1. Introduction

Northeastern China is one of the most important energy production and consumption regions of China. An increasing number of industrial wastes are produced year on year, such as fly ash (FA), slag, and oil fuel ash [

1,

2]. Oil shale ash (OSA) is the by-product of oil shale, which is considered as a substitute for conventional oil. Because of the low oil extraction from oil shale, a large amount of OSA has accumulated, which has been an urgent problem to be solved [

3,

4].

Soil stabilization is an effective measure to recycle residue wastes [

5,

6]. Compared with use in construction materials, such as cement, asphalt, and concrete, the application of waste residues in soil stabilization has the advantages of high utilization, low price, and simple technology. The stabilized soils often possess greater strength, swell properties, or resistance to erosion after freeze–thaw (F-T) cycles [

7]. FA is one of the most commonly used additives. Parsons and Milburn [

8] stabilized several different types of soils by using Class C FA. The strength and durability tests indicated that the FA-treated soils showed substantial improvement in soil performance for multiple soils. Prabakar et al. [

9] mixed different percentages of FA with soft soils and investigated the usefulness of FA as a soil additive. The result revealed that the CBR (California bearing ratio) and shear strength of the mixed soils increased with increasing FA percentage.

Many attempts have also been made to utilize OSA in soil stabilization. Turner [

10] studied the viability of using soils stabilized by OSA as subgrade filling based on compaction, unconfined compression, durability, and resilient modulus test. It was found that the significant increase in strength, durability, and resilient modulus was due to the cementing property of OSA. The testing data and the mixture design of the modified soil are an important reference for use in highway construction. Mymrin et al. [

11] investigated the physicochemical interaction and structure formation processes of several types of clayed soils with OSA. The obtained results showed that after hydration, the strength of the mixture increased as a result of the partial dissolution of the surface of hard particles and the growth of flocculation formations. In fact, the great engineering property of OSA-stabilized soils is mainly attributed to the cementing property of OSA [

10,

12,

13]. It has been revealed in previous literature that the combination of fuel ash waste and FA as additives has a significant effect on soil stabilization [

14,

15]. However, research on the application of soils stabilized by both OSA and FA is scarce, especially on the dynamic resilient modulus of the modified soil.

As the most important index in pavement structure design, dynamic resilient modulus can truly reflect the dynamic mechanical property of subgrade materials subjected to repeated traffic loading. Previous studies have focused on the influencing factors of resilient modulus, such as stress state, moisture content, and physical properties of subgrade materials. Uzan [

16] established the prediction model of resilient modulus relating to shear stress and bulk stress. This model was then revised by introducing confining pressure and deviator stress [

17]. In consideration of the main influencing factors of resilient modulus, a formula was also given to predict the resilient modulus in pavement design by AASHTO (American Association of State Highway and Transportation Officials) [

18]. According to the deformation characteristics for a series of subbase and subgrade materials, Lee et al. [

19] created the relationship between resilient modulus and elastic modulus. Subgrade materials are usually subjected to partially saturated conditions or regular moisture variation affected by seasonal variation. To obtain more effective constitutive models for unsaturated soils, an enhanced method incorporating matric suction with stress factors to calculate resilient modulus was proposed [

20]. Zhu et al. [

21] discussed the influence of initial modulus and stress path on resilient modulus by comparing the strength and deformation of two coarse-grained soils.

In addition to stress states and physical properties of subgrade materials, resilient modulus is significantly affected by external environmental factors, especially F-T cycles. For materials in seasonally frozen areas, the performance reduction caused by F-T cycles should be considered in construction design. Qi et al. [

22,

23] measured the resilient modulus after one F-T cycle and recognized a significant modulus reduction. Moreover, he found that after F-T cycles, the porosity of compacted soils became larger, but the porosity of loose soils became smaller. Lee et al. [

24] defined S

u1%, which represents the stress at the axial strain of 1% in unconfined compression tests. Their studies demonstrated that the performance reduction effect exhibited after the first F-T cycle is about 50% when S

u1% is greater than 103 kPa. The obvious reduction effect was also verified by Simonsen et al. based on measuring properties of several road materials after F-T cycles [

25]. Existing experimental studies about the influence of F-T cycles on soil property have provided valuable results. The physical and mechanical property of soils modified by multiple additives such as FA and OSA are unknown and worth studying. To evaluate the performance of a modified material as subgrade filling in seasonally frozen regions, it is necessary and crucial to master the variation characteristics of its dynamic resilient modulus after multiple F-T cycles.

In this study, a novel subgrade material obtained by modifying silty clay (SC) with OSA and FA was produced. The dynamic resilient moduli of unmodified SC and the modified SC under different stress states and F-T cycles were measured. The influence of various factors such as confining pressure, deviator stress, and F-T cycles on the resilient modulus for the two materials were analyzed. The damage ratio and its fitting equation were adopted to describe the relationship of resilient modulus versus F-T cycles. To better investigate the influence of F-T cycles on resilient modulus for test soils, SEM testing was conducted to analyze the variation characteristics of microstructure and pore distribution of soils.

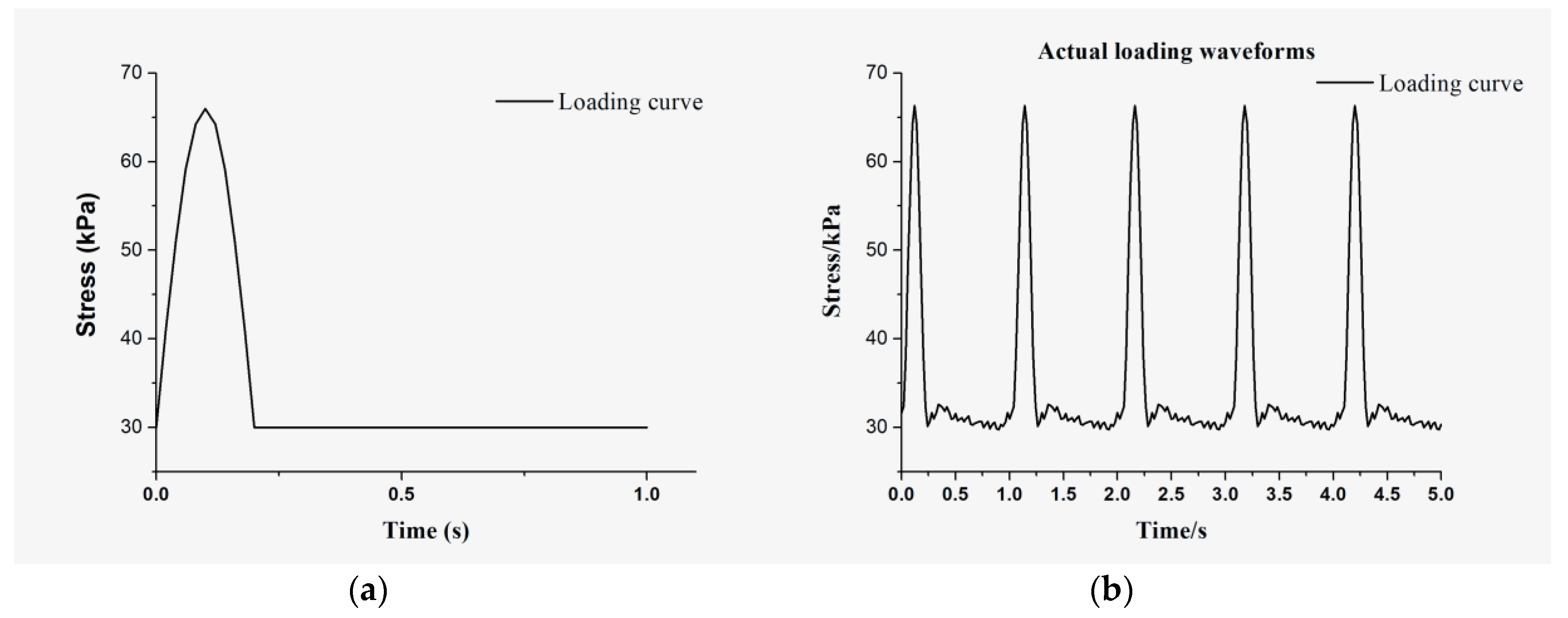

3. Results and Discussion

The resilient modulus and the corresponding standard deviation of unmodified SC and the modified SC are listed in

Table 3 and

Table 4, respectively.

The standard deviations of unmodified SC vary from 0.68 to 2.21, but most of them are between 1.0 and 2.0, while the standard deviations of the modified SC vary from 0.59 to 2.03, but most of them are less than 1.0. This demonstrates that the dispersion degree of the measured data is low. The result is reliable to be used for further analysis. Moreover, the standard deviations of the modified SC are lower and more stable than those of unmodified SC, especially after freeze–thaw cycles. This means that the stability of the resilient modulus with freeze–thaw cycles for the modified SC is better than that of unmodified soil. More detailed analysis is carried out in the following parts.

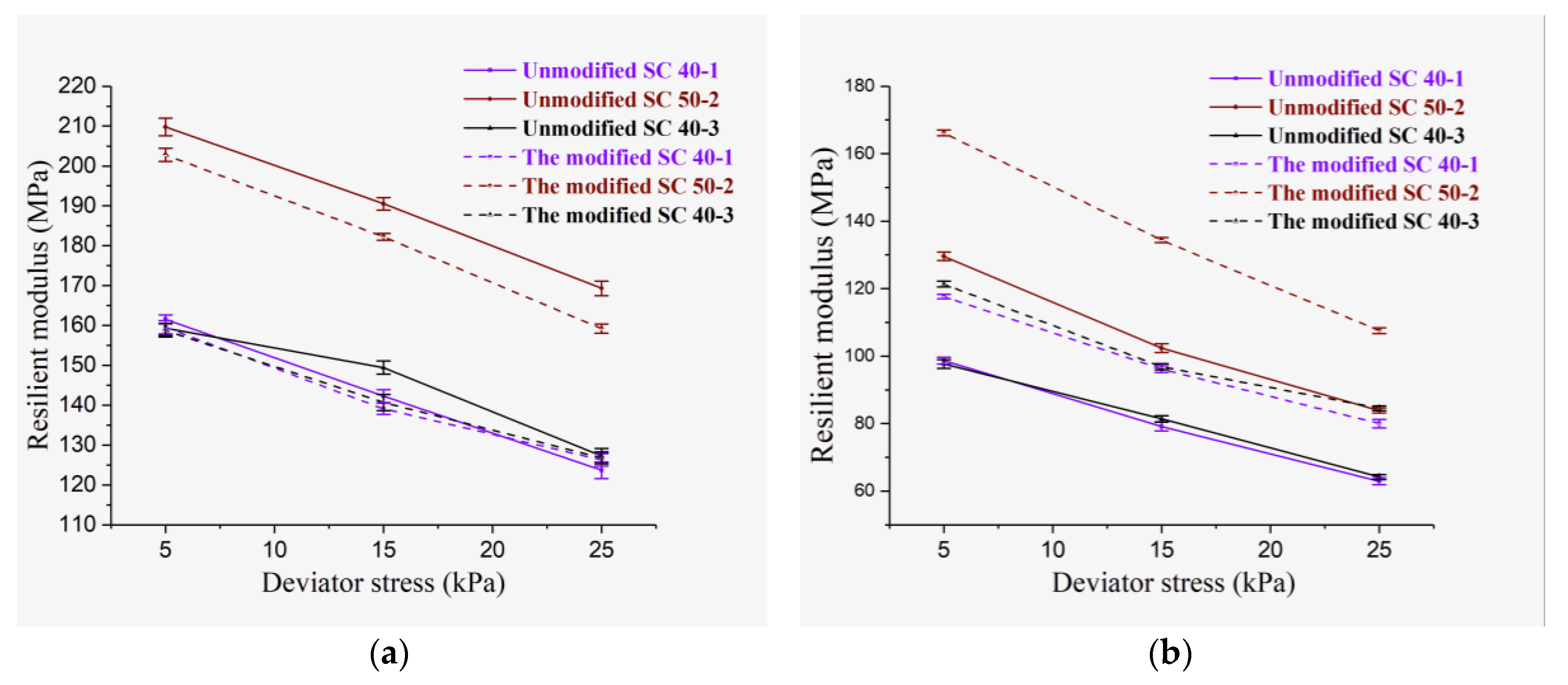

3.1. Effect of Stress State on Resilient Modulus

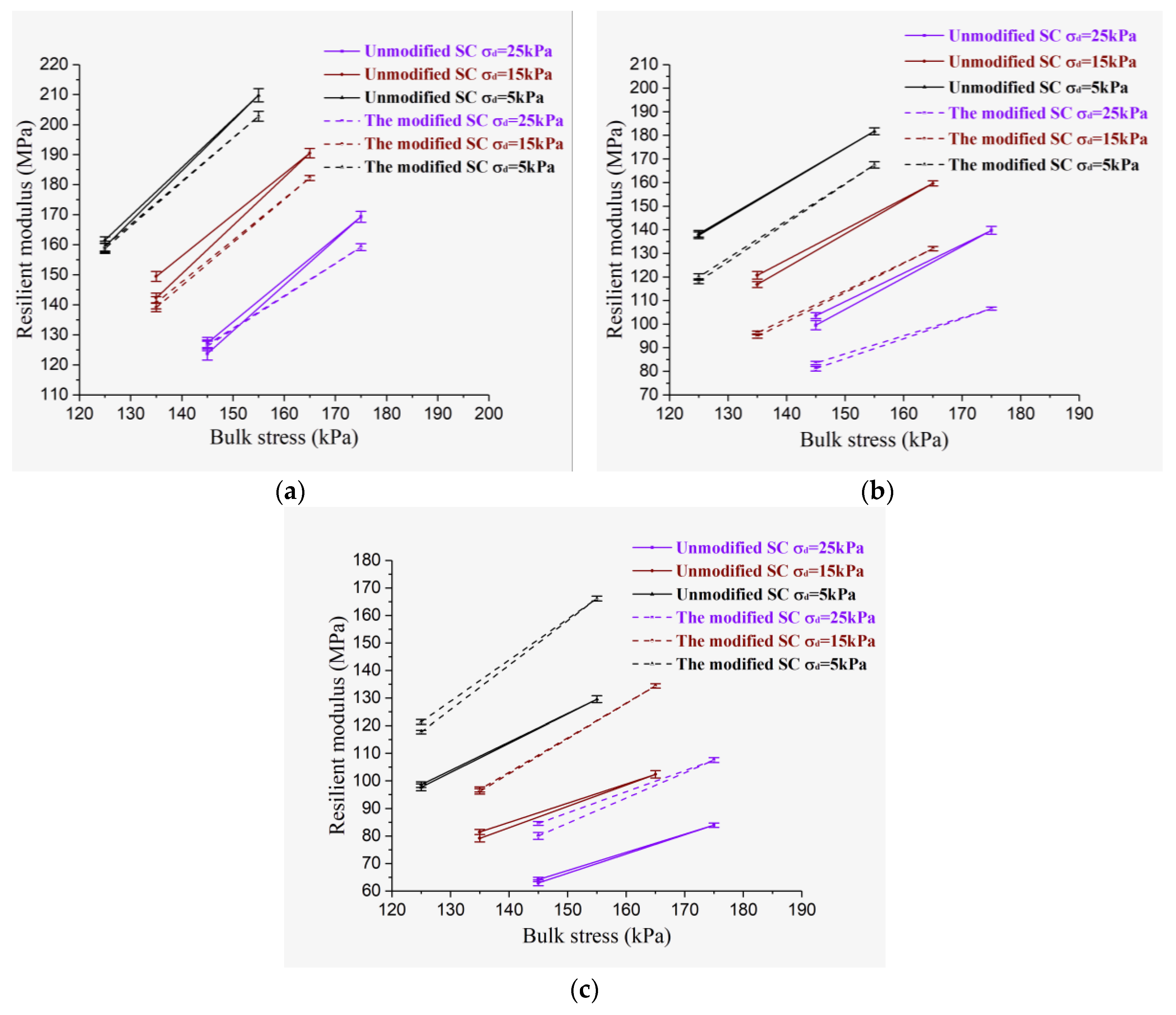

To investigate the effect of confining pressure and deviator stress on the variation trend of resilient modulus, the resilient moduli of two materials in an unfrozen state and after 1 to 7 F-T cycles were analyzed. The variation curves of resilient modulus versus deviator stress and bulk stress (

θ =

σ1 +

σ2 +

σ3) are shown in

Figure 4 and

Figure 5, respectively.

From

Figure 4, the resilient moduli of both unmodified SC and the modified SC decrease with increasing deviator stress. The resilient modulus in high confining pressure (

σc = 50 kPa) is higher than that in low confining pressure (

σc = 40 kPa). From

Figure 5, the resilient modulus increases with the increase of bulk stress. The variation trends of resilient modulus versus deviator stress and bulk stress are still significant after F-T cycles. In

Figure 5, It should be noted that the shape of each data curve in

Figure 5 is a break-line of horizontal “Λ”. The starting point and end point of the “Λ” curve are the resilient moduli of loading sequences 40-1 and 40-3, respectively. When the horizontal “Λ” curve is close to an “I” shape, it means that the resilient modulus values of 40-1 and 40-3 are exactly equal. This phenomenon is in accordance with the coincident curves of 40-1 and 40-3 in

Figure 4, which illustrates that the influence of loading path on resilient modulus is insignificant under the same stress state. In consideration of the close resilient modulus values of 40-1 and 40-3, the data of process 40-3 is not analyzed in the following parts.

Reasons for the variation characteristics of the resilient modulus lie in the fact that the particle structure of soils is significantly influenced by stress states. Soils are compacted by high confining pressure, hence resulting in denser particle structure and bigger resilient modulus, while the particle structure of soils is easily destroyed and rearranged by deviator stress. The rearrangement of structure could lead to the decrease of the resilient modulus. The results in this study are similar to the results of existing literature [

20,

35].

The influence of stress state on the resilient modulus is still significant after F-T cycles. Furthermore, the effect of F-T cycles on the resilient modulus of both materials is reduction, but the reduction variation characteristics are slightly different. The resilient modulus of unmodified SC drops gradually and stabilizes after 7 F-T cycles, while the resilient modulus of the modified soil decreases fast and then tends to be stable.

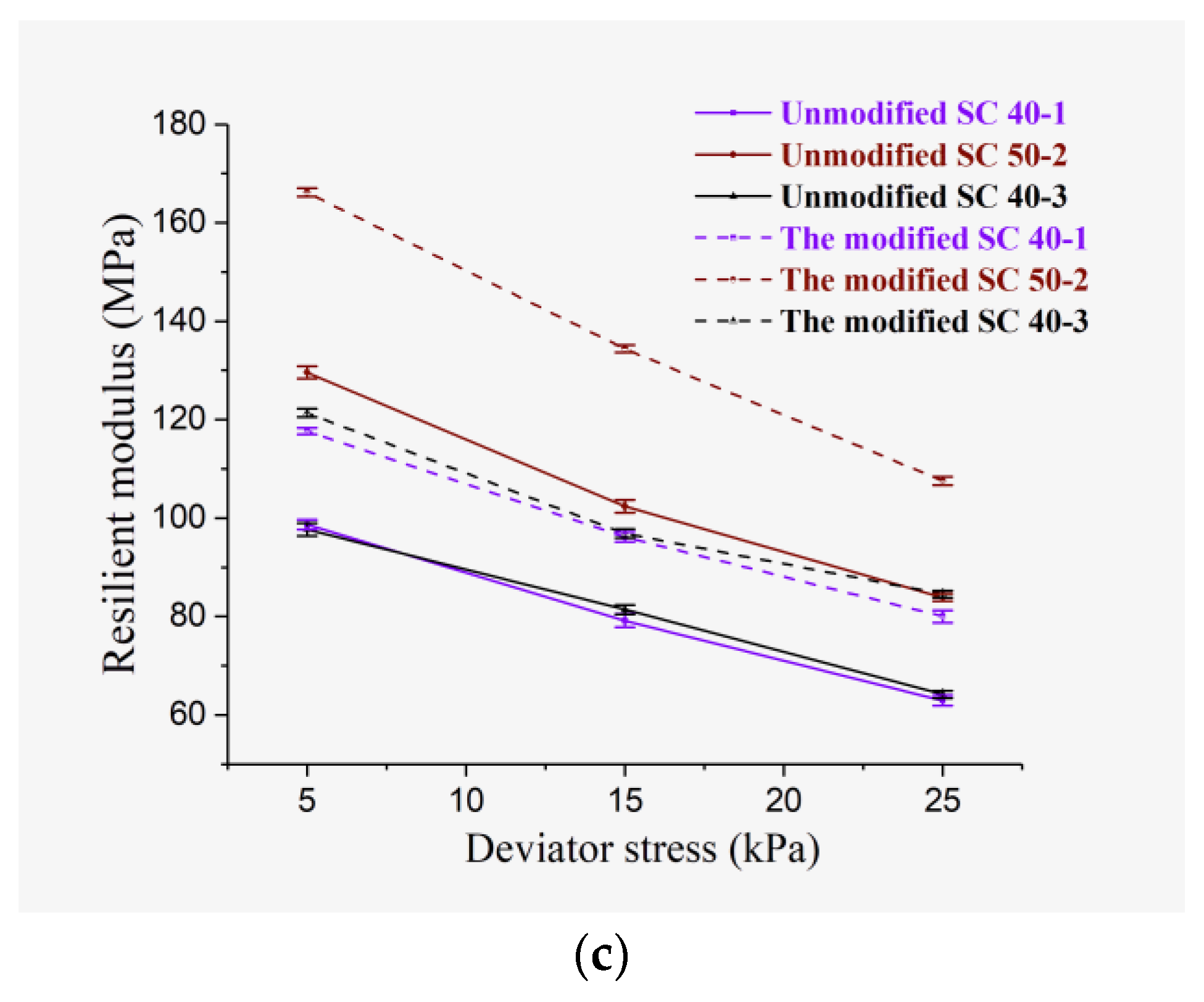

3.2. Effect of F-T Cycles on Resilient Modulus

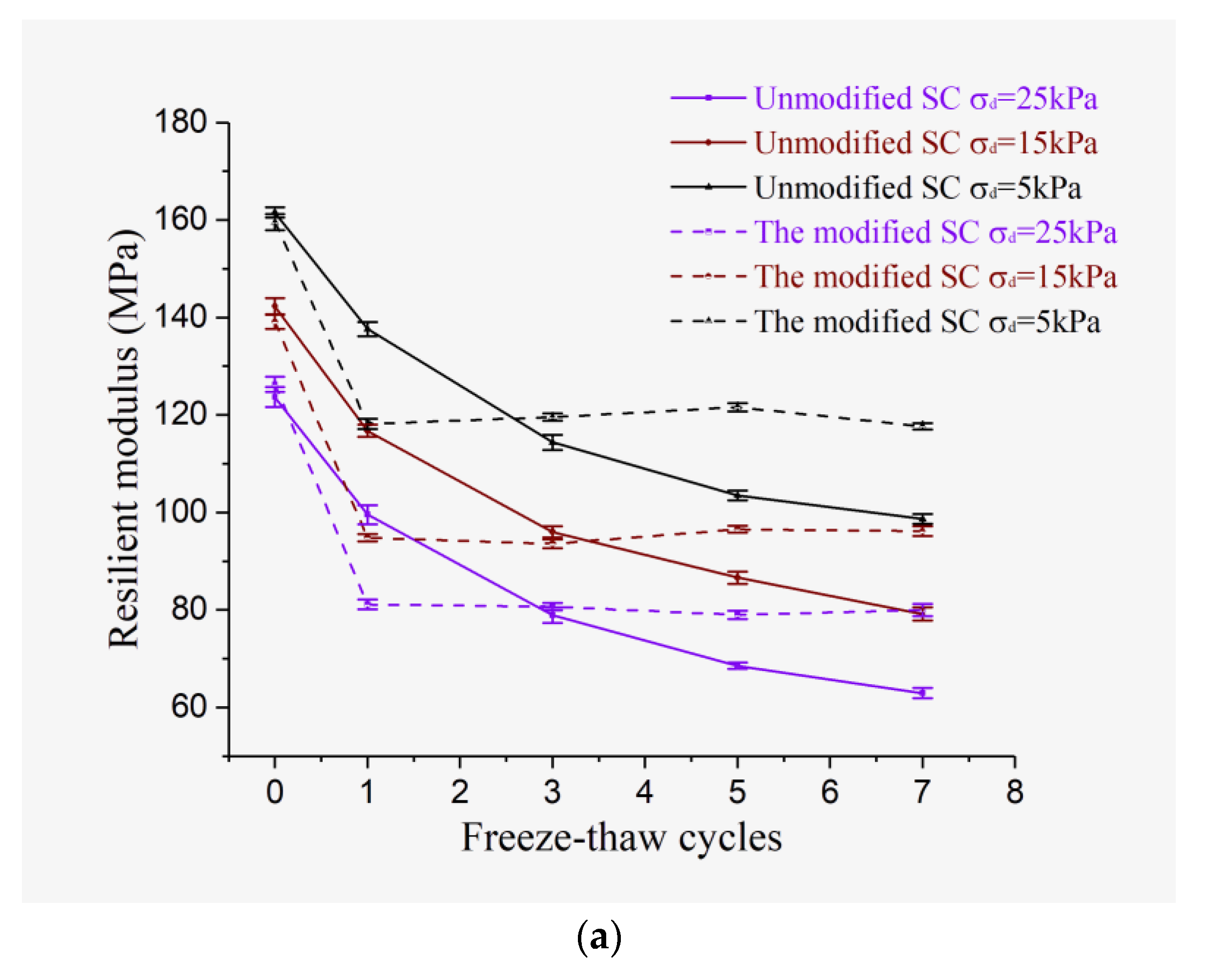

To better investigate the effect of F-T cycles on resilient modulus for the two materials, the variation curves of resilient modulus versus F-T cycles under different stress states are drawn in

Figure 6.

As

Figure 6 and

Figure 7 show, the resilient modulus of unmodified SC is slightly higher than that of the modified soil under the same deviator stress before F-T cycles. With increasing F-T cycles, the test data for the two materials show different variation characteristics. After the first F-T cycle, the resilient moduli of both materials decrease sharply. The resilient modulus value of unmodified SC is still higher than that of the modified soil. As F-T cycles continue, the resilient modulus of unmodified SC decreases continually, while the resilient modulus of the modified soil has remained stable. After 7 F-T cycles, the resilient modulus of unmodified SC is lower than that of the modified SC. This means that after sufficient numbers of F-T cycles, the mechanical performance of the modified soil is better than that of unmodified soil.

The calculated damage ratios of resilient modulus and the corresponding fitting equations for unmodified SC and the modified SC are listed in

Table 5 and

Table 6.

In

Table 5 and

Table 6, the damage ratios of unmodified SC increase gradually with increasing F-T cycles, while the calculated data of the modified soil decrease after the first F-T cycle and then remain stable. For unmodified SC, the damage ratios in low confining pressure (

σc = 40 kPa) are close to those under the same deviator stress (

σd) in high confining pressure (

σc = 50 kPa). As for the modified SC, the damage ratios in high confining pressure (

σc = 50 kPa) are slightly less than those in low confining pressure (

σc = 40 kPa). Furthermore, the damage ratios of both materials under the deviator stress of 25 kPa (

σd = 25 kPa) are higher than those under the deviator stresses of 15 and 5 kPa (

σd = 15 kPa and

σd = 5 kPa). It revealed that for both materials, deviator stress is the main factor affecting the damage ratio of the resilient modulus after F-T cycles.

The correlation coefficients of the fitting equations for both materials are strong. The constant term y0 represents the damage ratio of materials after sufficient numbers of F-T cycles. It can be called a stable damage ratio after F-T cycles. The fitting results indicate that the stable damage ratios of the modified soil are better than those of unmodified soil. Therefore, the modified SC will have better application potential than unmodified SC in seasonally frozen regions.

3.3. Significance Analysis of Influencing Factors on Resilient Modulus

The effect of confining pressure, deviator stress, and F-T cycles on resilient modulus is worth comparing and discussing. The variance of confining pressure, deviator stress, and F-T cycles on resilient modulus is analyzed using SPSS (Statistical Product and Service Solutions) 20.0 software. The resilient modulus is regarded as a dependent variable. Confining pressure, deviator stress, and F-T cycles are fixed factors. The results are listed in

Table 7.

From

Table 7, the significance analysis results for the two materials are similar. It illustrates that confining pressure, deviator stress, and F-T cycles all have a significant influence on the resilient modulus, which is consistent with the previous analysis. Furthermore, the magnitude of the F value reflects the level of significance. The greater value of F, the greater the significance of the effect. Based on the confidence interval of 95%, the significance result for the two materials is slightly different. For unmodified SC, the significance of confining pressure is the greatest, followed by F-T cycles and deviator stress. For the modified soil, the significance of confining pressure is also the greatest, then followed by deviator stress and F-T cycles.

The obtained results show that stress states are the most important factors affecting the resilient modulus, especially confining pressure. The effect of F-T cycles on the resilient modulus is determined by the property of materials. In comparison, the effect of F-T cycles on the resilient modulus of the modified SC is less significant than on that of unmodified SC. This is due to the difference in microstructure for the two materials, which will be discussed in the following part.

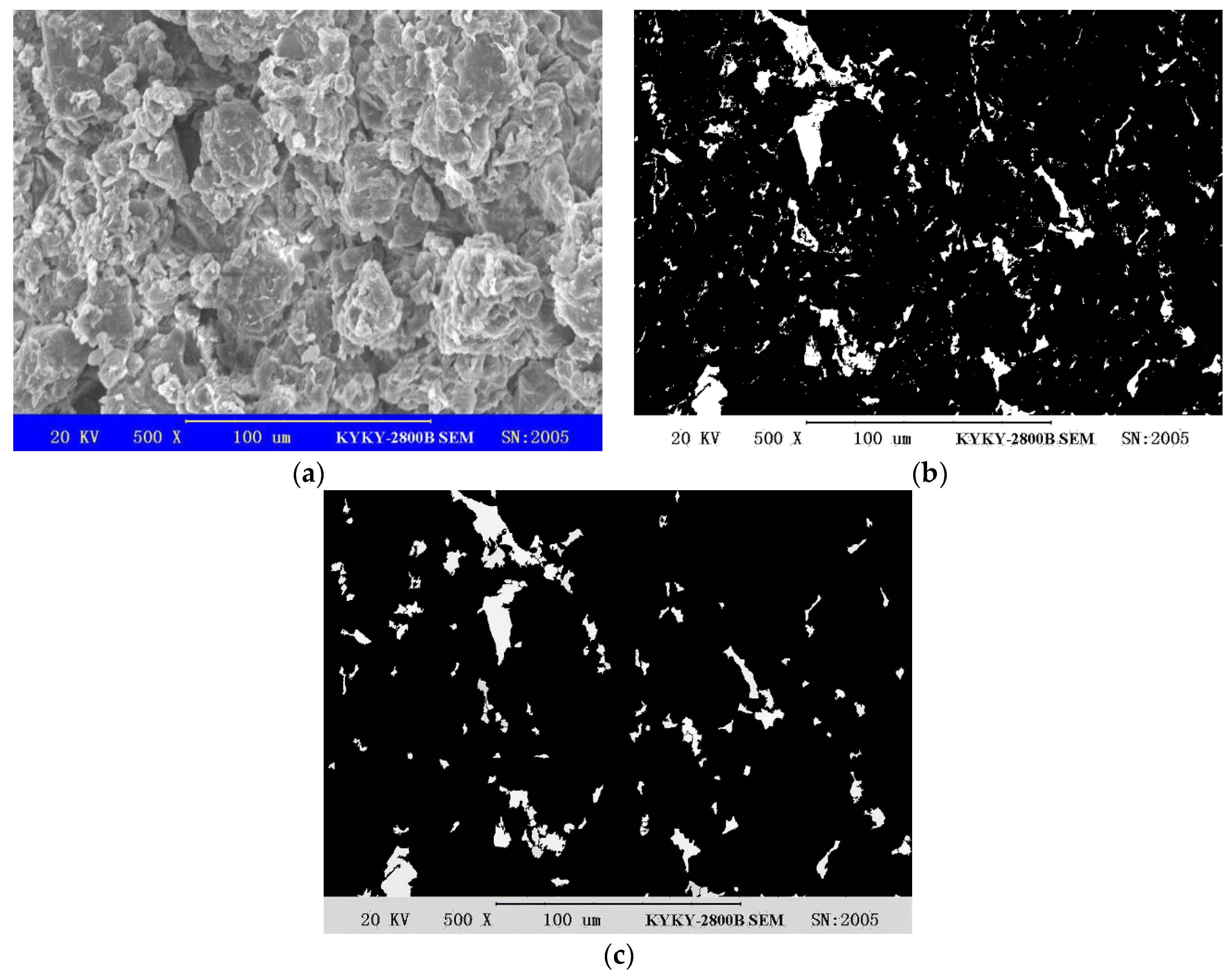

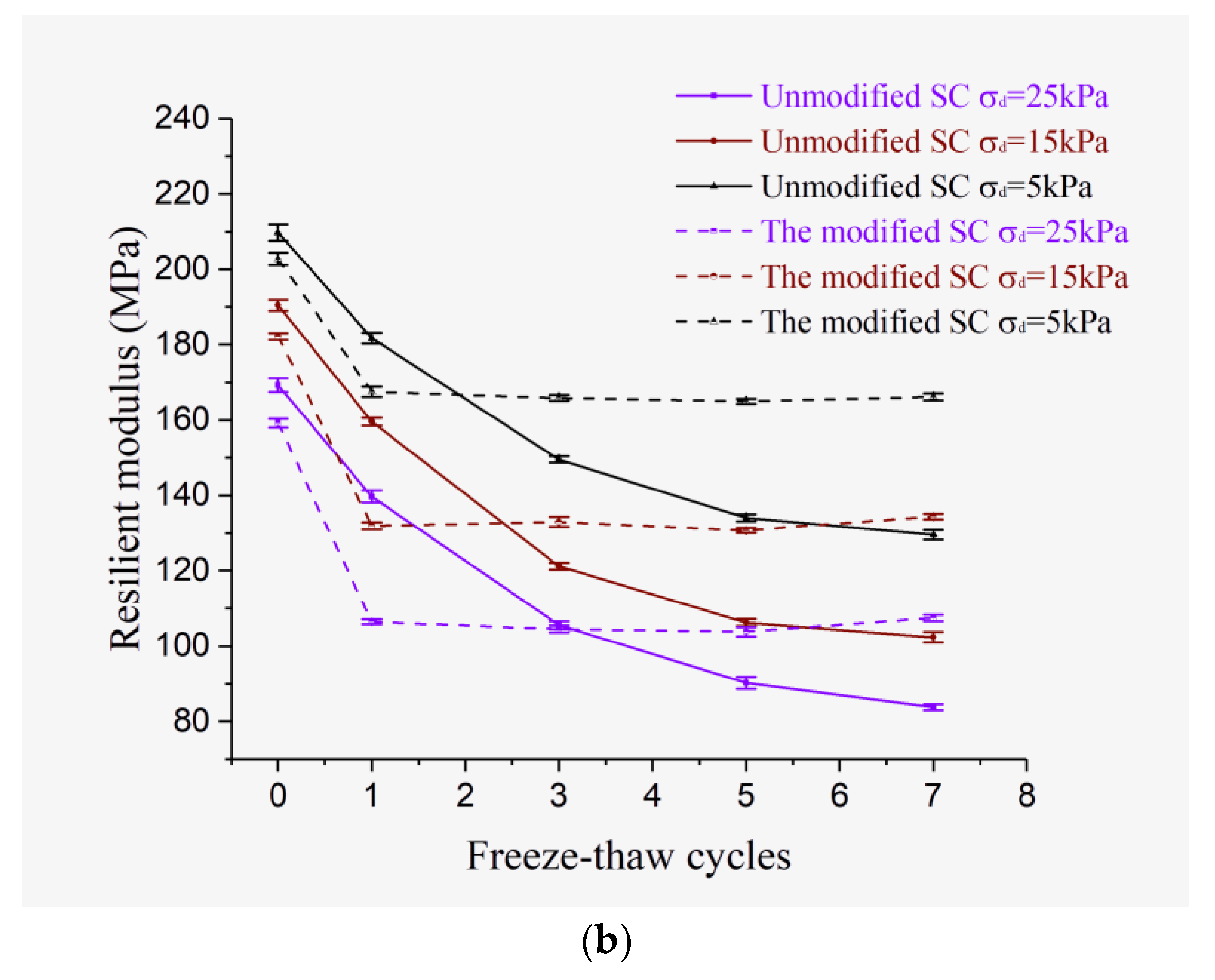

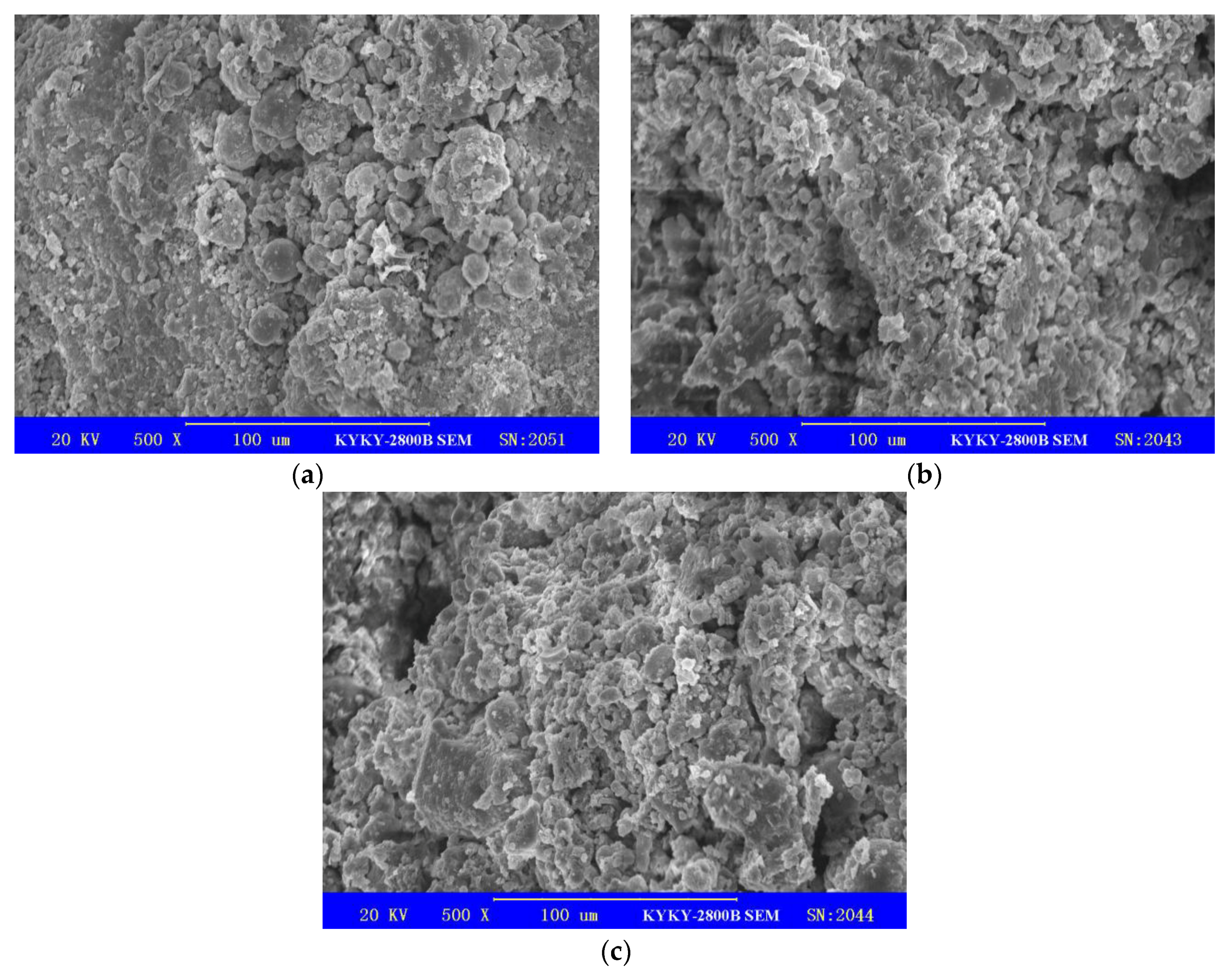

3.4. Effect of F-T Cycles on Microstructure for Soil Samples

It has been demonstrated that the significant decrease in resilient modulus after F-T cycles is mainly related to the water transfer, volume, and microstructure change of soils during the freezing and thawing process [

23,

25]. To investigate the effect of F-T cycles on microstructure change for the two materials, SEM tests were conducted to scan the soil samples after F-T cycles. The original scanning images for the two materials after 0, 1, and 5 F-T cycles are shown in

Figure 7 and

Figure 8.

As seen from

Figure 7a, the microstructure of unmodified SC is a whole platy structure with layered structures. It is dense and connected strongly with soil particles. After the first F-T cycle, there are cracks on the surface of the platy structure, and the dense particle arrangement is slightly destroyed (shown in

Figure 7b). As F-T cycles continue, cracks develop rapidly. The dense structure becomes loose and a lot of pores appear. Afterwards, the connection force between particles decreases. In the modified soil, there are a lot of fine particles and agglomerates. They connect with each other and contribute to the strength of soil samples. After the first F-T cycle, there are more small particles and pores, but the interlock structure of small particles and agglomerates possesses great stability. So, there are no distinct differences in the distribution of cracks and pores for samples after several F-T cycles (shown in

Figure 8b,c).

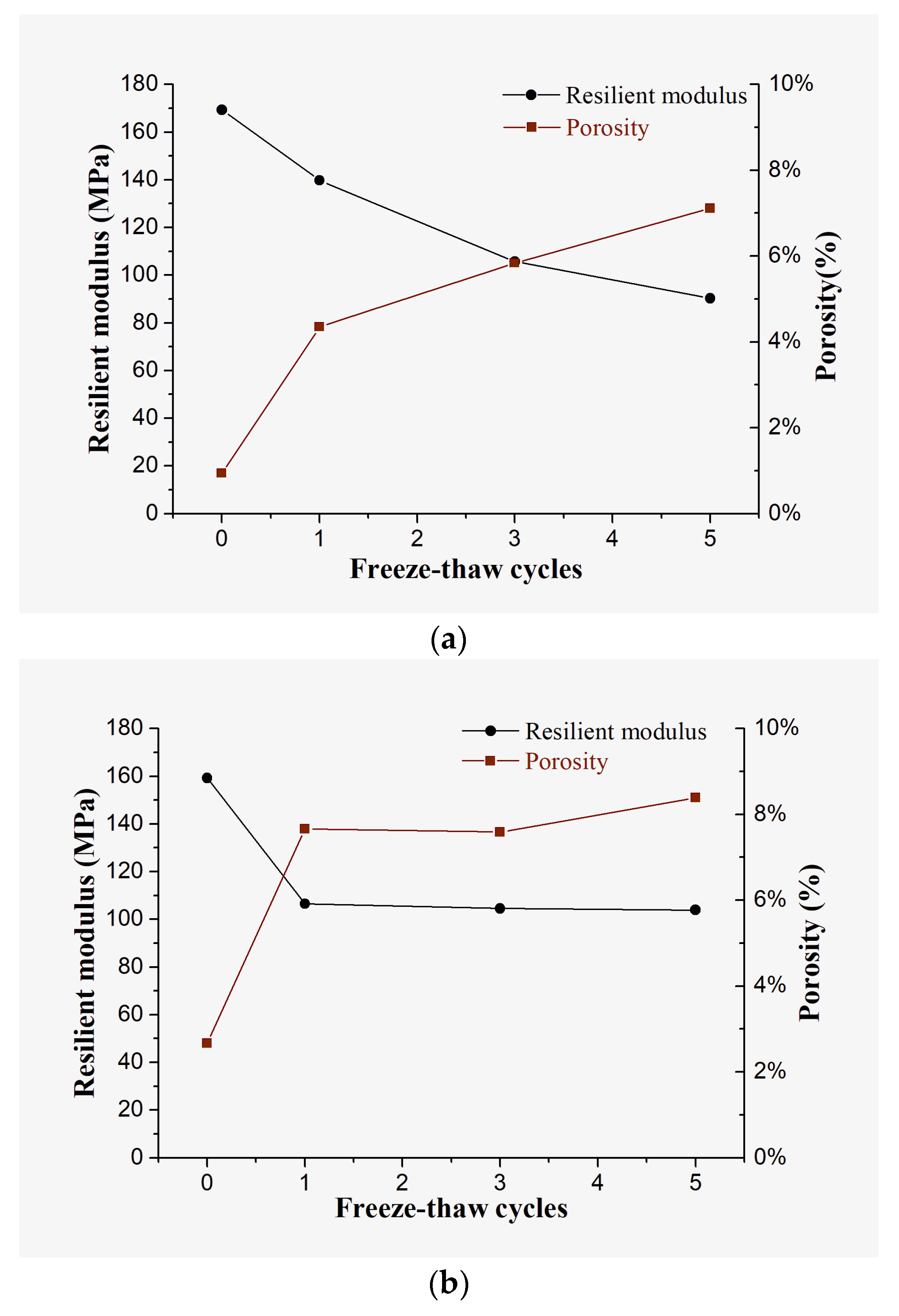

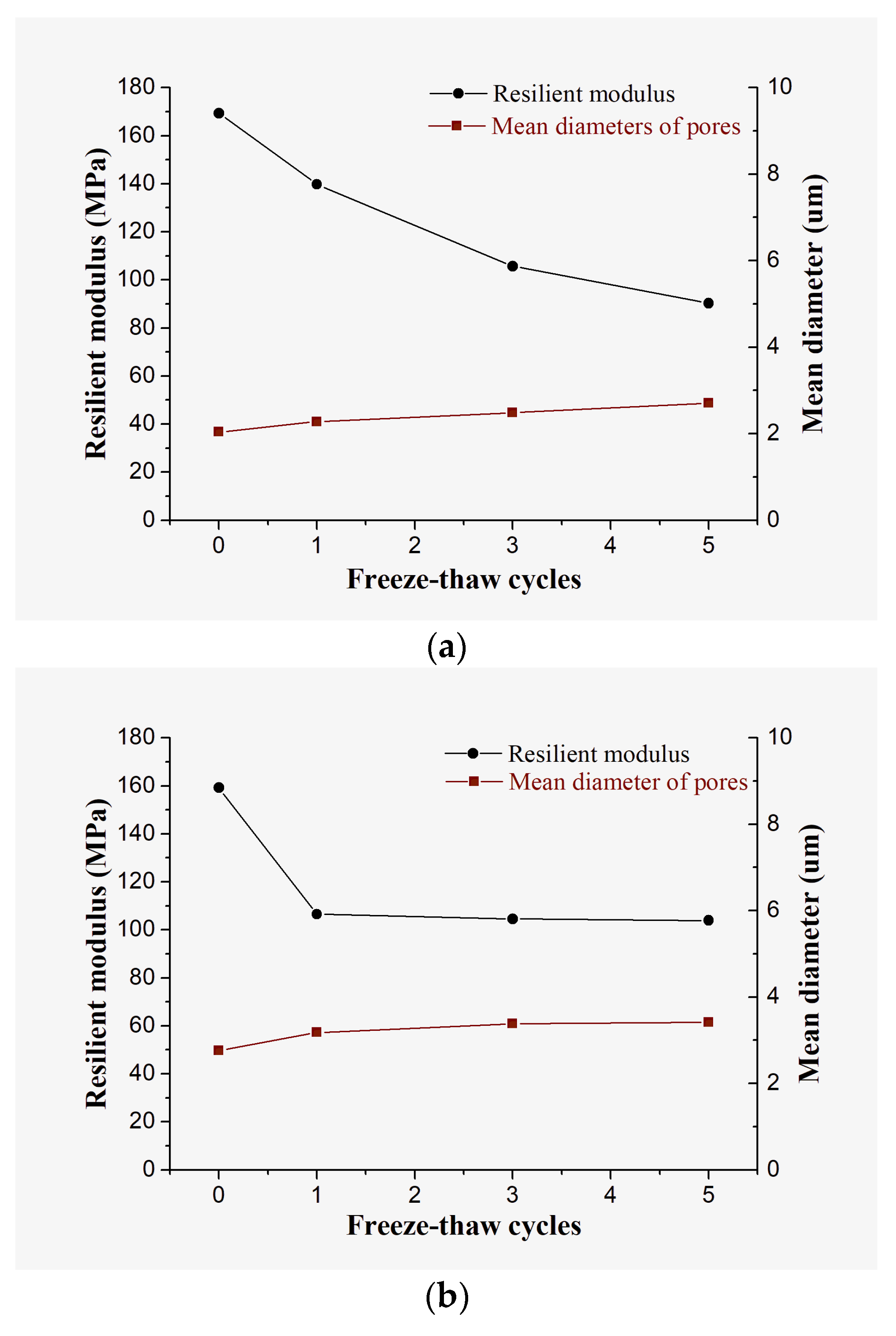

Pore distributions of soils are closely related to the performance change of the materials. Based on the image processing technology, the porosity and pore size of samples for the two materials after 0, 1, 3, and 5 F-T cycles were analyzed. The variation curves of resilient modulus (

σd = 25 kPa,

σc = 50 kPa) and pore parameters versus F-T cycles are drawn in

Figure 9 and

Figure 10.

In

Figure 9 and

Figure 10, the values of porosity and mean diameter of pores for the two materials are low before F-T cycles. With the increase of F-T cycles, the porosity and mean diameter of pores all increase. The growth trend of both porosity and mean diameter of pores seems correlated to the reduction trend of the resilient modulus. For unmodified SC, the variation trends of resilient modulus and pore parameters are opposite: the resilient modulus decreases with the increase of F-T cycles, but the porosity and mean diameter of pores increase with increasing F-T cycles. This trend is more significant in the variation trend of porosity. For the modified SC, the resilient modulus decreases sharply after the first F-T cycle, then it remains stable. The porosity and mean diameter show the similar opposite variation characteristics after F-T cycles. To better investigate this relationship, correlation analysis between resilient modulus and pore parameters was conducted; the results are shown in

Table 8 and

Table 9.

As shown from the results, the significance values (2-tailed) are 0.021, 0.007, 0.010, and 0.049, respectively, which are all lower than 0.05. This means that the resilient modulus is correlated with porosity and mean diameter at the level of 0.05 (2-tailed). The Pearson correlation coefficients of both unmodified SC and the modified SC are negative. The absolute values of them are all higher than 0.95. This means that there is very strong negative correlation of resilient modulus versus porosity and mean diameter.

To discuss the pore distribution change characteristics after F-T cycles, the pores of the two materials after F-T cycles were counted and classified into small pores (d < 2 µm), medium pores (2 µm < d < 5 µm), and large pores (d > 5 µm). The results are listed in

Table 10.

For unmodified SC, there are mainly small and medium pores before F-T cycles. With increasing F-T cycles, the amounts of medium and large pores increase and that of small pores decreases. The situation for the modified soil is slightly different. Compared with unmodified SC, the amounts of medium and large pores in the modified soil are larger than those in silty clay before F-T cycles. The mean diameter of pores for the modified soil is larger as well. As F-T cycles increase, the distribution of pores tends to be stable: the amounts of small pores slightly decrease, and the amounts of medium and large pores increase.

From the SEM test, the effect of F-T cycles on soils is mainly to destroy the initial structure, increasing the porosity and mean diameters of pores. It can be concluded that the microstructure change during F-T cycles is the main factor that results in the decrease of the resilient modulus.