Study on Sulfide Distribution in the Operating Oil of Power Transformers and Its Effect on the Oil Quality

Abstract

:1. Introduction

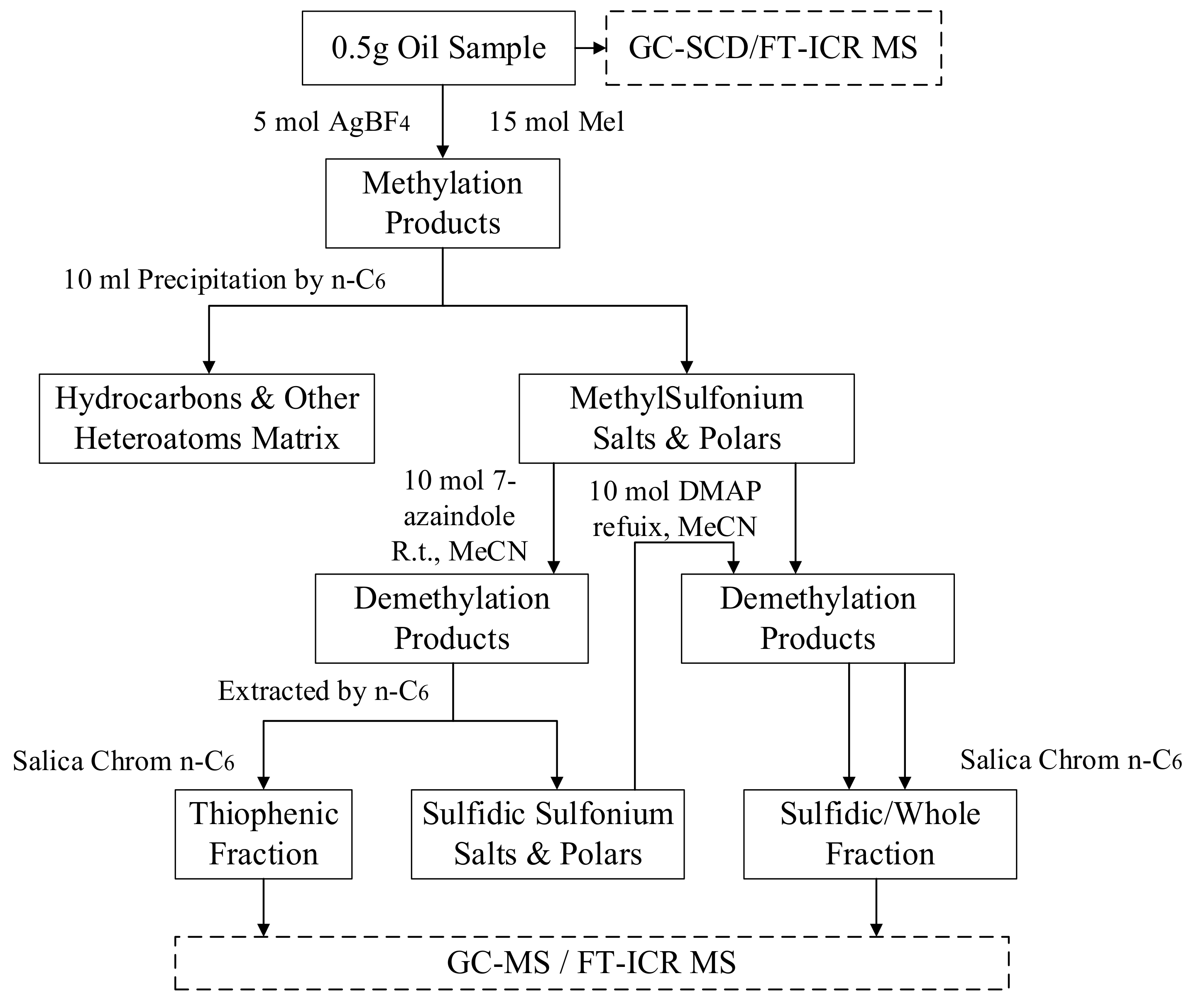

2. Quantitative Test Methods for Different Sulphides in Transformer Oil

3. Test Results of Different Sulfur Components in Transformer Oil

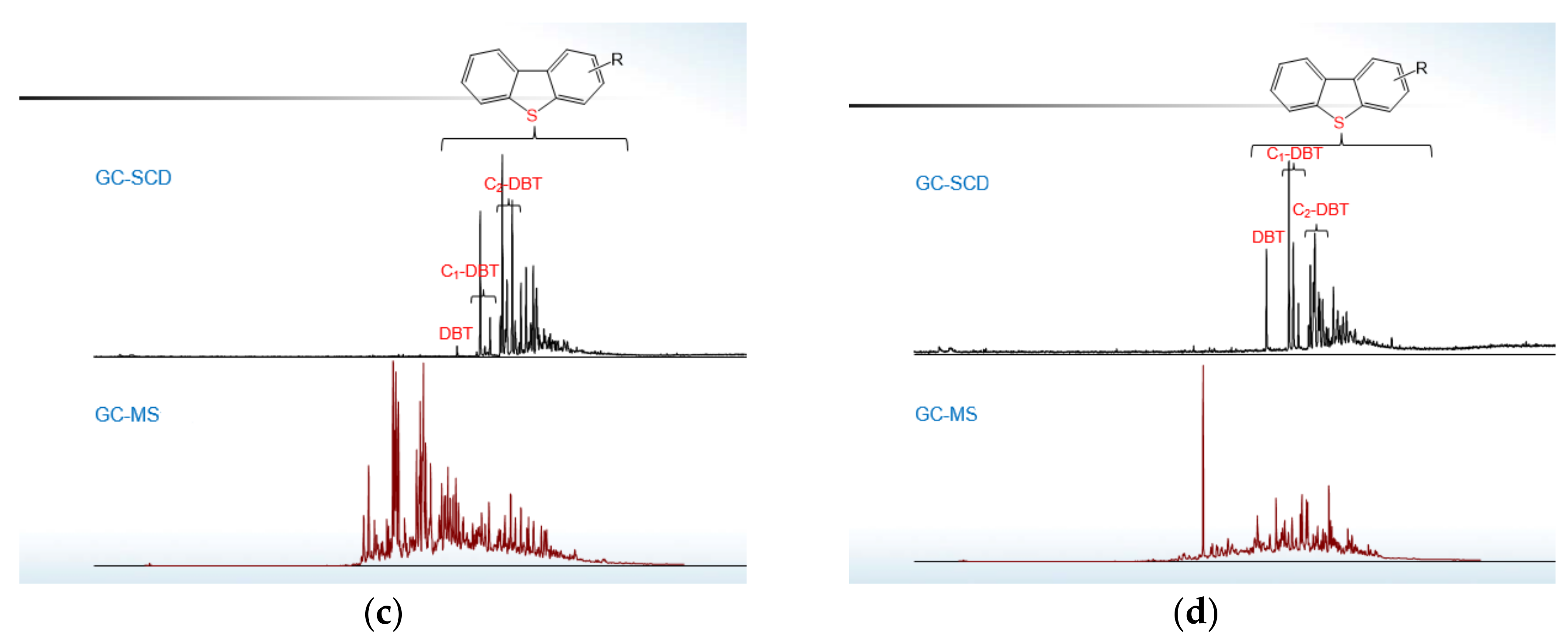

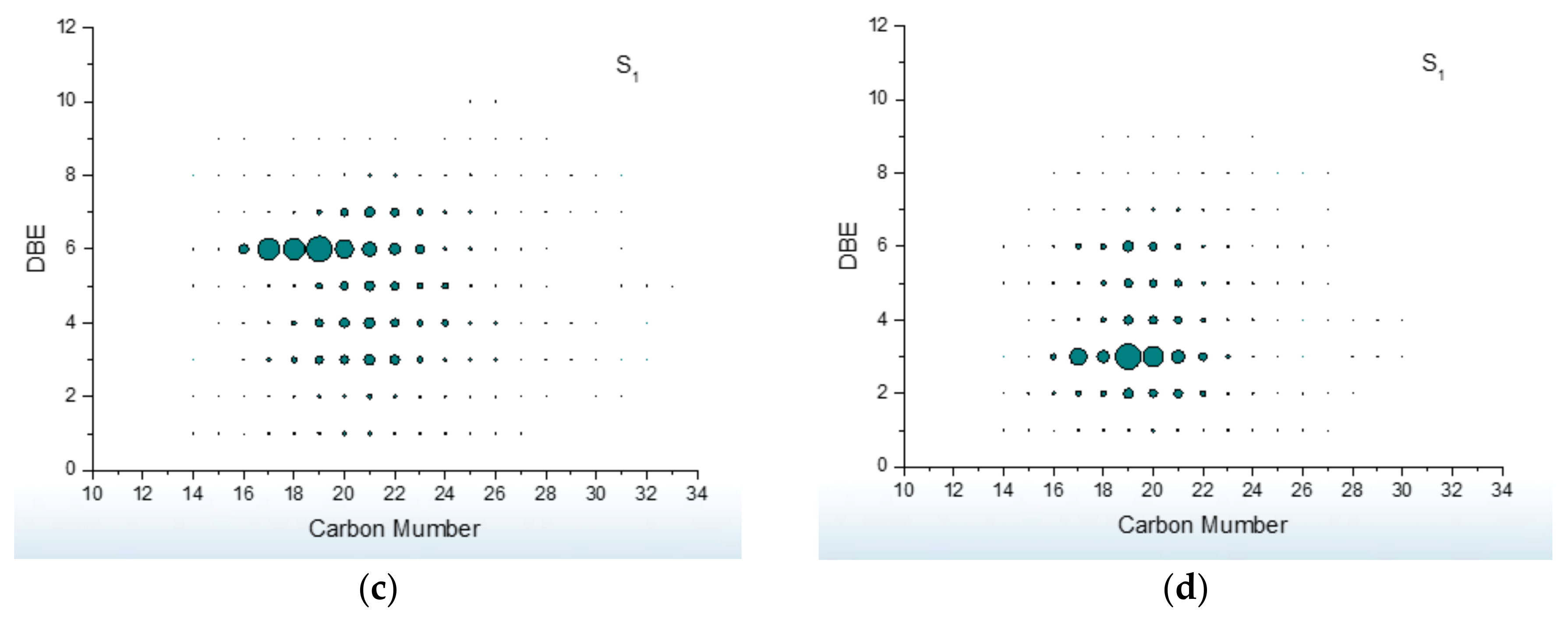

3.1. Thiophene Sulfur

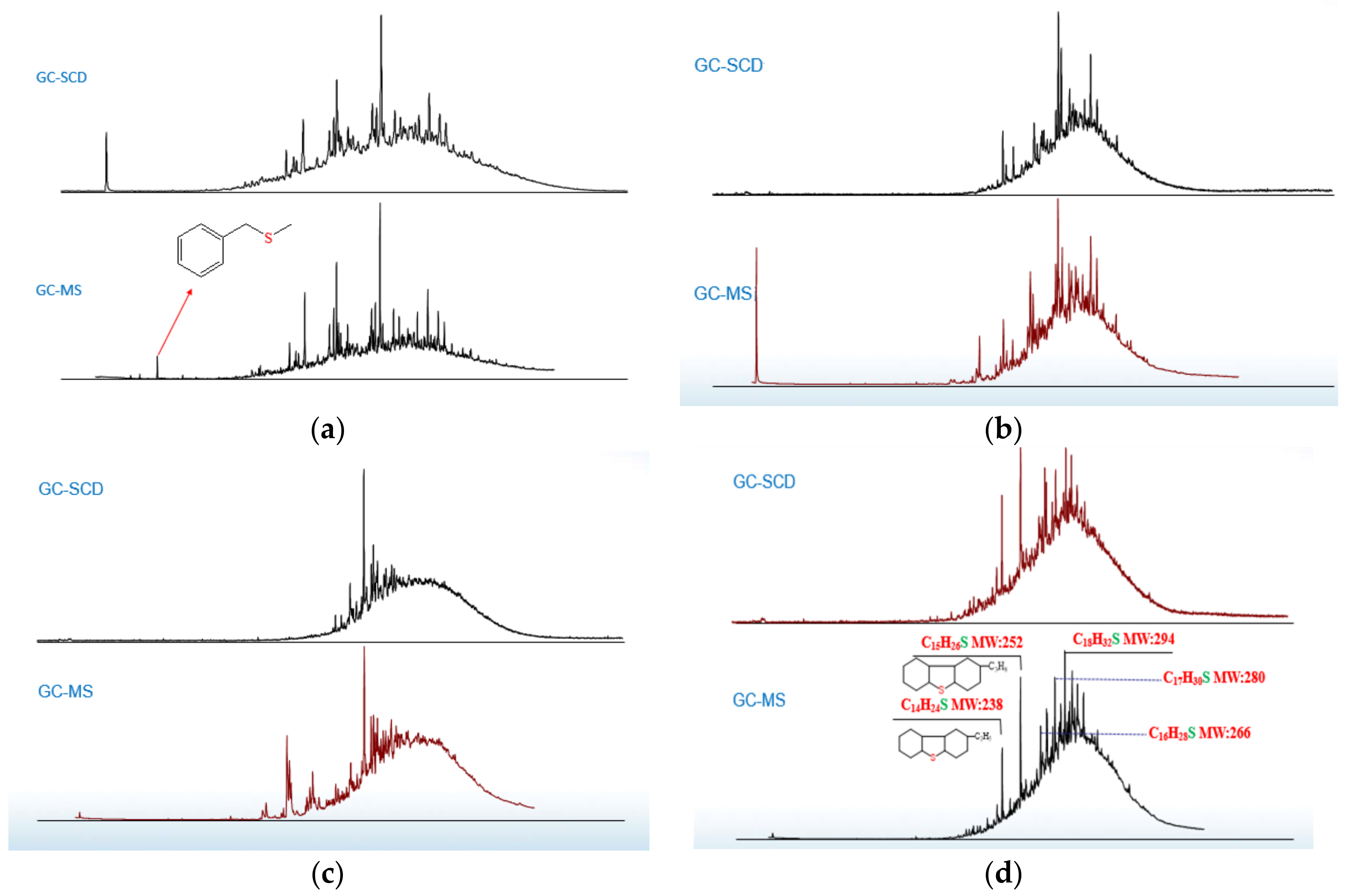

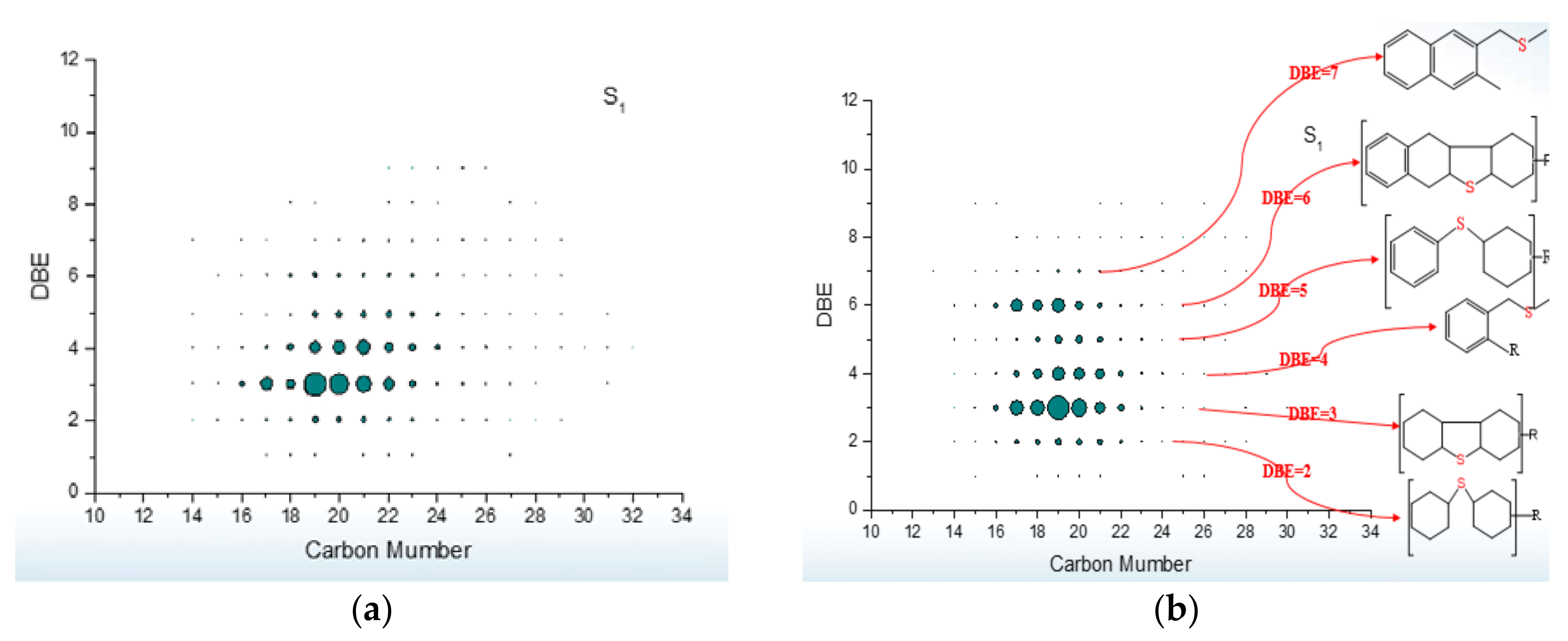

3.2. Monothioether Sulfides

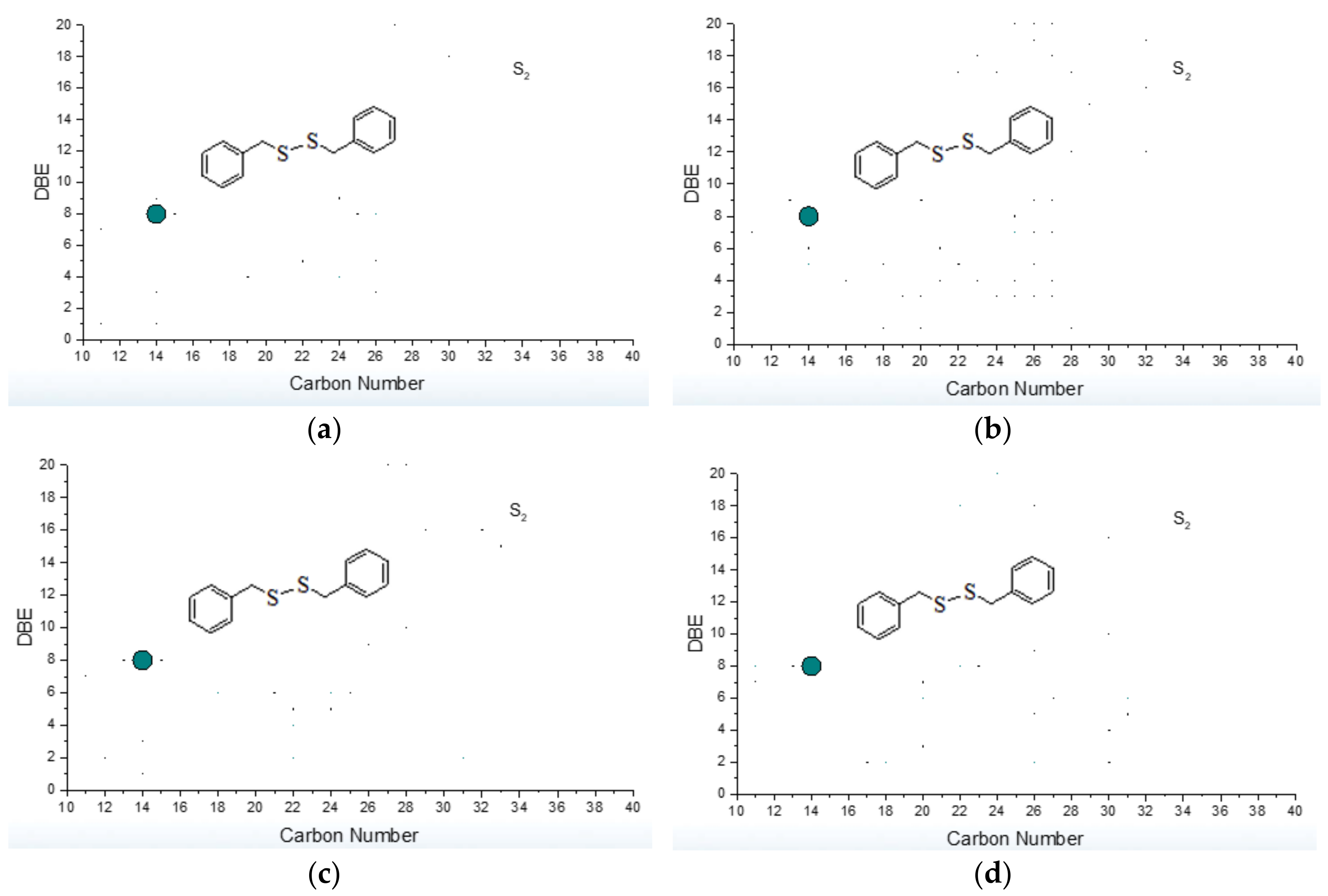

3.3. Disulfide Sulfides

4. Effects of Different Sulfur Components on Oil Quality

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yang, L.; Gao, S.; Deng, B.; Cheng, Z. Corrosion mechanisms for electrical fields leading to the acceleration of copper sulfide deposition on insulation windings. Ind. Eng. Chem. Res. 2017, 56, 9124–9134. [Google Scholar] [CrossRef]

- Wan, T.; Qian, H.; Zhou, Z.; Gong, S.; Hu, X.; Feng, B. Suppressive mechanism of the passivator irgamet 39 on the corrosion of copper conductors in transformers. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 454–459. [Google Scholar] [CrossRef]

- Wiklund, P.; Levin, M.; Pahlavanpour, B. Copper dissolution and metal passivators in insulating oil. IEEE Electr. Insul. Mag. 2007, 23, 6–14. [Google Scholar] [CrossRef]

- Maina, R.; Tumiatti, V.; Pompili, M.; Bartnikas, R. Corrosive sulfur effects in transformer oils and remedial procedures. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1655–1663. [Google Scholar] [CrossRef]

- Ren, S.; Zhong, L.; Yu, Q.; Cao, X.; Li, S. Influence of the Atmosphere on the Reaction of Dibenzyl Disulfide with Copper in Mineral Insulation Oil. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 849–854. [Google Scholar]

- Yang, L.; Gao, S.; Li, J.; Sun, W. Influence of the antioxidant on the long-term ageing characteristics of oil-paper insulation and the deposition and migration of copper sulphide in oil-immersed transformers. IET Electr. Power App. 2016, 10, 675–680. [Google Scholar] [CrossRef]

- Facciotti, M.; Amaro, P.S.; Holt, A.F.; Brown, R.C.D.; Lewin, R.L.; Pilgrim, J.A.; Wilson, G.; Jarman, P.N. Contact-based corrosion mechanism leading to copper sulphide deposition on insulating paper used in oil-immersed electrical equipment. Corros. Sci. 2014, 84, 172–179. [Google Scholar] [CrossRef]

- Oweimreen, G.A.; Jaber, A.M.Y.; Abulkibash, A.M.; Mehanna, N.A. The depletion of dibenzyl disulfide from a mineral transformer insulating oil. IEEE Trans. Dielectr. Electr. Insul. 2013, 19, 1962–1970. [Google Scholar] [CrossRef]

- CIGRE WG A2-32. Copper Sulphide in Transformer Insulation, 2009. Available online: http://www.eepublishers.co.za/view.php?sid=9308 (accessed on 14 June 2007).

- ASTM D3120. Standard Test Method for Trace Quantities of Sulfur in Light Liquid Petroleum Hydrocarbons by Oxidative Microcoulometry, 2014. Available online: https://www.astm.org/Standards/D3120.htm (accessed on 5 January 2014).

- ASTM D4294. Standard Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray Fluorescence Spectrometry, 2016. Available online: https://www.astm.org/Standards/D4294.htm (accessed on 1 January 2016).

- ASTM D2622. Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry, 2010. Available online: https://www.astm.org/Standards/D2622.htm (accessed on 15 February 2010).

- Ren, S.; Zhong, L.; Yu, Q.; Cao, X. Research on the Standard Test and Measuring Method for Corrosive Sulfur in Transformer Oils. High Voltage Apparatus 2011, 47, 40–43. [Google Scholar]

- IEC 62535. Insulating Liquids-Test Method for Detection of Potentially Corrosive Sulfurin Unused and Unused Insulating Oil, 2008. Available online: http://www.iec-standard.com (accessed on 8 October 2008).

- ASTM D1275. Standard Test Method for Corrosive Sulfur in Electrical Insulating Liquids, 2015. Available online: https://www.astm.org/Standards/D1275.htm (accessed on 15 November 2015).

- Flora, S.D.; Thirumurthy; Meena, K.P.; Rajan, J.S. Experimental simulation of effects of high temperatures on paper oil insulation of transformers in presence of DBDS in mineral oil. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2819–2827. [Google Scholar] [CrossRef]

- Yang, L.; Gao, S.; Deng, B. Inhibition method for the degradation of oil-paper insulation and corrosive sulphur in a transformer using adsorption treatment. IET Gener. Transm. Distrib. 2016, 10, 1893–1900. [Google Scholar] [CrossRef]

- Saavedra, T.M.; Tielens, F.; Santos, J.C. Dibenzyl disulfide adsorption on Cu(111) surface: A DFT study. Theor. Chem. Acc. 2016, 135, 1–9. [Google Scholar]

- Tumiatti, V.; Roggero, C.; Tumiatti, M. IEC 62697-2012: State of the Art Methods for Quantification of DBDS and Other Corrosive Sulfur Compounds in Unused and Used Insulating Liquids. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1633–1641. [Google Scholar] [CrossRef]

- ToJyama, S.; Tanimura, J.; Yamada, N. Highly Sensitive Detection Method of Dibenzyl Disulfide and the Elucidation of the Mechanism of Copper Sulfide Generation in Insulating Oil. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 509–515. [Google Scholar] [CrossRef]

- Holt, A.F.; Facciotti, M.; Amaro, P.; Brown, R.C.D.; Lewin, P.L.; Pilgrim, J.A.; Wilson, G.; Jarman, P. An Initial Study into Silver Corrosion in Tramsfomer Following Oil Reclamation. In Proceedings of the 31st Electrical Insulation Conference, Ottawa, ON, Canada, 2–5 June 2013. [Google Scholar]

| Company Name | Transformer Name | Corrosive Degree * | Voltage Level | Delivery Time | Oil Brand | Oil Manufacturer | Oil Group |

|---|---|---|---|---|---|---|---|

| Quan Zhou | Tuzhai No.1 | 3b~4a | 220 kV | 2 December 2004 | Nynas 10 GBX | Nynas | Cycloalkyl |

| Luotang No.2 | 4a~4b | 220 kV | 3 December 2003 | Nynas 10 GBX | Nynas | Cycloalkyl | |

| Nan An | Humei No.3 | 2e | 110 kV | 14 December 2008 | DB-25# | Karamay | Cycloalkyl |

| Pu Tian | Hualin No.2 | 2b | 110 kV | 18 December 2006 | DB-25# | Karamay | Cycloalkyl |

| Xia Men | Wuli No.2 | 3b~4a | 220 kV | 18 September 2001 | DB-25# | Karamay | Cycloalkyl |

| Fu An | Bingongchang No.1 | 1a~1b | Non-operation after detection as corrosive and the oil was returned oil | Paraffin base | |||

| Bingongchang No.2 | 1a~1b | Paraffin base | |||||

| Overhaul | Quanzhou No.1 | 2b | 500 kV | 29 March 1998 | DB-25# | JOMO | Paraffin base |

| Dayuan No.2 | 2b | 500 kV | 4 January 2009 | DB-25# | Karamay | Cycloalkyl | |

| Quanzhou Gaokang | 3a~3b | 500 kV | 29 March 1998 | DB-25# | Karamay | Intermediate base | |

| Xiamen No.1 | 2b | 500 kV | 22 March 1999 | DB-25# | Kansai | Cycloalkyl | |

| Haicang No.1 | 3a | 500 kV | 7 September 2007 | 10# | Nynas | Cycloalkyl | |

| Test Items | Reference Standard | Equipments |

|---|---|---|

| Determination of total sulfur | ASTM D5453-12 Standard Test Method for Determination of Total Sulfur in Light Hy (detection limit is 5 mg/L) | Jena-MultiEA3100 Sulfur nitrogen analyzer |

| Determination of elemental sulfur | Laboratory method Content of elemental sulfur in the sample should be determined by Oscillographic polarography (detection limit is 0.1 mg/L) | JP-2C Oscillographic polarograph |

| Determination of hydrogen sulfide | GB/T 26983-2011 determination of sulfureted hydrogen, methyl mercaptan and ethyl mercaptan in crude oil (detection limit is 2 mg/L) | Agilent-6890N gas chromatograph Gas chromatography PFPD detector |

| Determination of mercaptan sulfur | GB 1792-1988 Determination of mercaptan sulphur (Potentio metric titration method)(detection limit is 3 mg/L) | Kyoto Electronics AT-710M Automatic potentiometric itrant |

| Determination of DBDS | IEC 62697-1-2012 Test methods for quantitative determination of corrosive sulfur compounds in unused and used insulating liquids-Part 1: Test method for quantitative determination of dibenzyl disulphide (DBDS) | Gas chromatography-mass spectrometry(GC-MS) |

| Determination of thiophene sulfur and thioether sulfur | Laboratory method The distribution characteristics of thiophene sulfur and thioether sulfur should be analyzed in depth | FT-ICR MS (Bruker Apex Ultra 9.4T AS) Agilent 355SCD Sulfur Chemiluminescence Detector Agilent7890A-5975C Gas chromatography-mass spectrometry |

| Sulfur Type (mg/L) | QZT | WLT | HCT | HLT |

|---|---|---|---|---|

| Total sulfur content | 1562 | 190 | 203 | 457 |

| Hydrogen sulphide | 0 | 0 | 0 | 0 |

| Elemental sulfur | <0.1 | <0.1 | <0.1 | <0.1 |

| Mercaptan sulfur | <3 | <3 | <3 | <3 |

| Thiophene sulfur | 1380 | 150 | 42 | 65 |

| Thioether sulfur | 86 | 30 | 159 | 376 |

| Others | 52 | 0 | 2 | 16 |

| Sulfur balance | 97.18% | 100% | 99.99% | 99.96% |

| Unsaturation | Molecular Formula | Possible Structural Formula |

|---|---|---|

| 2 | CnH2n-2S |  |

| 3 | CnH2n-4S |  |

| 4 | CnH2n-6S |  |

| 5 | CnH2n-8S |  |

| 6 | CnH2n-10S |  |

| 7 | CnH2n-12S |  |

| 8 | CnH2n-14S |  |

| Sulfide | New Oil | DBDS | DDM | DBDS + DDM |

|---|---|---|---|---|

| DBDS (ppm) | - | 200 | - | 100 |

| DDM (ppm) | - | - | 400 | 200 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cong, H.; Zhang, M.; Li, Q. Study on Sulfide Distribution in the Operating Oil of Power Transformers and Its Effect on the Oil Quality. Appl. Sci. 2018, 8, 1577. https://doi.org/10.3390/app8091577

Cong H, Zhang M, Li Q. Study on Sulfide Distribution in the Operating Oil of Power Transformers and Its Effect on the Oil Quality. Applied Sciences. 2018; 8(9):1577. https://doi.org/10.3390/app8091577

Chicago/Turabian StyleCong, Haoxi, Minhao Zhang, and Qingmin Li. 2018. "Study on Sulfide Distribution in the Operating Oil of Power Transformers and Its Effect on the Oil Quality" Applied Sciences 8, no. 9: 1577. https://doi.org/10.3390/app8091577