1. Introduction

Switched reluctance motors (SRMs) are gaining interest in various applications such as electric vehicle driving system, starter-generators system, and power supply for aerospace applications, because of the many advantages that the SRMs have in comparison to other motors, including their low cost, durability, simple structure and robust construction [

1,

2]. Due to advances in high speed digital signal processing and power electronics technology, the controllable performance of the SRM has been improved greatly. However, one of the main drawbacks of the SRM used in servo-control is its large torque ripple, which leads to acoustic noise and vibration, thus causing the body vibration, transmission system parts damage, excessive bearings wear and even accidents involving the axis breaking [

3,

4].

There are two main methods to reduce the torque ripple: one is to optimize the structure and magnetic design of the motor, and the other is to adopt the advanced control algorithm [

5]. By optimizing the stator/rotor pole structures and the magnetic design, the torque ripple cannot be fully reduced, but the cost of the motor increases [

6]. The main operating parameters of an SRM include the supply voltage, the turn-on and turn-off angles, the current level, and the shaft torque. And the control algorithm is based on selecting an optimum combination of these parameters [

7,

8]. Therefore, an appropriate design for achieving a high SRM performance must take these factors into consideration and make an optimal choice.

As an effective method for torque ripple reduction, direct instantaneous torque control (DITC) has gained interest in the last few years, due to its simple control structure, which provides greater flexibility for the torque ripple reduction [

9,

10,

11,

12]. However, its implementation is not easy because it requires complex switching rules, uncontrolled switching frequency, and high sampling rates. In [

9,

10], an iterative learning method for generating the optimized current waveforms was presented. In [

11,

12], an online DITC technique that operates without torque profile functions and auxiliary phase commutating strategies was demonstrated. The optimal turn-on and turn-off angles for minimizing the torque ripple or the energy consumption has been described in [

13,

14,

15]. In [

16], a direct torque control based on the Lyapunov function was selected to minimize the torque ripples. In [

17,

18], the machine design was combined with the control algorithms in an innovative method of profiling the phase currents to reduce the torque ripples of an SRM.

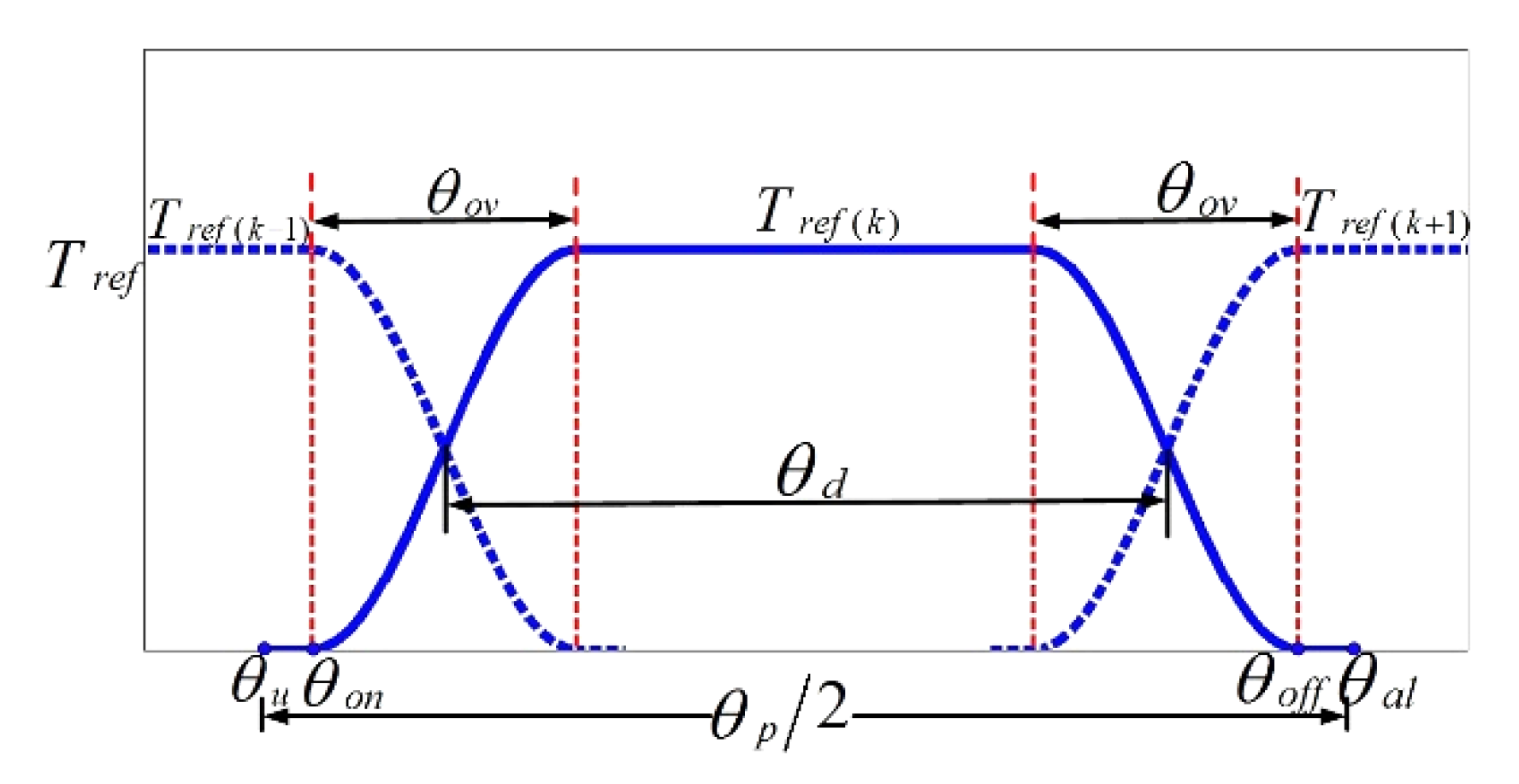

In the latest research, the torque sharing function (TSF) has been investigated as an important and effective approach for minimizing the torque ripple in an SRM [

19,

20,

21,

22,

23,

24]. Common TSFs curves contain linear, sinusoidal, exponential, cubic curves, and so on. In order to reduce the torque ripple, the phase current product and the individual phase torque harmoniously use the most suitable TSFs so that the total torque can align with the expected torque. Subsequently, the phase torque reference can be translated into the phase current reference based on the

T-

i-

θ characteristics. With increasing speed of the SRM, the phase current cannot ideally follow its reference because of the limited phase voltage and therefore the torque ripples increase. In addition, because the phase current reference can be derived from the phase torque reference, the choice of the TSF directly affects the copper loss and the current tracking performance. The current tracking performance should be improved to enhance the torque-speed capability. Thus, in order to obtain an optimum TSF, it is necessary to consider a secondary objective that includes the maximization of the torque-speed range and the minimization of copper loss. These two evaluation criteria affect the torque-speed performance and the drive efficiency of the motor. In [

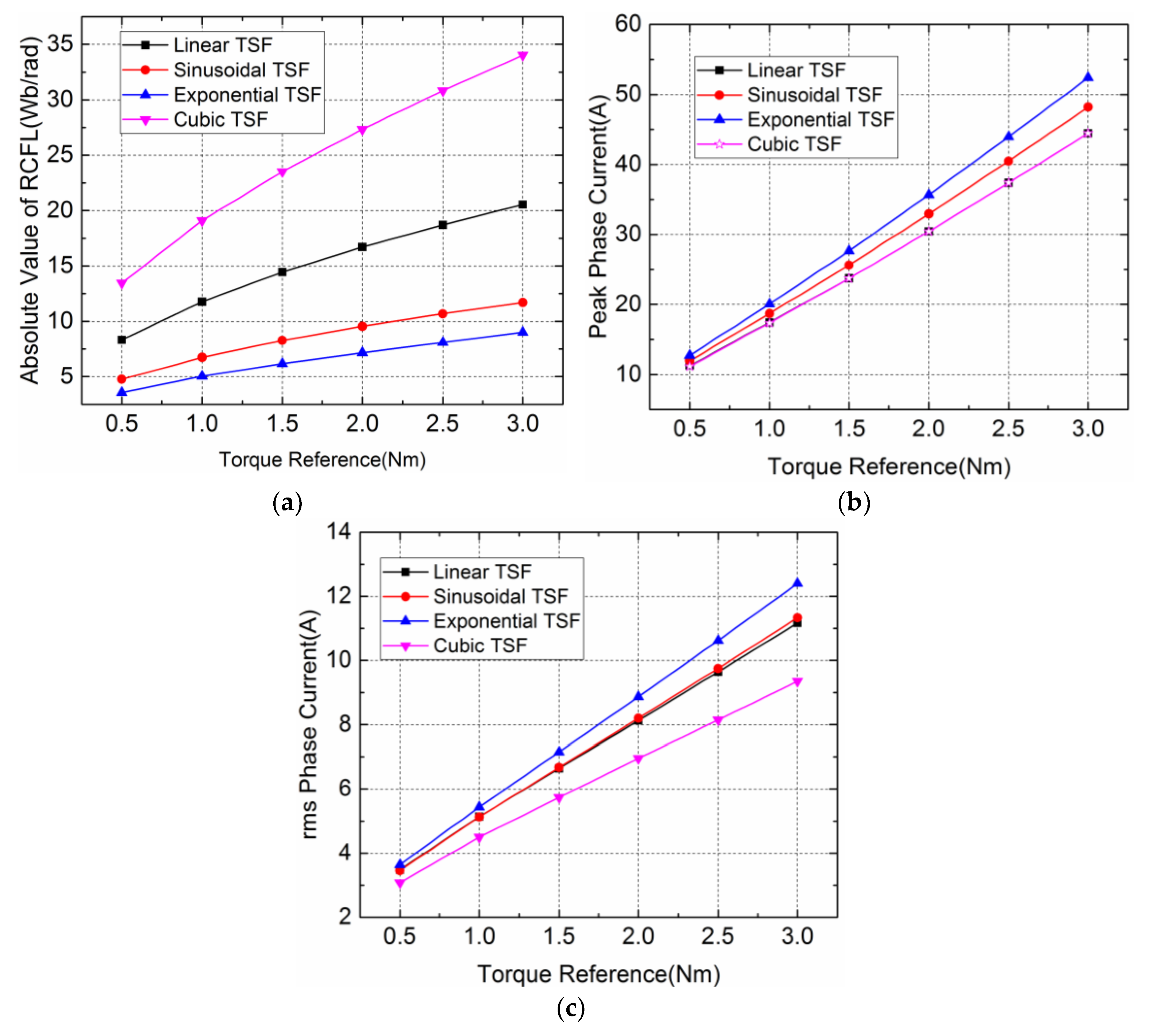

19], four conventional common TSFs were studied and evaluated after optimization. In order to minimize the rms (root mean square) phase current and the maximum absolute value of the rate-of-change of the flux linkage (MAV-RCFL), the turn-on and the overlap angle were extracted based on a genetic algorithm optimization method to select the optimal TSF. In [

20], for reducing the losses of the switched reluctance motors, a piecewise cubic TSF was optimized with six degrees of freedom. In [

21], an offline TSF with a wide torque-speed range for reducing torque ripple in an SRM was studied; the objective function adopted a Tikhonov factor among two objectives to minimize the maximum absolute value of RCFL and the copper loss. In [

22], an extended-speed low-ripple torque control in two modes using the TSF in an SRM was introduced. Because of the imperfect tracking of the phase current in high motor speed, a proportional-integral controller with a torque-compensation was added to the torque reference during the commutation range of two adjacent phases. In [

23], a novel and simple nonlinear logical TSF was proposed to reduce the torque ripple and improve the efficiency. The logical TSF was used online and was not fixed compared with the other TSFs. The incoming phase current was controlled in a ladder-like increase, and the current of the outgoing phase was tracked in the opposite direction. Therefore, torque sharing between the incoming and outgoing phases was achieved with a minimum current crossover. However, a theoretical analysis of the RCFL was not provided for this study.

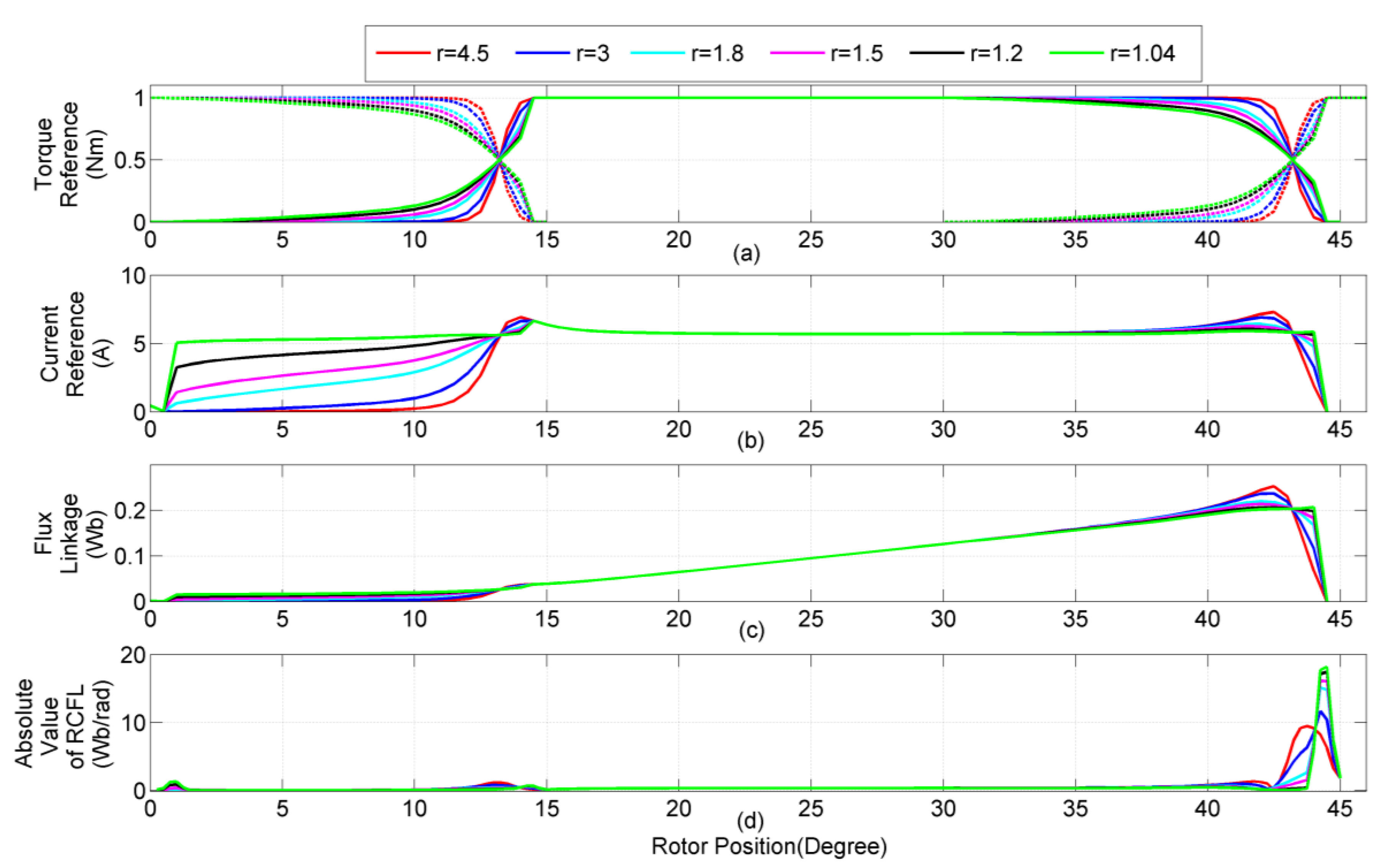

In this paper, taking into account the requirements for the maximization of the torque-speed range and the minimization of copper loss and balancing these secondary objectives by including a weighing factor, a family of TSFs deduced by an invertible torque function is proposed. Because the proposed TSF provides phase currents throughout the whole region, the torque-speed capability is improved as well. The solution of the TSFs selection becomes a multi-objective optimization problem. And then, the evaluation indices such as the peak phase current, the rms phase current, and the torque ripple factor are compared between the proposed and the classical TSFs by using a simulation. Finally, the simulation and experimental results show that the proposed control algorithm has advanced performance in reducing the copper loss and improving torque-speed performance.

2. The Finite Element Method Analysis for the SRM

The SRM only has stator windings, no rotor windings or magnets. The whole or part of each phase is comprised of two stator windings on diametrically opposite sides of the SRM. A three-phase 6/4 SRM with 7.5 kW, 3000 rpm, and 270 V DC-link voltage is designed (seen

Table A1 in

Appendix A).

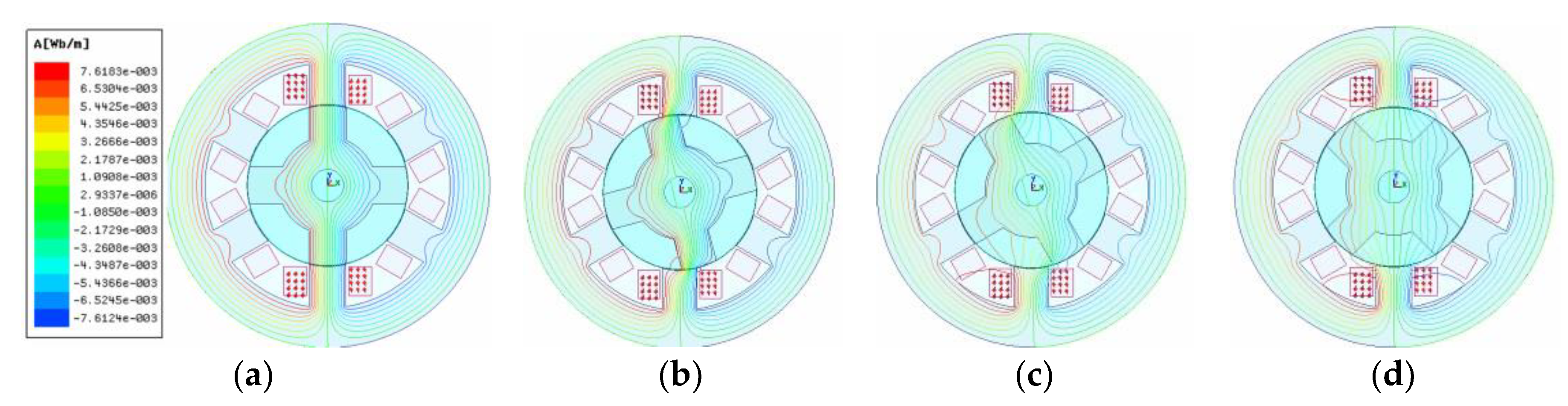

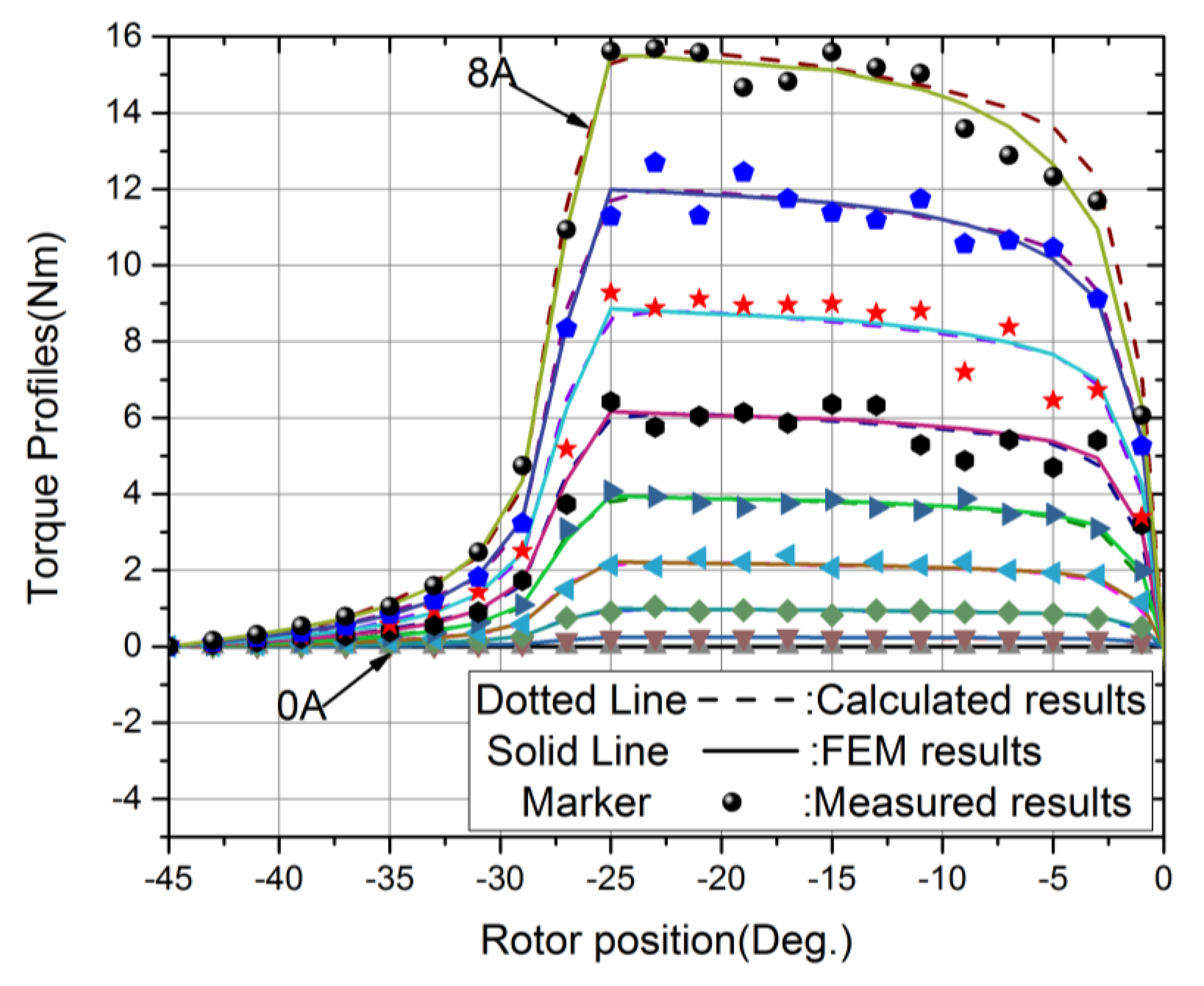

Figure 1a–d shows the analysis model of the studied motor using the finite element method (FEM) with the magnetic flux at rotor positions of 0°, 15°, 30°, and 45° respectively. The anti-clockwise is the positive direction of the rotor angular position

θ and the alignment position of the stator and rotor poles is defined as 0°.

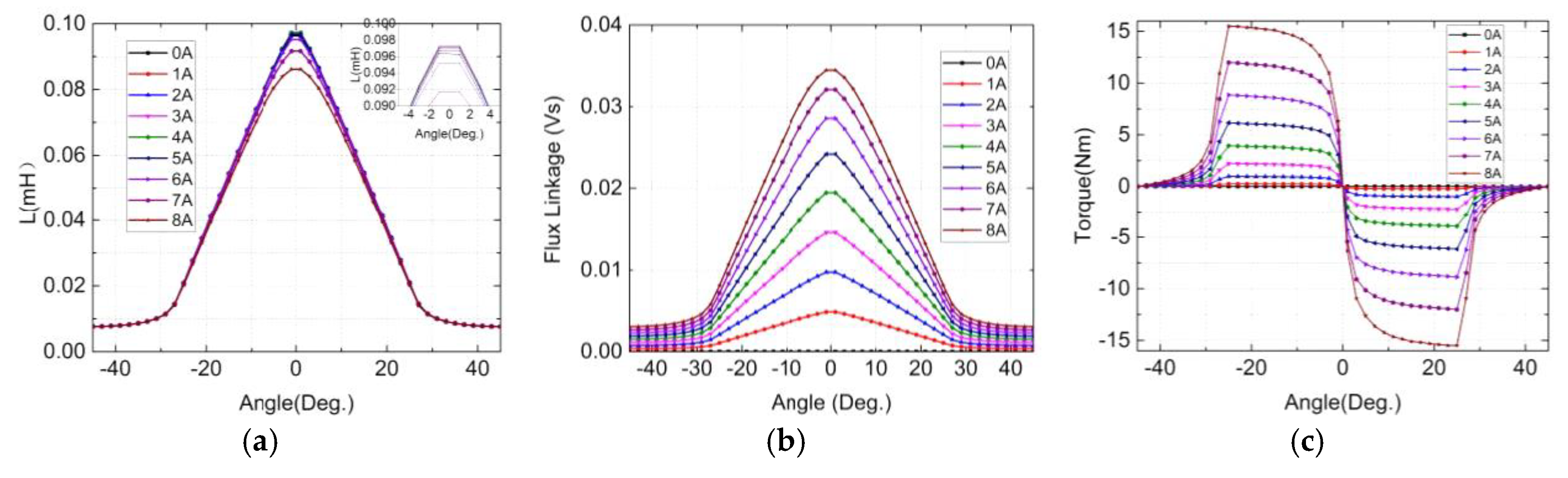

In practical SRM analysis, the non-linear characteristics and the electromagnetic analysis of the SRM are important. By using ANSOFT/Maxwell software (ANSOFT/Maxwell 14.0, Ansys Inc., Canonsburg, PA, USA), the flux linkage, the phase inductance profiles and the torque characteristics of the studied SRM were analyzed. And the results are shown in

Figure 2a–c. Due to the saturation effect, the maximum value of the phase inductance decreases with the increase of the current. In

Figure 2b, the flux linkage characteristics demonstrate the saturation effects. The lowest curve corresponds to a 0 A phase current and the top of the curve to an 8 A phase current. The torque generated by a constant current and a ±45° in the phase-A winding is shown in

Figure 2c and is the same as the other phases. The phase torque has nonlinear properties which strongly depends on the phase current values and the rotor position. It is significant that the phase torque decreases when the rotor position is near the alignment position of the stator and rotor poles. This is caused by the saturation effect, which leads to a decrease in the derivative of the co-energy to the rotor position. This, in turn, causes the large torque ripple of the SRM, which requires a complex control strategy to reduce. As shown in

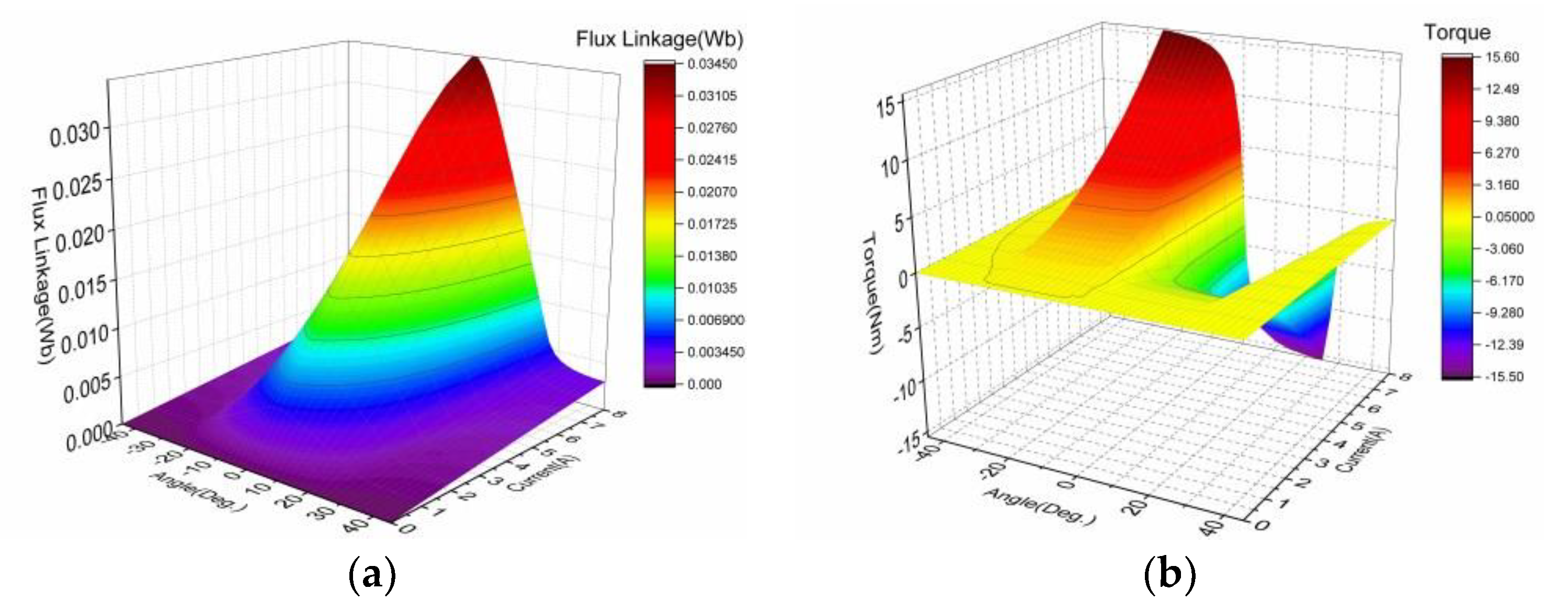

Figure 3a,b, the linear interpolation resulted in a surface fitting and this linear interpolation approach can be used for other non-test states to obtain the necessary data for the flux linkage and the torque for any given value (

i,

θ).

7. Simulation Results and Comparison

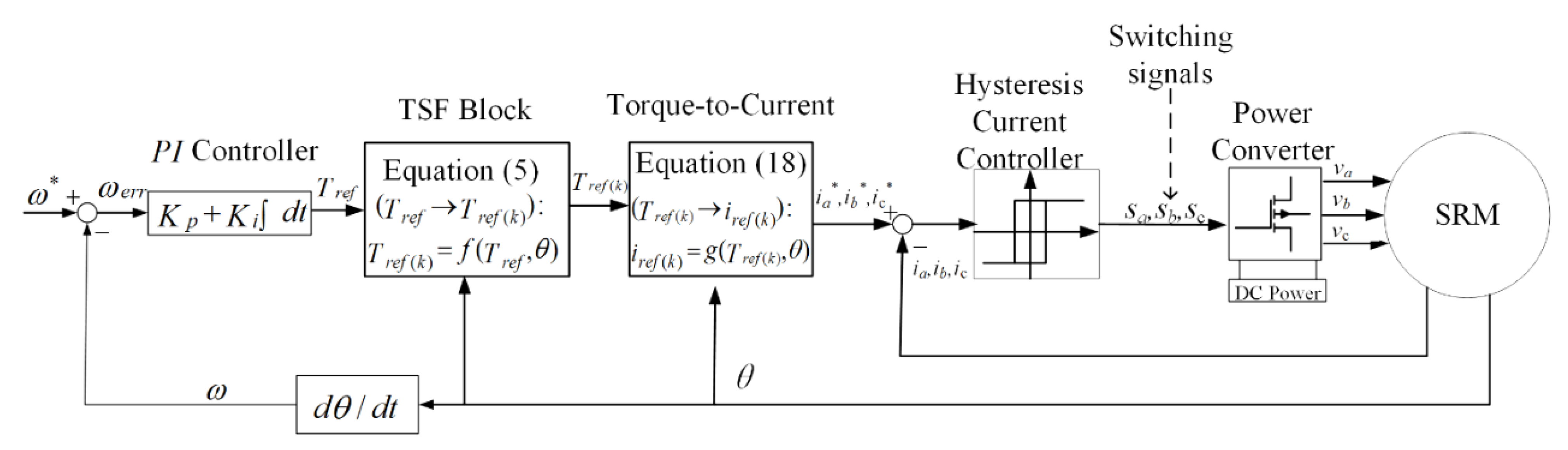

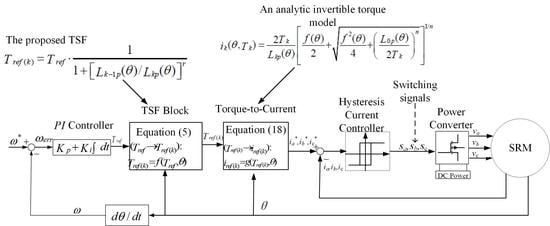

Figure 10 shows the block diagram of the torque control using the TSF method for the studied SRM. The individual phase torque reference is defined from the total torque reference by the TSF block. In the “Torque-to-Current” block, the phase torque references are converted into phase current references the rewritten torque-current profile model of the SRM (Equation (18)). A hysteresis current controller is used for the phase current tracking its reference waveforms.

Matlab/Simulink was used to for the simulation model of the three-phase 6/4 SRM with 7.5 kW, 3000 rpm, and 270 V DC-link voltage by using the static torque characteristic profiles shown in

Figure 9 and obtained using Equation (17). For the phase current tracking its reference waveforms accurately, it is appropriate to set the hysteresis band of the current controller to ±0.1 A through simulation test. The phase current reference is calculated using Equation (18). The same sampling time

tsample = 1 μs is set in all simulation. Finally, the evaluation indices in terms of peak phase current, rms phase current, and torque ripple factor are compared between the proposed and the classical TSFs.

The torque ripple factor is defined as follows:

where

Tmax,

Tmin, and

Tave are the maximum, minimum, and average torque, respectively.

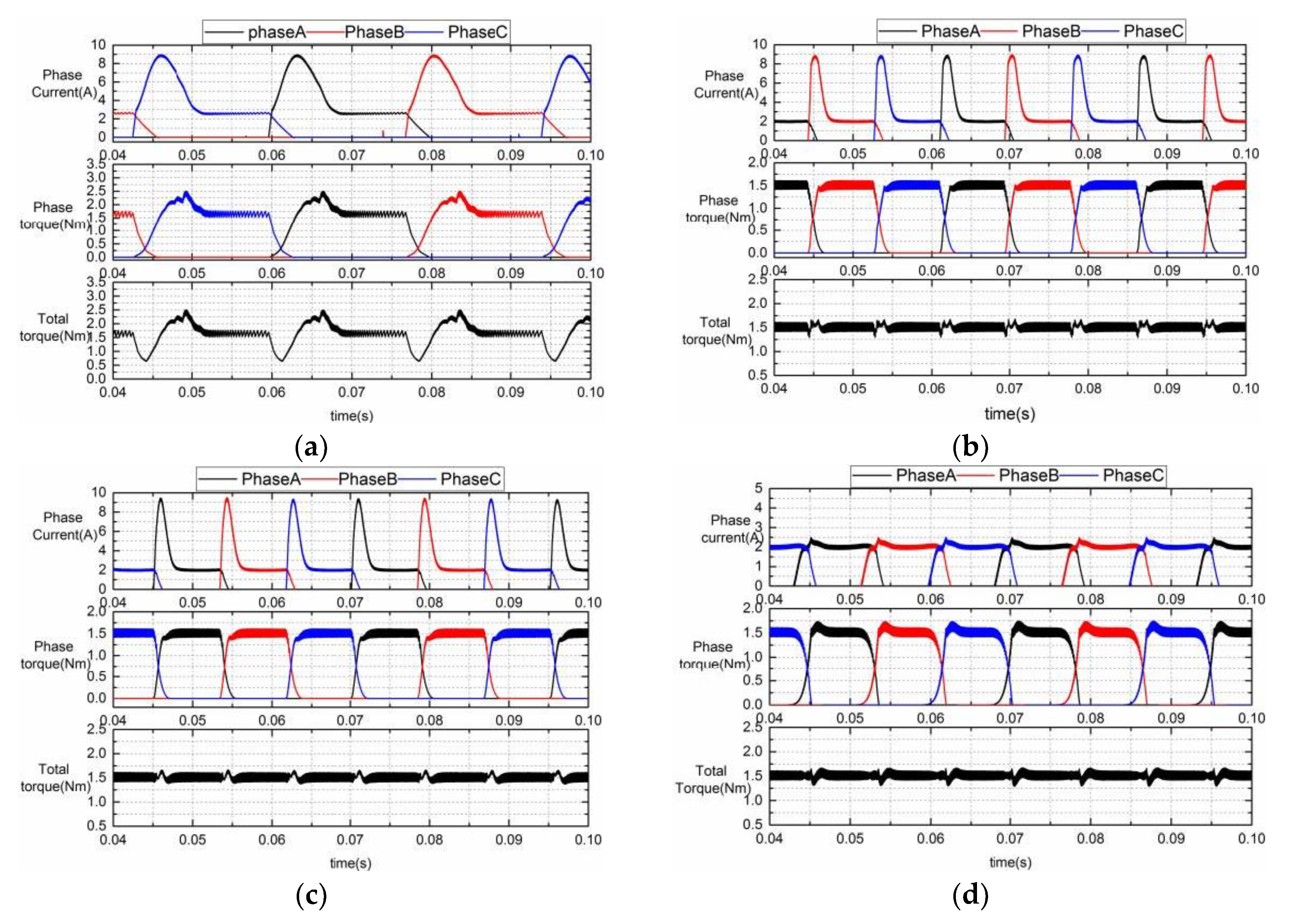

7.1. Simulation Results

The CCC (current chopping control) method is common in SRM control and was investigated in [

27]. The simulation results for the proposed TSF1 (

r = 4) are compared with the CCC and the conventional TSFs at a torque reference

Tref = 1.5 Nm and a rotor speed of 1000 rpm (

Figure 11a–d). Since the rotor speed 1000 rpm of all TSFs is higher than the maximum rotor speed

ωmax, the phase current cannot track its reference. The torque ripple factors T.R% for the CCC, the linear, sinusoidal, and the proposed TSFs are 116.7%, 28.7%, 22.0%, 23.5%, respectively. The rms currents are 3.5 A for the linear and sinusoidal TSFs, and 3 A for the TSF1 (

r = 4).

The simulation results for the CCC, the linear, the sinusoidal, and the proposed TSFs at a torque reference of

Tref = 1.5 Nm and a speed of 3000 rpm are shown in

Figure 12a–d. As the rotor speeds up, the phase current deviates from its reference significantly during the current rising region. And the phase current exhibits a tail phenomenon at the same time during the current declining region. Therefore, the output torque cannot track its reference accurately and the torque ripple increases obviously. The torque ripple factors

T.R% are 182.3%, 61.3%, 60.8%, and 36.6%, respectively. For the CCC, the linear, the sinusoidal, and the proposed TSF1 (

r = 4), the peak phase currents are 8.8 A, 9.4 A, 9.5 A, and 5.5 A, and the rms phase currents are about 5.4 A, 5.4 A, 5.3 A and 3.8 A, respectively. It is evident that the CCC method results in a comparatively smaller peak phase current compared with the conventional TSFs. However, the torque ripple is not acceptable, because it is three times higher than that of the proposed TSF1 (

r = 4). The linear and sinusoidal TSFs almost have the same performance with regard to the torque ripple and the peak phase current, which is approximately twice as high as those for the proposed TSF1 (

r = 4). The proposed TSF1 (

r = 4) results in the lowest torque ripple, which is 1/2 of the torque ripple of the linear TSF. In addition, the required phase current is lower than for the CCC. The control performance is clearly improved by using the proposed TSF1 (r = 4).

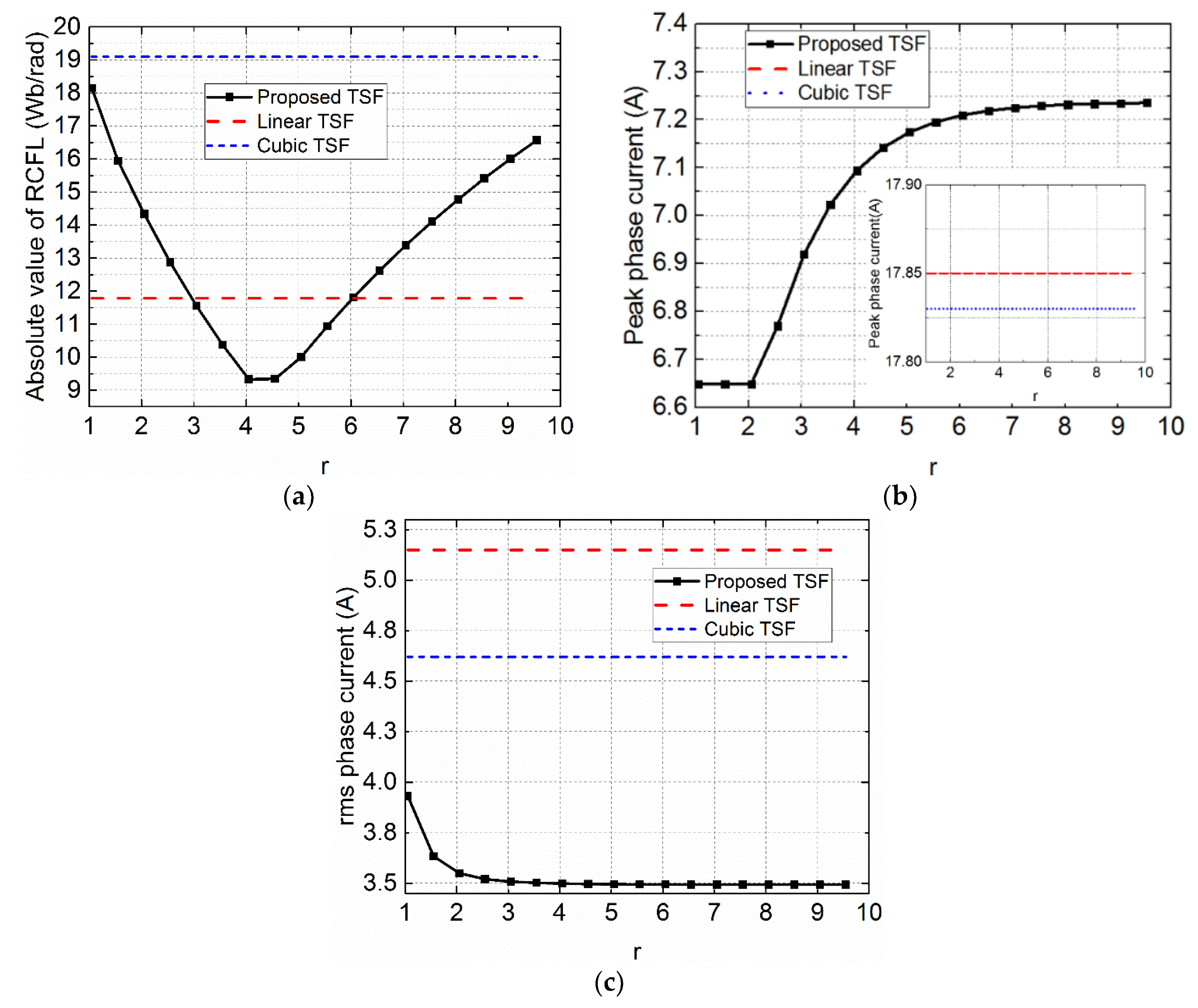

7.2. Comparison of the Simulation Results

Figure 13a shows the comparison results of the torque ripple between the CCC, the linear, the sinusoidal, and the proposed TSF1 (

r = 4) when the torque reference is set to 1.5 Nm. The CCC is the worst choice in all methods. For the conventional TSFs, the torque ripples are almost two to three times higher at 3000 rpm than at 1000 rpm. And at 3000 rpm, the torque ripple of the proposed TSF1 (

r = 4) is nearly one half of the other TSF methods. That means the proposed TSF1 (

r = 4) have a better performance than the other control method. Actually, at a lower rotor speed, the torque ripple of the proposed TSF is obviously affected by the hysteresis band of the current controller. Therefore, the torque ripple can be decreased further more by reducing the inherent current ripple of the hysteresis controller.

Figure 13b shows the comparison results of the rms current for all control methods and the CCC is also the worst choice. At the rotor speed less than 500 rpm, the proposed and the conventional TSFs exhibits almost a similar rms current. As the rotor speeds up, due to the poorer current tracking performance, the rms currents of the linear and sinusoidal TSFs increase significantly. However, the rms current for the proposed TSF remains relatively as the speed increases.

The peak current is much smaller for the TSF1 (

r = 4) than those of the other methods, which have smaller hardware pressure (

Figure 13c). At a higher speed, the peak currents of the conventional TSFs decrease significantly due to the poorer current tracking performance by the inductance effect. Therefore, the TSF1 (

r = 4) is a better choice for reducing torque ripple and lower copper loss relatively.

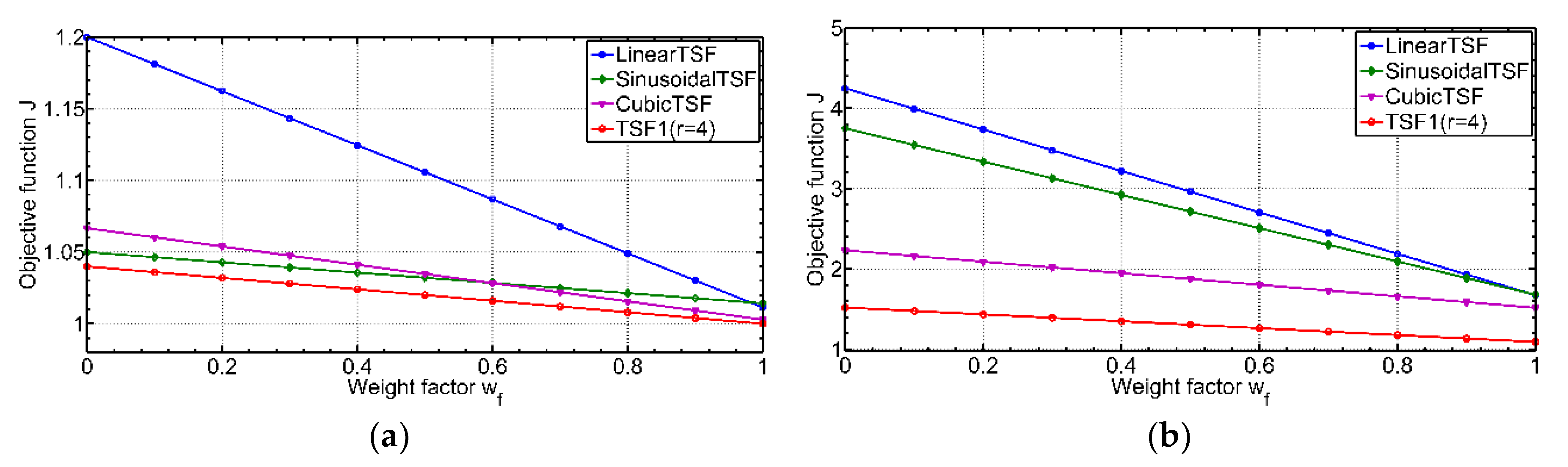

Figure 14a,b show the values of the evaluation function

J for different weight factors

wf at speeds of 1000 rpm and 3000 rpm. It is evident that the linear TSF is the worst choice because its

J values are always much larger than those of the other TSFs at any weighting factor. The sinusoidal and cubic TSFs have almost the same

J values at a speed of 1000 rpm. However, as the weight factor

wf value increases, the cubic TSF exhibits a better performance. So, the choice of weight factor wf is depended on the emphasis of reducing the copper loss or increasing the maximum speed range. At any weight factor

wf or any speed, the proposed TSF1 (

r = 4) has the best minimum

J values when compared to the sinusoidal or cubic TSFs.

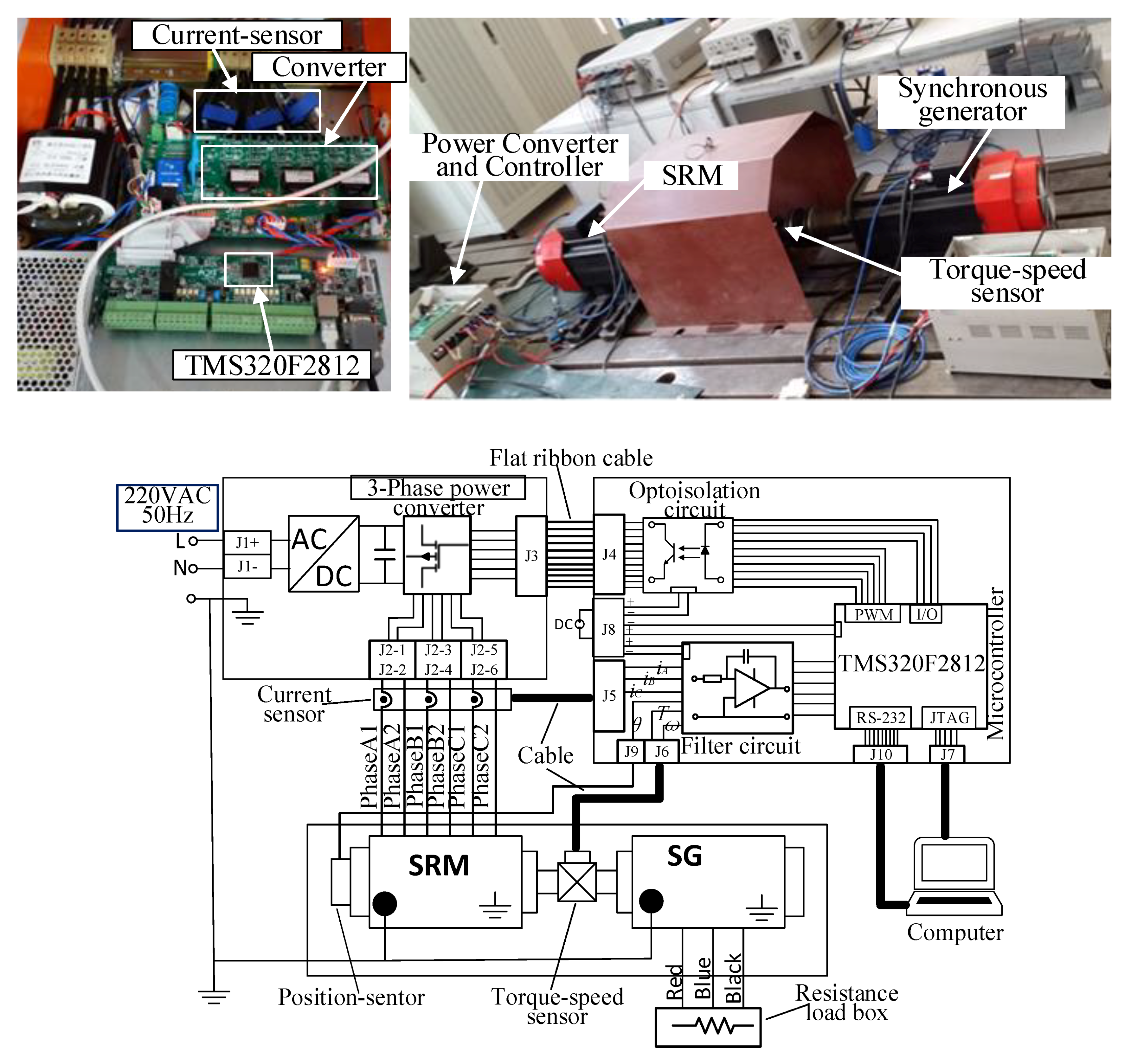

8. Experimental Results

The proposed TSF is validated with an experiment using a three-phase 6/4 SRM with 7.5 kW, 3000 rpm, and 270 V DC-link voltage (shown in

Figure 15). A Texas Instruments (TI) TMS320F2812 digital signal processor (DSP) is used as a digital controller, and the clock frequency of TMS320F2812 is 150 MHz. The

T-

i-

θ characteristics are stored as look-up tables in the DSP. The SRM is driven by a three-phase asymmetric inverter and the motor shaft is coupled with a torque-speed sensor and position sensor. The three-phase asymmetrical inverter uses the six-cell IGBT module of Infineon Corporation. The type of IGBT is FS450R12KE4 (withstand voltage 1200 V, normal current 450 A). The driving chip of the three-phase bridge uses the 6SD312EI (working frequency is up to 100 kHz) produced by CONCEPT Corporation in Switzerland. There is one current sensor on each phase line. A synchronous generator with a resistance box is used as the load.

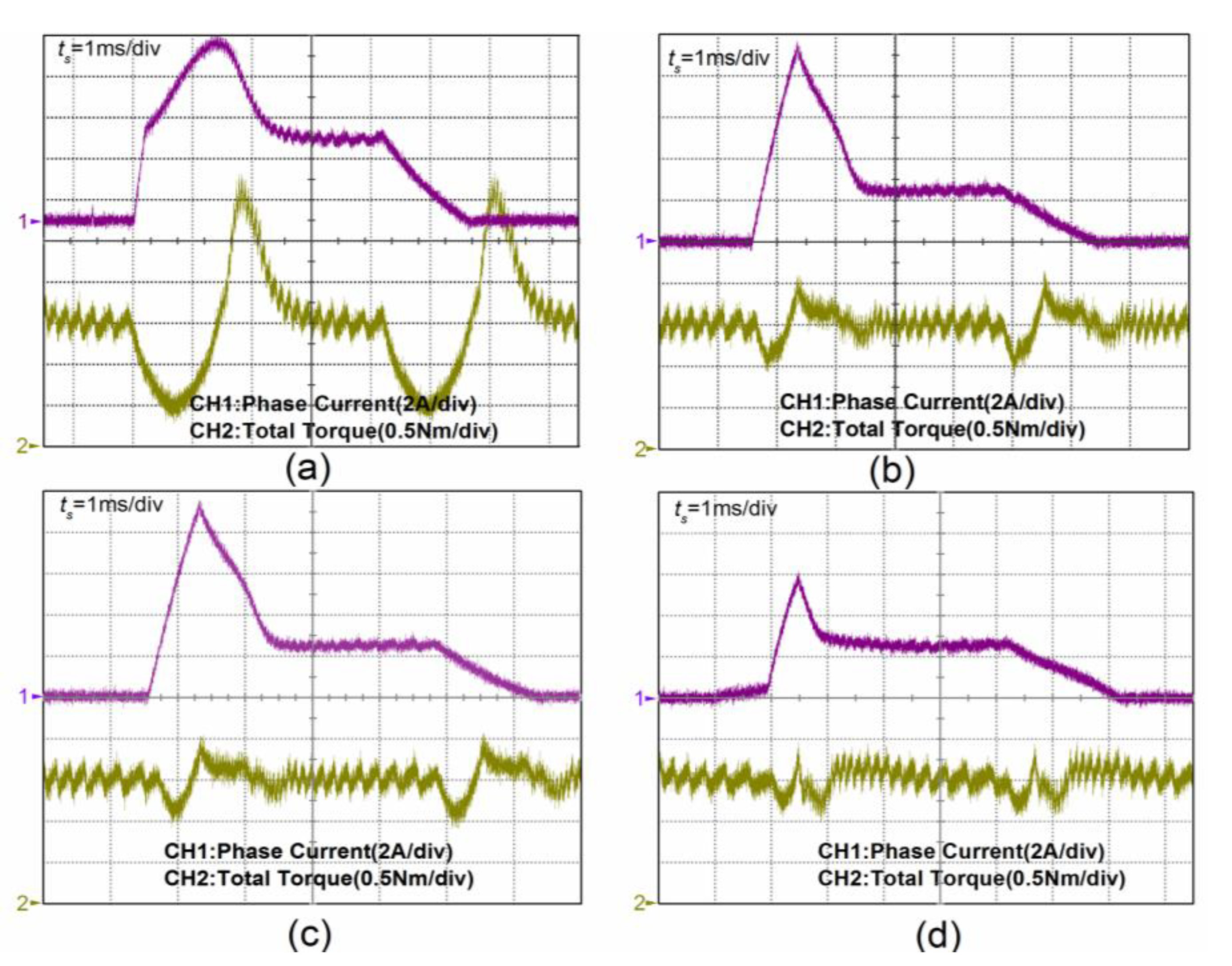

Figure 16 shows the measured phase current and instantaneous torque at 3000 rpm at a torque reference of

Tref = 1.5 Nm. For the CCC, the linear TSF, the sinusoidal TSF and the proposed TSF1 (

r = 4), the torque ripples are around 184%, 67.8%, 66.7%, and 40.4%, respectively compared to the values of 182.3%, 61.3%, 60.8%, and 36.6% in simulation results shown in

Figure 12. And the peak phase currents are 8.9 A, 9.5 A, 9.5 A, and 5.9 A, and the rms phase currents are about 5.6 A, 5.4 A, 5.4 A and 3.9 A, respectively. This indicates that the experimental results agree well with the results of the simulation in terms of current waveforms, torque ripple and torque response under the same operating conditions. Due to a current tracking error, the CCC and the conventional TSFs show much higher torque ripples compared to the TSF1 (

r = 4), which achieves better tracking and has a nearly flat output torque, ignoring the torque ripple caused by the inherent current ripple of the hysteresis controller.

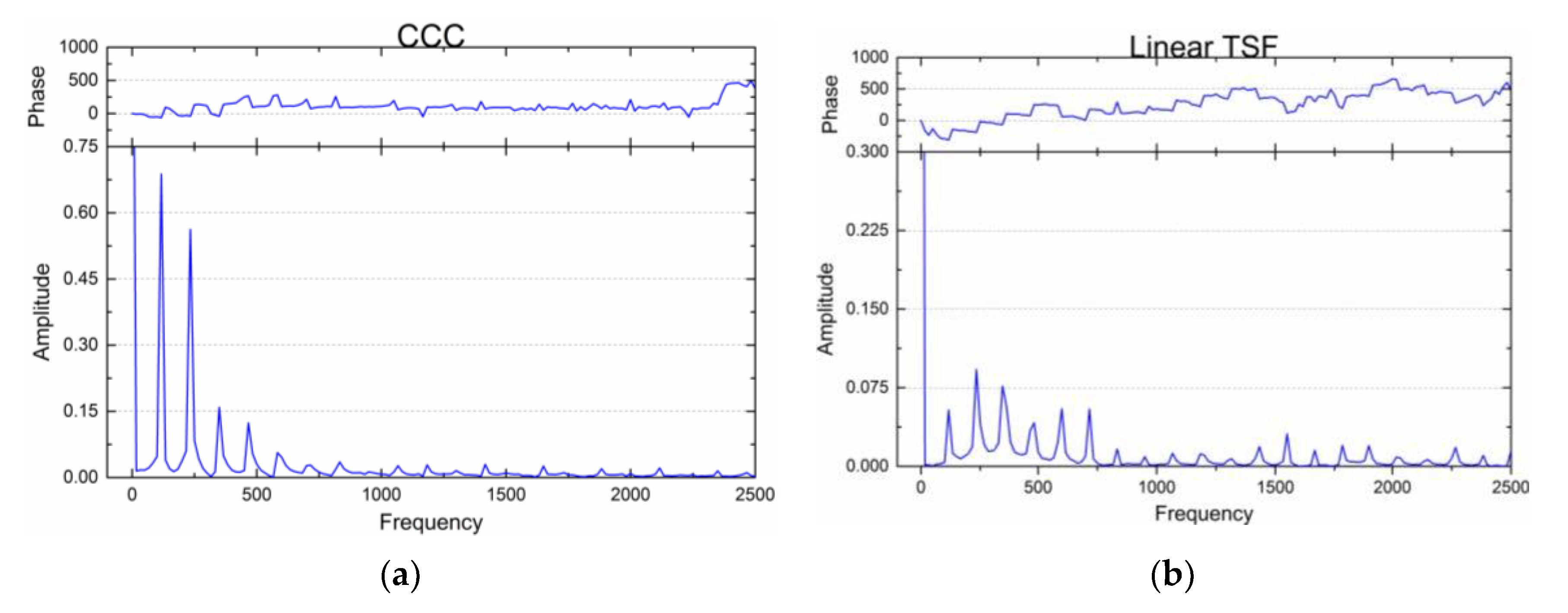

Assuming the total electromagnetic torque

T is periodic when the actuation current is constant or position-periodic, the total torque

T can be extended using a Fourier series as follows:

where

N = 3 for the three phases of the 6/4 SRM.

Figure 17a–d depicts the Fourier analysis of the experimental results of the total torque shown in

Figure 16; the units for the phase and amplitude on the y-axis are rad and Nm, respectively. It is evident that the harmonic component of the proposed TSF1 (

r = 4) is the least. Thus, the results of the simulation and experimental prove that the torque-speed performance and the drive efficiency are significantly improved by using the proposed TSF.

9. Conclusions

In this paper, based on the modified optimal criteria with the torque-speed performance and the drive efficiency, a computational procedure for the optimization model of a TSF has been described, including the maximization of the torque-speed range and the minimization of copper loss. In addition, by modifying the optimization objective of the qth-power current, a TSFs family with regard to torque capability is presented and the proposed TSF1 (r = 4) is compared with the conventional TSFs. The torque reference can be directly converted into the current reference using the rewritten torque-current profile model of the SRM either in the linear or the saturation magnetic region. The evaluation indices and the performance of the proposed and the classical methods are compared in terms of peak phase current, rms phase current, and torque ripple factor. The experimental results, which match the simulation results very well, show that no matter whether the rotor speed is low or high, the proposed TSF1 (r = 4) has the lowest peak and rms phase current compared with the CCC, the linear, and the sinusoidal TSF. Additionally, the proposed TSF1 (r = 4) has a commutation torque ripple ratio that is one-third less compared to the conventional TSFs in the saturation magnetic region at a speed of 3000 rpm. Moreover, the proposed TSF1 (r = 4) improves the drive efficiency, increases the rotor speed range of the torque-ripple-free operation, and reduces the requirements of the peak and rms phase current. The validity and superiority of the proposed control method have been experimentally proved.