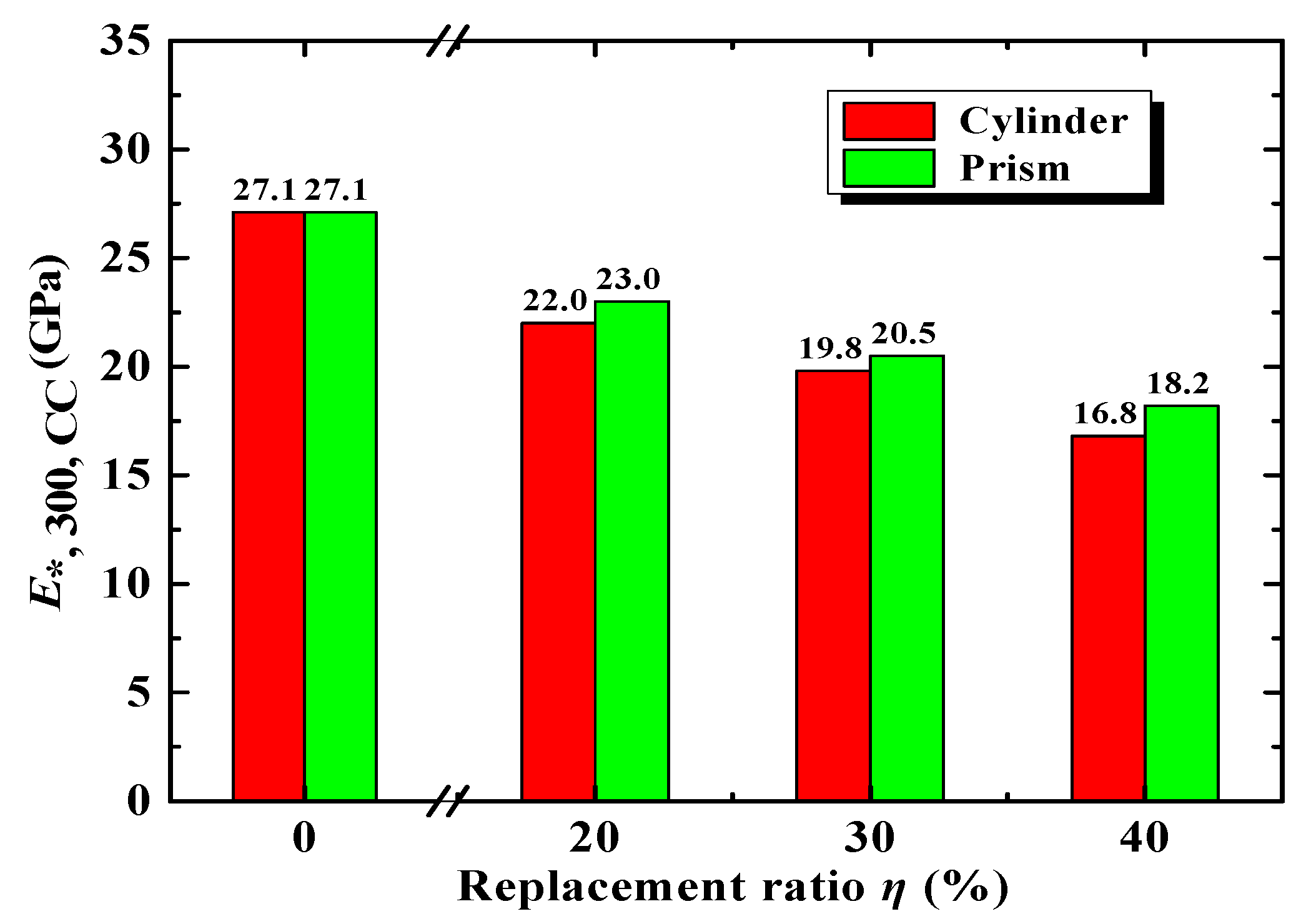

3.3.1. Combined Compressive Strength

The measured mechanical properties of the specimens in Groups 2, 3, and 4 are summarized in

Table 4. In that table, the subscripts CC and FC identify the specimens made with compound concrete and fresh concrete, respectively. So

f*,300,CC,

*,300,CC, and

E*,300,CC are, respectively, the combined compressive strength, combined peak strain, and combined elastic modulus of the 300 mm compound concrete specimens; and

f*,300,FC,

*,300,FC, and

E*,300,FC are, respectively, the compressive strength, peak strain, and elastic modulus of the 300 mm control fresh concrete specimens. The table shows that the cubic, prismatic, or cylindrical compressive strength of the compound concrete made of DCLs and FC decreased gradually with increased replacement ratio. This is presumably due to the 150 mm cubic compressive strength of the demolished concrete (40.8 MPa) being lower than that of the fresh concrete (53.0 MPa on the test day).

The strength ratios of

fcu,300,CC/

fcy,300,CC and

fpr,300,CC/

fcy,300,CC listed in

Table 4 are also presented in

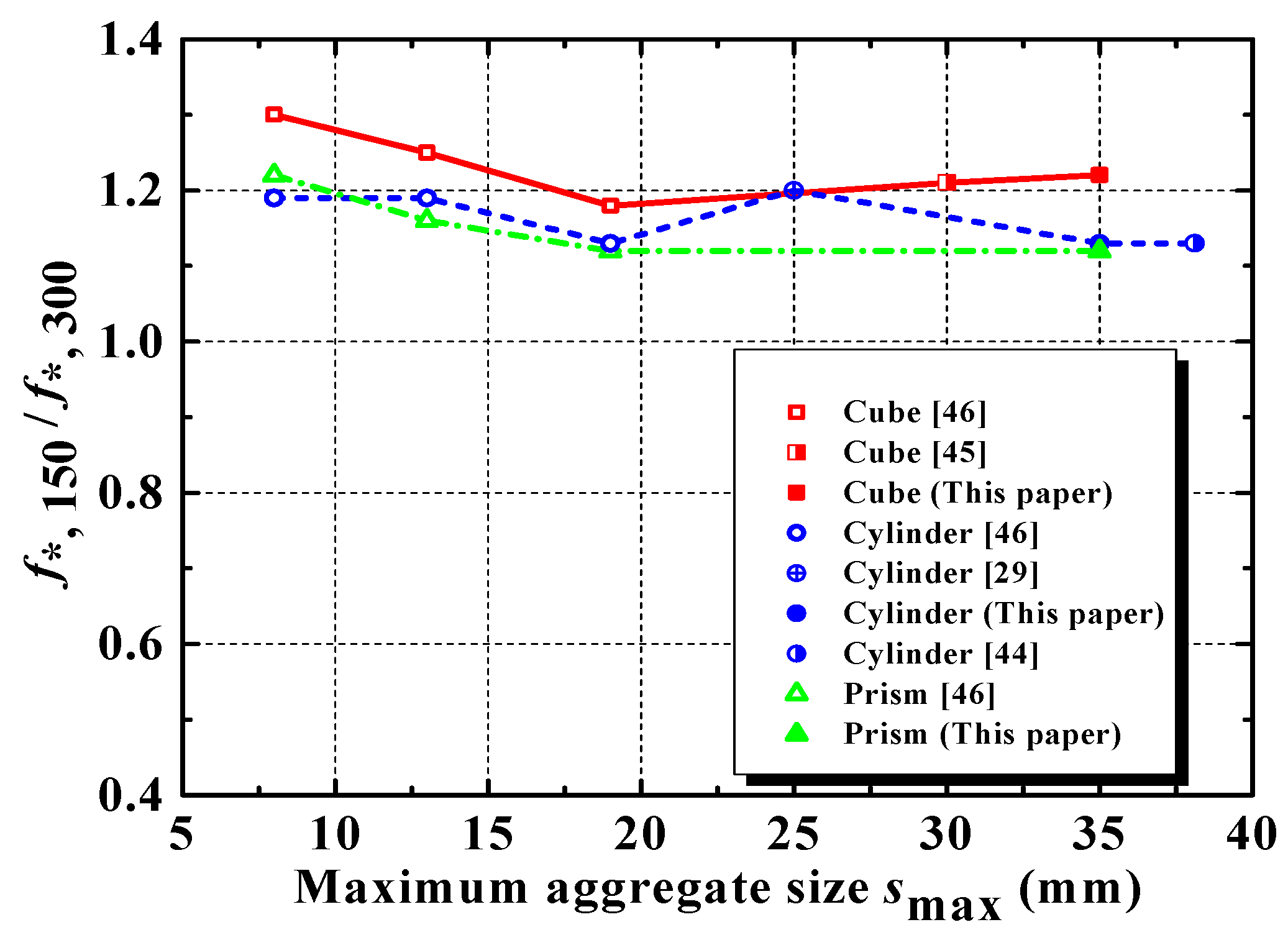

Figure 8. It is evident from this figure that:

- (a)

With increased replacement ratio of DCLs, the fcu,300,CC/fcy,300,CC strength ratio generally increased. The strength ratio for the specimens with a replacement ratio of 20% was almost the same as that for the specimens with a ratio of 30%, and about 4.7% higher than that for the control specimens made of FC alone. But when the replacement ratio was 40%, the strength ratio was 14.7% higher than that for the control specimens. This implies that although both the cubic and cylindrical compressive strengths of the compound concrete decreased with increasing replacement ratio, the cubic strength declined more slowly than the cylindrical strength, probably due to the end restraint of the machine’s platens on the lateral expansion of the cubic specimens being much more significant than for the cylindrical specimens. The negative effect of the DCLs is thus more prominent with cylinders.

- (b)

The

fpr,300,CC/

fcy,300,CC strength ratio did not change very much with increasing replacement ratio. This is because for cylinders and prisms with the same height, the same lateral dimension, and the constraint caused by the loading platens, the rate of decrease in

fpr,300,CC with increasing replacement ratio should be similar to that of

fcy,300,CC. For the prismatic and cylindrical specimens with replacement ratios of 20%, 30%, and 40%, the average value of that strength ratio was about 1.13, which is 13% higher than the

fpr,300,FC/

fcy,300,FC strength ratio of the control specimens made of fresh concrete alone. The prisms’ compressive strength apparently decreased more slowly than that of the cylinders. It should be noted that the cylindrical and prismatic specimens were cast in different placement directions: the cylinders were cast parallel to loading direction, while the prisms were cast perpendicular. Considering that the compressive strength of a vertically cast specimen is normally less than that of a horizontally cast one [

50,

51], it may be surmised that if prisms and cylinders made of DCLs and FC were cast in the same placement direction, the

fpr,300,CC/

fcy,300,CC strength ratio should be significantly smaller than the observed 1.13.

Based on the experimental results published in recent years, a linear formula Equation (3) has been suggested for predicting the cubic compressive strength of compound concrete made of normal-strength DCLs and FC [

27,

30]. Taking the observed shape effect into account, Equation (3) can be extended to Equations (4) and (5), which may approximately predict the combined compressive strength of prisms and cylinders:

Here the subscript asterisk (*) = cu for a cube, cy for a cylinder, and pr for a prism;

f*,300,CC is the predicted compressive strength of compound concrete with a lateral dimension of 300 mm;

f*,300,DC and

f*,300,FC are, respectively, the compressive strength of demolished concrete and fresh concrete with a lateral dimension of 300 mm;

η represents the replacement ratio; and a

* and b

* are coefficients related to the shape effect. The values of

acu,

acy, and

apr can be taken, respectively, as 0, 0.04, and 1.12, and

bcu,

bcy, and

bpr can be taken, respectively, as 0, 0.85, and 2.87, according to the test results listed in

Table 4. It should be noted that during the calculation, the subscript asterisk (*) on the left- and right-hand sides of Equations (4) and (5) must be assigned with the same meaning.

The combined compressive strengths of the cubic, prismatic, and cylindrical specimens in Groups 2, 3, and 4 predicted using Equation (4) were compared with the measured results presented in

Table 5. During the calculations, in order to determine the value of

f*,300,DC, it was assumed that the size and shape effects on demolished concrete’s strength are approximately the same as those on fresh concrete’s strength (i.e.,

f*,150,DC/

fcu,150,DC =

f*,150,FC/

fcu,150,FC, and

f*,300,DC/

f*,150,DC =

f*,300,FC/

f*,150,FC). If so,

f*,300,DC can be determined as:

Except for

fcu,150,DC, all the other strengths on the right-hand side of Equations (6) and (7) can be obtained from

Table 3. The measured 150 mm cubic compressive strength of demolished concrete,

fcu,150,DC, was 40.8 MPa, as described in

Section 2.1.

- (a)

The combined compressive strength (f*,300,CC) predicted using Equation (4) is generally higher than the measured one. This is mainly because Equation (4) is based on data from previous experiments in which the maximum aggregate size of fresh concrete did not exceed 25 mm. Spaces between the mold and the DCLs and gaps between adjacent DCLs may have been better filled with fresh concrete in that work. The fresh concrete’s aggregate size in this study ranged up to 35 mm. This may have allowed some spaces between the mold and the DCLs and some gaps between the adjacent lumps to be filled only with mortar without coarse aggregates. If the homogeneity of the compound concrete was poorer, that could explain the lower measured compressive strength.

- (b)

The larger the replacement ratio, generally the greater the discrepancy between the predicted and measured strengths. This might be explained in the same way. With increasing replacement ratio, the number of spaces between the mold and the DCLs and the number of gaps between adjacent lumps increased. But the spaces and gaps generally became narrower, so the heterogeneity of the compound concrete would increase if the aggregate was coarse.

With the test results listed in

Table 4 as a reference, a modified Equation (8) can be proposed for predicting the compressive strength of compound concrete made with normal-strength DCLs and FC with a maximum aggregate size not larger than 35 mm:

where

λ is a reduction coefficient not larger than 1.0,

α = 0.68 for a specimen with a lateral dimension of 300 mm, and

smax (in mm) denotes the maximum aggregate size of the fresh concrete;

λ = 1.0 when

smax ≤ 25 mm. In that case, Equation (8) reduces to Equation (4). The combined compressive strengths of the specimens in Groups 2, 3, and 4 predicted using Equations (8) and (9) are listed in

Table 5. The predicted results clearly agree well with the measured data on the whole.

3.3.2. Combined Elastic Modulus

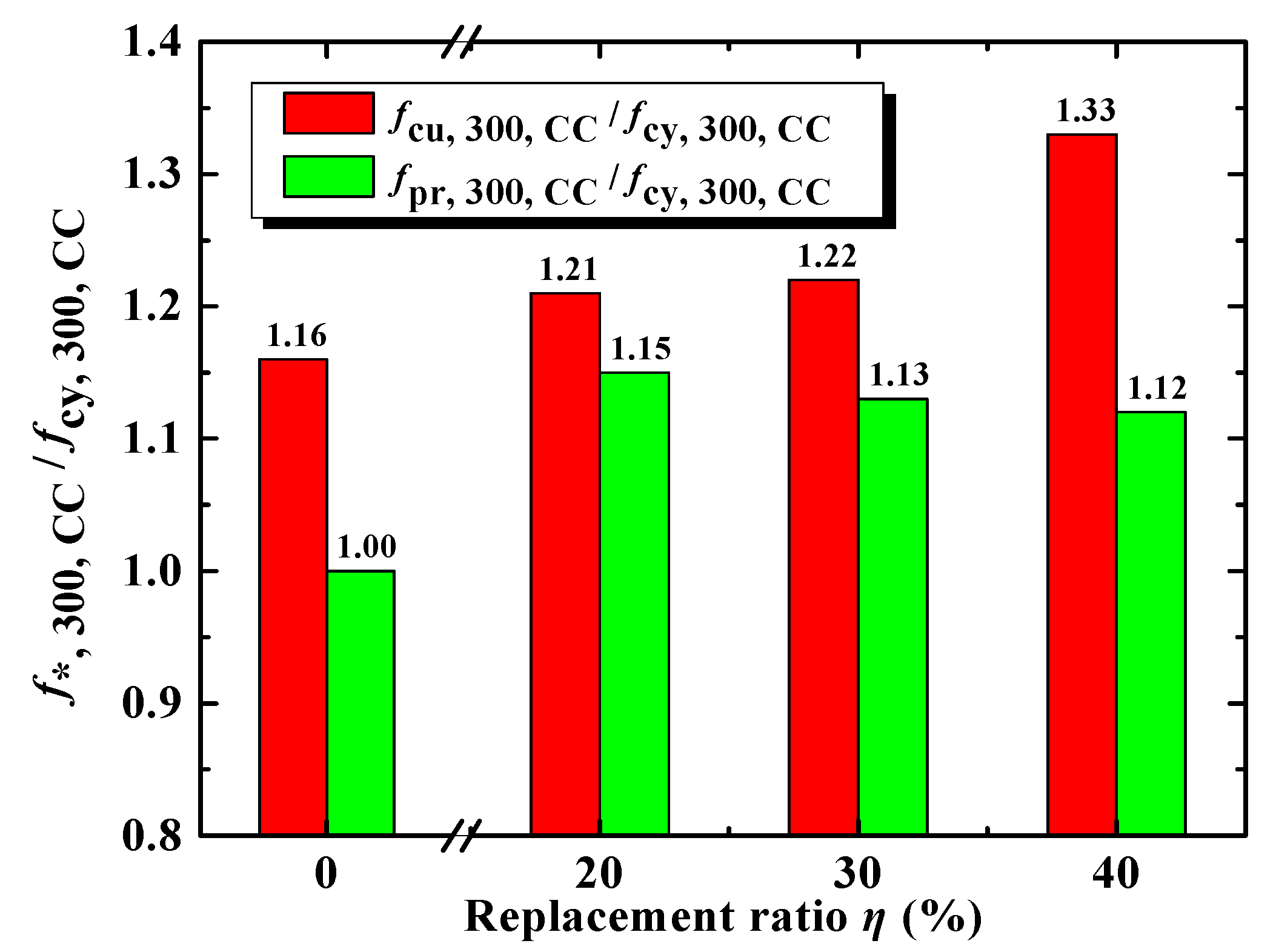

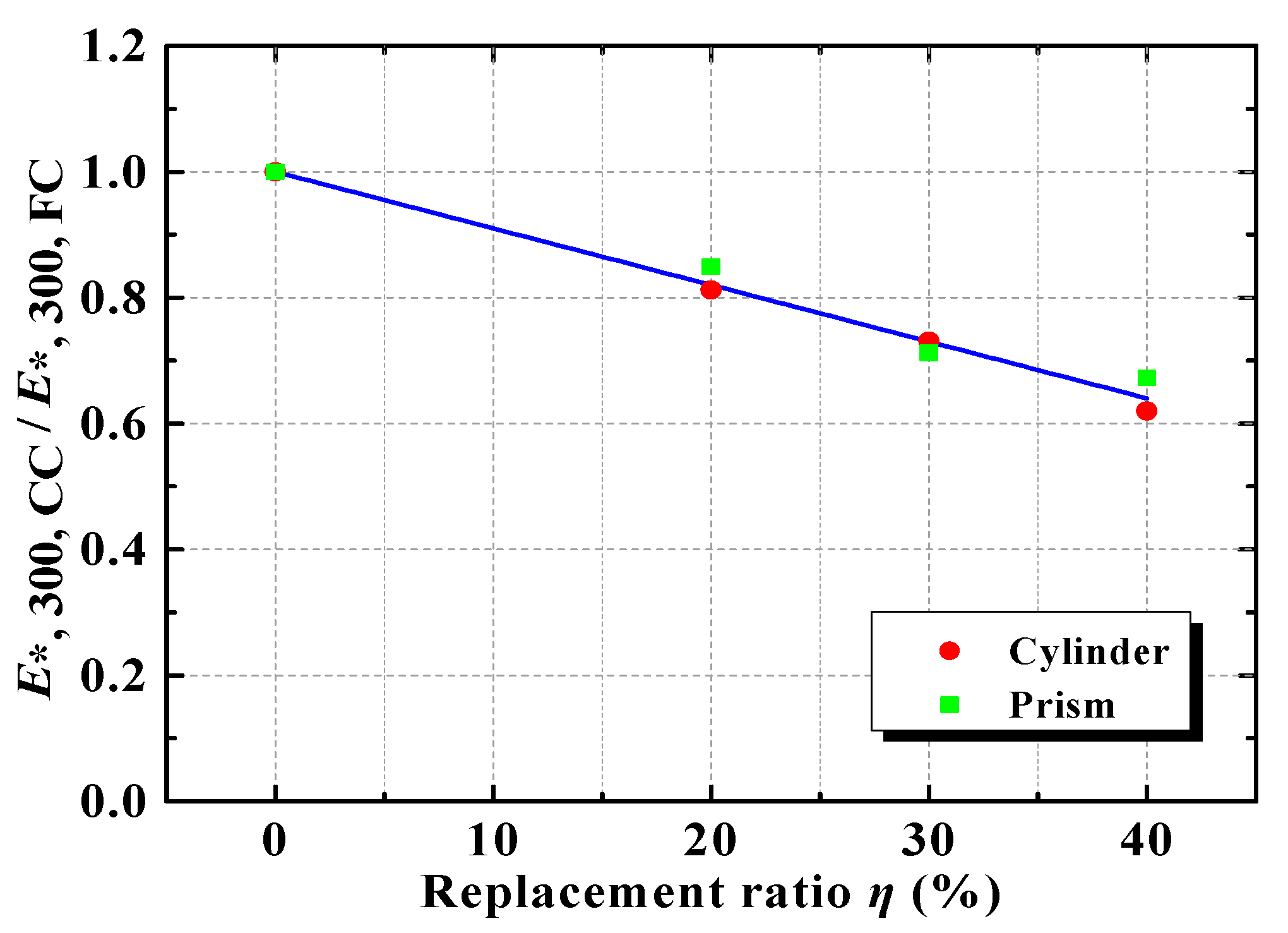

For the prisms and cylinders listed in

Table 4, the behavior of the relative elastic modulus (i.e.,

E*,300,CC/

E*,300,FC) with increased replacement ratio is depicted in

Figure 9. The figure shows that:

- (a)

The combined elastic modulus of the prisms or cylinders made with DCLs decreased gradually with increasing replacement ratio. This is presumably due to the low compressive strength of demolished concrete (40.8 MPa for a 150 mm cube) compared with fresh concrete (53.0 MPa on the test day). The modulus of elasticity of demolished concrete should also be less than that of fresh concrete.

- (b)

For any given replacement ratio, the relative elastic modulus of the prisms is very close to that of the cylinders. An approximately linear relationship between the relative elastic modulus and the replacement ratio holds for both.

Figure 10 shows that for a given replacement ratio, the combined elastic modulus of a prism is always larger than that of a cylinder, though the difference is generally small. For the prismatic and cylindrical specimens with replacement ratios of 20%, 30%, and 40%, the average value of

Epr,300,CC/

Ecy,300,CC is only about 1.05.

Equation (2) shows that

is in proportion to

for the specimens made of FC alone. To examine the relationship between

and

for DCL-filled specimens, a dimensionless parameter

R was defined:

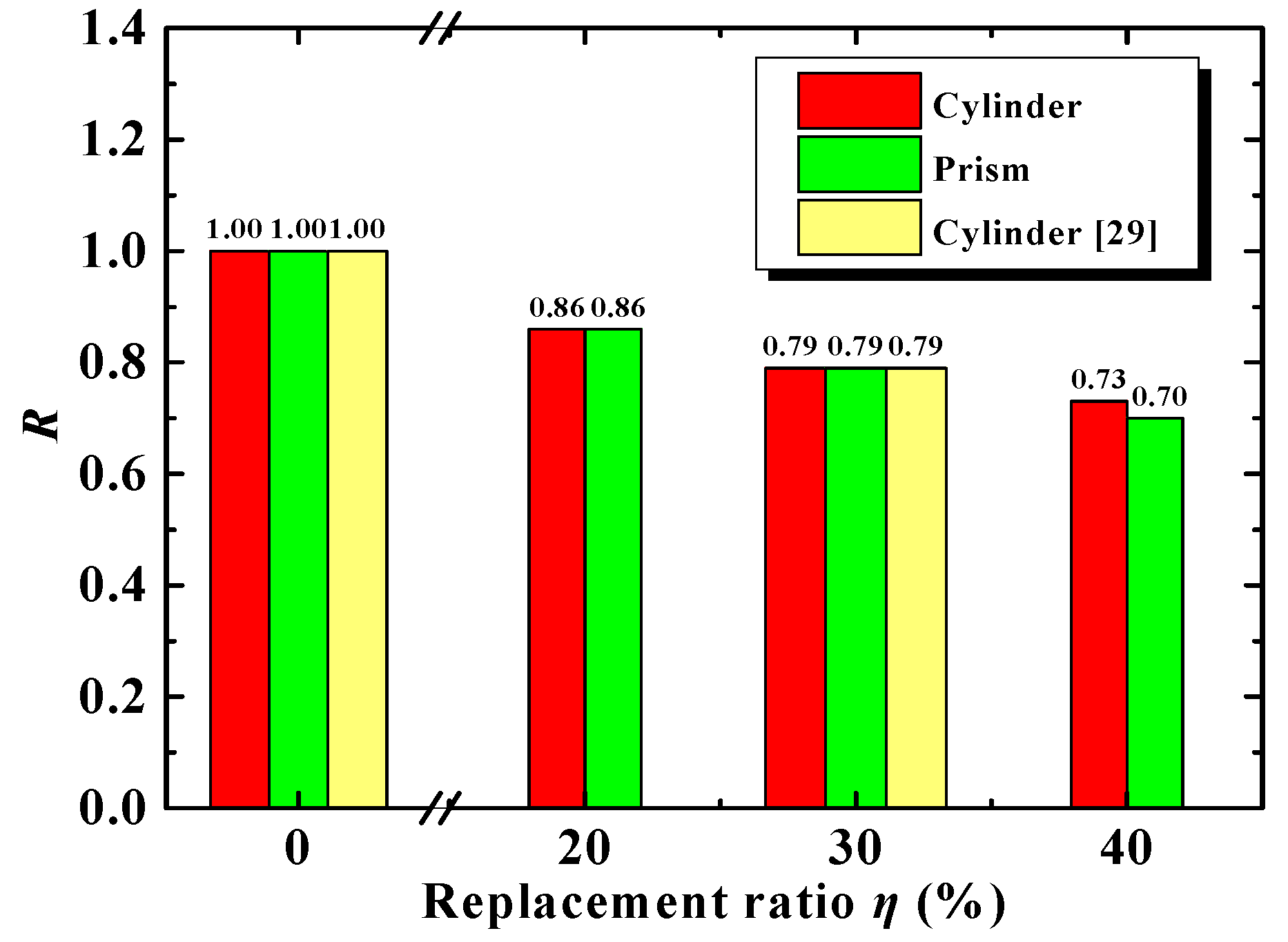

Figure 11 presents a plot of

R versus the replacement ratio. It is evident that:

- (a)

R is always less than 1.0. This implies that even when the compressive strength of compound concrete is equal to that of fresh concrete, the elastic modulus will be lower. A similar relationship can also be observed using published test data from previous research [

29]. This indicates that the negative effect of DCLs on the combined elastic modulus is more significant than that on the combined compressive strength.

- (b)

The maximum aggregate size of the fresh concrete in study [

29] was 25 mm, which is smaller than that of the fresh concrete in this study (35 mm); at the same time, replacement ratio (e.g., 30% in

Figure 9), the value of

R calculated from the published test data [

29], is almost the same as that based on the test results in this study. So the influence of maximum aggregate size on the value of

R is apparently limited.

- (c)

The value of R decreases gradually with increasing replacement ratio. This is presumably due to the greater heterogeneity of compound concrete.

Based on the test data listed in

Table 4, an empirical expression can be proposed for the relationship between the combined elastic modulus and the combined compressive strength applying to both horizontally cast prism and vertically cast cylinder.

The subscript asterisk (*) refers to the shape of the specimen (* = pr for a prism and cy for a cylinder).

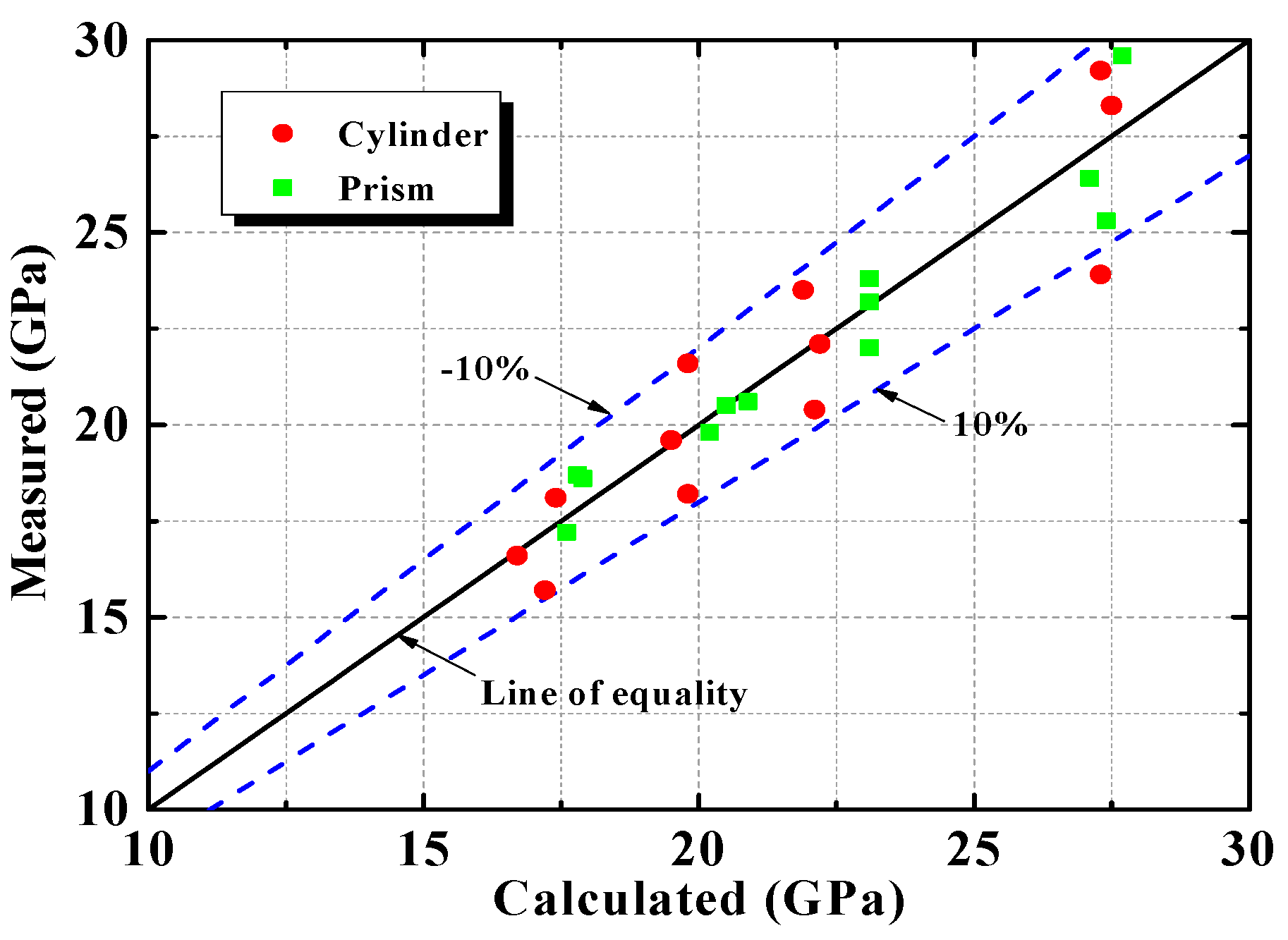

Figure 12 compares the calculated and measured elastic moduli. It shows that the measured results generally agree well with results calculated using Equation (11).

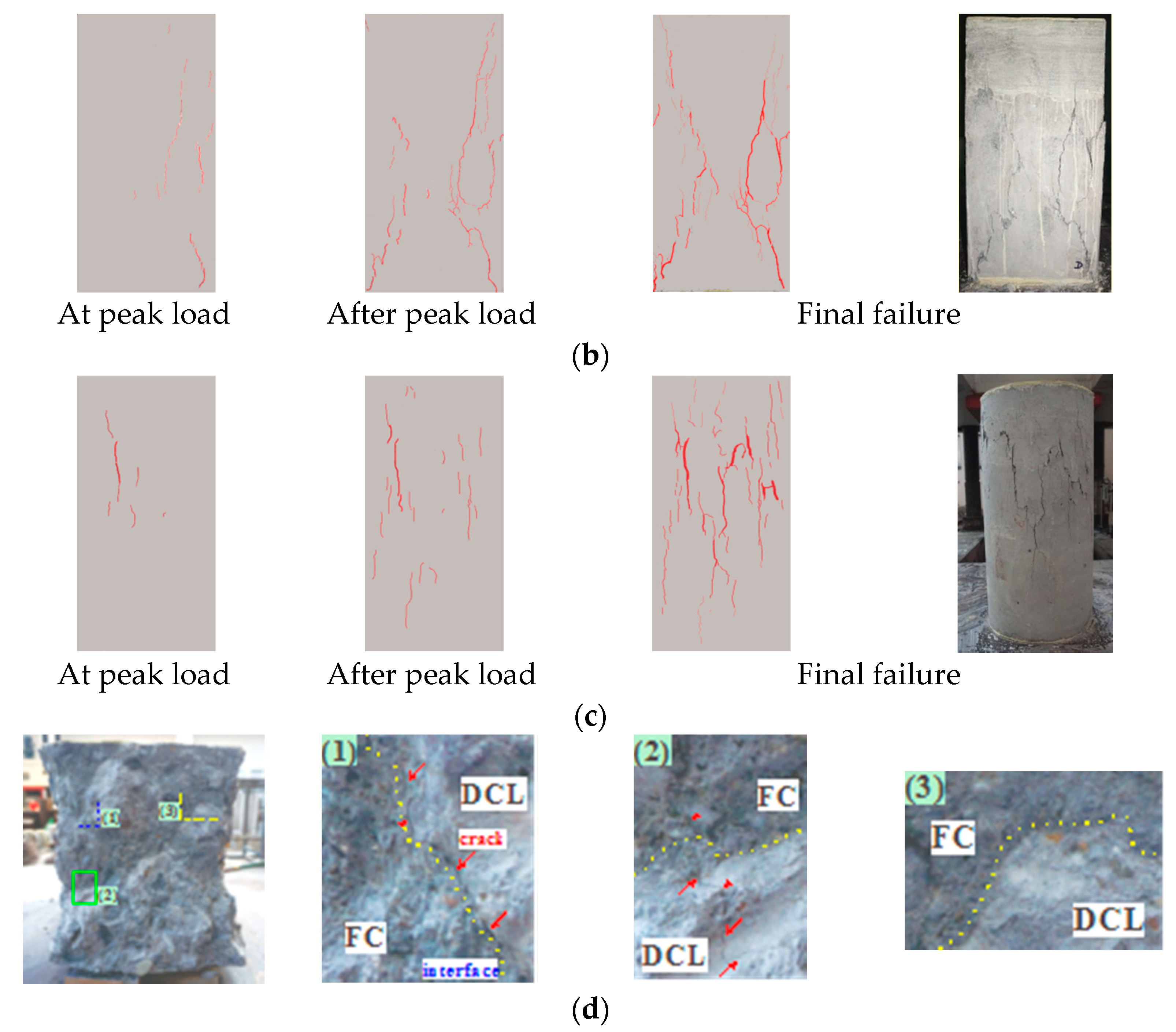

3.3.3. Combined Peak Strain

Figure 13 illustrates variation in combined peak strain with the replacement ratio for the prisms and cylinders listed in

Table 4. It can be seen from the figure that:

- (a)

With increased replacement ratio, both the average and the coefficient of variation of the combined peak strain generally increased. The peak strains of the prisms and cylinders with a replacement ratio of 40% were, respectively, 35.4% and 18.2% larger than the peak strains of the prisms and cylinders made of FC alone. It has been suggested that the strain at peak stress reflects the amount of micro-cracking that has occurred, and that increased strain at peak stress indicates more micro-cracks [

53,

54]. If so, it can be deduced that micro-cracking in compound concrete increases with the replacement ratio.

- (b)

For a given replacement ratio, the peak strain for a prism is always higher than that of a cylinder, and the difference between them increases with the replacement ratio. This is presumably because with a prism, the stress is concentrated at the edges in the early loading [

50]. With degradation of the edge concrete, the stress gradually shifts to the core concrete. More micro-cracks form during the process of stress transfer than with a cylinder, leading to greater peak strain for the prism.

Based on the test data listed in

Table 4, a quantitative relationship between the combined peak strain and the replacement ratio can be formulated as:

The subscript asterisk (*) again refers to the shape of the specimen (* = pr for a prism and cy for a cylinder). The value of

θ (0.79 for a prism and 0.44 for a cylinder) is determined through linear fitting of the test data.

Figure 13 shows that Equation (12) agrees well with the test results on the whole.

Based on the test results presented in

Table 4, an empirical expression can be proposed to determine the relationship between the combined peak strain and the combined compressive strength for both the horizontally cast prism and vertically cast cylinder.

Here, too, the subscript asterisk (*) denotes the shape of the specimen (* = pr for a prism and cy for a cylinder).

Figure 14 shows a comparison between the calculated and measured combined peak strains, and it is clear that the measured data generally agree well with the values calculated using Equation (13).

3.3.4. The Effect of the Characteristic Ratio for Prisms

The measured mechanical properties of the specimens in Group 5 are summarized in

Table 6.

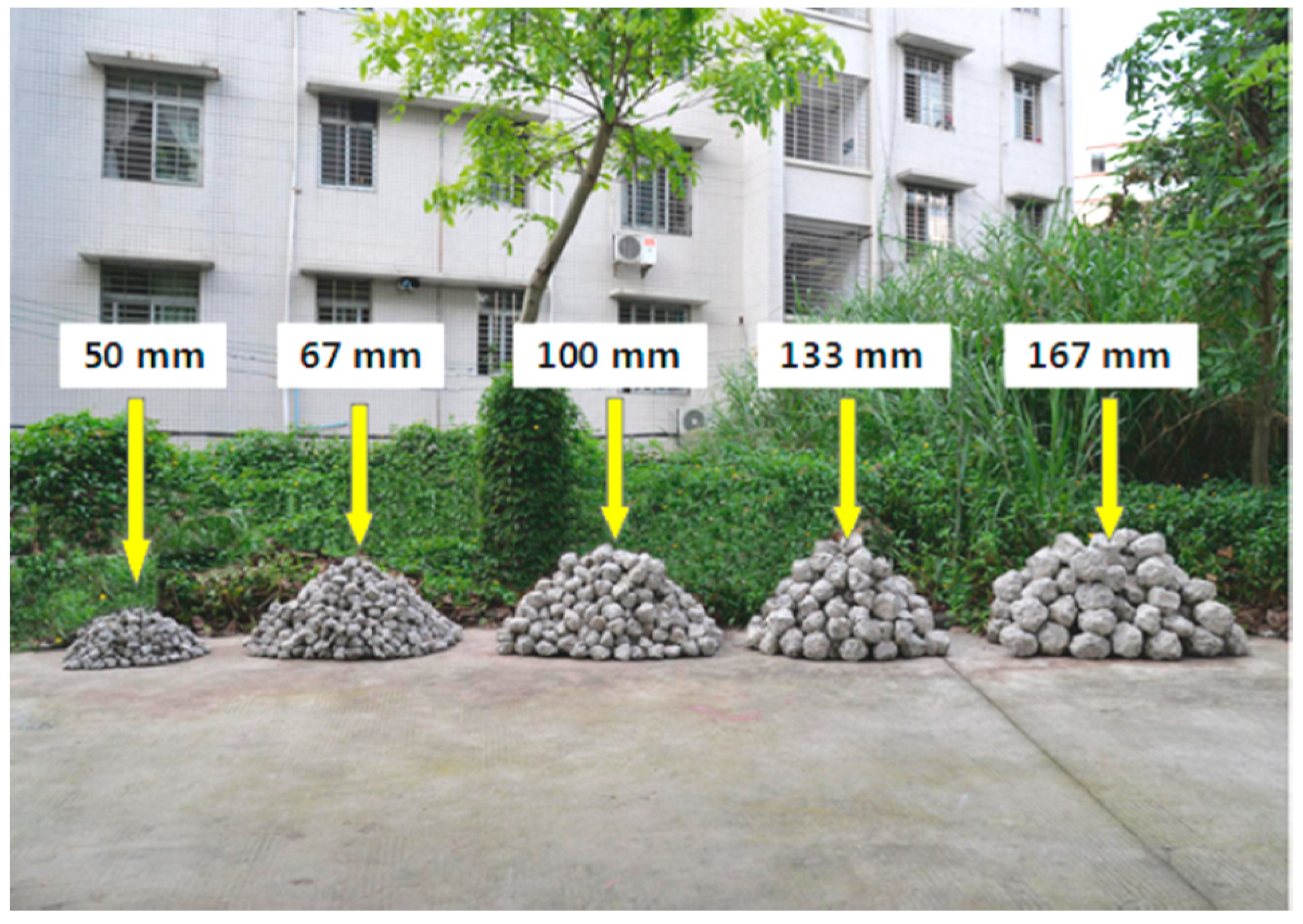

The variation of the combined compressive strength with the ratio of the characteristic size of the lumps to the specimen’s lateral dimension (designated as

β) is shown in

Figure 15. The ratio ranges from 0.22 to 0.44, and its relationship with the prismatic compressive strength is weak. But when this ratio reaches 0.55, about a 10% decrease in compressive strength is observed. A similar reduction has been reported in previous studies [

27,

29] using cubic and cylindrical specimens with different characteristic ratios. The observed relationship probably arises because larger lumps have less bonded surfaces with the FC, which is where micro-cracks tend to occur and develop during the loading process. So the occurrence and development of internal cracks and then the energy dissipation of a loaded prism with a larger characteristic ratio are less dispersive, leading to less energy being dissipated before failure and lower compressive strength.

Based on the test results listed in

Table 6, a bilinear empirical relationship between the combined compressive strength and the characteristic ratio can be established for prisms as:

Similar relationships have been proposed for cylindrical and cubic specimens [

27,

29]:

Comparing Equation (14) with Equations (15) and (16), it can be seen that with increasing β, the rate of decreasing compressive strength is in the order prism > cylinder > cube. The effect of the characteristic size of the lumps on compressive strength is greatest for prisms and least for cubes. This is probably an effect of the end restraints caused by the machine platens on lateral expansion. This would be more significant for cubes than for the lateral expansion of cylinders and prisms. For prisms, the non-uniform stress distribution caused by the presence of sharp edges would be expected to amplify the impact of characteristic lump size on compressive strength.

It can be seen from

Table 6 that as the characteristic ratio increases, the combined elastic modulus and combined peak strain for prisms varies within a relatively narrow range, and no monotonic trend is apparent. For simplicity, the influences of the characteristic ratio on the combined elastic modulus and combined peak strain can normally be neglected. Similar behavior has been observed for cubes and cylinders made of normal-strength DCLs and FC [

27,

29].