116, 143502. [Google Scholar] [CrossRef]

- Jany, B.R.; Szajna, K.; Nikiel, M.; Wrana, D.; Trynkiewicz, E.; Pedrys, R.; Krok, F. Energy dependence of nanopillars formation on InSb semiconductor surfaces under gallium FIB and noble gas ions beam irradiation. Appl. Surf. Sci. 2015, 327, 86–92. [Google Scholar] [CrossRef]

- Homma, Y. Anomalous sputtering of gallium-antimonide under cesium-ionbombardment. J. Vac. Sci. Tech. A 1987, 5, 321–326. [Google Scholar] [CrossRef]

- Callec, R.; Favennce, P.N.; Salvi, M.; L’ Haridon, H.; Gauneau, M. Anomalous behavior of ion-implanted GaSb. Appl. Phys. Lett. 1991, 59, 1872–1874. [Google Scholar] [CrossRef]

- Facsko, S.; Dekorsy, T.; Koerdt, C.; Trappe, C.; Kurz, H.; Vogt, A.; Hartnagel, H.L. Formation of Ordered Nanoscale Semiconductor Dots by Ion Sputtering. Science 1999, 285, 1551–1553. [Google Scholar] [CrossRef] [PubMed]

- Nitta, N.; Taniwaki, M.; Hayashi, Y.; Yoshiie, T. Formation of cellular defect structure on GaSb ion-implanted at low temperatur. J. Appl. Phys. 2002, 92, 1799–1802. [Google Scholar] [CrossRef]

- Perez-Bergqu, A.G.; Zhu, S.; Sun, K.; Xiang, X.; Zhang, Y.; Wang, L.M. Embedded Nanofibers Induced by High-Energy Ion Irradiation of Bulk GaSb. Small 2008, 4, 1119–1124. [Google Scholar] [CrossRef] [PubMed]

- Nitta, N.; Hasegawa, T.; Yasuda, H.; Sato, K.; Xu, Q.; Yoshiie, T.; Taniwaki, M.; Hatta, A. Beam flux dependence of ion-irradiation-induced porous structures in III–V compound semiconductors. Radiat. Eff. Defect Solid 2013, 168, 247–252. [Google Scholar] [CrossRef]

- Datta, D.P.; Kanjilal, A.; Garg, S.K.; Sahoo, P.K.; Satpati, B.; Kanjilal, D.; Som, T. Controlled shape modification of embedded Au nanoparticles by 3MeV Au 2+-ion irradiation. Appl. Surf. Sci. 2014, 310, 189–195. [Google Scholar] [CrossRef]

- Kluth, P.; Sullivan, J.; Li, W.; Weed, R.; Schnohr, C.S.; Giulian, R.; Araujo, L.L.; Lei, W.; Rodriguez, M.D.; Afra, T.; et al. Nano-porosity in GaSb induced by swift heavy ion irradiation. Appl. Phys. Lett. 2014, 104, 023105. [Google Scholar] [CrossRef]

- El-Atwani, O.; Norris, S.A.; Ludwig, K.; Gonderman, S.; Allain, J.P. Ion beam nanopatterning of III-V semiconductors: consistency of experimental and simulation trends within a chemistry-driven theory. Sci. Rep. 2015, 5, 18207. [Google Scholar] [CrossRef] [PubMed]

- Wilson, H. The effects of self-ion bombardment (30–500 keV) on the surface topography of single-crystal germanium. J. Appl. Phys. 1982, 53, 1698–1705. [Google Scholar] [CrossRef]

- Appleton, B.R.; Holland, O.W.; Narayan, J.; Schow, O.E., III; Williams, J.S.; Short, K.T.; Lawson, E. Characterization of damage in ion implanted Ge. Appl. Phys. Lett. 1982, 41, 711–712. [Google Scholar] [CrossRef]

- Wang, L.M.; Birtcher, R.C. Radiation induced formation of cavities in amorphous germanium. Appl. Phys. Lett. 1989, 55, 2494–2496. [Google Scholar] [CrossRef]

- Wang, L.M.; Birtcher, R.C. Amorphization, morphological instability and crystallization of Krypton ion irradiated germanium. Philos. Mag. A 1991, 64, 1209–1223. [Google Scholar] [CrossRef]

- Koffel, S.; Scheiblin, P.; Claverie, A.; Benassayag, G. Amorphization kinetics of germanium during ion implantation. J. Appl. Phys. 2009, 105, 013528. [Google Scholar] [CrossRef]

- Steinbach, T.; Wernecke, J.; Kluth, P.; Ridgway, M.C.; Wesch, W. Structural modifications of low-energy heavy-ion irradiated germanium. Phys. Rev. B 2011, 84, 104108. [Google Scholar] [CrossRef]

- Romano, L.; Impellizzeri, G.; Bosco, L.; Ruffino, F.; Miritello, M.; Grimaldi, M.G. Nanoporosity induced by ion implantation in deposited amorphous Ge thin films. J. Appl. Phys. 2012, 111, 113515. [Google Scholar] [CrossRef]

- Impellizzeri, G.; Romano, L.; Bosco1, L.; Spinella, C.; Grimaldi, M.G. Nanoporosity induced by ion implantation in germanium thin films grown by molecular beam epitaxy. Appl. Phys. Express 2012, 5, 5035201. [Google Scholar] [CrossRef]

- Rudawski, N.G.; Darby, B.L.; Yates, B.R.; Jones1, K.S.; Elliman, R.G.; Volinsky, A.A. Nanostructured ion beam-modified Ge films for high capacity Li ion battery anodes. Appl. Phys. Lett. 2012, 100, 083111. [Google Scholar]

- Alkhaldi, H.S.; Kremer, F.; Bierschenk, T.; Hansen, J.L.; Nylandsted-Larsen, A.; Williams, J.S.; Ridgway, M.C. Porosity as a function of stoichiometry and implantation temperature in Ge/Si1−xGex alloys. J. Appl. Phys. 2016, 119, 094303. [Google Scholar] [CrossRef]

- Alkhaldi, H.S.; Kremer, F.; Mota-Santiago, P.; Nadzri, A.; Schauries, D.; Kirby, N.; Ridgway, M.C.; Kluth, P. Morphology of ion irradiation induced nano-porous structures in Ge and Si1−xGex alloys. J. Appl. Phys. 2017, 121, 115705. [Google Scholar] [CrossRef]

- Biersack, J.P.; Haggmark, L.G. A Monte Carlo computer program for the transport of energetic ions in amorphous targets. Nucl. Instrum. Methods 1980, 174, 257. [Google Scholar] [CrossRef]

- Ziegler, J. Software web site. Available online: http://www.SRIM.org (accessed on 10 July 2017).

- Bauerlein, R.Z. Messung der Energie zur Verlagerung eines Gitteratoms durch Elektronenstoß in AIIIBV-Verbindungen. Physics 1963, 176, 498–509. [Google Scholar] [CrossRef]

| Sputtering Yield (Atoms/Ion) | |||

|---|---|---|---|

| Accelerating Voltage | 16 kV | 30 kV | 30 kV (45°) |

| Total | 7.975 | 8.537 | 14.698 |

| In | 4.19 | 4.47 | 7.68 |

| Sb | 3.78 | 4.07 | 7.02 |

| EDX Quantification (Atomic %) | |

|---|---|

| Ga | 3.5 |

| In | 52 |

| Sb | 45 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miyaji, T.; Nitta, N. Nanoporous Structure Formation on the Surface of InSb by Ion Beam Irradiation. Nanomaterials 2017, 7, 204. https://doi.org/10.3390/nano7080204

Miyaji T, Nitta N. Nanoporous Structure Formation on the Surface of InSb by Ion Beam Irradiation. Nanomaterials. 2017; 7(8):204. https://doi.org/10.3390/nano7080204

Chicago/Turabian StyleMiyaji, Takashi, and Noriko Nitta. 2017. "Nanoporous Structure Formation on the Surface of InSb by Ion Beam Irradiation" Nanomaterials 7, no. 8: 204. https://doi.org/10.3390/nano7080204