The following sections present the modeling of each individual aspect, considering the weather conditions, the structural properties of the turbine, modeling of the degrading health state, the quality of inspections, and the type of repair and transportation used for both inspections and repair.

3.4. Inspections

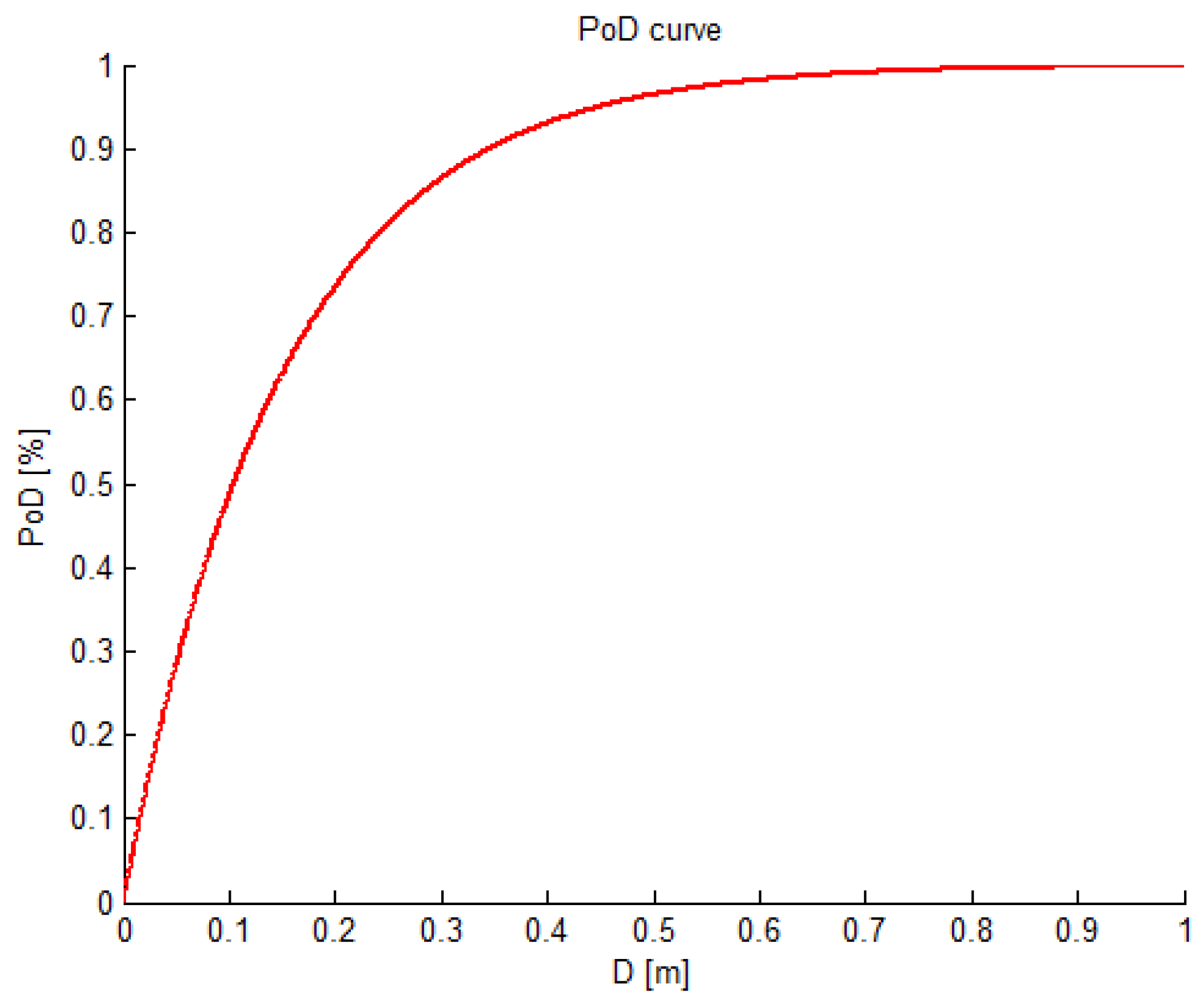

The inspection model considers the scheduled inspection time, the duration for an inspection and the probability that an inspection is successful. This is modeled using the probability of detection (

PoD) curve as a function of the damage size

D, modeled in this case by a crack length noted

a. The

PoD curve is obtained Equation (3), taken from [

4].

The maximum probability of detection,

P0 (for very large amounts of damage) and the expected value of the smallest detectable damage, λ are set to 1 and 0.2, respectively. These parameters are dependent on the inspection method that is being considered. For this study, the values are chosen for illustrative purposes and do not reflect a particular inspection procedure.

Figure 3 shows the probability of detection

(PoD) curve corresponding to these values.

Figure 3.

Probability of detection curve.

Figure 3.

Probability of detection curve.

In reality, a probability of false indication also exists. While this is not taken into consideration in this model, it is noted that false indications can lead to unnecessary maintenance interventions. Further, it is assumed for illustration that an inspection of the entire blade has a duration Tin of eight hours and, during this period, the turbine is stopped. This implies that, in addition to the cost of inspection, revenue losses are also present.

Inspections are assumed to take place at regular time intervals. The influence of this interval is studied in

Section 4. Alternatively, inspection times can be optimized following the general model in

Section 2.

3.5. Damage Model

In order to build a reliable damage model, a failure mechanism must first be considered so that its progression can be traced throughout the lifetime of the blade. However, identifying the failure mechanism of a turbine blade is not a trivial task, due to the complexity of the physical phenomenon itself and the limited amount of information available on blade fatigue behavior. [

6] makes an attempt of identifying the initial causes that eventually lead to failure, by performing both numerical experiments and a full-scale static test on a 40-m turbine blade. It is concluded in the paper that “the aerodynamic shells debonding from the adhesive joints is the initial failure mechanism followed by its instable propagation which can lead to collapse” [

6]. Therefore, although a detailed mechanism cannot be expressed, the damage model used in the present paper is based on the assumption that failure is achieved when cracks in the adhesive joints reach a certain length

afail.

The model is contains three stages that are described in the following subsections:

crack initiation at the start of the blade’s life

damage propagation during the blade’s lifetime

failure is achieved when a crack length reaches afail

The size and positions of the cracks at the beginning of the blades lifetime are unknown. This being the case, a random damage state is generated. The distances

l1,

l2 …. ln are generated from a Poisson process, with the intensity λ

p(l) and the size

a of each crack being randomly generated using a lognormal distribution. The input example values for the crack size model are shown in

Section 3.8.

The average number of cracks is set at 0.3 per meter length of the blade. It is noted that this model assumes cracks to be evenly distributed along the length of the whole blade. This may not be realistic, but other models with cracks concentrated in certain areas of the blade can easily be implemented.

Once the cracks are generated, their growth is modeled using a fracture mechanics approach, under the assumption of having one-dimensional cracks along the length of the blade.

The crack growth in the bondline is determined by the load cycles applied to the blade and the crack length at a given time. The crack growth is assessed for 10 min intervals following Paris law, as shown in Equation (4), taken from [

7]:

- da

Increase in crack length

- ΔK

Stress intensity factor

- Δt

Time period

- A,m,λw

Material parameters

- R

Stress ratio

The stress intensity factor

ΔK for a time interval

Δt is determined as a function of the wind speed, the crack size and the load cycle distribution corresponding to

Δt. The model is shown in Equation (5), taken from [

8]:

- Δs

Load range

- a

Crack length

- f(Δs|u,I)

Density function of load cycles

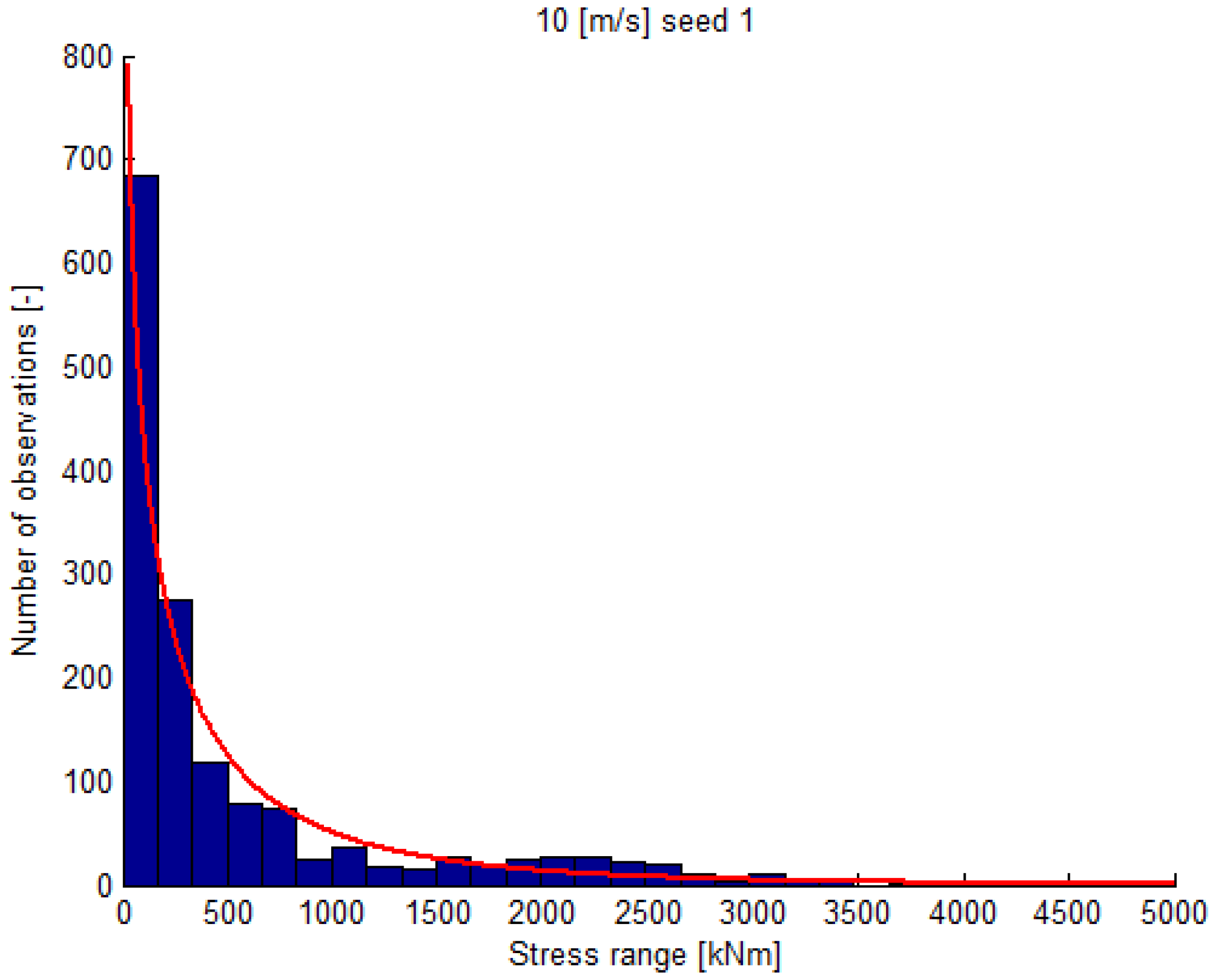

The statistical distribution function of the cycle ranges is dependent on the turbulence intensity for a given site and the mean wind speed. To determine the distribution of the load cycles as function of the environment, a series of 10-min simulations is made using the aero-elastic simulator FAST defined in [

5], covering all operational wind bins of the turbine. Data is collected for the flap-wise blade bending moment for 1 m/s wind bins from cut-in to cut-out wind speed, using a reference turbulence intensity of 0.08, as determined for the weather data used from the platform location. It is noted that other loads,

i.e., edge-wise bending, also contributes to the development of cracking, however, the model uses only flap-wise loading as it is considered to be the dominant load and sufficient for the study. To avoid large statistical uncertainties, 15 seeds are used for each wind bin.

The following step is to determine the load range distribution for each wind bin as a function of the wind speed. This is done by using a rainflow count, after which the results are fitted to a two-parameter Weibull distribution. The cycle count for a 10 m/s wind bin, along with the fit is shown in

Figure 4. Along with the stress ranges, the mean value of the cycle midpoints is determined in order to estimate the cycle ratio

R.

Figure 4.

Distribution of stress ranges in a 10 min simulation.

Figure 4.

Distribution of stress ranges in a 10 min simulation.

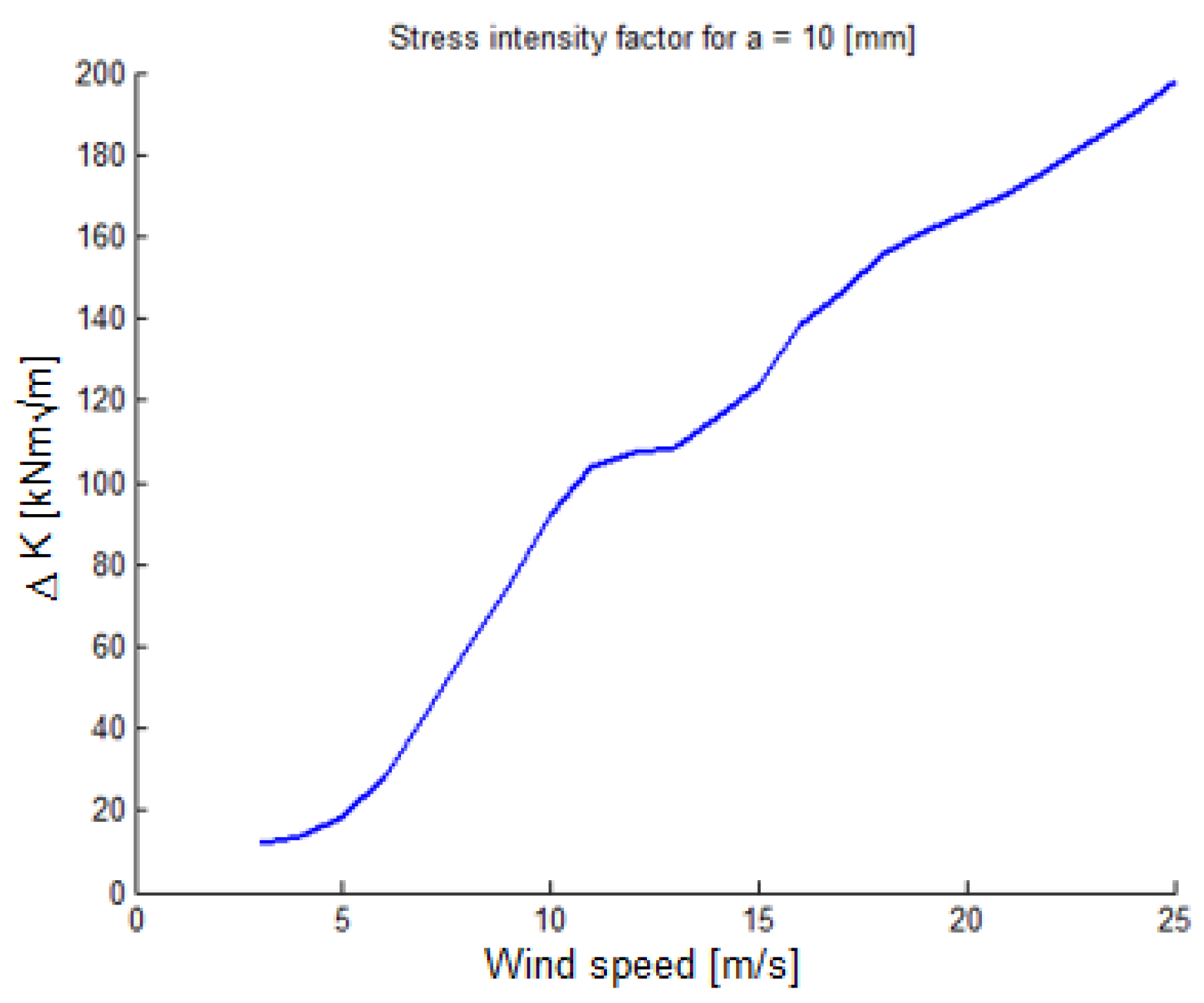

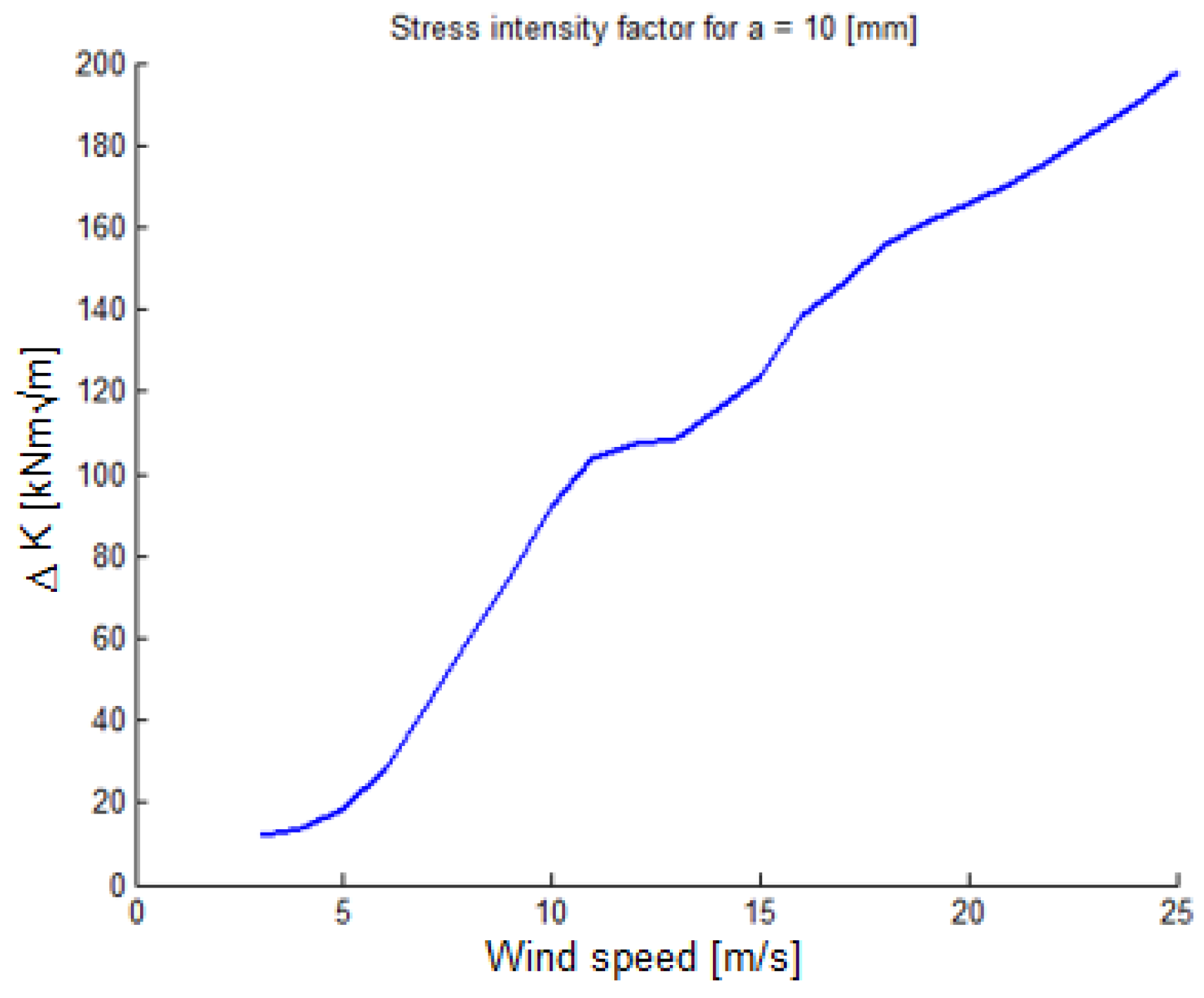

By integrating according to Equation (4), the stress intensity factor for a 10-min interval, given the wind speed, the turbulence intensity, and the crack size at the beginning of the time interval, is determined. This is shown in

Figure 5, for a crack size of 10 mm.

Figure 5 illustrates the influence of the blade’s pitching mechanism, reducing the loads after a rated wind speed. Because the stress intensity factor is highly dependent on the crack size, its value is updated after every 10-min interval, according to Equation (5), considering the new crack size, determined with Equation (4).

Figure 5.

Distribution of stress intensity factor.

Figure 5.

Distribution of stress intensity factor.

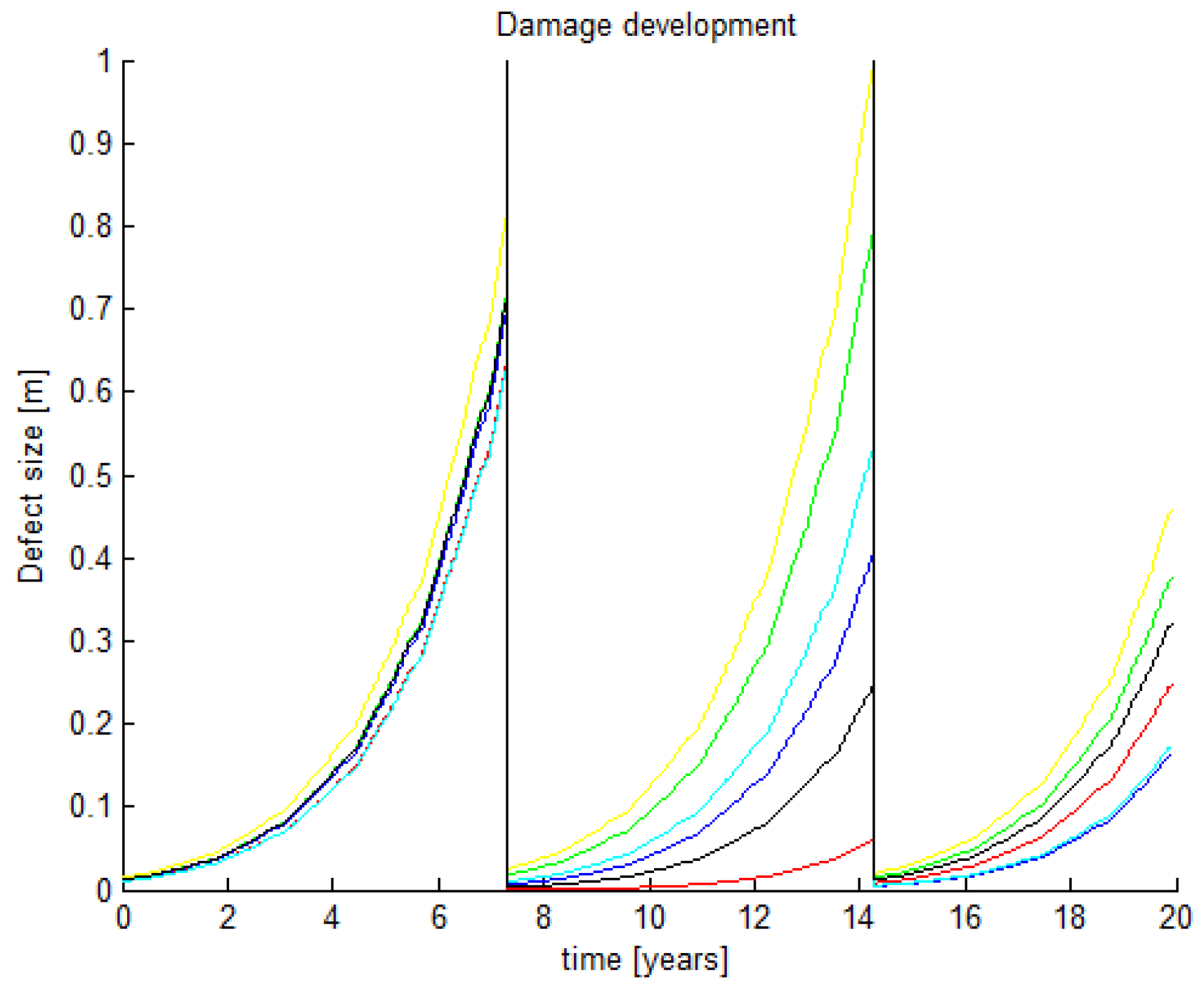

As stated previously, failure is assumed to occur when the cracks reach a certain value afail.

Figure 6 and

Figure 7 show an example run of the damage model, illustrating all stages, for a

fail of 1 m. The randomly generated initial damage state is seen in

Figure 6, while

Figure 7 shows how the cracks develop during the lifetime of the blade.

Figure 6.

Initial damage state.

Figure 6.

Initial damage state.

Figure 7.

Damage development and failure.

Figure 7.

Damage development and failure.

Figure 7 shows the evolution of a number of cracks with different starting sizes, each shown with a different color. It is seen that when one of the cracks reaches the failure limit of 1 m, the blade is considered to be collapsed. This position is marked by the vertical line in figure 7. At this point, the development of all cracks is stopped and the blade is replaced with a new one, after which the process is repeated.