1. Introduction

In recent years, many countries have paid more attention to ocean scientific research and resource exploration [

1,

2,

3]. As a result, ocean delivery platforms with better performance have been the focus of research, in which unmanned underwater vehicles (UUVs) play an important role. The UUV has been widely used in various missions of ocean development [

4] owing to its excellent environmental adaptation and scientific-observation abilities. However, a conventional UUV usually uses a screw propeller to provide thrust force, and this design has certain shortcomings; such as the propulsive system occupying a large space, consuming more energy, and a higher noise level. However, a bionic propulsor, which imitates the flapping caudal fin of fish, has several advantages; including higher efficiency, better maneuverability, lower noise, coupling of propulsion and control systems, etc. [

5,

6]. In addition, fish can utilize the surrounding unstable flow field energy using their caudal fin to improve swimming performance [

7,

8,

9,

10]. Therefore, studies on the propulsive performance and flow field evolution mechanism of bionic foil, flapping near the wave surface, are meaningful for the UUV in many aspects; such as utilizing wave favorable impact on foils propulsion, improving UUV navigation performance near the sea surface, increasing its endurance, and reducing ocean pollution.

When operating at sea, a UUV, propelled by a bionic propulsor, needs to navigate near the surface for a long time in various situations (such as data exchange). During this time, wave motions strongly affect the surrounding flow field of the UUV and its hydrodynamic performance. Another key issue is that most UUVs use gas or battery as their power source, which means that they have limited endurance and cause pollution easily. However, a new idea was proposed recently that suggested that UUVs extract energy from surrounding flows as their driving power or auxiliary propulsion [

11], as fish do. Similar to this idea, researchers have conducted studies on the application of flapping foils near the wave surface as an auxiliary propulsor for ships [

12,

13,

14], but fewer studies have been done for UUVs.

Researchers have analyzed the hydrodynamic performance of the flapping foil in an infinite flow field, which means the whole flow field is filled with water and there is no free surface. They usually focus on its mechanical parameters and flow field distribution; such as thrust force, resistance, input power, usable power, propulsive efficiency, and instantaneous vortex shape near the foil. Esfahani [

15] investigated the effect of caudal length on the hydrodynamic performance of flapping foils. In detail, Esfahani considered that the hydrodynamic performance of a flapping foil is optimum at lower and higher Strouhal numbers (

St < 0.2 and

St > 0.6). Additionally, Esfahani demonstrated the possibility of improving foil propulsive efficiency at moderate Strouhal numbers (0.2 <

St < 0.6) by manipulation of caudal length. However, comparing with rigid foil in above studies, a flexible foil is more similar to the caudal fin of fish. Therefore, Zhu [

16] simply treated the flexible foil as an inextensible filament. Then, Zhu used a solver to investigate the hydrodynamic effects of passive flexibility in chord direction on a self-propelled plunging foil in two-dimensions—incompressible and laminar flows. The solver coupled the immersed boundary method for the flow and the finite difference method for the structure. Considering the flexible deformation in a span-wise direction of bionic caudal fin, Zhou [

17,

18] found that its performance could be improved by adjusting the motion and flexibility parameters. The span-wise flexibility of caudal fin could increase thrust force with high propulsive efficiency. In order to obtain real velocity and vorticity fields of the foil, Lee [

19] then employed two-dimensional Digital Particle Image Velocimetry (DPIV), using hydrogen bubbles as seeding particles, to study the flow physics of a hydrofoil in angular reciprocating motion with negligible free-stream velocity to reveal the effects of aspect ratio on its hydrodynamic performance. Their results suggested that a lower aspect-ratio could improve thrust of the foil when it starts from rest, but at the expense of efficiency.

After looking at a steady infinite flow field, researchers have begun to study the mechanism of fish utilizing unsteady flow field energy from the perspective of multi-body disturbance. Shao [

20] numerically investigated the hydrodynamic performances of a fishlike undulating foil in the wake of a D-section cylinder by using a modified immersed boundary method. Firstly, Shao observed that the foil without undulation in the vortex street could gain a thrust, as a result of the fact that the passing vortices produce reverse flows with respect to the mainstream in vicinity of the foil surface. An undulating foil is then placed behind the D-section cylinder; Shao found that the undulation of foil plays different roles in its propulsion when the distance between foil and cylinder is changed. In Shao’s studies, the D-section cylinder remains still. Different with Shao’s model, Augier [

21] studied a propulsion system which was made up by tandem hydrofoils experimentally and numerically. An experimental measurement system is then developed to extract hydrodynamic loads on the foils and capture their twisting deformation during operation. The measuring data allowed researchers to assess the efficiency of the propulsion system as a function of travel speed and stroke frequency. Based on the Augier study, Liu [

22] discussed the distance between foils, pitch angle, and other parameters’ effects on tandem foils’ propulsive performance. By analyzing flow field disturbance between foils, effective ways to improve propulsor performance were proposed. Meanwhile, Xu [

23] analyzed the hydrodynamic performance of two flapping foils with the tandem configuration, while the velocity potential theory and the boundary element method were introduced to study the interactions of the vortices and the foils. Xu then found the optimal global phase shifts for the highest thrust and highest efficiency.

Summarizing the above research, studies on the hydrodynamic performance of the bionic flapping foil that propelled the UUV in deep sea, have obtained excellent results. Most studies on the foils were in unsteady flow fields and focused on the steady obstacle effect on the propulsive performance of the foil, or multi-foil effect on improving system maneuverability. In comparison, for the UUV, fewer studies have been carried out on the complex flow effect; such as waves at sea, on the performance of the nearby foils, especially on the flexible foils. Most existing research was mainly on the basis of using the passive moving rigid foils as an auxiliary propulsion for merchant ships. An early concept has been proposed by some researchers that a flapping foil can be used to extract energy from the unsteady flow field, formed by free-surface waves [

24,

25]. Indeed, in both experiments and theoretical analyses, it was discovered that a foil, submerging right below the free surface, could propel itself forward by using the energy from the incoming waves [

24,

26,

27]. The application of the flapping foils extracting energy from the uniform flows was first proposed by McKinney and DeLaurier [

28]. By applying a non-linear 3D panel method, Belibassakis [

29] then dealt with the hydrodynamic analysis of the flapping wings, which were located beneath the hull of a ship and operated in random waves. The ship was travelling at a constant forward speed and the free wake analysis was carried out around the flapping wings to obtain detailed characteristics of the unsteady flow. Their results presented significant thrust production, reduction of ship motion responses, and generation of anti-rolling moment for ship stabilization, over a range of motion parameters. Further, Silva [

30] numerically studied the possibility of extracting energy from gravity waves for marine propulsion by a two-dimensional oscillating hydrofoil. The investigated results of the simulation explained the increase of propeller efficiency in gravity waves. In addition, Silva suggested that when some key parameters are correctly maintained, the oscillating hydrofoil could take advantage of sea waves to increase its performance. In Silva’s study, the hydrofoil is defined as rigid. Esmaeilifar [

31] simulated unsteady, viscous and turbulent fluid flow around a plunging hydrofoil near the water free surface for different submergence depths and oscillation frequencies. The drag of the hydrofoil shows sudden increment in some critical unsteady parameters, such as Strouhal number and frequency. The main reason for this phenomenon is that waves under the above parameters transfer more momentum. In addition, the free surface affects trailing edge vortices from the foil, and causes the drag increment at all frequencies with submergence depth of 0.5

c, and at critical frequency with other submergence depths, where

c is the chord length of the foil.

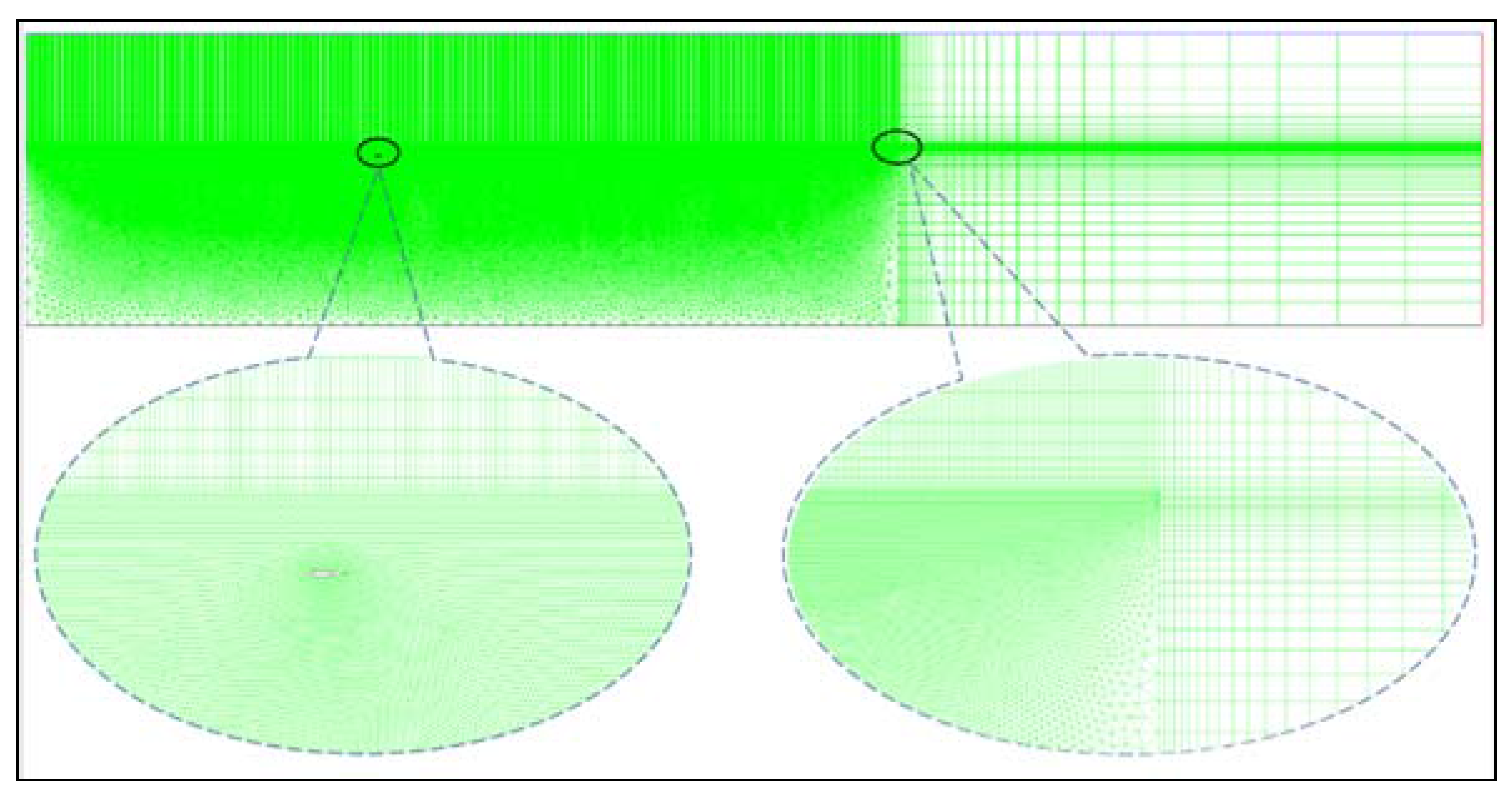

As seen from the above research, most of the authors consider a rigid foil, rather than a flexible foil, as the object of study, even though the caudal fin of fish is usually flexible. In this paper, the ability of a flexible bionic flapping foil to take advantage of waves is numerically studied for UUV propulsion. The commercially available computational fluid dynamics (CFD) software Fluent is used with an unstructured grid, based on Reynolds-averaged Navier–Stokes equations. The free surface waves, as well as motion and deformation of the flexible flapping foil were all implemented by customizing the Fluent solver using a user-defined function (UDF) technique. In addition, dynamic mesh technology and post-processing capabilities was fully used. The aim of this study is to investigate the hydrodynamic performance of the flexible foil when it operates near the wave surface, and then analyze ways to reduce the adverse influence of wave movements on the foil performance to utilize wave energy propulsion [

27,

30,

32]. Moreover, vortex forming, fusing, shedding and dissipating processes caused by the foil are discussed. The objectives are to develop a numerical estimation method that can predict the performance of the flexible flapping foil in a wave field.

4. Numerical Results and Analysis

In this paper, the effect of regular waves on the propulsive performance of a flexible foil is investigated, considering the encounter frequency

ω0, wavelength

λ, and wave amplitude

a. Other conditions, such as phase difference, foil motion, and flexible parameters, have been discussed in previous studies. One can find details in references [

38,

39]. For convenience, we change

ω0,

λ, and

a to

ω0/2

πf,

λ/c,

a/

c by non-dimensional treatment.

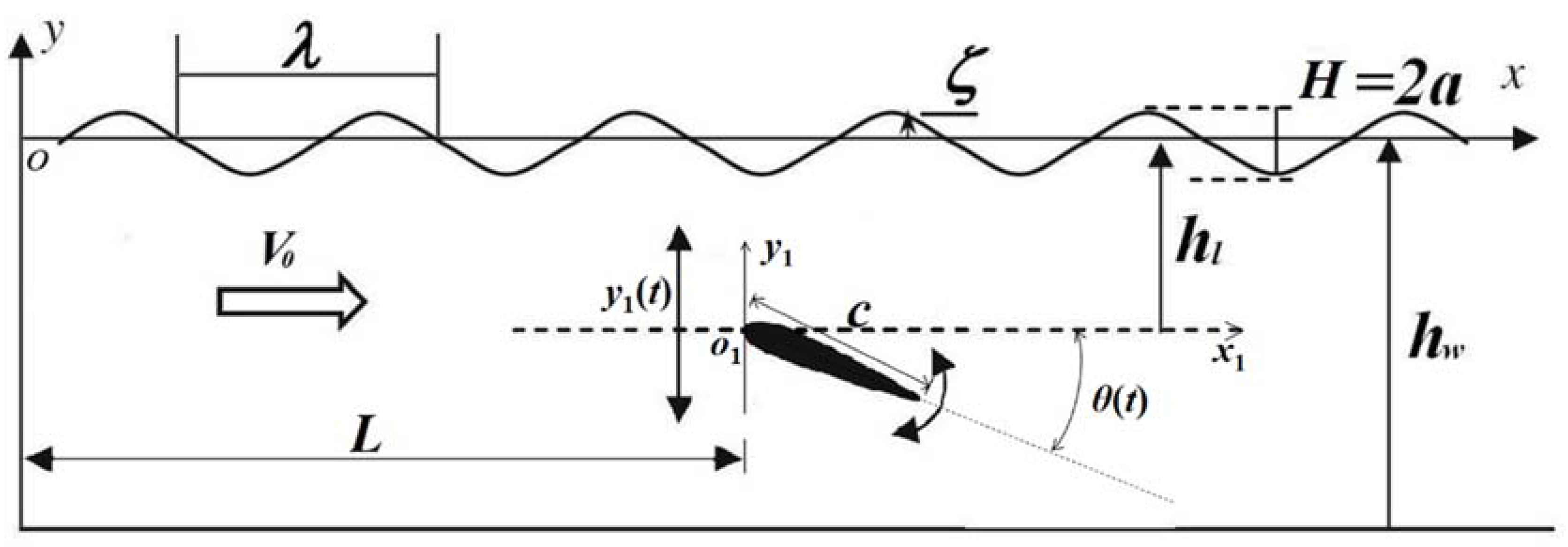

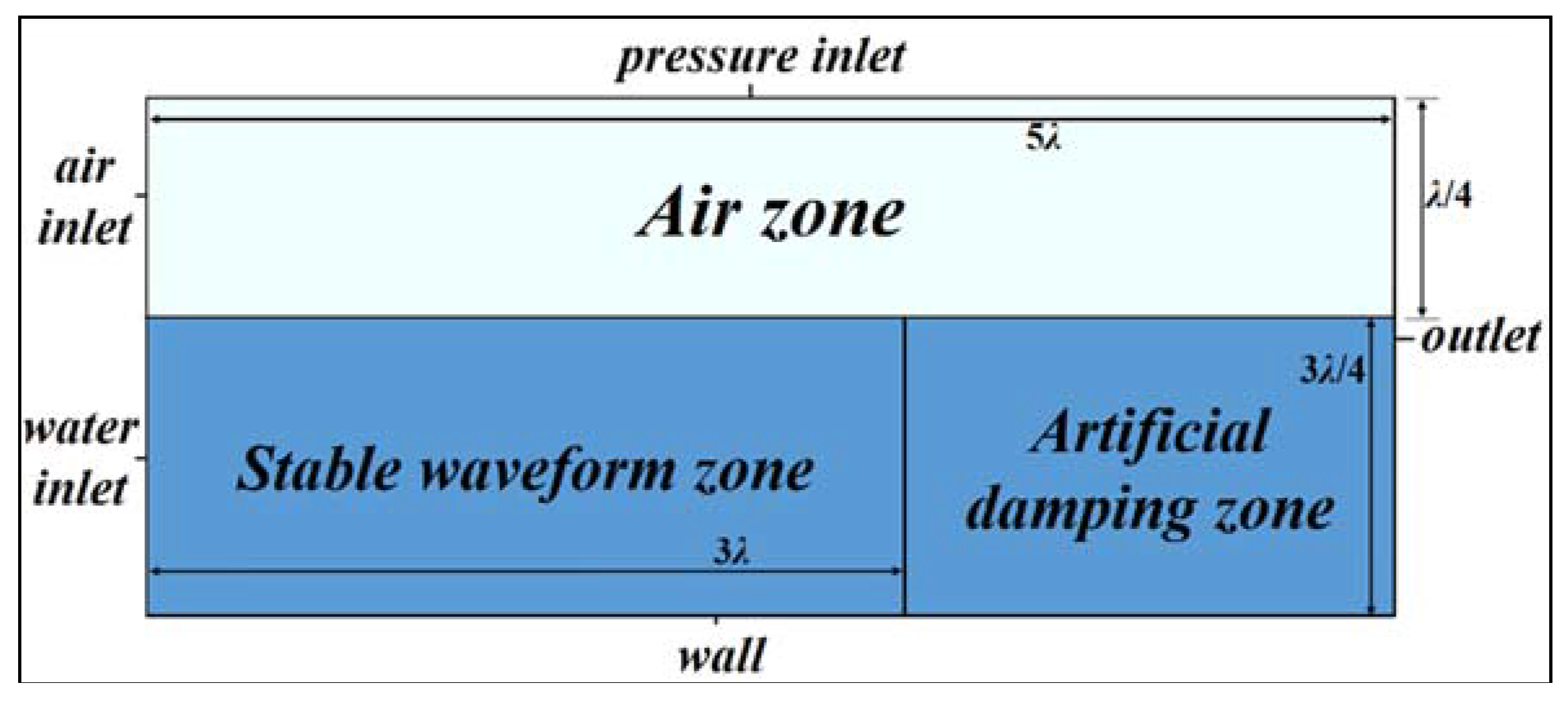

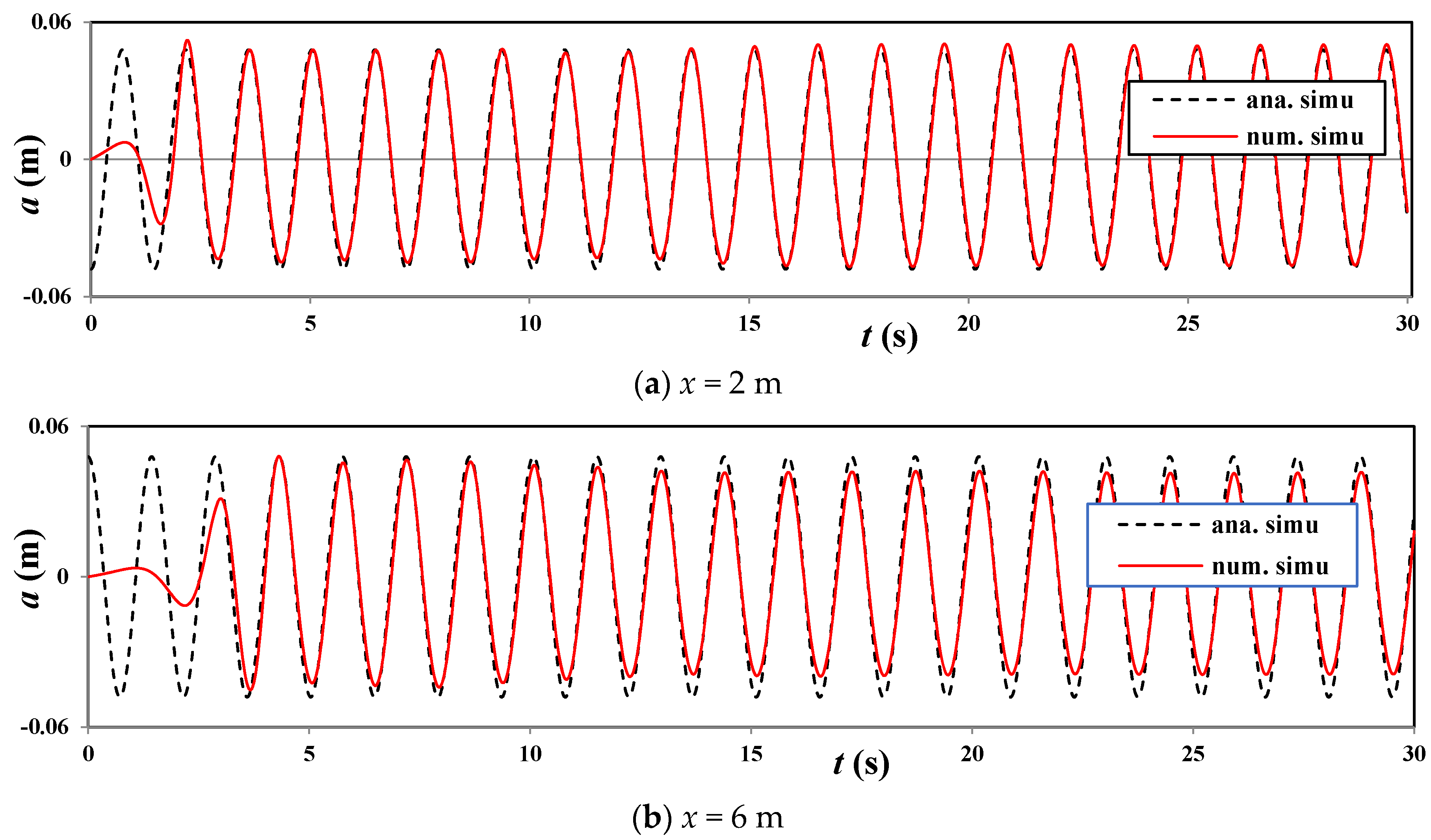

In our analysis, a basic parameter case is given and a controlling variate method is adopted, that is, only one variable of the basic case is changed in every working condition and the others remain constant. Therefore, we give the basic case setting as the inflow constant velocity V0 = 0.1 m/s. The regular wave height is H = 2a = 0.04 m and the wavelength λ = 6.64 m. The foil is profile NACA0012 with the chord length c = 0.1 m and the submergence depth hl = 0.12 m, and the phase difference between the heaving and pitching motion of the foil is = 90°. The foil motion period is T = 2 s = 1/f = 2π/ωf, where ωf is the angular frequency of foil motion. The phase between wave and foil motions is ψ = −90°. For foil flexible deforming, δc = 0.2 c, = −90°, while the controlling coefficients s = 100, ε = 2.0. The heaving amplitude of the foil is y0 = 0.5 c and the pitching angle is θ0 = 15°. The wave encounter frequency ω0 = ωf. In addition, for comparison, the performance in infinite flow field and under calm water of flexible, as well as the rigid foil, have also been calculated, where “infinite” means that no free surface exists and the whole computational domain is filled with water.

Before discussing the results, another important parameter should be mentioned—the submergence depth of foil hl—as the flow under waves in deep water is strongly affected by it. In our preliminary studies based on the above basic case for the flexible foil, with hl changing from 0.12 m to 0.20 m, the average thrust force coefficient CT descends from 3.21 to 2.8 and its decreasing rate slows down. Thus, combined with the following analysis, we can infer that the favorable effect of wave on the foil’s propulsive performance will be reduced with increasing hl and this effect will disappear when hl is deeper than half the wavelength.

4.1. Effect of Wave Encounter Frequency on Foil Performance

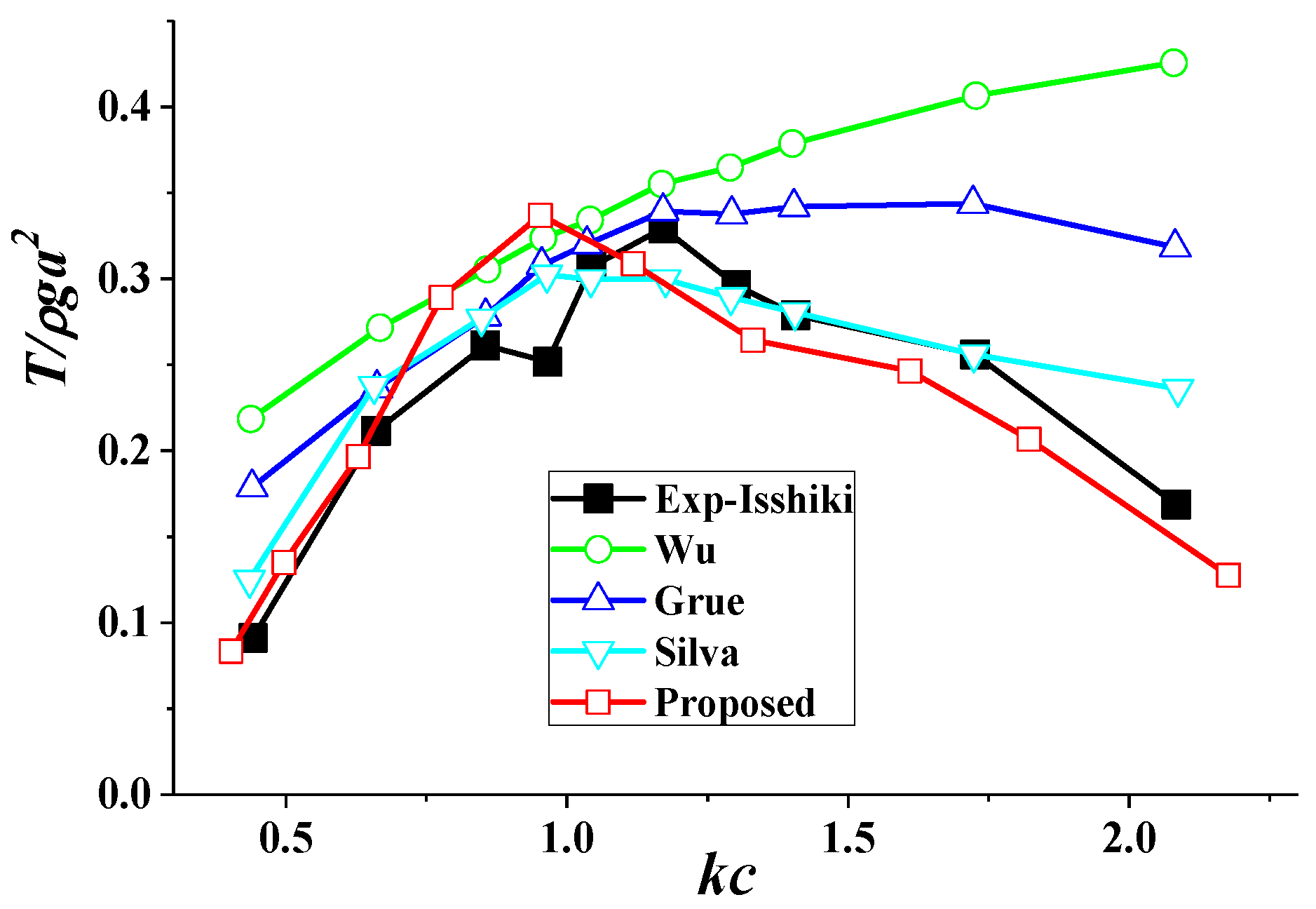

In Wu’s [

24] opinion, when

ω0 =

ωf, higher utilization efficiency can be obtained. In this section, this viewpoint will be validated and the effect of

ω0/

ωf on the flexible foil propulsive performance will be analyzed in detail. In these simulations, different

ω0/

ωf can be obtained by changing the wavelengths and keeping

ωf constant.

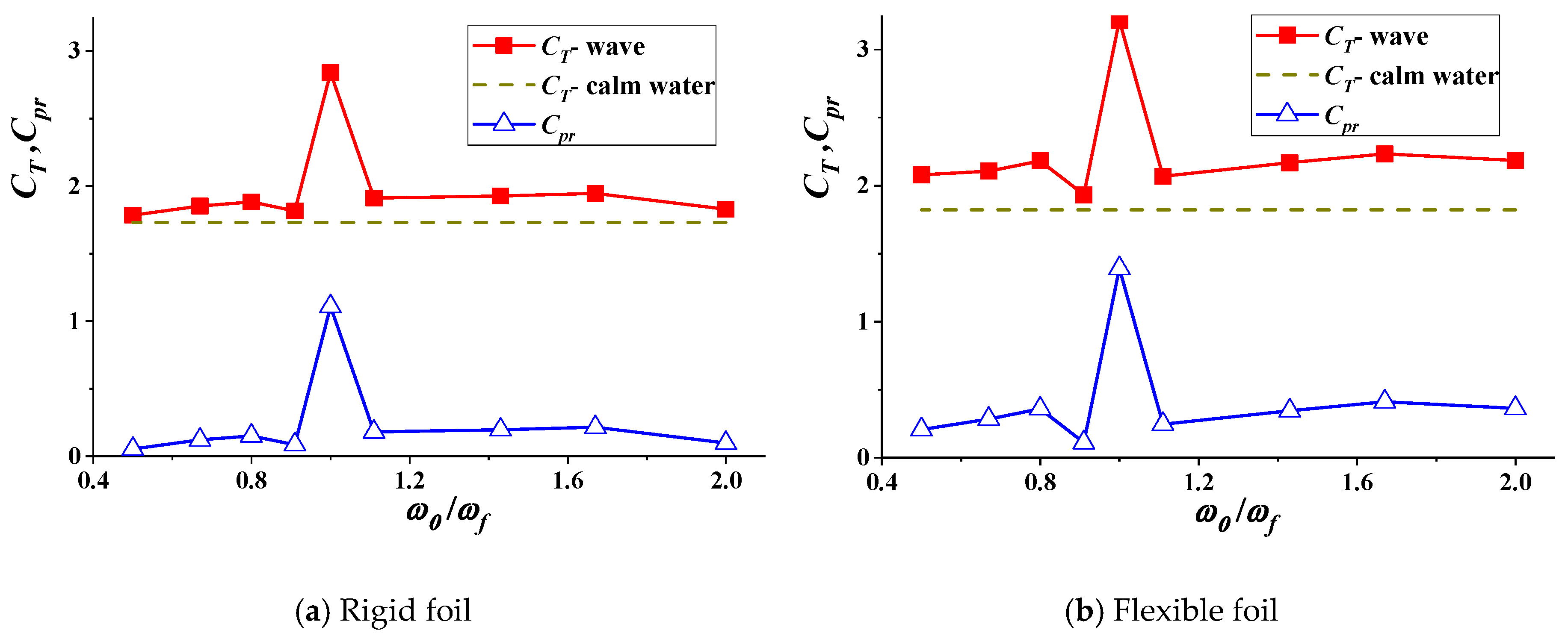

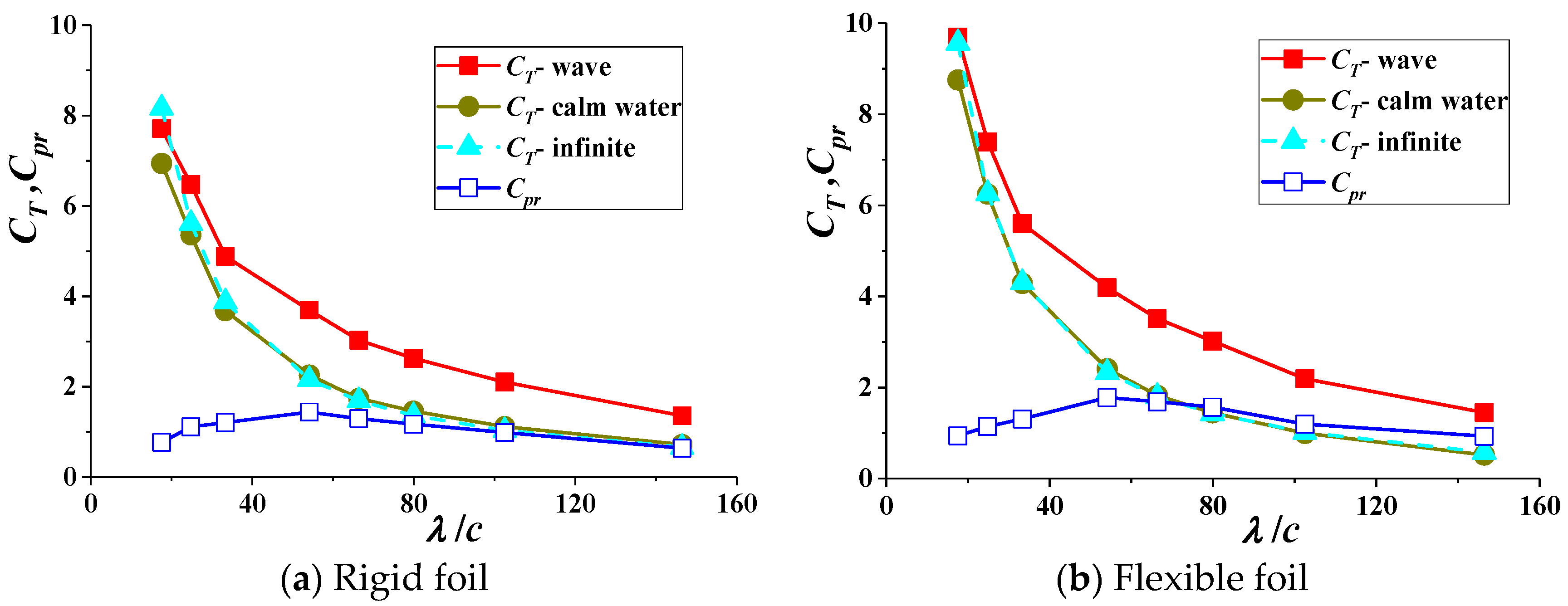

With different

ω0/

ωf, the average thrust force coefficient

CT and the utilization wave power coefficient

Cpr of the rigid and flexible foil, respectively, are shown in

Figure 6, in which “-wave” and “-calm water” represent corresponding parameters of the foil under the waves and the calm water, respectively; in later figures, their meanings are the same.

It is obvious that the peak values of

CT and

Cpr appear at

ω0/

ωf = 1; that is, the rigid and flexible foil can obtain higher thrust force and recovered wave power [

30] when the foil motion frequency is equal to its wave encountering frequency, as proposed by Wu. Meanwhile, as shown in

Figure 6, the thrust force of the foil, whether rigid or flexible, generated under waves, is always larger than that under calm water at any

ω0/

ωf. Therefore, we can conclude that the wave motions are beneficial to the thrust force generation, no matter what wave frequency the foil encounters. Compared with that under calm water, the thrust force of rigid and flexible foil in waves can be improved 64% and 76%, respectively, at

ω0/

ωf = 1. In addition, the thrust force and the wave power utilization coefficients of the flexible foil are 13% and 25% larger than those of rigid foil at

ω0/

ωf = 1 under waves. This phenomenon shows that flexible deformation can improve the propulsive performance of the foil, and this conclusion is in agreement with Zhou [

17,

18].

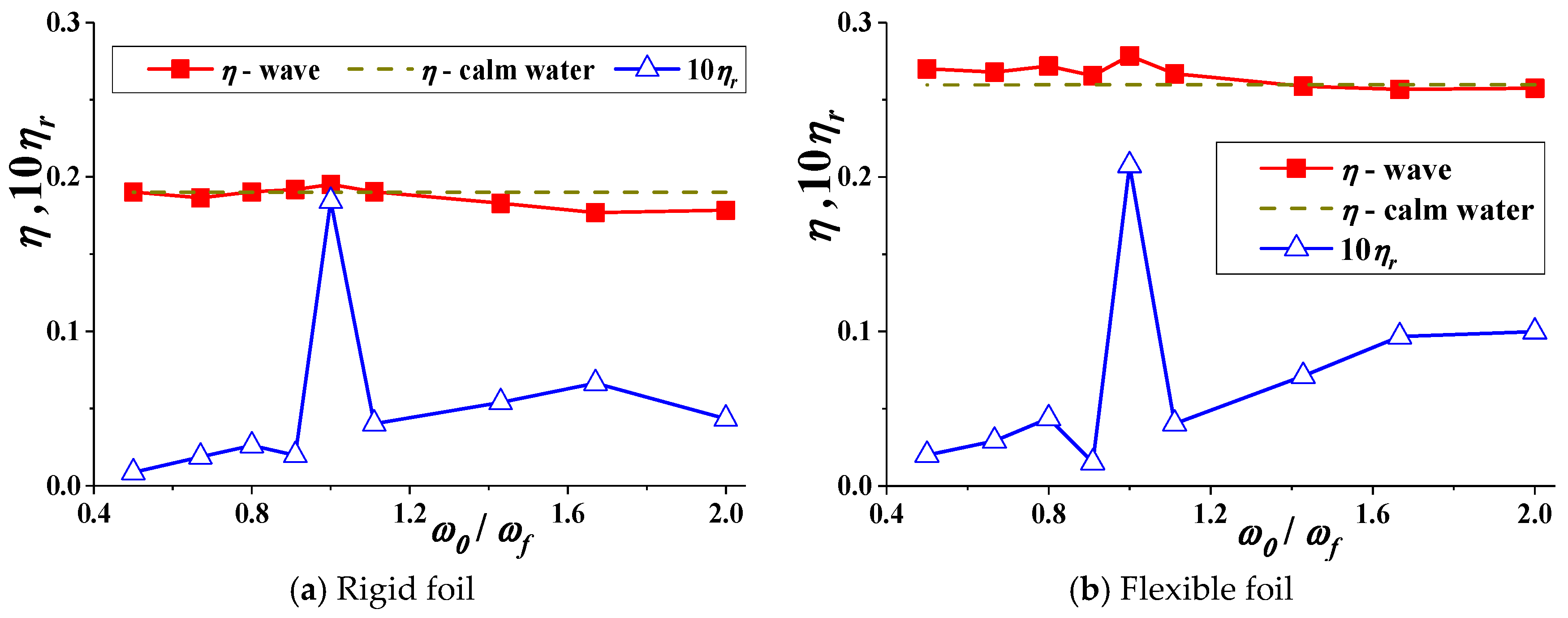

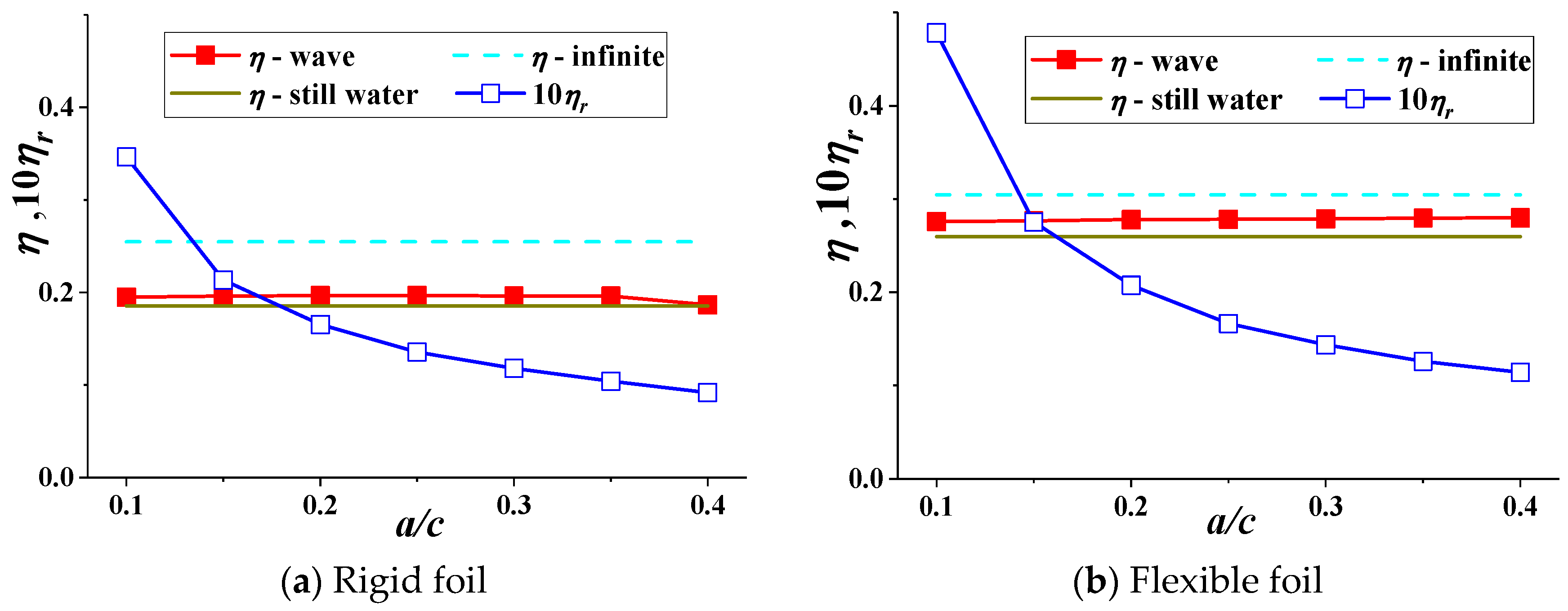

After obtaining

CT and

Cpr, the propulsive efficiency

η and the percentage of wave energy recovery

ηr can be calculated; their trends with

ω0/

ωf are shown in

Figure 7.

As seen in

Figure 7, when

ω0/

ωf < 1, the percentage of wave energy recovery

ηr of the rigid and flexible foil ascends slightly with increasing

ω0/

ωf, and reaches peak value rapidly when

ω0/

ωf is close to 1, where these curve trends validate Wu’s opinion. Obviously, the propulsive efficiency

η of the flexible foil is higher than that of rigid foil in various flow field environments, while also reaching

η peak value at

ω0/

ωf = 1 in waves. This value of the flexible foil is 43% higher than that of the rigid foil. Compared with the trends of

CT in

Figure 6,

η changes more smoothly near

ω0/

ωf = 1. In addition, the propulsive efficiency of the flexible foil and the rigid foil in waves will become smaller than that under calm water when

ω0/

ωf = 1.2 and 1.5, respectively. Above all, if the motion frequency of foil does not match its encounter frequency, the foil’s propulsive efficiency will be affected adversely, but the flexible deformation can reduce this adverse effect.

4.2. Effect of Wave Amplitudes on Foil Performance

According to Equation (14), a given wave amplitude

a denotes a certain velocity of water particles in waves. This motion disturbs the flow field of the nearby foil, thus impacting its hydrodynamic performance. The thrust force coefficient

CT and the wave power utilization coefficient

Cpr of the foil are shown in

Figure 8, relative to the non-dimensional wave amplitude

a/

c, where “-infinite” means the foil is located in the infinite flow field, and “-calm water” means the foil is located under the calm water surface with the same submergence as in waves. As no wave motion exists in the “infinite” and “calm water” flow fields, corresponding

CT and

Cpr are constant.

As seen in

Figure 8,

CT and

Cpr ascend with the increasing wave amplitude

a/

c, and the thrust force of the foil in waves is clearly larger than that in infinite flow fields and under calm water. Compared to calm water, the thrust force of the flexible and rigid foils in waves can be increased by 33.5% and 44.0% at

a/

c = 0.1, respectively, and by 142.3% and 168.0% at

a/

c = 0.4, respectively. Meanwhile the force of flexible foil is 13.5% and 16.4% higher than that of rigid foil at

a/

c = 0.1 and 0.4, respectively. Therefore, the wave motions and the flexible deformation are beneficial in obtaining a higher thrust force. The trend of

CT curves in

Figure 8 is similar to that of the heaving amplitude of the foil in reference [

38]. This phenomenon can be explained as maintaining a constant motion period, and increasing wave amplitudes will increase the velocity of water particles near the foil. Therefore, larger wave amplitudes or foil heaving amplitude can increase the moving velocity of the foil related to its surrounding water particles, and the thrust force can be improved correspondingly. In addition, flexible deformation can also cause this phenomenon, and thus result in higher thrust force than that of rigid foil.

The wave energy utilization power coefficient

Cpr of the flexible foil is also higher than that of the rigid foil, but its increment gets smaller with increasing wave amplitudes, specifically, 38.0% and 24.2% higher than the rigid foil at

a/

c = 0.1 and 0.4, respectively. This means the contribution of the flexible deformation to improving

Cpr reduces with decreasing wave amplitudes. After obtaining the thrust force and the wave power utilization coefficients, the propulsive efficiency and the percentage of wave energy recovery can be calculated, as shown in

Figure 9.

Changes in wave amplitudes have less influence on foil propulsive efficiency

η, as shown in

Figure 9. From

Figure 8 and Equation (9), in waves, increasing

a/

c not only increases the thrust force coefficient, but also the lateral force and moment coefficients, which means the input and output power of the foil ascend and then change less in

η. However, these values in waves are still larger than under calm water. Although the propulsive efficiency of the foil under a free surface is smaller than that in an infinite flow field, the flexible deformation can reduce this decreasing trend, and the flexible foil

η in waves is higher than the rigid foil

η in the infinite flow fields. However, increasing wave amplitudes reduces the percentage of wave energy recovery

ηr. To summarize, a higher sea state is beneficial to improving the thrust force of the foil, but not wave energy utilization ability. The flexible deformation can produce a larger thrust force, and have fewer adverse effects of the free surface on reducing the propulsive efficiency of the foil.

4.3. Effect of Wavelengths on the Foil Performance

In this section, the effects of wavelengths on the propulsive performance are discussed. Assuming the motion frequency of the foil is equal to its encounter frequency with waves, it should be illustrated that different wavelengths mean different motion periods for the foil in infinite flow fields and under calm water. The thrust force coefficient

CT and the wave power utilization coefficient

Cpr with the non-dimensional wavelength

λ/

c can then be calculated, as shown in

Figure 10.

The thrust force descends rapidly with increasing wavelength

λ/

c, because longer wavelengths mean longer motion periods for the foil, so the velocity of the foil, relative to the water particles, will descend in this situation with a given heaving amplitude. As a result, the thrust force of the foil will become smaller. However, as wave motion benefits the thrust force generation, the descending rate of the foil’s thrust force in waves is slower than in infinite flow fields and under calm water. Meanwhile, the wave power utilization coefficient

Cpr of the rigid and flexible foils first ascends and then descends with increasing wavelength

λ/

c. According to its expression,

Cpr reflects the difference in the thrust force of the foil between waves and calm water. Therefore, as seen in

Figure 10, with larger or smaller wavelengths, the wave effect on improving foil thrust force is limited. In addition, when

λ/

c ≈ 54,

Cpr of the flexible and rigid foil can reach peak values of 1.78 and 1.44, respectively.

The propulsive efficiency

η ascends with increasing wavelengths, as shown in

Figure 11. For the rigid foil,

η in the infinite flow fields is always larger than under the free surface, and the difference gets larger with increasing wavelengths. However, for the flexible foil, the difference of

η between the foil in waves and in infinite flow fields is not significant, and the former will be larger than the latter when

λ/

c > 130. At an arbitrary wavelength,

η of the flexible foil is always larger than that of the rigid foil, and is larger by 48.2% and 39.7% when

λ/

c = 20 and 140, respectively. Differing from the trend of

η monotonically increasing with the rigid foil,

η of the flexible foil can reach a peak value when

λ/

c = 100. Combined with

Figure 10, it can then be seen that the flexible deformation contributes to a higher thrust force and propulsive efficiency in waves than in infinite flow fields or under calm water.

Similarly, the percentage of wave energy recovery ηr of the rigid foil descends with increasing λ/c, but for the flexible foil, the trend is to first ascend and then descend, and its maximum value appears at λ/c = 60. Meanwhile, ηr of the rigid foil is slightly larger than that of the flexible foil at smaller wavelengths, by 16.5% at λ/c = 20. However, when λ/c = 35, they are approximately equal. Nevertheless, when λ/c > 35, ηr of the flexible foil will be larger than that of the rigid foil, by 31.4% at λ/c = 140. Therefore, we can conclude that the effect of the flexible deformation on improving the percentage of wave energy recovery works with certain wavelengths.

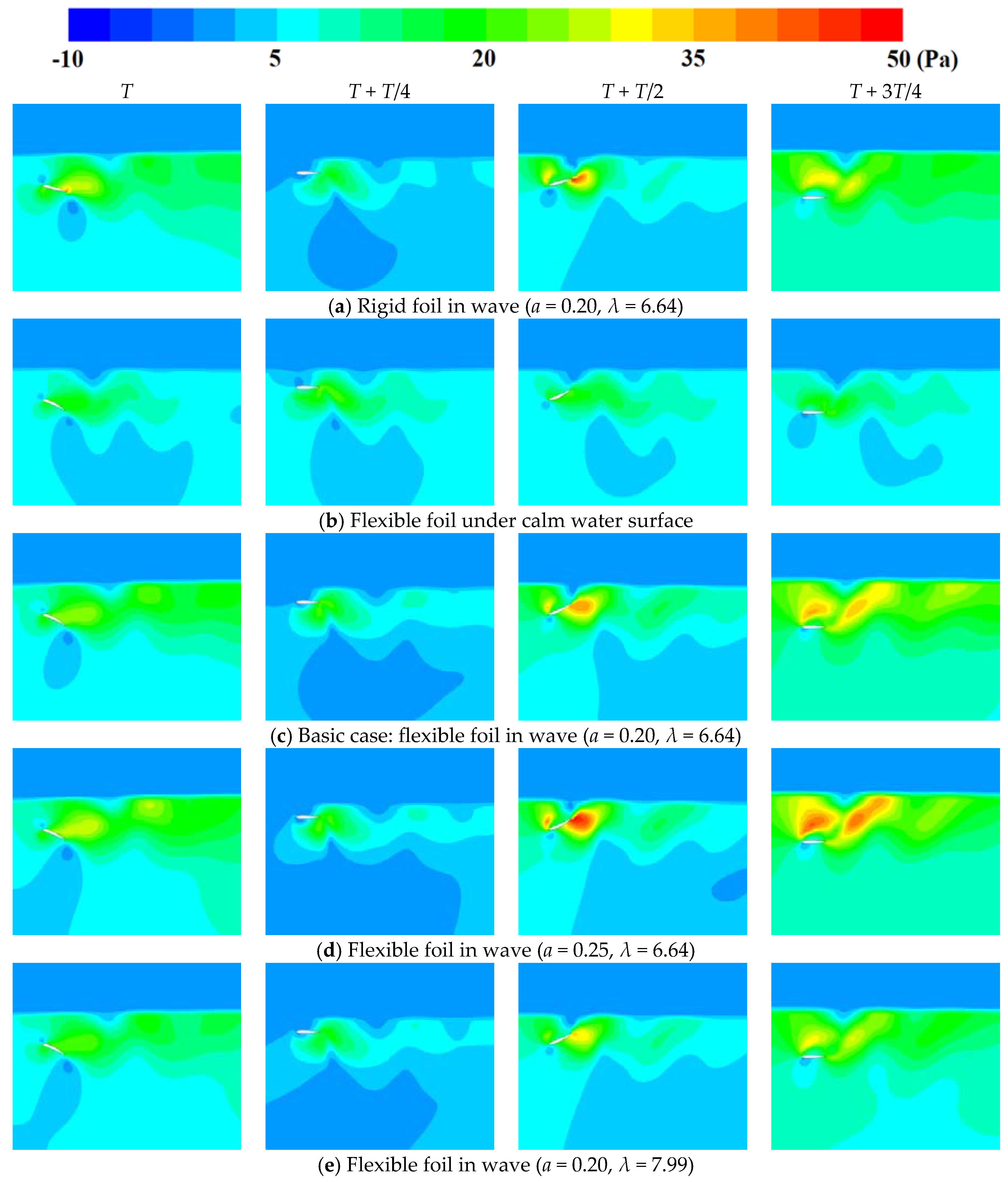

4.4. Effect of Waves on the Foil Wake Field

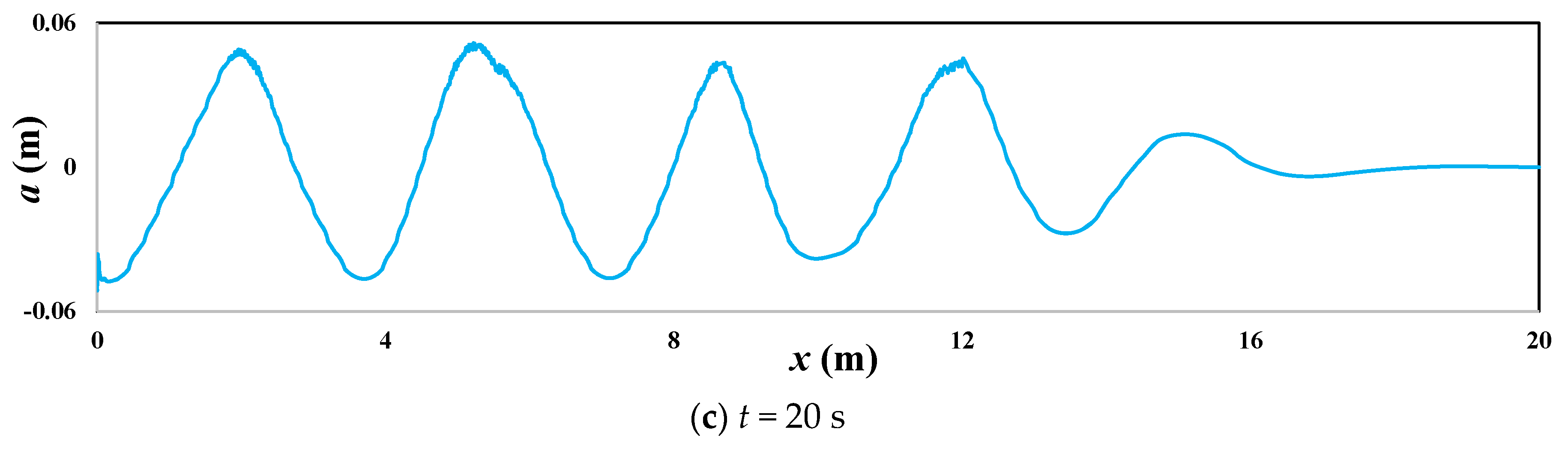

As mentioned above, the wave effect on the foil propulsive performance can be due to water particle motions disturbing the flow field of the foils. As seen in

Figure 12, instantaneous dynamic pressure near the foil is given at different times in various conditions. Although the dynamic pressure changes with time and we can obtain this distribution at any time from the Fluent software, several snapshots of the pressure field of characteristic time are selected to analyze the evolution process of flow field near the foil. Based on the Bernoulli equation in hydromechanics, the dynamic pressure can also reflect the water particle velocity and vortex structures. Other parameters, such as turbulent kinetic energy, can also then be obtained by operating on the water particle velocity or post-processing the flow field profile. In addition,

Figure 12c shows the flexible foil wake field of the basic case that is described in

Section 4.

Comparing

Figure 12c,d, there is little difference in vortex intensity between the rigid foil and the flexible foil in waves, so the instantaneous thrust force is approximately equal. But the vortex distribution range of the flexible foil is more concentrated and has better continuity. In addition, the time of vortices shedding from the flexible foil is later than that of the rigid foil. Therefore, the flexible deformation can slow down the shedding of vortices and then reduce energy wasting in a flow field. As a result, the flexible foil can obtain a higher propulsive efficiency.

On comparing

Figure 12c,e, different effects of calm water and waves on the flexible foil wake fields are shown. It is obvious that the vortices from the foil in waves are stronger than those under calm water, especially at time

T +

T/2. From a kinematics perspective, wave motion can increase foil velocity in surrounding water particles and the velocity gradient of the flow field near the foil, thus causing greater vortex intensity. From the perspective of energetics, as the foil utilizes extra wave energy, its wake field can contain more kinetic energy and slow down its vortex merging rate. Meanwhile, the output power of the foil can also be increased and the foil can generate a corresponding larger thrust force. In addition, extra input energy from waves can make the foil obtain a higher propulsive efficiency.

Comparing

Figure 12c,d the wave amplitude effect on the wake field of the flexible foil can be seen. The vortex intensity of the foil increases rapidly with larger wave amplitudes, especially at time

T +

T/2 and

T + 3

T/4 when the orbital velocity of the foil reverses. The instantaneous maximum thrust force of the foil is then much higher and its average value is increased correspondingly. However, larger wave amplitudes make the foil wake range wider, so more energy is dissipated in the wake field. This makes the foil to not have much higher propulsive efficiency.

Comparing

Figure 12c,e, the effect of wavelength on the wake field of the flexible foil can be analyzed. As the foil velocity related to water particles with longer wavelengths is lower than that with shorter wavelengths, the foil’s vortex intensity is also not higher with longer wavelengths, and the foil can only obtain a smaller thrust force. However, the vortex distribution range and the velocity gradient of the foil wake field with longer wavelengths can be smaller than those with shorter wavelengths, which means that only a small amount of energy will dissipate in the flow field and the flexible foil can achieve a relatively higher propulsive efficiency.

5. Conclusions

In this paper, a flexible foil was set to perform coupled heaving and pitching motions under a wave surface. Based on computational fluid dynamics, the propulsive performance of the foil, as well as the wave effect on the foil’s flow field evolution, are investigated by a numerical method. In these simulations, several techniques were employed; which include dynamic mesh, volume of fluid, and wake field analysis.

By changing the wavelength and keeping motion frequency constant, foil could have different encounter frequency relative to waves. We then found that foils could obtain higher propulsive performance and wave energy utilization ability only when their motion frequency was equal to encounter frequency. If this frequency equal condition is not satisfied, the foils’ performance will drop rapidly. Moreover, larger wave amplitudes are beneficial in improving the thrust force of flexible foil up to 142.3% than under calm water surface, but not in obtaining higher utilization efficiency of wave energy and it was less than 5% in our simulations. However, the propulsive efficiency of the flexible foil is less affected by wave amplitudes, and it maintains at about 27%. Smaller wavelengths are beneficial to the flexible foil obtaining a larger thrust force and higher percentage of wave energy recovery. Compared with the largest wavelength in our simulations, these two parameters can be improved up to five and four times, respectively, at the smallest wavelength. Meanwhile, the foil’s propulsive efficiency is higher at larger wavelengths and can be even higher than that in infinite flow filed. After analyzing wake fields of the foil, we found that the wave motion could change the relative velocity of flexible foil to its surrounding water particles in the flow field. This is also the main reason why the foil’s performance is affected by waves. In addition, the flexible deformation of the foil can increase the velocity gradient of its wake field and vortex intensity, and slow down the vortex shedding process from the foil’s trailing edge. As a result, flexible foil can obtain a larger thrust force, higher propulsive efficiency, and wave energy utilization ability in a regular wave environment. In summary, to improve the navigation performance of UUV, propulsion by flexible flapping foils rather than rigid ones is recommended. As the extra input power is extracted from surrounding waves, the foils can obtain better propulsive performance in high sea state without considering their wave energy utilization efficiency.