Integrated System Design for a Large Wind Turbine Supported on a Moored Semi-Submersible Platform

Abstract

:1. Introduction

- Shallow-draft platforms, such as barges with catenary mooring lines, that achieve stability via the extent of their water-plane area.

- Deep-draft platforms, such as spars with moored catenary or taut lines, that achieve stability and pitch-restoring moment via ballast.

- Buoyancy-driven platforms, such as tension-leg platforms (TLPs), that achieve stability via a series of mooring lines in tension.

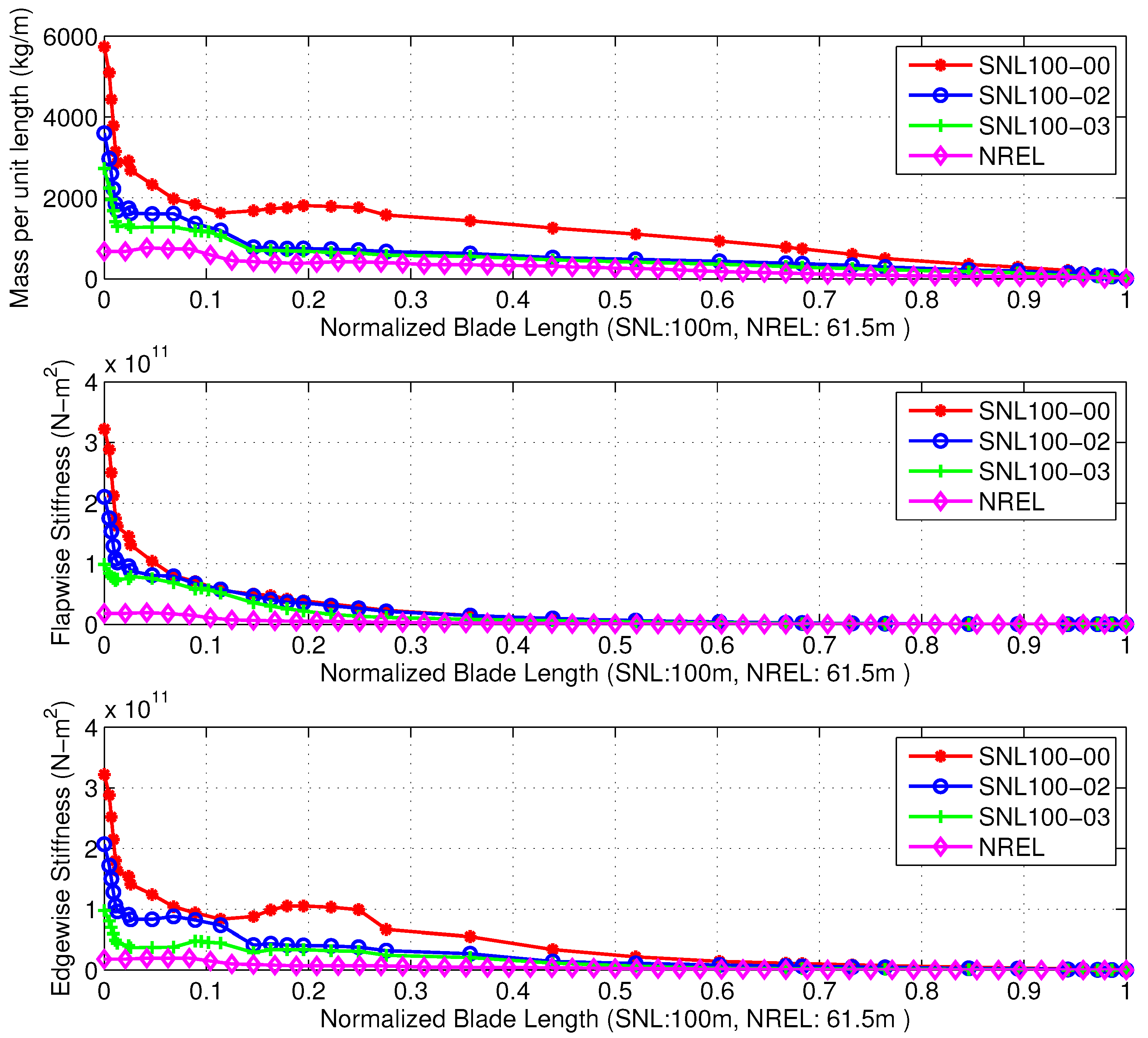

2. SNL 13.2-MW Wind Turbine and OC4 DeepCwind Platform Baseline Models

2.1. SNL 13.2-MW Baseline Turbine Properties

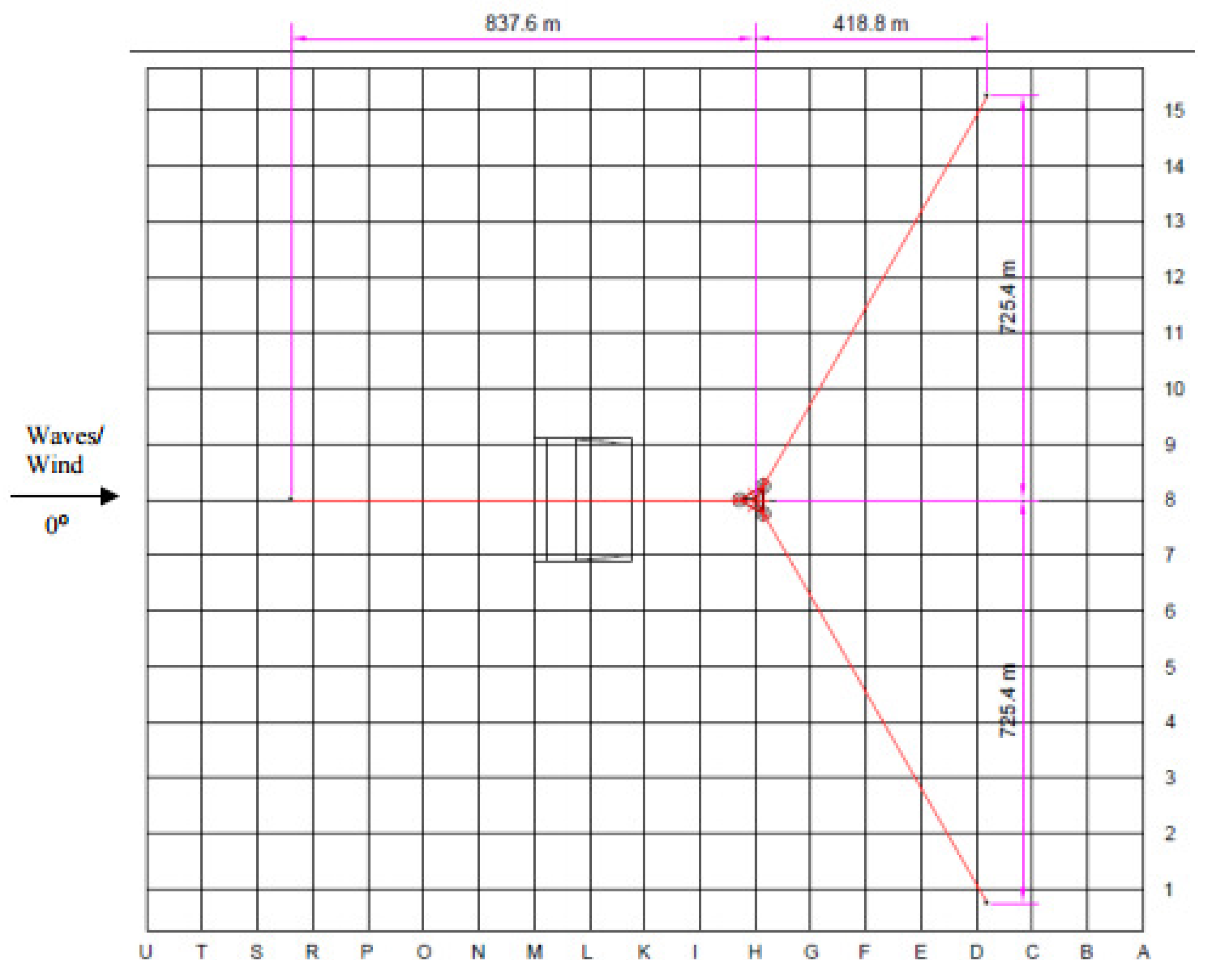

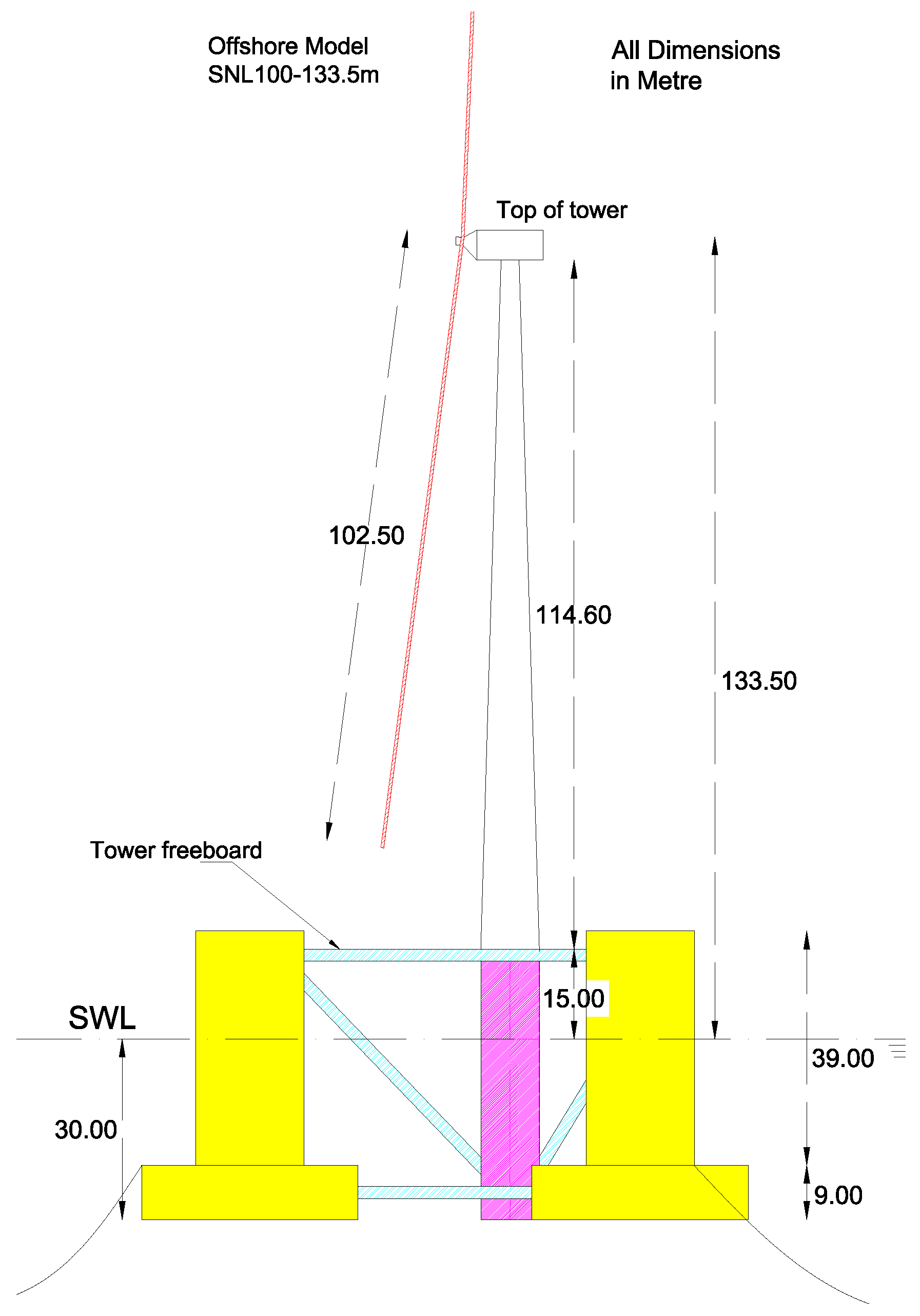

2.2. Baseline Semi-Submersible Platform and Mooring System

3. Preliminary Model Development of SNL 13.2-MW Semi-Submersible FOWT

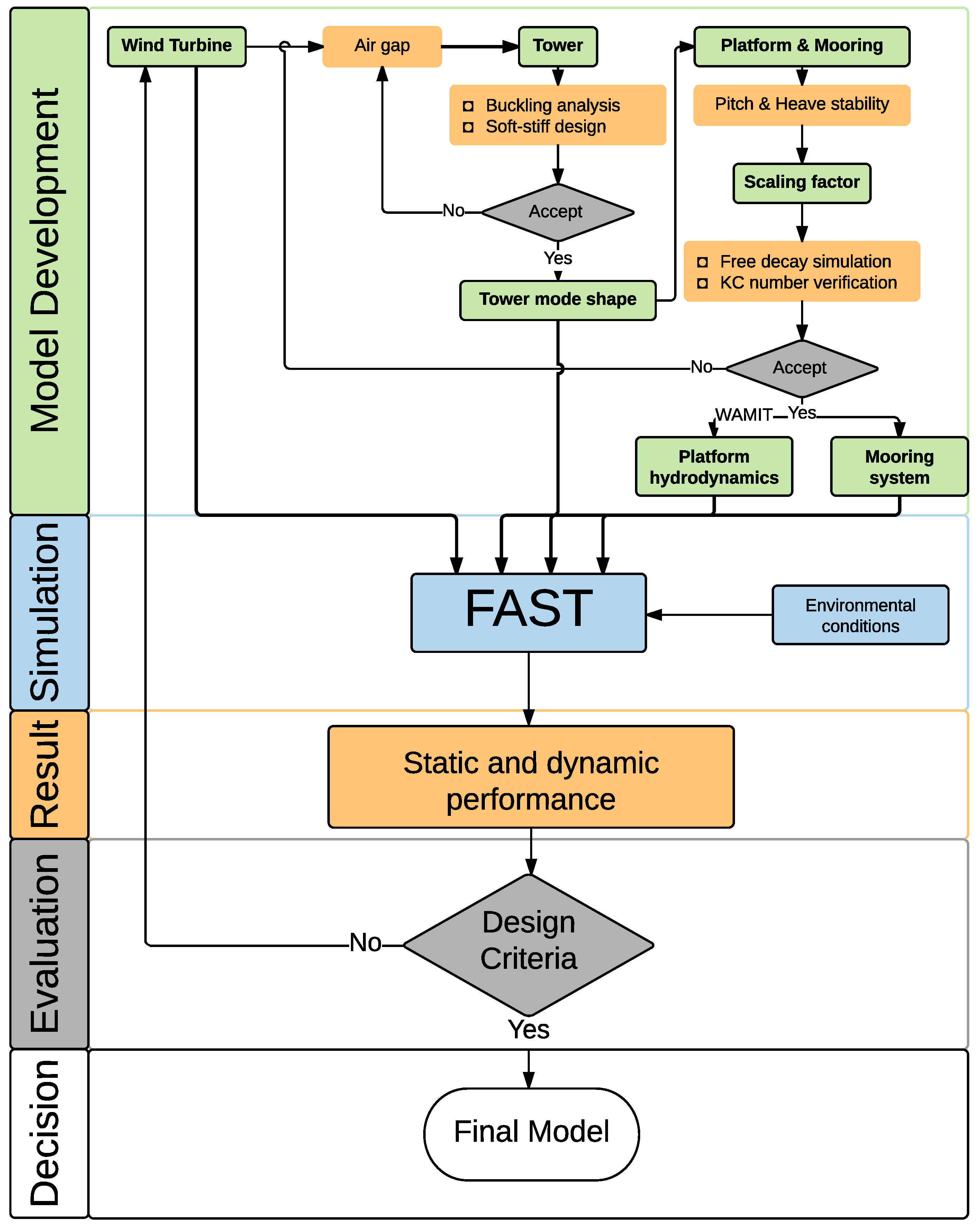

3.1. Design Methodology

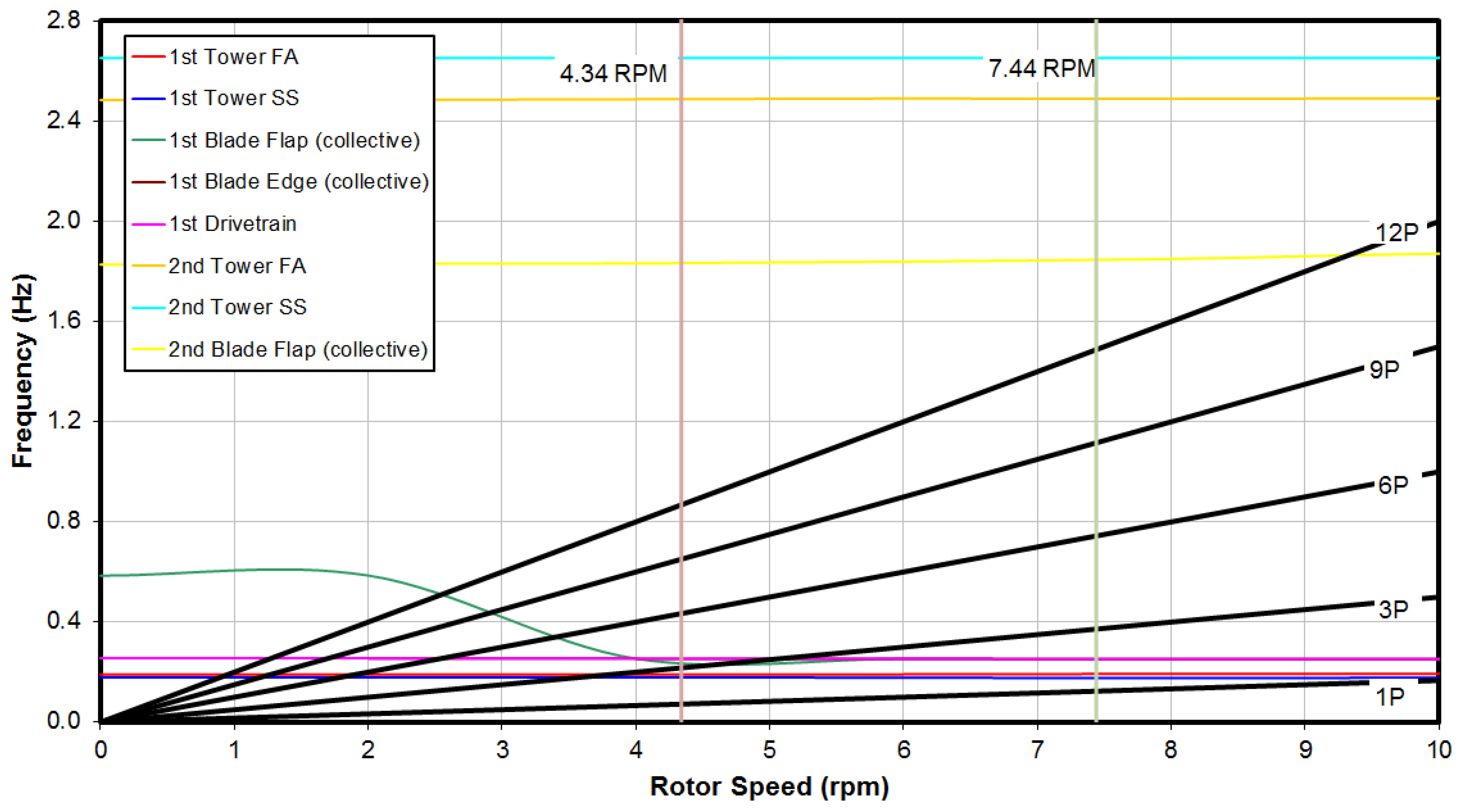

3.2. Tower Model Development

3.3. Platform and Mooring System Development

- NREL 5MW: NREL 5-MW land-based reference wind turbine model, hub height 90.0 m.

- SNL14602: SNL 13.2-MW land-based wind turbine model with SNL100-02 blades, hub height 146.0 m.

- SNL13302: SNL 13.2-MW land-based wind turbine model with SNL100-02 blades, hub height 133.5 m.

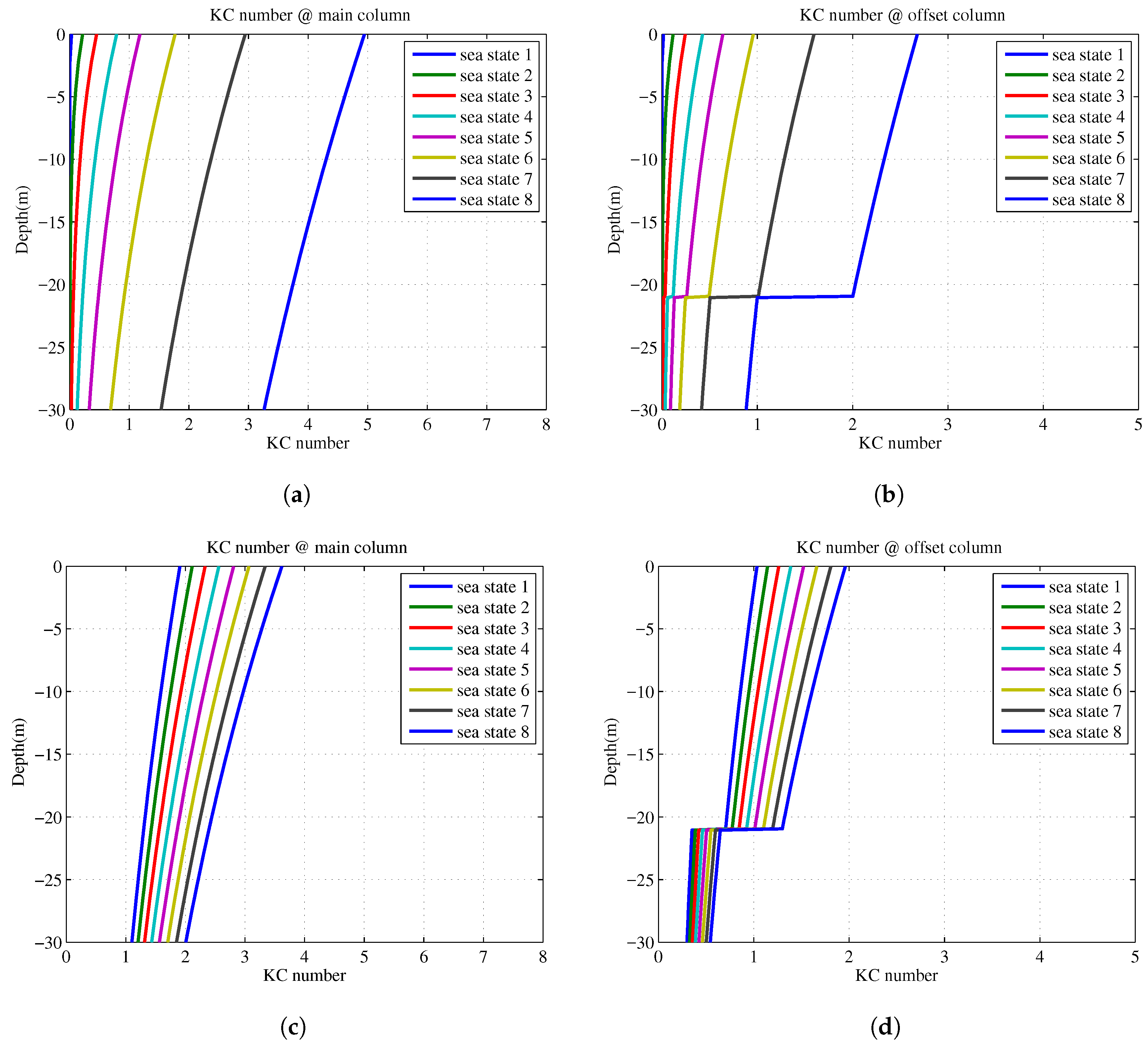

3.3.1. Keulegan–Carpenter Number: Flow-Structure Interaction

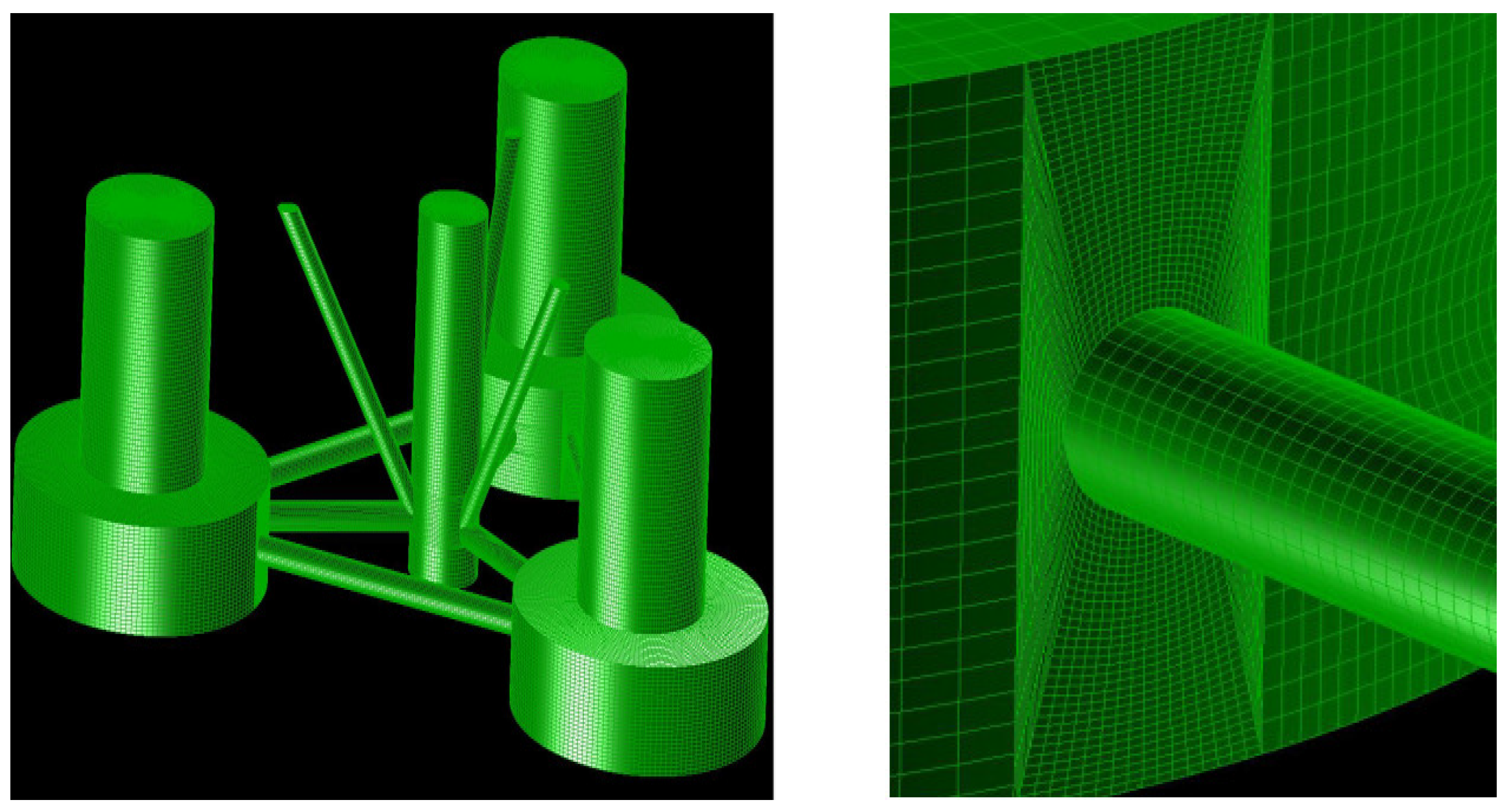

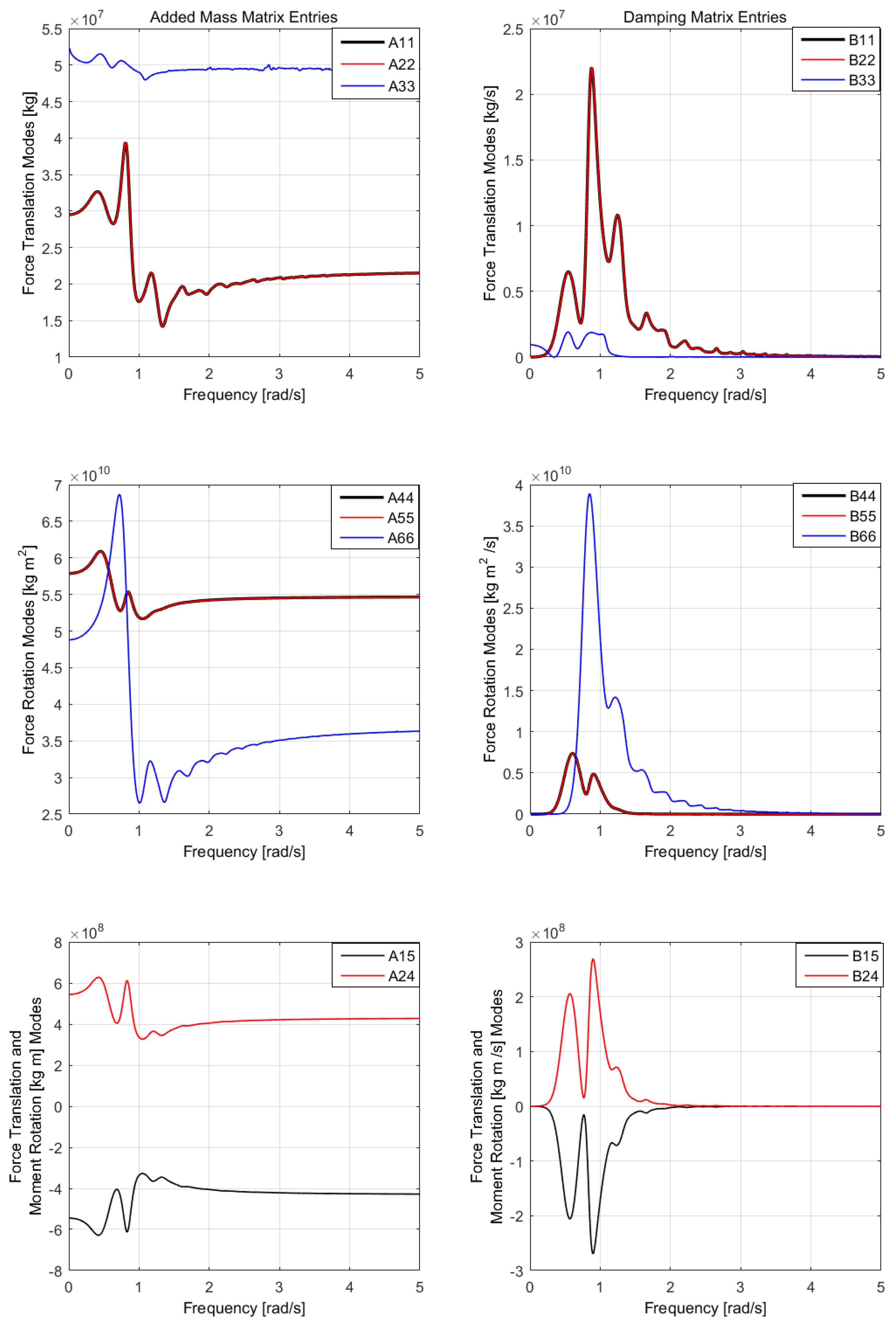

3.3.2. Platform Hydrodynamic Properties

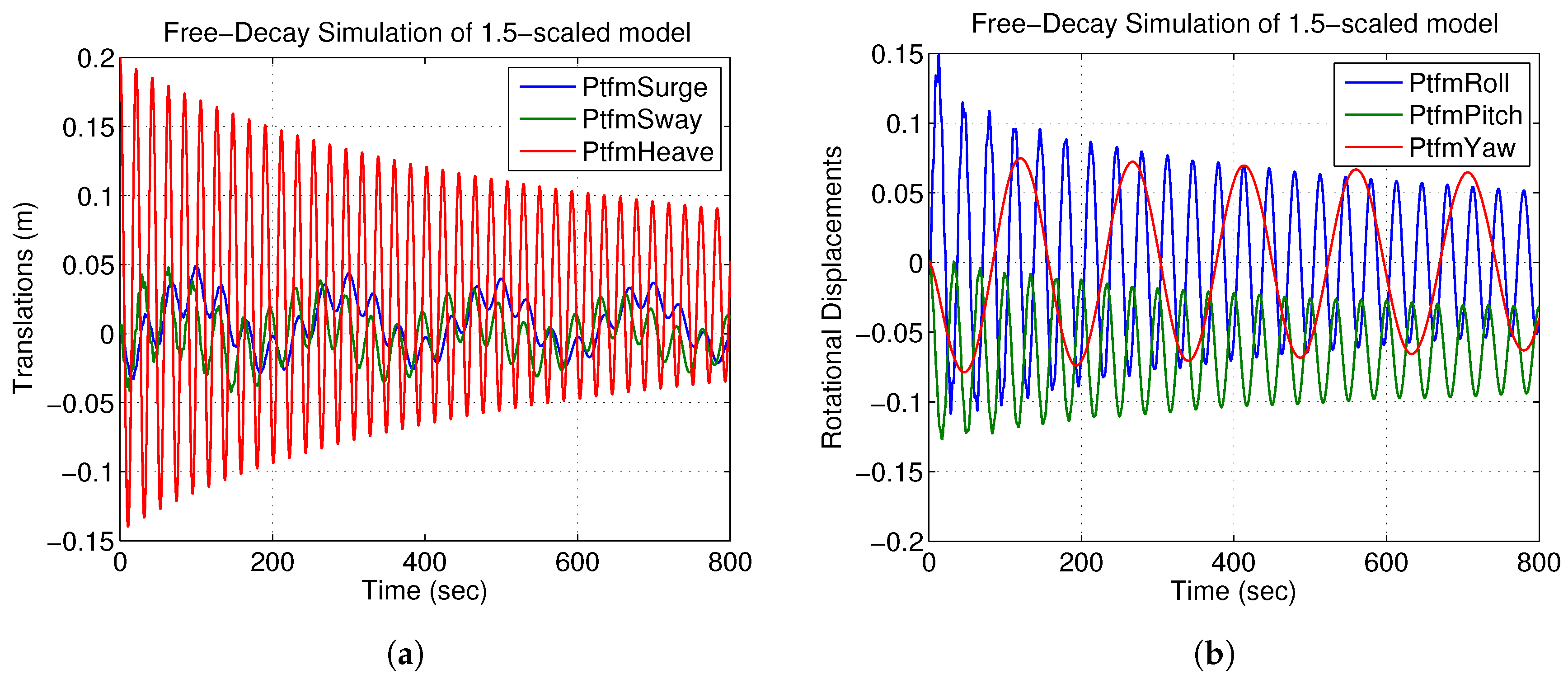

3.3.3. Free-Decay Simulation

4. Response Analysis of Integrated SNL 13.2-MW FOWT

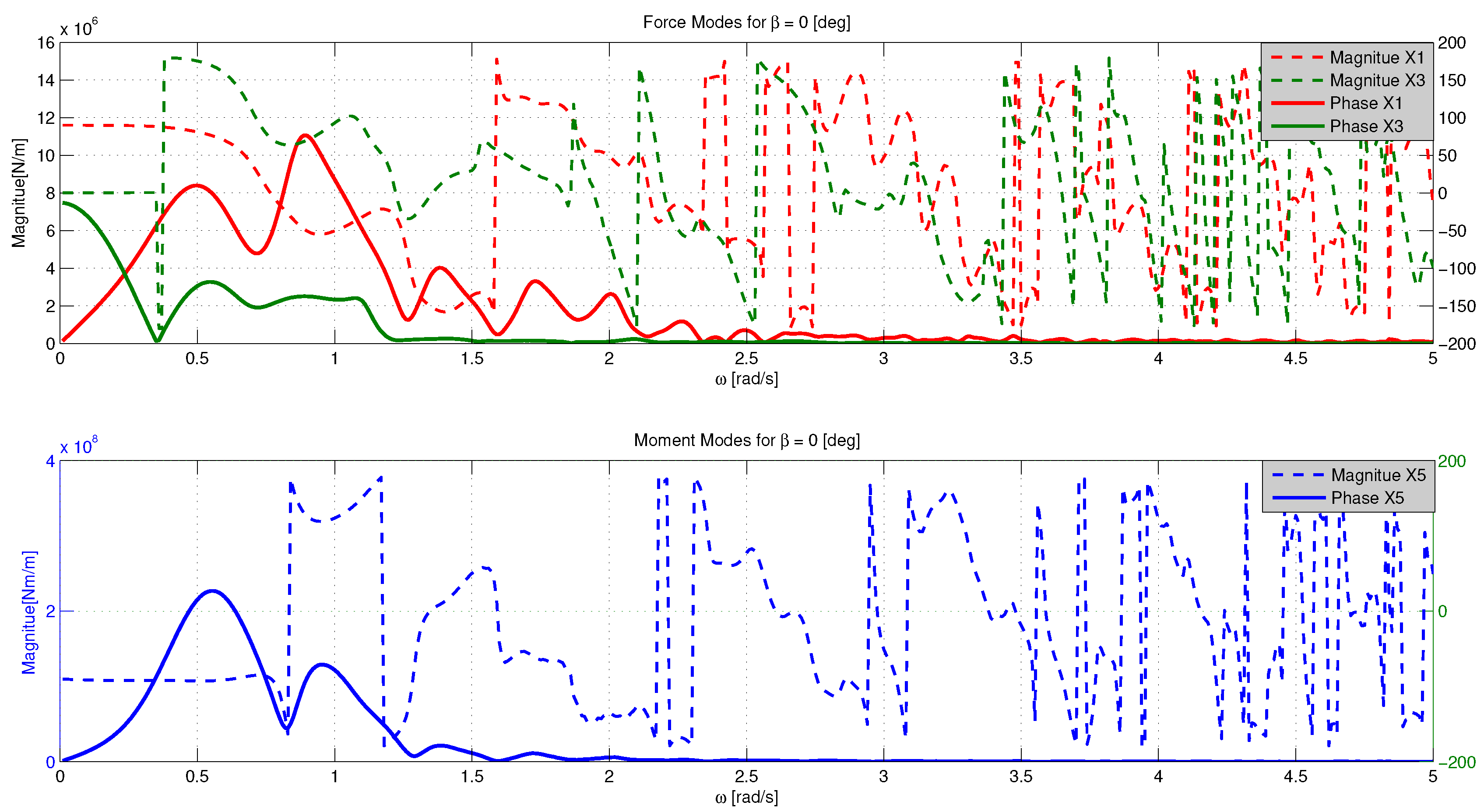

4.1. Response Amplitude Operators

4.2. Steady-State Response of Integrated System under Uniform Wind and Regular Waves

4.3. Selected Design Load Cases Analysis

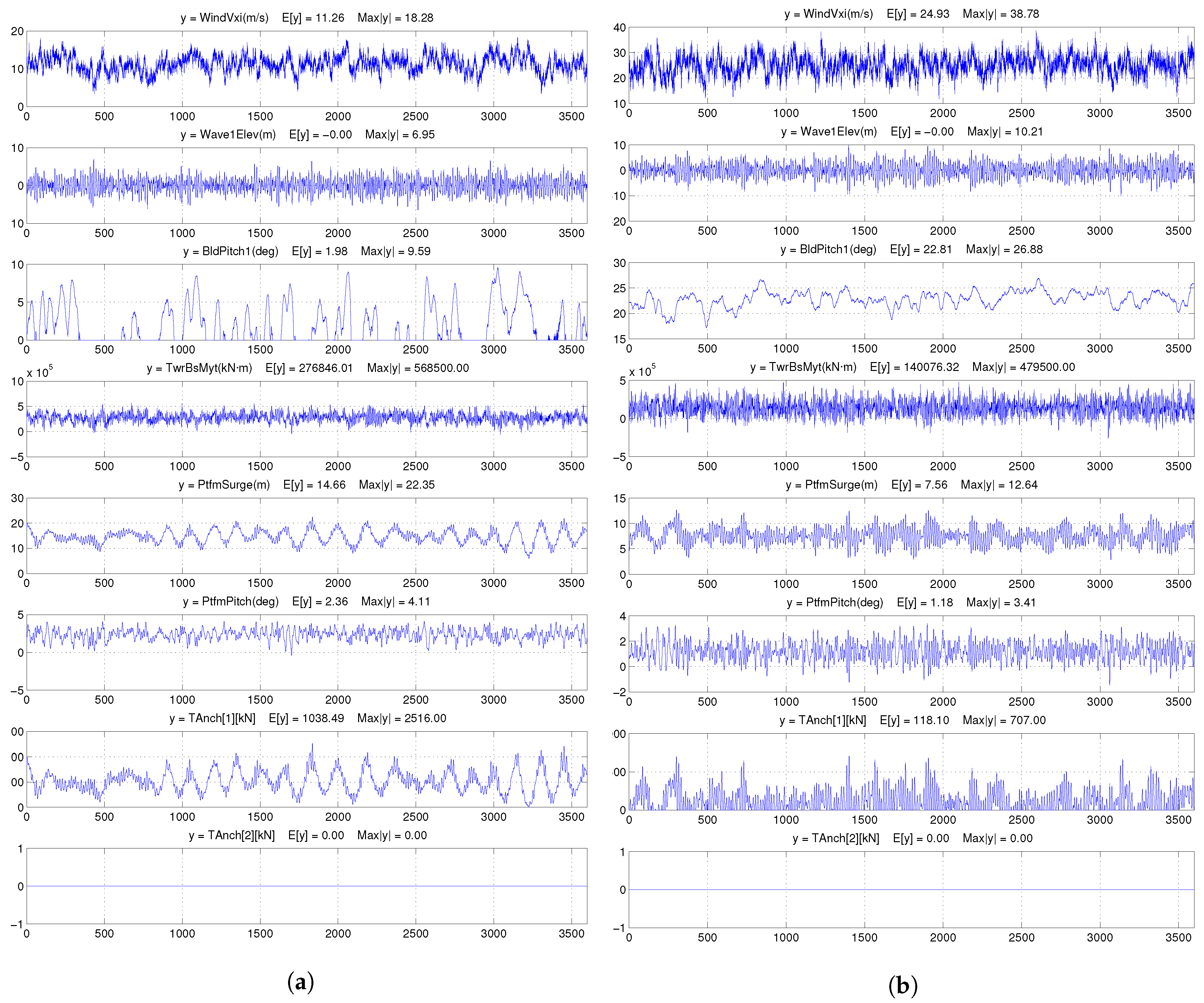

4.4. Dynamic Response Analysis under Turbulent Winds and Irregular Waves

5. Conclusions

- (i)

- An earlier semi-submersible platform model with a scale factor of 1.8 (on the OC4 model) for the 13.2-MW turbine was overdesigned. A more economical model with a scale factor of 1.5 for the platform and a mooring line scale factor of 2.0 was found to be adequate for the 13.2-MW wind turbine with SNL100-02 blades in stability and dynamic analyses.

- (ii)

- A new tower model was designed to support the wind turbine mounted on the semi-submersible platform. The tower height and thickness were chosen to meet design constraints such as an air gap or clearance requirement. A Campbell diagram analysis showed that the tower developed is in the soft-stiff design range and avoids resonance with important rotor rotation and blade-passing frequencies.

- (iii)

- Platform hydrodynamic properties were calculated using WAMIT, only considering linear hydrodynamic effects. KC numbers for several sea states were computed, and it was shown that the application of potential flow theory to this large-volume platform model can be justified. Computed hydrodynamic coefficients for the model developed are consistent with those for the OC4 DeepCwind model.

- (iv)

- The steady-state response of the integrated system showed that its behavior is satisfactory based on the design criteria. Static offsets in pitch and heave motions were in a reasonable range, and short-term maximum values were sufficiently low to help validate the model.

- (v)

- Response amplitude operators were generated for this integrated model in the time domain to account for nonlinear characteristics based on white-noise wave excitation using FAST. Response amplitudes are comparable with those for the OC4 DeepCwind model, but the dominant frequencies were somewhat lower, suggesting that this system is more sensitive to low-frequency forces.

- (vi)

- The performance of the integrated system under a turbulent wind field and irregular waves demonstrated its stability and satisfactory performance. Satisfactory pitch motion statistics including maxima, in the sea states studies, suggest that the model developed is adequate even for use in severe sea states.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Growth of the Wind Power Industry around the World. Available online: http://www.gwec.net/global-figures/graphs/ (accessed on 21 November 2015).

- American Wind Energy Association. U.S. Wind Industry Third Quarter 2017 Market Report: Executive Summary; Technical Report; American Wind Energy Association: Washington, DC, USA, 2017. [Google Scholar]

- United States Department of Energy. 20% Wind Energy by 2030: Increasing Wind Energy’s Contribution to US Electricity Supply; Technical Report; Report No. DOE/GO-102008-2567; United States Department of Energy: Washington, DC, USA, 2008.

- Schwartz, M.; Heimiller, D.; Haymes, S.; Musial, W. Assessment of Offshore Wind Energy Resources for the United States; Technical Report; Reprot No. NREL/TP-500-45889; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2010.

- Jonkman, J.M. Dynamics Modeling and Loads Analysis of an Offshore Floating Wind Turbine; Technical Report; Report No. NREL/TP-500-41958; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2007.

- Bulder, B.H.; van Hees, M.T.; Henderson, A.; Huijsmans, R.H.M.; Pierik, J.T.G.; Snijders, E.J.B.; Wijnants, G.H.; Wolf, M.J. Study to Feasibility of and Boundary Conditions for Floating Offshore Wind Turbines; Public Report 2002-CMC-R43; ECN, MARIN, MSC, Lagerway the Windmaster, TNO, TUD: Delft, The Netherlands, December 2002. [Google Scholar]

- Wayman, E.N. Coupled Dynamics and Economic Analysis of Floating Wind Turbine Systems. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2006. [Google Scholar]

- Tracy, C.C.H. Parametric Design of Floating Wind Turbines. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2007. [Google Scholar]

- Matha, D. Model Development and Loads Analysis of an Offshore Wind Turbine on a Tension Leg Platform with a Comparison to Other Floating Turbine Concepts; Technical Report; Report No. NREL/SR-500-45891; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2010.

- Jonkman, J.M.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development; Technical Report; Report No. NREL/TP-500-38060; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2009.

- Bossanyi, E.A. The Design of Closed Loop Controllers for Wind Turbines. Wind Energy 2000, 3, 149–163. [Google Scholar] [CrossRef]

- Griffith, D.T.; Resor, B.R. Description of Model Data for SNL 13.2-00-Land: A 13.2 MW Land-Based Turbine Model with SNL 100-00 Blades; Technical Report; Report No. SAND2011-9310P; Sandia National Laboratories: Albuquerque, NM, USA, 2011.

- Liu, J.; Thomas, E.; Manuel, L.; Griffith, D.T.; Ruehl, K.; Barone, M. On the Development of a Semi-Submersible Offshore Floating Platform and Mooring System for a 13.2 MW Wind Turbine. In Proceedings of the 34th Wind Energy Symposium, AIAA SciTech Forum, San Diego, CA, USA, 4–8 January 2016; Paper No. AIAA 2016–1994; The American Institute of Aeronautics and Astronautics: San Diego, CA, USA, January 2016. [Google Scholar]

- Offshore Wind RD&D: Large Offshore Rotor Development. Available online: http://energy.sandia.gov/energy/renewable-energy/wind-power/offshore-wind/offshore-wind-sandia-large-rotor-development/ (accessed on 21 November 2015).

- Griffith, D.T. The SNL100-01 Blade: Carbon Design Studies for the Sandia 100-m Blade; Technical Report; Report No. SAND2013-1178; Sandia National Laboratories: Albuquerque, NM, USA, 2013.

- Sahasakkul, W. Development of a Model for an Offshore Wind Turbine Supported by a Moored Semi-Submersible Platform. Master’s Thesis, University of Texas at Austin, Austin, TX, USA, 2014. [Google Scholar]

- Robertson, A.; Jonkman, J.M.; Masciola, M.; Song, H.; Goupee, A.; Coulling, A.; Luan, C. Definition of the Semisubmersible Floating System for Phase II of OC4; Technical Report; Report No. NREL/TP-5000-60601; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2012.

- Liu, J. On the Development of a Semi-Submersible Offshore Floating Platform and Mooring System for a 13.2 MW Wind Turbine. Master’s Thesis, University of Texas at Austin, Austin, TX, USA, 2016. [Google Scholar]

- Faltinsen, O. Sea Loads on Ships and Offshore Structures; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar]

- Thomas, E. Long-Term Loads on a Large Offshore Wind Turbine Supported by a Semi-Submersible Platform. Master’s Thesis, University of Texas at Austin, Austin, TX, USA, 2016. [Google Scholar]

- Newman, J.N. Marine Hydrodynamics; MIT Press: Cambridge, MA, USA, 1977. [Google Scholar]

- Jonkman, B.J. TurbSim User’s Guide: Version 1.50; National Renewable Energy Laboratory: Golden, CO, USA, 2009.

- Laino, D.J.; Hansen, A.C. Aerodyn User’s Guide; National Renewable Energy Laboratory: Golden, CO, USA, 2002.

- Masciola, M. Instructional and Theory Guide to the Mooring Analysis Program; National Renewable Energy Laboratory: Golden, CO, USA, 2013.

- Ramachandran, G.K.V.; Robertson, A.; Jonkman, J.M.; Masciola, M.D. Investigation of Response Amplitude Operators for Floating Offshore Wind Turbines. In Proceedings of the 32nd International Offshore and Polar Engineering Conference, Anchorage, AK, USA, 30 June–4 July 2013. [Google Scholar]

- Thomas, E.; Liu, J.; Goyal, A.; Manuel, L. Long-Term Loads on a Large Offshore Wind Turbine Supported by a Semi-Submersible Platform. In Proceedings of the 34th Wind Energy Symposium, AIAA SciTech Forum, San Diego, CA, USA, 4–8 January 2016; Paper No. AIAA 2016–1994; The American Institute of Aeronautics and Astronautics: San Diego, CA, USA, January 2016. [Google Scholar]

- Li, L.; Gao, Z.; Moan, T. Joint environmental data at five European offshore sites for design of combined wind and wave energy devices. In Proceedings of the 32nd International Conference on Ocean, Offshore and Arctic Engineering, Nantes, France, 9–14 June 2013; Paper No. OMAE2013-10156; American Society of Mechanical Engineers: Nantes, France, 2013. [Google Scholar]

- International Electrotechnical Commission. IEC 61400-3: Wind Turbines Part 3: Design Requirements for Offshore Wind Turbines; International Electrotechnical Commission: Geneva, Switzerland, 2009. [Google Scholar]

- Bayati, I.; Jonkman, J.; Robertson, A.; Platt, A. The effects of second-order hydrodynamics on a semisubmersible floating offshore wind turbine. J. Phys. Conf. Ser. 2014, 524, 012094. [Google Scholar] [CrossRef]

| Blade Designation | SNL100-00 | SNL100-01 | SNL100-02 | SNL100-03 |

|---|---|---|---|---|

| Material | all-glass baseline blade | carbon design | advanced core material | advanced geometry |

| Blade Weight (kg) | 114,172 | 73,995 | 59,047 | 49,519 |

| Span-wise CG(m) | 33.6 | 33.1 | 31.95 | 31.55 |

| Fixed-base (Hz) | 0.42 | 0.49 | 0.55 | 0.49 |

| Parameter | Value | Parameter | Value | Parameter | Value |

|---|---|---|---|---|---|

| Rated Power | 13.2 MW | Rotor Orientation | Upwind | Blade Designation | SNL100-02 |

| Rotor Dia. | 205 m | Hub Dia. | 5 m | Blade Length | 100 m |

| Hub Height | 133.5 m | Generator Eff. | 94.40% | No. of Blades | 3 |

| 3 m/s | Cut-in Rotor Speed | 4.34 rpm | Blade Weight | 59,047 kg | |

| 11.3 m/s | Rated Rotor Speed | 7.44 rpm | Span-wise CGloc. | 31.95 m | |

| 25 m/s | Rated Tip-speed | 80 m/s | Maximum Chord | 7.63 m | |

| Overhang | 8.16 m | Rotor Mass | 422,131 kg | Natural Frequency | 0.55 Hz |

| Precone | 2.5 deg | Tower Mass | 553,995 kg | Control System:Variable-speed; Collective-pitch | |

| Shaft Tilt | 5 deg | Tower-top Mass | 1,452,131 kg | ||

| Static Properties | Values | Multiplication Factor |

|---|---|---|

| Depth of platform base below SWL | 20 m | |

| Elevation of main column above SWL | 10 m | |

| Elevation of offset columns above SWL | 12 m | |

| Spacing between offset columns | 50 m | |

| Length of upper columns | 26 m | |

| Length of base columns | 6 m | |

| Depth to top of base columns below SWL | 14 m | |

| Diameter of main column | 6.5 m | |

| Diameter of offset (upper) columns | 12 m | |

| Diameter of base columns | 24 m | |

| Diameter of pontoons and cross braces | 1.6 m | |

| CM location below SWL | 13.46 m | |

| Platform mass, including ballast | 1.3473 kg | |

| Platform roll inertia about CM | 6.827 kg-m | |

| Platform pitch inertia about CM | 6.827 kg-m | |

| Platform yaw inertia about CM | 1.226 kg-m |

| Parameters | Values | Multiplication Factor |

|---|---|---|

| Number of Mooring Lines | 3 | (−) |

| Angle Between Adjacent Lines | 120 | (−) |

| Depth to Anchors Below SWL | 200 m | (−) |

| Depth to Fairleads Below SWL | 14 m | |

| Radius to Anchors from Platform Centerline | 837.6 m | (−) |

| Radius to Fairleads from Platform Centerline | 40.868 m | |

| Unstretched Mooring Line Length | 835.5 m | (−) |

| Mooring Line Diameter | 0.0766 m | |

| Equivalent Mooring Line Mass Density | 113.35 kg/m | |

| Equivalent Mooring Line Mass in Water | 108.63 kg/m | |

| Equivalent Mooring Line Extensional Stiffness | 753.6 MN | |

| Hydrodynamic Drag Coefficient for Mooring Lines | 1.1 | (−) |

| Hydrodynamic Added-Mass Coefficient for Mooring Lines | 1.0 | (−) |

| Seabed Drag Coefficient For Mooring Lines | 1.0 | (−) |

| Structural Damping of Mooring Lines | 2.0% | (−) |

| (−) indicates t parameter is not changed (relative to OC4 DeepCwind). | ||

| Physical Parameter | Units | Scale Factor |

|---|---|---|

| Length | m | |

| Structural mass | kg | |

| Force | N | |

| Moment | N-m | |

| Acceleration | m/s | 1 |

| Time | s | |

| Pressure | Pa or N/m |

| Elevation (m) | HtFract (−) | TMassDen (kg/m) | TwFAStif (N-m) | TwSSStif (N-m) | TwGJStif (N-m) | TwEAStif (N) | TwFAIner (kg-m) | TwSSIner (kg-m) |

|---|---|---|---|---|---|---|---|---|

| 0.00 | 0.0 | 7010.24 | 2.05 | 2.05 | 1.57 | 1.73 | 82,841.3 | 82,841.3 |

| 11.46 | 0.1 | 6527.08 | 1.75 | 1.75 | 1.35 | 1.61 | 71,011.8 | 71,011.8 |

| 22.92 | 0.2 | 6060.75 | 1.49 | 1.49 | 1.15 | 1.50 | 60,490.5 | 60,490.5 |

| 34.38 | 0.3 | 5611.23 | 1.26 | 1.26 | 9.73 | 1.39 | 51,177.7 | 51,177.7 |

| 45.84 | 0.4 | 5178.54 | 1.06 | 1.06 | 8.17 | 1.28 | 42,977.8 | 42,977.8 |

| 57.30 | 0.5 | 4762.67 | 8.84 | 8.84 | 6.81 | 1.18 | 35,799.1 | 35,799.1 |

| 68.76 | 0.6 | 4363.62 | 7.30 | 7.30 | 5.62 | 1.08 | 29,553.6 | 29,553.6 |

| 80.22 | 0.7 | 3981.39 | 5.97 | 5.97 | 4.59 | 9.84 | 24,157.5 | 24,157.5 |

| 91.68 | 0.8 | 3615.98 | 4.83 | 4.83 | 3.71 | 8.93 | 19,530.8 | 19,530.8 |

| 103.14 | 0.9 | 3267.39 | 3.85 | 3.85 | 2.97 | 8.07 | 15,597.3 | 15,597.3 |

| 114.60 | 1.0 | 2935.63 | 3.04 | 3.04 | 2.34 | 7.25 | 12,284.9 | 12,284.9 |

| Model | (kN-m) | (kN-m/rad) | (kN-m/rad) | R | Remarks | |

|---|---|---|---|---|---|---|

| NREL 5MW | 5.27 | 3.02 | 3.80 | 1.26 | 1 | (−) |

| SNL14602 | 2.81 | 1.61 | 3.99 | 2.48 | 1.8 | Ref. [16] |

| 1.46 | 0.91 | 1.4 | , fails | |||

| SNL13302 | 2.29 | 1.31 | 3.99 | 3.03 | 1.8 | , over-designed |

| 1.92 | 1.46 | 1.5 | , OK | |||

| 1.46 | 1.11 | 1.4 | , OK | |||

| : tower-base out-of-plane bending moment; | ||||||

| Models | SNL13302 | ||

|---|---|---|---|

| Scale Factor | 1.6 | 1.5 | 1.4 |

| Total Mass (kg) | 2.46 | 2.02 | 1.65 |

| Allowable Tower Mass, C (kg) | 1.00 | 5.72 | 1.94 |

| Actual Tower Mass, D (kg) | 5.86 | 5.54 | 5.21 |

| Remarks | , over-designed | OK | , fails |

| Sea States | Normal | 50-Year Return | ||

|---|---|---|---|---|

| T (s) | (m) | T (s) | (m) | |

| 1 | 2.0 | 0.09 | 14.83 | 5.91 |

| 2 | 4.8 | 0.67 | 14.65 | 6.55 |

| 3 | 6.5 | 1.40 | 14.51 | 7.22 |

| 4 | 8.1 | 2.44 | 14.41 | 7.94 |

| 5 | 9.7 | 3.66 | 14.35 | 8.71 |

| 6 | 11.3 | 5.49 | 14.32 | 9.51 |

| 7 | 13.6 | 9.14 | 14.3 | 10.35 |

| 8 | 17.0 | 15.24 | 14.31 | 11.52 |

| Coefficients | Value |

|---|---|

| Added-mass coefficient () for all members | 0.63 |

| Added-mass coefficient () for the base column in the z direction | 1.00 |

| Drag coefficient () for the main column | 0.56 |

| Drag coefficient () for the upper columns | 0.61 |

| Drag coefficient () for the base columns | 0.68 |

| Drag coefficient () for the pontoons and cross members | 0.63 |

| Drag coefficient () for the base columns in the z direction | 4.80 |

| V (m/s) | Low Wave Height | Medium Wave Height | High Wave Height | |||

|---|---|---|---|---|---|---|

| (m) | (s) | (m) | (s) | (m) | (s) | |

| 9 | 1.0 | 7.0 | 2.5 | 8.0 | 4.0 | 9.5 |

| 12 | 1.0 | 6.0 | 2.5 | 7.0 | 4.0 | 8.5 |

| 16 | 2.0 | 8.0 | 3.5 | 8.5 | 5.0 | 10.5 |

| No | Sea State | TwrBsMyt (kN-m) | PtfmSurge (m) | PtfmHeave (m) | PtfmPitch (Deg) | TFair [1] (kN) | |

|---|---|---|---|---|---|---|---|

| V | , | ||||||

| 1 | 9 | 1.0, 7.0 | 2.63 | 13.5 | −0.03 | 1.95 | 3106 |

| 2 | 2.5, 8.0 | 3.17 | 13.6 | −00.07 | 2.02 | 3112 | |

| 3 | 4.0, 9.5 | 3.33 | 13.7 | −00.15 | 2.24 | 3120 | |

| 4 | 12 | 1.0, 6.0 | 3.04 | 19.3 | −00.05 | 2.45 | 3833 |

| 5 | 2.5, 7.0 | 3.58 | 16.0 | −00.07 | 2.35 | 3387 | |

| 6 | 4.0, 8.5 | 4.02 | 15.4 | −00.12 | 2.49 | 3323 | |

| 7 | 16 | 2.0, 8.0 | 2.51 | 11.2 | 0.06 | 1.58 | 2875 |

| 8 | 3.5, 8.5 | 2.95 | 11.2 | 0.10 | 1.67 | 2878 | |

| 9 | 5.0, 10.5 | 2.79 | 11.5 | 0.32 | 1.99 | 2902 | |

| Design Situation | DLC | Wind Condition | PtfmSurge | PtfmPitch | RootMyc1 | TwrBsMyt | TFair |

|---|---|---|---|---|---|---|---|

| Power production | 1.1 | NTM | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| 1.3 | ETM | 1.03 | 1.10 | 1.11 | 1.01 | 1.04 | |

| 1.4 | ECD | 0.80 | 0.83 | 1.13 | 0.81 | 0.84 | |

| 1.5 | EWS | 0.81 | 0.82 | 0.90 | 0.85 | 0.83 | |

| Startup | 3.2 | EOG | 1.13 | 1.15 | 1.15 | 1.22 | 1.18 |

| 3.3 | EDC | 1.07 | 1.14 | 1.11 | 1.17 | 1.10 |

(m/s) | PtfmSurge (m) | PtfmPitch (deg) | RootMyc1 (MN-m) | TwrBsMyt (MN-m) | TAnch (KN) |

|---|---|---|---|---|---|

| 4 | 11.5 | 1.9 | 27.0 | 335.9 | 532.70 |

| 8 | 23.0 | 3.6 | 59.2 | 529.3 | 2719.00 |

| 11.3 | 23.6 | 4.8 | 64.1 | 628.7 | 2817.00 |

| 16 | 20.1 | 5.0 | 64.6 | 607.0 | 2029.00 |

| 20 | 16.9 | 4.3 | 56.3 | 605.3 | 1376.00 |

| 24 | 13.9 | 3.9 | 57.6 | 547.5 | 944.50 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Thomas, E.; Manuel, L.; Griffith, D.T.; Ruehl, K.M.; Barone, M. Integrated System Design for a Large Wind Turbine Supported on a Moored Semi-Submersible Platform. J. Mar. Sci. Eng. 2018, 6, 9. https://doi.org/10.3390/jmse6010009

Liu J, Thomas E, Manuel L, Griffith DT, Ruehl KM, Barone M. Integrated System Design for a Large Wind Turbine Supported on a Moored Semi-Submersible Platform. Journal of Marine Science and Engineering. 2018; 6(1):9. https://doi.org/10.3390/jmse6010009

Chicago/Turabian StyleLiu, Jinsong, Edwin Thomas, Lance Manuel, D. Todd Griffith, Kelley M. Ruehl, and Matthew Barone. 2018. "Integrated System Design for a Large Wind Turbine Supported on a Moored Semi-Submersible Platform" Journal of Marine Science and Engineering 6, no. 1: 9. https://doi.org/10.3390/jmse6010009