Vertical Distribution of Structural Components in Corn Stover

Abstract

:1. Introduction

2. Results and Discussion

| Location | Soil and Series | Hybrid/Relative Maturity | Average Ear Height a (cm) | Average Grain Yield a (Dry Mg·ha−1) | Growth Stage Sampled | |

|---|---|---|---|---|---|---|

| Physiological Maturity | Grain Harvest | |||||

| Fort Collins, CO | Fort Collins clay loam | Pioneer 39B77BtLL/88 day | 110 | 10.62 | Yes | Yes |

| Lincoln, NE | Aksarben silty clay loam | DeKalb 61-69/110 day | 108 | 11.74 | Yes | Yes |

| Mandan, ND | Temvik-Wilton silt loam | Legend LR9385RR/85 day | 77 | 6.55 | Yes | Yes |

| Legend LR9779RR/77 day | 75 | 6.55 | Yes | Yes | ||

| Morris, MN | Barnes clay loam | Cropland 296TS MF-B7/92 day | 93 | 8.70 | Yes | Yes |

| St. Paul, MN | Waukegan silt loam | Dekalb DKC 50-20/100 day | 98 | 8.75 | Yes | Yes |

2.1. Corn Stover Composition

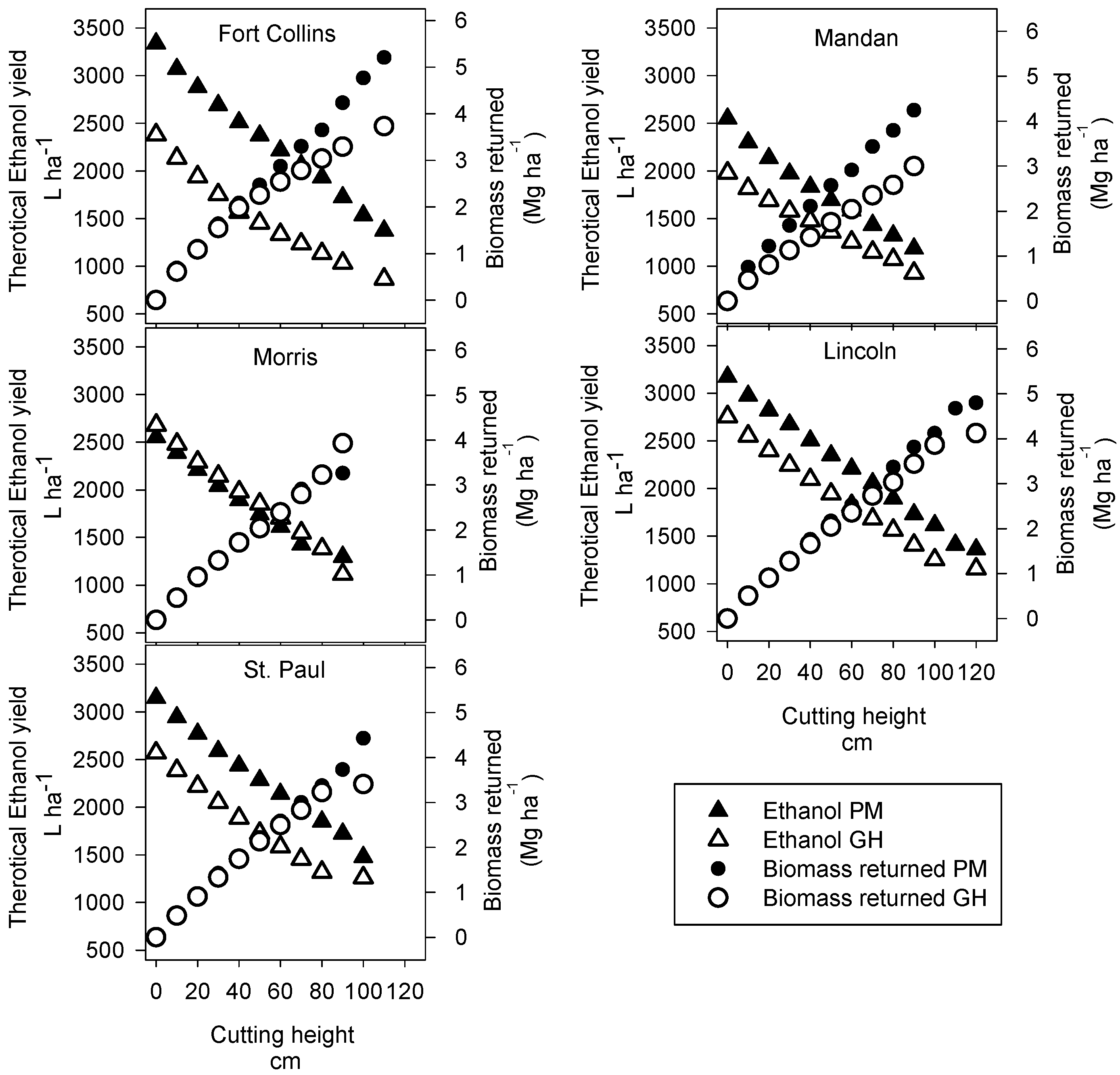

2.2. Theoretical Ethanol Yield

2.3. Thermochemical Feedstock Qualities

| Proximate | Ultimate | Calorimeter | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Volatile matter | Ash | Fixed C | H | C | N | O | S | HHV a | |

| mg·kg−1 | MJ·kg−1 | ||||||||

| Above the Ear | 727 ± 6.9 | 71 ± 6.6 | 150 ± 2.4 | 60 ± 0.32 | 425 ± 2.8 | 7.67 ± 0.48 | 435 ± 4.5 | 0.54 ± 0.01 | 16.54 ± 0.25 |

| Below the Ear | 728 ± 3.3 | 67 ± 2.1 | 151 ± 2.0 | 61 ± 0.16 | 430 ± 1.0 | 4.81 ± 0.25 | 437 ± 1.5 | 0.37 ±0.03 | 16.87 ± 0.10 |

3. Experimental Section

3.1. Compositional Analysis—Fourier Transform Near-Infrared (FT-NIR) Spectroscopy

3.2. Thermochemical Properties

3.3. Statistical Analysis

4. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Johnson, J.M.F.; Coleman, M.D.; Gesch, R.W.; Jaradat, A.A.; Mitchell, R.; Reicosky, D.C.; Wilhelm, W.W. Biomass-bioenergy crops in the united states: A changing paradigm. Amer J. Plant Sci. Biotechnol. 2007, 1, 1–28. [Google Scholar]

- Xie, H.; Shen, H.; Gong, Z.; Wang, Q.; Zhao, Z.K.; Bai, F. Enzymatic hydrolysates of corn stover pretreated by a n-methylpyrrolidone-ionic liquid solution for microbial lipid production. Green Chem. 2012, 14, 1202–1210. [Google Scholar] [CrossRef]

- Spatari, S.; Bagley, D.M.; MacLean, H.L. Life cycle evaluation of emerging lignocellulosic ethanol conversion technologies. Bioresour. Technol. 2010, 101, 654–667. [Google Scholar] [CrossRef] [PubMed]

- Archer, D.; Johnson, J. Evaluating local crop residue biomass supply: Economic and environmental impacts. BioEnergy Res. 2012, 5, 699–712. [Google Scholar] [CrossRef]

- Jaradat, A.A.; Johnson, J.M.-F.; Weyers, S.L.; Barbour, N.W. Determinants and prediction of carbon/nitrogen ratio in five diverse crop plants. Commun. Soil Sci. Plant Anal. 2009, 40, 2688–2711. [Google Scholar] [CrossRef]

- Johnson, J.M.F.; Barbour, N.W.; Weyers, S.L. Chemical composition of crop biomass impacts its decomposition. Soil Sci. Soc. Am. J. 2007, 71, 155–162. [Google Scholar] [CrossRef]

- Van Soest, P.J.; Wine, R.H. Determination of lignin and cellulose in acid-detergent fiber with permanganate. J. Off. Assoc. Anal. Chem. 1968, 51, 780–785. [Google Scholar]

- Lorenz, A.J.; Coors, J.G.; de Leon, N.; Wolfrum, E.J.; Hames, B.R.; Sluiter, A.D.; Weimer, P.J. Characterization, genetic variation, and combining ability of maize traits relevant to the production of cellulosic ethanol. Crop. Sci. 2009, 49, 85–98. [Google Scholar] [CrossRef]

- Bootsma, J.; Shanks, B. Hydrolysis characteristics of tissue fractions resulting from mechanical separation of corn stover. Appl. Biochem. Biotechnol. 2005, 125, 27–39. [Google Scholar] [CrossRef] [PubMed]

- Akin, D.; Morrison, W.H., III; Rigsby, L.; Barton, F., II; Himmelsbach, D.; Hicks, K. Corn stover fractions and bioenergy. Appl. Biochem. Biotechnol. 2006, 129, 104–116. [Google Scholar] [CrossRef]

- Hoskinson, R.L.; Karlen, D.L.; Birrell, S.J.; Radtke, C.W.; Wilhelm, W.W. Engineering, nutrient removal, and feedstock conversion evaluations of four corn stover harvest scenarios. Biomass Bioenerg. 2007, 31, 126–136. [Google Scholar] [CrossRef]

- Monono, E.M.; Haagenson, D.M.; Pryor, S.W. Developing and evaluating NIR calibration models for multi-species herbaceous perennials. Ind. Biotechnol. 2012, 8, 285–292. [Google Scholar] [CrossRef]

- Hou, S.; Li, L. Rapid characterization of woody biomass digestibility and chemical composition using near-infrared spectroscopy. J. Integr. Plant. Biol. 2011, 53, 166–175. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.P.; Ye, X.P.; Womac, A.R.; Sokhansanj, S. Variability of biomass chemical composition and rapid analysis using FT-NIR techniques. Carbohydr. Polym. 2010, 81, 820–829. [Google Scholar] [CrossRef]

- Johnson, J.M.F.; Wilhelm, W.W.; Karlen, D.L.; Archer, D.W.; Wienhold, B.; Lightle, D.; Laird, D.A.; Baker, J.; Ochsner, T.E.; Novak, J.M.; et al. Nutrient removal as a function of corn stover cutting height and cob harvest. BioEnergy Res. 2010, 3, 342–352. [Google Scholar] [CrossRef]

- Wilhelm, W.W.; Johnson, J.M.F.; Lightle, D.T.; Karlen, D.L.; Novak, J.M.; Barbour, N.W.; Laird, D.A.; Baker, J.; Ochsner, T.E.; Halvorson, A.D.; et al. Vertical distribution of corn stover dry mass grown at several US locations. BioEnergy Res. 2011, 4, 11–21. [Google Scholar] [CrossRef]

- Mourtzinis, S.; Cantrell, K.B.; Arriaga, F.J.; Balkcom, K.S.; Novak, J.M.; Frederick, J.R.; Karlen, D.L. Distribution of structural carbohydrates in corn plants across the Southeastern USA. BioEnergy Res. 2014, 7, 551–558. [Google Scholar] [CrossRef]

- U.S. Department of Energy Bioenergy Technologies Office. Theoretical Ethanol Yield Calculator. Available online: http://www1.eere.energy.gov/bioenergy/printable_versions/ethanol_yield_calculator.html (accessed on 7 February 2014).

- Johnson, J.M.F.; Novak, J.M.; Varvel, G.E.; Stott, D.E.; Osborne, S.L.; Karlen, D.L.; Lamb, J.A.; Baker, J.; Adler, P.R. Crop residue mass needed to maintain soil organic carbon levels: Can it be determined? BioEnergy Res. 2014, 7, 481–490. [Google Scholar] [CrossRef]

- Bonner, I.J.; Muth, D.J., Jr.; Koch, J.B.; Karlen, D.L. Modeled impacts of cover crops and vegetative barriers on corn stover availability and soil quality. BioEnergy Res. 2014, 7, 576–589. [Google Scholar] [CrossRef]

- Muth, D.J.; Koch, J.B.; McCorkle, D.S.; Bryden, K.M. Modeling sustainable agricultural residue removal at the subfield scale. Agron. J. 2012, 104, 970–981. [Google Scholar] [CrossRef]

- Halvorson, A.D.; Johnson, J.M.F. Corn cob characteristics in irrigated central Great Plains studies. Agron. J. 2009, 101, 390–399. [Google Scholar] [CrossRef]

- Demirbas, A. Calculation of higher heating values of biomass fuels. Fuel 1997, 76, 431–434. [Google Scholar] [CrossRef]

- Tortosa Masiá, A.A.; Buhre, B.J.P.; Gupta, R.P.; Wall, T.F. Characterising ash of biomass and waste. Fuel Process. Technol. 2007, 88, 1071–1081. [Google Scholar] [CrossRef]

- Cantrell, K.B.; Novak, J.M.; Frederick, J.R.; Karlen, D.L.; Watts, D.W. Influence of corn residue harvest management on grain, stover, and energy yields. BioEnergy Res. 2014, 7, 590–597. [Google Scholar] [CrossRef]

- Johnson, J.M.F.; Gresham, G.L. Do yield and quality of big bluestem and switchgrass feedstock decline over winter? BioEnergy Res. 2014, 7, 68–77. [Google Scholar] [CrossRef]

- Biomass Gasification: A Comprehensive Demonstration of a Community Scale Biomass Energy System, USDA Final Report. Available online: http://renewables.morris.umn.edu/biomass/documents/USDA_Report/USDA_Main_Report.pdf (accessed on 12 November 2014).

- Yu, F.; Ruan, R.; Steele, P. Consecutive reaction model for the pyrolysis of corn cob. Trans. ASABE 2008, 51, 1023–1028. [Google Scholar] [CrossRef]

- Sluiter, J.B.; Ruiz, R.O.; Scarlata, C.J.; Sluiter, A.D.; Templeton, D.W. Compositional analysis of lignocellulosic feedstocks. 1. Review and description of methods. J. Agric. Food Chem. 2010, 58, 9043–9053. [Google Scholar] [CrossRef] [PubMed]

- Wolfrum, E.J.; Sluiter, A.D. Improved multivariate calibration models for corn stover feedstock and dilute-acid pretreated corn stover. Cellulose 2009, 16, 567–576. [Google Scholar] [CrossRef]

- De Vries, S.; Ter Braak, C.J.F. Prediction error in partial least squares regression: A critique on the deviation used in the Unscrambler. Chemom. Intell. Lab. Syst. 1995, 30, 239–245. [Google Scholar] [CrossRef]

- CAMO Software AS The Unscrambler appendices: Method references. Available online: http://www.camo.com/downloads/U9.6%20pdf%20manual/The%20Unscrambler%20Method%20References.pdf (accessed on 23 September 2014).

- American Society for Testing and Materials. Standard Test Method for Proximate Analysis of the Analysis Sample of Coal and Coke by Instrumental Procedures; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- American Society for Testing and Materials. Standard Test Methods for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Laboratory Samples of Coal and Coke; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- American Society for Testing and Materials. Standard Test Method for Sulfur in the Analysis Sample of Coal and Coke Using High-Temperature Tube Furnace Combustion; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- American Society for Testing and Materials. Standard Test Method for Gross Calorific Value of Coal and Coke; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- SAS Institute. SAS System for Windows, Release 9.2; SAS Institute: Cary, NC, USA, 2009. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Johnson, J.M.F.; Karlen, D.L.; Gresham, G.L.; Cantrell, K.B.; Archer, D.W.; Wienhold, B.J.; Varvel, G.E.; Laird, D.A.; Baker, J.; Ochsner, T.E.; et al. Vertical Distribution of Structural Components in Corn Stover. Agriculture 2014, 4, 274-287. https://doi.org/10.3390/agriculture4040274

Johnson JMF, Karlen DL, Gresham GL, Cantrell KB, Archer DW, Wienhold BJ, Varvel GE, Laird DA, Baker J, Ochsner TE, et al. Vertical Distribution of Structural Components in Corn Stover. Agriculture. 2014; 4(4):274-287. https://doi.org/10.3390/agriculture4040274

Chicago/Turabian StyleJohnson, Jane M. F., Douglas L. Karlen, Garold L. Gresham, Keri B. Cantrell, David W. Archer, Brian J. Wienhold, Gary E. Varvel, David A. Laird, John Baker, Tyson E. Ochsner, and et al. 2014. "Vertical Distribution of Structural Components in Corn Stover" Agriculture 4, no. 4: 274-287. https://doi.org/10.3390/agriculture4040274