Unlocking the Energy Potential of Manure—An Assessment of the Biogas Production Potential at the Farm Level in Germany

Abstract

:1. Introduction

2. Methodology and Data

2.1. Identifying Relevant Livestock Systems

2.2. Data on Livestock

2.3. Data on Manure and Dung

2.4. Data for Methane Yields

2.5. Biogas Potential Calculation

2.6. Assumed Investment Costs for Biogas Concepts

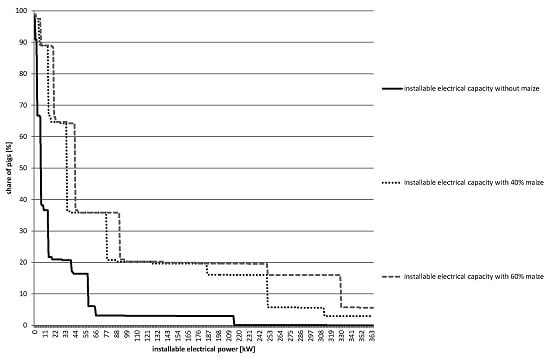

2.7. Considering Different Scenarios

3. Results and Discussion

- For the evaluation of biogas potential in farms with cattle, 95.8% of the livestock was considered. The remaining 4.2% do not have any biogas potential due to their type of livestock breeding without collectable excrement. Around 130,000 farms in total breed cattle in Germany with a total number of 12.37 million cattle. The number of cattle per farm ranges from 1 to 9 individuals to more than 500 cows per farm. The largest share of cattle is bred on medium- to small-sized farms with 200 to 499 cows per farm. Large farms with more than 500 cows, representing 2% of all farms with cattle have a share of 17% of the total number of cattle [25].

- For the evaluation of the manure and dung potential from pigs, 100% of the livestock were considered. Pigs are bred on 68,000 farms in Germany, totaling 28.7 million pigs. The range of farm sizes varies from small farms with up to 49 pigs to farms with more than 5,000 pigs. The majority of pigs are reared on farms with 1000 to 1999 pigs. Similar to the cattle farms, the largest pig farms have, in relation to the number of pigs that they breed, a relatively large share of the pig population, accounting for 16% [25].

4. Conclusions

Author Contributions

Conflicts of Interest

References

- IPCC. Climate Change 2014 Synthesis Report Summary for Policymakers; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- WRI. Climate Analysis Indicators Tool (CAIT) (version 9.0); World Resources Institute: Washington, DC, USA, 2012. [Google Scholar]

- UBA. Berichterstattung Unter Der Klimarahmenkonvention Der Vereinten Nationen Und Dem Kyoto-Protokoll 2013 Nationaler Inventarbericht Zum Deutschen Treibhausgasinventar 1990–2011; Umweltbundesamt: Dessau-Roßlau, Germany, 2013. [Google Scholar]

- Freibauer, A. Biogenic Greenhouse Gas Emissions from Agriculture in Europe-Quantificatio and Mitigation; Universität Hohenheim: Hohenheim, Germany, 2002. [Google Scholar]

- Monteny, G.J.; Bannink, A.; Chadwick, D. Greenhouse Gas Abatement Strategies for Animal Husbandry. Mitig. Greenh. Gas Emiss. Livest. Product. 2016, 112, 163–170. [Google Scholar] [CrossRef]

- Dämmgen, U.; Webb, J. The development of the EMEP/CORINAIR guidebook with respect to the emissions of different nitrogen and carbon species from animal production. Mitig. Greenh. Gas Emiss. Livest. Product. 2006, 112, 241–248. [Google Scholar] [CrossRef]

- Grübler, A.; Ishitani, H.; Johansson, T.; Marland, G.; Moreira, J.R.; Rogner, H.-H. B: Energy Primer. IPCC—Intergovernmental Panel on Climate Change. Available online: http://www.ipcc-wg2.gov/publications/SAR/SAR_Chapter%20B.pdf (accessed on 11 July 2014).

- Bundesregierung. Bundesregierung Erneuerbare Energien-Ein Neues Zeitalter Hat Begonnen. Available online: http://www.bundesregierung.de/Webs/Breg/DE/Themen/Energiewende/EnergieErzeugen/ErneuerbareEnergien-Zeitalter/_node.html;jsessionid=BEFF78D3A8ED2D8ECC35E6B4A09DE74E.s4t1#doc516106bodyText2 (accessed on 22 July 2015).

- Haenel, H.D.; Rösemann, C.; Dämmgen, U.; Poddey, E.; Freibauer, A.; Wulf, S.; Eurich-Menden, B.; Döhler, H.; Schreiner, C. Calculations of Gaseous and Particulate Emissions from German Agriculture 1990–2012; Johann Heinrich von Thünen-Institut: Braunschweig, Germany, 2014. [Google Scholar]

- Seyfert, U.; Bunzel, K.; Thrän, D.; Mauky, E.; Fritsche, B.; Schreiber, A.; Liebetrau, J.; Schmidt, T.; Ulbricht, T.; Lenz, V. DBFZ Report Nr. 8; Deutsches Biomasseforschungszentrum gemeinnützige GmbH: Leipzig, Germany, 2011. [Google Scholar]

- Scheftelowitz, M.; Thrän, D.; Hennig, C.; Krautz, A.; Lenz, V.; Liebetrau, J.; Daniel-Gromke, J.; Denysenko, V.; Hilebrand, K.; Naumann, K.; et al. Entwicklung Der Förderung Der Stromerzeugung Aus Biomasse Im Rahmen Des EEG; DBFZ Report Nr. 21; Nelles, M., Ed.; DBFZ Deutsches Biomasseforschungszentrum gemeinnützige GmbH: Leipzig, Germany, 2014. [Google Scholar]

- Federal Government of Germany 2012a. Act on Granting Priority to Renewable Energy Sources (Renewable Energy Sources Act-EEG). Federal Law Gazette on 4 August 2011 (BGBl. I, P. 1634 et Seq.). Vol. Federal Law Gazette on 4 August 2011 (BGBl. I, p. 1634 et seq.). Available online: http://www.bmu.de/english/renewable_energy/doc/47883.php (accessed on 23 July 2015).

- Thrän, D.; Krautz, A.; Scheftelowitz, M.; Lenz, V.; Liebetrau, J.; Daniel-Gromke, J.; Zeymer, M.; Nelles, M. Auswirkungen Der Gegenwärtig Diskutierten Novellierungs-Vorschläge Für Das EEG-2014. In Biogas 2014: 7. Innovationskongress; Tagungsband; 22–23 Mai 2014 Im Zentrum Für Umweltkommunikation Der Deutschen Bundesstiftung Umwelt (DBU) Osnabrück; 11–22; Profair Consult: Hildesheim, Germany, 2014. [Google Scholar]

- Kaltschmitt, M.; Hartmann, H.; Hofbauer, H. Energie Aus Biomasse: Grundlagen, Techniken Und Verfahren. 2; Corrected Aufl. 2009. 2., korr. Nachdruck 2009; Springer: Heidelberg, Germany, 2009. [Google Scholar]

- LKVBB. Untersuchung von Gülle-Notwendig Für Den Fachgerechten Einsatz Als Dünger Oder Als Substrat in Biogasanlagen. Landeskontrollverband Brandenburg e.V. Available online: http://www.lkvbb.de/hauptinf-Dateien/Guelle%20mit%20Tabellen.pdf (accessed on 13 January 2016).

- BMWi. Gesetz Für Den Ausbau Erneuerbarer Energien (Erneuerbare-Energien-Gesetz-EEG 2014); Bundesministerium für Wirtschaft und Energie: Berlin, Germany, 2014. [Google Scholar]

- BMWi. Referentenentwurf Des BMWi (IIIB2) Entwurf Eines Gesetzes Zur Einführung von Ausschreibungen Für Strom Aus Erneuerbaren Energien Und Zu Weiteren Änderungen Des Rechts Der Erneuerbaren Energien; Bundesministerium für Wirtschaft und Energie: Berlin, Germany, 2016. [Google Scholar]

- Dederer, M. Betriebswirtschaftliche Bewertung Kleiner Biogasanlagen; ALB Tagung: Hohenheim, Germany, 2012. [Google Scholar]

- TierSchNutztV. Verordnung Zum Schutz Landwirtschaftlicher Nutztiere Und Anderer Zur Erzeugung Tierischer Produkte Gehaltener Tiere Bei Ihrer Haltung (Tierschutz-Nutztierhaltungsverordnung—TierSchNutztV); Bundesministerium für Ernährung und Landwirtschaft: Bonn, Germany, 2014. [Google Scholar]

- Scheftelowitz, M.; Rensberg, N.; Denysenko, V.; Daniel-Gromke, J.; Stinner, W.; Hillebrand, K.; Naumann, K.; Peetz, D.; Henning, C. Stromerzeugung Aus Biomasse (Vorhaben IIa) Zwischenbericht Mai 2015; Deutsches Biomasseforschungszentrum gemeinnützige GmbH: Leipzig, Germany, 2015. [Google Scholar]

- Shen, X.L.; Huang, G.Q.; Yang, Z.L.; Han, L.J. Compositional characteristics and energy potential of Chinese animal manure by type and as a whole. Appl. Energy 2015, 160, 108–119. [Google Scholar] [CrossRef]

- Schultheiss, U.; Döhler, H.; Bach, M. Festmistaußenlagerung 1. überarbeitete Auflage; Kuratorium für Technik und Bauwesen in der Landwirtschaft KTBL: Darmstadt, Germany, 2011. [Google Scholar]

- Reinhold, G. Masse-Und Trockensubstanzbilanz in Landwirtschaftlichen Biogasanlagen-Langfassung Der Veröffentlichung Reinhold, G.: Genau Bilanzieren in Neue Landwirtschaft Heft 12/2005, S. 68 Bis 72; Thüringer Landesanstalt für Landwirtschaft TLL: Jena, Germany, 2015. [Google Scholar]

- Albert, E.; Förster, F.; Ernst, H. Wirksamkeit Organischer Dünger—Berechnung Der Pflanzenbaulichen Wirksamkeit Der Nährstoffe Organischer Dünger; Freistaat Sachsen, Sächsische Landesanstalt für Landwirtschaft: Dresden, Germany, 2007. [Google Scholar]

- BMEL. Statistisches Jahrbuch über Ernährung Landwirtschaft Und Forsten 2014; Bundesministerium für Ernährung und Landwirtschaft: Bonn, Germany, 2015; Volume 58. [Google Scholar]

- Achilles, W.; Brenndörfer, M.; Döhler, H.; Eckel, H.; Eurich-Menden, B.; Frisch, J.; Fritzsche, S.; Froeba, N.; Fuebbeker, A.; Funk, M.; et al. Betriebsplanung Landwirtschaft 2004/2005. KTBL-Datensammlung: Daten für die Betriebsplanung in der Landwirtschaft; Landwirtschaftsvlg Münster: Münster, Germany, 2004. [Google Scholar]

- Frisch, J.; Fritzsche, S.; Fröba, N.; Funk, M.; Gaio, Ch.; Grimm, E.; Grube, J.; Hartmann, S.; Hartmann, W.; Klocpfer, F.; et al. Betriebsplanung Landwirtschaft 2012/2013 KTBL Datensammlung; Kuratorium für Technik und Bauwesen in der Landwirtschaft KTBL: Darmstadt, Germany, 2012; Volume 23. [Google Scholar]

- BMU. Ordinance on the Generation of Electricity from Biomasse (Biomasse Ordinance—BiomasseV) Consolidated Version of the Ordinance in the Version Applicable as of 1 January 2012; BMU: Berlin, Germany, 2012. [Google Scholar]

- ASUE. BHKW-Kenndaten 2011; ASUE Arbeitsgemeinschaft für Sparsamen und Umweltfreundlichen Energieverbrauch e.V.: Berlin, Germany, 2011. [Google Scholar]

- Thrän, D.; Liebetrau, J.; Daniel-Gromke, J.; Jacobi, F. Smart Bioenergy. Technologies and Concepts for a More Flexible Bioenergy Provision in Future Energy Systems; Thrän, D., Ed.; Springer-Verlag: Heidelberg, Germany, 2015. [Google Scholar]

- FNR e.V. Faustzahlen Biogas. Available online: http://biogas.fnr.de/daten-und-fakten/faustzahlen/ (accessed on 16 September 2015).

| Type of Excrement | Dry Matter Content in% |

|---|---|

| Dung cattle | 25 |

| Manure cattle | 4–13 |

| Slurry cattle | 2 |

| Dung pigs | 23–25 |

| Manure pigs | 1.5–12 |

| Slurry pigs | 0.9–2 |

| Livestock and Form of Livestock Farming | Dung/Manure Per Animal in m3/yr |

|---|---|

| Cattle, slatted floors | 11.76/manure |

| Cattle, loose housing stable | 8.3/dung |

| Dairy cattle, slatted floors | 18/manure |

| Dairy cattle, loose housing stable | 14.4/dung |

| Pig (with piglets) | 2.15/dung |

| Pig (with piglets) | 5/manure |

| Pig (pup) | 0.3/dung |

| Pig (pup) | 0.6/manure |

| Pig (fattened pig) | 1.4/dung |

| Pig (fattened pig) | 1.5/manure |

| Substrate | Methane Yield in m3/tFM |

|---|---|

| Cattle dung | 53 |

| Cattle manure | 17 |

| Pig dung | 45 |

| Pig manure | 12 |

| Whole crop silage (rye) | 103 |

| Maize silage | 106 |

| Parameter | Description | Parameterization and Data Source |

|---|---|---|

| kWPOT | Potential of electrical capacity (kW) | Potential of maximum installable electrical power |

| Cf | Farm class | Section 2.1. |

| HUS | Husbandry system | Section 2.1. |

| nAP | Number of animal places | Section 2.1. |

| ṁEAP | Excrement per animal place (in m3/place per year) | Manure or dung per animal place depending on livestock and type of animal husbandry [27] |

| ṁmy ρi | Methane yield (in m3/tFM·per year) | Methane yield per t of fresh mass depending on livestock and type of manure, Section 2.4 |

| NCV | Net calorific value of methane | 36 MJ/m3 |

| fc | Conversion factor | Conversion factor for MJ to kWh (0.2777777) |

| ηel | Electrical efficiency | For chp up to 500 kW of installed power, an average electrical efficiency of 37% is assumed [29] |

| FLH | Full load hours | 8760 h/a, max. for y |

| ρi | Dung/manure density | Dung density depending on livestock: cattle 0.8 t/m3 [22], pigs 0.91 t/m3, manure density 1 t/m3 [23] |

| COSUB | Co-substrate | Maize silage |

| pCOSUB | Share of Co-substrate (in %) | Depending on the scenario, 40% or 60% of Co-substrate maize silage, depending on the mass of manure or dung |

| Farm Type | Main Form of Excrement Produced | Farm Size (Total Number of Animal Places) | Percentage of Total Livestock (Cattle or Pigs) (%) for Manure Production | Farm-Specific Manure Production (m3/yr) | Farm-Specific Biogas Production (m3/a Methane) | Farm-Specific Biogas Plant Capacity (kWel) (Manure and Dung Only) |

|---|---|---|---|---|---|---|

| Pigs with piglets | manure | 1–49 | 0.00% | 156 | 1875 | 0.8 |

| Pigs with piglets | manure | 50–99 | 0.00% | 580 | 6960 | 2.9 |

| Pigs with piglets | manure | 100–399 | 0.49% | 1107 | 13,280 | 5.6 |

| Pigs with piglets | manure | 400–999 | 0.30% | 5538 | 66,450 | 28.1 |

| Pigs with piglets | manure | 1000–1999 | 3.52% | 7863 | 94,354 | 39.9 |

| Pigs with piglets | manure | 2000–4999 | 2.66% | 12,897 | 154,760 | 65.4 |

| Pigs with piglets | manure | more than 5000 | 2.91% | 41,965 | 503,580 | 212.7 |

| Pigs | manure | 1–49 | 0.28% | 12.5 | 150 | 0.1 |

| Pigs | manure | 50–99 | 0.73% | 73.6 | 883 | 0.4 |

| Pigs | manure | 100–399 | 6.67% | 224.3 | 2691 | 1.1 |

| Pigs | manure | 400–999 | 22.22% | 683.0 | 8195 | 3.5 |

| Pigs | manure | 1000–1999 | 27.61% | 1408.1 | 16,898 | 7.1 |

| Pigs | manure | 2000–4999 | 14.86% | 2886.5 | 34,637 | 14.6 |

| Pigs | manure | more than 5000 | 10.31% | 10,359.7 | 124,316 | 52.5 |

| Pigs with piglets | dung | 1–49 | 0.04% | 61 | 2751 | 1.2 |

| Pigs with piglets | dung | 50–99 | 0.04% | 227 | 10,213 | 4.3 |

| Pigs with piglets | dung | 100–399 | 0.45% | 433 | 19,487 | 8.2 |

| Pigs with piglets | dung | 400–999 | 0.48% | 2167 | 97,507 | 41.2 |

| Pigs with piglets | dung | 1000–1999 | 0.36% | 3077 | 138,453 | 58.5 |

| Pigs with piglets | dung | 2000–4999 | 0.07% | 5046 | 227,091 | 95.9 |

| Pigs with piglets | dung | more than 5000 | 0.05% | 16,421 | 738,941 | 312.1 |

| Pigs | dung | 1–49 | 0.83% | 9 | 413 | 0.2 |

| Pigs | dung | 50–99 | 0.65% | 54 | 2440 | 1.0 |

| Pigs | dung | 100–399 | 1.81% | 165 | 7435 | 3.1 |

| Pigs | dung | 400–999 | 1.58% | 503 | 22,640 | 9.6 |

| Pigs | dung | 1000–1999 | 0.72% | 1037 | 46,680 | 19.7 |

| Pigs | dung | 2000–4999 | 0.25% | 2126 | 95,686 | 40.4 |

| Pigs | dung | more than 5000 | 0.12% | 7632 | 343,422 | 145.1 |

| Dairy cattle | manure | 1 to 9 | 0.1% | 95 | 1613 | 0.7 |

| Dairy cattle | manure | 10 to 19 | 0.8% | 205 | 3493 | 1.5 |

| Dairy cattle | manure | 20 to 49 | 6.5% | 568 | 9648 | 4.1 |

| Dairy cattle | manure | 50 to 99 | 9.6% | 1206.9 | 20,517 | 8.7 |

| Dairy cattle | manure | 100 to 199 | 5.1% | 2313.0 | 39,321 | 16.6 |

| Dairy cattle | manure | 200 to 499 | 2.5% | 5267.6 | 89,550 | 37.8 |

| Dairy cattle | manure | 500 and more | 2.8% | 14,376.0 | 244,392 | 103.2 |

| Cattle | manure | 1 to 9 | 0.1% | 64.0 | 1088 | 0.5 |

| Cattle | manure | 10 to 19 | 0.6% | 162.3 | 2759 | 1.2 |

| Cattle | manure | 20 to 49 | 4.7% | 374.3 | 6362 | 2.7 |

| Cattle | manure | 50 to 99 | 9.8% | 803.7 | 13,663 | 5.8 |

| Cattle | manure | 100 to 199 | 9.7% | 1561.7 | 26,549 | 11.2 |

| Cattle | manure | 200 to 499 | 6.3% | 3292.4 | 55,971 | 23.6 |

| Cattle | manure | 500 and more | 3.8% | 12,695.9 | 215,830 | 91.2 |

| Dairy cattle | dung | 1 to 9 | 0.3% | 60.7 | 3218 | 1.4 |

| Dairy cattle | dung | 10 to 19 | 0.8% | 164.4 | 8712 | 3.7 |

| Dairy cattle | dung | 20 to 49 | 1.9% | 363.2 | 19,251 | 8.1 |

| Dairy cattle | dung | 50 to 99 | 1.1% | 772.4 | 40,937 | 17.3 |

| Dairy cattle | dung | 100 to 199 | 0.7% | 1480.3 | 78,457 | 33.1 |

| Dairy cattle | dung | 200 to 499 | 1.0% | 3371.3 | 178,679 | 75.5 |

| Dairy cattle | dung | 500 and more | 0.6% | 9200.6 | 487,634 | 206.0 |

| Cattle | dung | 1 to 9 | 0.5% | 36.1 | 1915 | 0.8 |

| Cattle | dung | 10 to 19 | 1.6% | 91.6 | 4856 | 2.1 |

| Cattle | dung | 20 to 49 | 5.0% | 211.3 | 11,200 | 4.7 |

| Cattle | dung | 50 to 99 | 6.0% | 453.8 | 24,051 | 10.2 |

| Cattle | dung | 100 to 199 | 5.4% | 881.8 | 46,735 | 19.7 |

| Cattle | dung | 200 to 499 | 4.5% | 1859.0 | 98,525 | 41.6 |

| Cattle | dung | 500 and more | 3.9% | 7168.4 | 379,927 | 160.5 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scheftelowitz, M.; Thrän, D. Unlocking the Energy Potential of Manure—An Assessment of the Biogas Production Potential at the Farm Level in Germany. Agriculture 2016, 6, 20. https://doi.org/10.3390/agriculture6020020

Scheftelowitz M, Thrän D. Unlocking the Energy Potential of Manure—An Assessment of the Biogas Production Potential at the Farm Level in Germany. Agriculture. 2016; 6(2):20. https://doi.org/10.3390/agriculture6020020

Chicago/Turabian StyleScheftelowitz, Mattes, and Daniela Thrän. 2016. "Unlocking the Energy Potential of Manure—An Assessment of the Biogas Production Potential at the Farm Level in Germany" Agriculture 6, no. 2: 20. https://doi.org/10.3390/agriculture6020020