Effects of Heat Treatment on the Tribological Properties of Sicp/Al-5Si-1Cu-0.5Mg Composite Processed by Electromagnetic Stirring Method

Abstract

:1. Introduction

2. Experimental

2.1. Materials Preparation

2.2. Wear Testing

2.3. Characterization

3. Results and Discussion

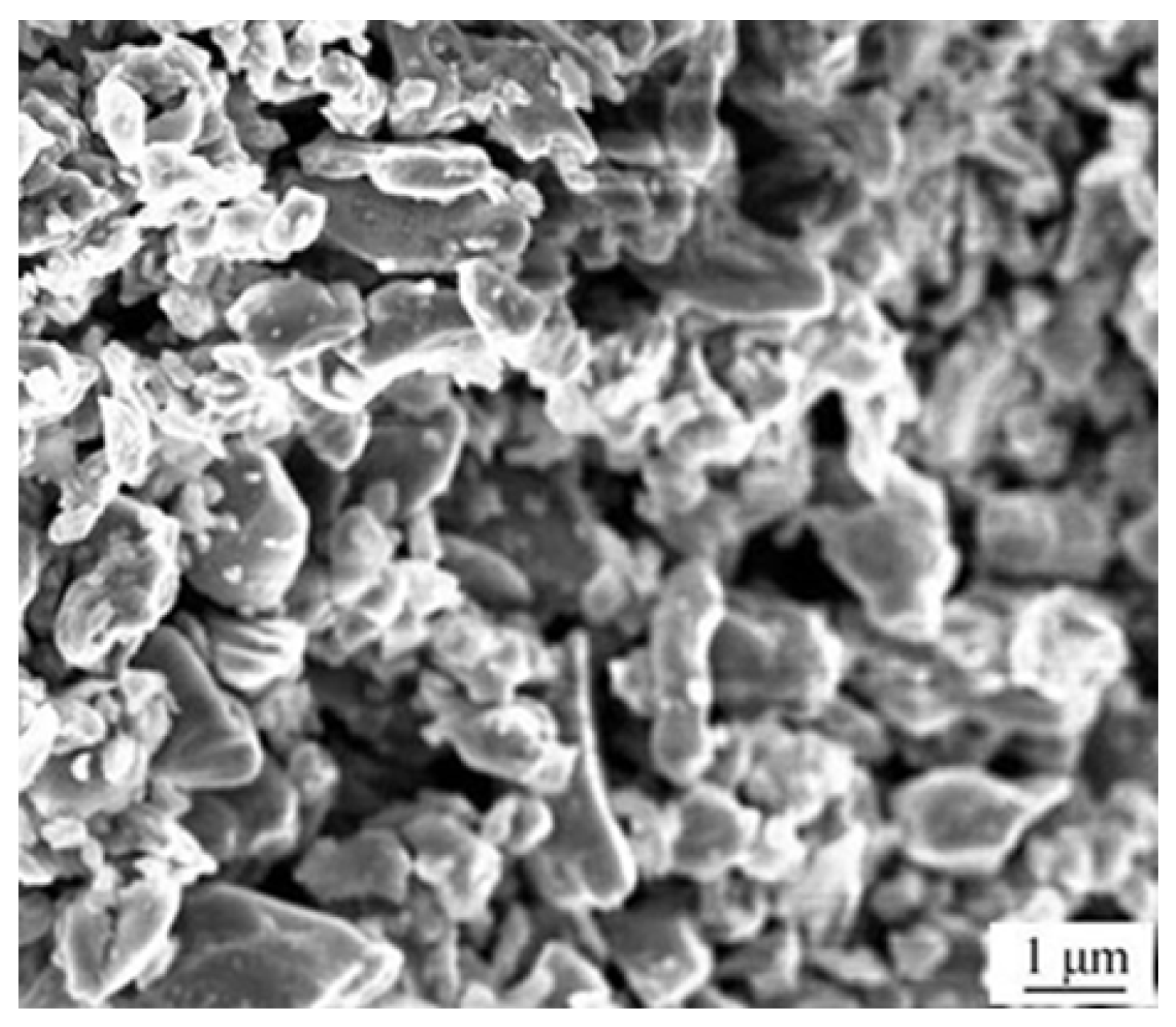

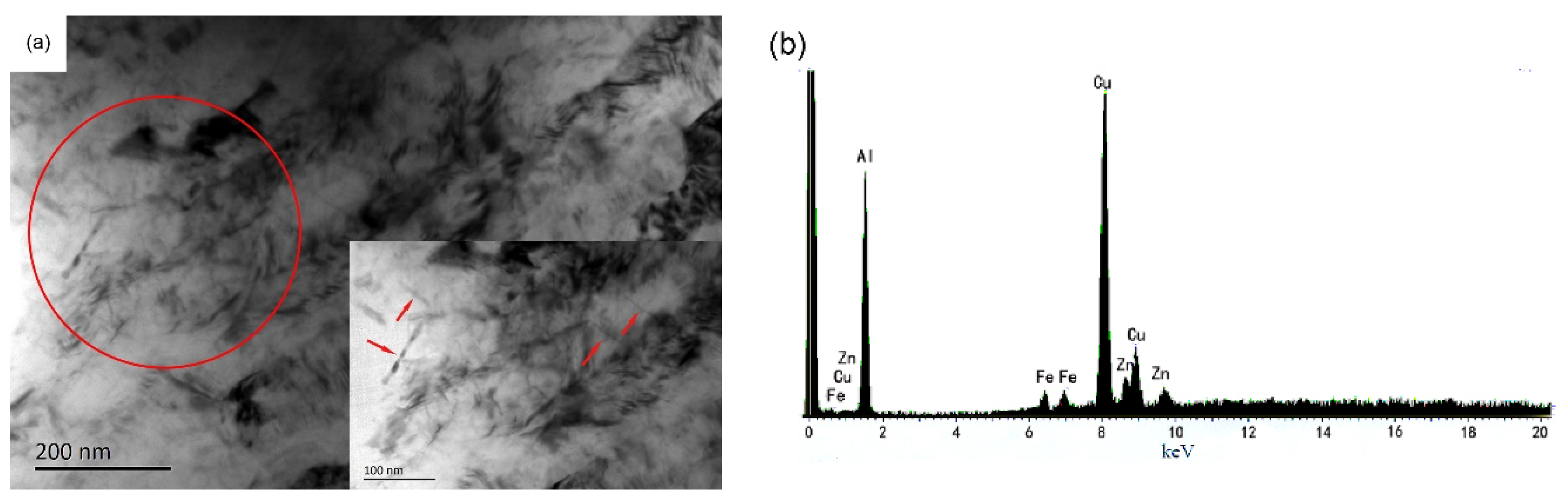

3.1. Microstructure Evolution

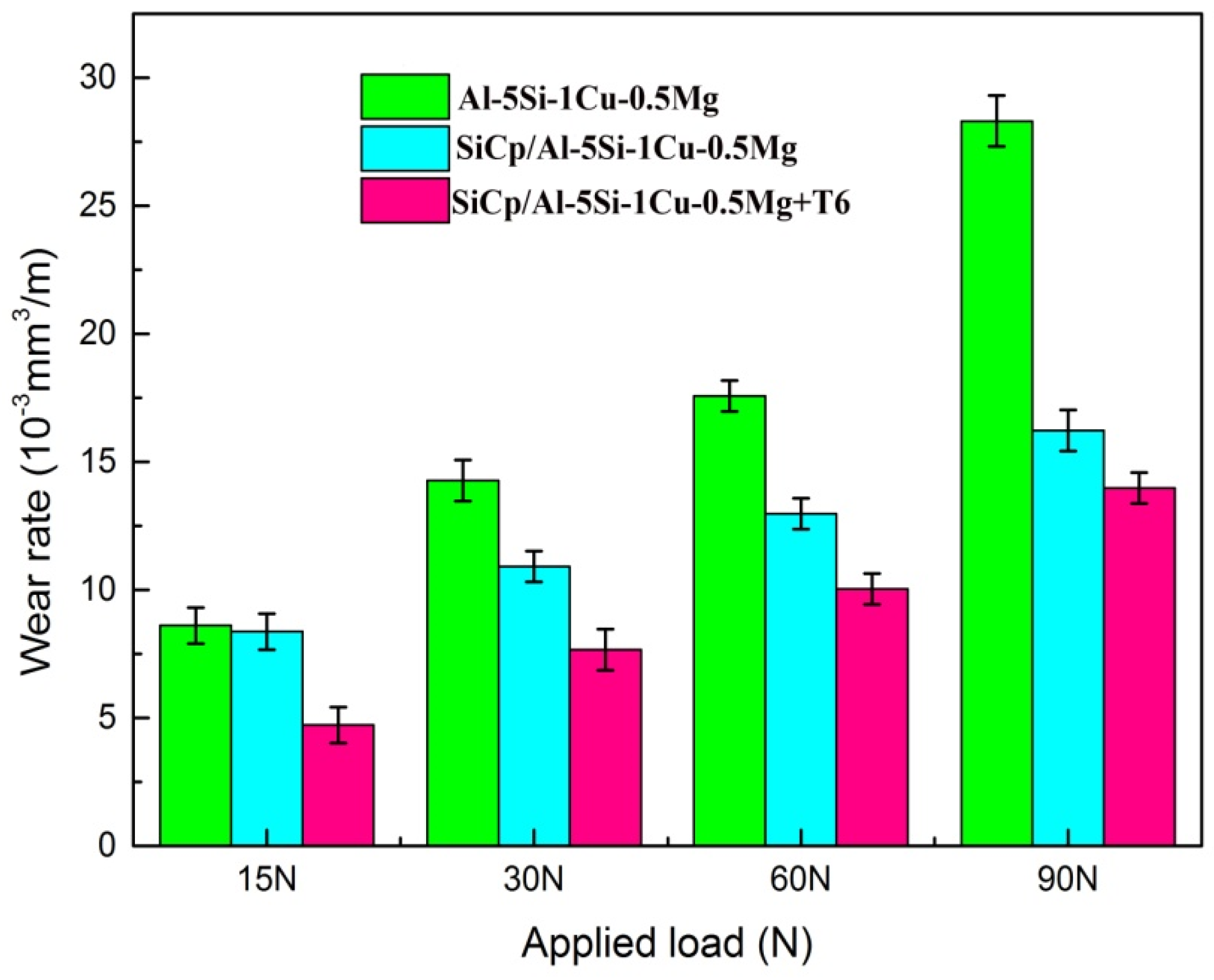

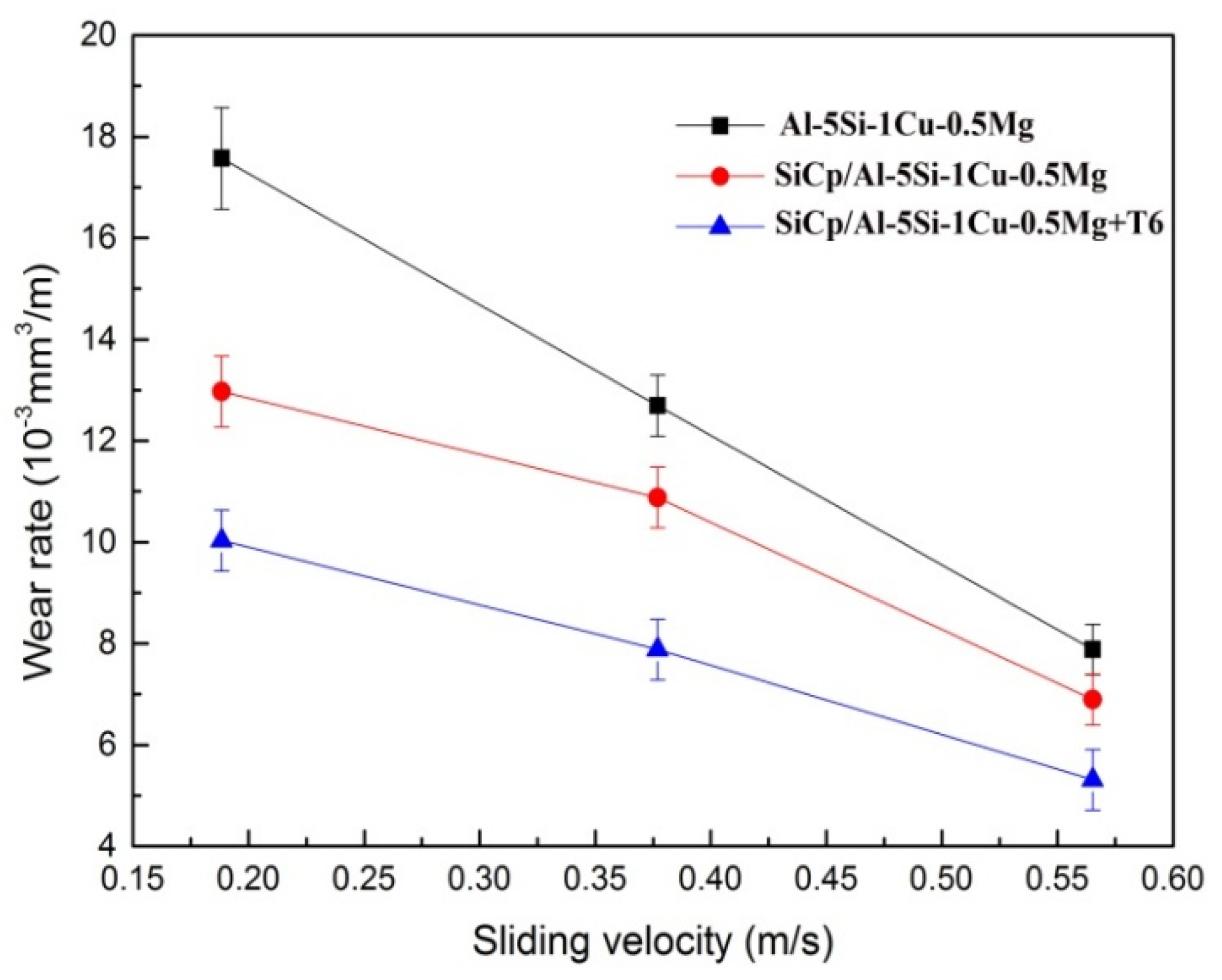

3.2. Wear Rates

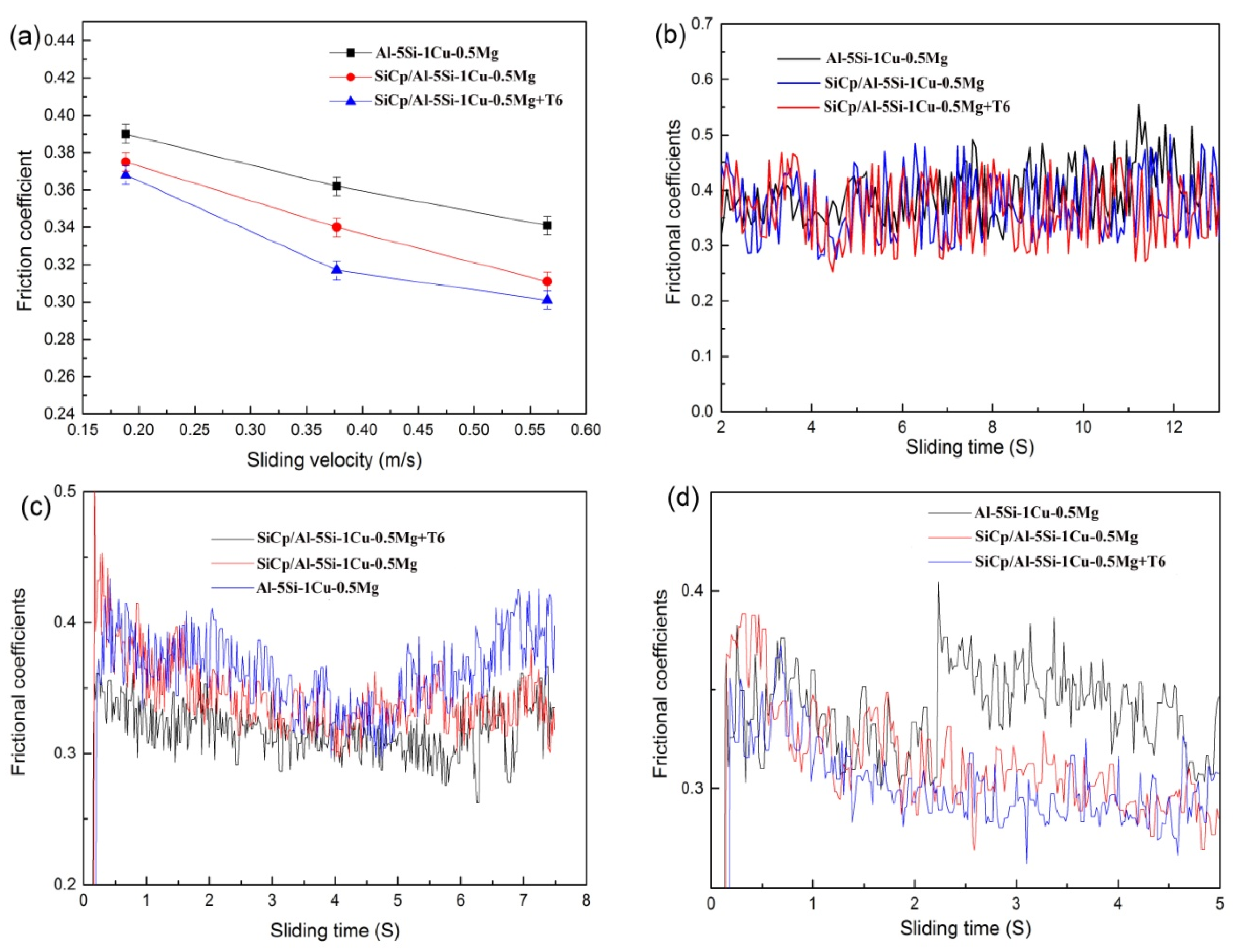

3.3. Friction Coefficient

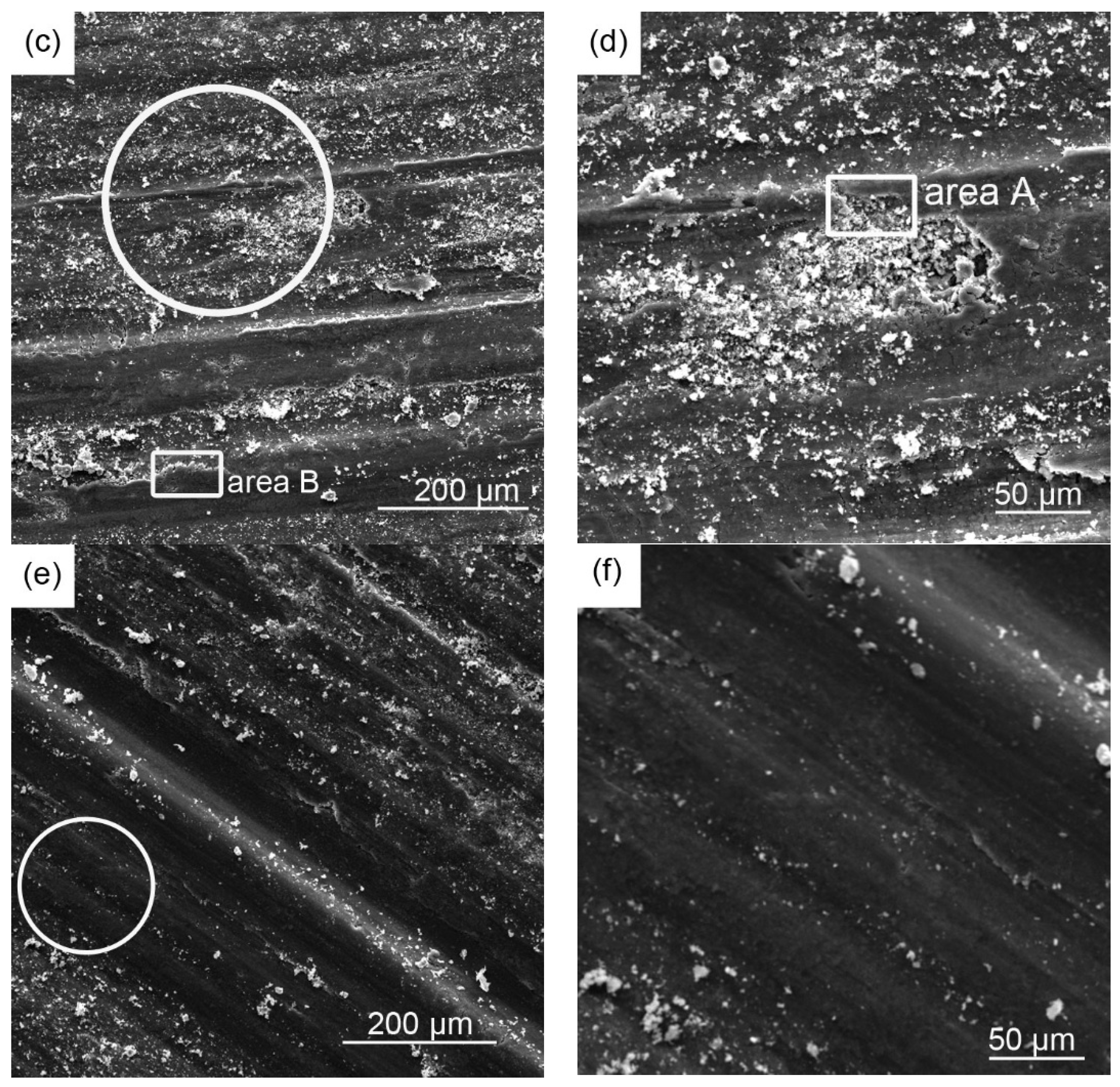

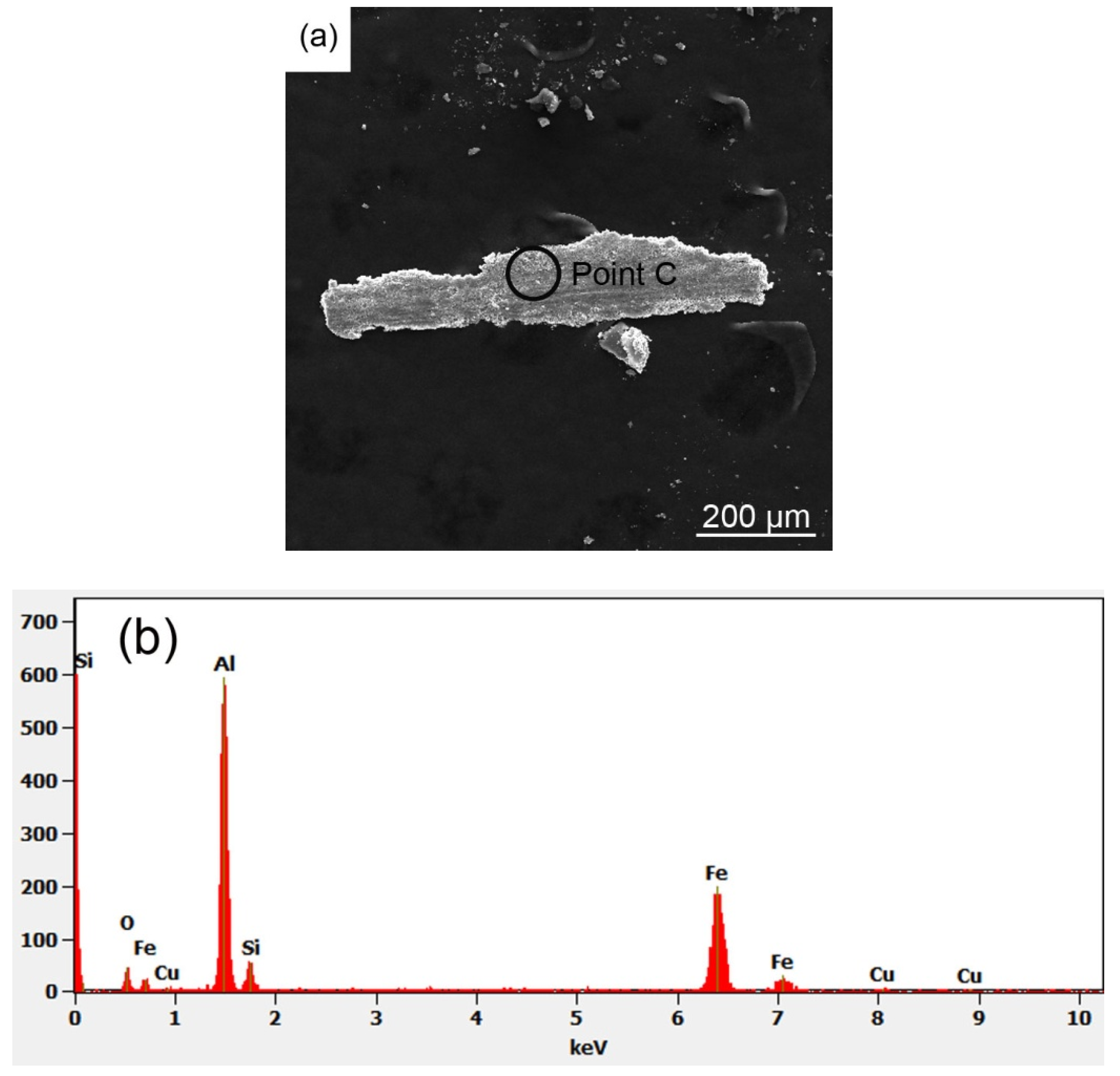

3.4. Wear Mechanisms

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Choi, S.W.; Cho, H.S.; Kang, C.S.; Kumai, S. Precipitation dependence of thermal properties for Al-Si-Mg-Cu-(Ti) alloy with various heat treatment. J. Alloys Compd. 2015, 647, 1091–1097. [Google Scholar] [CrossRef]

- Rao, Y.S.; Yan, H.; Hu, Z. Modification of eutectic silicon and β-Al5FeSi phases in as-cast ADC12 alloys by using samarium addition. J. Rare Earth. 2013, 9, 916–922. [Google Scholar] [CrossRef]

- Liu, G.; Li, G.D.; Cai, A.H.; Chen, Z.K. The influence of Strontium addition on wear properties of Al-20 wt% Si alloys under dry reciprocating sliding condition. Mater. Des. 2011, 32, 121–126. [Google Scholar] [CrossRef]

- Jian, X.S.; Wang, N.J.; Zhu, D.G. Friction and wear properties of in-situ synthesized Al2O3 reinforced aluminum composites. Trans. Nonferr. Met. Soc. China 2014, 24, 2352–2358. [Google Scholar] [CrossRef]

- Du, X.F.; Gao, T.; Liu, G.L.; Liu, X.F. In situ synthesizing SiC particles and its strengthening effect on an Al-Si-Cu-Ni-Mg piston alloy. J. Alloys Compd. 2017, 695, 1–8. [Google Scholar] [CrossRef]

- Rajeev, V.R.; Dwivedi, D.K.; Jain, S.C. Effect of load and reciprocating velocity on the transition from mild to severe wear behavior of Al-Si-SiCp composites in reciprocating conditions. Mater. Des. 2010, 31, 4951–4959. [Google Scholar] [CrossRef]

- Khosravi, H.; Akhlaghi, F. Comparison of microstructure and wear resistance of A356-SiCp composites processed via compocasting and vibration cooling slope. Trans. Nonferr. Met. Soc. China 2015, 25, 2490–2498. [Google Scholar] [CrossRef]

- Gupta, A.K.; Prasad, B.K.; Pajnoo, R.K.; Das, S. Effects of T6 heat treatment on mechanical, abrasive and erosive-corrosive wear properties of eutectic Al-Si alloy. Trans. Nonferr. Met. Soc. China 2012, 22, 1041–1050. [Google Scholar] [CrossRef]

- Singh, J.; Chauhan, A. Overview of wear performance of aluminum matrix composites reinforced with ceramic materials under the influence of controllable variables. Ceram. Int. 2016, 42, 56–81. [Google Scholar] [CrossRef]

- Choi, J.P.; Hur, Y.M.; Nam, T.W.; Yoon, E.P. The effect of frequency of electromagnetic vibration on the micro structure in hypoeutectic Al-Si Alloy. Solid State Phenom. 2006, 116–117, 213–216. [Google Scholar] [CrossRef]

- Yu, H.Q.; Zhu, M.Y. Effect of electromagnetic stirring in mold on the macroscopic quality of high carbon steel billet. Acta Metall. Sin. 2009, 22, 461–467. [Google Scholar] [CrossRef]

- Zhu, G.L.; Xu, J.; Zhang, Z.F.; Bai, Y.L.; Shi, L.K. Annular electromagnetic stirring—A new method for the production of semi-solid A357 aluminum alloy slurry. Acta Metall. Sin. 2009, 22, 408–414. [Google Scholar] [CrossRef]

- Metan, V.; Eigenfeld, K.; Rabiger, D.; Leonhardt, M.; Eckert, S. Grain size control in Al-Si alloys by grain refinement and electronmagnetic stirring. J. Alloys Compd. 2009, 487, 163–172. [Google Scholar] [CrossRef]

- Liu, Z.; Mao, W.M.; Liu, X.M. Characterization on morphology evolution of primary phase in semisolid A356 under slightly electromagnetic stirring. Trans. Nonferr. Met. Soc. China 2010, 20, 805–810. [Google Scholar] [CrossRef]

- Dwivedi, S.P.; Sharma, S.; Mishra, R.K. Microstructure and mechanical properties of A356/SiC composites fabricated by electromagnetic stir casting. Procedia Mater. Sci. 2014, 6, 1524–1532. [Google Scholar] [CrossRef]

- Liu, G.P.; Wang, Q.D.; Liu, T.; Ye, B.; Jiang, H.Y.; Ding, W.J. Effect of T6 heat treatment on microstructure and mechanical property of 6101/A356 bimetal fabricated by squeeze casting. Mater. Sci. Eng. A 2017, 696, 208–215. [Google Scholar] [CrossRef]

- Yan, H.; Wan, J.; Nie, Q. Wear Behavior of Extruded Nano-SiCp Reinforced AZ61 Magnesium Matrix Composites. Adv. Mech. Eng. 2015, 5, 489528. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Ray, S.; Asthana, R.; Narendranath, C.S. Interfaces in cast metal-matrix composites. Mater. Sci. Eng. A 1993, 162, 163–174. [Google Scholar] [CrossRef]

- Wang, W.; Ajersch, F.; Löfvander, J.P.A. Si phase nucleation on SiC particulate reinforcement in hypereutectic Al-Si alloy matrix. Mater. Sci. Eng. A 1994, 187, 65–75. [Google Scholar] [CrossRef]

- Sjölander, E.; Seifeddine, S. The heat treatment of Al-Si-Cu-Mg casting alloys. J. Mater. Process. Technol. 2010, 210, 1249–1259. [Google Scholar] [CrossRef]

- Chu, H.S.; Liu, K.S.; Yeh, J.W. Study of 6061-Al2O3p composites produced by reciprocasting extrusion. Metall. Mater. Trans. A 2000, 31, 2587–2596. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Yan, H.; Wang, Z.W. Effect of heat treatment on wear properties of extruded AZ91 alloy treated with yttrium. J. Rare Earths 2016, 34, 308–314. [Google Scholar] [CrossRef]

- Bowden, F.P.; Tabor, D. The Friction and Lubrication of Solids; Clarendon Press: London, UK, 1964; pp. 1–8. ISBN 9780198507772. [Google Scholar]

- An, J.; Li, R.G.; Lu, Y.; Chen, C.M.; Xu, Y.; Chen, X.; Wang, L.M. Dry sliding wear behavior of magnesium alloys. Wear 2008, 265, 97–104. [Google Scholar] [CrossRef]

- Ramezani, M.; Ripin, Z.M. A friction model for dry contacts during metal-forming process. Int. J. Adv. Manuf. Technol. 2010, 51, 93–102. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Sufizadeh, A.R.; Emamy, M. The effect of strontium on the microstructure and wear properties of A356–10%B4C cast composites. Mater. Des. 2010, 31, 2187–2195. [Google Scholar] [CrossRef]

- Dwivedi, D.K.; Arjun, T.S.; Thakur, P.; Vaidya, H.; Singh, K. Sliding wear and friction behaviour of Al–18% Si–0.5% Mg alloy. J. Mater. Process. Technol. 2004, 152, 323–328. [Google Scholar] [CrossRef]

- Abouei, V.; Shabestari, S.G.; Saghafian, H. Dry sliding wear behaviour of hypereutectic Al–Si piston alloys containing iron-rich intermetallics. Mater. Charact. 2010, 61, 1089–1096. [Google Scholar] [CrossRef]

- Suh, N.P. An overview of the delamination theory of wear. Wear 1977, 44, 1–16. [Google Scholar] [CrossRef]

- Zhu, J.B.; Yan, H. Fabrication of an A356/fly-ash-mullite interpenetrating composite and its wear properties. Ceram. Int. 2017, 43, 12996–13003. [Google Scholar] [CrossRef]

- Asl, K.M.; Masoudi, A.; Khomamizadeh, F. The effect of different rare earth elements content on microstructure, mechanical and wear behavior of Mg–Al–Zn alloy. Mater. Sci. Eng. A 2010, 527, 2027–2035. [Google Scholar]

| Si | Cu | Mg | Ti | Fe | Al |

|---|---|---|---|---|---|

| 5.13 | 1.27 | 0.55 | 0.16 | 0.13 | Bal. |

| Samples | ρ/(g·cm−3) | Porosity/% | Microhardness/HV | UTS/MPa |

|---|---|---|---|---|

| Al-5Si-1Cu-0.5Mg | 2. 695 | 0.55 | 80.17 ± 3.50 | 191.56 ± 4.77 |

| Al-5Si-1Cu-0.5Mg + SiCp | 2. 699 | 0.61 | 87.06 ± 4.39 | 238.62 ± 5.19 |

| Al-5Si-1Cu-0.5Mg + SiCp + T6 | 2. 698 | 0.65 | 101.86 ± 1.59 | 273.64 ± 6.47 |

| Samples | 15 N | 30 N | 60 N | 90 N |

|---|---|---|---|---|

| Al-5Si-1Cu-0.5Mg | 0.343 ± 0.003 | 0.364 ± 0.0025 | 0.390 ± 0.0025 | 0.401 ± 0.0025 |

| Al-5Si-1Cu-0.5Mg + SiCp | 0.335 ± 0.0025 | 0.358 ± 0.0025 | 0.375 ± 0.0025 | 0.388 ± 0.0025 |

| Al-5Si-1Cu-0.5Mg + SiCp + T6 | 0.326 ± 0.0025 | 0.350 ± 0.0025 | 0.368 ± 0.0025 | 0. 373 ± 0.003 |

| Position | C-K | O-K | Al-K | Si-K | Mn-K | Fe-K | Cu-K |

|---|---|---|---|---|---|---|---|

| Area A | - | 18.77 | 25.50 | 3.19 | - | 51.84 | 0.70 |

| Area B | 0.85 | 17.15 | 51.14 | 8.50 | 0.77 | 19.78 | 1.82 |

| Point C | - | 10.48 | 46.57 | 7.37 | - | 33.88 | 1.69 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, N.; Yan, H.; Wang, Z.-W. Effects of Heat Treatment on the Tribological Properties of Sicp/Al-5Si-1Cu-0.5Mg Composite Processed by Electromagnetic Stirring Method. Appl. Sci. 2018, 8, 372. https://doi.org/10.3390/app8030372

Li N, Yan H, Wang Z-W. Effects of Heat Treatment on the Tribological Properties of Sicp/Al-5Si-1Cu-0.5Mg Composite Processed by Electromagnetic Stirring Method. Applied Sciences. 2018; 8(3):372. https://doi.org/10.3390/app8030372

Chicago/Turabian StyleLi, Ning, Hong Yan, and Zhi-Wei Wang. 2018. "Effects of Heat Treatment on the Tribological Properties of Sicp/Al-5Si-1Cu-0.5Mg Composite Processed by Electromagnetic Stirring Method" Applied Sciences 8, no. 3: 372. https://doi.org/10.3390/app8030372