An Approach to the Classification of Cutting Vibration on Machine Tools

Abstract

:1. Introduction

2. Literature Review

2.1. Skills of Monitoring Machining Processes

2.2. Vibrations of Machine Tools

- (1)

- Out-of-balance rotating or reciprocating machine components. This is due to the fact that the mechanisms transfer energy in uniformly timed impulses to faulty gears, belts, balls, and roller bearings.

- (2)

- Vibrations transmitted from other machines through foundations.

- (3)

- Vibrations caused by chip formation. When a discontinuous type of chip is formed, the recurring fractures of the metal in the shear plane ahead of the tool produce periodic variations. Similarly, in the case of machining operations that produce a continuous chip with a built-up edge, there is a variation in the force on the cutting tool. Yet another source of forced variation may be caused by the formation of chips of varying thickness obtained. The frequency of these periodic variations depends upon the frequency of discontinuity in the chip of the built-up edge, or the number of teeth in the milling cutting.

2.3. Past Research Related to the Vibrations of Machine Tools

3. Previous Classification Approaches

3.1. Decision Tree

3.2. Support Vector Machine (SVM)

3.3. Naive Bayes Classifier

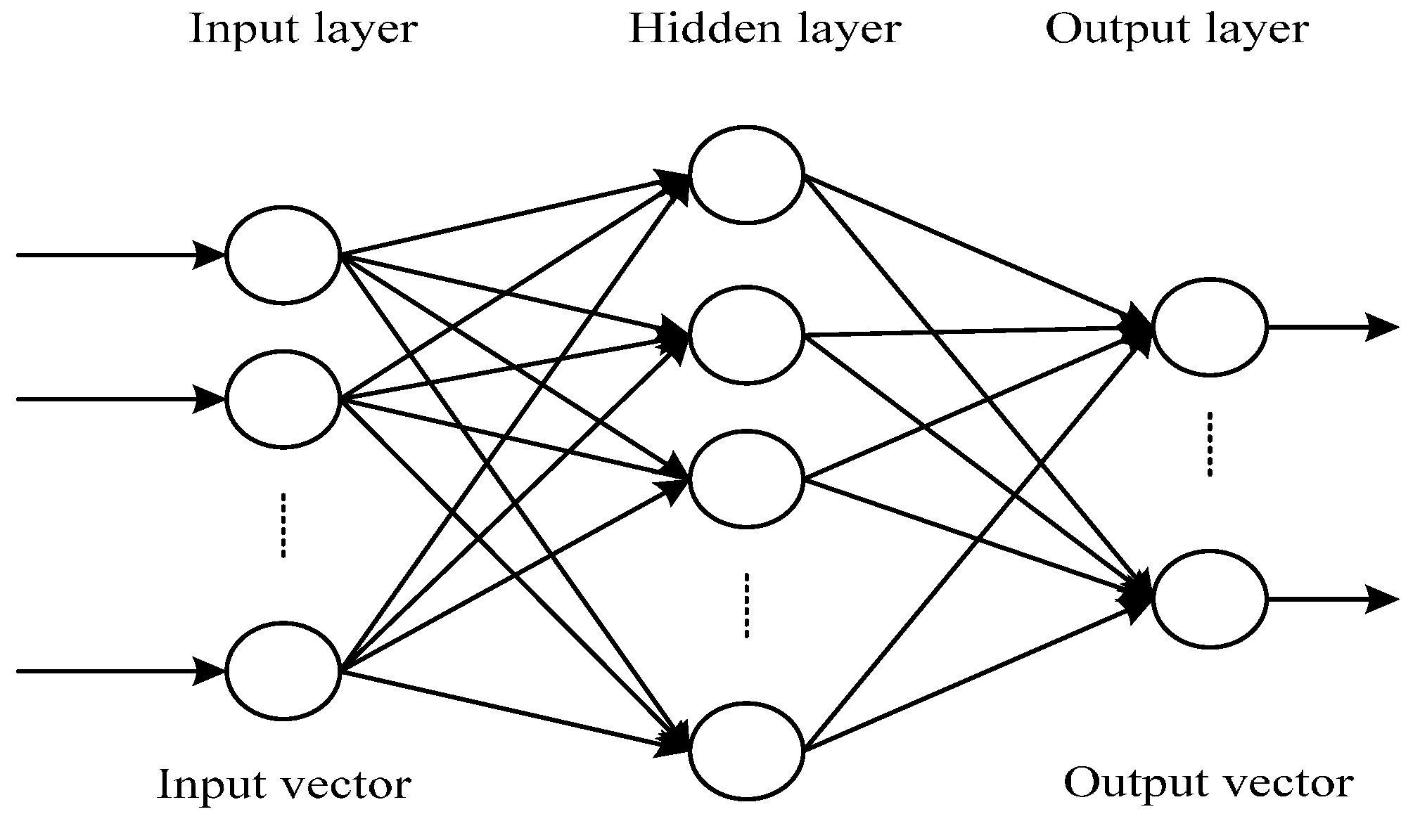

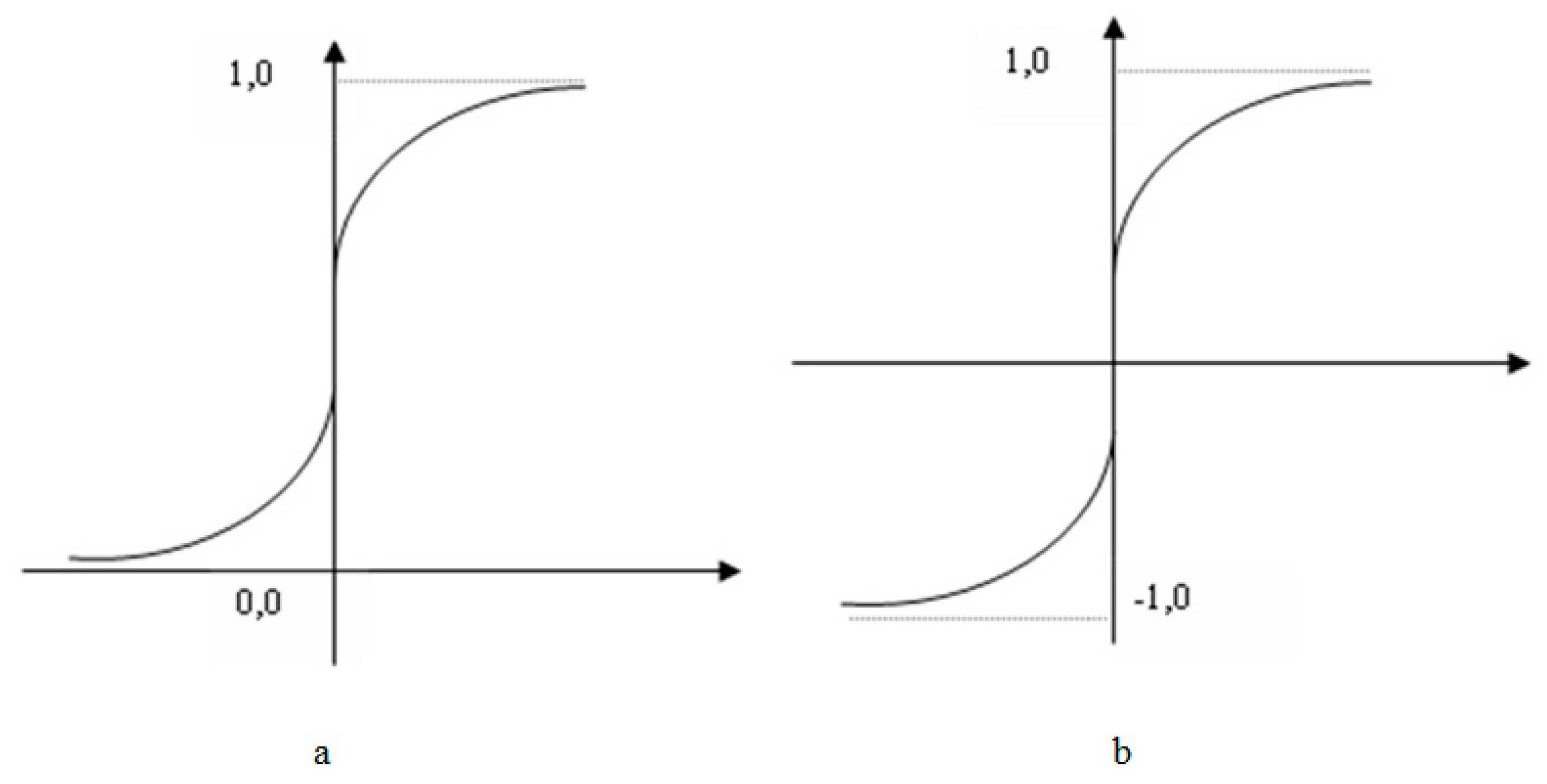

4. Artificial Neural Network (ANN) Architecture

4.1. The Feed-Forward Neural Network

4.2. Back-PropagationAlgorithm

- Step 1:

- Design the structure of FNN and set input parameters of the network.

- Step 2:

- Set learning rate and momentum rate .

- Step 3:

- Initialize the connection weights Wji, Wki and bias weights , to random values.

- Step 4:

- Set stopping criteria.

- Step 5:

- Start training by applying input patterns one at a time and propagate through the layers to calculate total error.

- Step 6:

- Back-propagate error through output and hidden layers and update biases and weights.

- Step 7:

- Back-propagate error through hidden and input layers and update biases and weights.

- Step 8:

- Repeat step 5 to step 8 until stopping criteria are reached.

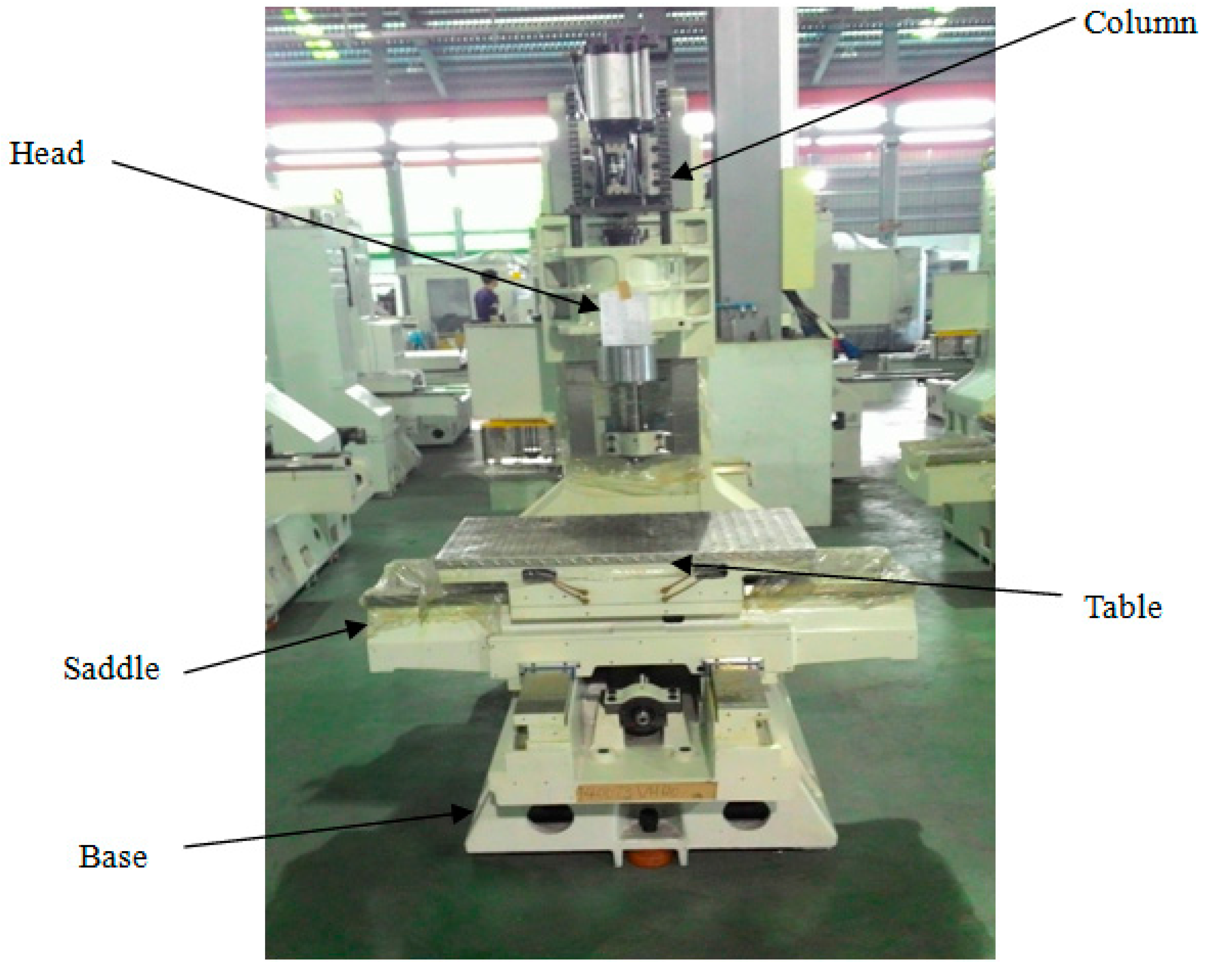

5. An Application of the Presented ANN Classifier

5.1. CNC MillingMachine

5.2. The Dynamic Behavior of Machine Tools

5.3. Identifying Input and Output Variables

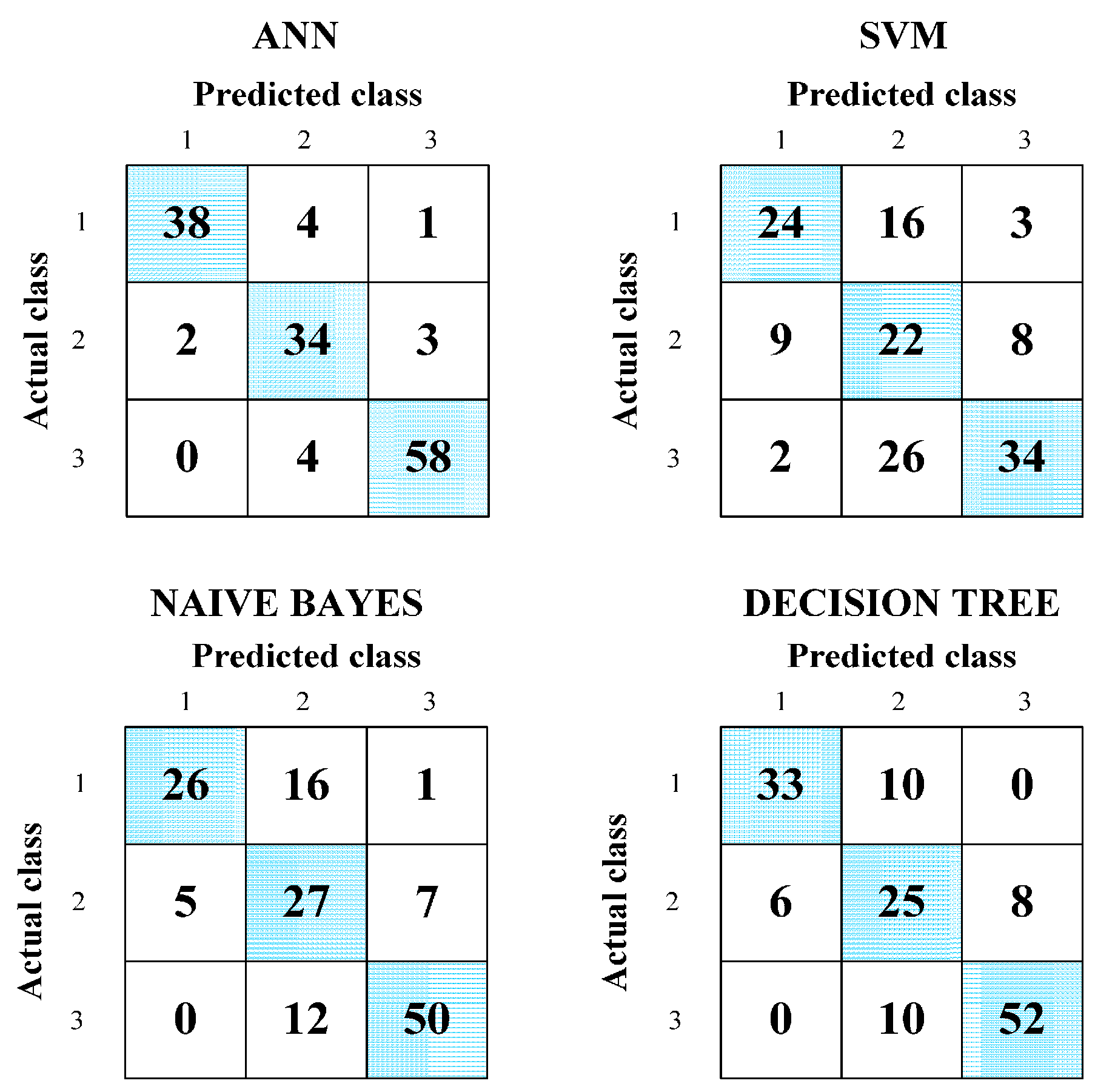

6. Results

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhu, J.; Ni, J.; Shih, A.J. Robust machine tool thermal error modeling through thermal Mode concept. J. Manuf. Sci. Eng. 2008, 130. [Google Scholar] [CrossRef]

- Whalley, R.; Abdul-Ameer, A.; Ebrahimi, M.; El-Shalabi, S. Adaptive machine tool system regulation. Control Theory Appl. IET 2009, 3, 33–48. [Google Scholar] [CrossRef]

- Altintas, Y. Research on metal cutting, machine tool vibrations and control. J. Jpn. Soc. Precis. Eng. 2011, 77, 470–471. [Google Scholar]

- Kruth, J.-P.; Van Ginderachter, T.; Tanaya, P.I.; Valckenaers, P. The use of finite state machines for task-based machine tool control. Comput. Ind. 2001, 46, 247–258. [Google Scholar] [CrossRef]

- Cho, D.W.; Leeb, S.J.; Chu, C.N. The state of machining process monitoring research in Korea. Int. J. Mach. Tools Manuf. 1999, 39, 1697–1715. [Google Scholar] [CrossRef]

- Meredith, D. Practical tool condition monitoring. Manuf. Eng. 1998, 120, 34–39. [Google Scholar]

- Westkämper, E.; Westerbusch, R. The Diagnosis and monitoring system DIAMANT. Product. Eng. 1993, 1, 131–134. [Google Scholar]

- Nakai, M.E.; Aguiar, P.R.; Junior, H.G.; Bianchi, E.C.; Spatti, D.H.; D’Addona, D.M. Evaluation of Neural Models Applied to the Estimation of Tool Wear in the Grinding of Advanced Ceramics. Expert Syst. Appl. 2015, 42, 7026–7035. [Google Scholar] [CrossRef]

- D’Addona, D.; Segreto, T.; Simeone, A.; Teti, R. ANN Tool Wear Modelling in the Machining of Nickel Superalloy Industrial Products. CIRP J. Manuf. Sci. Technol. 2011, 4, 33–37. [Google Scholar] [CrossRef]

- Leone, C.; D’Addona, D.; Teti, R. Tool Wear Modelling through Regression Analysis and Intelligent Methods for Nickel Base Alloy Machining. CIRP J. Manuf. Sci. Technol. 2011, 11, 327–331. [Google Scholar] [CrossRef]

- Ko, T.J.; Jung, M.Y. On-line monitoring of tool breakage in face milling using a self-organized neural network. J. Manuf. Syst. 1995, 14, 80–90. [Google Scholar] [CrossRef]

- Ko, T.J.; Dong, W.C. Cutting state monitoring in milling by a neural network. Int. J. Mach. Tools Manuf. 1994, 34, 695–676. [Google Scholar] [CrossRef]

- Ko, T.J.; Dong, W.C. Adaptive Optimization of Face Milling Operations Using Neural Networks. J. Manuf. Sci. Eng. 1998, 120, 443–451. [Google Scholar] [CrossRef]

- Ko, T.J.; Dong, W.C. Adaptive modelling of the milling process and application of a neural network for tool wear monitoring. Int. J. Adv. Manuf. Technol. 1996, 12, 5–13. [Google Scholar] [CrossRef]

- Siddhpura, M.; Paurobally, R. Experimental investigation of chatter vibration in facing and turning process. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2013, 7, 84–89. [Google Scholar]

- Choudhury, S.K.; Goudimenko, N.N.; Kudinov, V.A. On-Line control of machine tool vibration in turning. Int. J.Mach. Tools Manuf. 1997, 37, 801–811. [Google Scholar] [CrossRef]

- Ema, S.; Marui, E. Theoretical analysis on chatter vibration in drilling and its suppression. J. Mater. Process. Technol. 2003, 138, 572–578. [Google Scholar] [CrossRef]

- Quintana, G.; Garcia-Romeu, M.L.; Ciurana, J. Surface roughness monitoring application based on artificial neural networks for ball-end milling operations. J. Intell. Manuf. 2011, 22, 607–617. [Google Scholar] [CrossRef]

- Debeljak, M.; Dzeroski, S. Decision Trees in Ecological Modelling in Modelling Complex Ecological Dynamics; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Sharma, A.; Kumar, R.; Varadwaj, P.K.; Ahmad, A.; Ashraf, G.M. A comparative study of support vector machine, artificial neural network and Bayesian classifier for mutagenicity prediction. Interdiscip. Sci. Comput. Life Sci. 2011, 3, 232–239. [Google Scholar] [CrossRef] [PubMed]

- Bahler, D.; Stone, B.; Wellington, C.; Bristol, D.W. Symbolic, neural, and Bayesian machine learning models for predicting carcinogenicity of chemical compounds. J. Chem. Inf. Model. 2000, 40, 906–914. [Google Scholar] [CrossRef]

- Hornik, K.; Stinchombe, M.; White, H. Universal Approximation of an unknown Mapping and its Derivatives Using Multilayer Feed-forward Networks. Neural Netw. 1990, 3, 551–560. [Google Scholar] [CrossRef]

- Cybenko, G. Approximation by superposition of a sigmoid function. Math. Control Signals Syst. 1989, 2, 303–314. [Google Scholar] [CrossRef]

- Abdi, H.; Valentin, D.; Edelman, B.; O’Toole, A.J. A Widrow-Hoff Learning Rule for a Generalization of the Linear Auto-associator. J. Math. Psychol. 1996, 40, 175–182. [Google Scholar] [CrossRef]

- Siddhpura, M.; Paurobally, R. A review of chatter vibration research in turning. Int. J. Mach. Tools Manuf. 2012, 61, 27–47. [Google Scholar] [CrossRef]

- More, J.J. The Levenberg-Marquardt algorithm: Implementation and theory. Lect. Notes Math. 2006, 630, 105–116. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.-F.; Lo, S.-K.; Do, Q.H. An Approach to the Classification of Cutting Vibration on Machine Tools. Information 2016, 7, 7. https://doi.org/10.3390/info7010007

Chen J-F, Lo S-K, Do QH. An Approach to the Classification of Cutting Vibration on Machine Tools. Information. 2016; 7(1):7. https://doi.org/10.3390/info7010007

Chicago/Turabian StyleChen, Jeng-Fung, Shih-Kuei Lo, and Quang Hung Do. 2016. "An Approach to the Classification of Cutting Vibration on Machine Tools" Information 7, no. 1: 7. https://doi.org/10.3390/info7010007