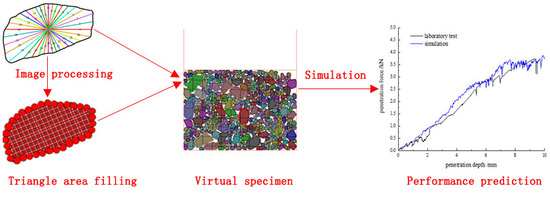

Algorithm for Virtual Aggregates’ Reconstitution Based on Image Processing and Discrete-Element Modeling

Abstract

:1. Introduction

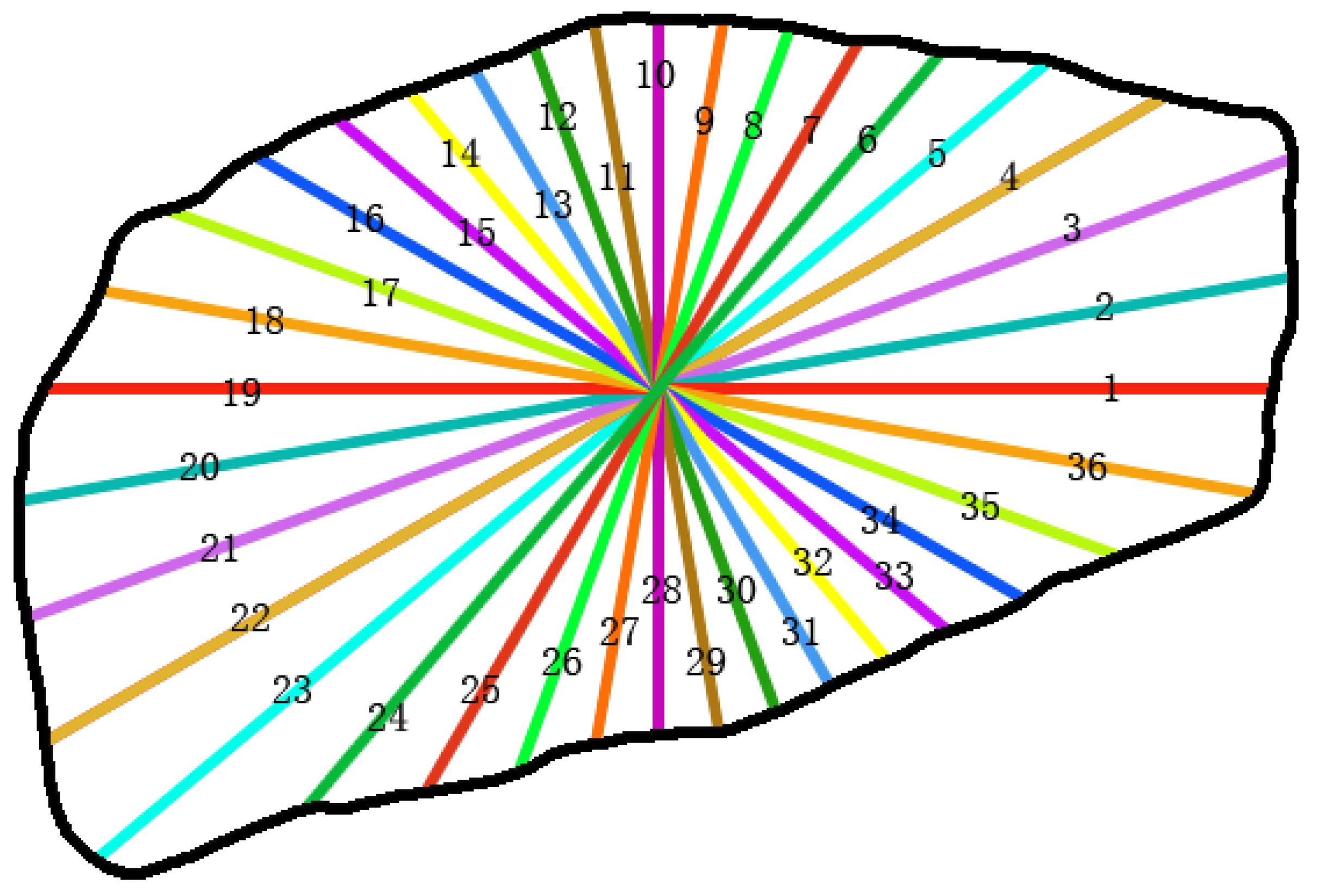

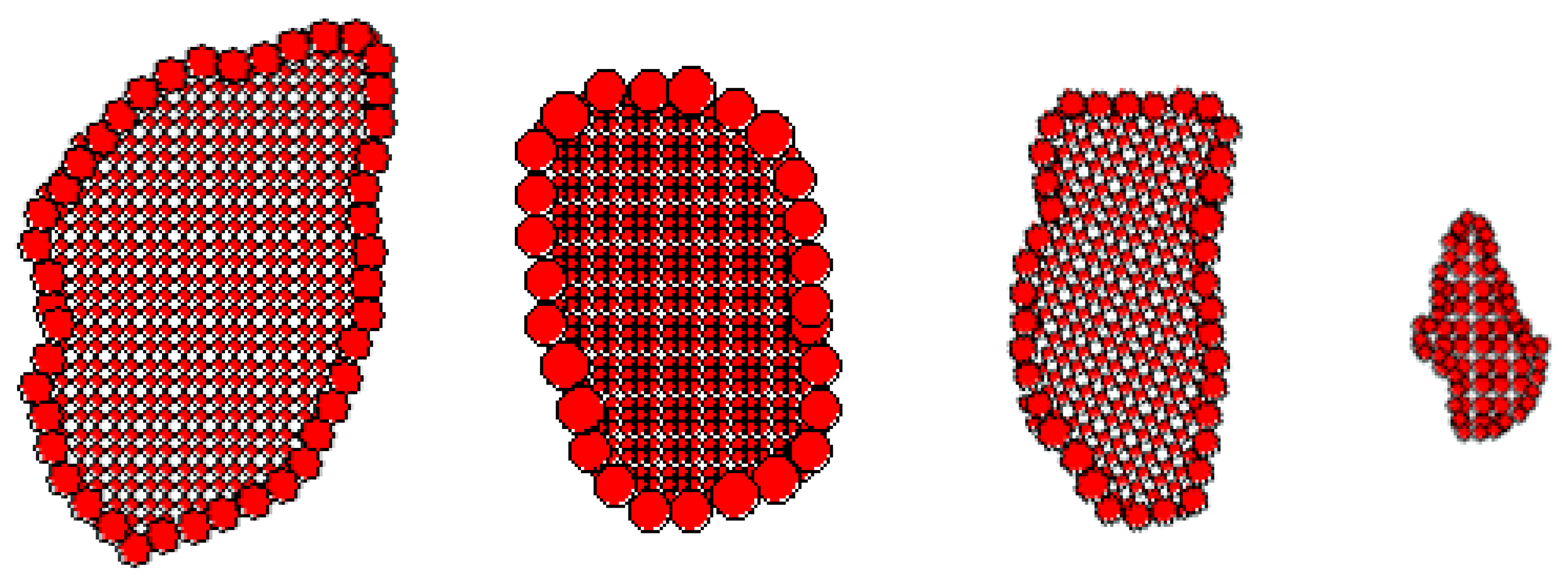

2. Image Preprocessing and Shape Measurement

3. Image Preprocessing and Shape Measurement

3.1. Triangle Area Divisions

3.2. Filling Area Judgments

- ①Start the ball generation from Point A with the coordinate of (0, 0);

- ②Determine the variable . It is calculated as the following equation:where is the X-coordinate of the next column of balls that will be generated; is the X-coordinate of the former column of balls that has been generated; is the radius of the filled balls.

- ③Determine the variable h, calculated as shown in Equation (4):where h is the required height of the next column of balls; the others are the same as the former.

- ④Generate uniform balls with coordinates of (, 0), (, ), (, ), (, ) … until the Y-coordinate exceeds h;

- ⑤Start to generate the next column of balls by cycling from Steps 2–4 until the X-coordinate exceeds .

- ①Start the ball generation from Point A with the coordinate of (0,0);

- ②Determine the variable . It is calculated as Equation (3):

- ③Determine the variable , calculated as shown in Equations (5) and (6):where is the required height of the next column of balls; the others are the same as the former.where is the required height of the next column of balls; is the lower limit of the column height when exceeds ; the others are the same as the former;

- ④When , generate uniform balls with coordinates of (, 0), (, 2 rad), (, 4 rad), (, 6 rad) … until the Y-coordinate exceeds ; when , generate uniform balls with the coordinates of (, ), (, ), (, ), (, ) … until the Y-coordinate exceeds ;

- ⑤Start to generate the next column of balls by cycling from Step 2–4 until the X-coordinate exceeds .

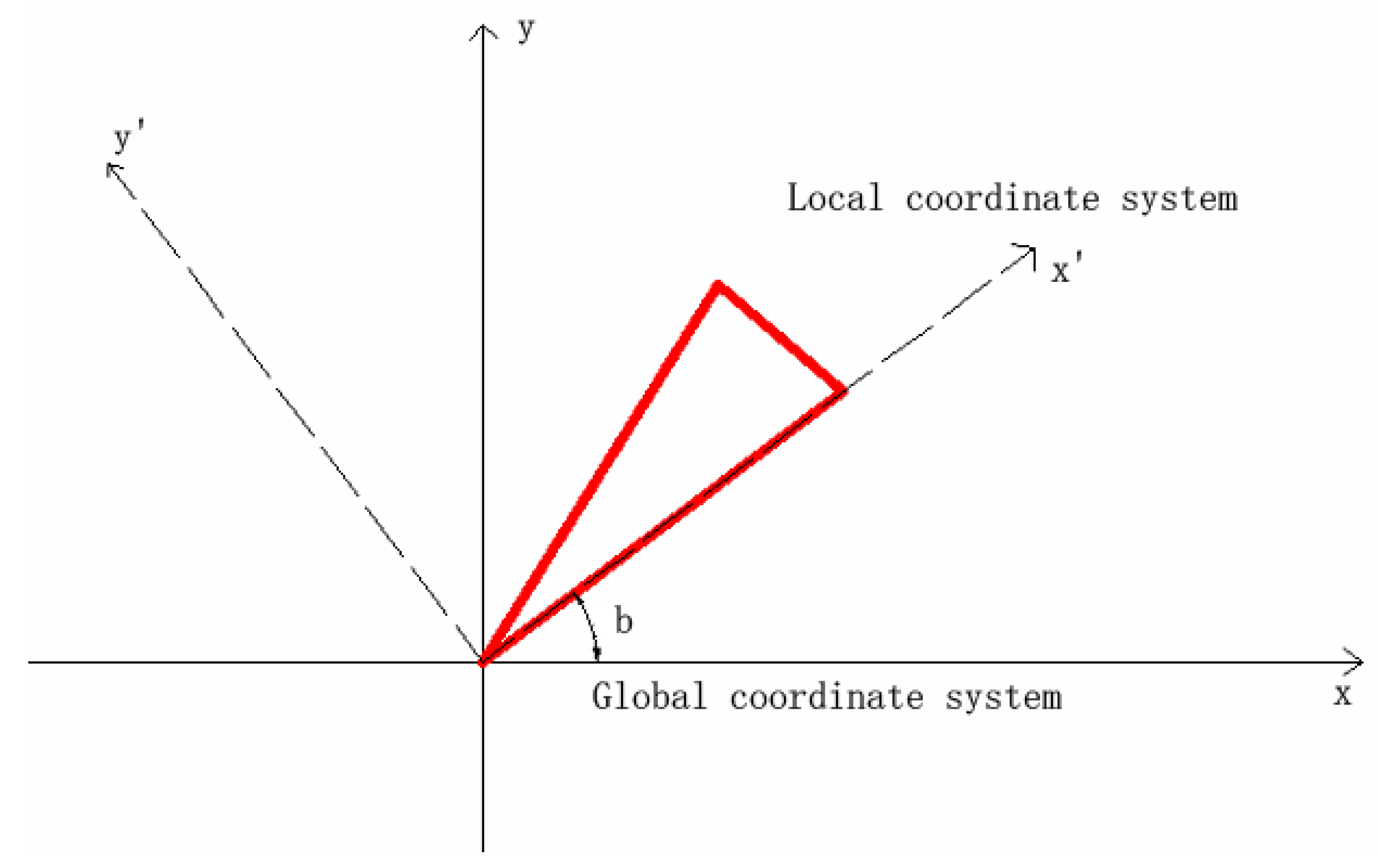

3.3. Coordinate Systems’ Conversion

4. Algorithm for Developing Virtual Specimens

4.1. Mapping Area Calculation for Two-Dimensional Specimens

- ①The differences of the densities among particles were not obvious, so the same density value of can be assigned to all the virtual particles in the simulations;

- ②The virtual specimens consist of particles and voids only without any water.

4.2. Generation Process for Virtual Particles with Random Shapes and Sizes

- ①If , only 4.75-mm particles would be generated;

- ②If , only 9.5-mm particles would be generated;

- ③If , only 13.2-mm particles would be generated;

- ④If , only 16-mm particles would be generated;

- ①If , only 4.75-mm particles with the angularity index ranging from 1500–2000 would be generated;

- ②If , only 4.75-mm particles with the angularity index ranging from 2000–2500 would be generated;

- ③If , only 4.75-mm particles with the angularity index ranging from 2500–3000 would be generated;

- ④If , only 4.75-mm particles with the angularity index ranging from 3000–3500 would be generated;

- ⑤If , only 4.75-mm particles with the angularity index ranging from 3500–4000 would be generated;

- ⑥If , only 4.75-mm particles with the angularity index ranging from 4000–4500 would be generated;

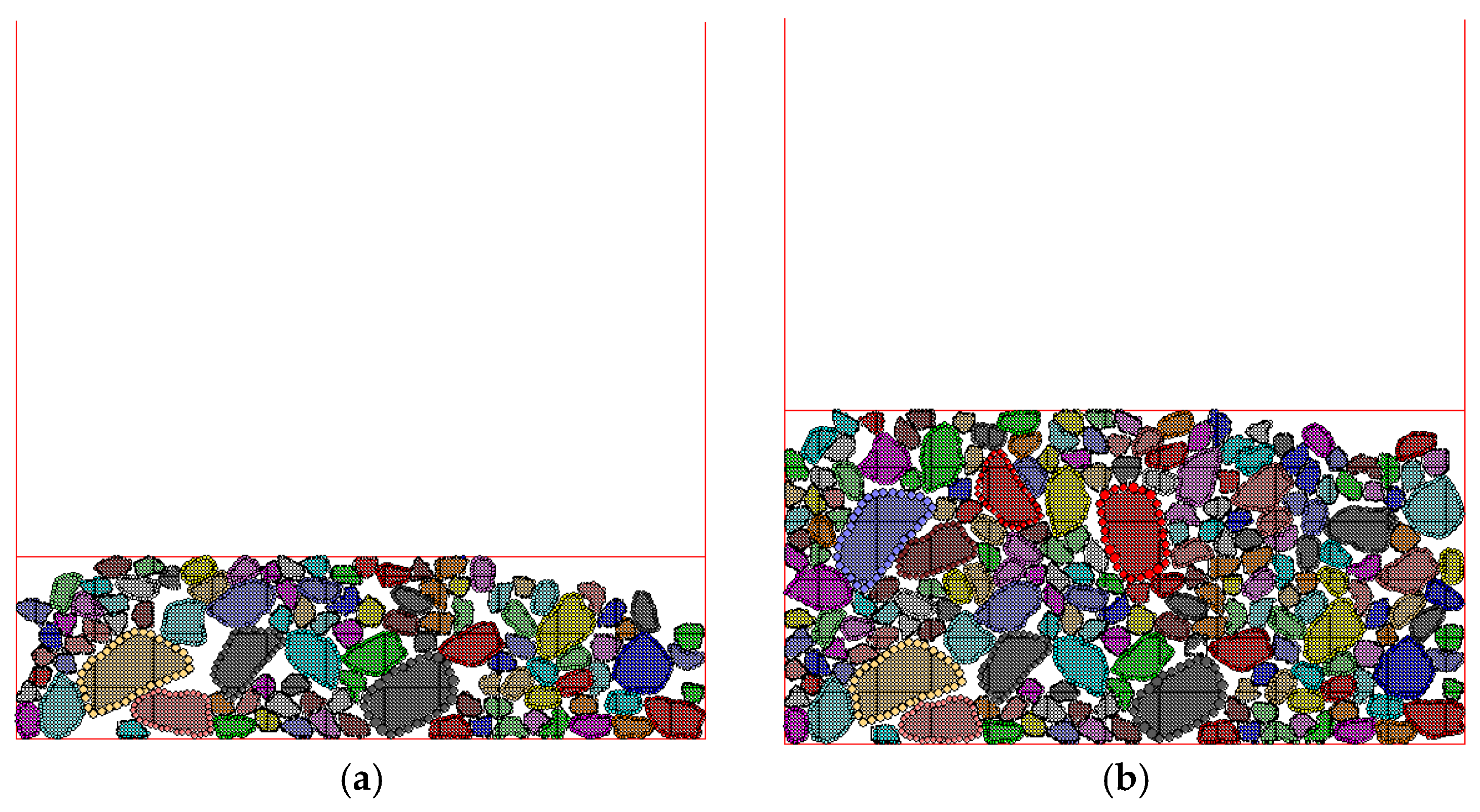

4.3. Example of Generating a Virtual Specimen

5. Performance Prediction of the Rebuilt Models

5.1. Experiments

5.2. Simulations for Performance Prediction

6. Conclusions

- (1)

- The scanning images from the AIMS are significant and guarantee the precise modelling of the coarse aggregates. The realistic shapes of the aggregates were captured and quantified through the inner software within AIMS. By generating the balls in the shape contours and then filling the inner area with balls by the proposed triangle-dividing algorithm, the virtual particles could be rebuilt, which had the same shapes as the realistic ones;

- (2)

- The mapping area was calculated to convert the three-dimensional volume to a two-dimensional area. Two random variables drawn from the uniform distribution (0, 1) were utilized to control the particles’ generation randomly. It was shown that the developed virtual specimen had a good accordance with the required gradations with minor errors of 5.51%, 3.86% and 3.70% for the 13.2-, 9.5- and 4.75-mm coarse aggregates, respectively. Thus, not only the particle shape, but also the heterogeneous composition within the structures could be modelled accurately;

- (3)

- Based on the calibrated micro-parameters, the mechanical performance of the aggregate skeleton could be well predicted through the proposed algorithm, which was verified by the virtual penetration test of the coarse aggregate skeleton with the SMA-13 gradation.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Pan, T.; Tutumluer, E.; Carpenter, S.H. Effect of Coarse Aggregate Morphology on Permanent Deformation Behavior of Hot Mix Asphalt. J. Transp. Eng. 2015, 132, 580–589. [Google Scholar] [CrossRef]

- Ramli, I. Effect of Fine Aggregate Angularity on Rutting Resistance of Asphalt Concrete AC10; Universiti Teknologi Malaysia: Iskandar Puteri, Malaysia, 2013. [Google Scholar]

- Shah, S.M.R.; Abdullah, M.E. Effect of Aggregate Shape on Skid Resistance of Compacted Hot Mix Asphalt (HMA). In Proceedings of the 2010 the 2nd International Conference on Computer and Network Technology (ICCNT), Bangkok, Thailand, 23–25 April 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 421–425. [Google Scholar]

- Campen, W.H.; Smith, J.R. A study of the role of angular aggregates in the development of stability in bituminous mixtures. Proc. AAPT 1948, 17, 114–143. [Google Scholar]

- Kandhal, P.S.; Parker, F. Aggregate Tests Related to Asphalt Concrete Performance in Pavements; National Cooperative Highway Research Program Report 405; Transportation Research Board: Washington, DC, USA, 1998. [Google Scholar]

- Cheung, L.W.; Dawson, A. Effects of particle and mix characteristics on performance of some granular materials. Transp. Res. Rec. J. Transp. Res. Board 2002, 1787, 90–98. [Google Scholar] [CrossRef]

- Hossain, M.; Parker, F., Jr.; Kandhal, P. Tests for evaluating fine aggregate particle shape, angularity, and surface texture. Transp. Res. Rec. J. Transp. Res. Board 1999, 1673, 64–72. [Google Scholar] [CrossRef]

- Hossain, M.S.; Parker, F.; Kandhal, P.S. Comparison and evaluation of tests for coarse aggregate particle shape, angularity, and surface texture. J. Test. Eval. 2000, 28, 77–87. [Google Scholar]

- Cundall, P.A. Ball-A Program to Model Granular Media Using the Distinct Element Method; Technical Note; Advanced Technology Group, Dames & Moore: London, UK, 1978. [Google Scholar]

- Ma, T.; Wang, H.; Zhang, D.; Zhang, Y. Heterogeneity effect of mechanical property on creep behavior of asphalt mixture based on micromechanical modeling and virtual creep test. Mech. Mater. 2017, 104, 49–59. [Google Scholar] [CrossRef]

- Mishra, B.K.; Rajamani, R.K. The discrete element method for the simulation of ball mills. Appl. Math. Model. 1992, 16, 598–604. [Google Scholar] [CrossRef]

- Su, O.; Akcin, N.A. Numerical simulation of rock cutting using the discrete element method. Int. J. Rock Mech. Min. Sci. 2011, 48, 434–442. [Google Scholar] [CrossRef]

- Lu, M.; McDowell, G.R. The importance of modelling ballast particle shape in the discrete element method. Granul. Matter 2007, 9, 69. [Google Scholar] [CrossRef]

- Das, N.; Thomas, S.; Kopmann, J.; Donovan, C.; Hurt, C.; Daouadji, A.; Ashmawy, A.K.; Sukumaran, B. Modeling Granular Particle Shape Using Discrete Element Method. Mon. Not. R. Astron. Soc. 2008, 420, 3368–3380. [Google Scholar]

- Coetzee, C.J. Calibration of the discrete element method and the effect of particle shape. Powder Technol. 2016, 297, 50–70. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, X.; Zhao, Y. Algorithms for generating three-dimensional aggregates and asphalt mixture samples by the discrete-element method. J. Comput. Civ. Eng. 2012, 27, 111–117. [Google Scholar] [CrossRef]

- Stahl, M.; Konietzky, H. Discrete element simulation of ballast and gravel under special consideration of grain-shape, grain-size and relative density. Granul. Matter 2011, 13, 417–428. [Google Scholar] [CrossRef]

- Huang, H. Discrete Element Modeling of Railroad Ballast Using Imaging Based Aggregate Morphology Characterization. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Urbana, IL, USA, 2010. [Google Scholar]

- Liu, Y.; You, Z. Visualization and simulation of asphalt concrete with randomly generated three-dimensional models. J. Comput. Civ. Eng. 2009, 23, 340–347. [Google Scholar] [CrossRef]

- Liu, Y.; You, Z. Accelerated Discrete-Element Modeling of Asphalt-Based Materials with the Frequency-Temperature Superposition Principle. J. Eng. Mech. 2011, 137, 355–365. [Google Scholar] [CrossRef]

- Tutumluer, E.; Qian, Y.; Hashash, Y.M.A.; Davis, D. Field validated discrete element model for railroad ballast. In Proceedings of the Annual Conference of the American Railway Engineering and Maintenance-of-Way Association, Minneapolis, MN, USA, 18–21 September 2011; pp. 18–21. [Google Scholar]

- Dondi, G.; Simone, A.; Vignali, V.; Manganelli, G. Numerical and experimental study of granular mixes for asphalts. Powder Technol. 2012, 232, 31–40. [Google Scholar] [CrossRef]

- Dondi, G.; Simone, A.; Vignali, V.; Manganelli, G. Discrete Element Modelling of Influences of Grain Shape and Angularity on Performance of Granular Mixes for Asphalts. Procedia Soc. Behav. Sci. 2012, 53, 399–409. [Google Scholar] [CrossRef]

- Vignali, V. Discrete particle element analysis of aggregate interaction in granular mixes for asphalt: Combined DEM and experimental study. In 7th Rilem International Conference on Cracking in Pavements; Springer: Berlin, Germany, 2012; pp. 389–398. [Google Scholar]

- Fu, Y.; Wang, L.; Tumay, M.T.; Li, Q. Quantification and simulation of particle kinematics and local strains in granular materials using X-ray tomography imaging and discrete-element method. J. Eng. Mech. 2008, 134, 143–154. [Google Scholar] [CrossRef]

- Moreno-Atanasio, R.; Williams, R.A.; Jia, X. Combining X-ray microtomography with computer simulation for analysis of granular and porous materials. Particuology 2010, 8, 81–99. [Google Scholar] [CrossRef]

- Wang, L.; Park, J.Y.; Fu, Y. Representation of real particles for DEM simulation using X-ray tomography. Constr. Build. Mater. 2007, 21, 338–346. [Google Scholar] [CrossRef]

- Hall, S.A.; Bornert, M.; Desrues, J.; Pannier, Y.; Lenoir, N.; Viggiani, G.; Bésuelle, P. Discrete and continuum analysis of localised deformation in sand using X-ray μCT and volumetric digital image correlation. Géotechnique 2010, 60, 315–322. [Google Scholar] [CrossRef]

- Alshibli, K.A.; Reed, A.H. Comparison of X-Ray CT and Discrete Element Method in the Evaluation of Tunnel Face Failure. In Advances in Computed Tomography for Geomaterials: GeoX 2010; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2013; pp. 397–405. [Google Scholar]

- Liu, Y.; Zhou, X.; You, Z.; Yao, S.; Gong, F.; Wang, H. Discrete element modeling of realistic particle shapes in stone-based mixtures through MATLAB-based imaging process. Constr. Build. Mater. 2017, 143, 169–178. [Google Scholar] [CrossRef]

- Liu, Y.; You, Z.; Zhao, Y. Three-dimensional discrete element modeling of asphalt concrete: Size effects of elements. Constr. Build. Mater. 2012, 37, 775–782. [Google Scholar] [CrossRef]

- Gates, L.L. Experimental Evaluation of New Generation Aggregate Image Measurement System. Ann. Emerg. Med. 2010, 33, 611. [Google Scholar]

- Araujo, V.M.C.; Bessa, I.S.; Branco, V.T.F.C. Measuring skid resistance of hot mix asphalt using the aggregate image measurement system (AIMS). Constr. Build. Mater. 2015, 98, 476–481. [Google Scholar] [CrossRef]

- Rezaei, A.; Hoyt, D.; Martin, A.E. Simple Laboratory Method for Measuring Pavement Macrotexture Pavement Cores and Aggregate Image Measurement System. Transp. Res. Rec. J. Transp. Res. Board 2011, 2227, 146–152. [Google Scholar] [CrossRef]

- Luce, A.D. Analysis of Aggregate Imaging System (AIMS) Measurements and Their Relationship to Asphalt Pavement Skid Resistance; Texas A & M. University: College Station, TX, USA, 2009. [Google Scholar]

- Ministry of Transport of the People’s Republic of China. Test. Methods of Soils for Highway Engineering; JTG E40-2007; China Communications Press: Beijing, China, 2007.

- Ministry of Transport of the People’s Republic of China. Test. Methods of Aggregates for Highway Engineering; JTG E42-2005; China Communications Press: Beijing, China, 2005.

- Itasca Consulting Group. PFC 2D Version 4.0; Itasca Consulting Group: Minneapolis, MN, USA, 2004. [Google Scholar]

| Sample | Angularity | Reduction Scale | Particle Area (m2) |

|---|---|---|---|

| 1 | 2864.41 | 4109.07 | 0.00033 |

| 2 | 3358.80 | 2882.90 | 0.00040 |

| 3 | 1803.25 | 1692.92 | 0.00045 |

| 4 | 2354.54 | 2015.89 | 0.00053 |

| 5 | 4329.94 | 2174.40 | 0.00038 |

| 6 | 3641.75 | 1925.21 | 0.00056 |

| 7 | 2192.07 | 3589.41 | 0.00036 |

| 8 | 3716.14 | 3527.46 | 0.00043 |

| 9 | 2040.78 | 4591.80 | 0.00028 |

| Sample | Adjustments of X-Coordinate | Adjustments of Y-Coordinate |

|---|---|---|

| 1 | −74.53354 | −100.6707 |

| 2 | −75.23496 | −103.149 |

| 3 | −76.80114 | −100.0369 |

| 4 | −74.9621 | −104.7988 |

| 5 | −75.26646 | −102.7743 |

| 6 | −72.68012 | −100.83 |

| 7 | −78.78299 | −98.05279 |

| 8 | −74.50542 | −101.9675 |

| 9 | −80.44268 | −105.0318 |

| Gradation | Passing Ratio (%) for Different Sieving Sizes (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| SMA-13 | 100 | 95 | 79.5 | 48.9 | 36.7 | 25.8 | 16.7 | 9.7 | 7.1 | 6.5 |

| Sieving size (mm) | 13.2 | 9.5 | 4.75 |

| Required mapping area () | 11.44 | 35.21 | 70.06 |

| Total area of generated particles () | 12.07 | 36.57 | 72.65 |

| Error (%) | 5.51 | 3.86 | 3.70 |

| Sieving Size (mm) | Particle Density (g/cm3) | Density of Compacted Specimen (g/cm3) | Void Contents of Compacted Specimens (%) |

|---|---|---|---|

| 13.2 | 2.744 | 1.625 | 39.55 |

| 9.5 | 2.730 | 1.616 | 39.66 |

| 4.75 | 2.729 | 1.594 | 40.70 |

| Size/mm | μ | |||

|---|---|---|---|---|

| ball | 4.75 | 2.2e6 | 1.5e6 | 0.6 |

| 9.5 | 2.5e6 | 2.5e6 | 0.55 | |

| 13.2 | 1.2e6 | 1.2e6 | 0.5 | |

| wall | 1e10 | 1e10 | 0.6 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Ding, X.; Ma, T.; Zhang, W.; Zhang, D. Algorithm for Virtual Aggregates’ Reconstitution Based on Image Processing and Discrete-Element Modeling. Appl. Sci. 2018, 8, 738. https://doi.org/10.3390/app8050738

Wang D, Ding X, Ma T, Zhang W, Zhang D. Algorithm for Virtual Aggregates’ Reconstitution Based on Image Processing and Discrete-Element Modeling. Applied Sciences. 2018; 8(5):738. https://doi.org/10.3390/app8050738

Chicago/Turabian StyleWang, Danhua, Xunhao Ding, Tao Ma, Weiguang Zhang, and Deyu Zhang. 2018. "Algorithm for Virtual Aggregates’ Reconstitution Based on Image Processing and Discrete-Element Modeling" Applied Sciences 8, no. 5: 738. https://doi.org/10.3390/app8050738