Experimental Study on Radiation Noise Frequency Characteristics of a Centrifugal Pump with Various Rotational Speeds

Abstract

:1. Introduction

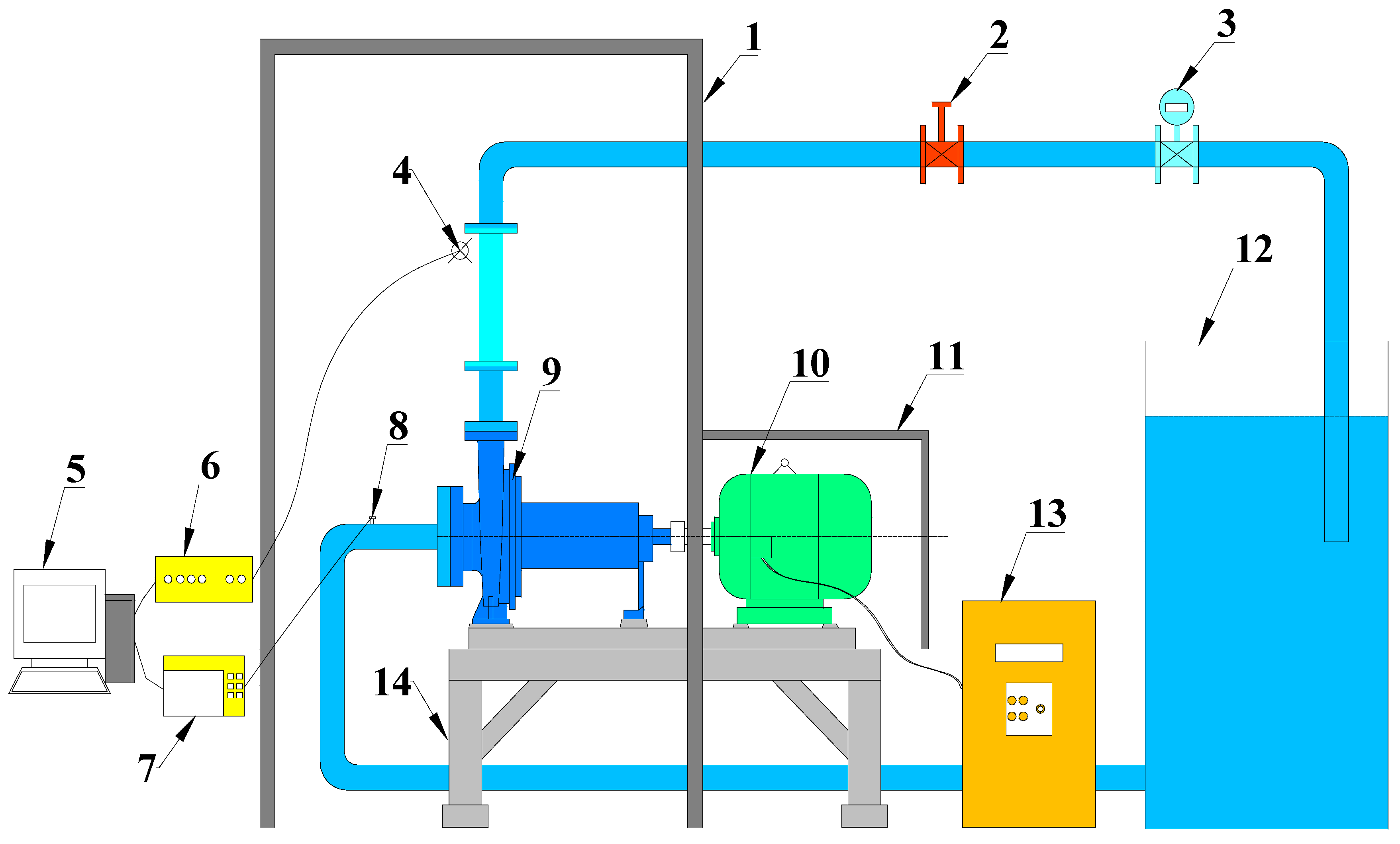

2. Experimental Facility and Procedure

2.1. Parameters of the Test Pump

2.2. Radiation Noise Measurement System

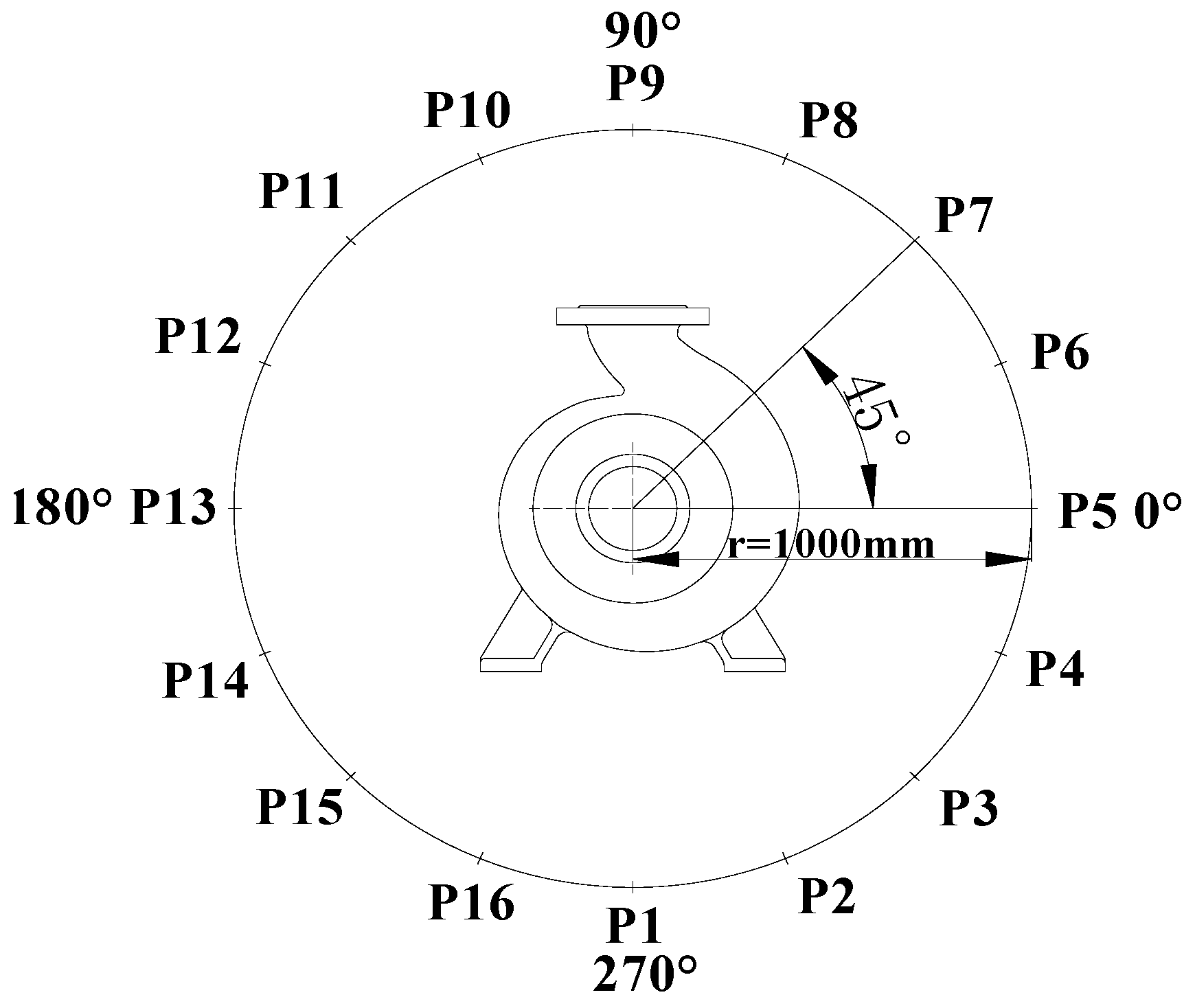

2.3. Arrangement of the Monitoring Points

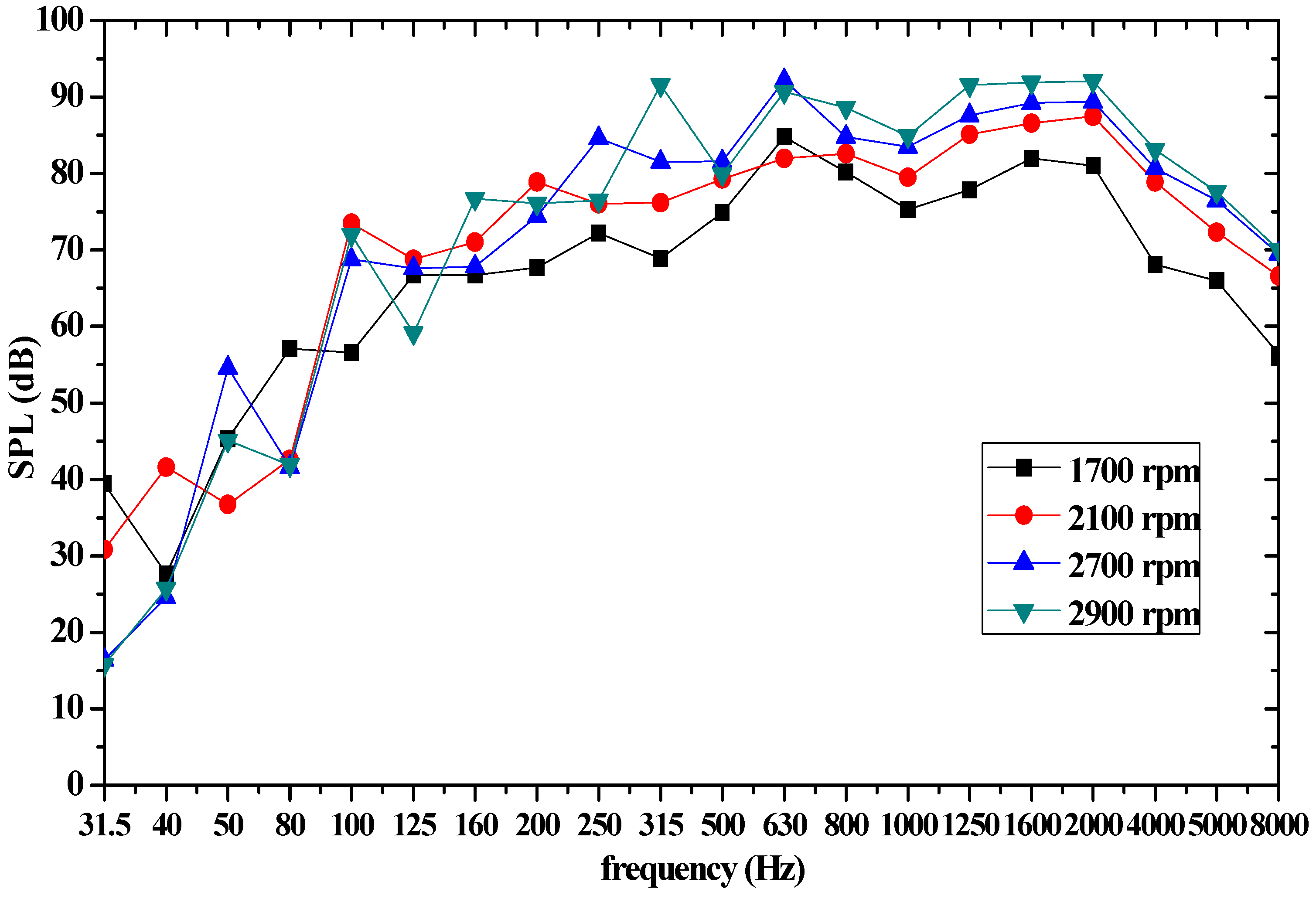

3. Frequency Characteristics of Radiation Noise under Various Rotational Speeds

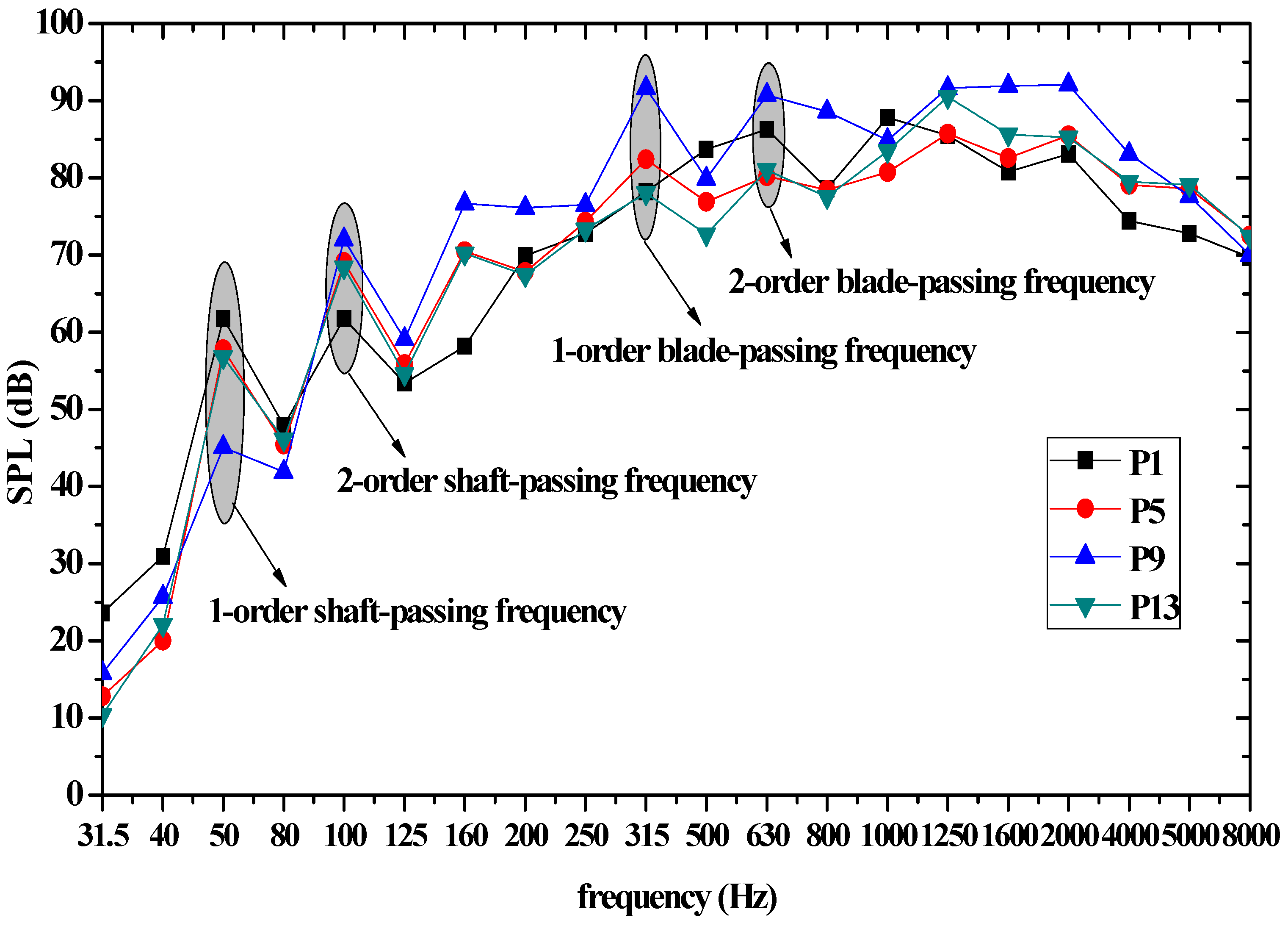

3.1. Changing Patterns of Radiation Noise in a Wide Frequency Range

3.2. Changing Patterns of Radiation Noise in Different Frequency Ranges

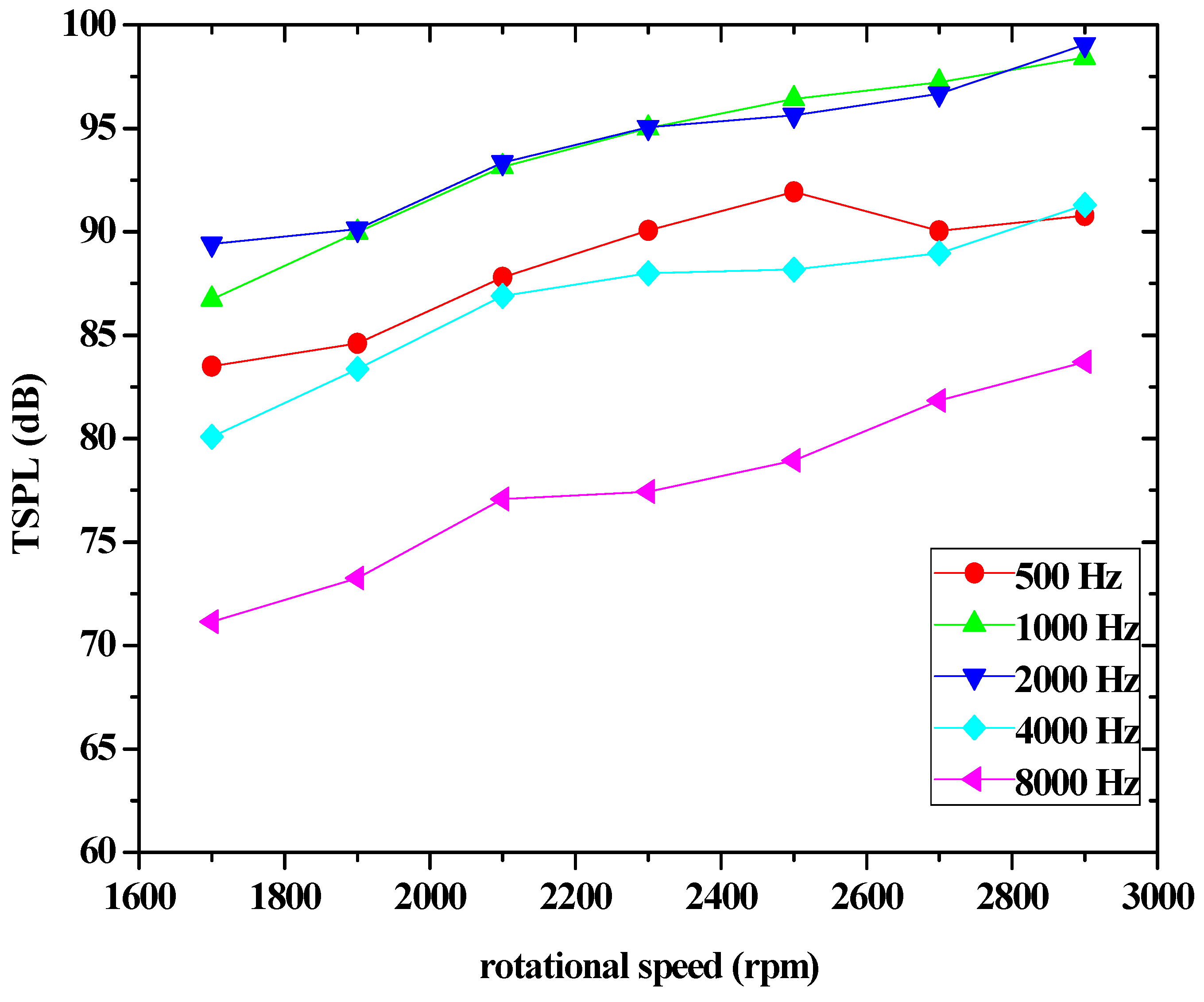

3.3. Changes in Radiation Noise at Certain Frequencies

4. Conclusions

- (1)

- Sound pressure levels (SPLs) at different monitoring points show a fluctuating ascending trend in the low frequency range from 31.5 to 1000 Hz, then reach a maximum value between 1000 and 2000 Hz and this is also the main contribution range to overall noise. When the frequency is higher than 2000 Hz, SPLs decrease gradually. Additionally, SPLs at most frequencies of the monitoring points in the outlet direction are generally higher than those of other monitoring points.

- (2)

- The acoustic energy between 1000 and 2000 Hz accounts for more than half of the total acoustic energy and the proportion also increases by 22.61% when rotational speed increases from 1700 to 2900 rpm. While the acoustic energy between 0 and 1000 Hz accounts for about 0.30, the proportion in this range shows a decreasing trend and decreases by 38.55%. When frequency is higher than 2000 Hz, however, the radiation noise contributes very little to overall noise, the acoustic energy between 2000 and 8000 Hz accounts for about 0.12, but the proportion shows little change with the change of rotational speed.

- (3)

- With increasing rotational speed, total sound pressure levels (TSPLs) at various frequencies increase gradually and the increase of radiation noise at high frequency is higher than that at low frequency, specifically, when rotational speed increases from 1700 to 2900 rpm, TSPLs at 500, 1000, 2000, 4000 and 8000 Hz increase 8.72%, 13.46%, 10.77%, 14.01% and 17.66%, respectively.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Tao, Z.; Yong’ou, Z.; Huajiang, O.; Tao, G. Flow-induced Noise and Vibration Analysis of a Piping Elbow with/without a Guide Vane. J. Mar. Sci. Appl. 2014, 13, 394–401. [Google Scholar]

- Mattia, B.; Mario, I.; Raffaele, T.; Luigi, F. Combined CFD-Stochastic Analysis of an Active Fluidic Injection System for Jet Noise Reduction. Appl. Sci. 2017, 7, 623. [Google Scholar] [CrossRef]

- Yong-Ju, C.; Yong-Sang, S.; Seung-Yop, L. Aerodynamic Analysis and Noise-Reducing Design of an Outside Rear View Mirror. Appl. Sci. 2018, 8, 519. [Google Scholar] [CrossRef]

- Shah, S.R.; Jain, S.V.; Patel, R.N.; Lakhera, V.J. CFD for centrifugal pumps: A review of the state-of-the-art. Procedia Eng. 2013, 51, 715–720. [Google Scholar] [CrossRef]

- Wu, D.F.; Liu, Y.S.; Li, D.L.; Zhao, X.F.; Li, C. Effect of materials on the noise of a water hydraulic pump used in submersible. Ocean Eng. 2017, 131, 107–113. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Yin, Y.X.; Zhang, Q.Z. Active control of repetitive impulsive noise in a non-minimum phase system using an optimal iterative learning control algorithm. J. Sound Vib. 2013, 332, 4089–4102. [Google Scholar] [CrossRef]

- Brennen, C.E. A review of the dynamics of cavitating pumps. J. Fluids Eng. 2012, 135, 061301. [Google Scholar] [CrossRef]

- Rzentkowski, G.; Zbroja, S. Experimental characterization of centrifugal pumps as an acoustic source at the blade-passing frequency. J. Fluids Struct. 2000, 14, 529–558. [Google Scholar] [CrossRef]

- Rzentkowski, G.; Zbroja, S. Acoustic characterization of a CANDU primary heat transport pump at the blade-passing frequency. Nucl. Eng. Des. 2000, 196, 63–80. [Google Scholar] [CrossRef]

- Parrondo, J.; Pérez, J.; Barrio, R.; González, J. A simple acoustic model to characterize the internal low frequency sound field in centrifugal pumps. Appl. Acoust. 2011, 72, 59–64. [Google Scholar] [CrossRef]

- Si, Q.R.; Yuan, S.Q.; Yuan, J.P.; Yang, J. Flow-induced Noise Calculation of Centrifugal Pumps Based on CFD/CA Method. J. Mech. Eng. 2013, 49, 177–184. [Google Scholar] [CrossRef]

- Yang, J.; Yuan, S.Q.; Yuan, J.P.; Si, Q.R.; Pei, J. Numerical and Experimental Study on Flow-induced Noise at Blade-passing Frequency in Centrifugal Pumps. Chin. J. Mech. Eng. 2014, 27, 606–614. [Google Scholar] [CrossRef]

- Ke, B. Study on hydrodynamic noise of centrifugal pump in different operation conditions. Technol. Acoust. 2016, 35, 92–96. [Google Scholar]

- Ye, X.M.; Pei, J.J.; Li, C.X.; Liu, Z. Experimental Study on Nosie Characteristics of Centrifugal Pump Based on Near-Field Acoustic Pressure Method. Chin. J. Power Eng. 2013, 33, 375–380. [Google Scholar]

- Jeon, W.H.; Lee, D.J. A numerical study on the flow and sound fields of centrifugal impeller located near a wedge. J. Sound Vib. 2003, 266, 785–804. [Google Scholar] [CrossRef]

- Jeon, W.H. A numerical study on the effects of design parameters on the performance and noise of a centrifugal fan. J. Sound Vib. 2003, 265, 221–230. [Google Scholar] [CrossRef]

- Khelladi, S.; Kouidri, S.; Bakir, F.; Rey, R. Predicting tonal noise from a high rotational speed centrifugal fan. J. Sound Vib. 2008, 313, 113–133. [Google Scholar] [CrossRef]

- Wang, M.; Freund, J.B.; Lele, S.K. Computational prediction of flow-generated sound. Annu. Rev. Fluid Mech. 2005, 38, 483–512. [Google Scholar] [CrossRef]

- Sanghyeon, K.; Cheolung, C.; Warn-Gyu, P. Numerical Investigation into Effects of Viscous Flux Vectors on Hydrofoil Cavitation Flow and Its Radiated Flow Noise. Appl. Sci. 2018, 8, 289. [Google Scholar] [CrossRef]

- Langthjem, M.A.; Olhoff, N. A numerical study of flow-induced noise in a two-dimensional centrifugal pump. Part I. Hydrodynamics. J. Fluids Struct. 2004, 19, 349–368. [Google Scholar] [CrossRef]

- Langthjem, M.A.; Olhoff, N. A numerical study of flow-induced noise in a two-dimensional centrifugal pump. Part II. Hydroacoustics. J. Fluids Struct. 2004, 19, 369–386. [Google Scholar] [CrossRef]

- Huang, J.X.; Geng, S.J.; Wu, R.; Liu, K.; Nie, C.Q.; Zhang, H.W. Comparison of noise characteristics in centrifugal pumps with different types of impellers. Acta Acoust. 2010, 35, 113–118. [Google Scholar]

- Gao, M.; Dong, P.X.; Lei, S.H.; Turan, A. Computational Study of the Noise Radiation in a Centrifugal Pump When Flow Rate Changes. Energies 2017, 10, 221. [Google Scholar] [CrossRef]

- Liu, H.L.; Dai, H.W.; Ding, J.; Tan, M.G.; Wang, Y.; Huang, H.Q. Numerical and experimental studies of hydraulic noise induced by surface dipole sources in a centrifugal pump. J. Hydrodyn. 2016, 28, 43–51. [Google Scholar] [CrossRef]

- Ding, J.; Liu, H.L.; Wang, Y.; Tan, M.G.; Cui, J.B. Numerical study on the effect of blade outlet angle on centrifugal pump noise. J. Vib. Shock 2014, 33, 122–127. [Google Scholar]

- Tao, J.Y.; Lu, X.N.; Wang, L.L. Methods of Measuring and Evaluating Noise of Pumps; Chinese Quality Supervision Bureau: Beijing, China, 2013.

- Du, G.H.; Zhu, Z.M.; Gong, X.F. Fundamentals of Acoustics; Nanjing University Press: Nanjing, China, 2001. [Google Scholar]

- Guo, C.; Gao, M.; Lu, D.Y.; Wang, K. An Experimental Study on the Radiation Noise Characteristics of a Centrifugal Pump with Various Working Conditions. Energies 2017, 10, 2139. [Google Scholar] [CrossRef]

- Chu, S.; Dong, R.; Katz, J. Relationship between unsteady flow, pressure fluctuation, and noise in a centrifugal pump—Part B: Effects of blade-tongue interactions. J. Fluids Eng. 1995, 117, 30–35. [Google Scholar] [CrossRef]

- Ma, Z.L.; Chen, E.Y.; Guo, Y.L.; Yang, A.L. Numerical Simulation of the Influence of the Diameter at the Outlet of an Impeller on the Noise Level Induced by the Flow Inside a Centrifugal Pump. J. Eng. Therm. Energy Power 2016, 31, 93–98. [Google Scholar]

- Lu, D.Y. Experimental Study on Flow-Noise of Centrifugal Pump in Variable Working Condition. Master’s Thesis, Shandong University, Jinan, China, 2017. [Google Scholar]

- Dong, P.X.; Gao, M.; Guan, H.J.; Lu, D.Y.; Song, K.Q.; Sun, F.Z. Numerical simulation for variation law of volute radiated noise in centrifugal pumps under variable rotating speed. J. Vib. Shock 2017, 36, 128–133. [Google Scholar]

- Wang, Y. Research on Cavitation and Its Induced Vibration and Noise in Centrifugal Pumps. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2011. [Google Scholar]

- Lu, J.X.; Yuan, S.Q.; Yuan, J.P.; Ren, X.D.; Pei, J.; Si, Q.R. Research on the noise induced by cavitation under the asymmetric cavitation condition in a centrifugal pump. In Proceedings of the 9th International Symposium on Cavitation, Lausanne, Switzerland, 6–10 December 2015. [Google Scholar]

| Parameter | Value |

|---|---|

| Inlet diameter, mm | 80 |

| Impeller diameter, mm | 250 |

| Outlet diameter, mm | 50 |

| Rated flow rate, m3/h | 50 |

| Design head, m | 80 |

| Rated rotational speed, rpm | 2900 |

| Blade number | 6 |

| Blade-passing frequency, Hz | 290 |

| Shaft-passing frequency, Hz | 48.3 |

| Instruments | Type | Application | Measuring Range | Accuracy or Sensitivity |

|---|---|---|---|---|

| Flow meter | SLDG-800 | Measuring flow rate | 0–100 m3/h | 0.2% (accuracy) |

| Pressure transducer | MIK-300 | Measuring inlet pressure | −100–0 kPa (inlet pipe) | 0.5% (accuracy) |

| Pressure recorder | RX-200D | Recording pressure | / | / |

| Microphone | AWA14423L | Measuring radiation noise | 10–20,000 Hz | 50 mV/Pa (sensitivity) |

| Two channel signal analyzer | AWA6290M+ | Analyzing radiation noise signal | / | / |

| Rotational Speed, rpm | Flow Rate, m3/h |

|---|---|

| 1700 | 56.9 |

| 1900 | 64.8 |

| 2100 | 69.6 |

| 2300 | 74 |

| 2500 | 78.2 |

| 2700 | 82.1 |

| 2900 | 86 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, C.; Gao, M.; Lu, D.; Guan, H. Experimental Study on Radiation Noise Frequency Characteristics of a Centrifugal Pump with Various Rotational Speeds. Appl. Sci. 2018, 8, 796. https://doi.org/10.3390/app8050796

Guo C, Gao M, Lu D, Guan H. Experimental Study on Radiation Noise Frequency Characteristics of a Centrifugal Pump with Various Rotational Speeds. Applied Sciences. 2018; 8(5):796. https://doi.org/10.3390/app8050796

Chicago/Turabian StyleGuo, Chang, Ming Gao, Dongyue Lu, and Hongjun Guan. 2018. "Experimental Study on Radiation Noise Frequency Characteristics of a Centrifugal Pump with Various Rotational Speeds" Applied Sciences 8, no. 5: 796. https://doi.org/10.3390/app8050796