1. Introduction

In recent decades, the semiconductor and optoelectronics industries have become important contributors to Taiwan’s economic development. For example, the semiconductor industry, especially the wafer foundry, is the most competitive Taiwanese industry in the international market. Therefore, developing ways to reduce the manufacturing costs and improve the wafer yield are an important concern for the semiconductor manufacturers during the production of highly complex devices, using advanced manufacturing processes. The cleanliness of the manufacturing environment influences the product yield and the device performance [

1,

2,

3]. For example, moisture and oxygen will induce oxidation or a loss of Cu on a wafer during the waiting period [

4,

5]. In addition, there are three major factors (materials, contamination prevention or removal, and cleaning methods) that influence the cleanliness level of a storage box (such as a front opening unified pod [FOUP]) [

6]. Gwon et al. [

7] proposed a novel cleaning system of the FOUP for the next generation of manufacturing. Herrán et al. [

8] explored the cross-contamination between FOUPs and wafers, and their results demonstrated that the contamination concentration was affected by the solubility or diffusivity of the FOUP. They further suggested that the choice of FOUP materials should be based on the fabrication processes of the products. However, the traditional large-space clean room does not meet the rigorous cleanliness requirements (e.g., a lower particle concentration and lower degree of relative humidity [RH]) that have resulted from the rapid development of semiconductor technology. Therefore, an ultra-clean environment, which has been called a mini-environment, is generally installed inside a clean room, in order to reduce the possibility of cross-contamination (such as contamination from workers) and to maintain a high-cleanliness area for the process tools. The size of this mini-isolation region is much smaller than that of the external clean room, which can significantly reduce the maintenance (or operating) cost of this high-cleanliness region.

In general, wafers are stored in a FOUP while waiting in the line of the manufacturing processes, and this FOUP will be mounted on the load port unit (LPU) in the mini-environment. Many studies have focused on the prevention (or removal) of the contamination that occurs while the FOUP door is closed. Purging a FOUP with a gas (such as nitrogen or clean dry air [CDA]) is an efficient method to prevent (or remove) contamination from the FOUP. The vacuum method is another efficient way to maintain the cleanliness of a FOUP [

9,

10]. For example, Hu et al. [

11] employed a purge or vacuum approach to remove the moisture from a FOUP. Their results demonstrated that a higher purging flow rate using CDA provided better moisture removal. In addition, the moisture removal performance was improved by introducing flow distributors into the FOUP. They also reported that the RH distribution was more uniform at different locations in the FOUP when using the vacuum method, compared with the CDA purge process; and the RH evolutions during the purging and vacuuming processes showed exponential and linear decrease trends, respectively. Their results indicated that the vacuum method could successfully meet the rigorous RH limitation and rapidly reach the ultra-low RH level.

For practical fabrication processes, the FOUP door is frequently opened, and during this time, a vertical air flow occurs in the downward direction and over the open cavity. Here, the FOUP is considered to be a cavity, and the air flow is provided by fan filter units (FFUs) on the clean room ceiling or on the top of the mini-environment. Kang and Sung [

12] reported that the length-to-depth ratio of the cavity (L/D) affected the number of vortices generated in the cavity. For example, only one large vortex formed in the cavity when L/D = 1, which was very close to the condition of the FOUP, without loading any wafer during the door opening in the mini-environment. When the FOUP was loaded with several wafers, several vortices could be generated near the front regions of the FOUP. Those vortices would transport the moisture and contamination from the surroundings into the FOUP. In addition, the Reynolds number of the air flow is another important parameter that affects the characteristics of the induced vortex [

13,

14]. Therefore, when a FOUP door is opened, additional methods are generally used to prevent outside contamination (such as moisture, oxygen, and particles) from entering the FOUP, for example, Keyhani et al. [

15] employed an air curtain to meet this goal.

However, few studies in the available literature have considered the condition where the FOUP door was opened. In one example, Wang et al. [

16], explored the humidity evolution in the FOUP during a door-closed process, with an equipment-front-end-module (EFEM) load port unit. They found that the outside airflow would cause a vortex near the lower regions of the FOUP, which made it difficult to decrease the RH to a very-low level. To solve this problem, they further developed flow distributors (i.e., diffusers) for the FOUP, and the results demonstrated that the RH could be reduced to less than 10%. Kim and Schelske [

17] reported that the air flow pattern from the EFEM affected the performance of the diffuser-purge process, especially for a condition where the EFEM’s air flow was much stronger than the purging flow. They further developed and installed an EFEM flow converter above the FOUP opening, which could turn the air flow into a uniform-downward laminar flow, and therefore improve the purge performance. Recently, Hu et al. [

18] employed two different approaches to study the moisture prevention performance while opening the FOUP door in a mini-environment. The results showed that better moisture prevention was obtained near the FOUP’s lower regions when using a diffuser purge, whereas better prevention was obtained near the FOUP’s upper regions when using the air curtain. They further suggested that the diffuser purge integrated with air curtain is an appropriate way to prevent moisture in a practical application.

Although the use of diffusers in a FOUP while purging can efficiently prevent or remove the contamination from the FOUP when its door is opened or closed, a higher purging flow rate would induce particle contamination and vibration problems. In addition, it should be mentioned that, if the vibration of the FOUP or wafers is too strong, wafer breakage could occur, especially for a wafer with already fabricated patterns. During the practical manufacturing processes, the purging flow rate is generally limited to 130 L/min (or even lower), in order to avoid the previously mentioned problems. The present study investigates the effect of the CDA flow rate, supplied to the purge system and air curtain, on the moisture prevention performance while opening the FOUP door. To reduce any possible vibration, we further developed and tested a prototype for a new panel-purge device in the FOUP, instead of the diffuser or conventional purge, during the FOUP purging with the door opened and the air curtain in use.

2. Experiment and Apparatus

The experiments were carried out in a clean room with ISO Class-6 level (

Figure 1a), where a mini-environment with ISO Class-2 level was established (

Figure 1b). The temperature and RH values in the clean room were maintained at 22 ± 0.5 °C and 42 ± 2%, respectively. In this clean room, twelve FFUs and three fan dry coil units (FDCUs) were mounted on the ceiling, and four dry cooling coil (DCC) units were installed on the ceiling near two side-walls (in the pathways for the return air). In order to establish a higher cleanliness level, three FFUs were also installed on the top of the mini-environment. In addition, to ensure improve the uniformity for the air flow provided by the FFUs in the mini-environment, a perforated plate with an opening ratio of 46.5% was used at a location 5 cm below the FFUs, and three perforated plates with an opening ratio of 30% were installed on the ground level of the mini-environment. The velocities of airflow from the FFUs in the clean room and mini-environment were 0.45 m/s and 0.4 m/s, respectively. An LPU module (model: KWF-12F-M, Hirata, Japan) combined with the purging system (Brillian Network & Automation Integrated System, Miaoli, Taiwan) was employed. It was mounted on the interface of the mini-environment, as shown in

Figure 1b.

Figure 2 further illustrates the procedures for the LPU when mounting the FOUP on the interface of the mini-environment. This figure shows that the FOUP door was opened by the front-opening interface mechanism of the LPU (steps II to IV), after the FOUP was located on the LPU (step I). Step IV illustrates the situation of air flowing downward and over an open cavity (if the FOUP does not store any wafer), as previously mentioned.

This study employed three different purge types for the FOUP, as shown in

Figure 3, in order to investigate the moisture prevention performance.

Figure 3a illustrates the FOUP using the conventional purge, which has two inlets (near the back-bottom region, which cannot be observed in the figure) and two outlets (near the front-bottom region of the FOUP) for the purge gas.

Figure 3b depicts the FOUP-purge inlets mounted with two diffusers, which are porous tubes with a diameter of 1.3 cm and length of 23.6 cm. These porous tubes were made of ultra-high molecular weight polyethylene (UPE). The FOUP, which can store 25,300 mm wafers and is used for both the conventional-purge and diffuser-purge experiments, was provided by Entegris (model: A300, Hsinchu, Taiwan).

Figure 3c shows the appearance of the FOUP used for the panel-purge experiments, which was developed by the present research team and fabricated using three-dimensional (3D) printing with polylactic acid polymer materials. As shown in

Figure 3c, three UPE porous boards with a pore size of 0.1 μm were installed in the back region of this homemade FOUP. These UPE boards could serve as ventilation plates (and panel-purge inlets), which improved the flow uniformity while purging with CDA.

Figure 4 provides a detailed schematic of the developed FOUP with the panel-purge device. Three back-side covers were further mounted on the exterior of these boards, and each cover had two inlet holes for the purging process. In addition, the small regions between the UPE boards and the outer covers could serve as buffer regions while purging.

We used aluminum alloy #6061 to prepare a dummy wafer that was 1 mm thick (i.e., a supporting base for mounting the RH sensors) and had a diameter of 302 mm. Most of the surface area of the dummy wafer was removed, as shown in

Figure 5, in order to make the FOUP environment approximately empty. The surface of this supporting frame was polished and electroplated in advance, so as to prevent the humidity from being absorbed on it. In addition,

Figure 5 depicts the five RH sensors that were embedded on the dummy wafer to measure the RH evolutions at different FOUP locations. For the present study, five dummy wafers were installed at slots 1 (the lowest slot in the FOUP), 7, 13, 19, and 25 (the top slot in the FOUP). Therefore, 25 RH sensors were used in the experiments. The reported RH in the following sections is the mean value from the results of those 25 RH sensors. The measurement range of the RH sensor (DICKSON, model: TK150, IL, USA) was from RH = 0% to 95%, with an accuracy of ±3% (for RH >60%) or ±2% (for RH <60%). Accordingly, the measurement uncertainty of the mean RH in the FOUP was estimated to be only 0.4%.

Figure 6 depicts the testing loop of the experiments for the different purge methods in the FOUP. The purge gas for the FOUP and for the air curtain was the CDA generated from the same system, which was also employed in the previous study [

11]. The use of the air curtain reduced the moisture entering the purged FOUP (with an initial RH = 0%) when opening its door in the mini-environment, as reported in our previous study [

18]. Here, the air curtain, which had the dimensions of 410 mm (length) × 60 mm (height) × 60 mm (width), was made of aluminum alloy 7075, and five UPE ventilation plates were installed inside so as to generate a uniform air flow. For the cases of the conventional-purge and diffuser-purge experiments, the CDA supplied to the FOUP or air curtain, respectively, was controlled by a mass flow controller (Fujikin, model: FCST1500FC-8F3-F500L, maximum flow rate of 500 L/min, ±2% accuracy, Tokyo, Japan) or a digital flow meter (SMC, model: PF2A721, maximum flow rate of 210 L/min, ±2% accuracy, Tokyo, Japan), respectively. For the panel-purge experiments, the CDA supplied to both the purge system and the air curtain was controlled by four digital flow meters. More specifically, in order to stabilize the CDA supplied tank and the airflow uniformity to the FOUP, we used three flow meters to control the CDA supplied to the three UPE ventilation plates in this particular case.

In the present study, tests were conducted with different CDA flow rates supplied to the FOUP-purge system and air curtain.

Table 1 summarizes the details of the experimental conditions. In this table,

QA,

QC,

QD, and

QP represent the CDA flow rates supplied to the air curtain, conventional-purge, diffuser-purge, and panel-purge processes, respectively. Here, the purging flow rate stands for the air flow rate that is purging into the FOUP; such a definition of the purging flow rate is similar, but not identical, to that used in the study of Sandberg and Sjöberg [

19]. As indicated in

Table 1, four different CDA flow rates were supplied to both the air curtain and the FOUP-purge system during the experiments (i.e., 200, 250, 300, and 400 L/min, which were cataloged as cases A, B, C, and D, respectively). The maximum CDA flow rate of 400 L/min was limited by the CDA generation system employed in the present study. In the beginning of the experiments, the FOUP with the door closed was pre-purged using a CDA flow rate of 60 L/min (i.e., 30 L/min for each FOUP-purge inlet or 10 L/min for each panel-purge inlet) for 10 min, so as to ensure that the RH decreased to approximately 0%. After that, the FOUP door was opened via the front-opening interface mechanism of the LPU, and the FOUP and LPU systems were further rested for 3 min (without using either the purge system or air curtain), to simulate the practical conditions of the manufacturing process. Finally, the FOUP-purge system and the air curtain were turned on at a given flow rate. When the FOUP door was opened in the mini-environment, the RH data was recorded for 10 min, in order to obtain the results at the steady condition. After each test, the FOUP with the door opened was rested in the clean room for 30 min to keep the initial RH in the un-purged FOUP nearly the same for each test.

3. Results and Discussion

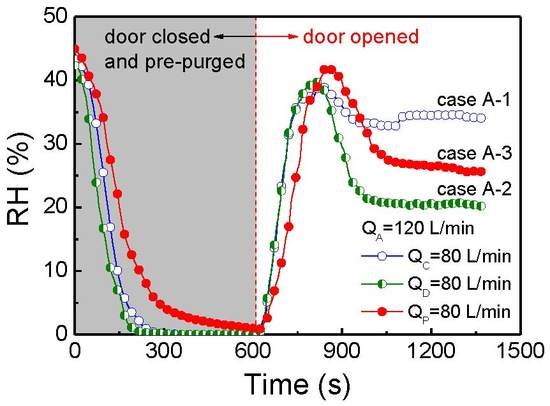

Figure 7 shows an example of the RH evolutions in the FOUP for different purge processes, that is, cases A-1 (conventional-purge), A-2 (diffuser-purge), and A-3 (panel-purge), with CDA flow rates of 120 L/min and 80 L/min for the air curtain and the FOUP-purge system, respectively. The air change rate per hour in the FOUP is around 100 for the case with the CDA flow rate of 80 L/min to the purge system. During the pre-purged period,

Figure 7 demonstrates that the RHs decreased rapidly from the initial value of approximately 43% to the lower level of less than 10%, within 5 min. It then gradually approached the zero level at the end of the pre-purged process. Such RH evolutions when the door was closed approximately followed the exponential decay, as generally reported in the literature, such as Hu et al. [

11]. In addition, the RH decreasing characteristics of case A-3 were somewhat different from those of cases A-1 and A-2 during the pre-purged period. More specifically, the RH of case A-3 decreased much more slowly than those of cases A-1 and A-2. This was because the FOUP that was used in case A-3 was our homemade prototype with the panel-purge device, whereas the FOUP that was employed in cases A-1 and A-2 was one that is available commercially. Here, we want to emphasize that the main focus of this study was to investigate the RH evolution after opening the FOUP door in the mini-environment. The purpose of the pre-purged process in the FOUP was to ensure the same initial RH value, which was approximately 0% before opening the door, as shown in

Figure 7. Therefore, the difference between our prototype and the commercial FOUP while purging with the door closed is not within the scope of the present study, but it might be interesting and needs to be further studied.

After the pre-purged process and opening the FOUP door, the RH values for the three studied cases, as shown in

Figure 7, increased rapidly and reached the maximum value within 4 min (both the purge system and air curtain were not used for 3 min in the beginning of this period, as previously mentioned). The maximum RH was between 40% and 42%, which was very close to the RH in the mini-environment. This result indicated that the moisture in the surroundings rapidly entered the FOUP when the door was opened in the mini-environment, without using either the purge system or the air curtain. In addition, it should be mentioned that even for the condition with the door closed, the moisture would slowly diffuse or penetrate into the purged FOUP, because of the nature of the mass transfer or leakage of the FOUP. For example, Moon and Extrand [

20] reported that the estimated RH in a purged FOUP (made of polycarbonate) could increase to more than 20% within 2 h after purging. After the previously mentioned procedure, the CDA was supplied to both the purge system and air curtain at a given flow rate for the present experiments. Therefore, the RH values in the FOUP decreased again within the following 2 min. In addition, the results showed that the drop slope of the RH for the diffuser- and panel-purge processes was much larger than that of the conventional-purge process, indicating that the conventional purge inefficiently removed or prevented the moisture from entering the FOUP. In the final stage, the RH gradually approached steady values for the different purge processes.

Figure 7 shows that the final RH values for cases A-1, A-2, and A-3 were approximately 34%, 20%, and 26%, respectively. Here, the final RH level could be used to evaluate the overall moisture prevention ability of the purge process, where a lower RH value represents a better moisture prevention ability when opening the door of the pre-purged FOUP in the mini-environment. Accordingly, the diffuser purge might be the best approach among these three studied cases.

Figure 8 depicts the RH evolutions in the FOUP as a function of the CDA flow rate to the air curtain, with a given CDA flow rate of 80 L/min to the diffuser-purge system. Again, this figure demonstrates that the RH decreased rapidly and approached approximately 0% within 5 min, which was maintained until the door was opened. When the FOUP door was opened, the RH increased dramatically from 0% to approximately 40% within 4 min and, then, decreased rapidly again from its maximal value to a lower steady RH condition, because of the use of the air curtain and diffuser purge with CDA.

Figure 8 also demonstrates that a higher CDA flow rate (supplied to the air curtain) yielded a lower RH at the end of the process. Specifically, the final RH values for cases A-2, B-2, and C-2, as shown in

Figure 8, were approximately 20%, 13%, and 7%, respectively. Correspondingly, increasing the CDA flow rate by 42% (i.e., from 120 to 170 L/min) and 83% (i.e., from 120 to 220 L/min) resulted in decreases in the final RH of 35% (i.e., RH = 20% to 13%) and 65% (i.e., RH = 20% to 7%), respectively. The results indicated that the use of the air curtain with the CDA flow rate of 220 L/min, at a given CDA flow rate of 80 L/min, to the diffuser purge could successfully maintain the mean RH in the FOUP at less than 10% during the FOUP door opening in the mini-environment, which might be a suitable condition for practical application. Consequently, we can conclude that when a small RH in the FOUP is needed under the condition of an open door, supplying a higher CDA flow rate to the air curtain would be better than increasing the CDA flow rate supplied to the purge system, which might cause wafer vibration or induce particle contamination in the FOUP, as previously mentioned.

Figure 9 further shows the RH evolutions in the FOUP as a function of the CDA flow rate to the air curtain at a given CDA flow rate of 80 L/min to the panel-purge system. Overall, it is clear that the RH evolution in the FOUP for the cases in

Figure 9 is similar to that depicted in

Figure 8. The main difference in the RH characteristics among the results presented in

Figure 8 and

Figure 9 is that the final RH levels were maintained for the diffuser- and panel-purge approaches. For example, the final RH values for cases A-3, B-3, and C-3, as shown in

Figure 9, were approximately 26%, 18%, and 13%, respectively. Correspondingly, increasing the CDA flow rate (supplied to the air curtain) by 42% (i.e., from 120 to 170 L/min) and 83% (i.e., from 120 to 220 L/min), resulted in decreases in the final RH in the FOUP of 31% (i.e., RH = 26% to 18%) and 50% (i.e., RH = 26% to 13%), respectively. The present results indicated that the moisture prevention performance when the panel-purge system was used was slightly lower than that when using the diffuser-purge system.

However, it should be mentioned that the use of the panel-purge method could sufficiently suppress the vibration problem, especially under the condition of a higher purging flow rate. Therefore, we further studied the effects of the flow rates supplied to the air curtain and panel-purge system on the moisture prevention performance, under the condition of an open door. The total CDA flow rates supplied to the air curtain and the panel-purge system were controlled at 400 L/min for this studied case (i.e., case D). Here, cases D-1 and D-9 represent the condition where only the air curtain or panel-purge system was used, respectively.

Table 2 summarizes the RH results of case D. The mean RH ranged from 1.3% to 9.8%, which indicated that all of the studied conditions of case D could maintain the mean RH in the FOUP as low as 10% or lower during the FOUP door opening. As previously mentioned, the mean RH value was calculated using 25 RH sensors in the FOUP. Therefore, the maximum and standard deviations of the RH were also important parameters and are listed in

Table 2. Although the mean RH values of cases D-1, D-2, D-3, and D-4 were less than 3%, the maximum RH values were as high as 22.4–30.4%. In addition, the smallest standard deviation of the RH (i.e., 0.4%) occurred in case D-9, which indicated that the RH uniformity for this case was the best. Furthermore,

Table 2 indicates that case D-6 had the best moisture prevention performance, because the smallest values for both the mean and maximum RH values (i.e., 1.3% and 9.5%, respectively) were obtained.