Hydrothermal Fabrication of WO3 Hierarchical Architectures: Structure, Growth and Response

Abstract

:1. Instructions

2. Experimental

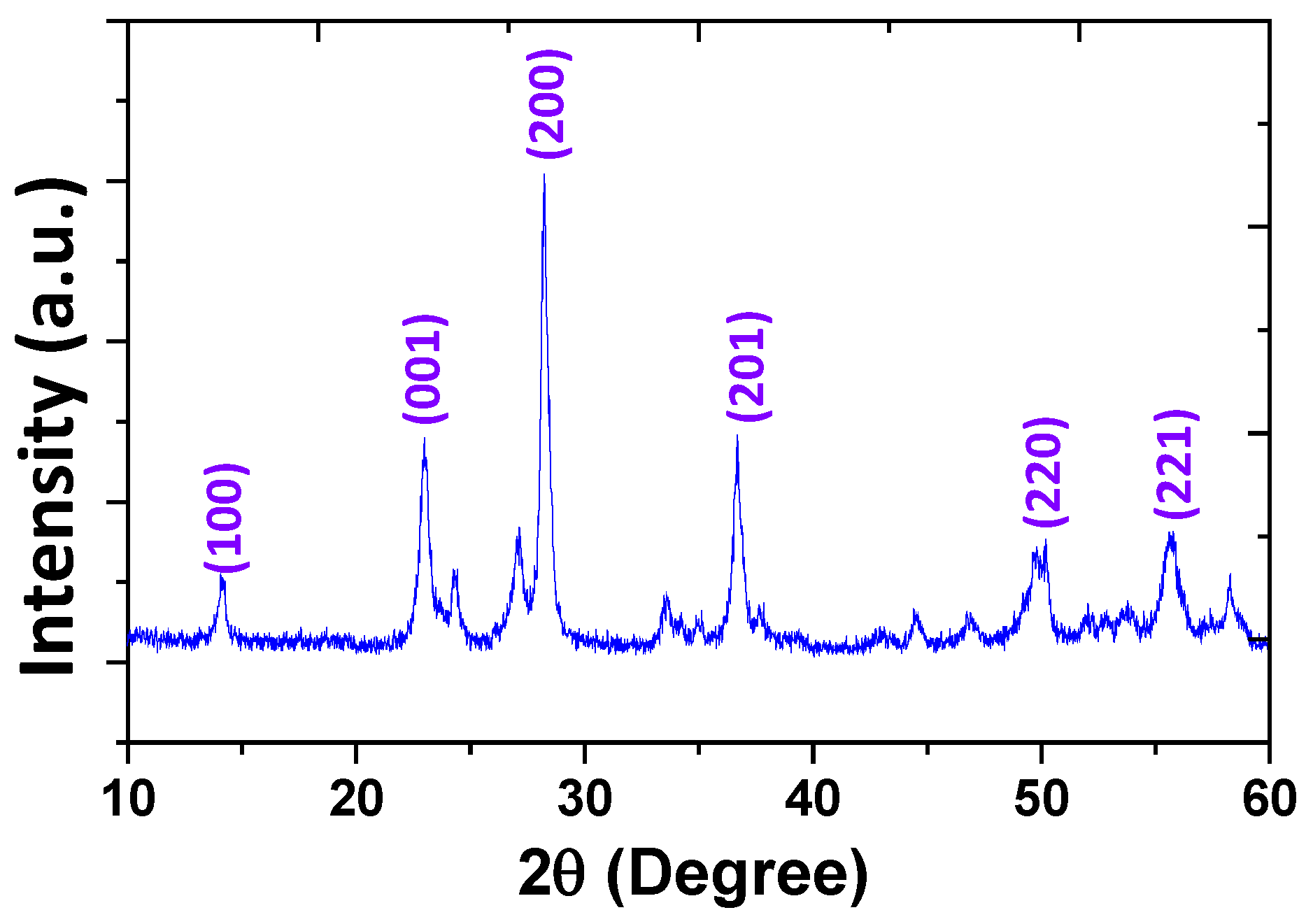

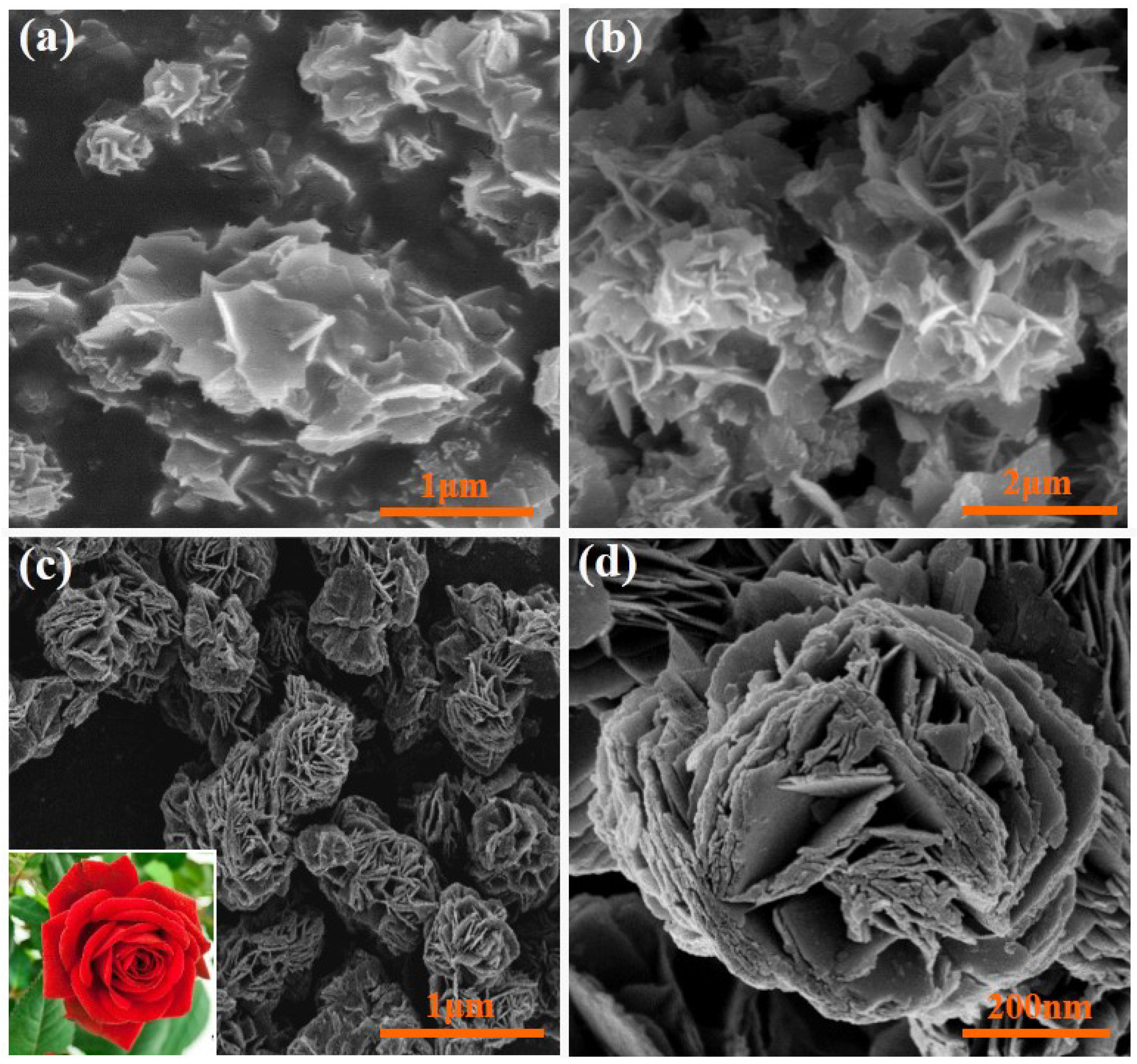

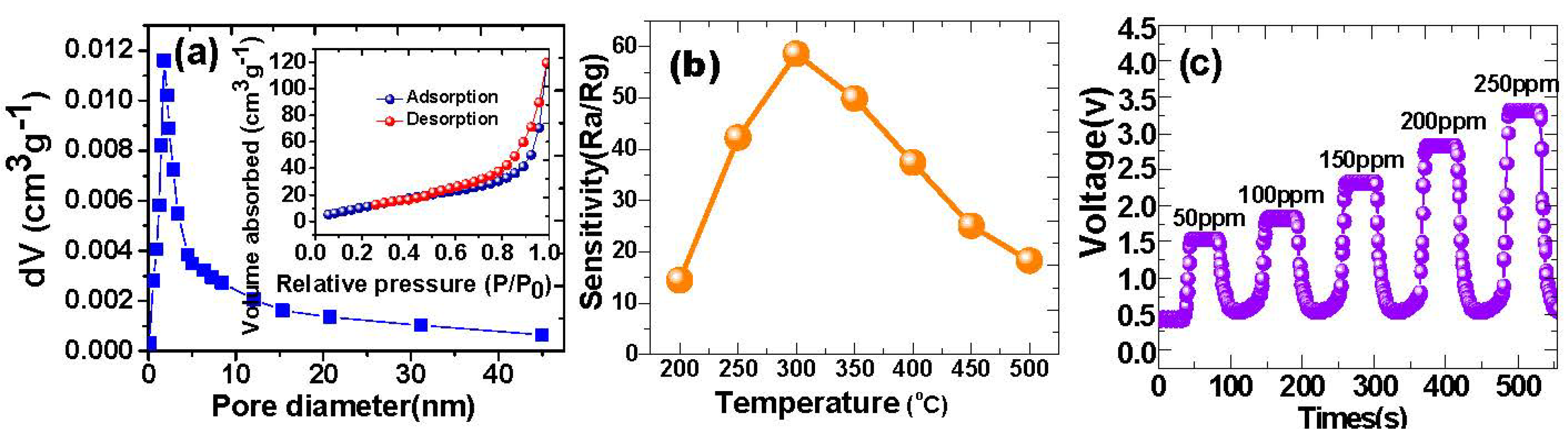

3. Results and Discussion

4. Conclusions

Acknowledgements

Conflicts of Interest

References

- Song, L.M.; Zhang, S.J.; Wu, X.; Wang, Z.; Wei, Q.W. One-step synthesis, growth mechanism, and optical properties of 3D YIO3 hollow microspheres consisting of nanotube arrays. Powder Technol. 2013, 235, 712–716. [Google Scholar] [CrossRef]

- Chen, J.K.; Gui, X.C.; Wang, Z.W.; Li, Z.; Xiang, R.; Wang, K.L.; Wu, D.H.; Xia, X.G.; Zhou, Y.F.; Wang, Q.; et al. Superlow thermal conductivity 3D carbon nanotube network for thermoelectric applications. ACS Appl. Mater. Interface 2011, 4, 81–86. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.S.; Zhen, L.; Xu, C.Y.; Yang, L.; Shao, W.Z. Room temperature synthesis of hierarchical SrCO3 architectures by a surfactant-free aqueous solution route. Cryst. Growth Des. 2008, 8, 1734–1740. [Google Scholar] [CrossRef]

- Chang, C.M.; Hon, M.H.; Leu, I.C. Improvement in CO sensing characteristics by decorating ZnO nanorod arrays with Pd nanoparticles and the related mechanisms. RSC Adv. 2012, 2, 2469–2475. [Google Scholar] [CrossRef]

- Chen, D.; Xu, J.; Xie, Z.; Shen, G.Z. Nanowires assembled SnO2 nanopolyhedrons with enhanced gas sensing properties. ACS Appl. Mater. Interface 2011, 3, 2112–2117. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Fan, H.Q.; Jia, X.H. Multilayered ZnO nanosheets with 3D porous architectures: Synthesis and gas sensing application. J. Phys. Chem. C 2010, 114, 14684–14691. [Google Scholar] [CrossRef]

- Hu, H.; Yu, L.; Gao, X.H.; Lin, Z.; Lou, X.W. Hierarchical tubular structures constructed from ultrathin TiO2 nanosheets for highly reversible lithium storage. Energy Environ. Sci. 2015, 8, 1480–1483. [Google Scholar] [CrossRef]

- Yu, X.Y.; Hu, H.; Wang, Y.W.; Chen, H.Y.; Lou, X.W. Ultrathin MoS2 nanosheets supported on N-doped carbon nanoboxes with enhanced lithium storage and electrocatalytic properties. Angew. Chem. Int. Edition 2015, 54, 7395–7398. [Google Scholar] [CrossRef] [PubMed]

- Hieu, N.V.; Quang, V.V.; Hoa, N.D.; Kim, D. Preparing large-scale WO3 nanowire-like structure for high sensitivity NH3 gas sensor through a simple route. Curr. Appl. Phys. 2011, 11, 657–661. [Google Scholar] [CrossRef]

- Li, Y.; Hsu, P.C.; Chen, S.M. Multi-functionalized biosensor at WO3–TiO2 modified electrode for photoelectrocatalysis of norepinephrine and riboflavin. Sens. Actuators B Chem. 2012, 174, 427–435. [Google Scholar] [CrossRef]

- Krüger, P.; Koutiri, I.; Bourgeois, S. First-principles study of hexagonal tungsten trioxide: Nature of lattice distortions and effect of potassium doping. Phys. Rev. B 2012, 86, 224102. [Google Scholar] [CrossRef]

- Sonia, A.; Djaoued, Y.; Subramanian, B.; Jacques, R.; Eric, M.; Ralf, B.; Achour, B. Synthesis and characterization of novel nanorod superstructures and twin octahedral morphologies of WO3 by hydrothermal treatment. Mater. Chem. Phys. 2012, 136, 80–89. [Google Scholar] [CrossRef]

- Park, S.; Kim, H.; Jin, C.; Choi, S.; Kim, S.S.; Lee, C. Enhanced CO gas sensing properties of Pt-functionalized WO3 nanorods. Thermochim. Acta 2012, 542, 69–73. [Google Scholar] [CrossRef]

- Xiang, Q.; Meng, G.F.; Zhao, H.B.; Zhang, Y.; Li, H.; Ma, W.J.; Xu, J.Q. Au nanoparticle modified WO3 nanorods with their enhanced properties for photocatalysis and gas sensing. J. Phys. Chem. C 2010, 114, 2049–2055. [Google Scholar] [CrossRef]

- Sun, S.B.; Chang, X.T.; Li, Z.J. Growth study and photocatalytic properties of Co-doped tungsten oxide mesocrystals. Mater. Charact. 2012, 73, 130–136. [Google Scholar] [CrossRef]

- Lou, X.W.; Zeng, H.C. An inorganic route for controlled synthesis of W18O49 nanorods and nanofibers in solution. Inorg. Chem. 2003, 42, 6169–6171. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Xu, X.J.; Gu, C.P.; Fu, G.; Wang, W.; Liu, J. Flower-like and hollow sphere-like WO3 porous nanostructures: Selective synthesis and their photocatalysis property. Mater. Res. Bull. 2012, 47, 3224–3232. [Google Scholar] [CrossRef]

- Yu, J.; Qi, L.F. Template-free fabrication of hierarchically flower-like tungsten trioxide assemblies with enhanced visible-light-driven photocatalytic activity. J. Hazard. Mater. 2009, 169, 221–227. [Google Scholar] [CrossRef] [PubMed]

- Susanti, D.; Kusuma, G.E.; Muttaqin, A. Synthesis and application of WO3 as material for poisonous CO gas sensor. Prosiding InSINas 2012, 115, 55–60. [Google Scholar]

- Susanti, D.; Perdana, A.S.; Purwaningsih, H.; Noerochim, L.; Kusuma, G.E. Preparation of CO gas sensor from WO3 nanomaterial synthesized via sol-gel method followed by hydrothermal process. AIP Conf. Proc. 2014, 1586, 14–19. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.-S. Hydrothermal Fabrication of WO3 Hierarchical Architectures: Structure, Growth and Response. Nanomaterials 2015, 5, 1250-1255. https://doi.org/10.3390/nano5031250

Wu C-S. Hydrothermal Fabrication of WO3 Hierarchical Architectures: Structure, Growth and Response. Nanomaterials. 2015; 5(3):1250-1255. https://doi.org/10.3390/nano5031250

Chicago/Turabian StyleWu, Chuan-Sheng. 2015. "Hydrothermal Fabrication of WO3 Hierarchical Architectures: Structure, Growth and Response" Nanomaterials 5, no. 3: 1250-1255. https://doi.org/10.3390/nano5031250