Novel Automatic Idle Speed Control System with Hydraulic Accumulator and Control Strategy for Construction Machinery

Abstract

:1. Introduction

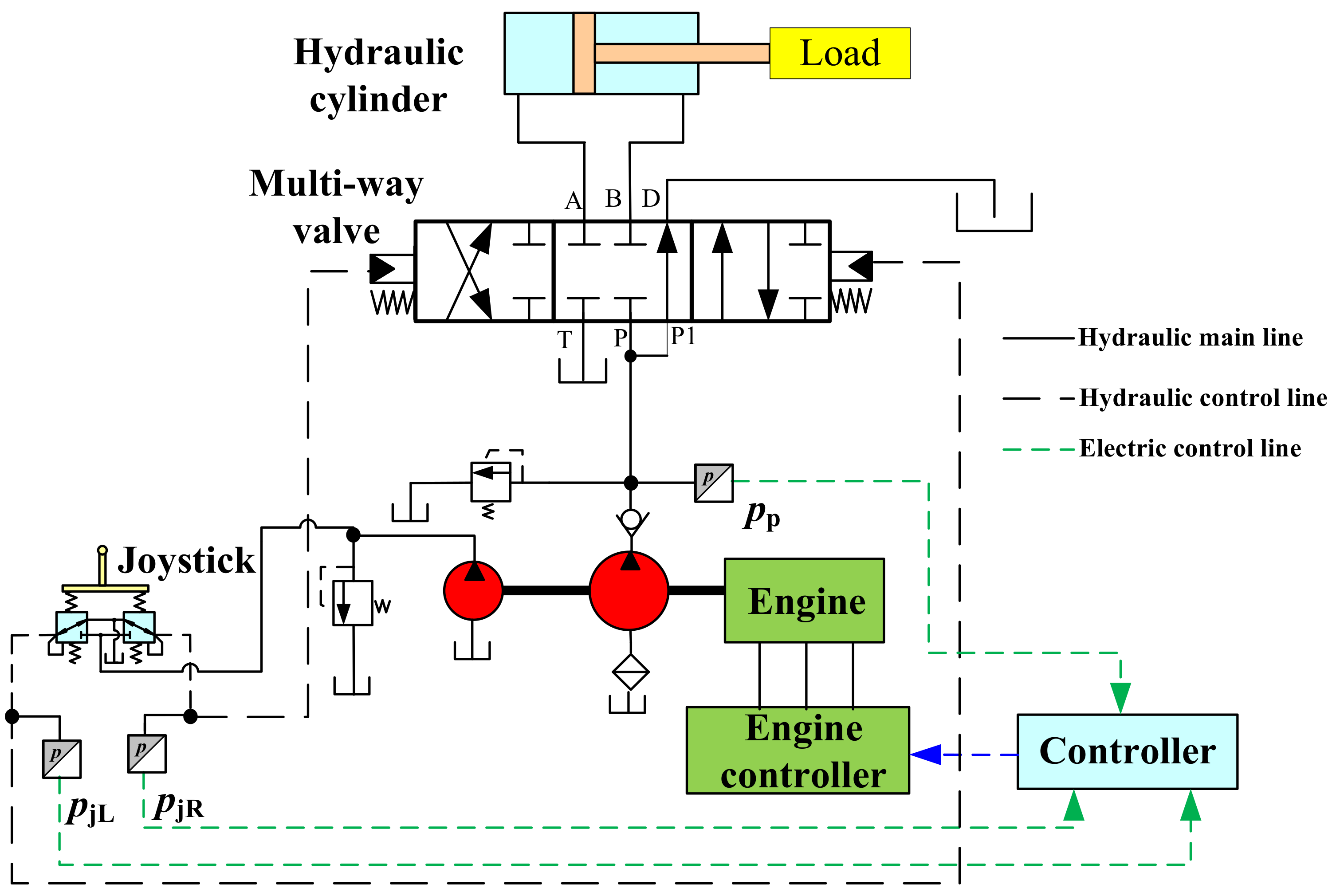

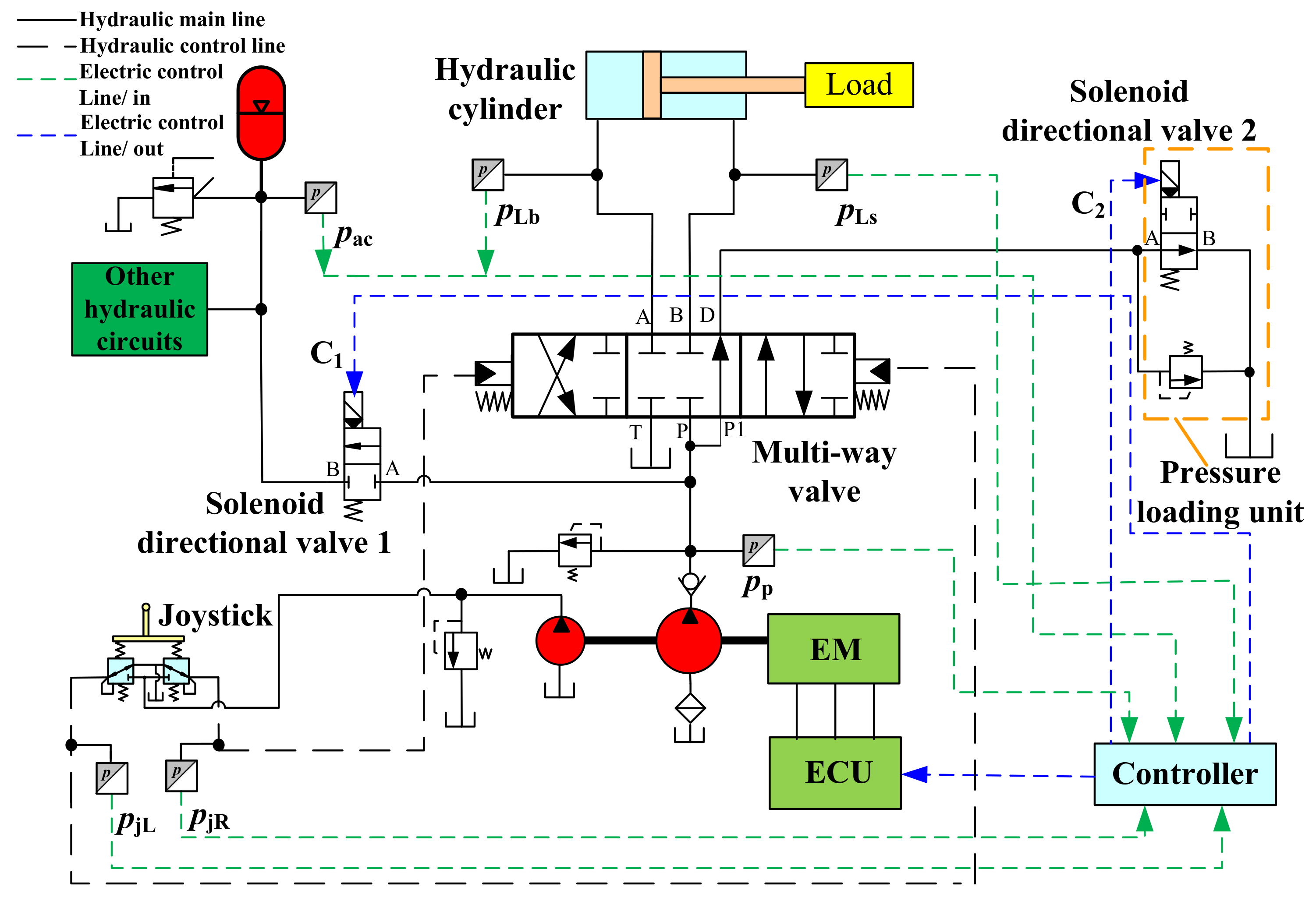

2. Structure and Working Principle of the Novel AISCS

- A HA is connected to the outlet of the pump via a solenoid directional valve 1. The HA is used to store energy during the first level idle mode, which can be serve as an auxiliary energy source to drive the actuator when the idle mode is cancelled.

- There is a pressure loading unit at the bypass way of the multi-way valve. When the multi-way valve is at middle working position and the solenoid directional valve 2 is powered off, it can separate the pump from the tank by the solenoid directional valve 2 and charge the HA.

- The EM has a faster response than the traditional engine and a high efficiency within a wider speed range. Thanks to the utilization of the EM, there is no pollution at all.

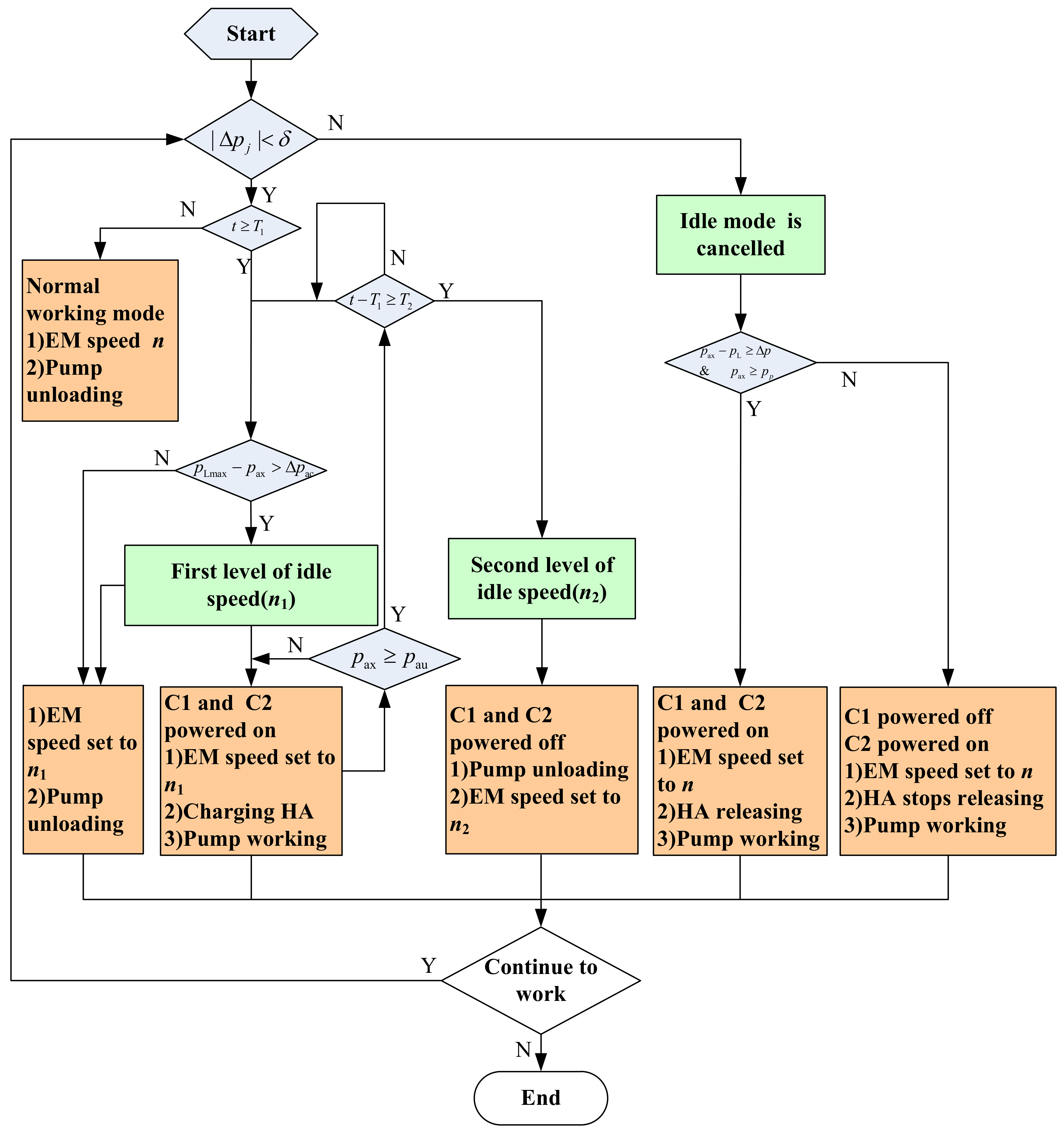

3. Control Strategy

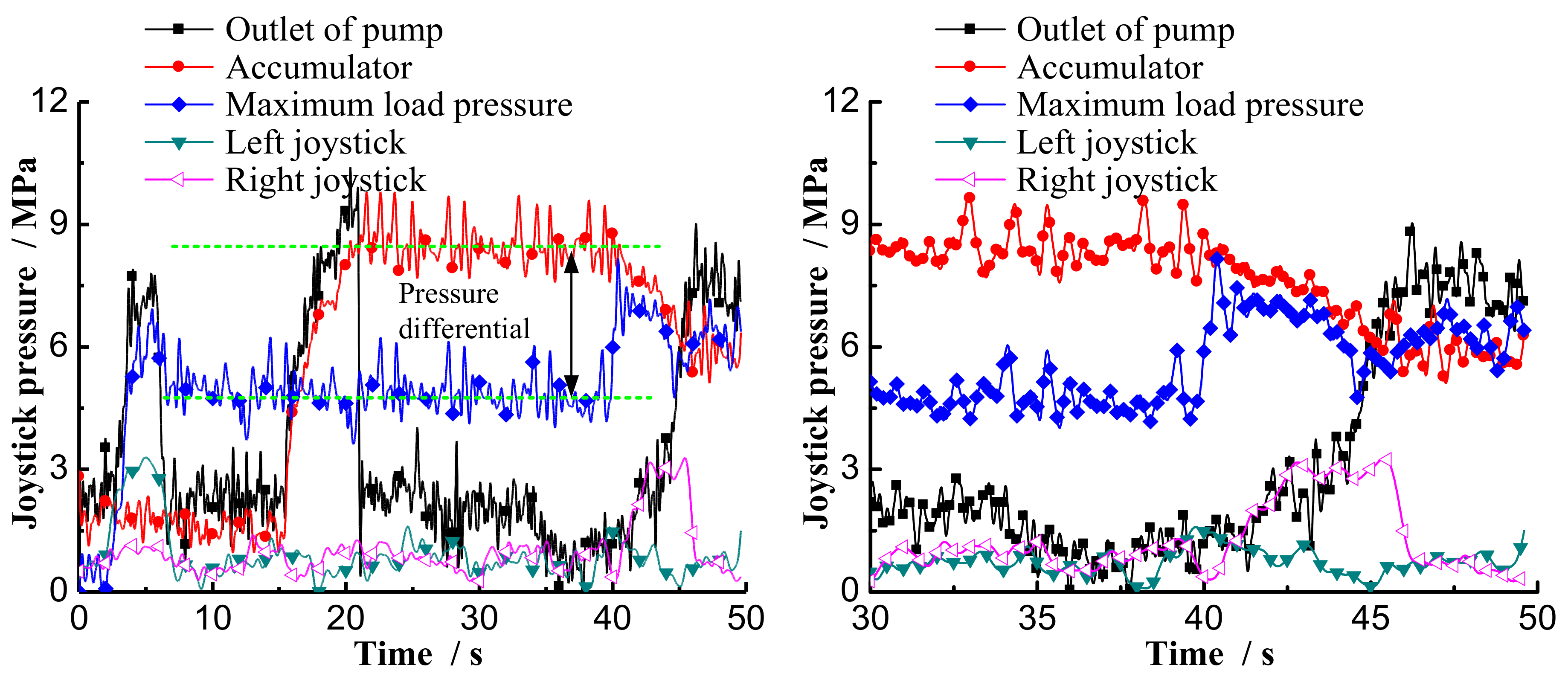

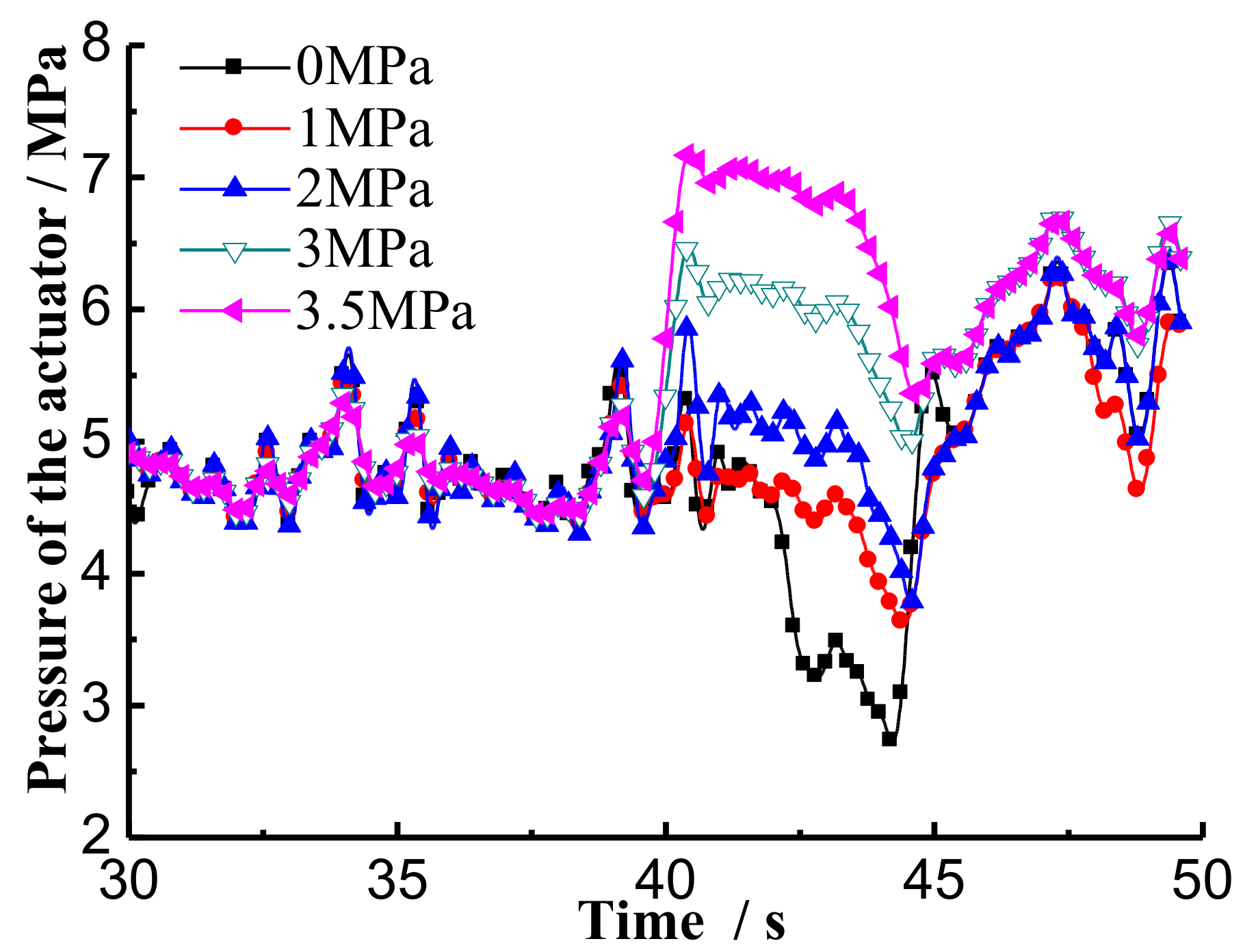

3.1. Optimization of Pressure Differential Δp between the HA and the Maximum Load Pressure

3.2. Control Law

- ●

- Mode 1: First level idle mode

- ●

- Mode 2: Second level idle mode

- ●

- Mode 3: Idle mode is cancelled

4. Experiment Research

4.1. Test Rig

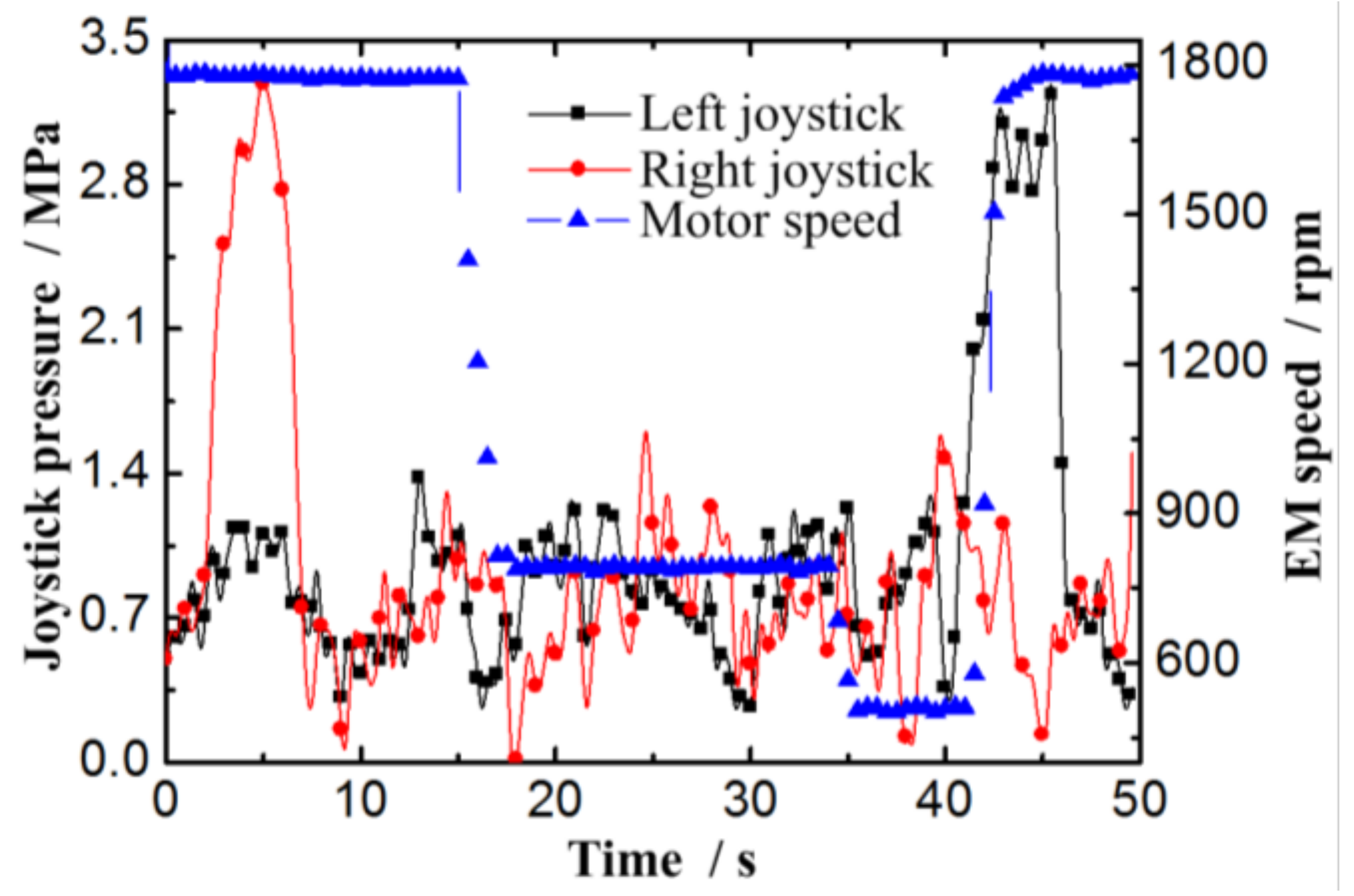

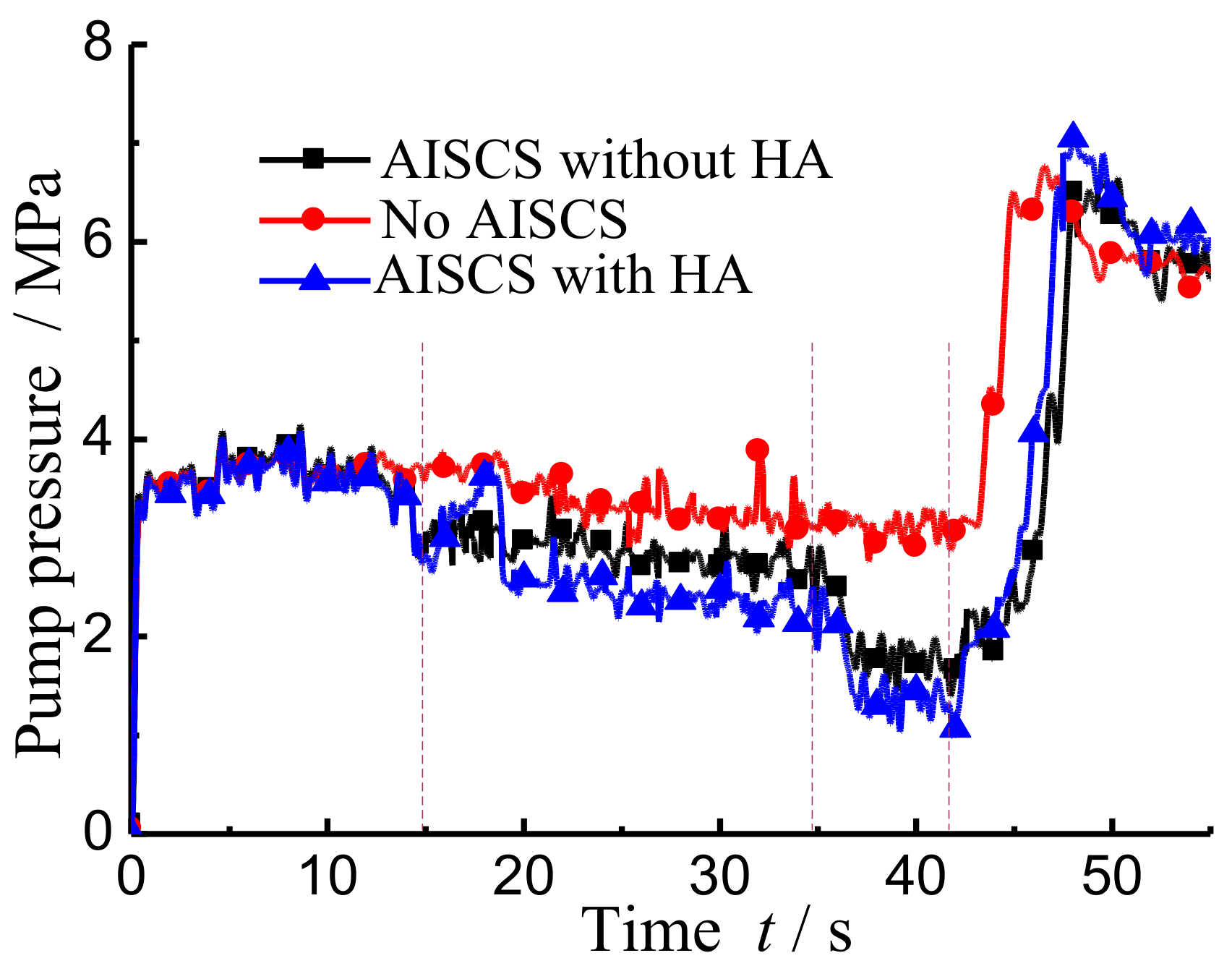

4.2. Control Performance

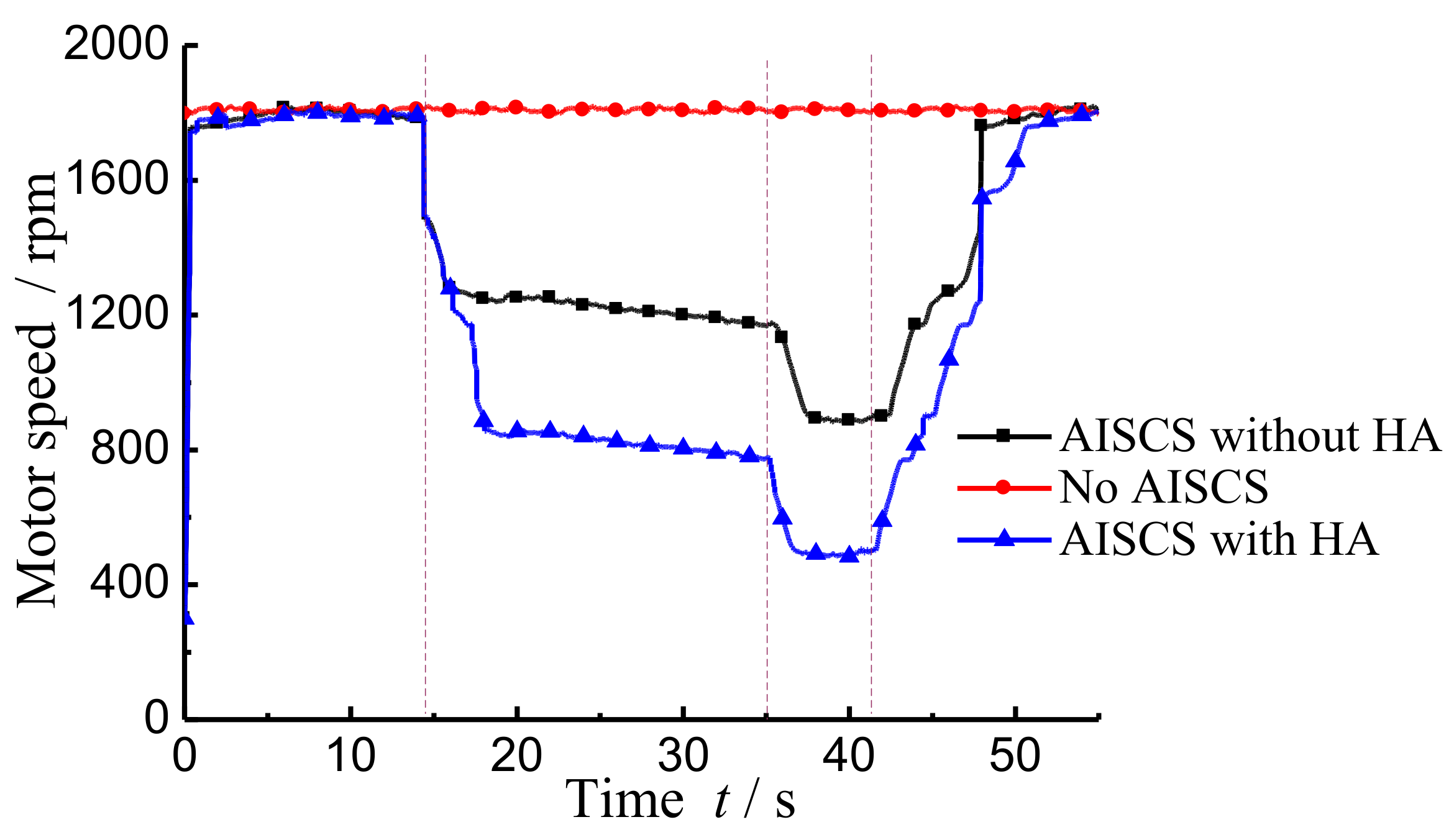

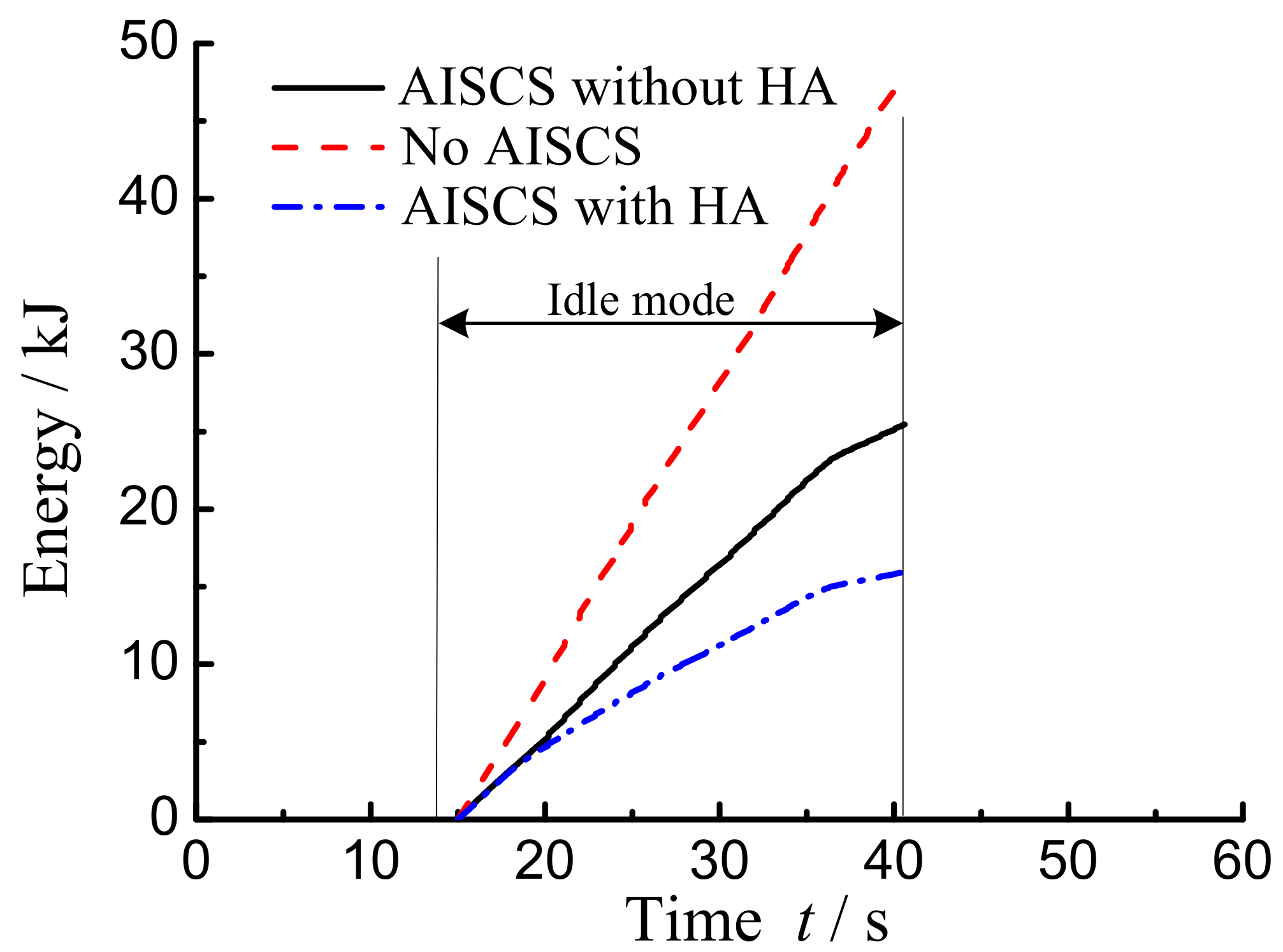

4.3. Energy Saving

5. Summary and Conclusions

- The proposed AISCS can realize the EM speed switching among the first level idle speed, second level idle speed, and normal speed based on the control strategy. The idle speed can set to a low value, which is 500 rpm in the proposed AISCS to reduce the energy consumption.

- The proposed AISCS with the HA can build up the load pressure quickly and make the load follow the action of the joystick rapidly when the idle mode is cancelled. This can make the actuator move more stably and smoothly.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| EM | Electric motor |

| HA | Hydraulic accumulator |

| HE | Hydraulic excavator |

| AISCS | Automatic idle speed control system |

| CNG | Compressed natural gas |

| PWM | Pulse-width modulation |

Nomenclature

| AL | effective area of drive chamber of the cylinder |

| Cep | external leakage coefficient of the pump |

| Cip | internal leakage coefficient of the pump |

| k | proportionality coefficient between the target velocity and the joystick pressure |

| np | speed of the pump |

| n | polytrophic exponent |

| pa0 | pre-charge pressure of the HA |

| pa1 | minimum working pressure of HA |

| pa2 | maximum working pressure of HA |

| pau | upper limited pressure of the HA |

| pax | working pressure of the HA |

| pjL | left side output pressure of the joystick |

| pjR | right side output pressure of the joystick |

| ∆pj | pressure differential of the two sides of the joystick |

| pL | load pressure |

| pLb | non-rod chamber pressure of the actuator |

| pLs | rod chamber pressure of the actuator |

| pLmax | maximum pressure of the load |

| ∆pac | Preset pressure differential of HA |

| pp | output port pressure of the pump |

| ∆p | the pressure differential between the HA and the load |

| ∆pvalve | pressure drop across the solenoid directional valve 1, multi-way valve and oil pipes |

| Qac | flow rate of the HA |

| qp | displacement of the pump |

| t | time |

| T1 | time that the system stay at the first level idle speed |

| T2 | time that the system stay at the second level idle speed |

| V0 | gas volume under the pressure p a0 of the HA |

| ∆V | volume change of the HA |

| v | actual velocity of the load |

| vt | target velocity of the load |

| vtmax | maximum target velocity of the actuator |

| δ | a small positive value |

| ηc | volumetric efficiency of the pump |

References

- Chen, Q.; Wu, W.; Liu, W.; Zhang, X. Research on pump control signal of excavator positive control system. J. Hefei Univ. Technol. 2014, 37, 645–649. [Google Scholar]

- Cheng, M.; Xu, B.; Yang, H. Efficiency Improvement for Electrohydraulic Flow Sharing Systems. In Proceedings of the 9th International Fluid Power Conference, RWTH Aachen University, Aachen, Germany, 24–26 March 2014. [Google Scholar]

- Sugimura, K.; Murrenhoff, H. Hybrid Load Sensing—Displacement Controlled Architecture for Excavators. In Proceedings of the 14th Scandinavian International Conference on Fluid Power (SICFP'15), Tampere University of Technology, Tampere, Finland, 20–22 May 2015; pp. 20–22. [Google Scholar]

- Jackson, R.S.; Clanton, R.R.; Pfaff, J.L. Hydraulic Control Valve System with Electronic Load Sense Control, U.S. Patent 7,089,733, 15 August 2006. [Google Scholar]

- Lin, T.; Wang, Q.; Hu, B.; Gong, W. Development of hybrid powered hydraulic construction machinery. Autom. Constr. 2010, 19, 11–19. [Google Scholar] [CrossRef]

- Hippalgaonkar, R.; Ivantysynova, M.; Zimmerman, J. Fuel savings of a mini-excavator through a hydraulic hybrid displacement controlled system. In Proceedings of the 8th International Fluid Power Conference, Dresden, Germany, 26–28 March 2012; pp. 139–153. [Google Scholar]

- Montazeri-Gh, M.; Poursamad, A.; Ghalichi, B. Application of genetic algorithm for optimization of control strategy in parallel hybrid electric vehicles. J. Frankl. Inst. 2006, 343, 420–435. [Google Scholar] [CrossRef]

- Cipek, M.; Pavković, D.; Petrić, J. A control-oriented simulation model of a power-split hybrid electric vehicle. Appl. Energy 2013, 101, 121–133. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Q. Optimization design of a permanent magnet synchronous generator for a potential energy recovery system. IEEE Trans. Energy Convers. 2012, 27, 856–863. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Q.; Lin, T. Improvement of boom control performance for hybrid hydraulic excavator with potential energy recovery. Autom. Constr. 2013, 30, 161–169. [Google Scholar] [CrossRef]

- Minav, T.A.; Virtanen, A.; Laurila, L.; Pyrhönena, J. Storage of energy recovered from an industrial forklift. Autom. Constr. 2012, 22, 506–515. [Google Scholar] [CrossRef]

- Lin, T.; Wang, Q.; Hu, B.; Gong, W. Research on the energy regeneration systems for hybrid hydraulic excavators. Autom. Constr. 2010, 19, 1016–1026. [Google Scholar] [CrossRef]

- Cairano, S.D.; Yanakiev, D.; Bemporad, A.; Kolmanovsky, L.V.; Hrovat, D. Model predictive idle speed control: Design, analysis, and experimental evaluation. IEEE Trans. Control Syst. Technol. 2012, 20, 84–97. [Google Scholar]

- He, Y.; Ma, F.; Deng, J.; Shaoa, Y.; Jian, X. Reducing the idle speed of an SI CNG engine fueled by HCNG with high hydrogen ratio. Int. J. Hydrog. Energy 2012, 37, 8698–8703. [Google Scholar] [CrossRef]

- Li, X.; Yurkovich, S. Sliding mode control of delayed systems with application to engine idle speed control. IEEE Trans. Control Syst. Technol. 2001, 9, 802–810. [Google Scholar]

- Hrovat, D.; Sun, J. Models and control methodologies for IC engine idle speed control design. Control Eng. Pract. 1997, 5, 1093–1100. [Google Scholar] [CrossRef]

- Huang, X.; Xie, H.; Song, K. Idle speed control of FSAE racing engines based on Mid-ranging ADRC. In Proceedings of the 33rd Chinese Control Conference (CCC), Nanjing, China, 28–30 July 2014; pp. 201–206. [Google Scholar]

- Chien, T.L.; Chen, C.C.; Hsu, C.Y. Tracking control of nonlinear automobile idle-speed time-delay system via differential geometry approach. J. Frankl. Inst. 2005, 342, 760–775. [Google Scholar] [CrossRef]

- Kandler, C.; Koenings, T.; Ding, S.X.; Weinhold, N.; Schultalbers, M. Stability Investigation of an Idle Speed Control Loop for a Hybrid Electric Vehicle. IEEE Trans. Control Syst. Technol. 2015, 23, 1189–1196. [Google Scholar] [CrossRef]

- Laurain, T.; Lauber, J.; Palhares, R.M. Observer design to control individual cylinder spark advance for idle speed management of a SI engine. In Proceedings of the IEEE International Conference on Industrial Electronics and Applications (ICIEA), Auckland, New Zealand, 15–17 June 2015; pp. 262–267. [Google Scholar]

- Chen, T.; Xie, H.; Li, L.; Zhang, L.; Wang, X.; Zhao, H. Methods to achieve HCCI/CAI combustion at idle operation in a 4VVAS gasoline engine. Appl. Energy 2014, 116, 41–51. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhang, P.; Guo, S. Control and experiment research of XR220D rotary drilling Rig. Equip. Manuf. Technol. 2015, 81, 240–241. [Google Scholar]

- Liu, R. Research on the power matching control system for the hydraulic excavators. Mach. Tool Hydraul. 2015, 43, 111–115. [Google Scholar]

- Hao, P.; He, Q.; Zhang, X.; Xie, S. Study on Load and Operating Mode Identification of Excavator. Hydraul. Pneum. Seals 2008, 5. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-YYQD200805005.htm (accessed on 23 March 2018).

| Key Components | Parameter | Value |

|---|---|---|

| Actuator | Rod diameter/mm | 35 |

| Cylinder diameter/mm | 63 | |

| Maximum stroke/mm | 100 | |

| Electric motor | Power/kW | 8 |

| Rated speed/(rpm) | 1800 | |

| Pump | Displacement/(mL·r−1) | 16 |

| Hydraulic accumulator | Volume/L | 1.6 |

| Pre-charge pressure/MPa | 2 |

| System Type | Energy Consumed | Energy Efficiency |

|---|---|---|

| No idle speed control | 48,233 J | - |

| AISCS with HA | 15,950 J | 67% |

| AISCS without HA | 25,459 J | 47% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, H.; Lin, T.; Zhou, S.; Huang, W.; Miao, C. Novel Automatic Idle Speed Control System with Hydraulic Accumulator and Control Strategy for Construction Machinery. Appl. Sci. 2018, 8, 496. https://doi.org/10.3390/app8040496

Ren H, Lin T, Zhou S, Huang W, Miao C. Novel Automatic Idle Speed Control System with Hydraulic Accumulator and Control Strategy for Construction Machinery. Applied Sciences. 2018; 8(4):496. https://doi.org/10.3390/app8040496

Chicago/Turabian StyleRen, Haoling, Tianliang Lin, Shengyan Zhou, Weiping Huang, and Cheng Miao. 2018. "Novel Automatic Idle Speed Control System with Hydraulic Accumulator and Control Strategy for Construction Machinery" Applied Sciences 8, no. 4: 496. https://doi.org/10.3390/app8040496