Dense Plasma Focus-Based Nanofabrication of III–V Semiconductors: Unique Features and Recent Advances

Abstract

:1. Introduction

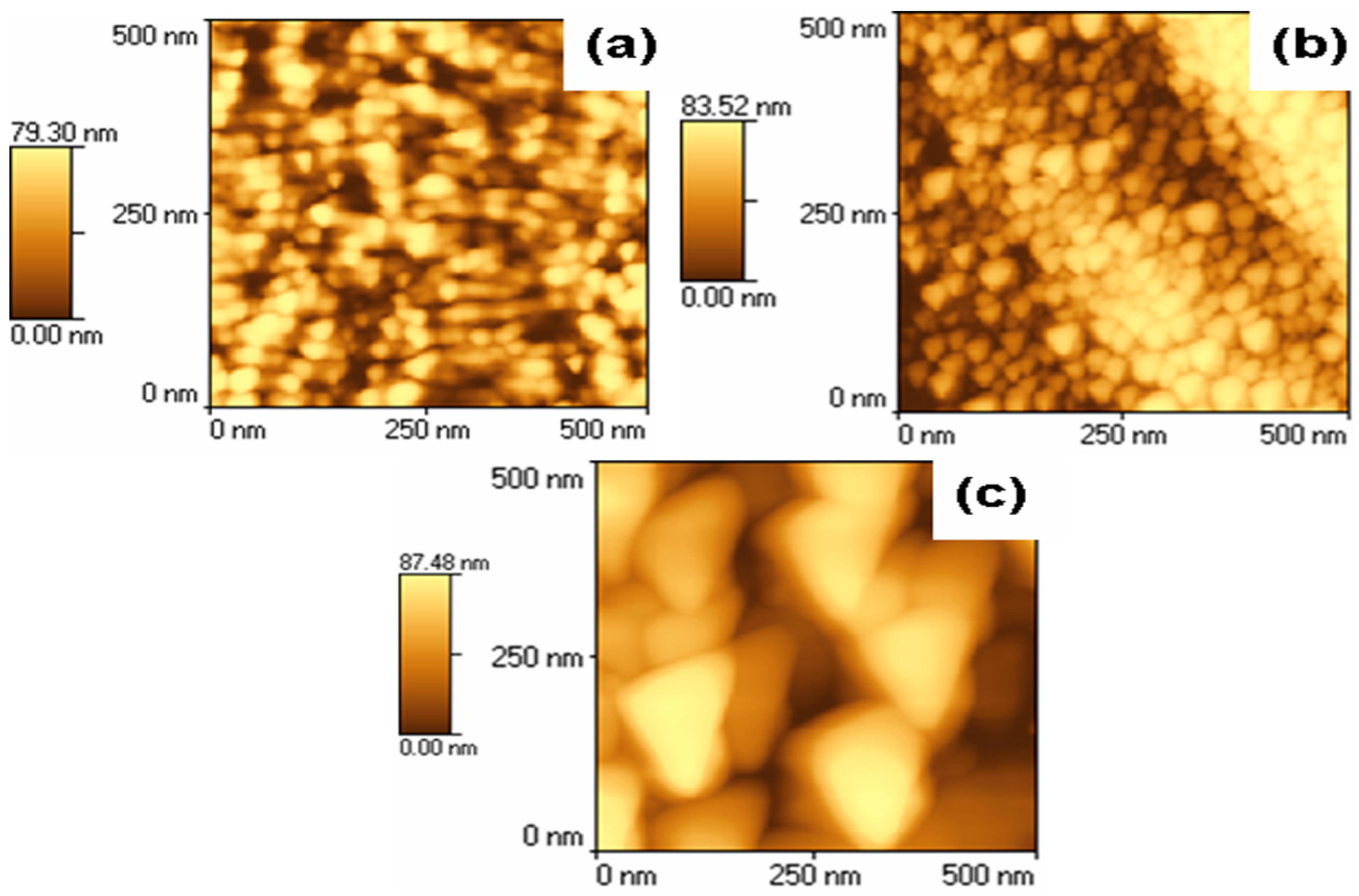

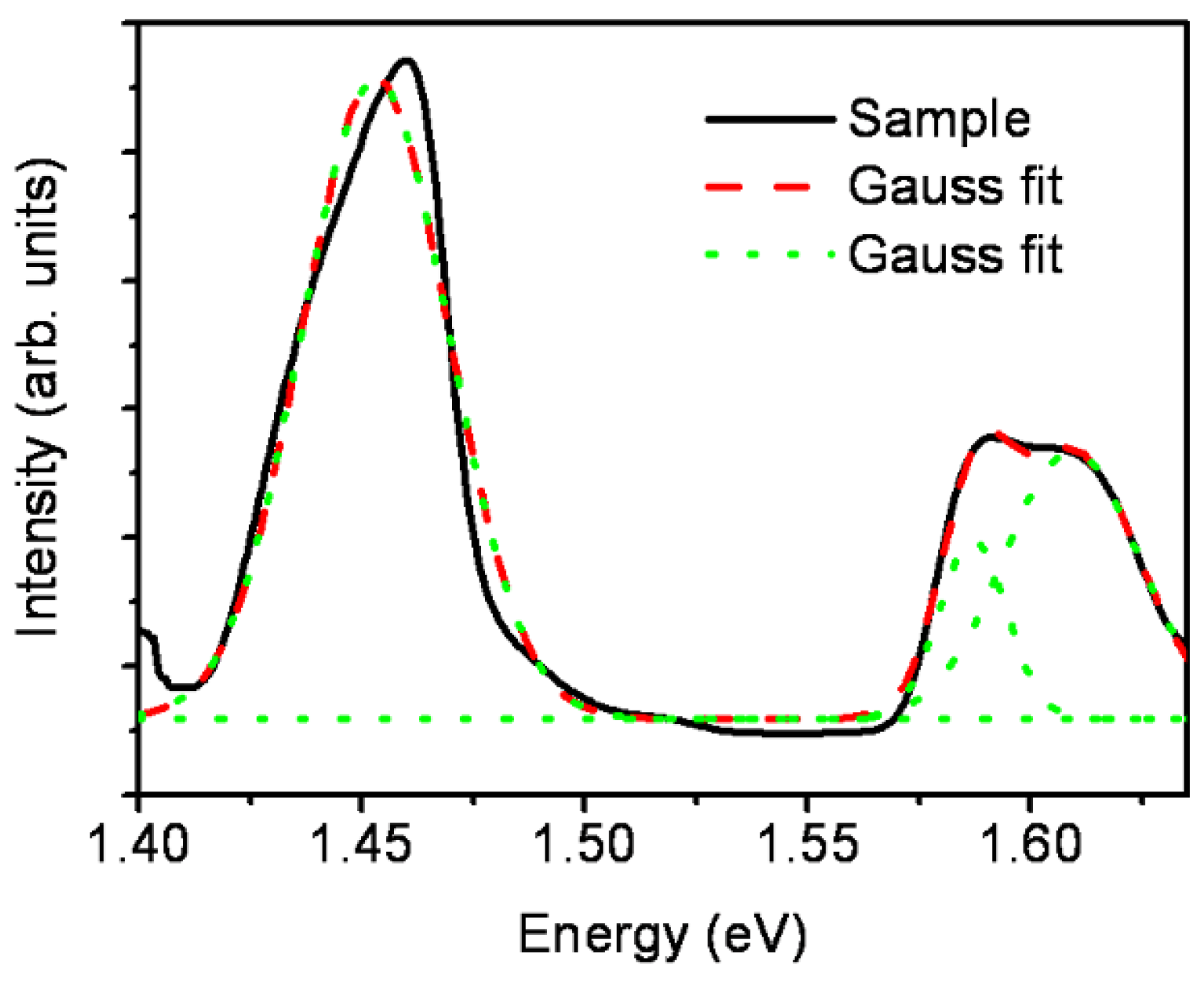

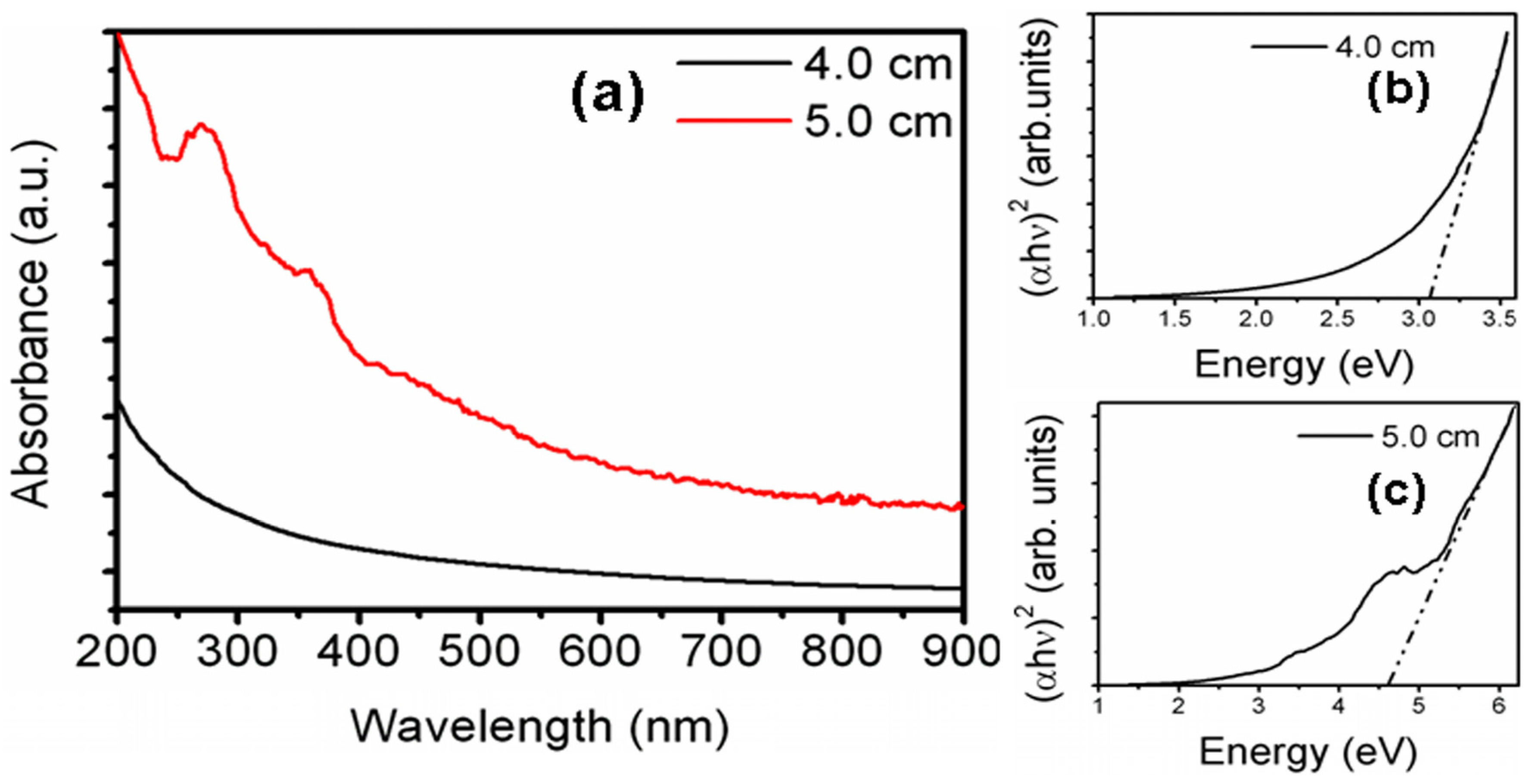

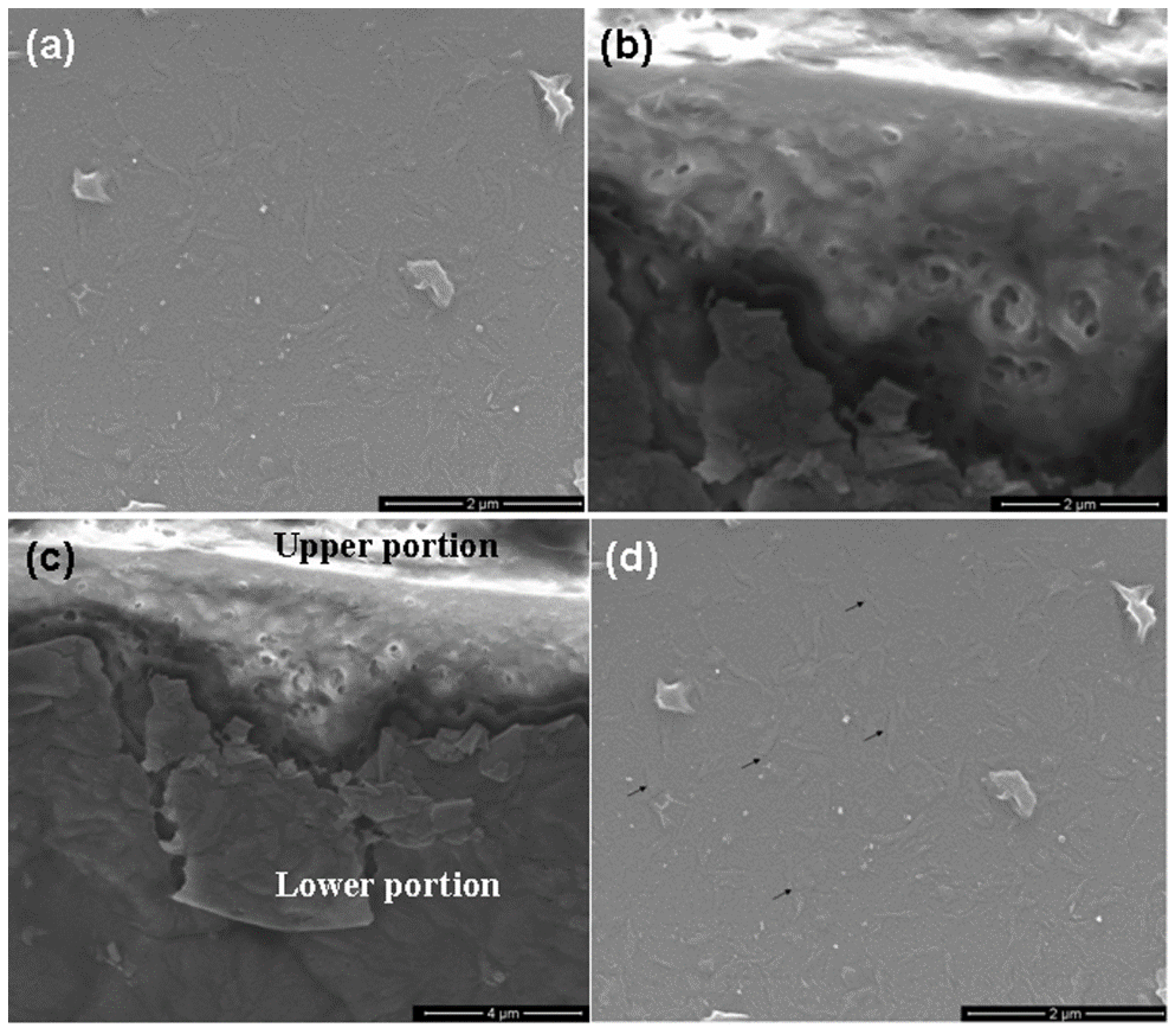

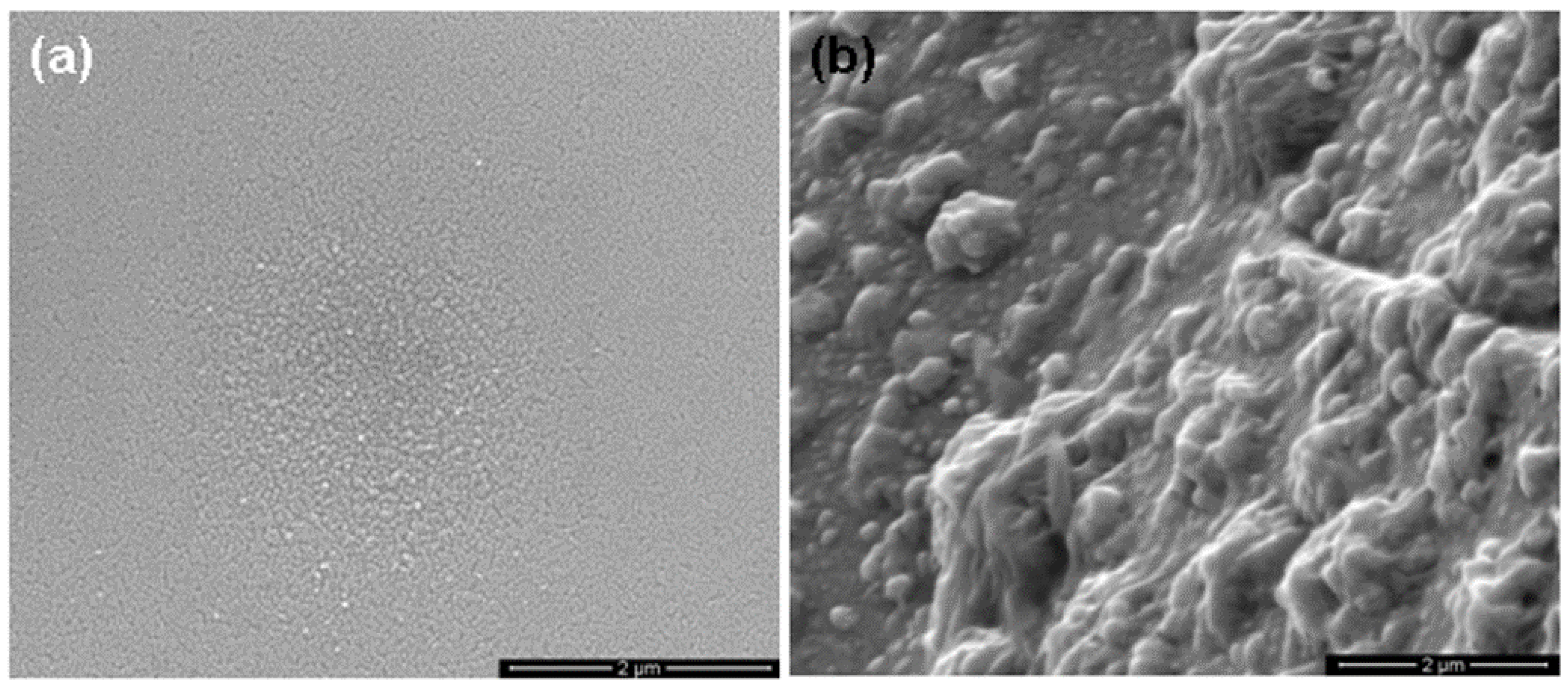

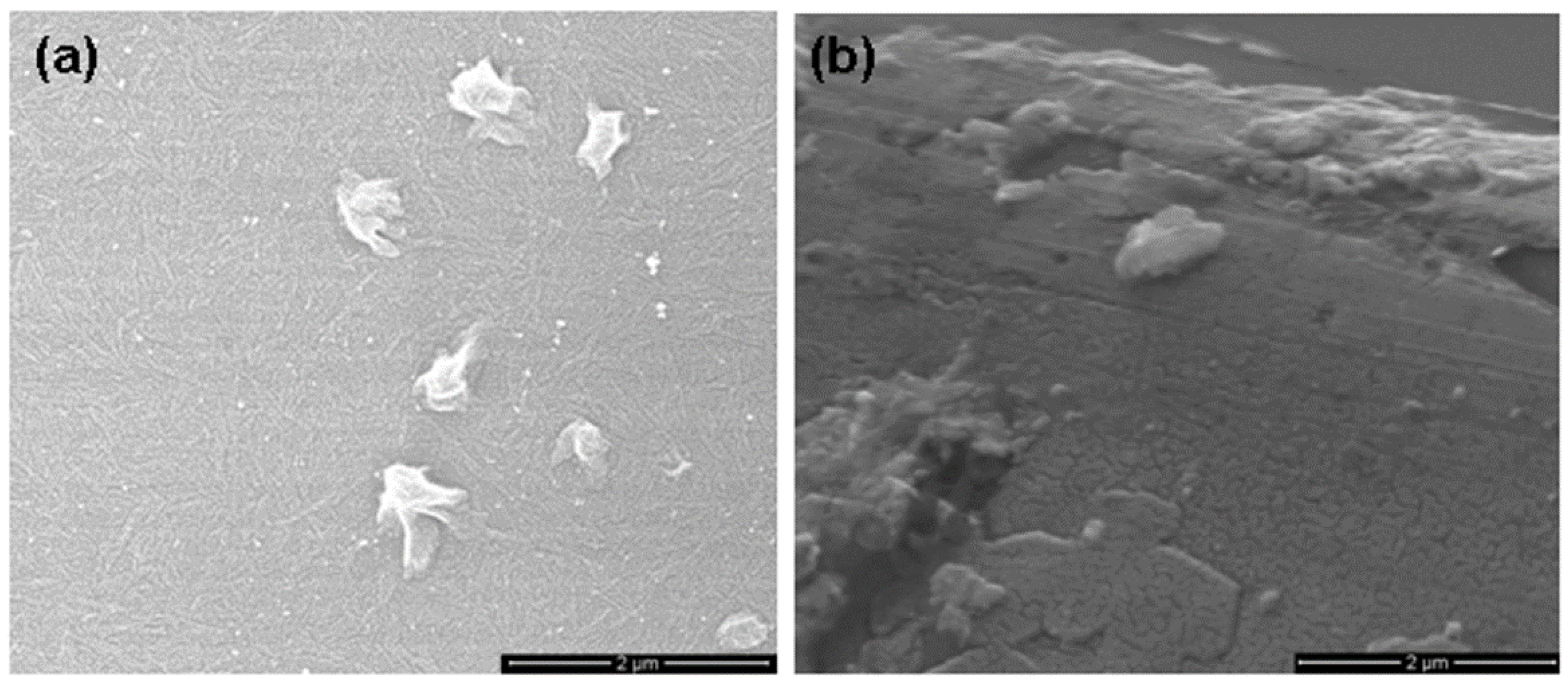

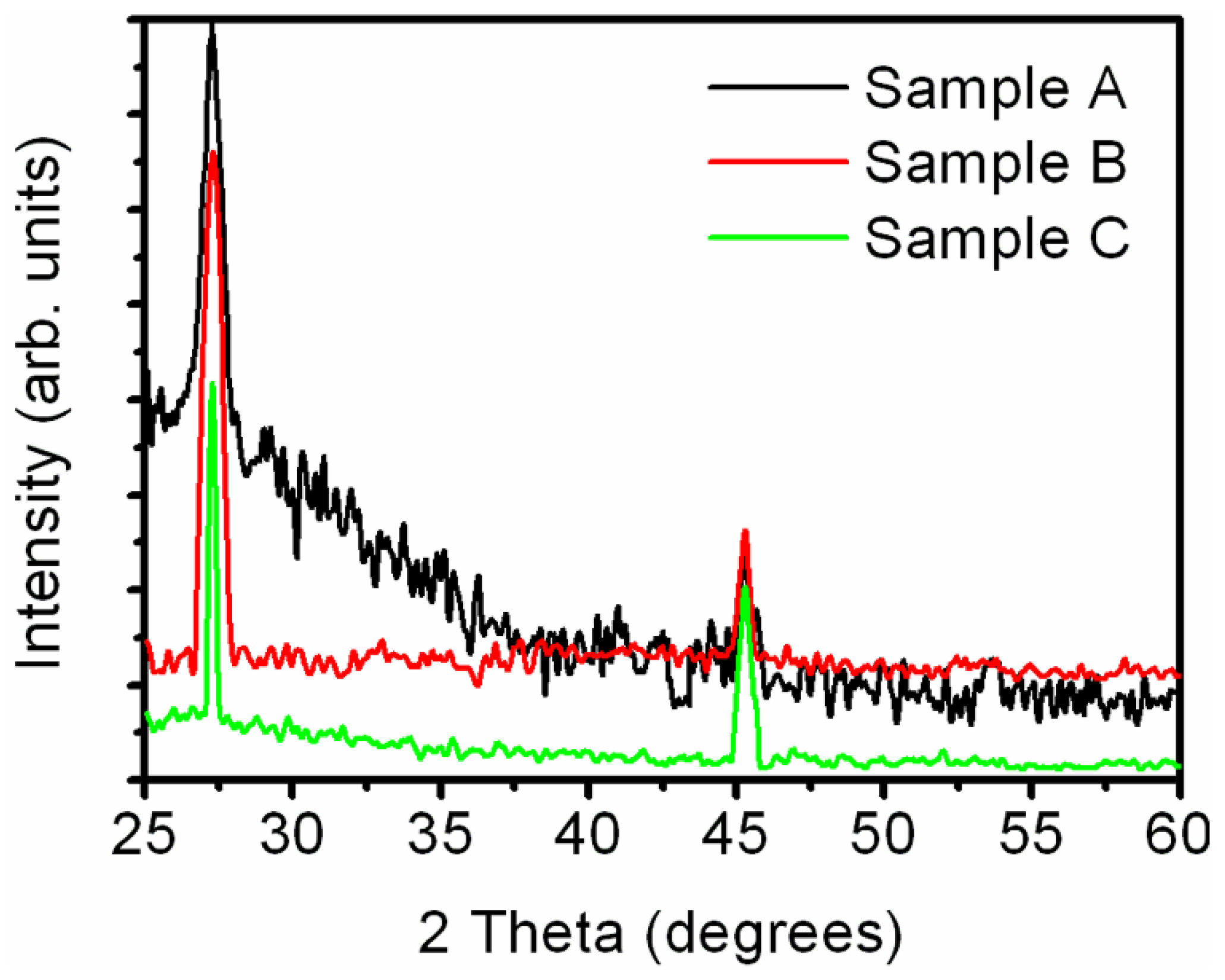

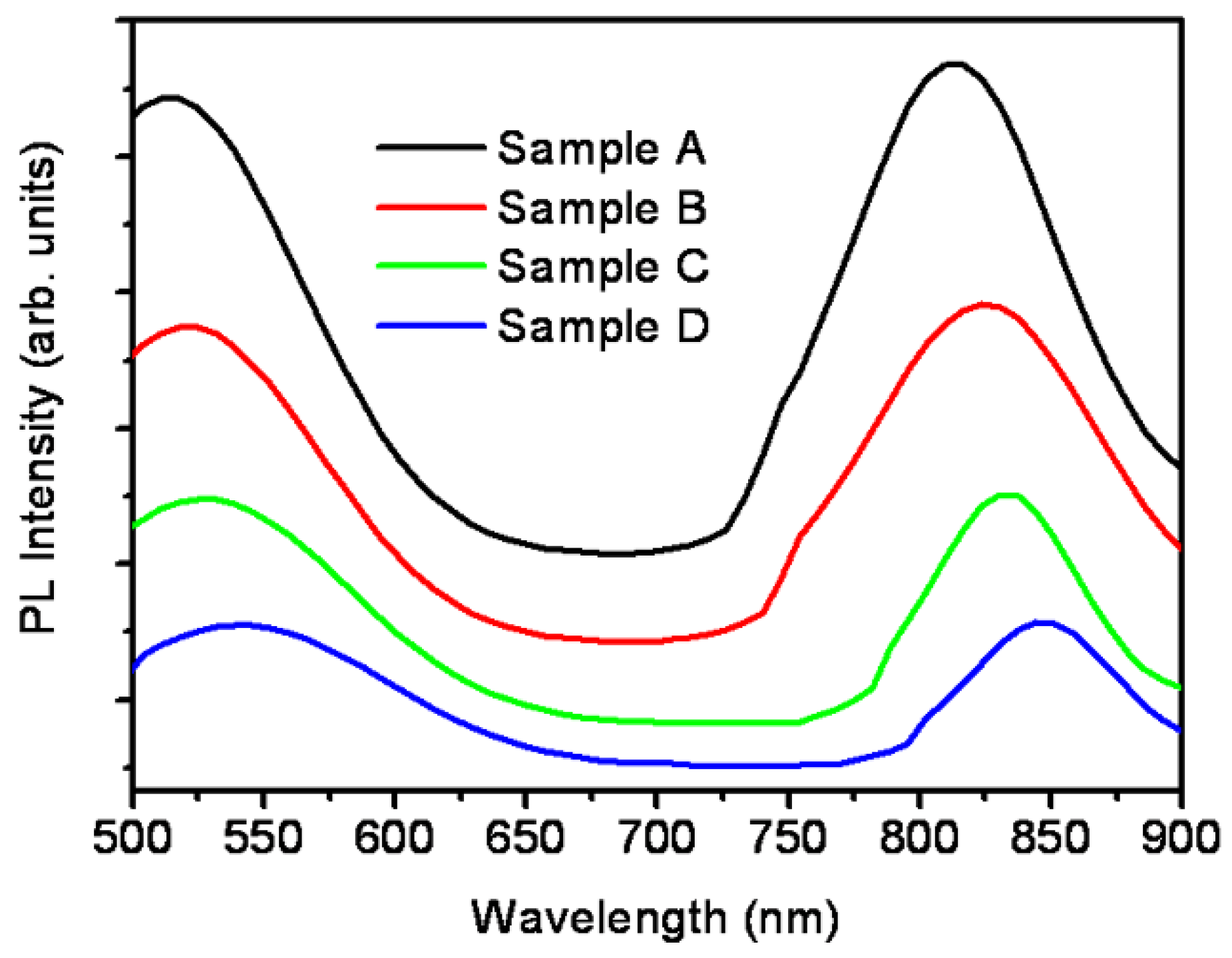

2. Results and Discussion

3. Experimental Section

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Surla, V.; Ruzic, D. High-energy density beams and plasmas for micro- and nano-texturing of surfaces by rapid melting and solidification. J. Phys. D 2011, 44. [Google Scholar] [CrossRef]

- Rawat, R.S. High-Energy-Density Pinch Plasma: A Unique Nonconventional Tool for Plasma Nanotechnology. IEEE Trans. Plasma Sci. 2013, 41, 701–715. [Google Scholar] [CrossRef]

- Umar, Z.A.; Rawat, R.S.; Tan, K.S.; Kumar, A.K.; Ahmad, R.; Hussain, T.; Kloc, C.; Chen, Z.; Shen, L.; Zhang, Z. Hard TiCx/SiC/a-C:H nanocomposite thin films using pulsed high energy density plasma focus device. Nucl. Instrum. Methods Phys. Res. B 2013, 301, 53–61. [Google Scholar] [CrossRef]

- Khalid, M.; Mujahid, M.; Khan, A.N.; Rawat, R.S. Dip Coating of Nano Hydroxyapatite on Titanium Alloy with Plasma Assisted γ-Alumina Buffer Layer: A Novel Coating Approach. J. Mater. Sci. Technol. 2013, 29, 557–564. [Google Scholar] [CrossRef]

- Umar, Z.A.; Rawat, R.S.; Ahmad, R.; Kumar, A.K.; Wang, Y.; Hussain, T.; Chen, Z.; Shen, L.; Zhang, Z. Mechanical properties of Al/a-C nanocomposite thin films synthesized using a plasma focus device. Chin. Phys. B 2014, 23, 1–6. [Google Scholar] [CrossRef]

- Hussain, A.; Rawat, R.S.; Ahmad, R.; Hussain, T.; Umar, Z.A.; Ikhlaq, U.; Chen, Z.; Shen, L. A study of structural and mechanical properties of nano-crystalline tungsten nitride film synthesis by plasma focus. Radiat. Eff. Def. Solids 2015, 170, 73–83. [Google Scholar] [CrossRef]

- Srivastava, M.P. Plasma Route to Nanosciences and Nanotechnology Frontiers. J. Plasma Fusion Res. 2009, 8, 512–516. [Google Scholar]

- Singh, W.P.; Srivastava, M.P.; Roy, S. Nanoparticles and Nanostructured Cobalt Deposition Using Dense Plasma Focus Device. J. Plasma Fusion Res. 2009, 8, 526–529. [Google Scholar]

- Singh, W.P.; Roy, S.; Srivastava, M.P. Formation of iron nanoparticles on quartz substrate using dense plasma focus device. J. Phys. Conf. Ser. 2010, 208. [Google Scholar] [CrossRef]

- Devi, N.B.; Roy, S.; Srivastava, M.P. Deposition of aluminium nanoparticles using dense plasma focus device. J. Phys. Conf. Ser. 2010, 208. [Google Scholar] [CrossRef]

- Naorem, B.D.; Roy, S.; Malhotra, Y.; Srivastava, M.P. Fabrication of gold nanostructures and studies of their morphological and surface plasmonic properties. Plasmonics 2013, 8, 1273–1278. [Google Scholar] [CrossRef]

- Malhotra, Y.; Srivastava, M.P. AFM, XRD and Optical Studies of Silver Nanostructures Fabricated under Extreme Plasma Conditions. J. Phys. Conf. Ser. 2014, 511. [Google Scholar] [CrossRef]

- Srivastava, M.P.; Naorem, B.D. Surface Plasmon Properties of Silver Nanostructures Fabricated using Extremely Non-Equilibrium Hot and Dense Plasma. Adv. Mater. Res. 2015, 1110, 226–230. [Google Scholar] [CrossRef]

- Malhotra, Y.; Roy, S.; Srivastava, M.P.; Kant, C.R.; Ostrikov, K. Extremely non-equilibrium synthesis of luminescent zinc oxide nanoparticles through energetic ion condensation in a dense plasma focus device. J. Phys. D 2009, 42, 155202–155208. [Google Scholar] [CrossRef]

- Malhotra, Y.; Roy, S.; Srivastava, M.P. Deposition and surface characterization of nanoparticles of zinc oxide using dense plasma focus device in nitrogen atmosphere. J. Phys. Conf. Ser. 2010, 208. [Google Scholar] [CrossRef]

- Mangla, O.; Srivastava, M.P. GaN nanostructures by hot dense and extremely non-equilibrium plasma and their characterizations. J. Mater. Sci. 2013, 48, 304–310. [Google Scholar] [CrossRef]

- Mangla, O.; Roy, S.; Srivastava, M.P. Synthesis and characterization of gallium arsenide nanostructured film for optoelectronic applications. Adv. Sci. Eng. Med. 2014, 6, 1200–1204. [Google Scholar] [CrossRef]

- Mangla, O.; Roy, S. A study on aberrations in energy band gap of quantum confined gallium arsenide spherical nanoparticles. Mater. Lett. 2015, 143, 48–50. [Google Scholar] [CrossRef]

- Srivastava, A.; Nahar, R.K.; Sarkar, C.K.; Singh, W.P.; Malhotra, Y. Study of hafnium oxide deposited using Dense Plasma Focus machine for film structure and electrical properties as a MOS device. Microelectron. Reliab. 2011, 51, 751–755. [Google Scholar] [CrossRef]

- Mangla, O.; Srivastava, A.; Malhotra, Y.; Ostrikov, K. Lanthanum oxide nanostructured films synthesized using hot dense and extremely non-equilibrium plasma for nanoelectronic device applications. J. Mater. Sci. 2014, 49, 1594–1605. [Google Scholar] [CrossRef]

- Mangla, O.; Srivastava, A.; Malhotra, Y.; Ostrikov, K. Metal-insulator-metal capacitors based on lanthanum oxide high-κ dielectric nanolayers fabricated using dense plasma focus device. J. Vac. Sci. Technol. B 2014, 32. [Google Scholar] [CrossRef]

- Sinha, G.; Panda, S.K.; Mishra, P.; Ganguli, D.; Chaudhuri, S. Gallium nitride quantum dots in nitrogen-bonded silica gel matrix. J. Phys. Condens. Matter 2007, 19. [Google Scholar] [CrossRef]

- Hirasawa, M.; Ichikawa, N.; Egashira, Y.; Honma, I.; Komiyama, H. Synthesis of GaAs nanoparticles by digital radio frequency sputtering. Appl. Phys. Lett. 1995, 67, 3483–3485. [Google Scholar] [CrossRef]

- Shetty, S.; Kesaria, M.; Ghatak, J.; Shivaprasad, S.M. The Origin of Shape, Orientation, and Structure of Spontaneously Formed Wurtzite GaN Nanorods on Cubic Si(001) Surface. Cryst. Growth Des. 2013, 13, 2407–2412. [Google Scholar] [CrossRef]

- Davydok, A.; Biermanns, A.; Pietsch, U.; Grenzer, J.; Paetzelt, H.; Gottschalch, V.; Bauer, J. Submicron resolution X-ray diffraction from periodically patterned GaAs nanorods grown onto Ge[111]. Phys. Stat. Solidi A 2009, 206, 1704–1708. [Google Scholar] [CrossRef]

- Li, H.D.; Zhang, S.L.; Yang, H.B.; Zou, G.T.; Yang, Y.Y.; Yue, K.T.; Wu, X.H.; Yan, Y. Raman spectroscopy of nanocrystalline GaN synthesized by arc plasma. J. Appl. Phys. 2002, 91, 4562–4567. [Google Scholar] [CrossRef]

- Okamoto, S.; Kanemitsu, Y.; Min, K.S.; Atwater, H.A. Photoluminescence from GaAs nanocrystals fabricated by Ga+ and As+ co-implantation into SiO2 matrices. Appl. Phys. Lett. 1998, 73, 1829–1831. [Google Scholar] [CrossRef]

- Wang, Y.D.; Chua, S.J.; Tripathy, S.; Sander, M.S.; Chen, P.; Fonstad, C.G. High optical quality GaN nanopillar arrays. Appl. Phys. Lett. 2005, 86. [Google Scholar] [CrossRef]

- DeJarld, M.; Shin, J.C.; Chern, W.; Chanda, D.; Balasundaram, K.; Rogers, J.A.; Li, X. Formation of High Aspect Ratio GaAs Nanostructures with Metal-Assisted Chemical Etching. Nano Lett. 2011, 11, 5259–5263. [Google Scholar] [CrossRef] [PubMed]

- Wierzbicka, A.; Zytkiewicz, Z.R.; Kret, S.; Borysiuk, J.; Dluzewski, P.; Sobanska, M.; Klosek, K.; Reszka, A.; Tchutchulashvili, G.; Cabaj, A.; et al. Influence of substrate nitridation temperature on epitaxial alignment of GaN nanowires to Si(111) substrate. Nanotechnology 2013, 24. [Google Scholar] [CrossRef] [PubMed]

- Jahn, U.; Lahnemann, J.; Pfuller, C.; Brandt, O.; Breuer, S.; Jenichen, B.; Ramsteiner, M.; Geelhaar, L.; Riechert, H. Luminescence of GaAs nanowires consisting of wurtzite and zinc-blende segments. Phys. Rev. B 2012, 85. [Google Scholar] [CrossRef]

- Ghosh, C.; Pal, S.; Goswami, B.; Sarkar, P. Theoretical Study of the Electronic Structure of GaAs Nanotubes. J. Phys. Chem. C 2007, 111, 12284–12288. [Google Scholar] [CrossRef]

- Hemmingsson, C.; Pozina, G.; Khromov, S.; Monemar, B. Growth of GaN nanotubes by halide vapor phase epitaxy. Nanotechnology 2011, 22. [Google Scholar] [CrossRef] [PubMed]

- Hwang, G.; Dockendorf, C.; Bell, D.; Dong, L.; Hashimoto, H.; Poulikakos, D.; Nelson, B. 3-D InGaAs/GaAs Helical Nanobelts for Optoelectronic Devices. Inter. J. Optomech. 2008, 2, 88–103. [Google Scholar] [CrossRef]

- Yu, R.; Dong, L.; Pan, C.; Niu, S.; Liu, H.; Liu, W.; Chua, S.; Chi, D.; Wang, Z.L. Piezotronic Effect on the Transport Properties of GaN Nanobelts for Active Flexible Electronics. Adv. Mater. 2012, 24, 3532–3537. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.Y.; Kwon, H.Y.; Shin, M.J.; Choi, Y.J.; Ahn, H.S.; Chang, J.H.; Yi, S.N.; Yun, Y.J.; Ha, D.H.; Park, S.H. Growth behavior of GaN nanoneedles with changing HCl/NH3 flow ratio. Mater. Lett. 2009, 63, 2695–2697. [Google Scholar] [CrossRef]

- Chuang, L.C.; Sedgwick, F.G.; Chen, R.; Ko, W.S.; Moewe, M.; Ng, K.W.; Tran, T.T.D.; Chang-Hasnain, C. GaAs-Based Nanoneedle Light Emitting Diode and Avalanche Photodiode Monolithically Integrated on a Silicon Substrate. Nano Lett. 2011, 11, 385–390. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.M.; Kim, D.S.; Park, Y.S.; Kim, D.Y.; Kang, T.W.; Chung, K.S. Growth of GaN Nanorods by a Hydride Vapor Phase Epitaxy Method. Adv. Mater. 2002, 14, 991–993. [Google Scholar] [CrossRef]

- Yang, Y.G.; Ma, H.L.; Xue, C.S.; Zhuang, H.Z.; Ma, J.; Hao, X.T. Preparation and properties of GaN nanostructures by post-nitridation technique. Phys. B 2003, 334, 287–291. [Google Scholar] [CrossRef]

- Hung, J.; Lee, S.C.; Chia, C.T. The structural and optical properties of gallium arsenic nanoparticles. J. Nanopart. Res. 2004, 6, 415–419. [Google Scholar] [CrossRef]

- Nayak, J.; Mythili, R.; Vijayalakshmi, M.; Sahu, S.N. Size quantization effect in GaAs nanocrystals. Phys. E 2004, 24, 227–233. [Google Scholar] [CrossRef]

- Czaban, J.A.; Thompson, D.A.; LaPierre, R.R. GaAs Core-Shell Nanowires for Photovoltaic Applications. Nano Lett. 2009, 9, 148–154. [Google Scholar] [CrossRef] [PubMed]

- Ng, D.K.T.; Tan, L.S.; Hong, M.H. Synthesis of GaN nanowires on gold-coated substrates by pulsed laser ablation. Curr. Appl. Phys. 2006, 6, 403–406. [Google Scholar] [CrossRef]

- Lei, M.; Yang, H.; Li, P.G.; Tang, W.H. Synthesis of GaN nanowires on gold-coated SiC substrates by novel pulsed electron deposition technique. Appl. Surf. Sci. 2008, 254, 1947–1952. [Google Scholar] [CrossRef]

- Dinh, L.N.; Hayes, S.; Saw, C.K.; McLean, W., II; Balooch, M.; Reimer, J.A. GaAs nanostructures and films deposited by a Cu-vapor laser. Appl. Phys. Lett. 1999, 75, 2208–2210. [Google Scholar] [CrossRef]

- Duan, X.; Wang, J.; Lieber, C.M. Synthesis and optical properties of gallium arsenide nanowires. Appl. Phys. Lett. 2000, 76, 1116–1118. [Google Scholar] [CrossRef]

- Yusa, G.; Sakaki, H. Trapping of photogenerated carriers by InAs quantum dots and persistent photoconductivity in novel GaAs/n-AlGaAs field-effect transistor structures. Appl. Phys. Lett. 1997, 70, 345–347. [Google Scholar] [CrossRef]

- Page, H.; Becker, C.; Robertson, A.; Glastre, G.; Ortiz, V.; Sirtori, C. 300 K operation of a GaAs-based quantum-cascade laser at λ ≈ 9 μm. Appl. Phys. Lett. 2001, 78, 3529–3531. [Google Scholar] [CrossRef]

- Belogorokhov, A.I.; Gavrilov, S.A.; Belogorokhov, I.A. Structural and optical properties of porous gallium arsenide. Phys. Status Solidi C 2005, 2, 3491–3494. [Google Scholar] [CrossRef]

- Grym, J.; Nohavica, D.; Vanis, J.; Piksova, K. Preparation of nanoporous GaAs substrates for epitaxial growth. Phys. Status Solidi C 2012, 9, 1531–1533. [Google Scholar] [CrossRef]

- Oskam, G.; Natarajan, A.; Searson, P.C.; Ross, F.M. The formation of porous GaAs in HF solution. Appl. Surf. Sci. 1997, 119, 160–168. [Google Scholar] [CrossRef]

- Beji, L.; Sfaxi, L.; Ismail, B.; Missaoui, A.; Hassen, F.; Maaref, H.; Ouada, H.B. Visible photoluminescence in porous GaAs capped by GaAs. Phys. E 2005, 25, 636–642. [Google Scholar] [CrossRef]

- Dmitruk, N.; Kutovyi, S.; Dmitruk, I.; Simkiene, I.; Sabataityte, J.; Berezovska, N. Morphology, Raman scattering and photoluminescence of porous GaAs layers. Sens. Actuators B 2007, 126, 294–300. [Google Scholar] [CrossRef]

- Srinivasan, R.; Ramachandran, K. Synthesis and thermal diffusion of nanostructured porous GaAs. Cryst. Res. Technol. 2008, 43, 953–958. [Google Scholar] [CrossRef]

- Madelung, O. Semiconductors: Group IV Elements and III–V Compounds; Springer: Berlin, Germany, 1991; pp. 101–103. [Google Scholar]

- Schmuki, P.; Lockwood, D.J.; Labbe, H.J.; Fraser, J.W. Visible photoluminescence from porous GaAs. Appl. Phys. Lett. 1996, 69, 1620–1622. [Google Scholar] [CrossRef]

- Schmuki, P.; Erickson, L.E.; Lockwood, D.J.; Fraser, J.W.; Champion, G.; Labbe, H.J. Formation of visible light emitting porous GaAs micropatterns. Appl. Phys. Lett. 1998, 72, 1039–1041. [Google Scholar] [CrossRef]

- Lockwood, D.J.; Schmuki, P.; Labbe, H.J.; Fraser, J.W. Optical properties of porous GaAs. Phys. E 1999, 4, 102–110. [Google Scholar] [CrossRef]

- Skolnick, M.S.; Reed, L.J.; Pitt, A.D. Photoinduced quenching of infrared absorption nonuniformities of large diameter GaAs crystals. Appl. Phys. Lett. 1984, 44, 447–449. [Google Scholar] [CrossRef]

- Rudolph, P. Non-stoichiometry related defects at the melt growth of semiconductor compound crystals—A review. Cryst. Res. Technol. 2003, 38, 542–554. [Google Scholar] [CrossRef]

- Yamamoto, N.; Nakanishi, T.; Mano, A.; Nakagawa, Y.; Okumi, S.; Yamamoto, M.; Konomi, T.; Jin, X.; Ujihara, T.; Takeda, Y.; et al. High brightness and high polarization electron source using transmission photocathode with GaAs-GaAsP superlattice layers. J. Appl. Phys. 2008, 103. [Google Scholar] [CrossRef]

- Salehi, A.; Kalantari, D.J. Characteristics of highly sensitive Au/porous-GaAs Schottky junctions as selective CO and NO gas sensors. Sens. Actuators B Chem. 2007, 122, 69–74. [Google Scholar] [CrossRef]

- Mather, J.W. Investigation of the high energy acceleration mode in the coaxial gun. Phys. Fluids 1964, 7, S28–S34. [Google Scholar] [CrossRef]

- Rawat, R.S.; Srivastava, M.P.; Tandon, S.; Mansingh, A. Crystallization of an amorphous lead zirconate titanate thin film with a dense-plasma-focus device. Phys. Rev. B 1993, 47, 4858–4862. [Google Scholar] [CrossRef]

- Ostrikov, K.; Neyts, E.C.; Meyyappan, M. Plasma nanoscience: From nano-solids in plasmas to nano-plasmas in solids. Adv. Phys. 2013, 62, 113–224. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mangla, O.; Roy, S.; Ostrikov, K. Dense Plasma Focus-Based Nanofabrication of III–V Semiconductors: Unique Features and Recent Advances. Nanomaterials 2016, 6, 4. https://doi.org/10.3390/nano6010004

Mangla O, Roy S, Ostrikov K. Dense Plasma Focus-Based Nanofabrication of III–V Semiconductors: Unique Features and Recent Advances. Nanomaterials. 2016; 6(1):4. https://doi.org/10.3390/nano6010004

Chicago/Turabian StyleMangla, Onkar, Savita Roy, and Kostya (Ken) Ostrikov. 2016. "Dense Plasma Focus-Based Nanofabrication of III–V Semiconductors: Unique Features and Recent Advances" Nanomaterials 6, no. 1: 4. https://doi.org/10.3390/nano6010004