Effect of Thin Cement-Based Renders on the Structural Response of Masonry Wall Panels

Abstract

:1. Introduction

2. Description of the On-Site Experimental Campaign

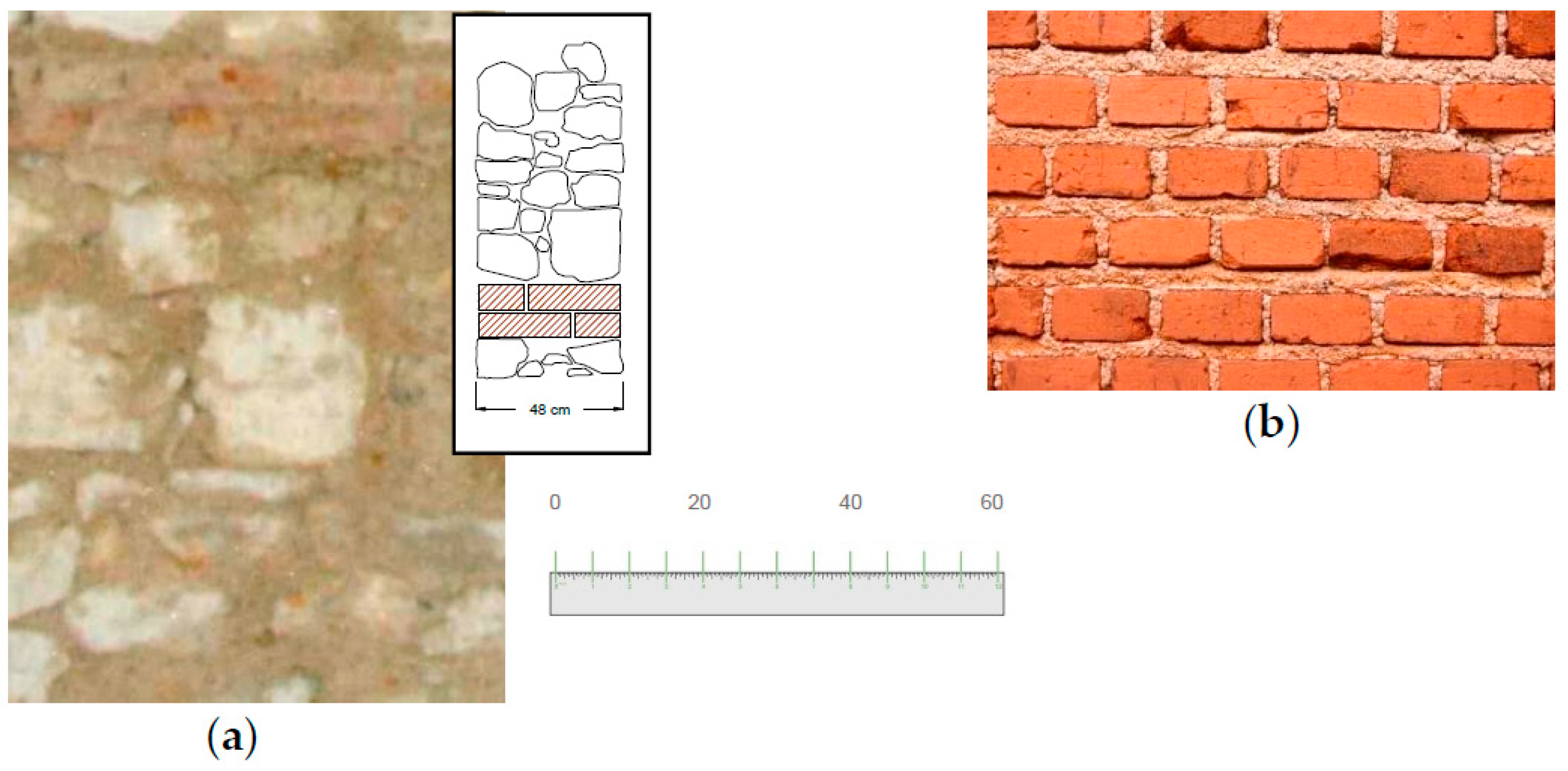

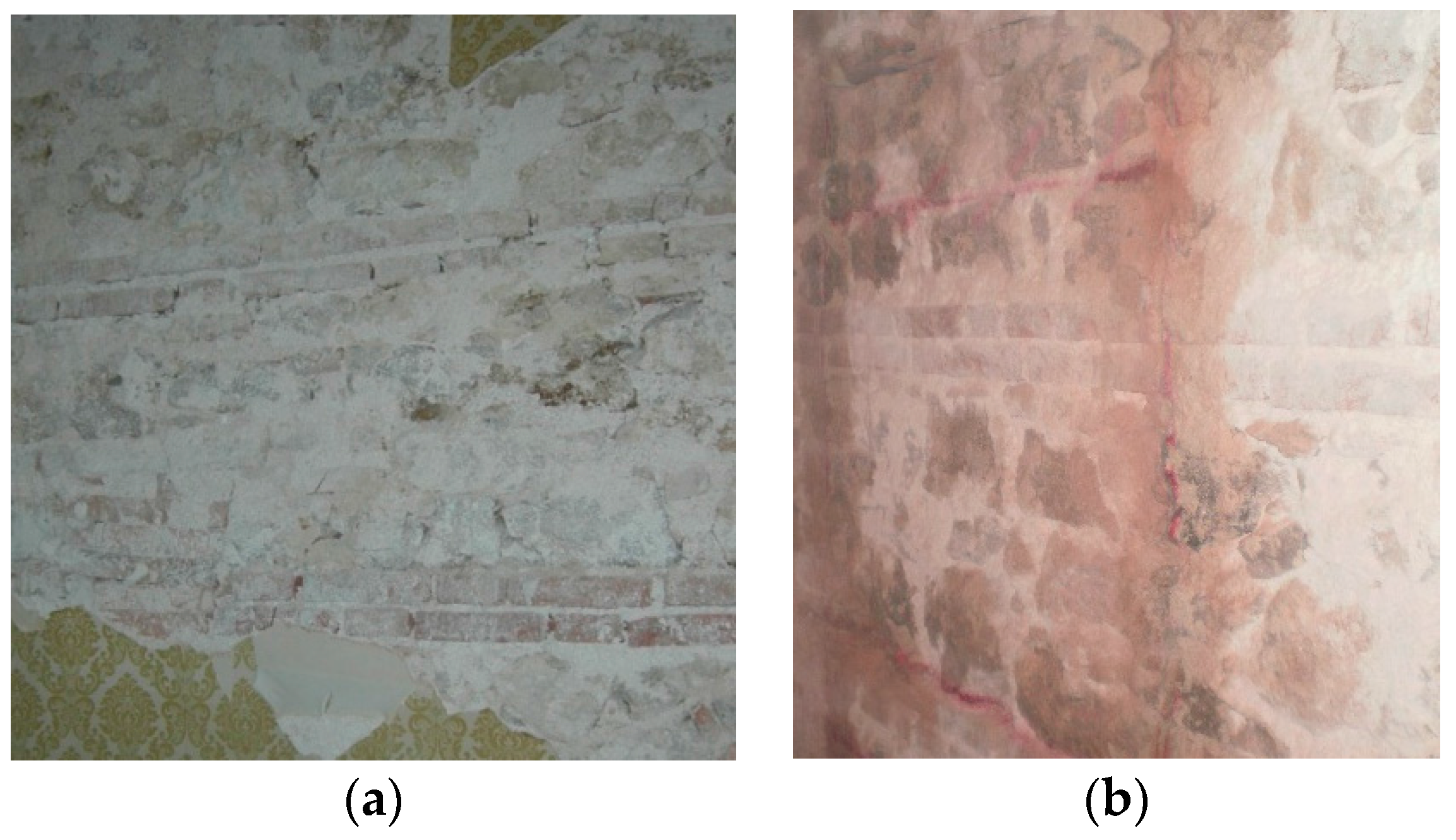

2.1. Masonry Typologies and Walling Materials

2.2. The Render

3. Test Layout

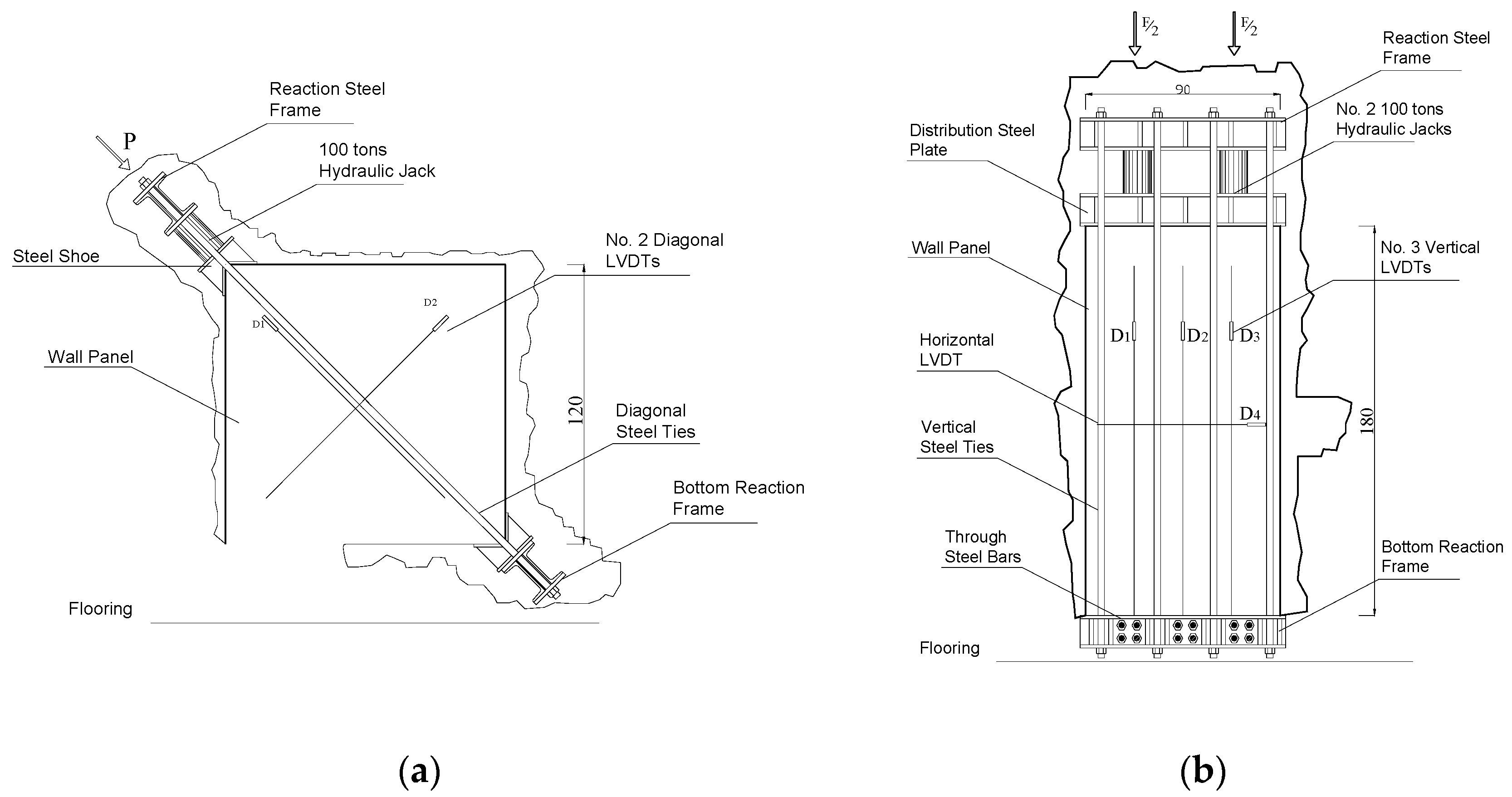

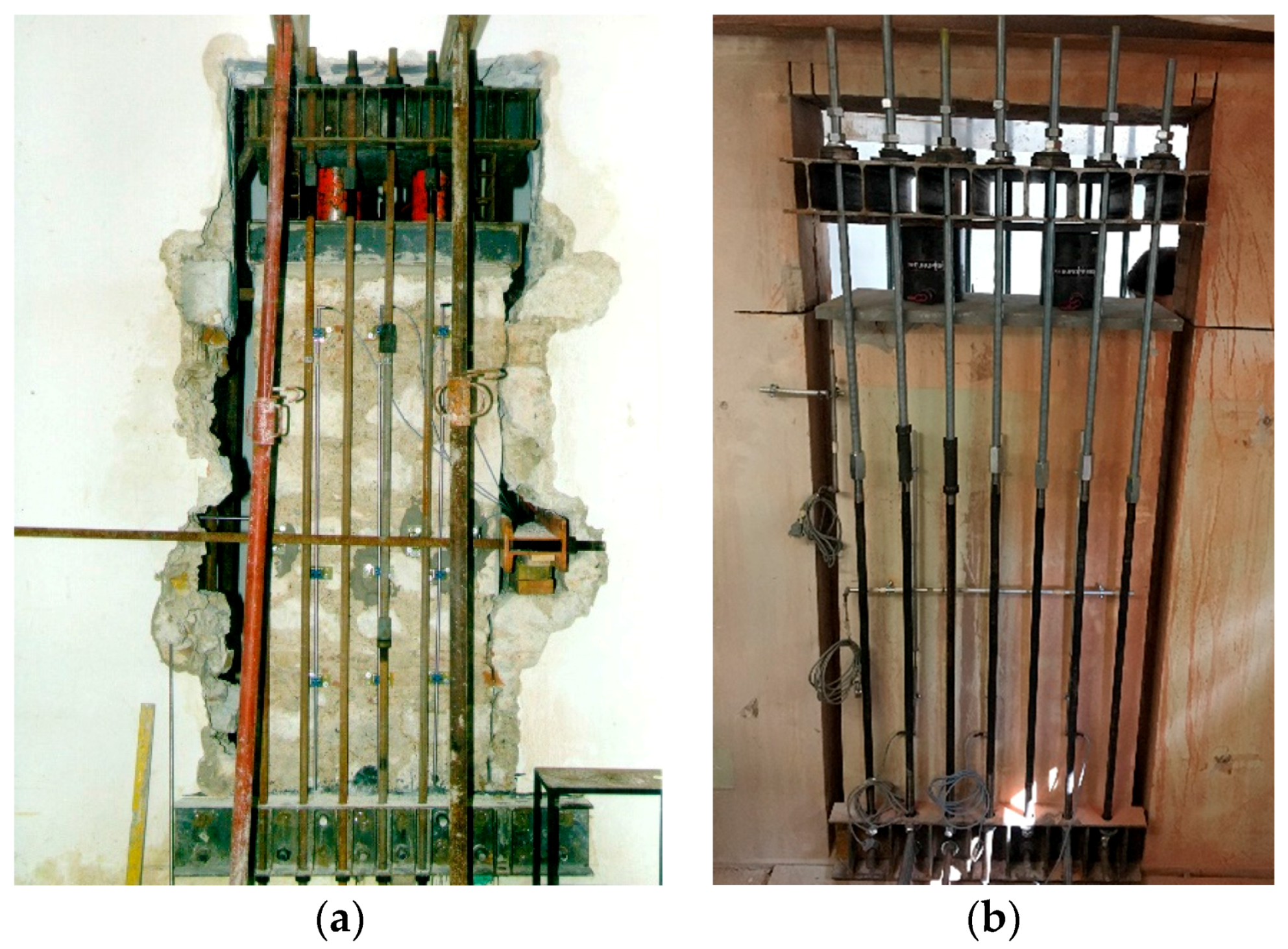

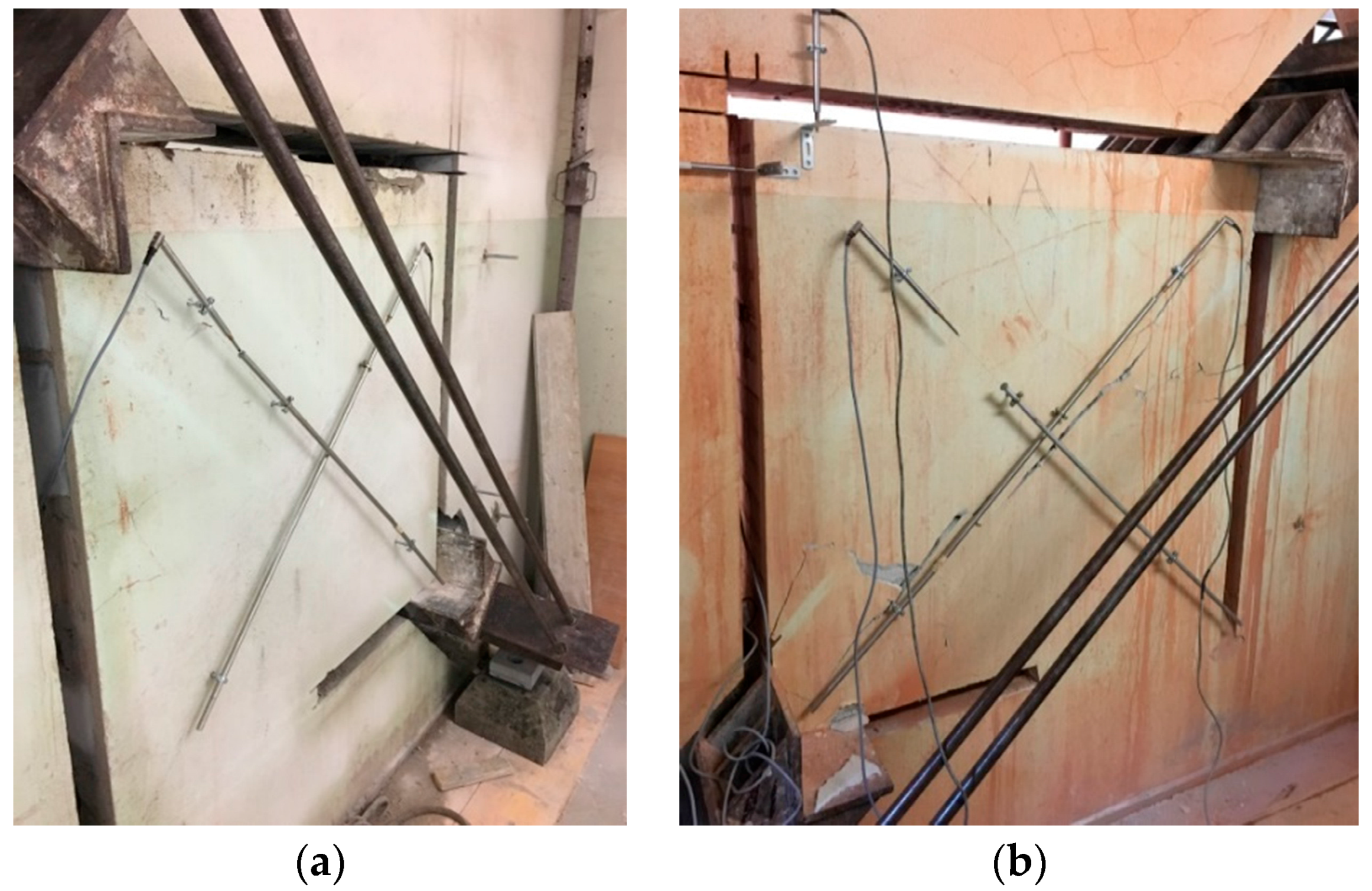

3.1. Shear Tests

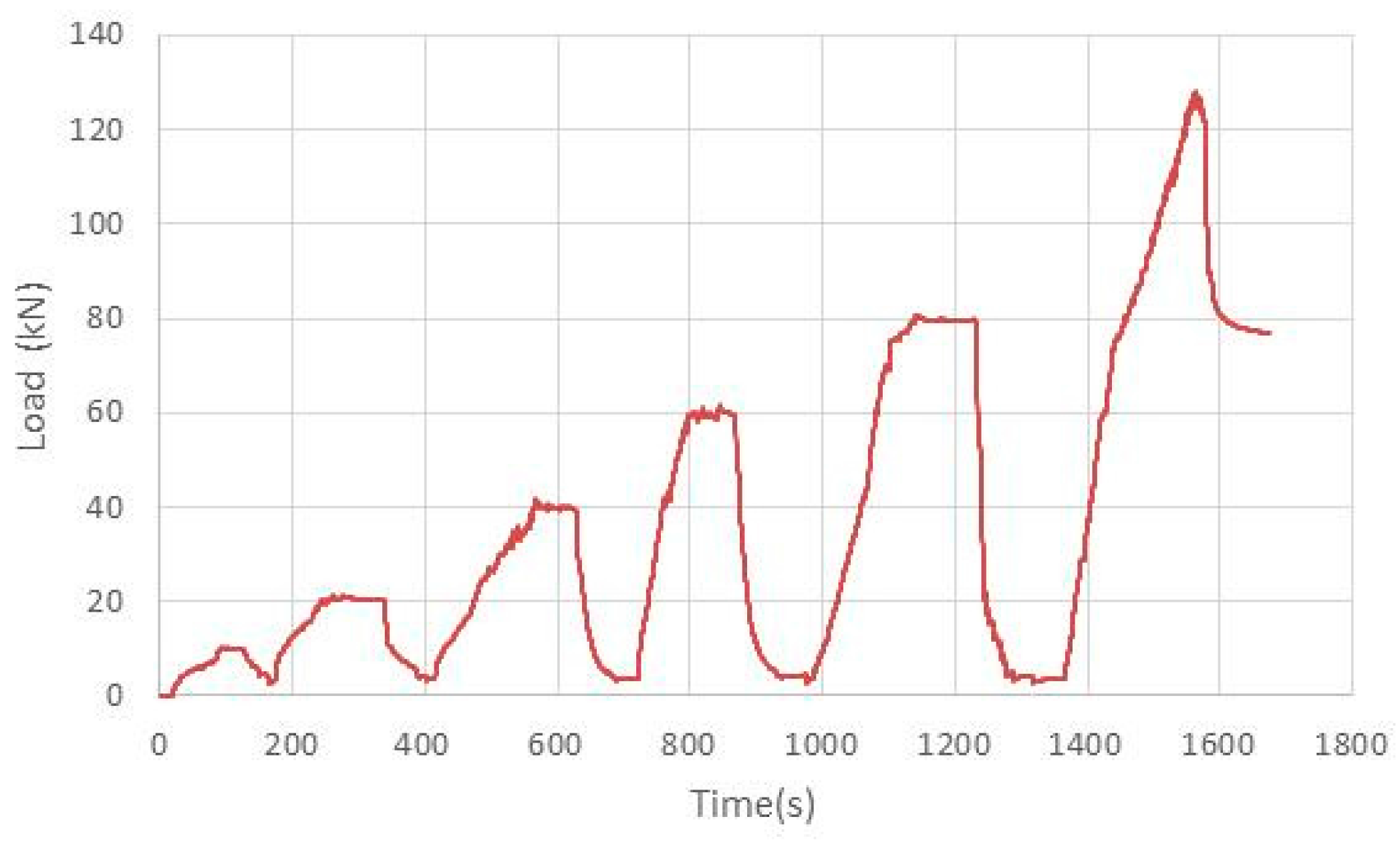

3.2. Compression Tests

3.3. Instrumentation

4. Results and Discussion

4.1. Results and Analysis of Compression Tests

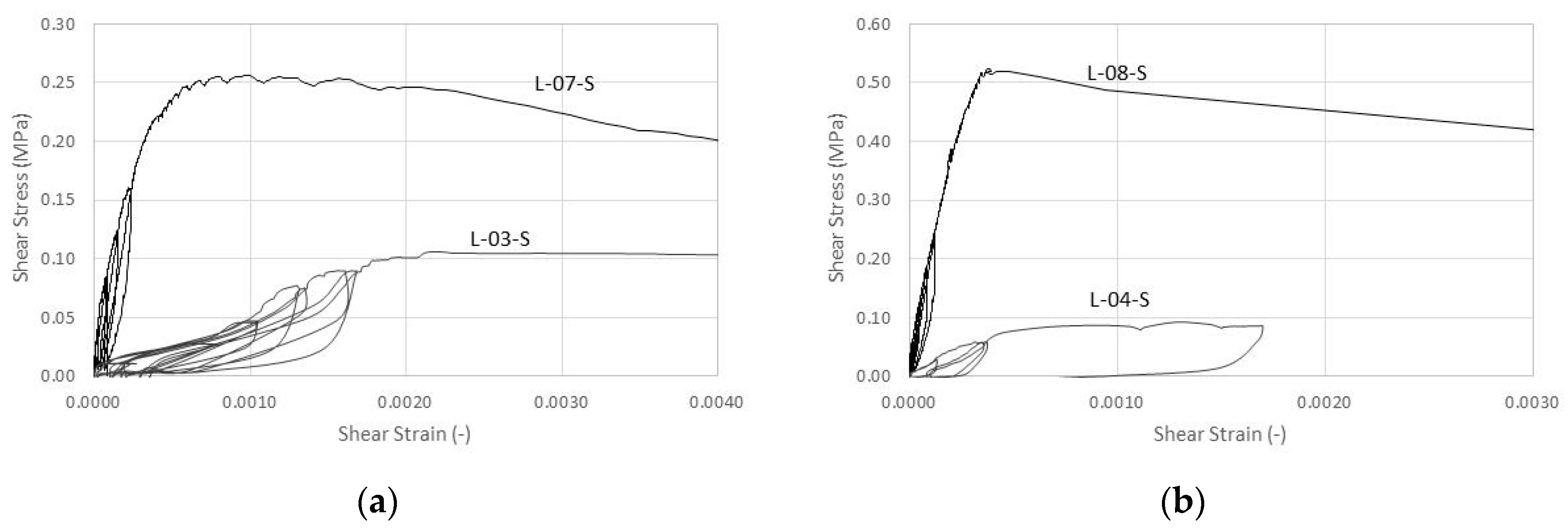

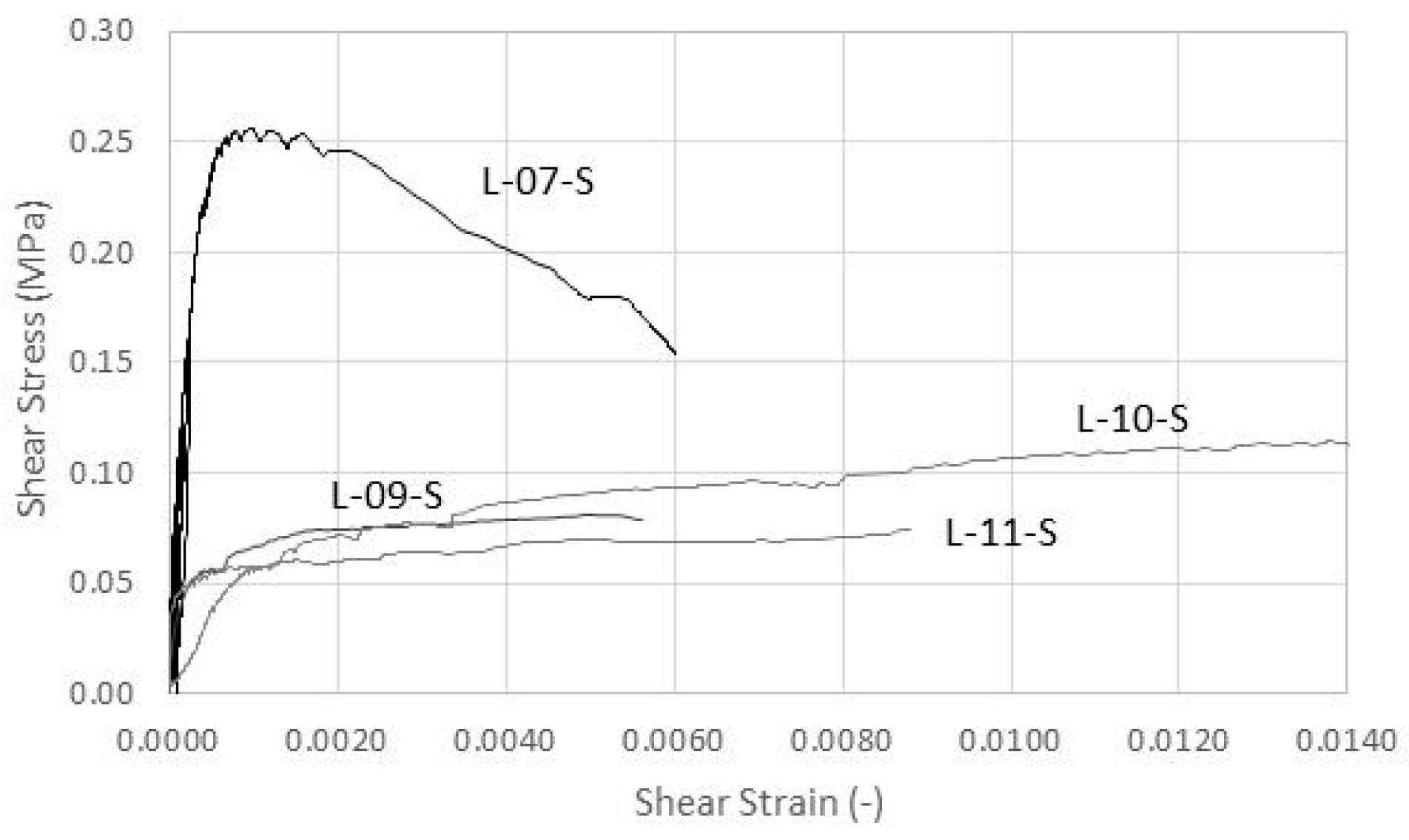

4.2. Results and Analysis of Shear Tests

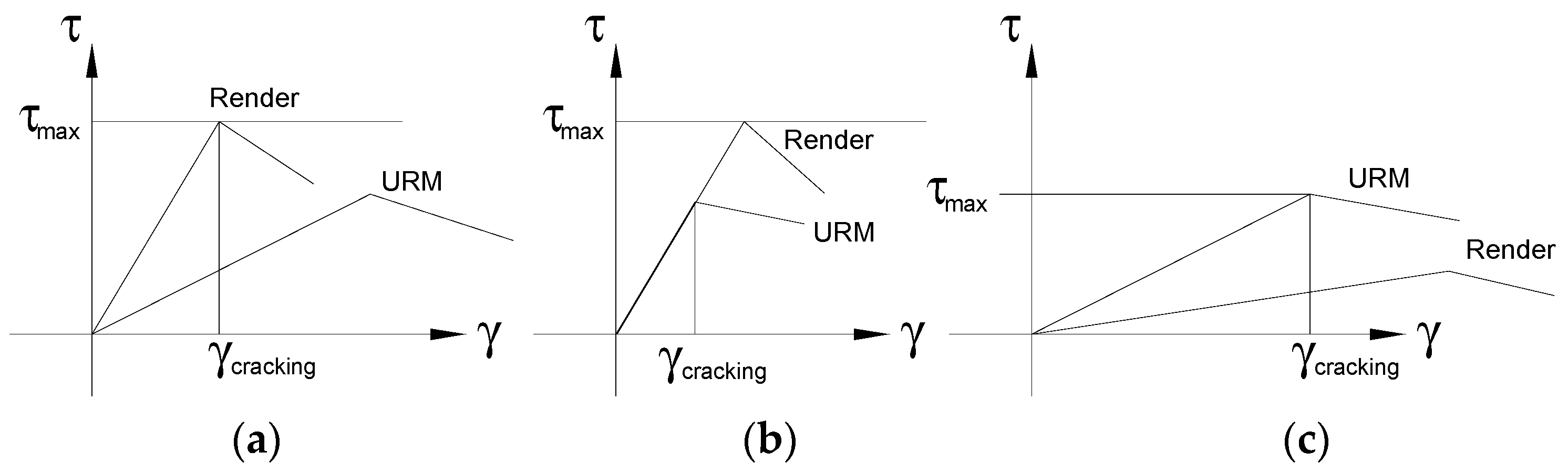

5. Design

6. Conclusions

- The lateral load-capacity and shear stiffness of historic wall panels can increase considerably as the walls are rendered with a cement-based mortar; significant shear strength and stiffness increments were observed for barely-cut (irregular) double-leaf stone and brickwork panels;

- The application of a cement-based render did not significantly alter the failure mode of the wall panels, both under shear and compressive loading;

- Limited effect was produced by the render when the wall specimens were tested in compression. For these tests, the behavior of the wall panels was governed by the bond between the masonry and the render. As cracking and debonding of the cement render occurred, the positive effect of the render, both in terms of load capacity and stiffness, became negligible;

- With regard to the shear tests, the bonding between renders and masonry substrate remained effective for the entire duration of the test. Shear failure occurred with characteristic diagonal cracks along the diagonal in compression. If maintaining the bond is critical for the performance of a wall panel, shear modulus of the render material should not be substantially different from the one of the masonry material.

- A main limitation of this study is that masonry specimens were cut from different buildings, making a direct comparison difficult, given the intrinsic variability in mechanical properties of historic masonry and the different conditions of conservation of the buildings. However, an emerging trend was noted, indicating the effects of a cement-based render applied to historic wall panels.

- Finally, more systematic tests are needed to clarify the force transfer from the masonry substrate to the render under different test configurations, and a more in-depth study should be conducted. Tests should be carried out on purposely constructed masonry specimens, having controlled and reproducible properties, to obtain more conclusive data.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Corradi, M.; Osofero, A.I.; Coventry, K.; Richardson, A.E.; Udeaja, C.; Vo, T. Analysis and classification of historic construction within the north-east of England. In Proceedings of the 16th International Conference Structural Faults & Repair-2014, London, UK, 8–10 July 2014. [Google Scholar]

- Morandi, P.; Magenes, G.; Albanesi, L. Mechanical characterization of different typologies of masonry made with thin shell/web clay units. In Proceedings of the 12th Canadian Masonry Symposium, Vancouver, BC, Canada, 2–5 June 2013. [Google Scholar]

- Mastrodicasa, S. Dissesti Statici Delle Strutture Edilizie: Diagnosi, Consolidamento, Istituzioni Teoriche; Hoepli: Milan, Italy, 1978. (In Italian) [Google Scholar]

- Magenes, G.; Penna, A.; Galasco, A.; Rota, M. Experimental characterization of stone masonry mechanical properties. In Proceedings of the 8th International Masonry Conference, Dresden, Germany, 4–7 July 2010. [Google Scholar]

- Valluzzi, M.R.; Da Porto, F.; Modena, C. Behavior and modeling of strengthened three-leaf stone masonry walls. Mater. Struct. 2004, 37, 184–192. [Google Scholar] [CrossRef]

- Binda, L.; Cardani, G.; Saisi, A. A classification of structures and masonries for the adequate choice of repair. In Proceedings of the International RILEM Workshop on Repair for Historic Masonry, Delft, The Netherlands, 26–28 January 2005. [Google Scholar]

- Giuffrè, A. Letture Sulla Meccanica Delle Murature storiche; Kappa: Rome, Italy, 1999. (In Italian) [Google Scholar]

- Benedetti, A. Interaction of shear and flexural collapse modes in the assessment of in plane capacity of masonry walls. In Proceedings of the 12th Canadian Masonry Symposium, Vancouver, BC, Canada, 2–5 June 2013. [Google Scholar]

- Cardoso, R.; Lopes, M.; Bento, R. Seismic evaluation of old masonry buildings. Part I: Method description and application to a case-study. Eng. Struct. 2005, 27, 2024–2035. [Google Scholar] [CrossRef]

- D’Ayala, D.; Speranza, E. Definition of collapse mechanisms and seismic vulnerability of historic masonry buildings. Earthq. Spe. 2003, 19, 479–509. [Google Scholar] [CrossRef]

- D’Ayala, D.F.; Paganoni, S. Assessment and analysis of damage in L’Aquila historic city centre after 6th April 2009. Bull. Earthq. Eng. 2011, 9, 81–104. [Google Scholar] [CrossRef]

- Penna, A.; Morandi, P.; Rota, M.; Manzini, C.F.; Da Porto, F.; Magenes, G. Performance of masonry buildings during the Emilia 2012 earthquake. Bull. Earthq. Eng. 2014, 12, 2255–2273. [Google Scholar] [CrossRef]

- Borri, A.; Castori, G.; Corradi, M.; Giannantoni, A.; Speranzini, E. A reinforced repointing grid for strengthening historic stone masonry walls. In Proceedings of the 8th International Masonry Conference, Dresden, Germany, 4–7 July 2010. [Google Scholar]

- Corradi, M.; Borri, A.; Vignoli, A. Seismic upgrading of masonry structures with FRP. In Proceedings of the 7th International Conference on Inspection Appraisal Repairs and Maintenance of buildings and structures, Nottingham, UK, 11–13 September 2001. [Google Scholar]

- Cattari, S.; Degli Abbati, S.; Ferretti, D.; Lagomarsino, S.; Ottonelli, D.; Tralli, A. Damage assessment of fortresses after the 2012 Emilia earthquake (Italy). Bull. Earthq. Eng. 2014, 12, 2333–2365. [Google Scholar] [CrossRef]

- Gattesco, N.; Boem, I. Experimental and analytical study to evaluate the effectiveness of an in-plane reinforcement for masonry walls using GFRP meshes. Constr. Build. Mater. 2015, 88, 94–104. [Google Scholar] [CrossRef]

- Coburn, A.; Spence, R. Earthquake Protection; Wiley and Sons: Chichester, UK, 1992. [Google Scholar]

- Lourenço, P.B.; Mendesa, N.; Ramosa, L.F.; Oliveira, D.V. Analysis of masonry structures without box behavior. Int. J. Arch. Herit. 2011, 5, 369–382. [Google Scholar] [CrossRef] [Green Version]

- Galati, N.; Tumialan, G.; Nanni, A. Strengthening with FRP bars of URM walls subject to out-of-plane loads. Constr. Build. Mater. 2006, 20, 101–110. [Google Scholar] [CrossRef]

- Vintzileou, E.; Miltiadou-Fezans, A. Mechanical properties of three-leaf stone masonry grouted with ternary or hydraulic lime-based grouts. Eng. Struct. 2008, 30, 2265–2276. [Google Scholar] [CrossRef]

- Borri, A.; Castori, G.; Corradi, M. Shear behavior of unreinforced and reinforced masonry panels subjected to in-situ diagonal compression tests. Int. J. Arch. Herit. 2014, 9, 913–927. [Google Scholar] [CrossRef]

- Corradi, M.; Tedeschi, C.; Binda, L.; Borri, A. Experimental evaluation of shear and compression strength of masonry wall before and after reinforcement: Deep repointing. Constr. Build. Mater. 2008, 22, 463–472. [Google Scholar] [CrossRef]

- Corradi, M.; Borri, A.; Vignoli, A. Experimental evaluation of in-plane shear behavior of masonry walls retrofitted using conventional and innovative methods. Mason. Int. 2008, 21, 29–42. [Google Scholar]

- Stratford, T.; Pascale, G.; Manfroni, O.; Bonfiglioli, B. Shear strengthening masonry panels with sheet glass–fiber reinforced polymer. J. Compos. Constr. 2004, 8, 434–443. [Google Scholar] [CrossRef]

- Marcari, G.; Manfredi, G.; Prota, A.; Pecce, M. In-plane shear performance of masonry panels strengthened with FRP. Compos. Part B 2007, 38, 887–901. [Google Scholar] [CrossRef]

- El Gawady, M.A.; Lestuzzi, P.; Badoux, M. Static cyclic response of masonry walls retrofitted with fiber-reinforced polymers. J. Compos. Constr. 2007, 11, 50–61. [Google Scholar] [CrossRef]

- Roca, P.; Araiza, G. Shear response of brick masonry small assemblages strengthened with bonded FRP laminates for in-plane reinforcement. Constr. Build. Mater. 2010, 24, 1372–1384. [Google Scholar] [CrossRef]

- Foti, D.; Vacca, S. Mechanical behavior of concrete columns reinforced with rheoplastic mortar. Mater. Constr. 2013, 63, 267–282. [Google Scholar] [CrossRef]

- Ivorra, S.; Bru, D.; Galvan, A.; Silvestri, S.; Apera, C.; Foti, D. TRM Reinforcement of masonry specimens for seismic areas. Int. J. Saf. Secur. Eng. 2017, 7, 463–474. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education Limited: Harlow, UK, 2011. [Google Scholar]

- Borri, A.; Corradi, M.; Castori, G.; De Maria, A. A method for the analysis and classification of historic masonry. Bull. Earthq. Eng. 2015, 13, 1–19. [Google Scholar] [CrossRef]

- British Standard BS EN 12504-2. Testing Concrete in Structures. Non-Destructive Testing. Determination of Rebound Number. 2012. Available online: https://shop.bsigroup.com/ (accessed on 11 August 2016).

- Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. 1992. Available online: https://landingpage.bsigroup.com/LandingPage/Undated?UPI=000000000030286962 (accessed on 11 January 2018).

- American Society for Testing and Materials (ASTM). E519 Standard Test Method for Diagonal Tension (Shear) in Masonry Assemblages. In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- RILEM TC. 76-LUM. Diagonal tensile strength tests of small wall specimens. In RILEM, Recommendations for the Testing and Use of Constructions Materials; E&FN SPON: London, UK, 1994; pp. 488–489. [Google Scholar]

- Turnšek, V.; Čačovič, F. Some experimental results on the strength of brick masonry walls. In Proceedings of the 2nd International brick Masonry Conference, Stoke-on-Trent, UK, 12–15 April 1970. [Google Scholar]

- Italian Ministry of Infrastructures and Transportation. Istruzioni per L’applicazione Delle «Nuove Norme Tecniche per le Costruzioni» di Cui al Decreto Ministeriale 14 Gennaio 2008; Italian Building Code, Circ. 02.02.2009, n. 617; Italian Ministry of Infrastructures and Transportation: Rome, Italy, 2009. (In Italian)

- Benedetti, D.; Benzoni, G.M. Esperienze a taglio su pannelli in tufo. Ingegneria Sismica 1985, 2, 15–24. [Google Scholar]

| Code | Test Type | Walling Material | Render | Code | Test Type | Walling Material | Render |

|---|---|---|---|---|---|---|---|

| C-01-S | Compression | Stone | No | L-07-S | Shear | Stone | Yes |

| C-02-B | Compression | Brick | No | L-08-B | Shear | Brick | Yes |

| L-03-S | Shear | Stone | No | L-09-S | Shear | Stone | No |

| L-04-B | Shear | Brick | No | L-10-S | Shear | Stone | No |

| C-05-S | Compression | Stone | Yes | L-11-S | Shear | Stone | No |

| C-06-B | Compression | Brick | Yes | L-12-S | Shear | Stone | No |

| Code | Load-Capacity Fmax (kN) | No. of Cycles | Compressive Strength σ0 (MPa) | E0.33 (MPa) | Eu (MPa) | Strain at σ0 (−) | Residual Strength at εv,max (MPa) |

|---|---|---|---|---|---|---|---|

| C-01-S | 343.35 | 4 | 0.796 | 933 | 488 | 0.00158 | 0.792 |

| C-02-B | 496.77 | 6 | 1.84 | 1554 | 395 | 0.00451 | 1.81 |

| C-05-S * | 408.04 | 4 | 0.830 | 989 | 534 | 0.00146 | 0.781 |

| C-06-B * | 538.21 | 7 | 2.14 | 1888 | 488 | 0.00424 | 1.96 |

| Masonry Typology | Compressive Strength σ0 (MPa) | Shear Strength τ0 (MPa) | Young’s Modulus E (MPa) | Shear Modulus G (MPa) |

|---|---|---|---|---|

| min–max | min–max | min–max | min–max | |

| Stone masonry (pebbles, irregular stone) | 1.0–1.8 | 0.020–0.032 | 690–1050 | 230–350 |

| Barely cut stone masonry with infill core | 2.0–3.0 | 0.035–0.051 | 1020–1440 | 340–480 |

| Properly dressed stone masonry | 2.6–3.8 | 0.056–0.074 | 1500–1980 | 500–660 |

| Soft stone masonry (tuff, limestone, etc.) | 1.4–2.4 | 0.028–0.042 | 900–1260 | 300–420 |

| Perfectly cut stone masonry | 6.0–8.0 | 0.090–0.120 | 2400–3200 | 780–940 |

| Solid brick masonry with lime mortar | 2.4–4.0 | 0.060–0.090 | 1200–1800 | 400–600 |

| Clay hollow brick with cement mortar | 5.0–8.0 | 0.240–0.320 | 3500–5600 | 875–1400 |

| Code | Load-Capacity Pmax (kN) | Shear Strength τ0 (MPa) | G0.33 (MPa) | Gu (MPa) | Strain γ at τ0 (−) | Residual Strength at γmax (MPa) |

|---|---|---|---|---|---|---|

| L-03-S | 58.81 | 0.0337 | 44.8 | 48.0 | 0.00221 | 0.0254 |

| L-04-B | 34.31 | 0.0317 | 248 | 38.8 | 0.00240 | 0.0263 |

| L-07-S * | 127.92 | 0.0813 | 940 | 317 | 0.000772 | 0.0514 |

| L-08-B * | 172.47 | 0.1655 | 1986 | 1329 | 0.000375 | 0.0257 |

| L-09-S | 43.55 | 0.0257 | 411 | 16.5 | 0.00494 | 0.0244 |

| L-10-S | 60.74 | 0.0363 | 75.9 | 8.31 | 0.01373 | 0.0356 |

| L-11-S | 39.02 | 0.0236 | n.a. | 8.44 | 0.00869 | 0.0233 |

| L-12-S | 61.71 | 0.0220 | n.a. | 9.24 | 0.00941 | 0.0217 |

| Code | Experimental Load-Capacity Pmax (kN) | Theoretical Wall Pwall (kN) | Theoretical Render Prender (kN) | Theoretical Pmax (kN) |

|---|---|---|---|---|

| L-07-S | 127.92 | 49.01 | 100.47 | 149.49 |

| L-08-B | 172.47 | 28.59 | 129.06 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corradi, M.; Sisti, R.; Borri, A. Effect of Thin Cement-Based Renders on the Structural Response of Masonry Wall Panels. Appl. Sci. 2018, 8, 98. https://doi.org/10.3390/app8010098

Corradi M, Sisti R, Borri A. Effect of Thin Cement-Based Renders on the Structural Response of Masonry Wall Panels. Applied Sciences. 2018; 8(1):98. https://doi.org/10.3390/app8010098

Chicago/Turabian StyleCorradi, Marco, Romina Sisti, and Antonio Borri. 2018. "Effect of Thin Cement-Based Renders on the Structural Response of Masonry Wall Panels" Applied Sciences 8, no. 1: 98. https://doi.org/10.3390/app8010098