Surface Evolution of Nano-Textured 4H–SiC Homoepitaxial Layers after High Temperature Treatments: Morphology Characterization and Graphene Growth

Abstract

:1. Introduction

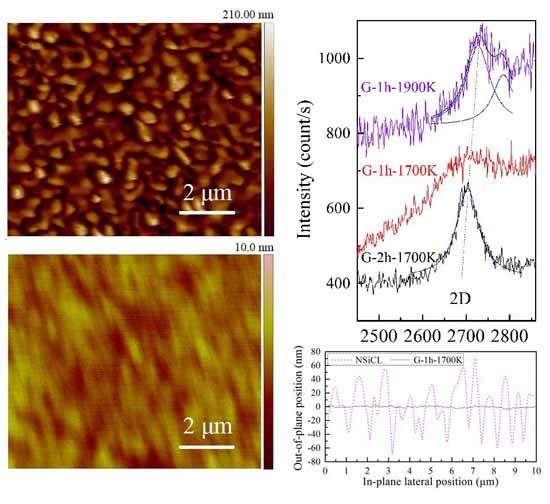

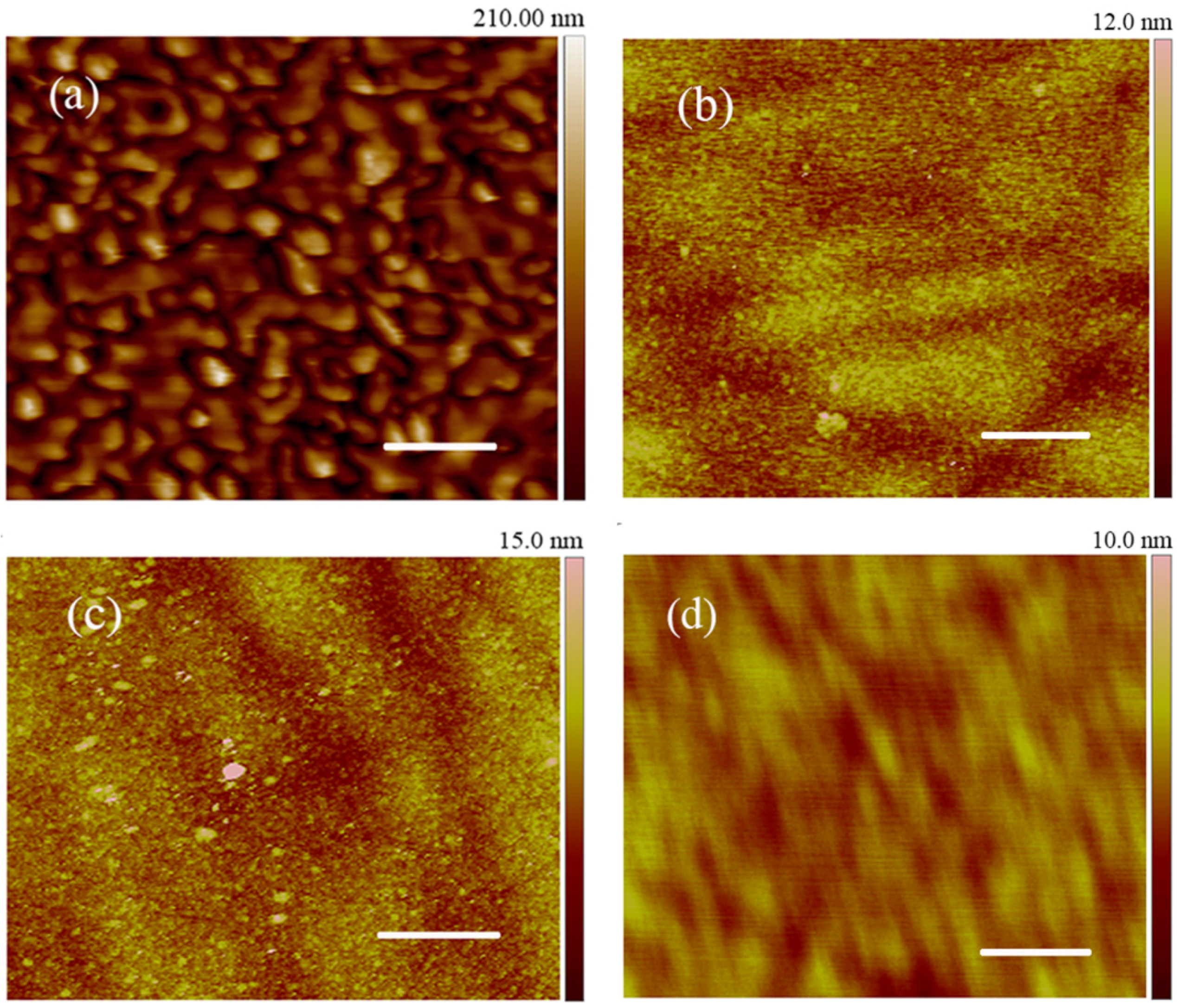

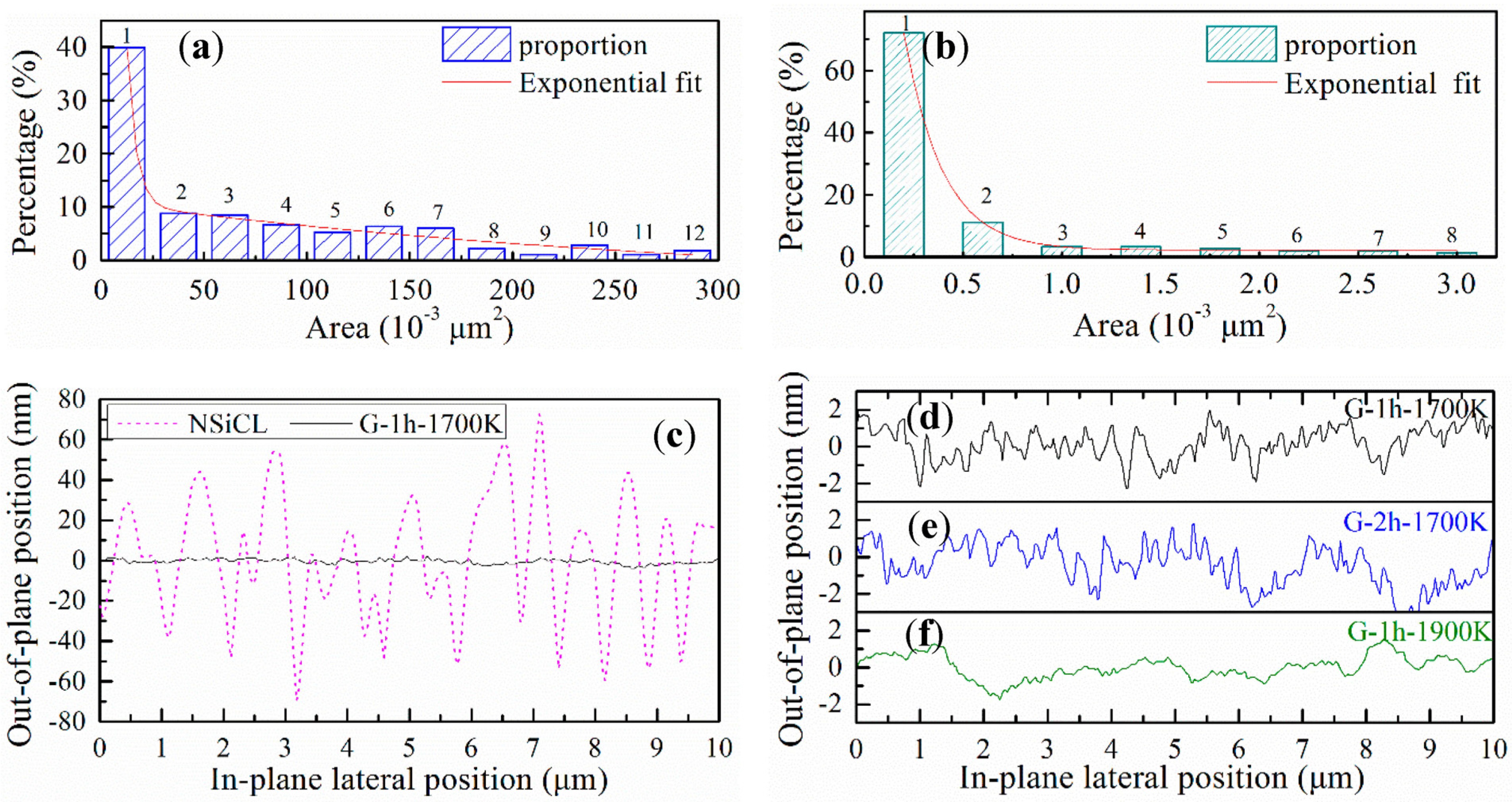

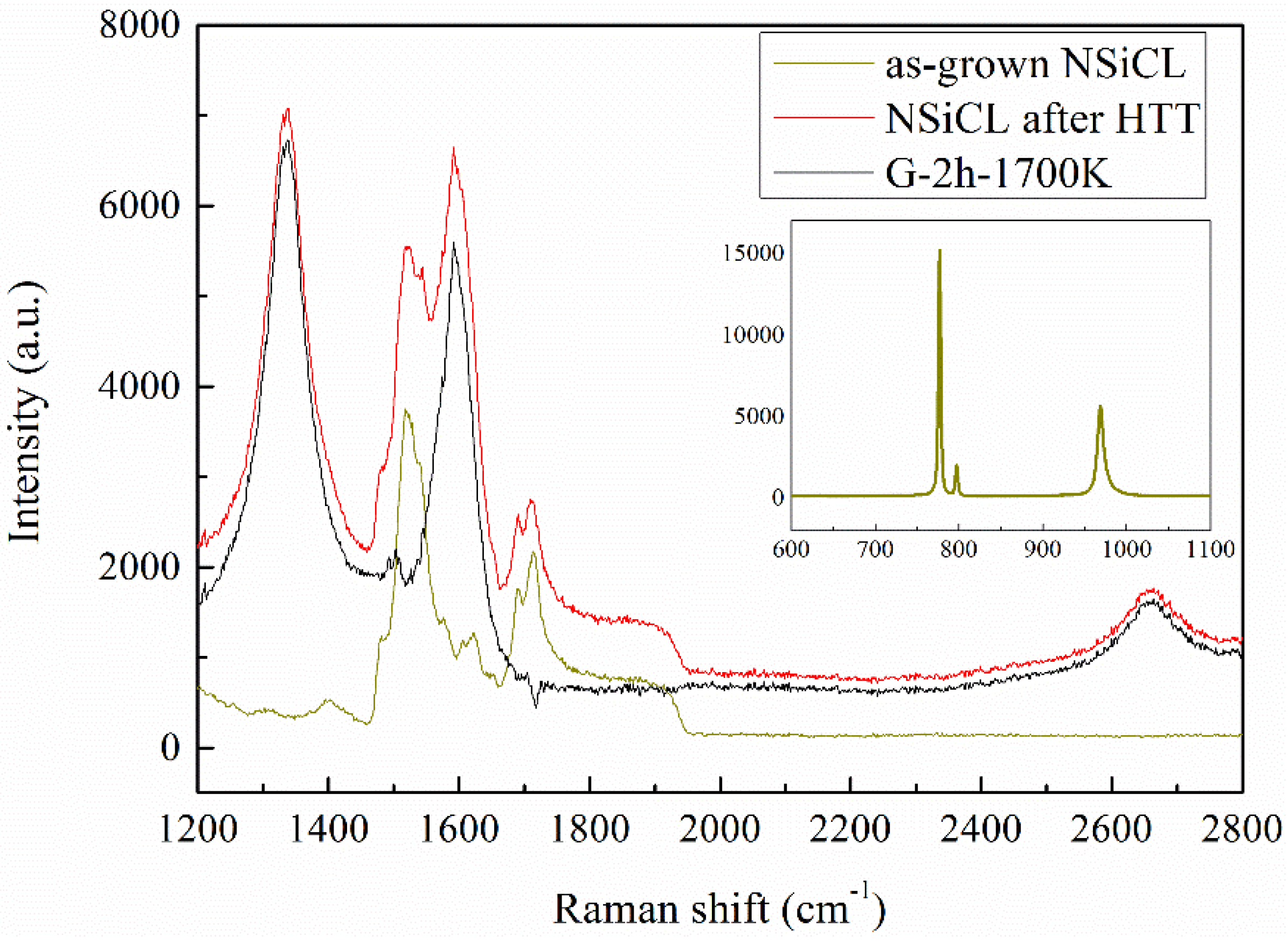

2. Results and Discussion

3. Experimental Section

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Berger, C.; Song, Z.M.; Li, T.B.; Li, X.B.; Ogbazghi, A.Y.; Feng, R.; Dai, Z.T.; Marchenkov, A.N.; Conrad, E.H.; First, P.N.; et al. Ultrathin epitaxial graphite: 2D electron gas properties and a route toward graphene-based nanoelectronics. J. Phys. Chem. B 2004, 108, 19912–19916. [Google Scholar] [CrossRef]

- Gonzalez, J.; Guinea, F.; Vozmediano, M.A.H. Electron-electron interactions in graphene sheets. Phys. Rev. B 2001, 6313, 134421. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Berger, C.; Song, Z.; Li, X.; Wu, X.; Brown, N.; Naud, C.; Mayou, D.; Li, T.; Hass, J.; Marchenkov, A.N.; et al. Electronic confinement and coherence in patterned epitaxial graphene. Science 2006, 312, 1191–1196. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.S.; Zhao, Y.; Jang, H.; Lee, S.Y.; Kim, J.M.; Kim, K.S.; Ahn, J.-H.; Kim, P.; Choi, J.-Y.; Hong, B.H. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 2009, 457, 706–710. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E.; et al. Large-Area Synthesis of High-Quality and Uniform Graphene Films on Copper Foils. Science 2009, 324, 1312–1314. [Google Scholar] [CrossRef] [PubMed]

- Emtsev, K.V.; Bostwick, A.; Horn, K.; Jobst, J.; Kellogg, G.L.; Ley, L.; McChesney, J.L.; Ohta, T.; Reshanov, S.A.; Rohrl, J.; et al. Towards wafer-size graphene layers by atmospheric pressure graphitization of silicon carbide. Nat. Mater. 2009, 8, 203–207. [Google Scholar] [CrossRef] [PubMed]

- Cai, T.; Jia, Z.; Yan, B.; Yu, D.; Wu, X. Hydrogen assisted growth of high quality epitaxial graphene on the C-face of 4H–SiC. Appl. Phys. Lett. 2015, 106, 013106. [Google Scholar] [CrossRef]

- Adan-Mas, A.; Wei, D. Photoelectrochemical Properties of Graphene and Its Derivatives. Nanomaterials 2013, 3, 325–356. [Google Scholar] [CrossRef]

- Tedesco, J.L.; VanMil, B.L.; Myers-Ward, R.L.; McCrate, J.M.; Kitt, S.A.; Campbell, P.M.; Jernigan, G.G.; Culbertson, J.C.; Eddy, C.R.; Gaskill, D.K. Hall effect mobility of epitaxial graphene grown on silicon carbide. Appl. Phys. Lett. 2009, 95, 122102. [Google Scholar] [CrossRef]

- Cummings, A.W.; Duong, D.L.; Nguyen, V.L.; Dinh Van, T.; Kotakoski, J.; Barrios, V.J.E.; Lee, Y.H.; Roche, S. Charge Transport in Polycrystalline Graphene: Challenges and Opportunities. Adv. Mater. 2014, 26, 5079–5094. [Google Scholar] [CrossRef] [PubMed]

- Kumari, A.; Prasad, N.; Bhatnagar, P.K.; Mathur, P.C.; Yadav, A.K.; Tomy, C.V.; Bhatia, C.S. Electrical transport properties of polycrystalline CVD graphene on SiO2/Si substrate. Diam. Relat. Mater. 2014, 45, 28–33. [Google Scholar] [CrossRef]

- Lin, Y.M.; Dimitrakopoulos, C.; Jenkins, K.A.; Farmer, D.B.; Chiu, H.Y.; Grill, A.; Avouris, P. 100-GHz Transistors from Wafer-Scale Epitaxial Graphene. Science 2010, 327, 662–662. [Google Scholar] [CrossRef] [PubMed]

- Tung, V.C.; Allen, M.J.; Yang, Y.; Kaner, R.B. High-throughput solution processing of large-scale graphene. Nat. Nanotechnol. 2009, 4, 25–29. [Google Scholar] [CrossRef] [PubMed]

- Yi, M.; Shen, Z. A review on mechanical exfoliation for the scalable production of graphene. J. Mater. Chem. A 2015, 3, 11700–11715. [Google Scholar] [CrossRef]

- Grodecki, K.; Bozek, R.; Strupinski, W.; Wysmolek, A.; Stepniewski, R.; Baranowski, J.M. Micro-Raman spectroscopy of graphene grown on stepped 4H–SiC (0001) surface. Appl. Phys. Lett. 2012, 100, 261604. [Google Scholar] [CrossRef]

- Ouerghi, A.; Silly, M.G.; Marangolo, M.; Mathieu, C.; Eddrief, M.; Picher, M.; Sirotti, F.; el Moussaoui, S.; Belkhou, R. Large-Area and High-Quality Epitaxial Graphene on Off-Axis SiC Wafers. ACS Nano 2012, 6, 6075–6082. [Google Scholar] [CrossRef] [PubMed]

- Camara, N.; Jouault, B.; Caboni, A.; Jabakhanji, B.; Desrat, W.; Pausas, E.; Consejo, C.; Mestres, N.; Godignon, P.; Camassel, J. Growth of monolayer graphene on 8 degrees off-axis 4H–SiC (000-1) substrates with application to quantum transport devices. Appl. Phys. Lett. 2010, 97, 093107. [Google Scholar] [CrossRef]

- Ouerghi, A.; Balan, A.; Castelli, C.; Picher, M.; Belkhou, R.; Eddrief, M.; Silly, M.G.; Marangolo, M.; Shukla, A.; Sirotti, F. Epitaxial graphene on single domain 3C–SiC(100) thin films grown on off-axis Si(100). Appl. Phys. Lett. 2012, 101, 021603. [Google Scholar] [CrossRef]

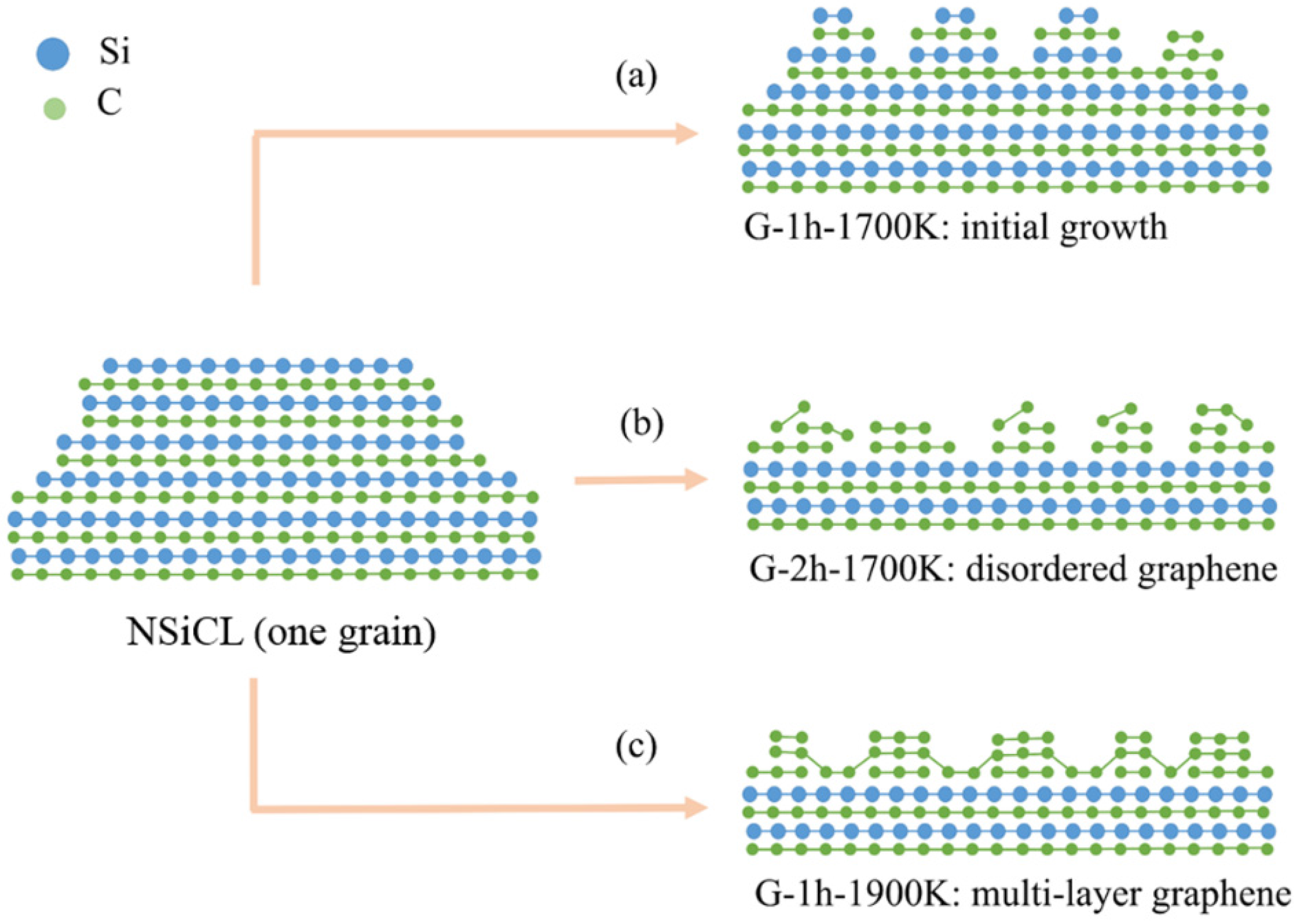

- Gupta, B.; Notarianni, M.; Mishra, N.; Shafiei, M.; Iacopi, F.; Motta, N. Evolution of epitaxial graphene layers on 3C SiC/Si (111) as a function of annealing temperature in UHV. Carbon 2014, 68, 563–572. [Google Scholar] [CrossRef] [Green Version]

- Safron, N.S.; Kim, M.; Gopalan, P.; Arnold, M.S. Barrier-Guided Growth of Micro- and Nano-Structured Graphene. Adv. Mater. 2012, 24, 1041–1045. [Google Scholar] [CrossRef] [PubMed]

- Dharmaraj, P.; Jeganathan, K.; Parthiban, S.; Kwon, J.Y.; Gautam, S.; Chae, K.H.; Asokan, K. Selective area growth of bernal bilayer epitaxial graphene on 4H–SiC (0001) substrate by electron-beam irradiation. Appl. Phys. Lett. 2014, 105, 181601. [Google Scholar] [CrossRef]

- Pallecchi, E.; Lafont, F.; Cavaliere, V.; Schopfer, F.; Mailly, D.; Poirier, W.; Ouerghi, A. High Electron Mobility in Epitaxial Graphene on 4H–SiC(0001) via post-growth annealing under hydrogen. Sci. Rep. 2014, 4, 4558. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Ruan, M.; Guo, Z.; Dong, R.; Palmer, J.; Hankinson, J.; Berger, C.; Heer, W.A.D. Structured Epitaxial Graphene: Growth and Properties. J. Phys. D Appl. Phys. 2012, 45, 154010. [Google Scholar] [CrossRef]

- Zhu, K.; Guo, L.; Lin, J.; Hao, W.; Shang, J.; Jia, Y.; Chen, L.; Jin, S.; Wang, W.; Chen, X. Graphene covered SiC powder as advanced photocatalytic material. Appl. Phys. Lett. 2012, 100, 023113. [Google Scholar] [CrossRef]

- Dong, L.; Sun, G.; Yu, J.; Zheng, L.; Liu, X.; Zhang, F.; Yan, G.; Li, X.; Wang, Z. Growth of 4H–SiC epilayers with low surface roughness and morphological defects density on 4 degrees off-axis substrates. Appl. Surf. Sci. 2013, 270, 301–306. [Google Scholar] [CrossRef]

- Itoh, A.; Akita, H.; Kimoto, T.; Matsunami, H. High-quality 4H–SiC homoepitaxial layers grown by step-controlled epitaxy. Appl. Phys. Lett. 1994, 65, 1400–1402. [Google Scholar] [CrossRef]

- Henry, A.; Hassan, J.; Bergman, J.P.; Hallin, C.; Janzen, E. Thick silicon carbide homoepitaxial layers grown by CVD techniques. Chem. Vap. Depos. 2006, 12, 475–482. [Google Scholar] [CrossRef]

- Liu, B.; Sun, G.-S.; Liu, X.-F.; Zhang, F.; Dong, L.; Zheng, L.; Yan, G.-G.; Liu, S.-B.; Zhao, W.-S.; Wang, L.; et al. Fast Homoepitaxial Growth of 4H–SiC Films on 4 Degrees Off-Axis Substrates in a SiH4–C2H4–H–2 System. Chin. Phys. Lett. 2013, 30, 128101. [Google Scholar] [CrossRef]

- Nakashima, S.; Harima, H. Raman investigation of SiC polytypes. Phys. Status Solidi A 1997, 162, 39–64. [Google Scholar] [CrossRef]

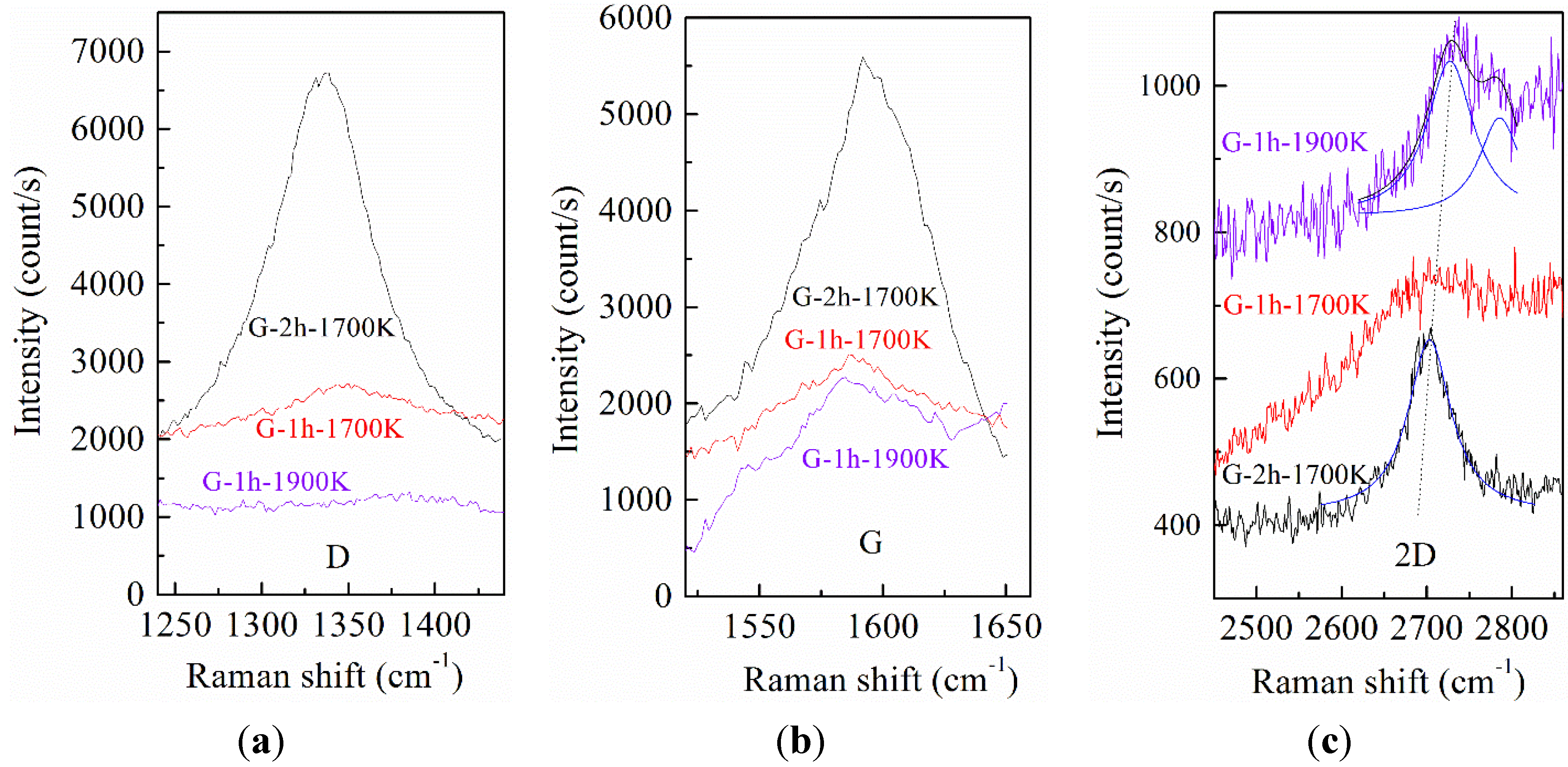

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [PubMed]

- Rohrl, J.; Hundhausen, M.; Emtsev, K.V.; Seyller, T.; Graupner, R.; Ley, L. Raman spectra of epitaxial graphene on SiC(0001). Appl. Phys. Lett. 2008, 92, 201918. [Google Scholar] [CrossRef]

- Hao, Y.; Wang, Y.; Wang, L.; Ni, Z.; Wang, Z.; Wang, R.; Koo, C.K.; Shen, Z.; Thong, J.T.L. Probing Layer Number and Stacking Order of Few-Layer Graphene by Raman Spectroscopy. Small 2010, 6, 195–200. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.S.; Riedl, C.; Krauss, B.; von Klitzing, K.; Starke, U.; Smet, J.H. Raman Spectra of Epitaxial Graphene on SiC and of Epitaxial Graphene Transferred to SiO2. Nano Lett. 2008, 8, 4320–4325. [Google Scholar] [CrossRef] [PubMed]

- Berciaud, S.; Ryu, S.; Brus, L.E.; Heinz, T.F. Probing the Intrinsic Properties of Exfoliated Graphene: Raman Spectroscopy of Free-Standing Monolayers. Nano Lett. 2009, 9, 346–352. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Lee, K.; Zhong, Z. Wafer Scale Homogeneous Bilayer Graphene Films by Chemical Vapor Deposition. Nano Lett. 2010, 10, 4702–4707. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.A.; Puls, C.P.; Staley, N.E.; Stitt, J.P.; Fanton, M.A.; Emtsev, K.V.; Seyller, T.; Liu, Y. Raman Topography and Strain Uniformity of Large-Area Epitaxial Graphene. Nano Lett. 2009, 9, 964–968. [Google Scholar] [CrossRef] [PubMed]

- Shlimak, I.; Haran, A.; Zion, E.; Havdala, T.; Kaganovskii, Y.; Butenko, A.V.; Wolfson, L.; Richter, V.; Naveh, D.; Sharoni, A.; et al. Raman scattering and electrical resistance of highly disordered graphene. Phys. Rev. B 2015, 91, 045414. [Google Scholar] [CrossRef]

- Riedl, C.; Coletti, C.; Iwasaki, T.; Zakharov, A.A.; Starke, U. Quasi-Free-Standing Epitaxial Graphene on SiC Obtained by Hydrogen Intercalation. Phys. Rev. Lett. 2009, 103, 246804. [Google Scholar] [CrossRef] [PubMed]

- Nicotra, G.; Deretzis, I.; Scuderi, M.; Spinella, C.; Longo, P.; Yakimova, R.; Giannazzo, F.; la Magna, A. Interface disorder probed at the atomic scale for graphene grown on the C face of SiC. Phys. Rev. B 2015, 91, 155411. [Google Scholar] [CrossRef]

- Ostler, M.; Deretzis, I.; Mammadov, S.; Giannazzo, F.; Nicotra, G.; Spinella, C.; Seyller, T.; la Magna, A. Direct growth of quasi-free-standing epitaxial graphene on nonpolar SiC surfaces. Phys. Rev. B 2013, 88, 085408. [Google Scholar] [CrossRef]

- Nicotra, G.; Ramasse, Q.M.; Deretzis, I.; la Magna, A.; Spinella, C.; Giannazzo, F. Delaminated Graphene at Silicon Carbide Facets: Atomic Scale Imaging and Spectroscopy. ACS Nano 2013, 7, 3045–3052. [Google Scholar] [CrossRef] [PubMed]

- Cai, S.; Liu, Z.; Zhong, N.; Liu, S.; Liu, X. Effect of Growth Pressure on Epitaxial Graphene Grown on 4H–SiC Substrates by Using Ethene Chemical Vapor Deposition. Materials 2015, 8, 5586–5596. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Chen, Y.; Sun, C.; Guan, M.; Zhang, Y.; Zhang, F.; Sun, G.; Zeng, Y. Surface Evolution of Nano-Textured 4H–SiC Homoepitaxial Layers after High Temperature Treatments: Morphology Characterization and Graphene Growth. Nanomaterials 2015, 5, 1532-1543. https://doi.org/10.3390/nano5031532

Liu X, Chen Y, Sun C, Guan M, Zhang Y, Zhang F, Sun G, Zeng Y. Surface Evolution of Nano-Textured 4H–SiC Homoepitaxial Layers after High Temperature Treatments: Morphology Characterization and Graphene Growth. Nanomaterials. 2015; 5(3):1532-1543. https://doi.org/10.3390/nano5031532

Chicago/Turabian StyleLiu, Xingfang, Yu Chen, Changzheng Sun, Min Guan, Yang Zhang, Feng Zhang, Guosheng Sun, and Yiping Zeng. 2015. "Surface Evolution of Nano-Textured 4H–SiC Homoepitaxial Layers after High Temperature Treatments: Morphology Characterization and Graphene Growth" Nanomaterials 5, no. 3: 1532-1543. https://doi.org/10.3390/nano5031532