Experimental Analysis of Pore and Permeability Characteristics of Coal by Low-Field NMR

Abstract

:1. Introduction

2. Coal Samples and Experiments

2.1. Sample Description

2.2. Low-Field NMR Test

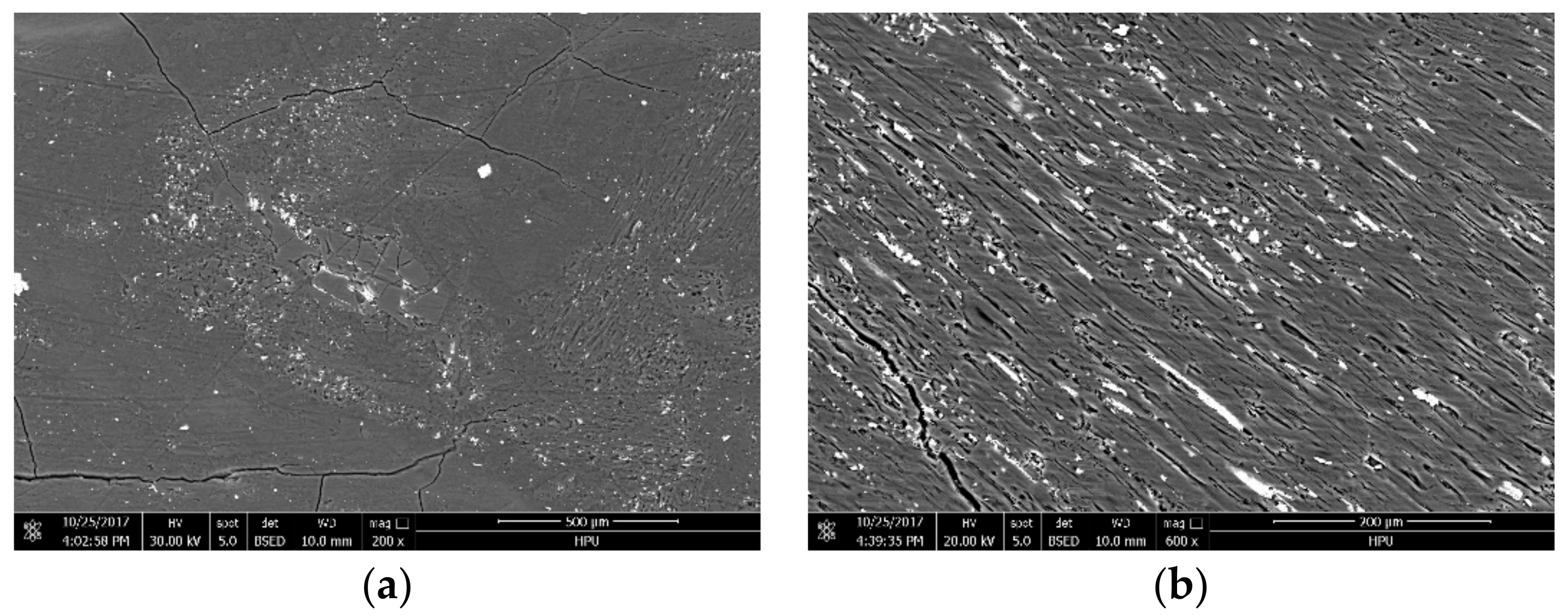

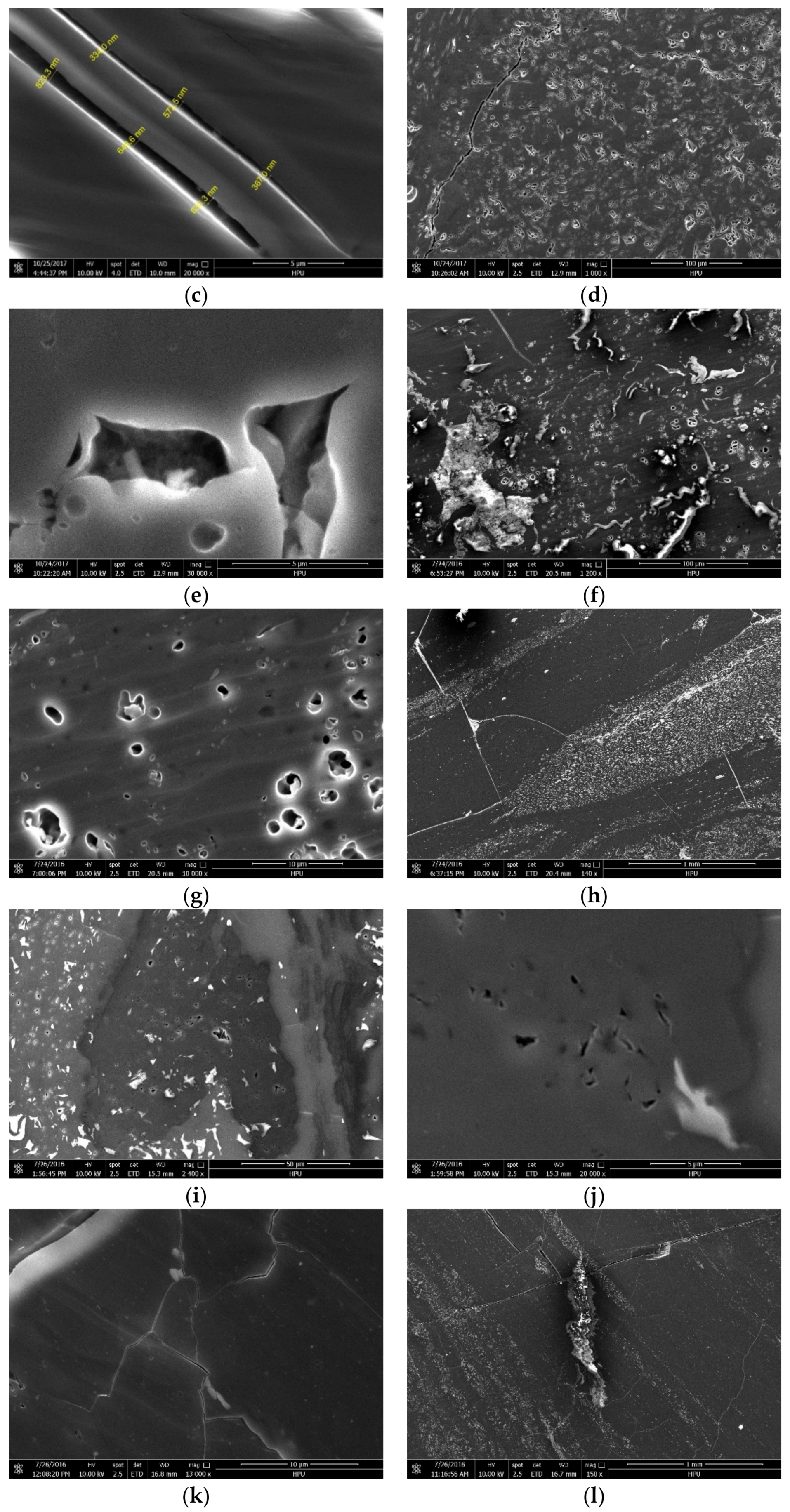

2.3. MIP, SEM, and Permeability Test

3. Discussion

3.1. Pore Type of NMR

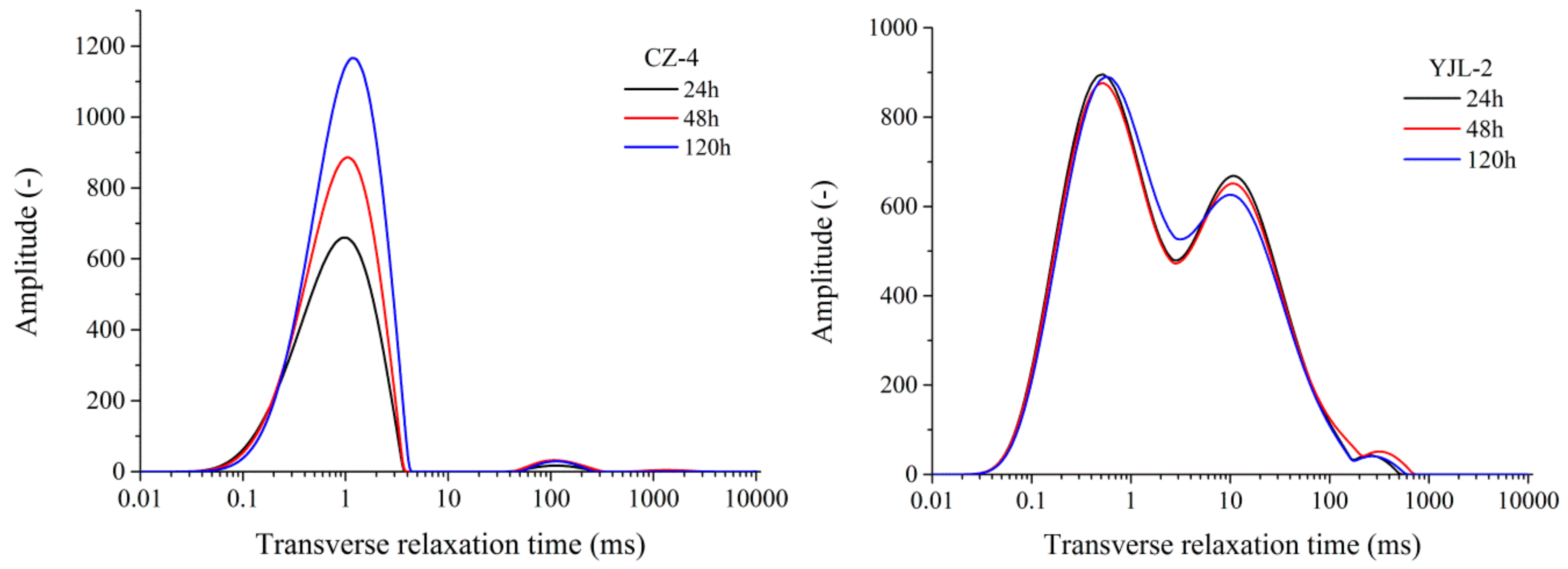

3.1.1. Morphology and Variation of T2 Spectra

3.1.2. Pore Types and Development Characteristics

3.1.3. Influence of Pore Type on Fluid

3.2. NMR Porosity

3.2.1. Porosity of Different Types of Pores

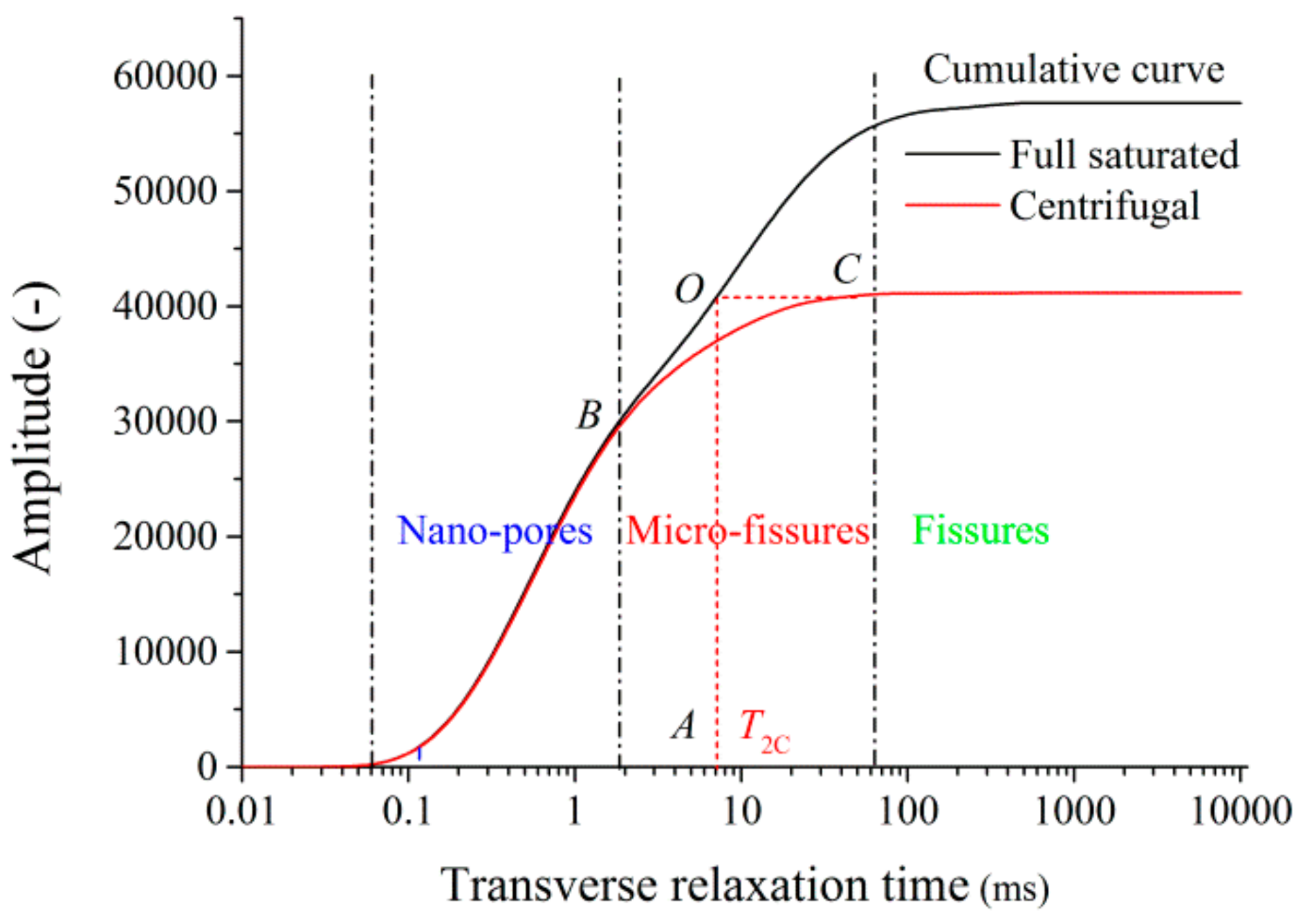

3.2.2. Movable Fluid Porosity

3.3. NMR Pore Structure

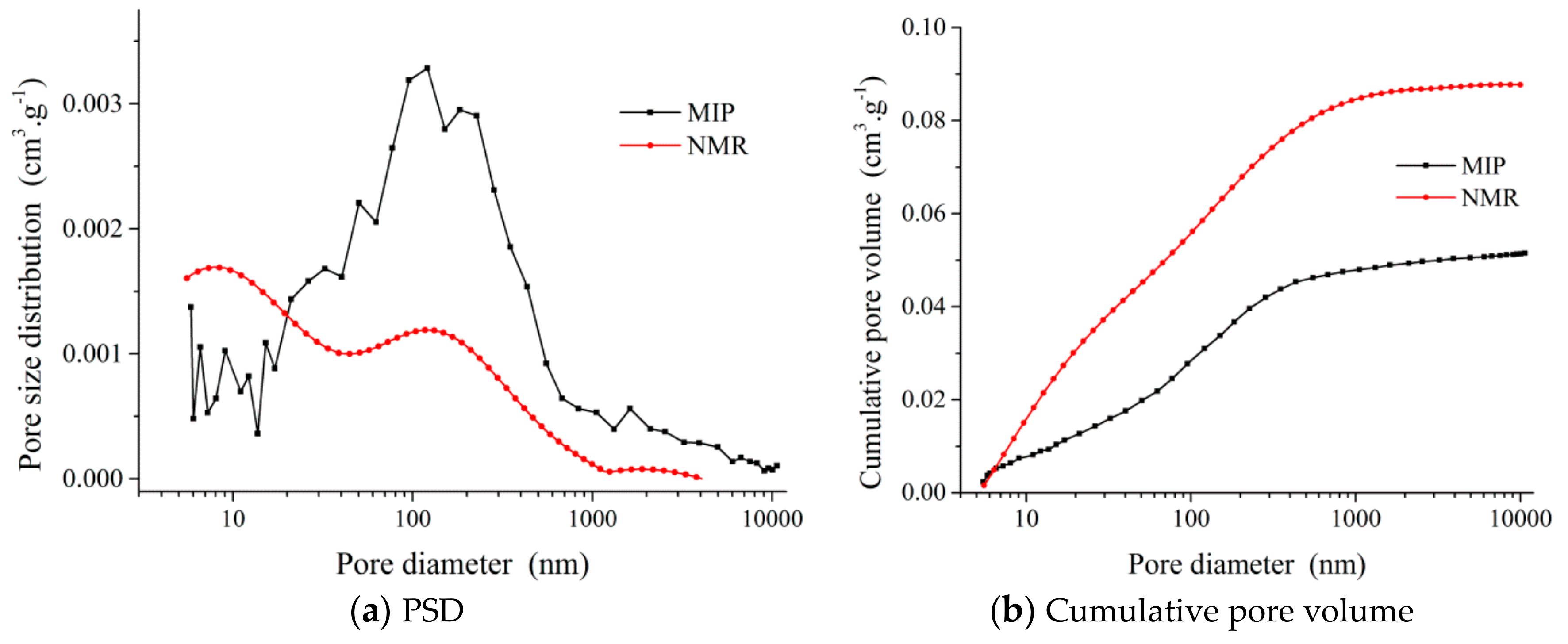

3.3.1. PSD of NMR

3.3.2. NMR Permeability

3.4. Significance of NMR to CBM Development

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Scott, R.; Larry, P. Advanced reservoir modeling in desorption-controlled reservoirs. In Proceedings of the SPE Rocky Mountain Petroleum Technology Conference, Keystone, CO, USA, 21–23 May 2001. [Google Scholar]

- Okolo, G.N.; Everson, R.C.; Neomagus, H.W.J.P.; Roberts, M.J.; Sakurovs, R. Comparing the Porosity and Surface Areas of Coal as Measured by Gas Adsorption, Mercury Intrusion and SAXS Techniques. Fuel 2015, 141, 293–304. [Google Scholar] [CrossRef]

- Qu, Z.; Jiang, B.; Wang, J.; Li, M. Study of Nanopores of Tectonically Deformed Coal Based on Liquid Nitrogen Adsorption at Low Temperatures. J. Nanosci. Nanotechnol. 2017, 17, 6566–6575. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, S.; Elsworth, D.; Jiang, Y.; Jie, Z. Pore Structure Characterization of Coal by Synchrotron Small-Angle X-ray Scattering and Transmission Electron Microscopy. Energy Fuels 2014, 28, 3704–3711. [Google Scholar] [CrossRef]

- O’Brien, G.; Gu, Y.; Adair, B.J.I.; Firth, B. The Use of Optical Reflected Light and SEM Imaging Systems to Provide Quantitative Coal Characterisation. Miner. Eng. 2011, 24, 1299–1304. [Google Scholar] [CrossRef]

- Radlinski, A.P.; Mastalerz, M.; Hinde, A.L.; Hainbuchner, M.; Rauch, H.; Baron, M.; Lin, J.S.; Fan, L.; Thiyagarajan, P. Application of SAXS and SANS in Evaluation of Porosity, Pore Size Distribution and Surface Area of Coal. Int. J. Coal Geol. 2004, 59, 245–271. [Google Scholar] [CrossRef]

- Zhou, H.W.; Zhong, J.C.; Ren, W.G.; Wang, X.Y.; Yi, H.Y. Characterization of Pore-Fracture Networks and Their Evolution at Various Measurement Scales in Coal Samples Using X-ray μCT and a Fractal Method. Int. J. Coal Geol. 2018, 189, 35–49. [Google Scholar] [CrossRef]

- Li, X.; Kang, Y.; Haghighi, M. Investigation of Pore Size Distributions of Coals with Different Structures by Nuclear Magnetic Resonance (NMR) and Mercury Intrusion Porosimetry (MIP). Measurement 2018, 116, 122–128. [Google Scholar] [CrossRef]

- Kleinberg, R.L.; Vinegar, H.J. NMR Properties of Reservoir Fluids. Log Anal. 1996, 37, 20–32. [Google Scholar] [CrossRef]

- Seevers, D.O. A Nuclear Magnetic Method for Determining the Permeability of Sandstones. In Proceedings of the SPWLA 7th Annual Logging Symposium, Tulsa, OK, USA, 9–11 May 1966. [Google Scholar]

- Yao, Y.; Liu, D.; Che, Y.; Tang, D.; Tang, S.; Huang, W. Petrophysical Characterization of Coals by Low-Field Nuclear Magnetic Resonance (NMR). Fuel 2010, 89, 1371–1380. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Pan, Z.; Yao, Y.; Li, J.; Qiu, Y. Petrophysical Characterization of Chinese Coal Cores with Heat Treatment by Nuclear Magnetic Resonance. Fuel 2013, 108, 292–302. [Google Scholar] [CrossRef]

- Zou, M.; Wei, C.; Miao, Z.; Jian, S.; Chen, Y.; Yu, Q. Classifying Coal Pores and Estimating Reservoir Parameters by Nuclear Magnetic Resonance and Mercury Intrusion Porosimetry. Energy Fuels 2013, 27, 3699–3708. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D. Comparison of Low-Field NMR and Mercury Intrusion Porosimetry in Characterizing Pore Size Distributions of Coals. Fuel 2012, 95, 152–158. [Google Scholar] [CrossRef]

- Song, L.; Tang, D.; Hao, X.; Zi, Y.; Guo, L. Porosity and Permeability Models for Coals Using Low-Field Nuclear Magnetic Resonance. Energy Fuels 2012, 26, 5005–5014. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Pan, Z.; Che, Y.; Liu, Z. Investigating the Effects of Seepage-Pores and Fractures on Coal Permeability by Fractal Analysis. Transp. Porous Media 2016, 111, 479–497. [Google Scholar] [CrossRef]

- Method of Determining Microscopically the Reflectance of Vitrinite in Coal; GB/T 6948; Standardization Administration of the People’s Republic of China: Beijing, China, 2008; pp. 1–12.

- Proximate Analysis of Coal; GB/T 212; Standardization Administration of the People’s Republic of China: Beijing, China, 2008; pp. 1–15.

- Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption Part 1: Mercury Porosimetry; GB/T 21650.1; Standardization Administration of the People’s Republic of China: Beijing, China, 2008; pp. 1–18.

- Yao, Y.B.; Liu, D.M. Advanced Characterization of Pores and Fractures in Coals by Nuclear Magnetic Resonance and X-ray Computed Tomography. Sci. China Ser. D Earth Sci. 2010, 53, 854–862. [Google Scholar] [CrossRef]

- Kleinberg, R.L. Utility of NMR T2 Distributions, Connection with Capillary Pressure, Clay Effect, and Determination of The Surface Relaxivity Parameter ρ2. Magn. Reson. Imag. 1996, 14, 761–767. [Google Scholar] [CrossRef]

- Cohen, M.H.; Mendelson, K.S. Nuclear Magnetic Relaxation and the Internal Geometry of Sedimentary Rocks. J. Appl. Phys. 1982, 53, 1127–1135. [Google Scholar] [CrossRef]

- Harmer, J.; Callcott, T.; Maeder, M.; Smith, B.E. A Novel Approach for Coal Characterization by NMR Spectroscopy: Global Analysis of Proton T1 and T2 Relaxations. Fuel 2001, 80, 417–425. [Google Scholar] [CrossRef]

- Rock Capillary Pressure Measurement; GB/T 29171; Standardization Administration of the People’s Republic of China: Beijing, China, 2012; pp. 1–24.

- Finn, R. Capillary Surface Interfaces. Notices AMS 1999, 46, 771–781. [Google Scholar]

- Washburn, E.W. The Dynamics of Capillary Flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Timur, A. An Investigation of Permeability, Porosity, and Residual Water Saturation Relationship for Sandstone Reservoirs. In Proceedings of the SPWLA 9th Annual Logging Symposium, New Orleans, LA, USA, 23–26 June 1968. [Google Scholar]

- Coates, G.; Denoo, S. The Producibility Answer Product. Tech. Rev. 1981, 29, 54–63. [Google Scholar]

- Kenyon, W.E.; Day, P.I.; Straley, C.; Willemsen, J.F. A Three-part Study of NMR longitudinal Relaxation Properties of Water-saturated Sandstones. SPE Form. Eval. 1988, 3, 622–636. [Google Scholar] [CrossRef]

- Timur, A. Pulsed Nuclear Magnetic Resonance Studies of Porosity, Movable Fluid, and permeability of Sandstones. J. Pet. Technol. 1969, 21, 775–786. [Google Scholar] [CrossRef]

- Coates, G.R.; Xiao, L.; Prammer, M.G. NMR Logging Principles and Applications; Haliburton Energy Service: Houston, TX, USA, 1999; Volume 234. [Google Scholar]

- Westphal, H.; Surholt, I.; Kiesl, C.; Thern, H.F.; Kruspe, T. NMR Measurements in Carbonate Rocks: Problems and an Approach to a Solution. Pure Appl. Geophys. 2005, 162, 549–570. [Google Scholar] [CrossRef]

- Carman, P.C. Permeability of Saturated Sands, Soils and Clays. J. Agric. Sci. 1939, 29, 262–273. [Google Scholar] [CrossRef]

- Carman, P.C. Fluid Flow Through Granular Beds. Chem. Eng. Res. Des. 1997, 75, S32–S48. [Google Scholar] [CrossRef]

- Pape, H.; Clauser, C.; Iffland, J. Variation of Permeability with Porosity in Sandstone Diagenesis Interpreted with a Fractal Pore Space Model. Pure Appl. Geophys. 2000, 157, 603–619. [Google Scholar] [CrossRef]

- Yu, B.; Li, J. A Geometry Model for Tortuosity of Flow Path in Porous Media. Chin. Phys. Lett. 2004, 21, 1569–1571. [Google Scholar] [CrossRef]

- Shan, C.; Zhang, T.; Guo, J.; Zhang, Z.; Yang, Y. Characterization of the Micropore Systems in the high-rank Coal Reservoirs of the Southern Sichuan Basin, China. AAPG Bull. 2015, 99, 2099–2119. [Google Scholar] [CrossRef]

- Choi, J.G.; Do, D.D.; Do, H.D. Surface diffusion of adsorbed molecules in porous media: Monolayer, multilayer, and capillary condensation regimes. Ind. Eng. Chem. Res. 2001, 40, 4005–4031. [Google Scholar] [CrossRef]

- Si, L.; Li, Z.; Yang, Y. Coal Permeability Evolution with the Interaction Between Nanopore and Fracture: Its Application in Coal Mine Gas Drainage for Qingdong Coal Mine in Huaibei Coalfield, China. J. Nat. Gas Sci. Eng. 2018, 56, 523–535. [Google Scholar] [CrossRef]

| Sample ID | Mining Area | Sample Direction | Coal Rank | Ro,max (%) | Mad (%) | Ad (%) | Vdaf (%) | FCd (%) |

|---|---|---|---|---|---|---|---|---|

| CZ-1 | Jincheng | bedding | anthracitic | 2.69 | 3.53 | 9.72 | 7.23 | 83.75 |

| CZ-2 | Jincheng | bedding | anthracitic | 2.87 | 2.58 | 9.90 | 7.72 | 83.14 |

| CZ-3 | Jincheng | vertical | anthracitic | 2.79 | 2.56 | 9.87 | 7.74 | 83.15 |

| CZ-4 | Jincheng | bedding | anthracitic | 3.10 | 3.46 | 11.45 | 7.32 | 82.07 |

| WY-1 | Luan | bedding | bitumite | 1.94 | 1.03 | 8.91 | 13.13 | 79.13 |

| WY-2 | Luan | vertical | bitumite | 2.05 | 1.00 | 8.92 | 13.20 | 79.06 |

| YJL-1 | Yulin | bedding | sub-bitumite | 0.66 | 6.17 | 3.77 | 29.51 | 67.83 |

| YJL-2 | Yulin | vertical | sub-bitumite | 0.69 | 6.18 | 3.78 | 29.51 | 67.83 |

| Sample ID | Volume (cm3) | ρ (g/cm3) | Suv | ϕt (%) | ϕp (%) | ϕmf (%) | ϕf (%) |

|---|---|---|---|---|---|---|---|

| CZ-1 | 25.36 | 1.47 | 1031.45 | 8.26 | 8.18 | 0 | 0.08 |

| CZ-2 | 25.44 | 1.47 | 1016.76 | 8.14 | 7.96 | 0 | 0.17 |

| CZ-3 | 25.16 | 1.45 | 977.27 | 7.83 | 7.65 | 0 | 0.17 |

| CZ-4 | 25.82 | 1.49 | 955.97 | 7.66 | 7.56 | 0 | 0.10 |

| WY-1 | 24.84 | 1.42 | 372.77 | 3.05 | 2.58 | 0.36 | 0.11 |

| WY-2 | 24.80 | 1.40 | 334.02 | 2.75 | 2.34 | 0.30 | 0.10 |

| YJL-1 | 25.05 | 1.32 | 1900.47 | 15.12 | 9.43 | 5.53 | 0.16 |

| YJL-2 | 25.19 | 1.33 | 1831.65 | 14.58 | 8.67 | 5.78 | 0.13 |

| Sample ID | T2C (ms) | FFI (%) | BVI (%) | ϕFFI (%) | ϕBVI (%) | ϕCFFI (%) |

|---|---|---|---|---|---|---|

| CZ-1 | 1.78 | 17.95 | 82.05 | 1.48 | 6.78 | 1.36 |

| CZ-2 | 1.84 | 16.99 | 83.01 | 1.38 | 6.76 | 1.41 |

| CZ-3 | 1.88 | 16.93 | 83.07 | 1.33 | 6.50 | 1.36 |

| CZ-4 | 1.93 | 16.91 | 83.09 | 1.30 | 6.36 | 1.28 |

| WY-1 | 1.36 | 23.35 | 76.65 | 0.71 | 2.34 | 0.68 |

| WY-2 | 1.76 | 23.05 | 76.95 | 0.63 | 2.12 | 0.61 |

| YJL-1 | 6.94 | 28.79 | 71.21 | 4.35 | 10.77 | 4.26 |

| YJL-2 | 7.39 | 28.61 | 71.39 | 4.17 | 10.41 | 4.23 |

| Sample ID | T2,log mean | Sp (m−1) | DNMR | kTC (mD) | ks (mD) | kpp (mD) | kCR (mD) | kNMRF (mD) | kT (mD) |

|---|---|---|---|---|---|---|---|---|---|

| CZ-1 | 0.93 | 0.48 | 2.9933 | 0.0936 | 0.0284 | 0.9295 | 10.4002 | 0.9810 | 0.0317 |

| CZ-2 | 1.14 | 0.50 | 2.9912 | 0.0772 | 0.0400 | 0.8249 | 7.7132 | 0.8979 | 0.1317 |

| CZ-3 | 1.01 | 0.51 | 2.9903 | 0.0656 | 0.0267 | 0.7681 | 6.4302 | 0.8655 | 0.0067 |

| CZ-4 | 0.97 | 0.48 | 2.9923 | 0.0599 | 0.0229 | 0.7391 | 5.8221 | 0.9762 | 0.0215 |

| WY-1 | 0.83 | 9.32 | 2.9633 | 0.0034 | 0.0004 | 0.2904 | 0.4461 | 0.0024 | 0.0998 |

| WY-2 | 0.88 | 9.96 | 2.9616 | 0.0022 | 0.0003 | 0.2436 | 0.2705 | 0.0021 | 0.0033 |

| YJL-1 | 2.16 | 430.24 | 2.9442 | 3.5890 | 1.7126 | 11.7815 | 6.0027 | 1.0068 × 10−6 | 2.2253 |

| YJL-2 | 2.18 | 450.66 | 2.9434 | 3.0460 | 1.5007 | 10.2214 | 5.0976 | 1.1061 × 10−6 | 1.7177 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, X.; Song, D.; Zhao, H.; Li, Y.; He, K. Experimental Analysis of Pore and Permeability Characteristics of Coal by Low-Field NMR. Appl. Sci. 2018, 8, 1374. https://doi.org/10.3390/app8081374

Ji X, Song D, Zhao H, Li Y, He K. Experimental Analysis of Pore and Permeability Characteristics of Coal by Low-Field NMR. Applied Sciences. 2018; 8(8):1374. https://doi.org/10.3390/app8081374

Chicago/Turabian StyleJi, Xiaofeng, Dangyu Song, Haotian Zhao, Yunbo Li, and Kaikai He. 2018. "Experimental Analysis of Pore and Permeability Characteristics of Coal by Low-Field NMR" Applied Sciences 8, no. 8: 1374. https://doi.org/10.3390/app8081374