Application of Nanosize Zeolite Molecular Sieves for Medical Oxygen Concentration

Abstract

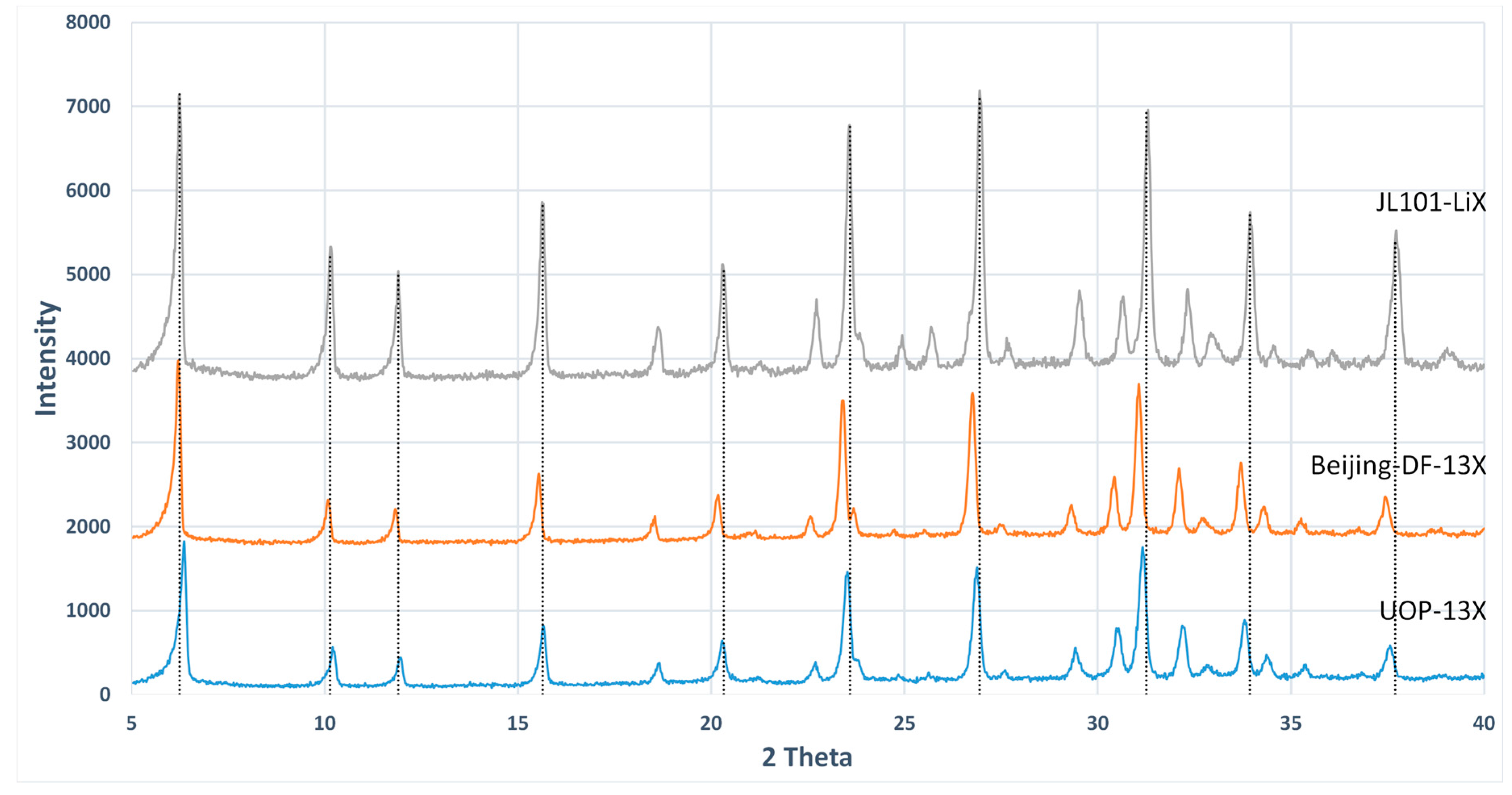

:1. Background

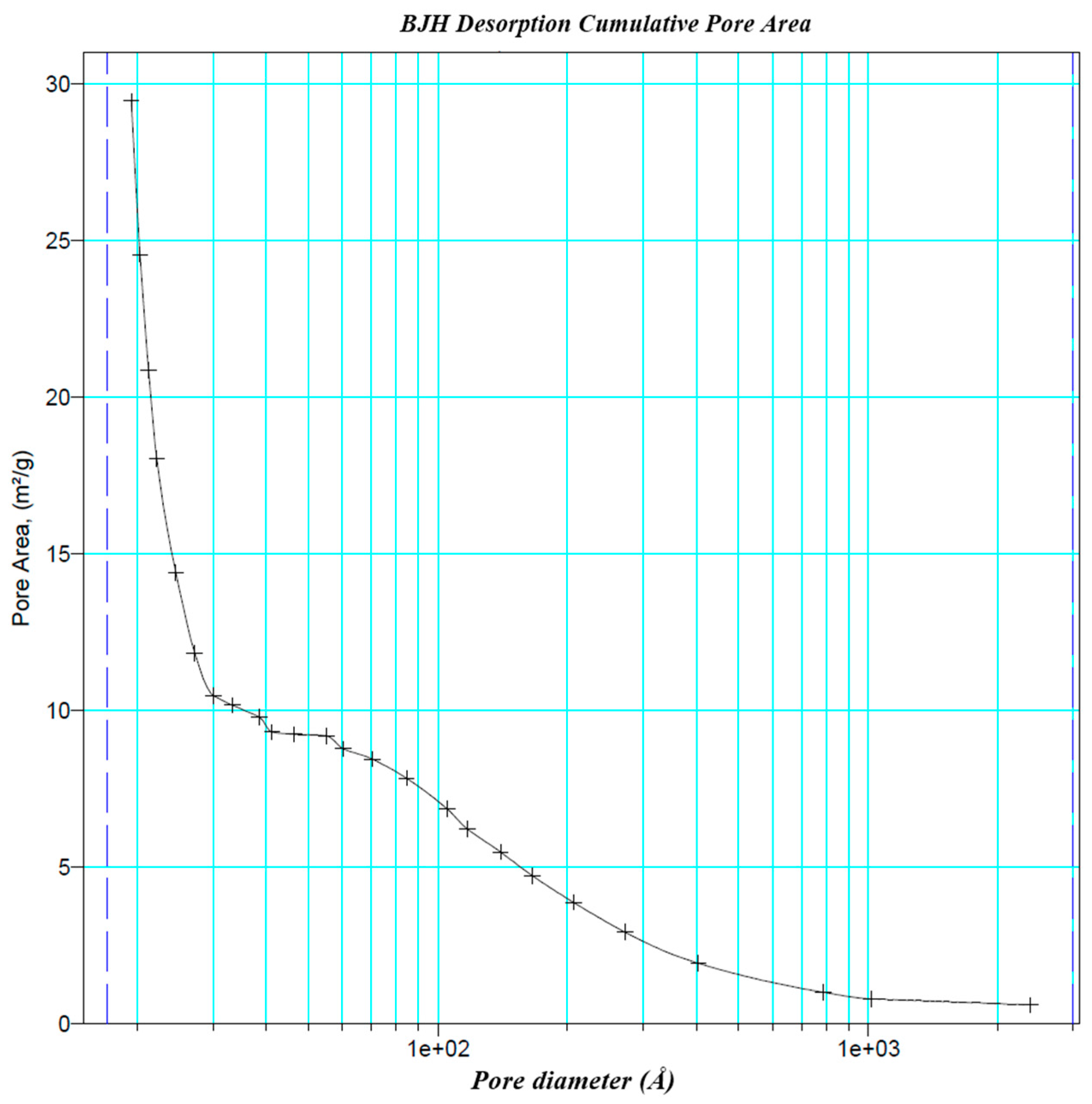

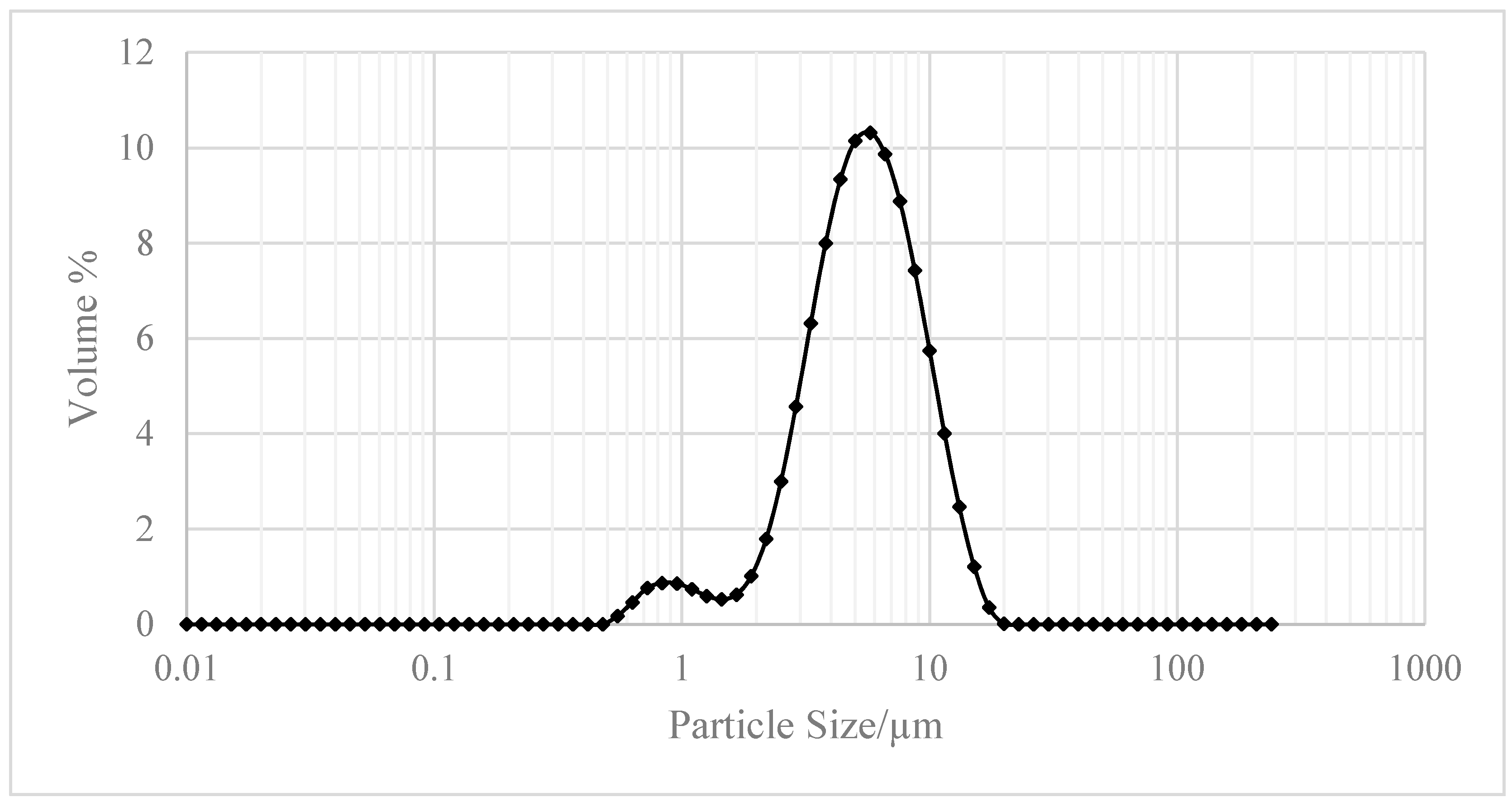

2. Materials and Methods

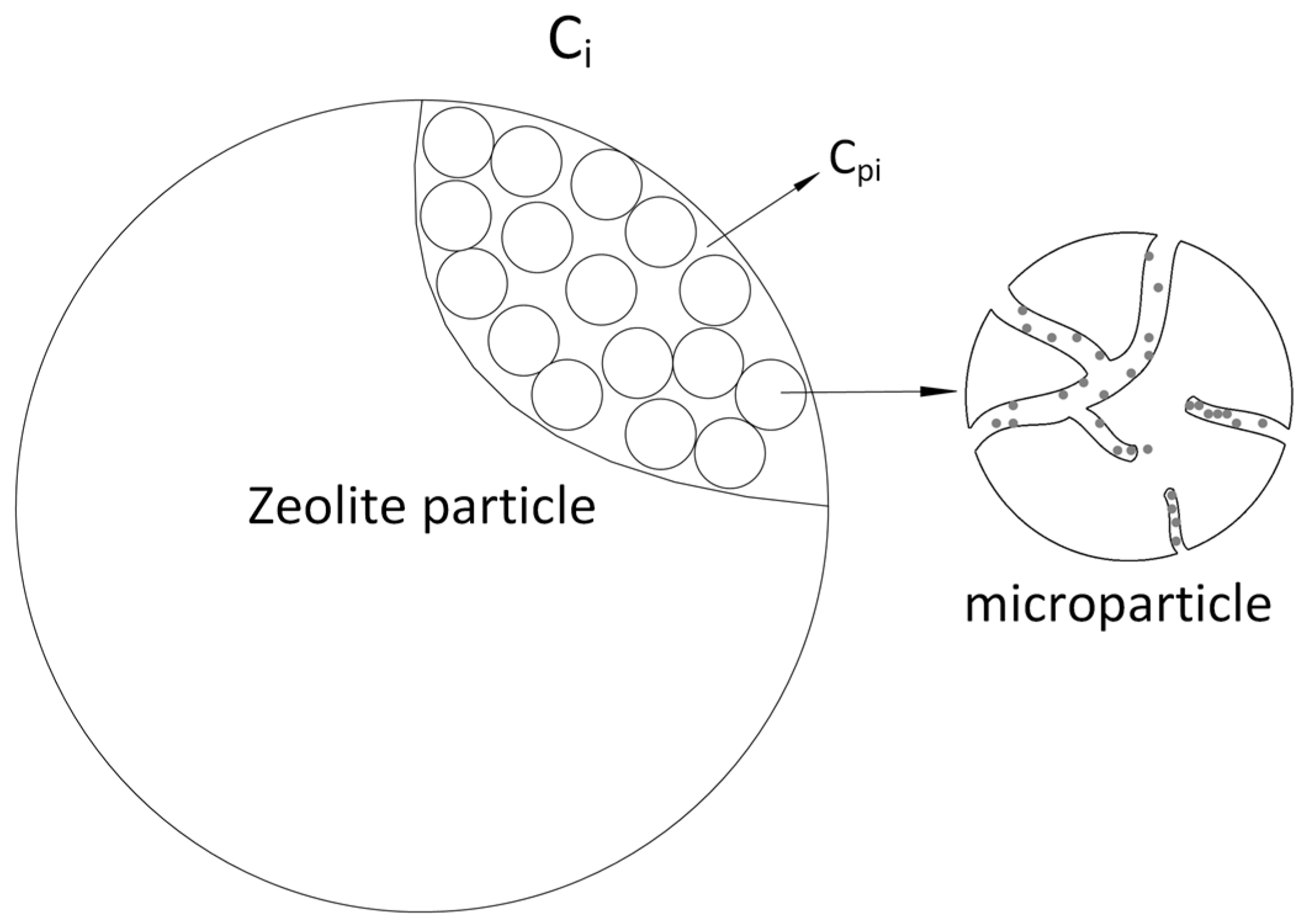

3. Mathematical Model

3.1. Transport and Adsorption Equations

- (a)

- The air source is assumed to be a binary ideal gas with 79% N2 and 21% O2.

- (b)

- Uniform bed voidage and particle diameter.

- (c)

- The stabilized gas temperature at inlet and outlet is measured to be 22.5 and 23.8 °C by thermocouple, checking the temperature dependent adsorption model (Santos et al., 2008), the nitrogen and oxygen capacity difference (error = ) at 1.79 barg is calculated to be 1.47% and 1.03%, respectively, which is negligible compared to the adsorption equilibrium equations, so the system is assumed to be isothermal [17].

- (d)

- Gravity effects on fluid flow are negligible.

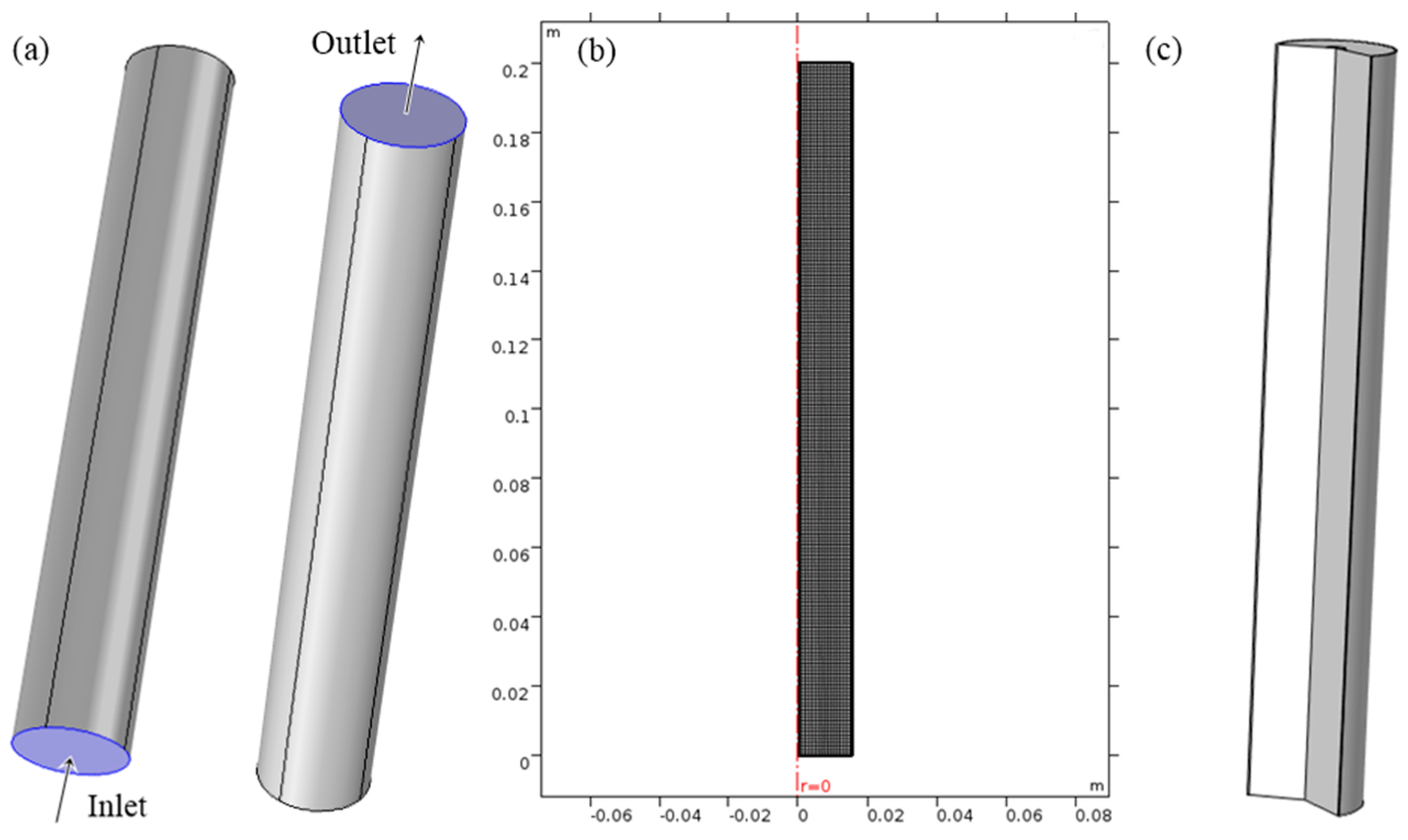

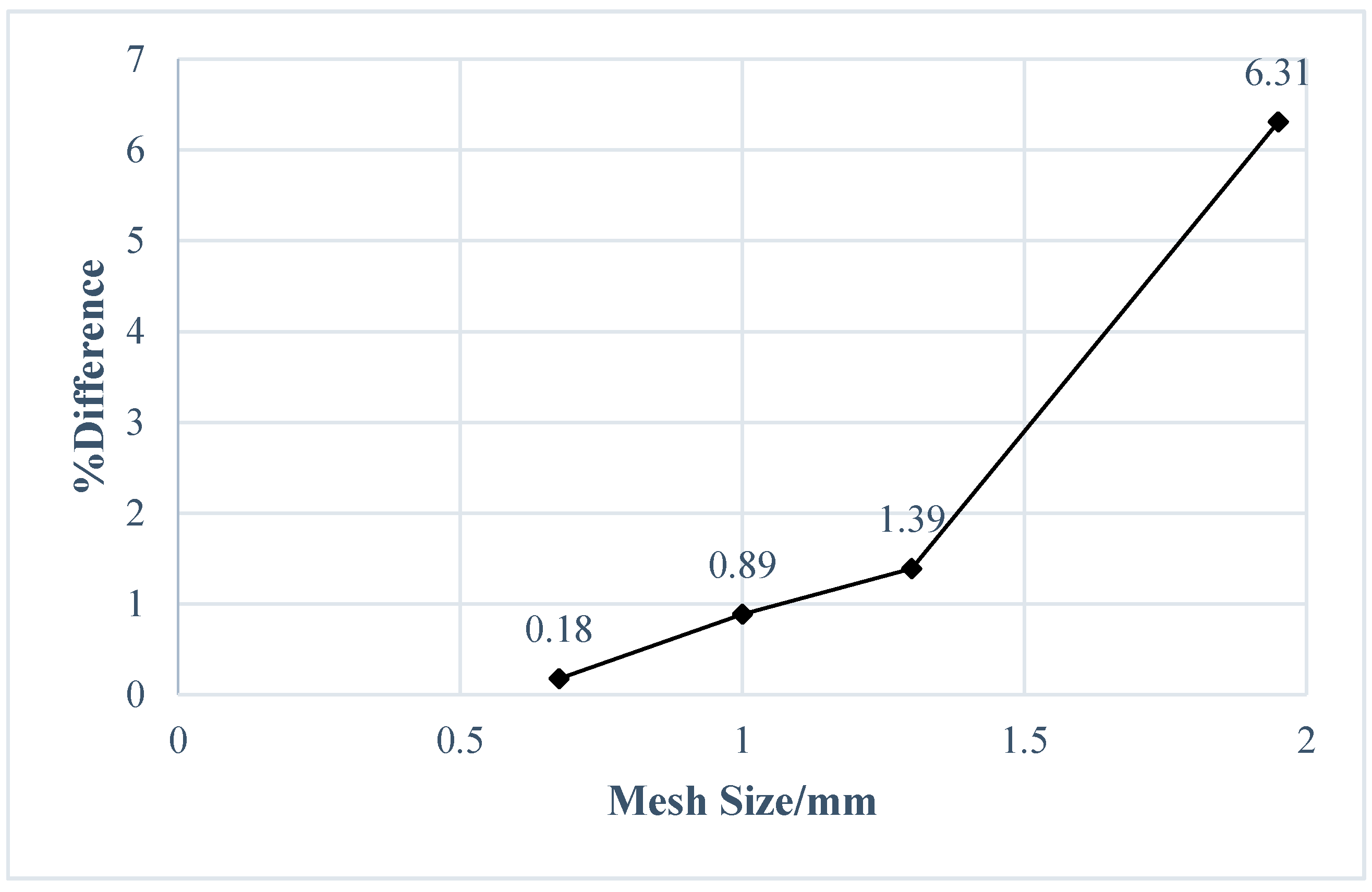

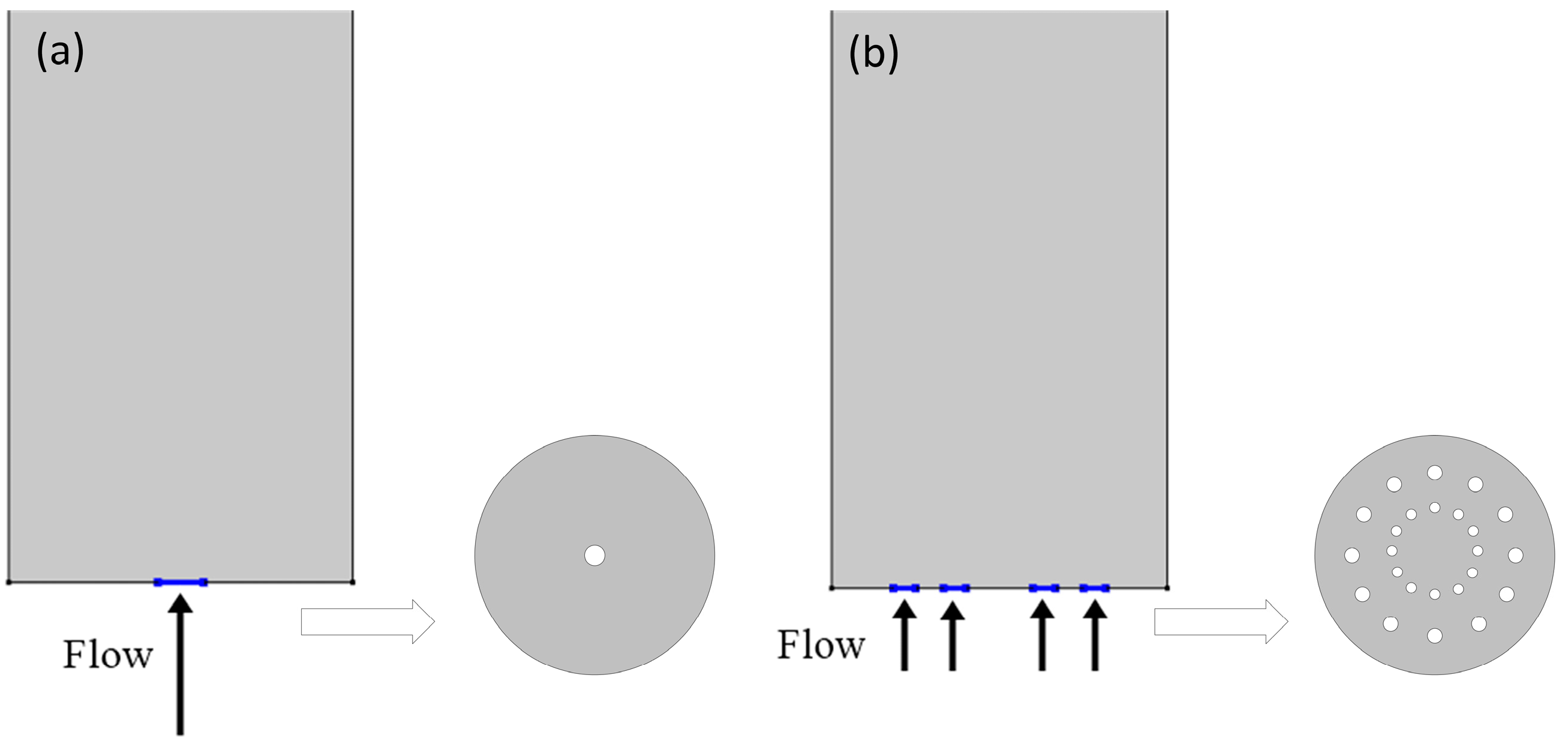

3.2. Geometry and Meshing of the Finite Element Algorithm

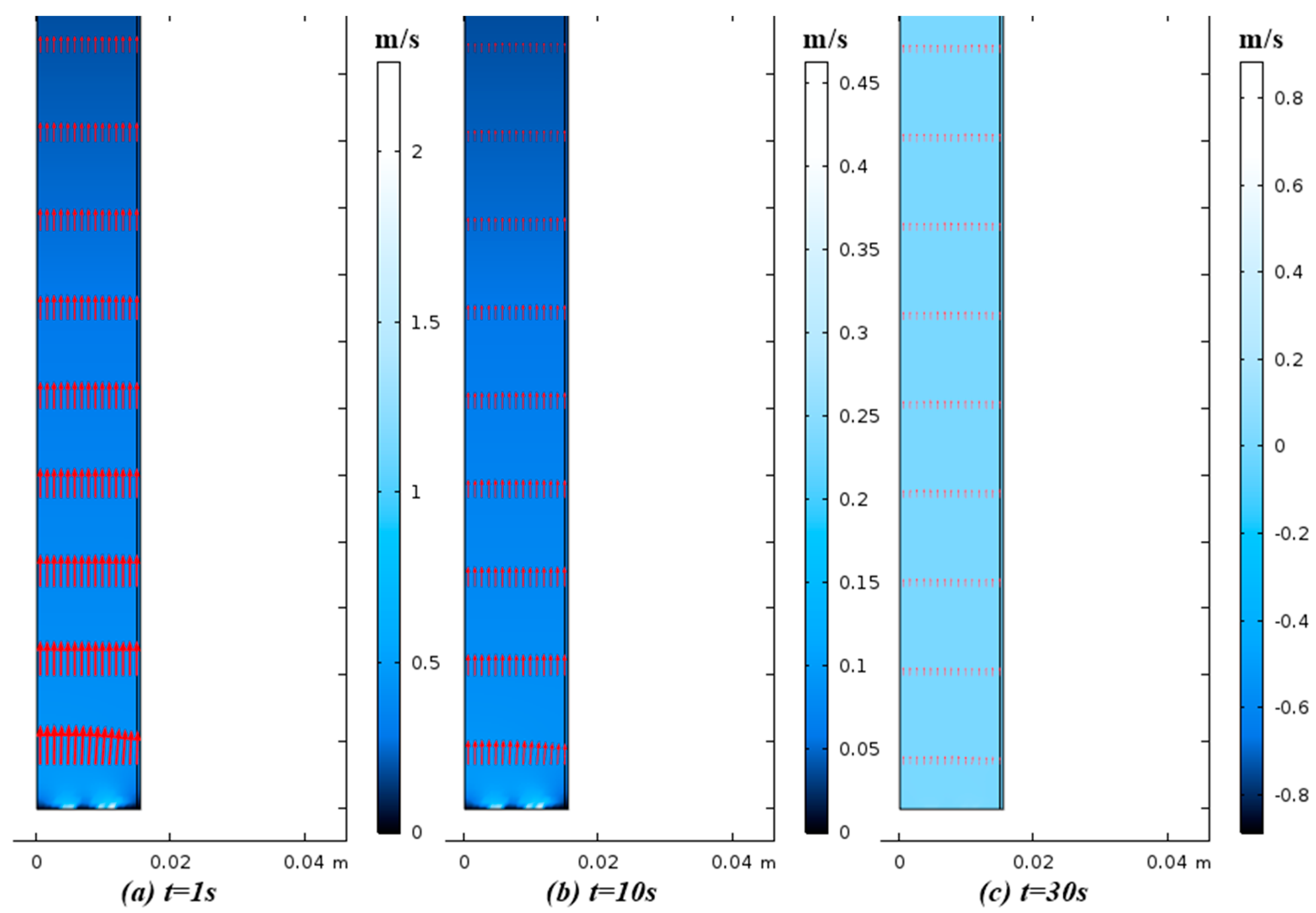

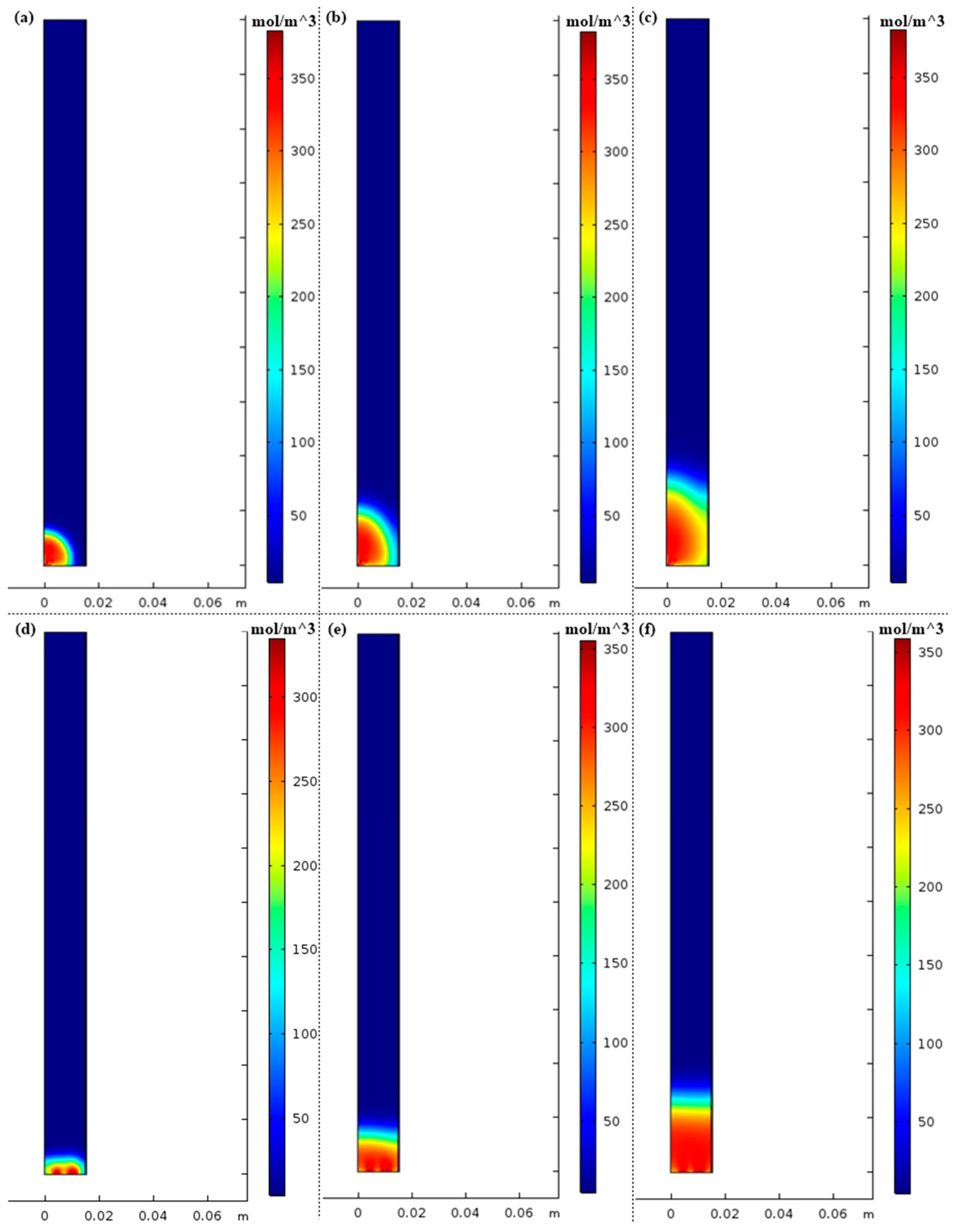

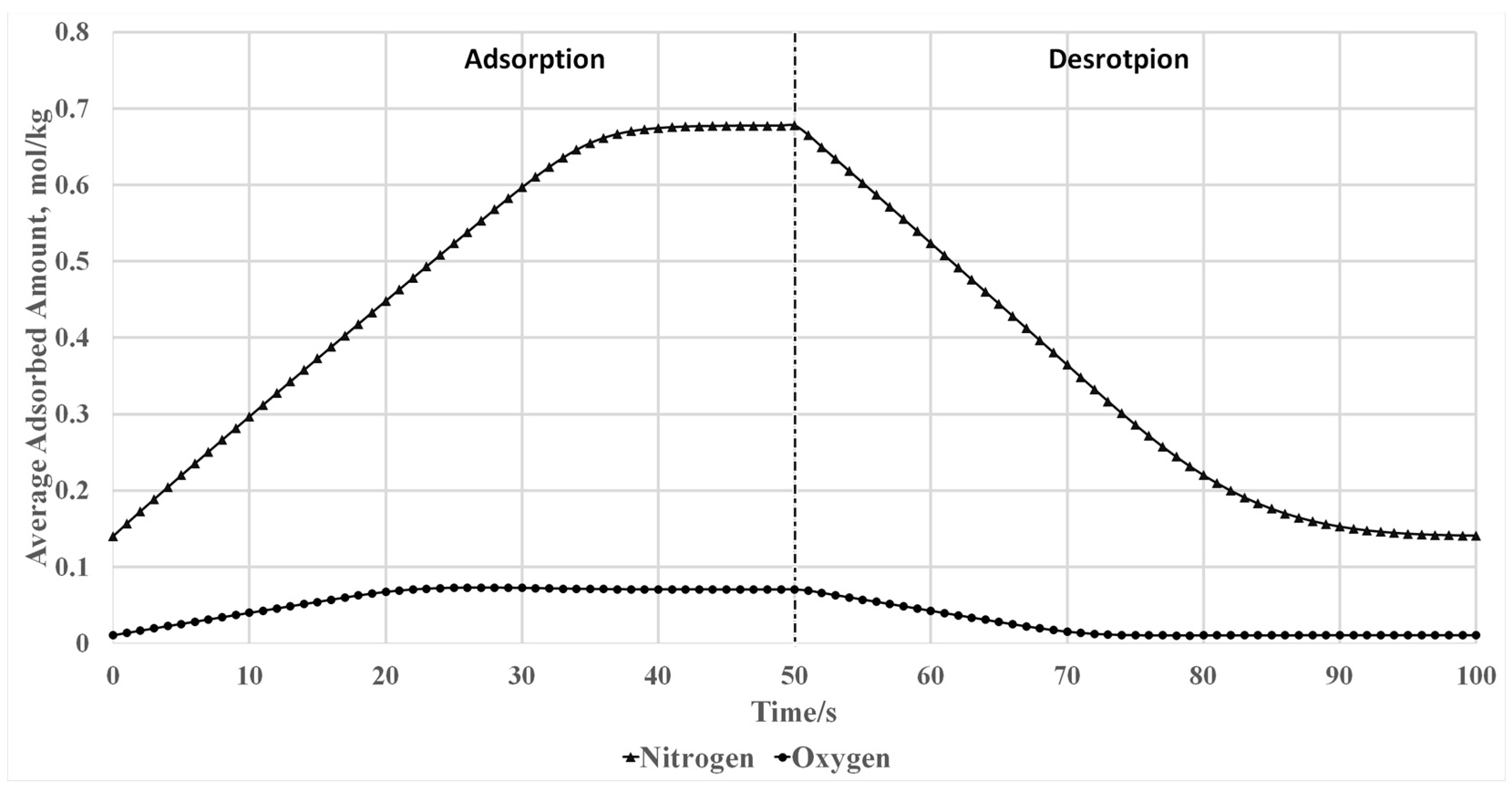

4. Results and Discussion

4.1. Concentrator Output

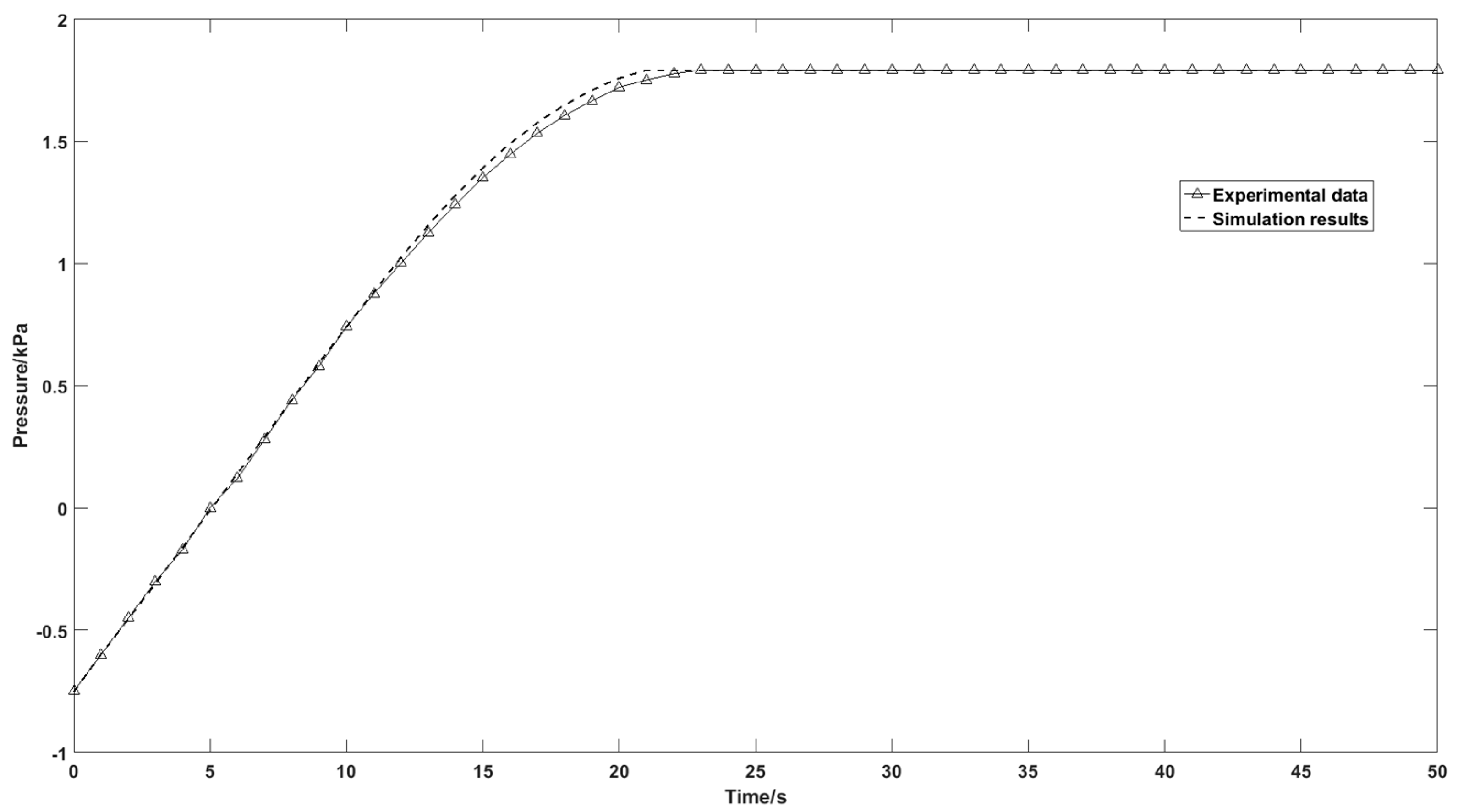

4.2. Model Validation

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Crittenden, B.; Thomas, W.J. Adsorption Technology and Design; Butterworth-Heinemann: Oxford, UK, 1998. [Google Scholar]

- Skarstrom, C.W. Method and Apparatus for Fractionating Gaseous Mixtures by Adsorption. U.S. Patent 2,944,627, 12 July 1960. [Google Scholar]

- Daniel, D.; Montgareuil, P.G.D. Process for Separating a Binary Gaseous Mixture by Adsorption. U.S. Patent 3,155,468, 3 November 1964. [Google Scholar]

- Drain, L.E. Permanent electric quadrupole moments of molecules and heats of adsorption. Trans. Faraday Soc. 1953, 49, 650–654. [Google Scholar] [CrossRef]

- Ackley, M.W.; Stewart, A.B.; Henzler, G.W.; Leavitt, F.W.; Kane, M.S. PSA Apparatus and Process Using Adsorbent Mixtures. U.S. Patent 6,027,548, 22 February 2000. [Google Scholar]

- Feuerstein, M.; Accardi, R.J.; Lobo, R.F. Adsorption of nitrogen and oxygen in the zeolites LiA and LiX investigated by 6Li and 7Li MAS NMR spectroscopy. J. Phys. Chem. B 2000, 104, 10282–10287. [Google Scholar] [CrossRef]

- Feuerstein, M.; Lobo, R.F. Influence of oxygen and nitrogen on 7Li MAS NMR spectra of zeolite LiX-1.0. Chem. Commun. 1998, 16, 1647–1648. [Google Scholar] [CrossRef]

- Molecular Sieve JLOX-101. Luoyang Jianlong Chemical: Yanshi, Henan, China, 2016. Available online: http://www.psamolecularsieve.com/vpsa-molecular-sieve/molecular-sieve-jlox-100.html (accessed on 22 July 2017).

- Rao, V.R.; Kothare, M.V.; Sircar, S. Novel design and performance of a medical oxygen concentrator using a rapid pressure swing adsorption concept. AIChE J. 2014, 60, 3330–3335. [Google Scholar] [CrossRef]

- Santos, J.C.; Portugal, A.F.; Magalhaes, F.D.; Mendes, A. Optimization of medical PSA units for oxygen production. Ind. Eng. Chem. Res. 2006, 45, 1085–1096. [Google Scholar] [CrossRef]

- Thakur, R.S.; Kaistha, N.; Rao, D.P. Novel single-bed and twin-bed pressure swing adsorption systems. Chem. Eng. Proc. Proc. Intensif. 2015, 95, 165–174. [Google Scholar] [CrossRef]

- TTC-IIS Series Miniature Diaphragm Pumps; Precision Fluidics Division Parker Hannifin Corporation: Hollis, NH, USA, 2013.

- X-Valve; Precision Fluidics Division, Parker Hannifin Corporation: Hollis, NH, USA, 2015.

- Lauer, J. Sensors for Gas Phase Oxygen Analysis; Teledyne Analytical Instruments: Industry, CA, USA, 2003. [Google Scholar]

- MPXV7002 Series Integrated Silicon Pressure Sensor; Freescale Semiconductor, Inc.: Austin, Texas, 2009.

- Model GB300 Percent Portable Oxygen Analyzer; Teledyne Analytical Instruments, A Teledyne Technologies Company: Thousand Oaks, CA, USA, 2011.

- Santos, J.C.; Magalhaes, F.D.; Mendes, A. Contamination of zeolites used in oxygen production by PSA: Effects of water and carbon dioxide. Ind. Eng. Chem. Res. 2008, 47, 6197–6203. [Google Scholar] [CrossRef]

- MOLSIV 13X APG; UOP Adsorbents Honeywell UOP: Des Plaines, IL, USA, 2010.

- Zeolite 13X; Beijing Dongfang Guansen Technology Co., Ltd.: Beijing, China, 2014.

- Chai, S.W.; Mayuresh, V.K.; Sircar, S. Rapid pressure swing adsorption for reduction of bed size factor of a medical oxygen concentrator. Ind. Eng. Chem. Res. 2011, 50, 8703–8710. [Google Scholar] [CrossRef]

- De Klerk, A. Voidage variation in packed beds at small column to particle diameter ratio. AIChE J. 2003, 49, 2022–2029. [Google Scholar] [CrossRef]

- Rao, V.; Rama, S.F.; Krantz, W.B. Design of a two-step pulsed pressure-swing adsorption-based oxygen concentrator. AIChE J. 2010, 56, 354–370. [Google Scholar] [CrossRef]

- Santos, J.C.; Cruz, P.; Regala, T.; Magalhães, F.D.; Mendes, A. High-purity oxygen production by pressure swing adsorption. Ind. Eng. Chem. Res. 2007, 46, 591–599. [Google Scholar] [CrossRef]

- Activated Alumina; Micromeritics Instrument Corporation: Norcross, GA 30093, USA, 2011.

- Farooq, S.; Ruthven, D.M.; Boniface, H.A. Numerical simulation of a pressure swing adsorption oxygen unit. Chem. Eng. Sci. 1989, 44, 2809–2816. [Google Scholar] [CrossRef]

- Azevedo, D.C.S.; Alírio, E.R. Bilinear driving force approximation in the modeling of a simulated moving bed using bidisperse adsorbents. Ind. Eng. Chem. Res. 1999, 38, 3519–3529. [Google Scholar] [CrossRef]

- COMSOL. COMSOL Documentation, 2016. Available online: www.comsol.com (accessed on 22 July 2017).

- Rao, V.; Rama, M.; Kothare, V.; Shivaji, S. Numerical simulation of rapid pressurization and depressurization of a zeolite column using nitrogen. Adsorption 2014, 20, 53–60. [Google Scholar] [CrossRef]

- Hejazi, S.A.H.; Rajendran, A.; Sawada, J.A.; Steven, M. Kuznicki Dynamic Column Breakthrough and Process Studies of High-Purity Oxygen Production Using Silver-Exchanged Titanosilicates. Ind. Eng. Chem. Res. 2016, 55, 5993–6005. [Google Scholar] [CrossRef]

- Rege, S.U.; Ralph, T.Y. Limits for air separation by adsorption with LiX zeolite. Ind. Eng. Chem. Res. 1997, 36, 5358–5365. [Google Scholar] [CrossRef]

- Chapman, S.; Cowling, G.C.; Cercignani, C. The Mathematical Theory of Non-Uniform Gases: An Account of the Kinetic Theory of Viscosity, Thermal Conduction and Diffusion in Gases; Cambridge University Press: Cambridge, UK, 1970. [Google Scholar]

- Omar, H.M.; Sohrab, R. Removal of CO2 from landfill gas with landfill leachate using absorption process. Int. J. Greenh. Gas Control 2017, 58, 159–168. [Google Scholar] [CrossRef]

- Akgiray, Ö.; Saatçı, A.M. A New Look at Filter Backwash Hydraulics. Water Sci. Technol. Water Supply 2001, 1, 65–72. [Google Scholar]

- Satterfield, C.N. Mass Transfer in Heterogeneous Catalysis; The MIT Press: Cambridge, MA, USA, 1970. [Google Scholar]

- Kumar, R.; Sircar, S. Skin resistance for adsorbate mass transfer into extruded adsorbent pellets. Chem. Eng. Sci. 1986, 41, 2215–2223. [Google Scholar] [CrossRef]

- Reid, R.C.; Prausnitz, J.M.; Sherwood, T.K. The Properties of Gases and Liquids, 3rd ed.; McGraw-Hill: New York, NY, USA, 1977; p. 548. [Google Scholar]

- Cunningham, R.E.; Williams, R.J.J. Diffusion in Gases and Porous Media; Plenum Press: Berlin, Germany, 1980. [Google Scholar]

- Smits, A.J.; Dussauge, J.P. Turbulent Shear Layers in Supersonic Flow, 2nd ed.; Springer Science & Business Media: Berlin, Germany, 2006. [Google Scholar]

- Sander, R. Compilation of Henry’s law constants (version 4.0) for water as solvent. Atmos. Chem. Phys. 2015, 15, 4399–4981. [Google Scholar] [CrossRef]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Lightfoot. In Transport Phenomena; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

| Step | Stage | Column 1 | Stage | Column 2 | ||

|---|---|---|---|---|---|---|

| Valve 1 | Valve 3 | Valve 2 | Valve 4 | |||

| 1 | Pressurization | P1 | P1 | Blowdown | P2 | P2 |

| 2 | Production | P1 | P1 | Vacuum | P2 | P1 |

| 3 | Blowdown | P2 | P2 | Pressurization | P1 | P1 |

| 4 | Vacuum | P2 | P1 | Production | P1 | P1 |

| Zeolite | JLOX-101 | 13X-BJ-DF |

|---|---|---|

| BET surface area (m2/g) | 574.77 | 522.93 |

| Micropore area (m2/g) | 515.39 | 477.04 |

| Single Point Adsorption Total Pore Volume (cm3/g) | 0.31 | 0.29 |

| Micropore Volume (cm3/g) | 0.24 | 0.22 |

| Adsorption Average Pore Diameter (Å) | 21.26 | 22.36 |

| Adsorbent | Zeolite LiX | Unit |

|---|---|---|

| Average zeolite particle size | 600 | µm |

| Average microparticle size | 5.75 | µm |

| Zeolite bulk density | 790 | kg/m3 |

| Particle voidage, | 0.35 | 1 |

| Maximum surface excess of N2, | 3.42 | mol/kg |

| Maximum surface excess of O2, | 6.06 | mol/kg |

| Adsorption constant, | 0.09 | 1/bar |

| Adsorption constant, | 0.02 | 1/bar |

| Pore tortuosity, | 3 | - |

| BET Surface Area | 574.77 | m2/g |

| Micropore Volume | 0.240007 | cm3/g |

| Adsorption Average Pore Diameter | 21.2609 | Å |

| Desiccant Type | Activated Alumina | |

| Particle density | 765 | kg/m3 |

| Average desiccant particle size | 600 | µm |

| Adsorption Column | - | - |

| Length | 10 | cm |

| Inside radius | 1.5 | cm |

| Column voidage, | 0.36 | 1 |

| Material | aluminum | - |

| Adsorbent | Zeolite LiX | Unit | Reference |

|---|---|---|---|

| Dynamic viscosity of the fluid, | 1.84 × 10−5 | Pa·s | Smits et al., 2006 |

| Dimensionless Henry’s law constant of N2, | 1.5 × 10−2 | - | Sander, 2015 |

| Dimensionless Henry’s law constant of O2, | 3.2 × 10−2 | - | |

| Average collision diameter of N2, | 3.67 | 10−10 m | Bird et al., 2007 |

| Average collision diameter of O2, | 6.06 | 10−10 m | |

| Characteristic energy of N2, | 99.8 | K | |

| Characteristic energy of O2, | 113 | K | |

| Molecular Weight, MN2 | 28.01 | 10−3 kg/mol | |

| Molecular Weight, MO2 | 31.99 | 10−3 kg/mol | |

| Gas constant, R | 8.31 | J/(K·mol) |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, M.; Omar, H.M.; Rohani, S. Application of Nanosize Zeolite Molecular Sieves for Medical Oxygen Concentration. Nanomaterials 2017, 7, 195. https://doi.org/10.3390/nano7080195

Pan M, Omar HM, Rohani S. Application of Nanosize Zeolite Molecular Sieves for Medical Oxygen Concentration. Nanomaterials. 2017; 7(8):195. https://doi.org/10.3390/nano7080195

Chicago/Turabian StylePan, Mingfei, Hecham M. Omar, and Sohrab Rohani. 2017. "Application of Nanosize Zeolite Molecular Sieves for Medical Oxygen Concentration" Nanomaterials 7, no. 8: 195. https://doi.org/10.3390/nano7080195