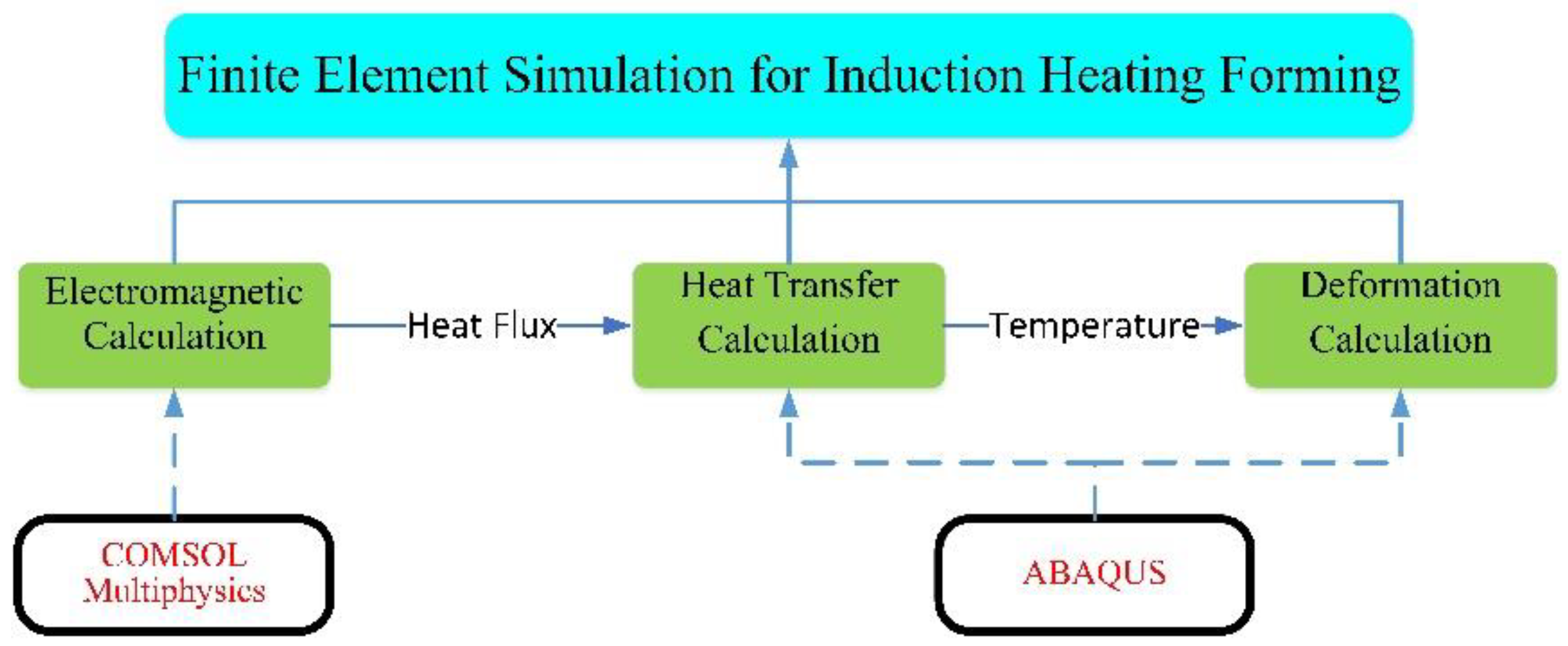

2.1. Finite Element Method Calculation

The entire calculation process is divided into three steps: electromagnetic calculation, heat transfer calculation and deformation calculation. The electromagnetic calculation is to obtain the heat flux distribution of the induction coil under specific conditions. COMSOL Multiphysics (Version 5.2, COMSOL Co., Ltd., Stockholm, Sweden) is used in this step to simulate the heat flux density along the two directions of the induction coil. The heat flux distribution calculated is then used as an input during heat transfer calculation in order to obtain the temperature field of the plate. The deformation calculation is to calculate the mechanical response of the plate under a specific temperature field. ABAQUS (Version 6.13-4, Dassault Systèmes, Vélizy-Villacoublay, France) is used during the last two steps. The overall process is illustrated in

Figure 1.

The induction heating frequency used for ship hull forming is usually 8–50 kHz. When current flows through an inductor that is near a steel workpiece, an eddy current is induced at the surface of the plate. Induction heat is generated in the plate.

The eddy current during induction heating can be given by Maxwell’s equations in the frequency domain as [

12]:

where

stands for permeability,

is the magnetic vector potential,

is the angular velocity,

is the electric conductivity and

is the external current. The magnetic vector potential

can be obtained from Equation (1) when the external current

is given.

The resistance heat generated by the eddy current in the plate can be obtained as follows:

where

refers to eddy current density and can be described as

.

For induction heating, the eddy current generated inside the steel plate is mainly concentrated on the plate surface. For a plate during induction heating, the heat flux can be considered as a surface heat source and obtained as follows:

where

refers to the heat flux on the surface of the steel plate and

denotes the plate thickness.

The heat flux calculated before is used as the initial input for thermal analysis. The heat flow in a plate can be expressed as follows:

where

refers to density,

is the specific heat capacity,

is the temperature of the plate and

is the thermal conductivity. Thermal deformation calculation is followed after the temperature field, which is treated as the thermal load obtained from Equation (4).

The basic equations related to mechanical analysis are considered as follows:

where

refers to stress tensor and

represents the body force.

The stress–strain relationship can be expressed as:

where

refers to the stress increment,

is the elastoplastic matrix,

is the strain increment,

is the thermal stiffness matrix and

is the temperature increment. Deformation of the plate can be obtained by solving the equations under actual boundary conditions.

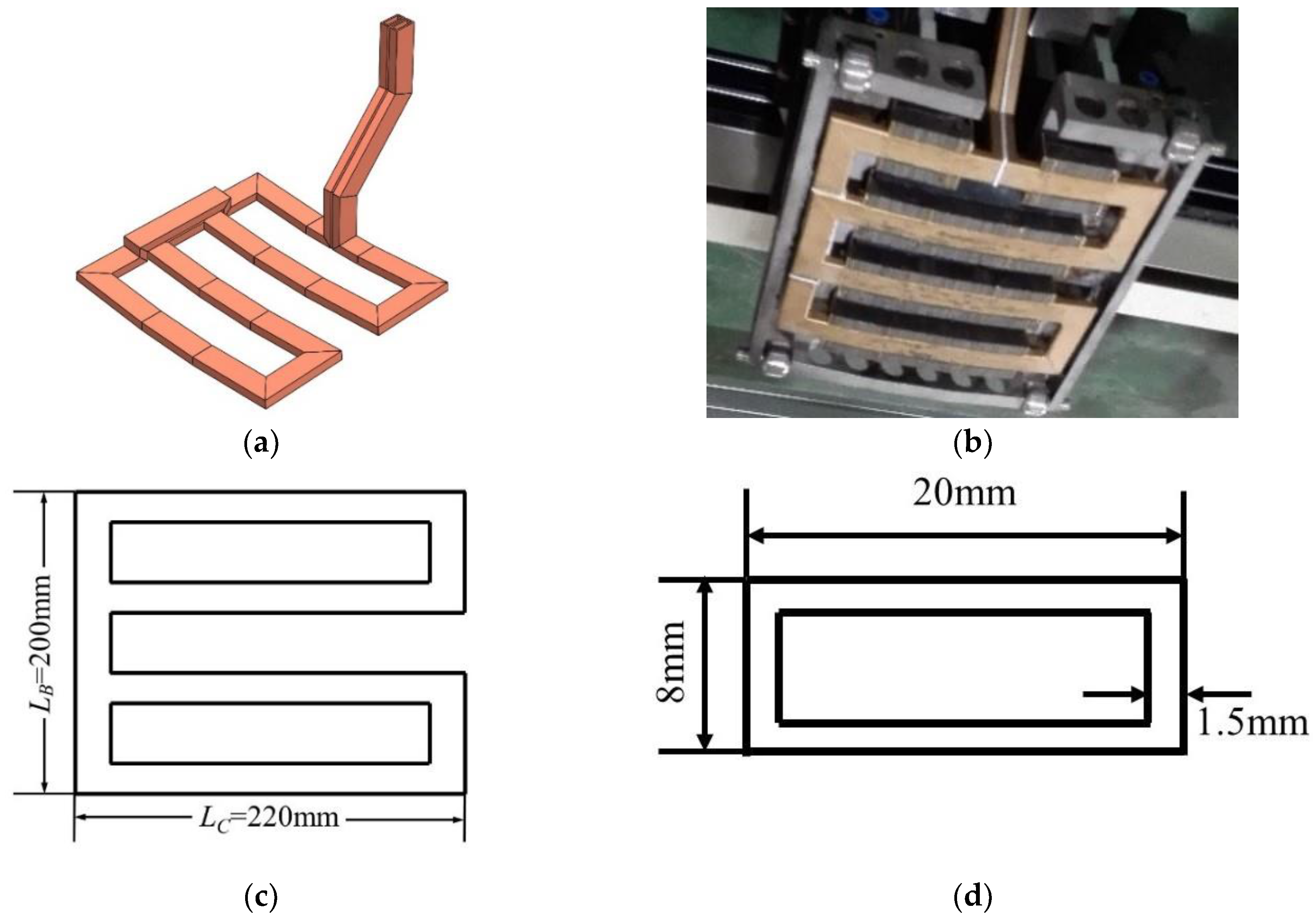

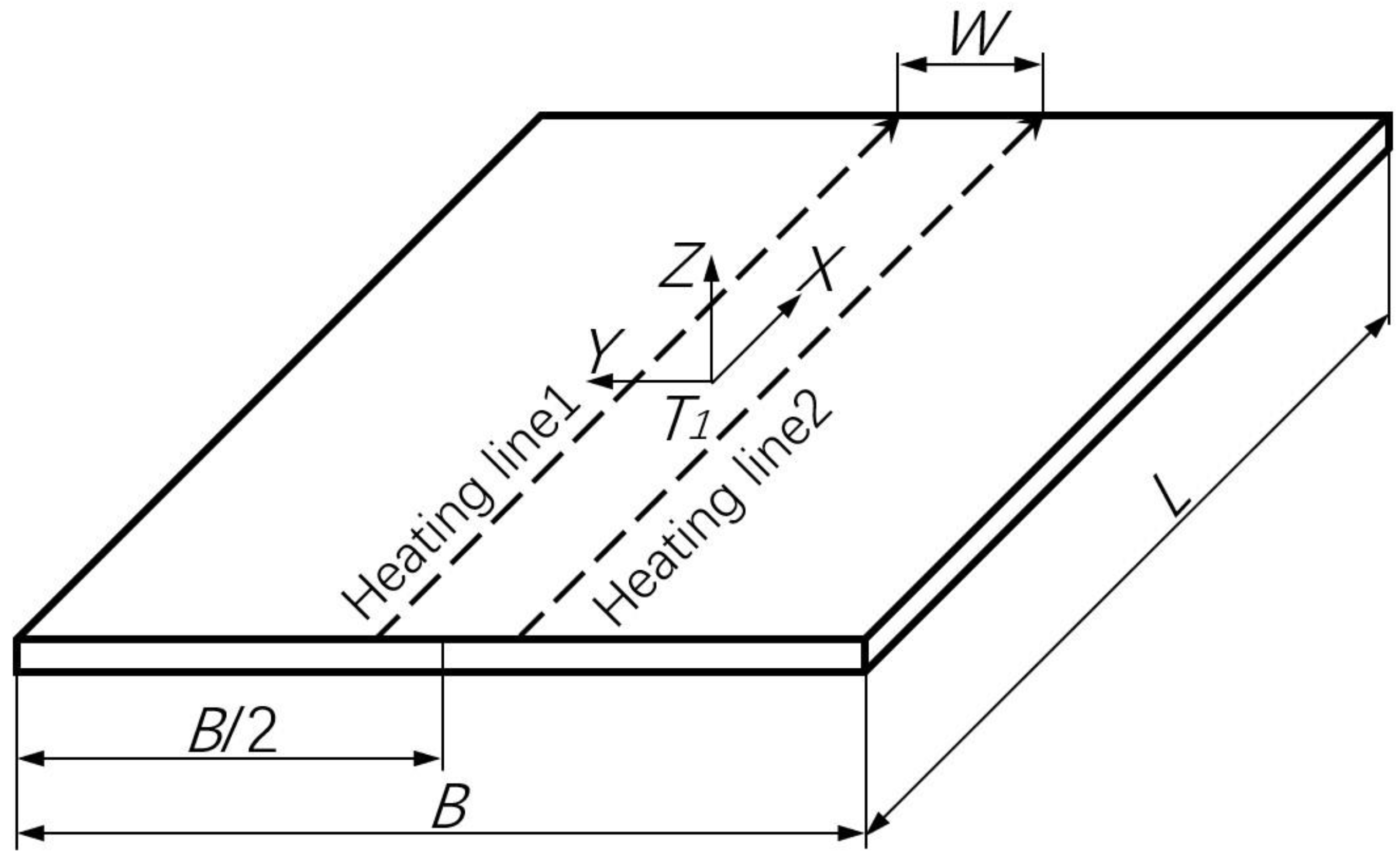

The induction coil used in this study is shown in

Figure 2. The entire coil is divided equally into three internal frames, as shown in

Figure 2a. Considering plate bending deformation, the coil is designed to be slightly curved, and the horizontal curvature radius is 1000 mm. The coil projection outer edge width is

LC = 220 mm, the outer edge length is

LB = 200 mm, and

LB is the direction of coil movement.

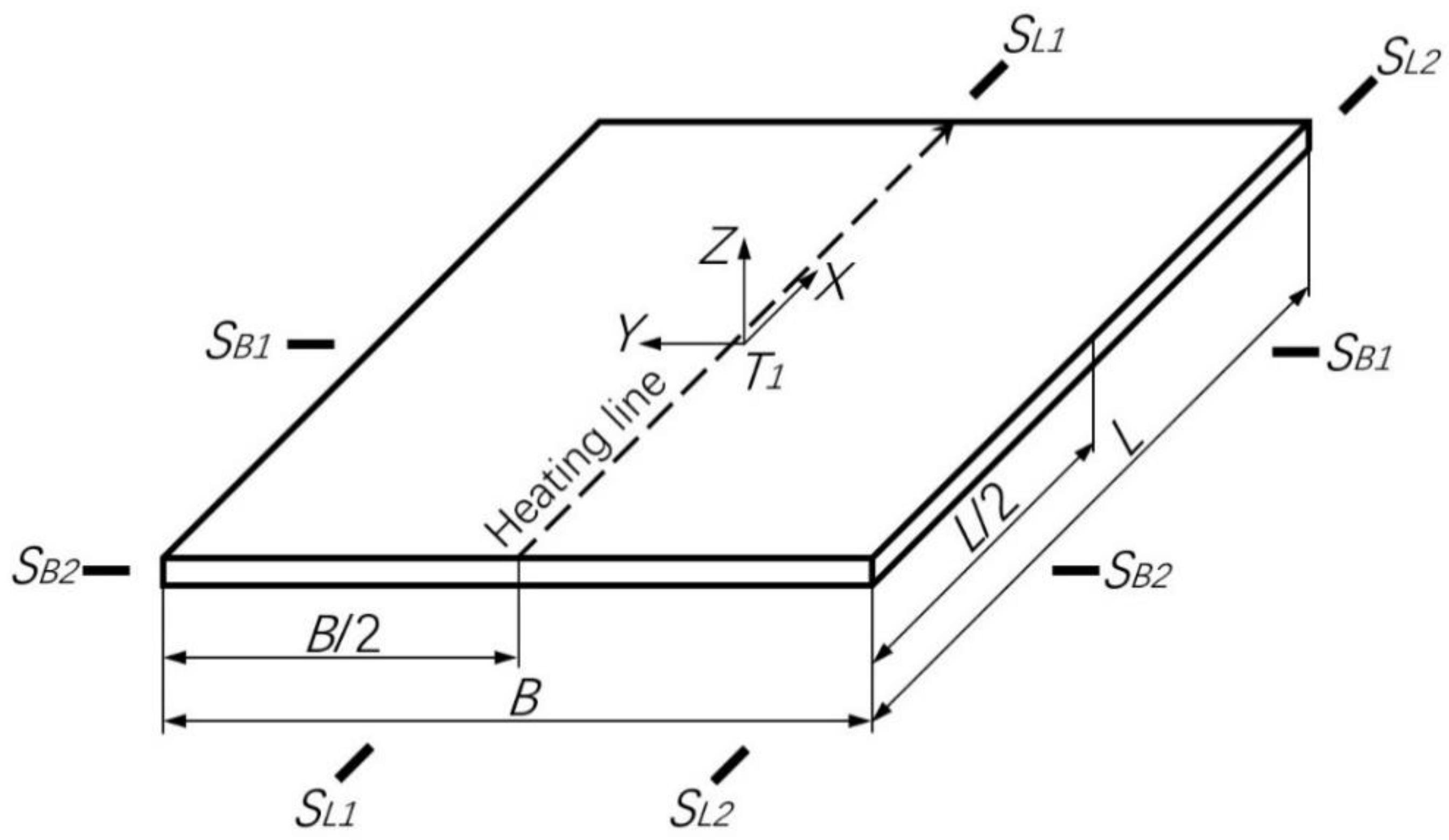

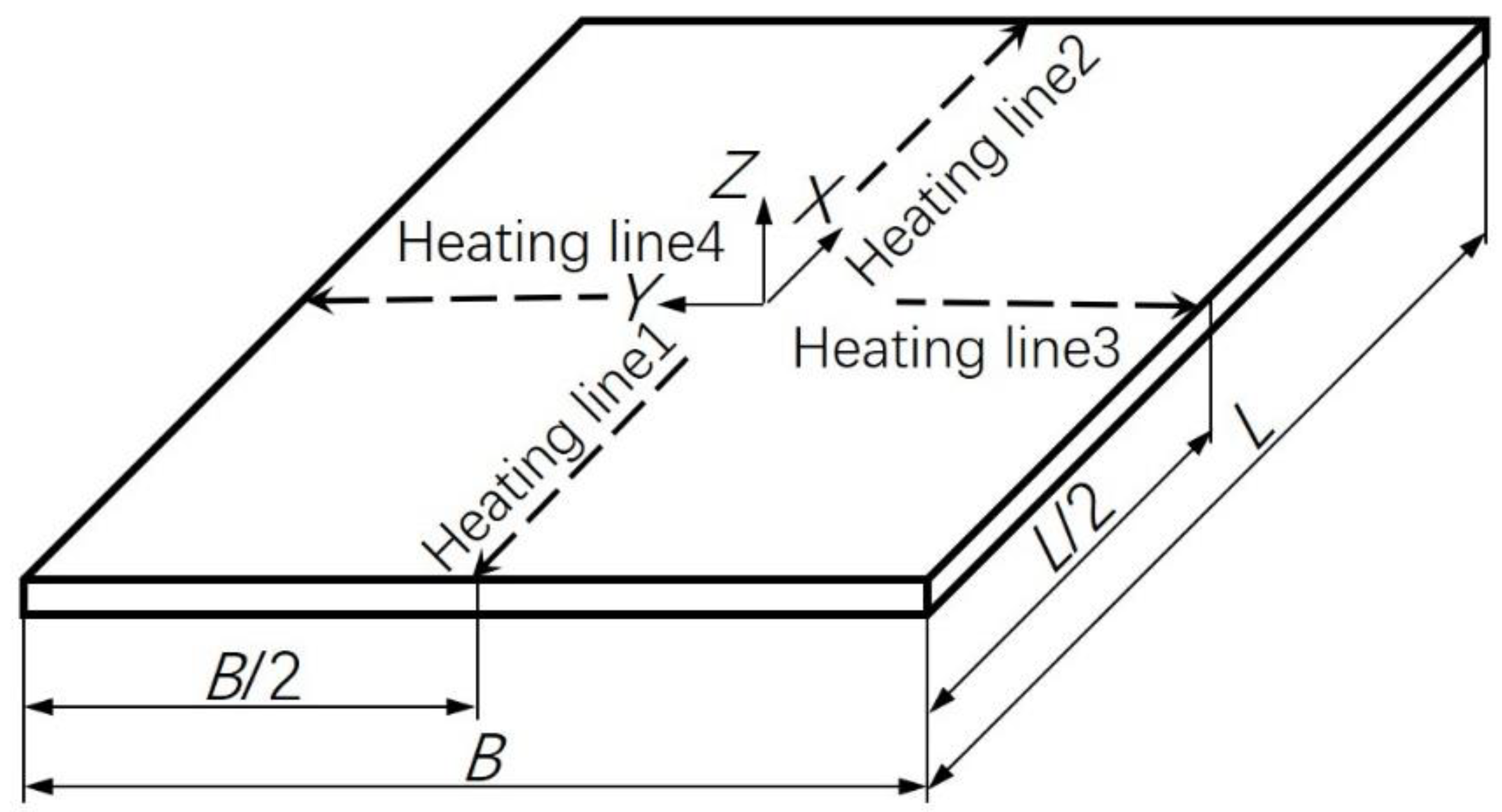

The dimensions of the plate are 1000 mm × 800 mm × 16 mm (L × B × t). The element type of the plate is DC3D8 for heat transfer simulation and C3D8R for deformation calculation. Fine grids are generated near the heating lines and the element size is 5 mm × 5 mm × 4 mm. Sparse grids are generated away from the heating lines and the element size is 50 mm × 20 mm × 8 mm. Transitional grids are generated between them and the whole model consists of 68,600 elements and 86,399 nodes. The rigid body displacement of the plate is constrained during the calculation.

2.2. Induction Heating Experiment

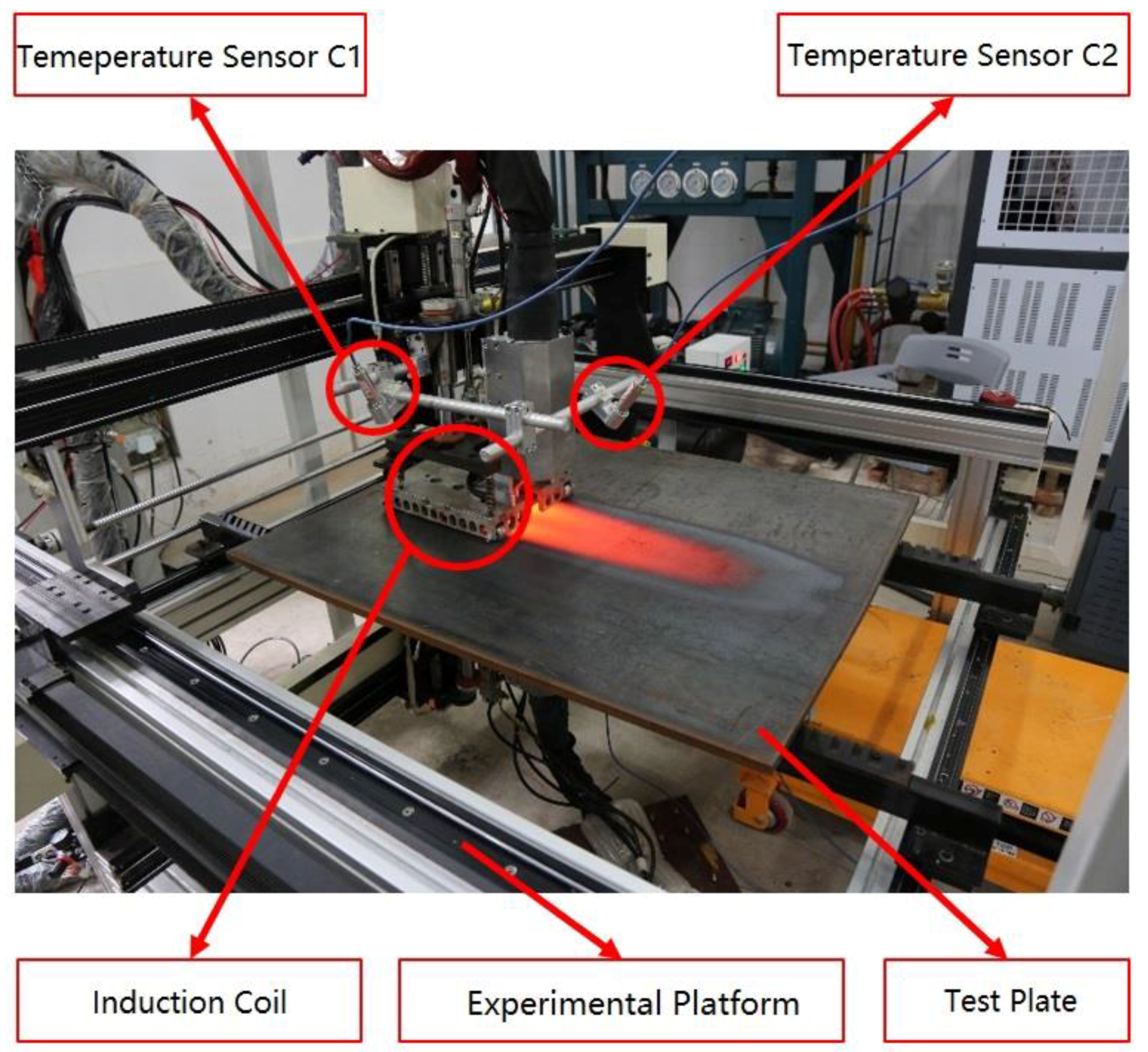

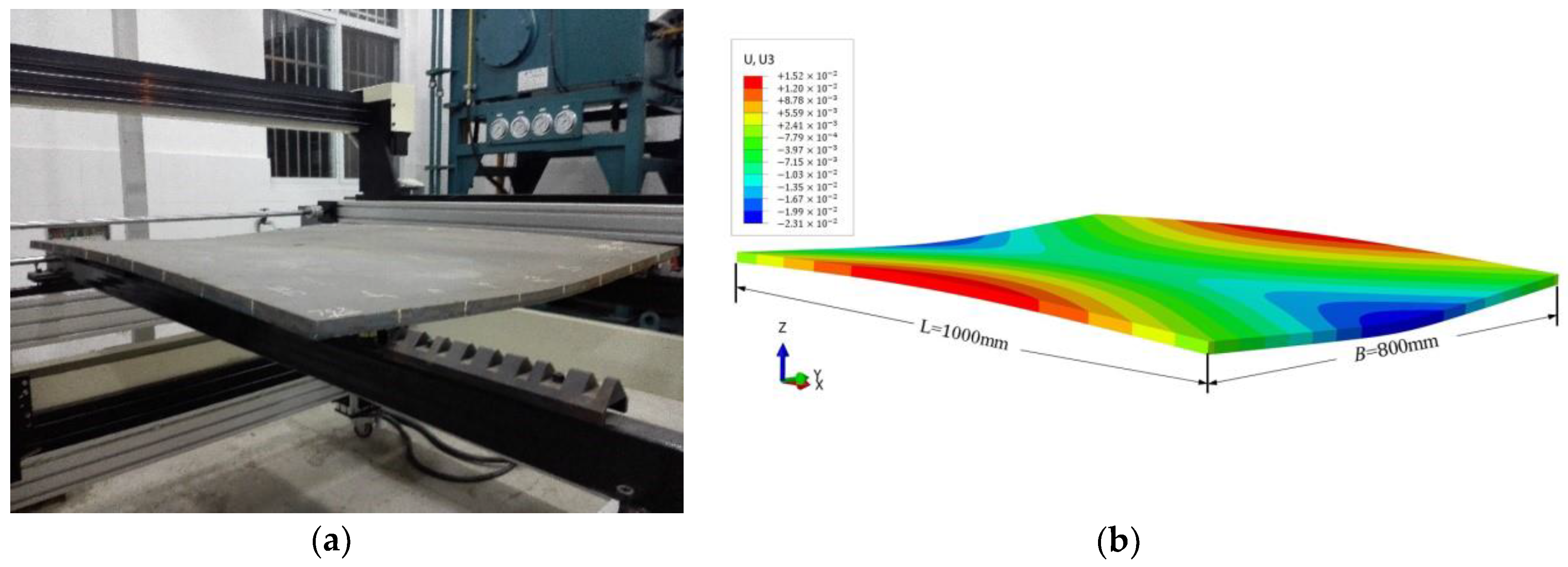

To verify the accuracy of the finite element method, an induction heating test is designed. In this test, an experimental platform made of triaxial motion of the coil is developed that can easily control the coil’s positioning, motion direction and travel speed over the test plate. The positioning precision of the experimental platform is 1 mm; and the controllable speed precision is 1 mm/s. To ensure a stable distance between the coil and the plate after plate deformation, the coil is embedded in the frame of a small vehicle, and the trolley wheel of the vehicle maintains rolling contact with the plate, which ensures no contact between the coil and plate, as shown in

Figure 2b. For the initial condition, the lowest position of the coil center is 5 mm from the bottom of the trolley wheel. The experimental platform and test scenario are shown in

Figure 3.

The test plate is carbon steel, of which major thermal, physical and mechanical properties are listed in

Table 1 and

Table 2 which is similar to Reference [

13]. The plate dimensions are as follows: the length

L = 1000 mm, the width

B = 800 mm, and the thickness

t = 16 mm.

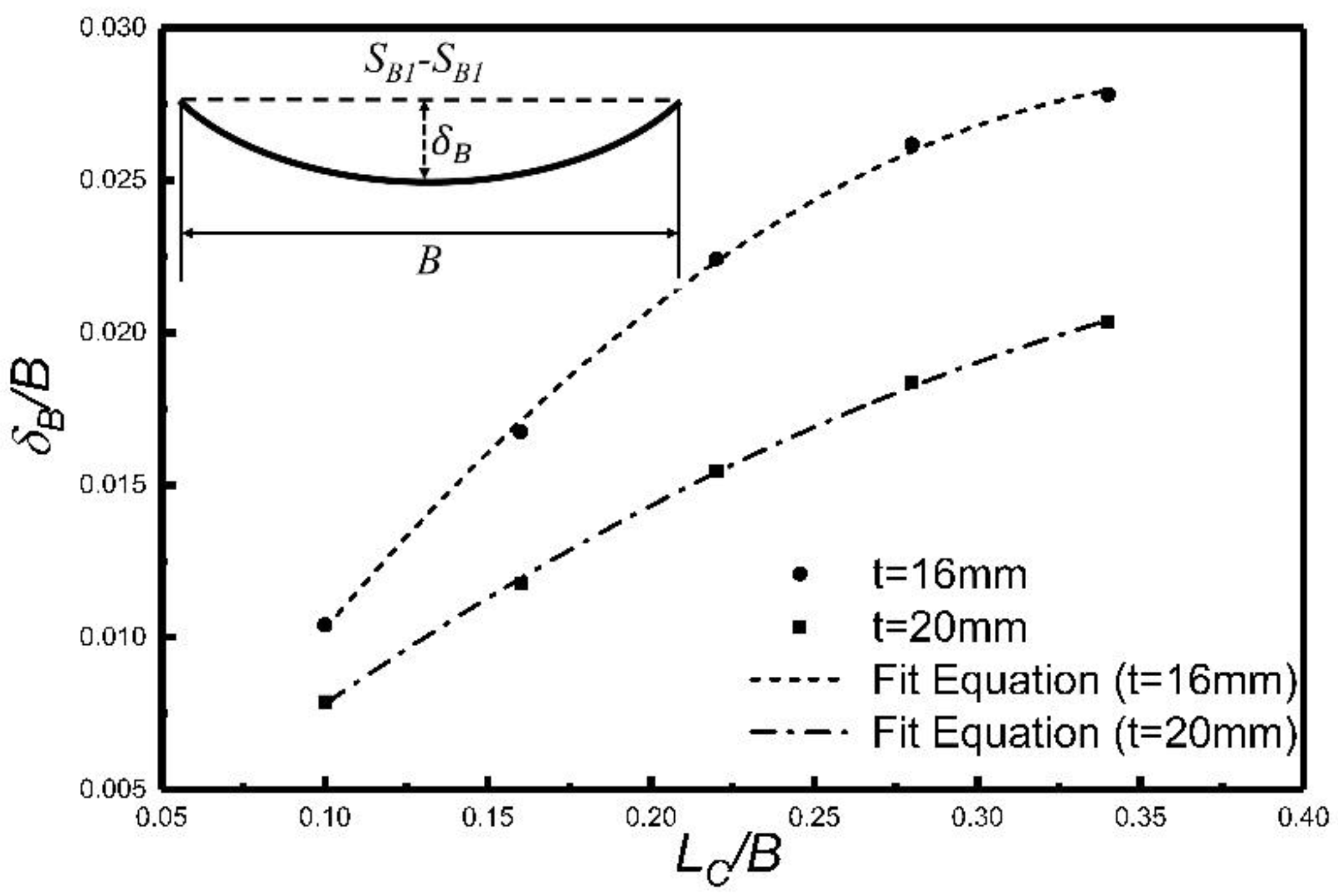

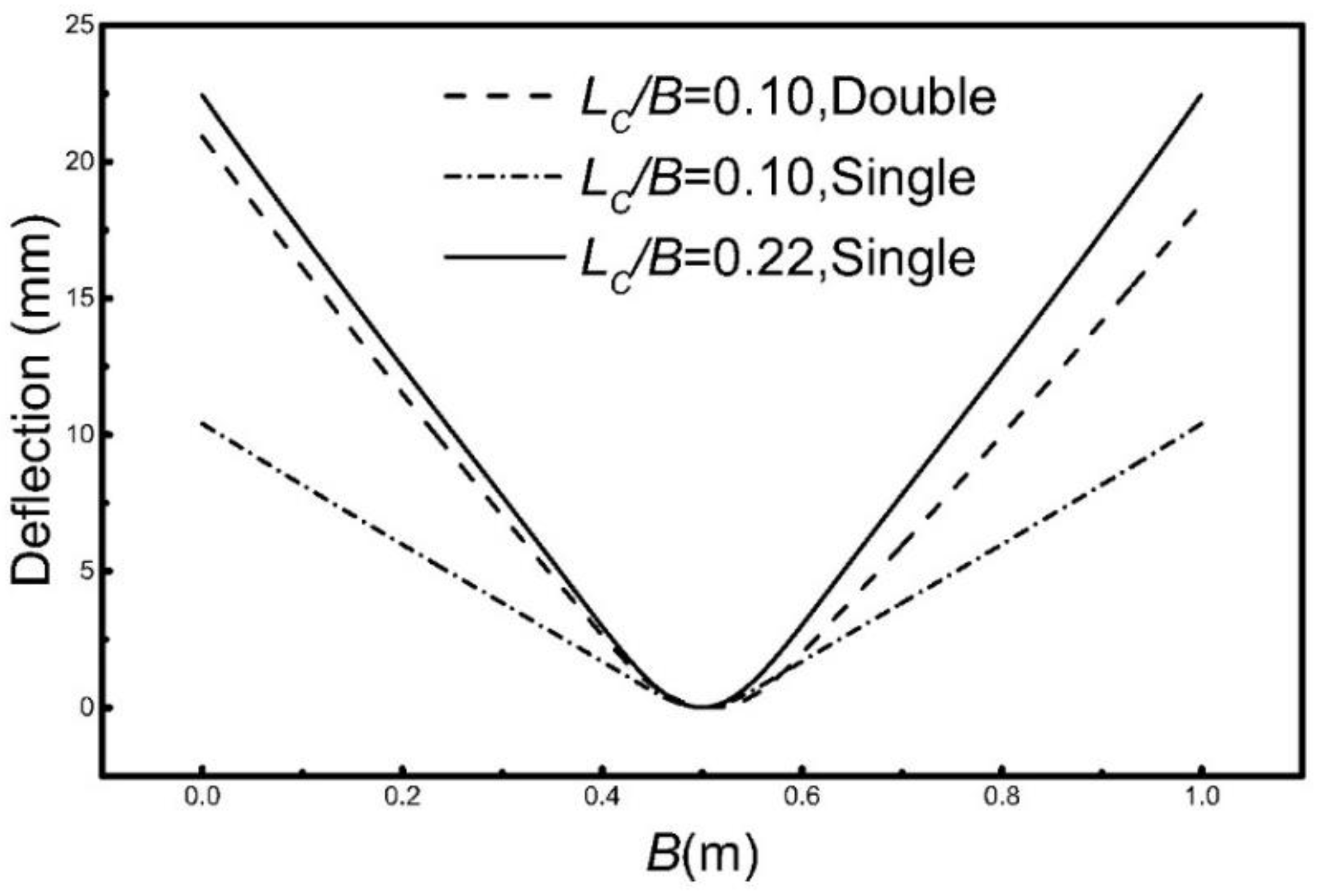

L is the coil movement direction over the plate. Here,

LC/B = 0.275.

In the test, the heating line is the upper surface central line along the plate width direction (i.e., B/2). The coil length LB is aligned with the plate length L and is moved along the heating line. In the test, the electromagnetic induction frequency is 15 kHz, the heat source output power is 60 kW, and the coil travel speed is 5 mm/s. As the coil moves over the plate surface in a small rolling vehicle, the distance between the coil and the plate during heating is essentially constant.

In the test, the infrared temperature sensor (with a measurement range of 250–1450 °C) detects the plate temperature change during heating, as shown in

Figure 3. Temperature sensors are deployed on one side and at the rear of the coil, and they move together with the coil, i.e., temperature sensors

C1 and

C2 in

Figure 3. The point measured by

C2 is 20 mm from the coil rear edge. A fixed temperature measurement point is deployed on one side of the plate to measure the temperature variation at the plate center

T1. The final deformation of the plate is measured via a three-dimensional laser scanner measurement system after the entire plate cools to room temperature.

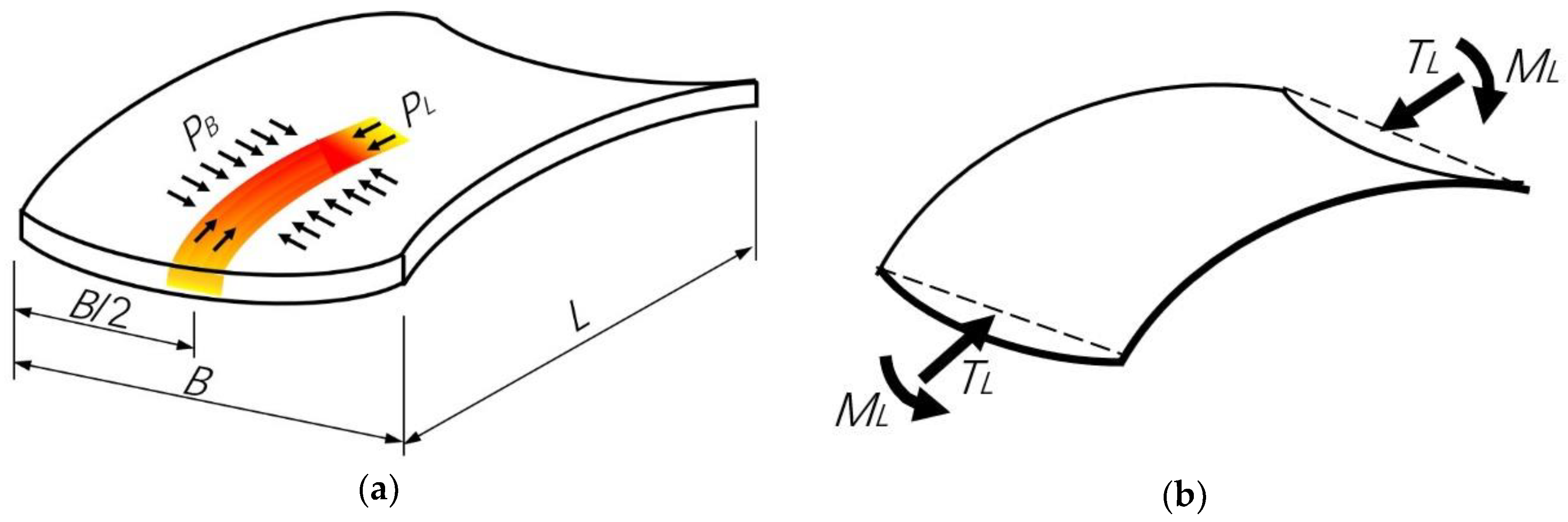

At the initial stage of the test, the entire coil is placed over the plate, and the trailing edge of the movement direction coincides with the plate’s rear end. As the coil moves continuously, the first notable phenomenon is the upward bending deformation of the plate along the B direction. In contrast, the plate deformation along the L direction is smaller and demonstrates a downward-bending trend. This phenomenon continues until the coil has completed its movement over the entire heating line. After the entire coil moves away from the plate and the plate temperature drops, the upward-bending deformation of the plate along the B direction changes slightly. However, the downward bending of the plate along the L direction gradually becomes prominent, and the plate eventually becomes saddle-shaped. In the study, similar tests are performed under other conditions with different plate thicknesses, heat source input powers and the coil movement speeds, with essentially the same results.

Although both the side ratio and shape of the coil and plate are close, the constraints from plate regions outside the heat expansion area on the coil-induced heat expansion of the plate are different along the

L and

B directions because the coil motion is directional; i.e., the coil moves along the plate’s

L direction, as shown in

Figure 4. Under the local contraction force

PB along the

B direction, the plate bends first along the

B direction. Due to the deformation constraints of the plate itself and the heating movement direction, the contraction force

PL along the plate’s

L direction lags behind

PB. As shown in

Figure 4b, after bending, deformation occurs along the

B direction, the

PL resultant force (

TL) is applied to the centroid of the

B direction section, and a bending moment

ML is created. Under

ML, a deformation occurs along the plate’s

L direction that is opposite to the plate’s

B bending direction. This is why all of the shapes tested by the heating along the upper surface central line of the plate in the experiments are saddles.

2.3. Comparison between Experiment and Finite Element Method

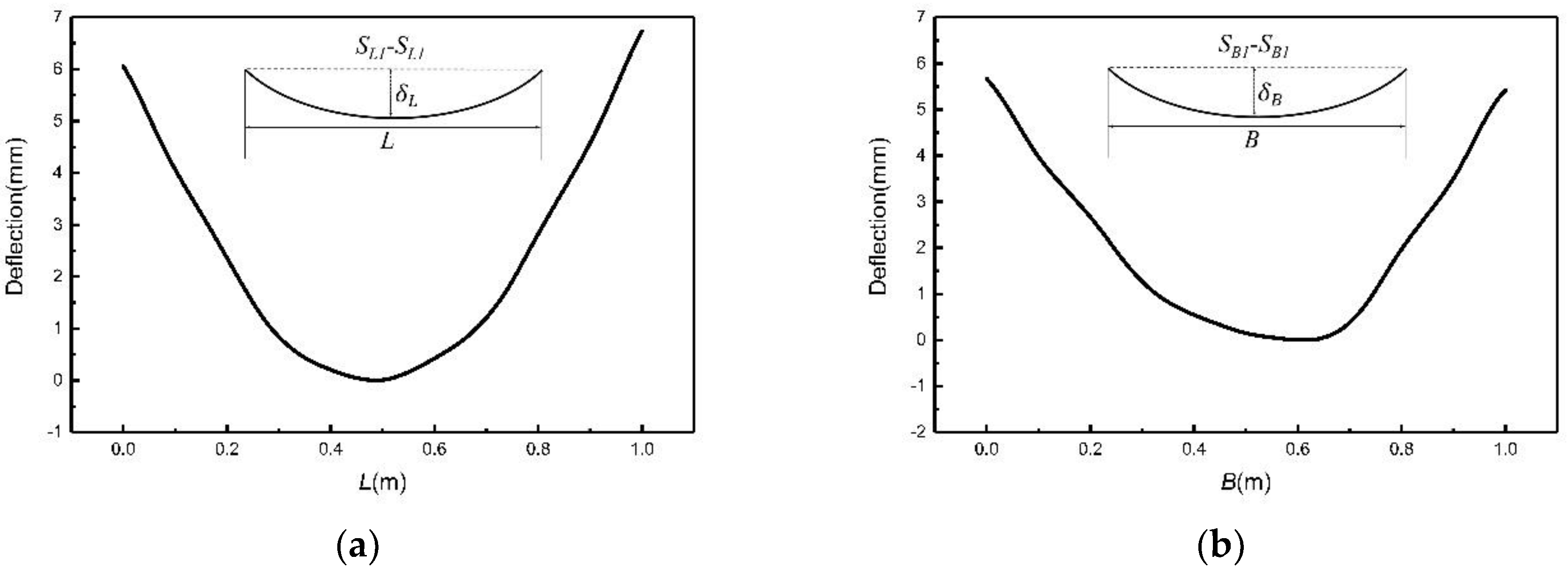

Several sections and points in

Figure 5 are selected to compare the temperature and deformation from the finite element calculation with the test results. The sections include the

SL1-SL1 section, which coincides with the heating line, the

SL2-SL2 section at the plate end, which is parallel to the heating line, the

SB2-SB2 section at the plate end, which is vertically oriented to the heating line and the

SB1-SB1 section at

L/2. The point selected is point

T1 at the plate’s center.

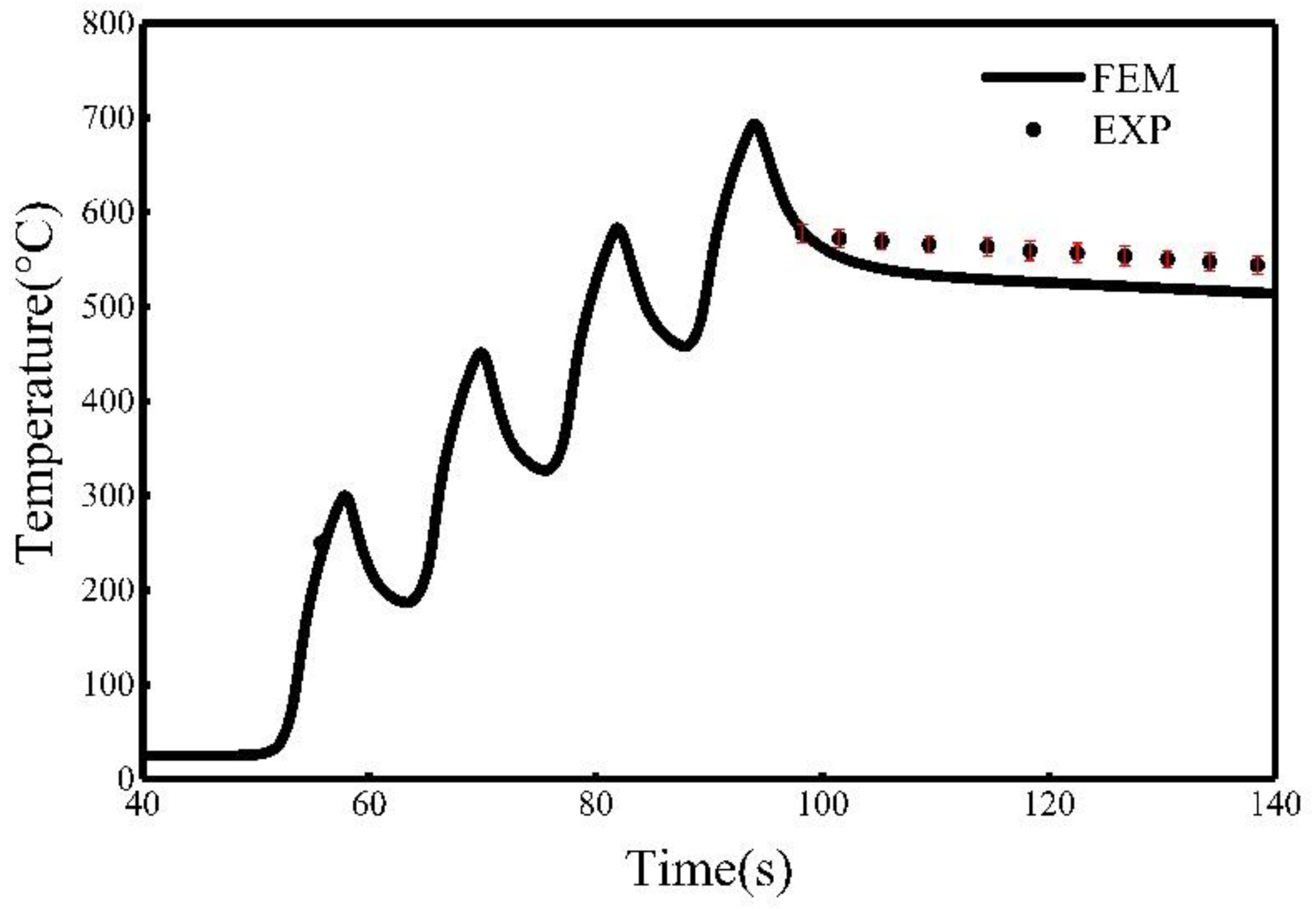

Figure 6 compares the temperature variation from the finite element calculations with the test results at the plate’s central point,

T1, during heating. The diagram shows that based on the coil’s dimensions, time record and speed, the relative position of the coil versus

T1 at any moment can be derived. The finite element calculation results show that before 50 s, the temperature at

T1 does not rise. Next, the temperature fluctuates in a small range and rises continuously until approximately 97 s. Thereafter, it declines steadily. The coil center passes

T1 approximately 80 s after the beginning of the test. When the coil center and

T1 coincide, the temperature at

T1 is not at the highest level.

The finite element calculation shows that the temperature at

T1 fluctuates slightly before reaching its highest level. There are two reasons for this: the coil panel is not continuous. Before passing

T1, there is a large amount of heat dissipation from the coil toward the unheated “cold plate” in the front. After the coil passes

T1, the “cold plate” before

T1 becomes a “hot plate”, and the temperature at

T1 declines steadily after a short period of fluctuation and increase. Additionally, because the temperature monitoring point at

T1 is blocked by the moving coil near 80 s, the measurement data during this period are invalid. Because the temperature is measured at regular intervals (a discontinuous measurement method), small temperature fluctuations are not reflected. However, the finite element calculation results and the test data are closely related throughout the process. To further validate the finite element calculation method, data are collected from the temperature sensor

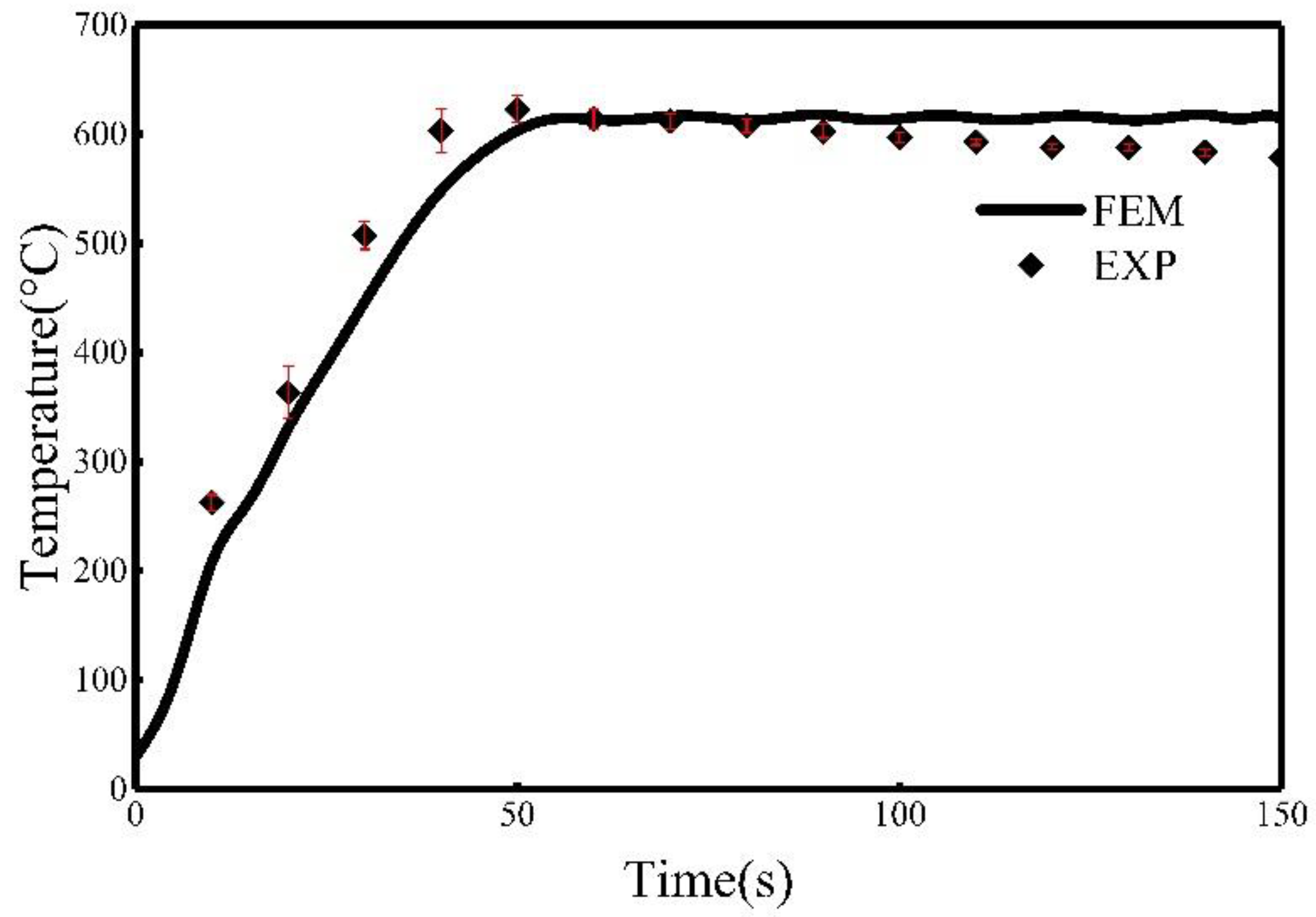

C2 for comparison. The temperature variation versus time at

C2 is the variation of the highest temperature at the plate heating line after 4 s (

C2 is 20 mm from the coil edge, and the coil travel speed is 5 mm/s). The test results are compared with the finite element calculation and shown in

Figure 7, which confirms that the two match closely.

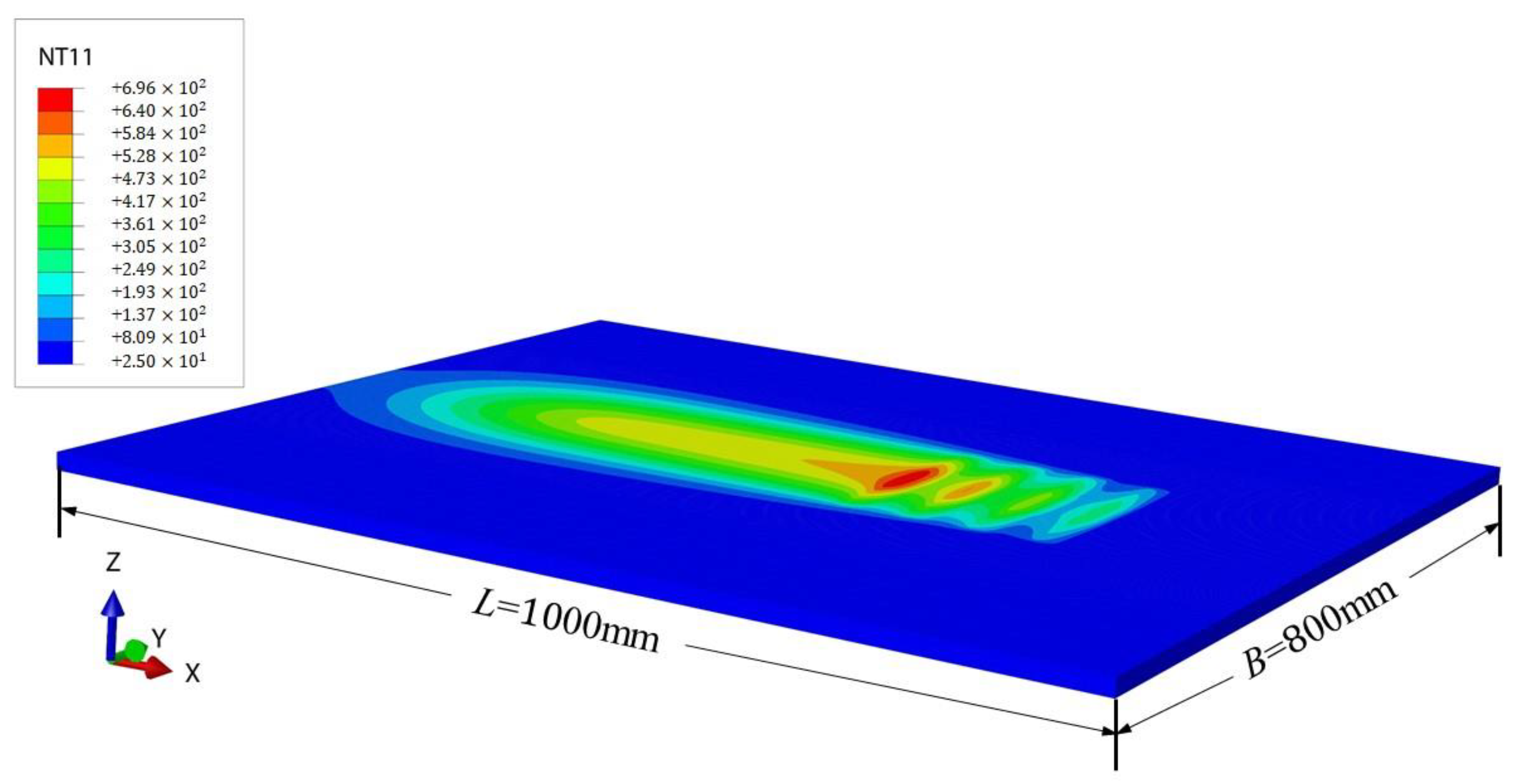

Figure 8 shows the heat distribution from the finite element model of heat transmission after heating for 115 s. The plate deformation shapes from the test and the finite element calculation are shown in

Figure 9. Both results are saddle-shaped.

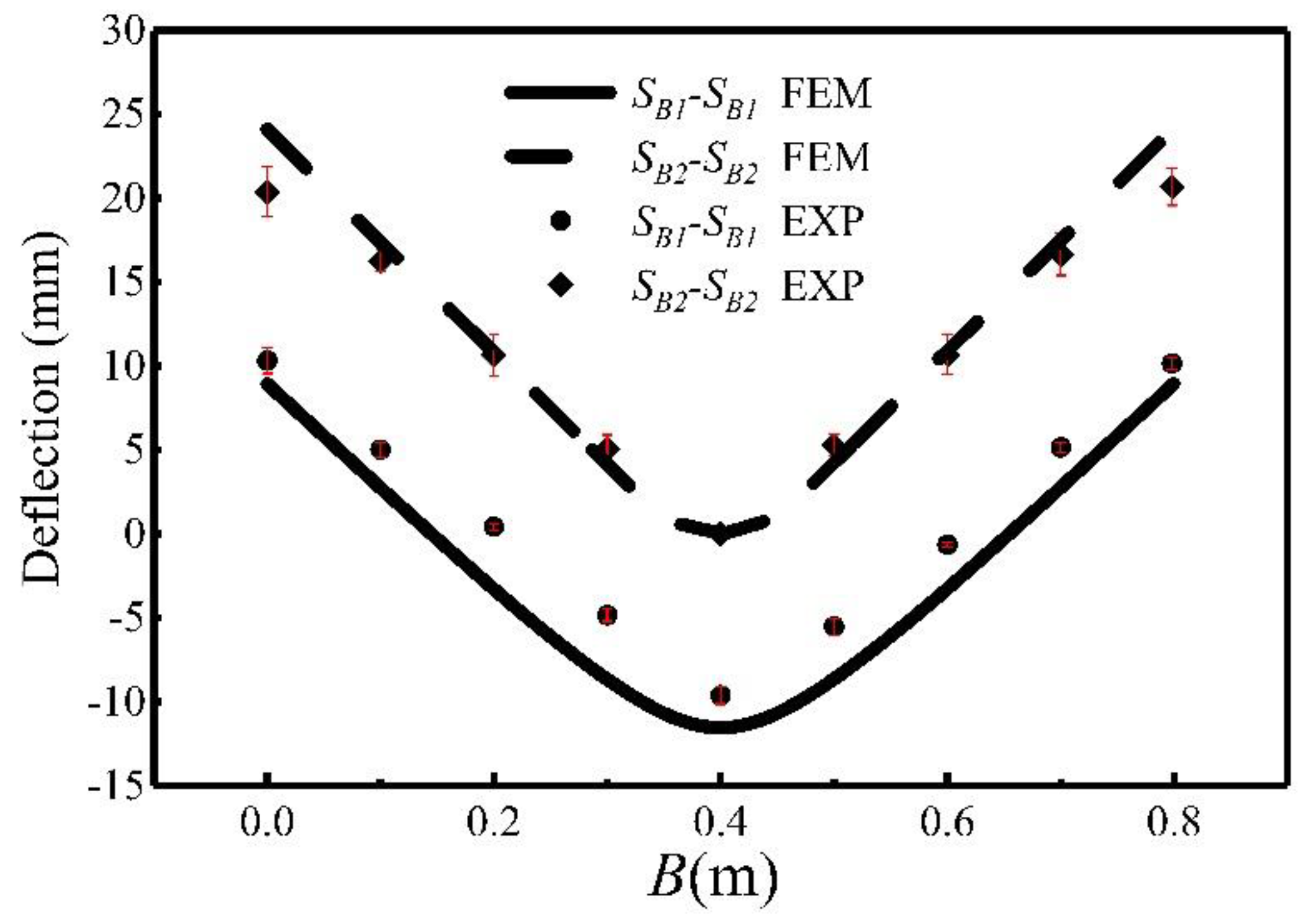

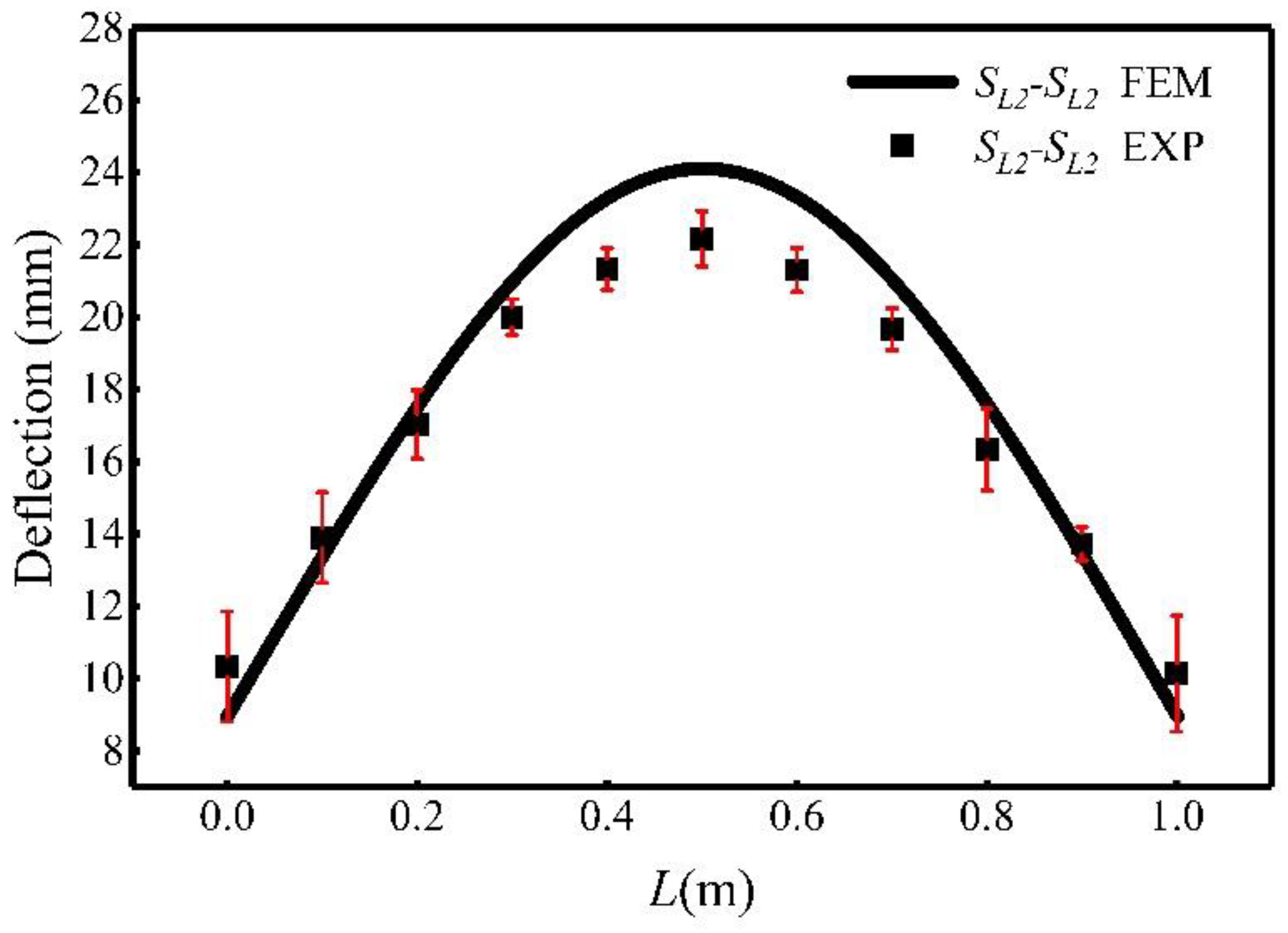

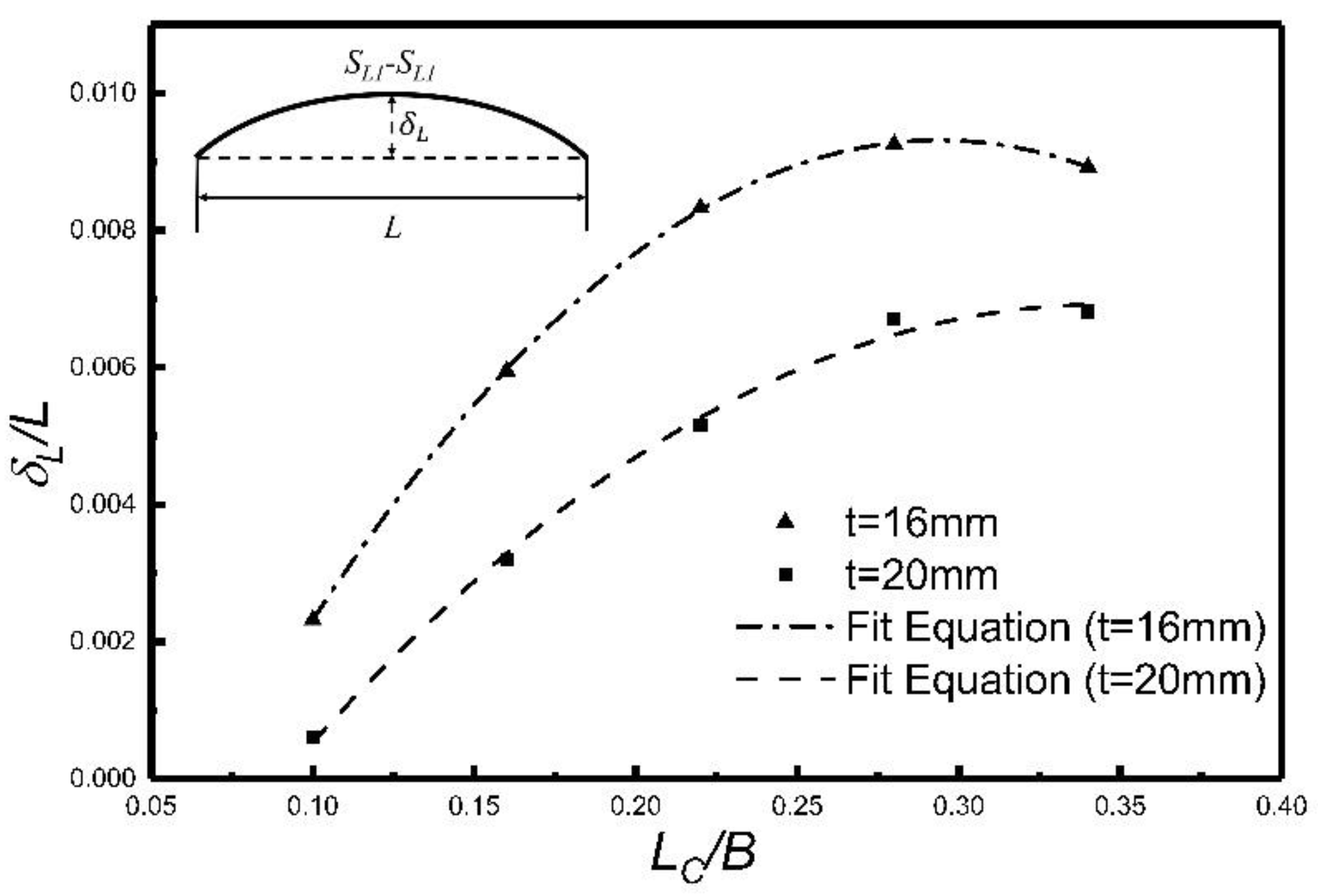

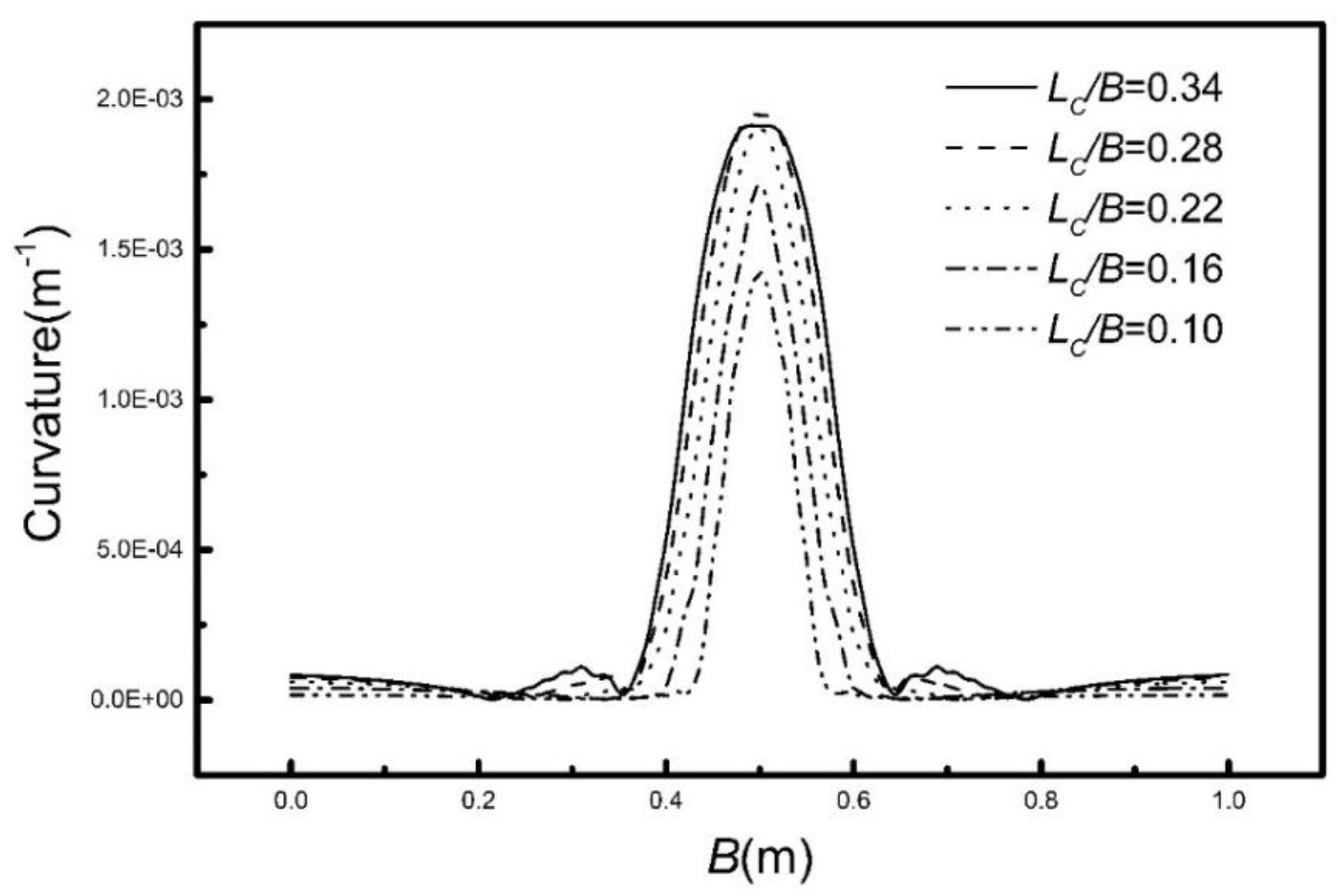

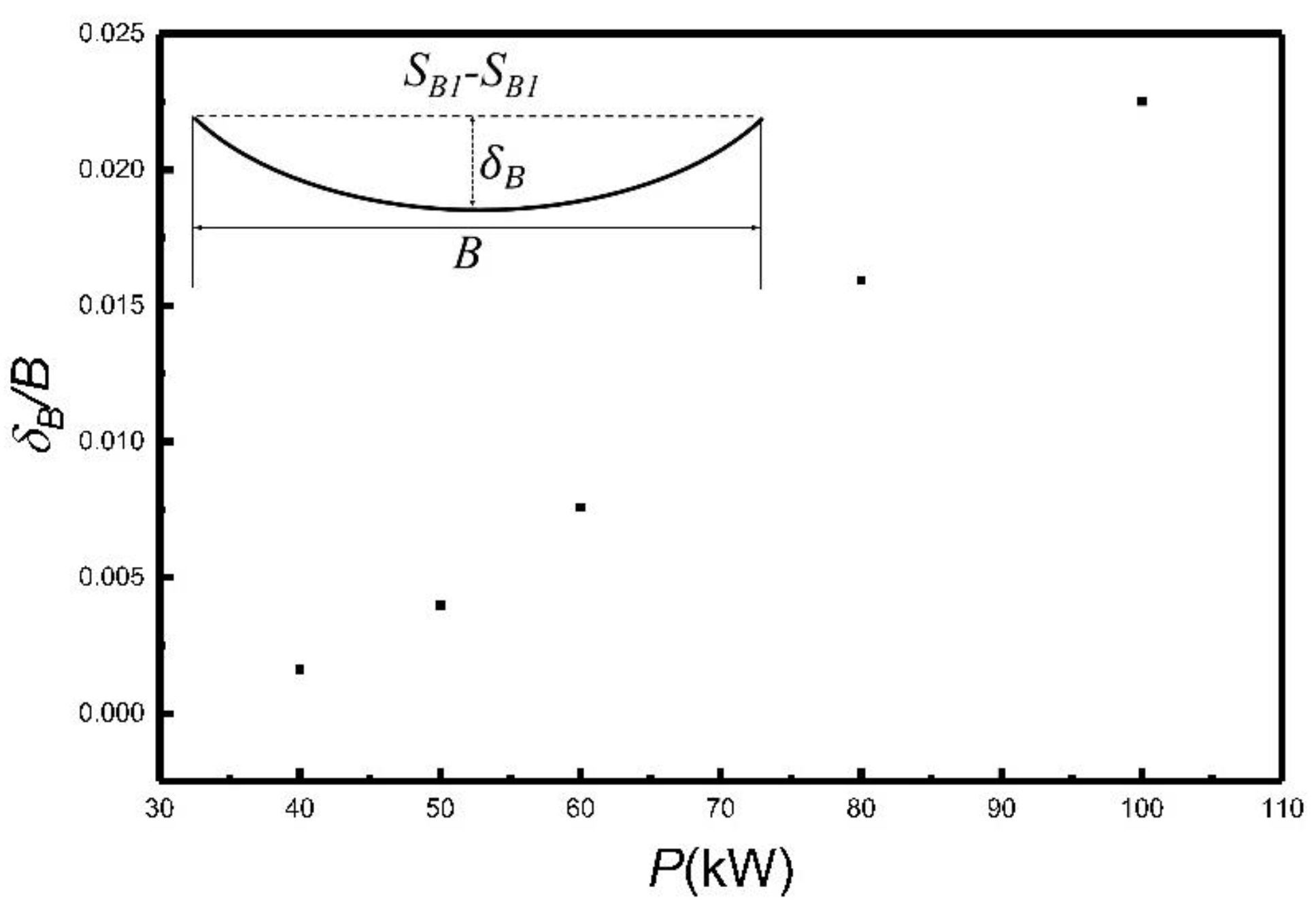

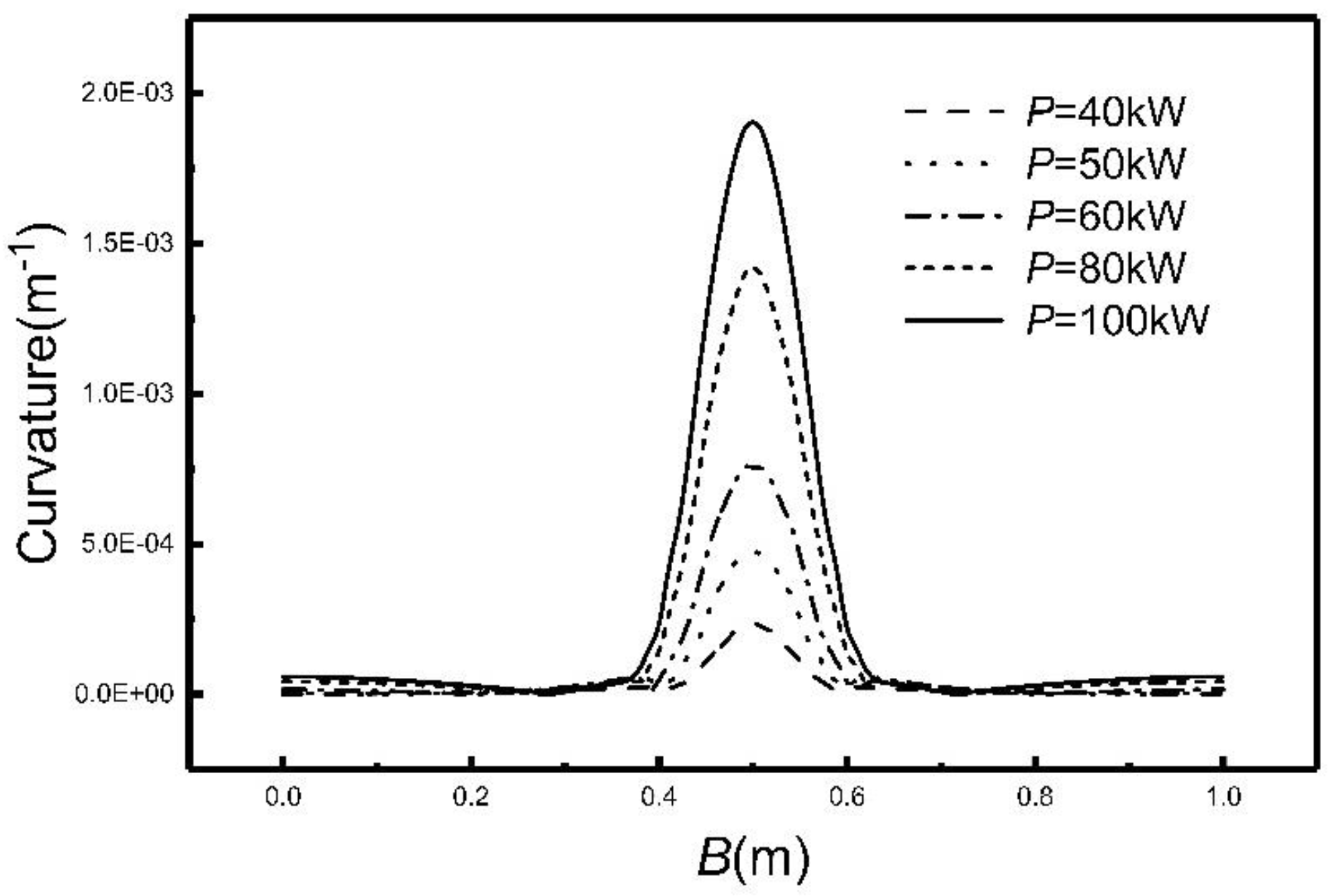

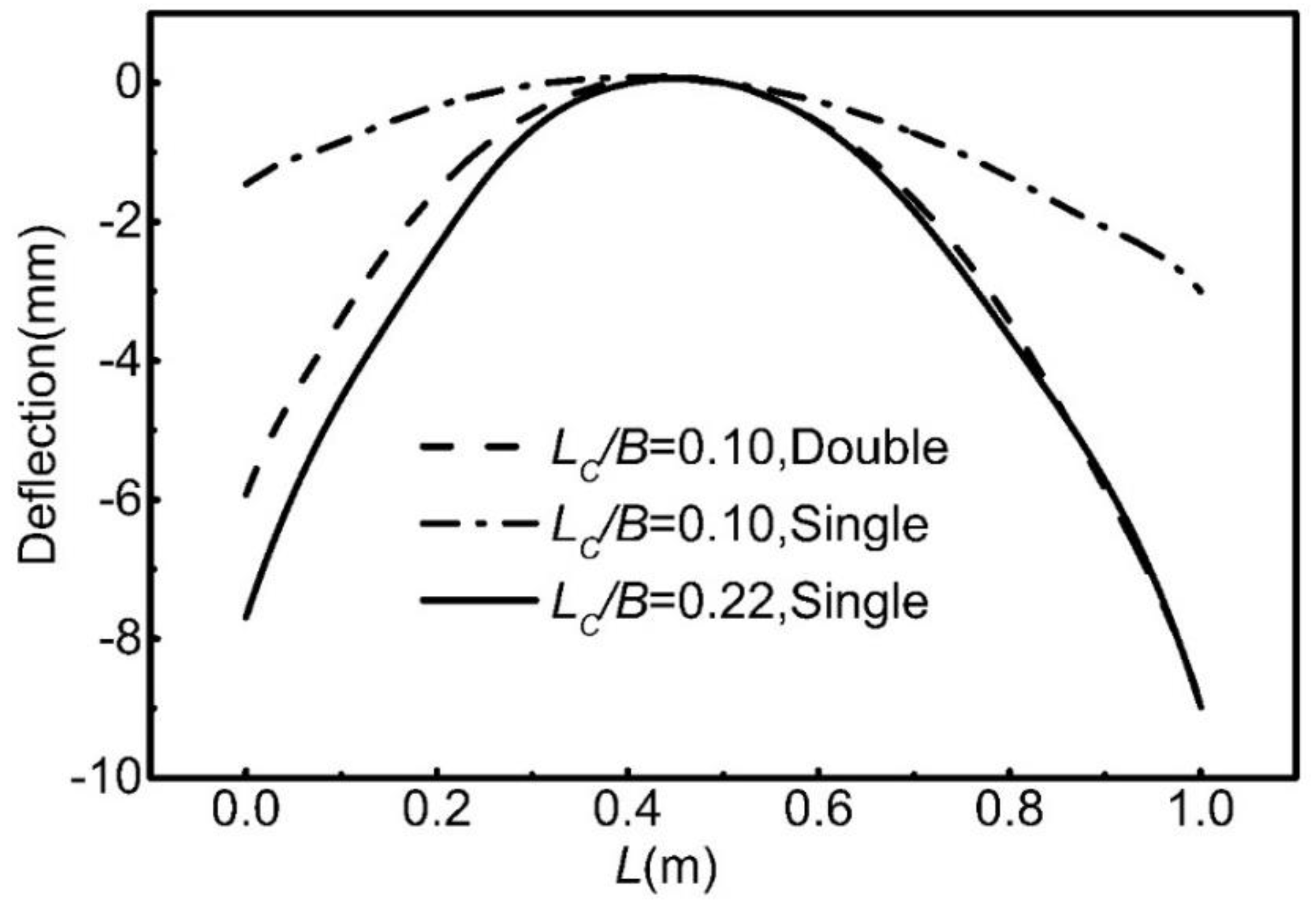

Figure 10 and

Figure 11 show the bending deformations of the heated plate in the transversal and longitudinal directions. The diagrams show that the finite element calculation and the test result have an excellent correlation. The maximum relative errors of the transversal and longitudinal deflections are approximately 10% and 9%, respectively, and both are located at the center of bending.

These results show that the current finite element computing model and method can accurately simulate plate deformation under induction heating.