Fault Detection of Stator Inter-Turn Short-Circuit in PMSM on Stator Current and Vibration Signal

Abstract

:1. Introduction

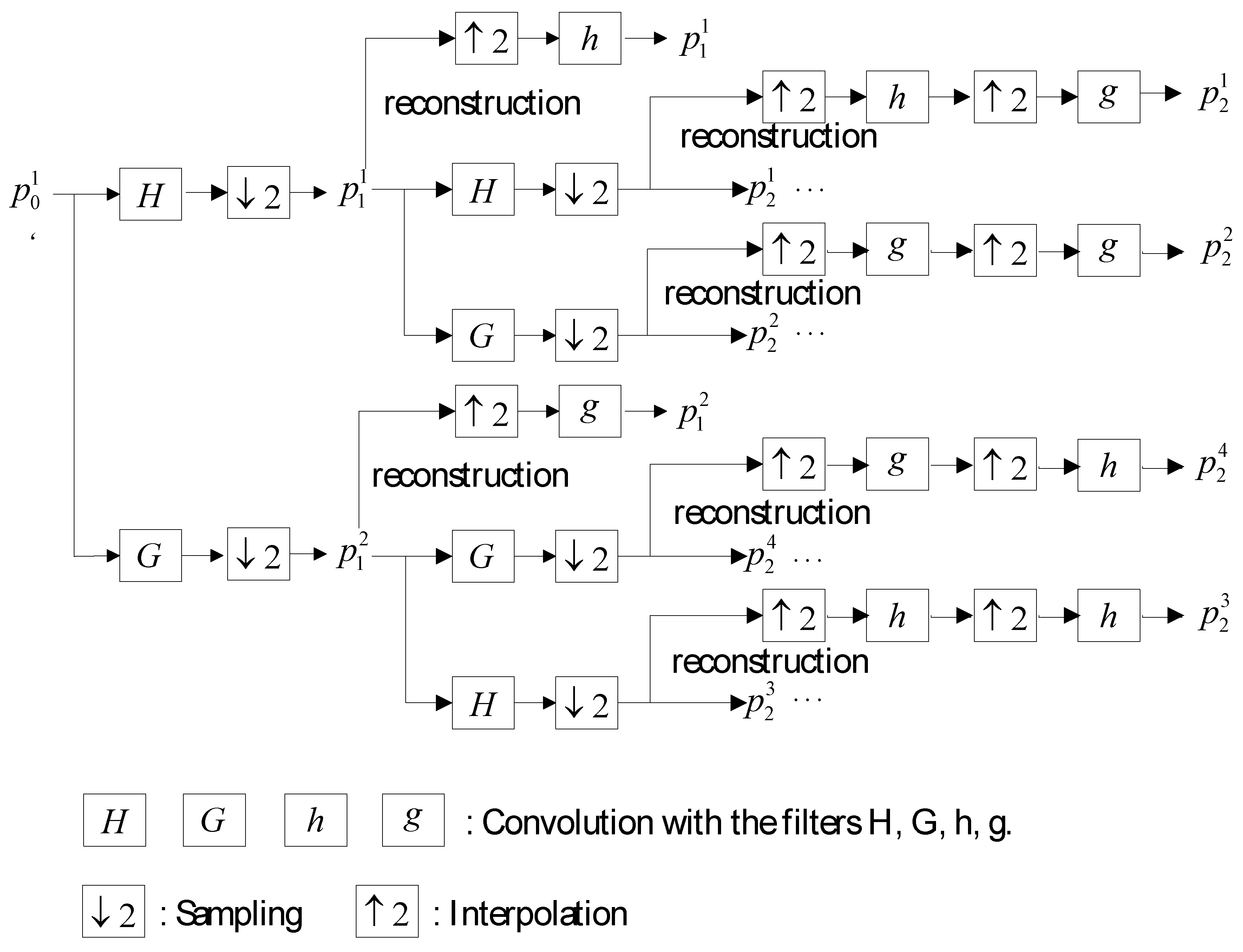

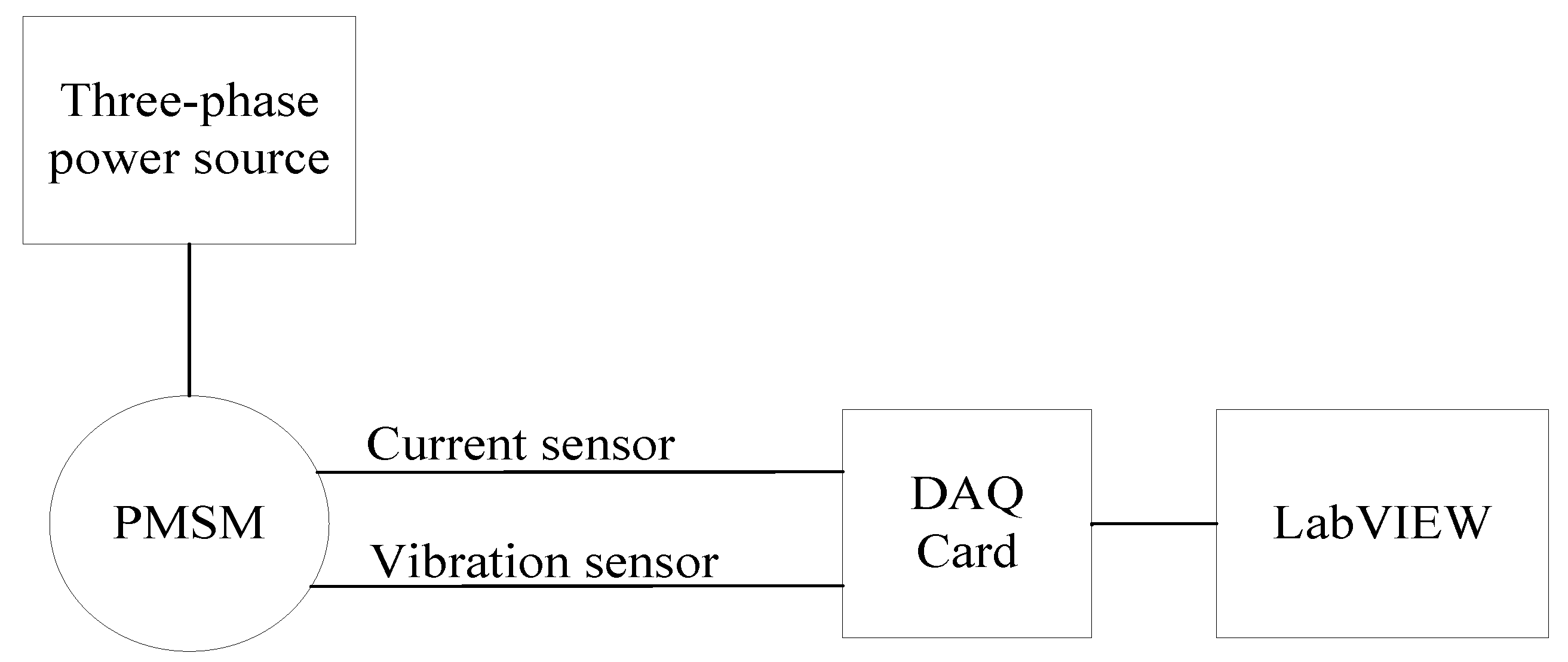

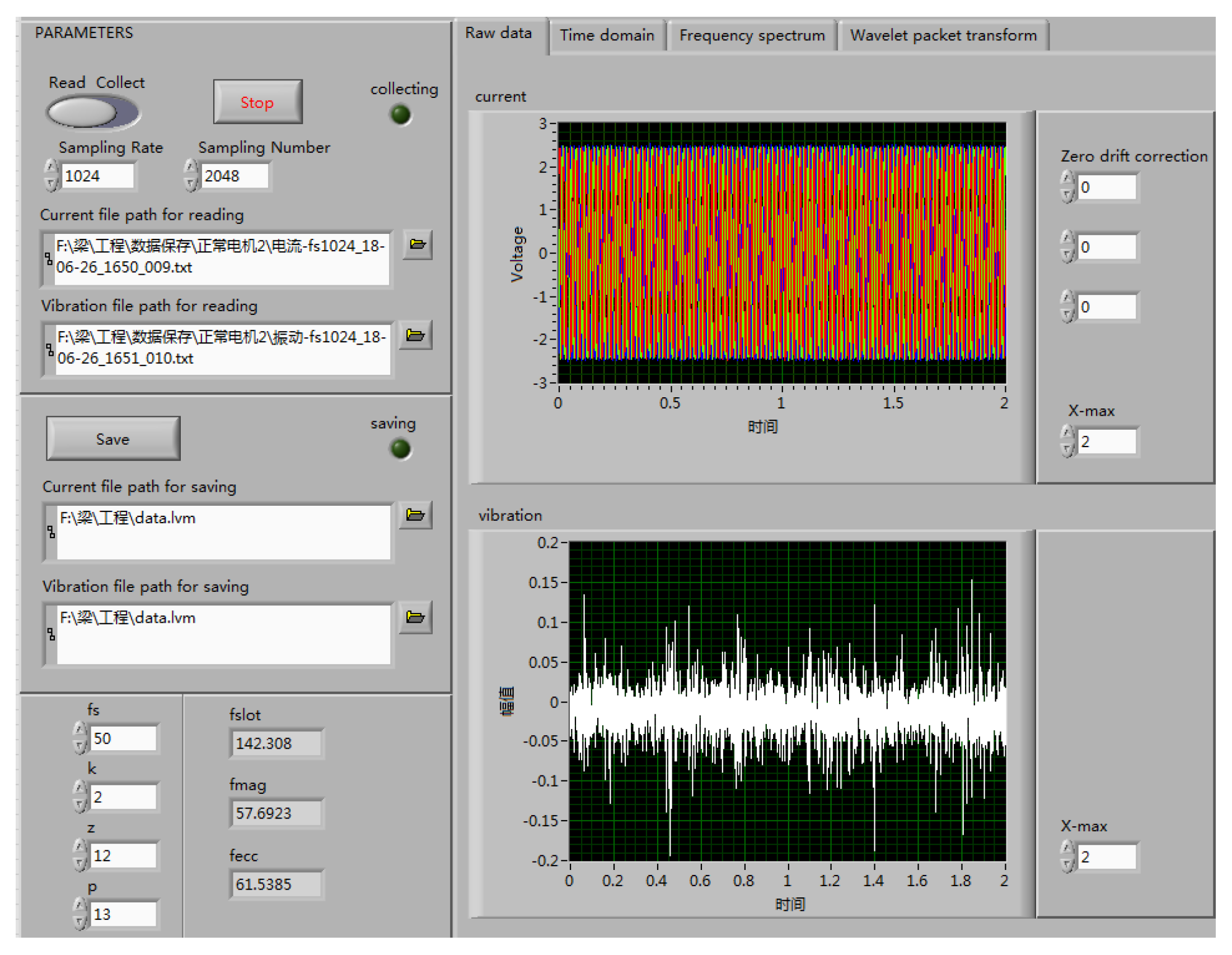

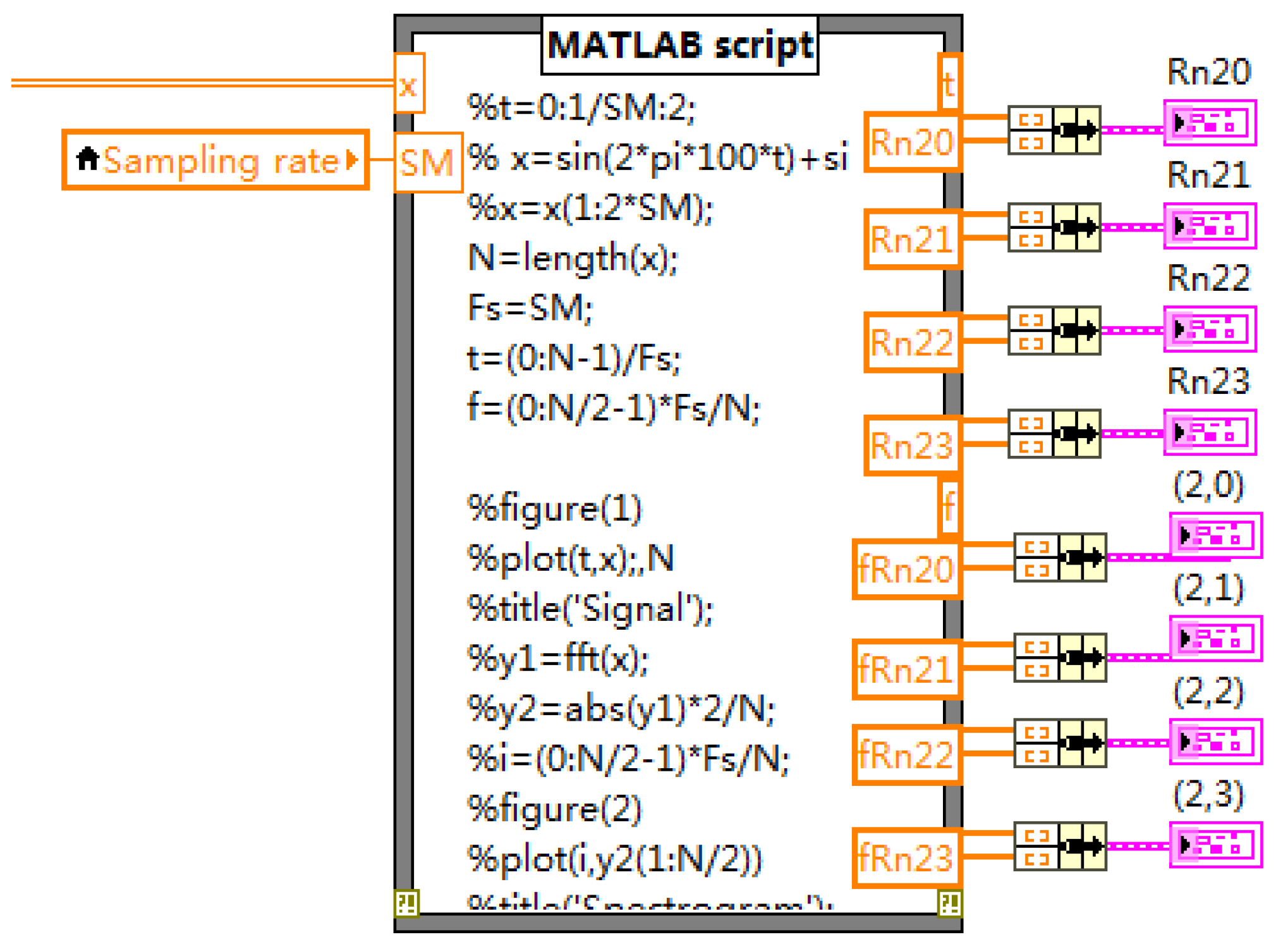

2. Materials and Methods

3. Results

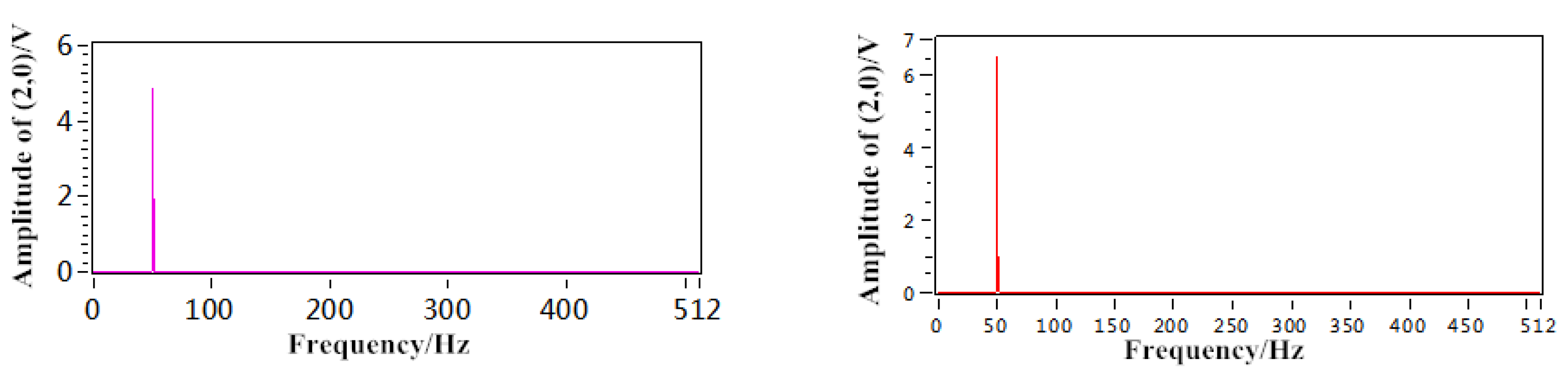

3.1. Current Signal

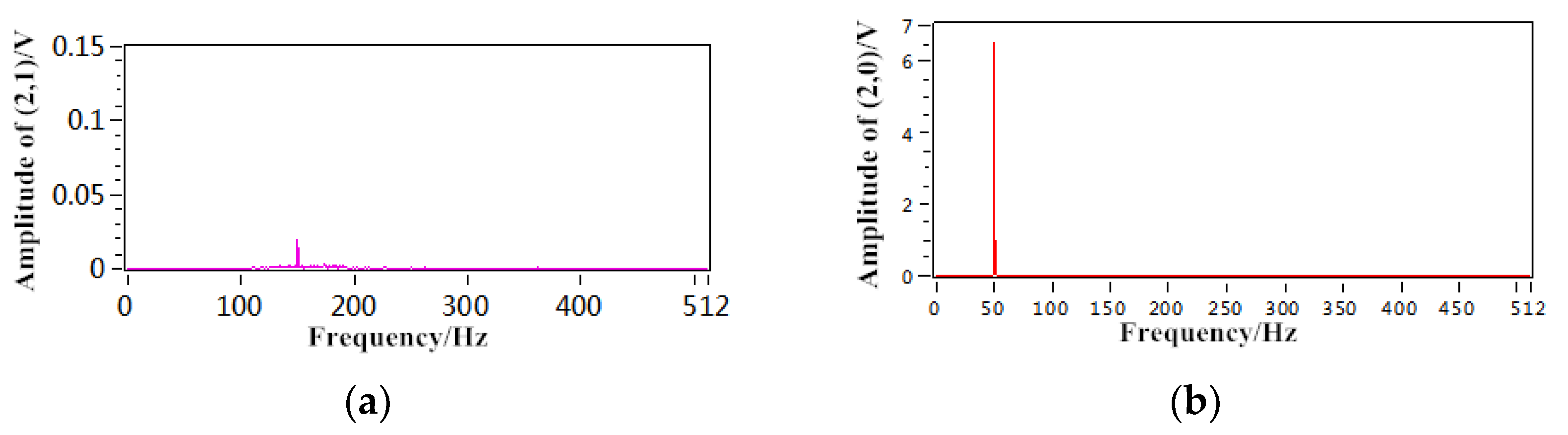

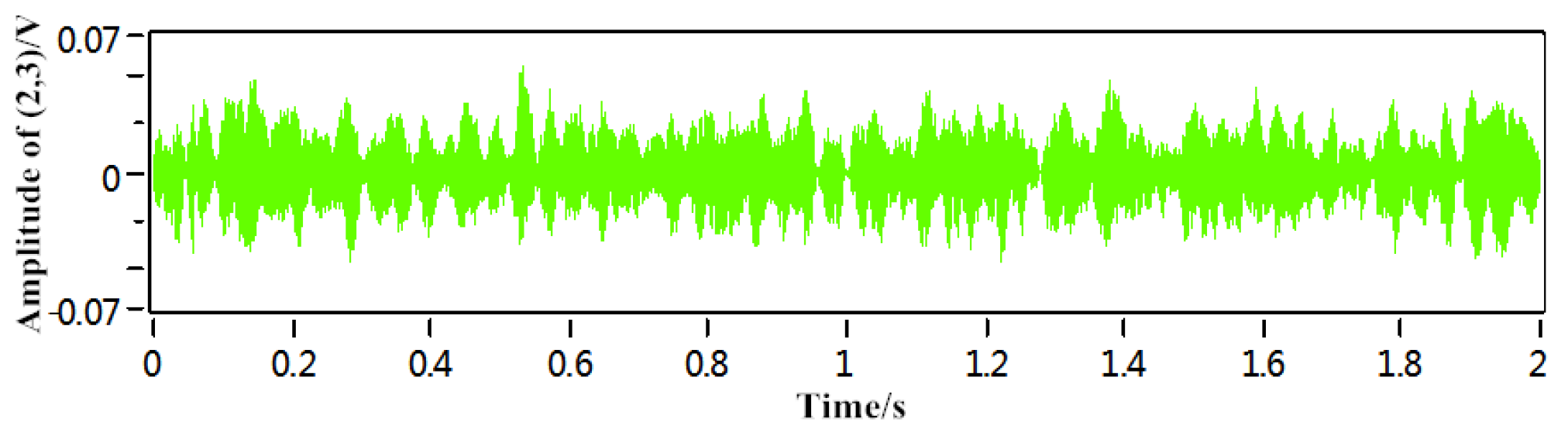

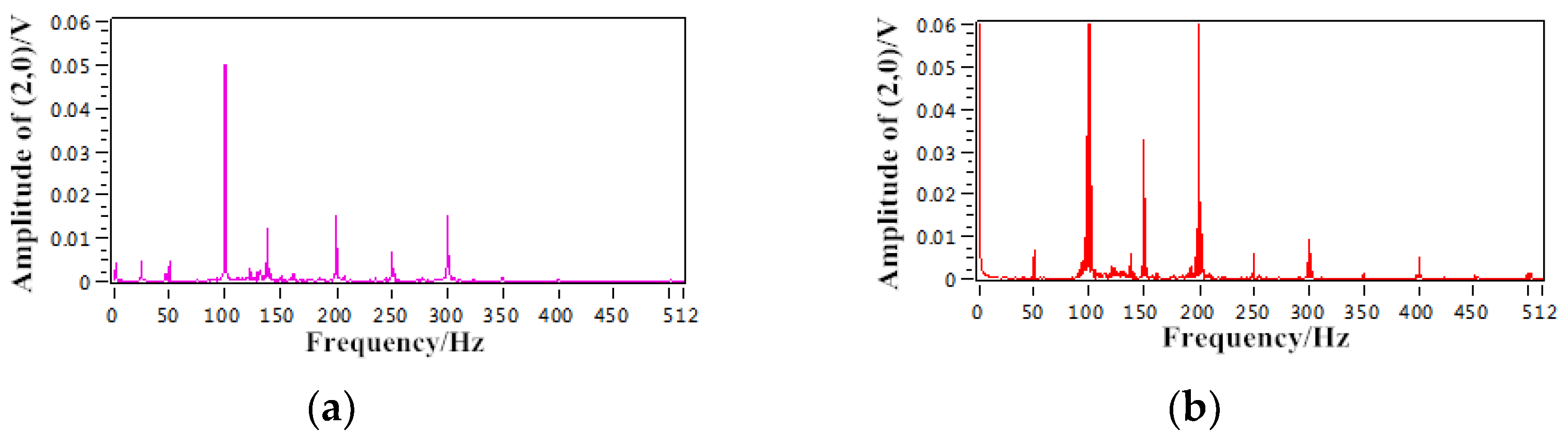

3.2. Vibration Signal

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mazzoletti, M.A.; Bossio, G.R.; Angelo, C.H.D.; Espinoza-Trejo, D.R. A Model-Based Strategy for Interturn Short-Circuit Fault Diagnosis in PMSM. IEEE Trans. Ind. Electron 2017, 64, 7218–7228. [Google Scholar] [CrossRef]

- Wang, Z.F.; Yang, J.; Ye, H.; Zhou, W. A review of Permanent Magnet Synchronous Motor fault diagnosis. In Proceedings of the IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–5. [Google Scholar]

- Maraaba, L. An Efficient Stator Inter-Turn Fault Diagnosis Tool for Induction Motors. Energies 2018, 11, 653. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, Y.; Hu, C.; Peng, Z. Recent progress on decoupling diagnosis of hybrid failures in gear transmission systems using vibration sensor signal: A review. Measurement 2016, 90, 4–19. [Google Scholar] [CrossRef]

- Glowacz, A. Fault diagnostics of acoustic signals of loaded synchronous motor using SMOFS-25-EXPANDED and selected classifiers. The. Vjesn. Tech. Gaz. 2016, 23, 1365–1372. [Google Scholar]

- Krolczyk, G.M.; Krolczyk, J.B.; Legutko, S.; Hunjet, A. Effect of the disc processing technology on the vibration level of the chipper during operations. The. Vjesn. Tech. Gaz. 2014, 21, 447–450. [Google Scholar]

- Glowacz, A.; Glowacz, W.; Glowacz, Z. Recognition of armature current of DC generator depending on rotor speed using FFT, MSAF-1 and LDA. Eksploat. i Niezawodn. Maint. Reliab. 2015, 17, 64–69. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhu, H.; Li, Z. A new compound faults detection method for rolling bearings based on empirical wavelet transform and chaotic oscillator. Chaos, Solitons Fractals 2016, 89, 8–19. [Google Scholar] [CrossRef]

- Stavrou, A.; Sedding, H.G.; Penman, J. Current monitoring for detecting inter-turn short circuits in induction motors. IEEE Trans. Enrgye Convers. 2001, 16, 32–37. [Google Scholar] [CrossRef]

- Henao, H.; Demian, C.; Capolino, G.A.A. Frequency-domain detection of stator winding faults in induction machines using an external flux sensor. IEEE Trans. Ind. Appl. 2003, 39, 1272–1279. [Google Scholar] [CrossRef]

- Sdiri, F.; Bensalem, Y.; Trabelsi, H.; Abdelkrim, M.N. Inter-turn short-circuit fault detection in the vectorial control PMSM drive. In Proceedings of the 2017 18th International Conference on Sciences and Techniques of Automatic Control and Computer Engineering (STA), Monastir, Tunisia, 21–23 December 2017; pp. 362–367. [Google Scholar]

- Zheng, A.P.; Yang, J.; Wang, L. Fault Detection of Stator Winding Interturn Short Circuit in PMSM Based on Wavelet Packet Analysis. In Proceedings of the 2013 Fifth International Conference on Measuring Technology and Mechatronics Automation, Hong Kong, China, 16–17 January 2013; pp. 566–569. [Google Scholar]

- Çira, F.; Arkan, M.; Gümüş, B.; Goktas, T. Analysis of stator inter-turn short-circuit fault signatures for inverter-fed permanent magnet synchronous motors. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 1453–1457. [Google Scholar]

- Zajac, M.; Sulowicz, M. Wavelet detectors for extraction of characteristic features of induction motor rotor faults. In Proceedings of the 2016 International Conference on Signals and Electronic Systems (ICSES), Krakow, Poland, 5–7 September 2016; pp. 212–218. [Google Scholar]

- Moosavi, S.S.; Esmaili, Q.; Djerdir, A.; Amirat, Y.A. Inter-Turn Fault Detection in Stator Winding of PMSM Using Wavelet Transform. In Proceedings of the 2017 IEEE Vehicle Power and Propulsion Conference (VPPC), Belfort, France, 11–14 December 2017; pp. 1–5. [Google Scholar]

- Obeid, N.H.; Boileau, T.; Nahid-Mobarakeh, B. Modeling and diagnostic of incipient inter-turn faults for a three phase permanent magnet synchronous motor using wavelet transform. In Proceedings of the 2015 IEEE Industry Applications Society Annual Meeting, Addison, TX, USA, 18–22 October 2015; pp. 1–8. [Google Scholar]

- Saucedo-Dorantes, J.J.; Delgado-Prieto, M.; Ortega-Redondo, J.A.; Osornio-Rios, R.A.; Romero-Troncoso, R.D.J. Multiple-Fault Detection Methodology Based on Vibration and Current Analysis Applied to Bearings in Induction Motors and Gearboxes on the Kinematic Chain. Shock Vib. 2016, 2016, 1–13. [Google Scholar] [CrossRef]

- Liang, Y. Diagnosis of inter-turn short-circuit stator winding fault in PMSM based on stator current and noise. In Proceedings of the 2014 IEEE International Conference on Industrial Technology (ICIT), Busan, South Korea, 26 February–1 March 2014; pp. 138–142. [Google Scholar]

- Li, Y.; Liang, Y. The correlation analysis of PM inter-turn fault based on stator current and vibration signal. In Proceedings of the 2015 IEEE International Conference on Mechatronics and Automation (ICMA), Beijing, China, 2–5 August 2015; pp. 1733–1737. [Google Scholar]

- Urresty, J.; Riba, J.; Romeral, L.; Rosero, J.; Serna, J. Stator short circuits detection in PMSM by means of Hilbert-Huang transform and energy calculation. In Proceedings of the 2009 IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cargese, France, 31 August–3 September 2009; pp. 1–7. [Google Scholar]

- Cruz, S.M.A.; Cardoso, A.J.M. Diagnosis of stator inter-turn short circuits in DTC induction motor drives. IEEE Trans. Ind. Appl. 2004, 40, 1349–1360. [Google Scholar] [CrossRef]

- Nandi, S.A. Detailed model of induction machines with saturation extendable for fault analysis. IEEE Trans. Ind. Appl. 2004, 40, 302–1309. [Google Scholar] [CrossRef]

- Ye, Z.M.; Wu, B. A review on induction motor online fault diagnosis. In Proceedings of the 2000 third International Power Electronics and Motion Control Conference, Beijing, China, 15–18 August 2000; pp. 1353–1358. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, H.; Chen, Y.; Liang, S.; Wang, C. Fault Detection of Stator Inter-Turn Short-Circuit in PMSM on Stator Current and Vibration Signal. Appl. Sci. 2018, 8, 1677. https://doi.org/10.3390/app8091677

Liang H, Chen Y, Liang S, Wang C. Fault Detection of Stator Inter-Turn Short-Circuit in PMSM on Stator Current and Vibration Signal. Applied Sciences. 2018; 8(9):1677. https://doi.org/10.3390/app8091677

Chicago/Turabian StyleLiang, Hong, Yong Chen, Siyuan Liang, and Chengdong Wang. 2018. "Fault Detection of Stator Inter-Turn Short-Circuit in PMSM on Stator Current and Vibration Signal" Applied Sciences 8, no. 9: 1677. https://doi.org/10.3390/app8091677