Review and Perspectives of Aurivillius Structures as a Lead-Free Piezoelectric System

Abstract

:1. Overview

- -

- Oxygen octahedral in the a-axis.

- -

- Relative displacements in the opposite direction to B cations of the perovskite with respect to the octahedral.

- -

- Displacement through the a-axis of the oxygen ions of the Bi-O layer.

2. Processing of Ceramics with Aurivillius Type Structure

- (a)

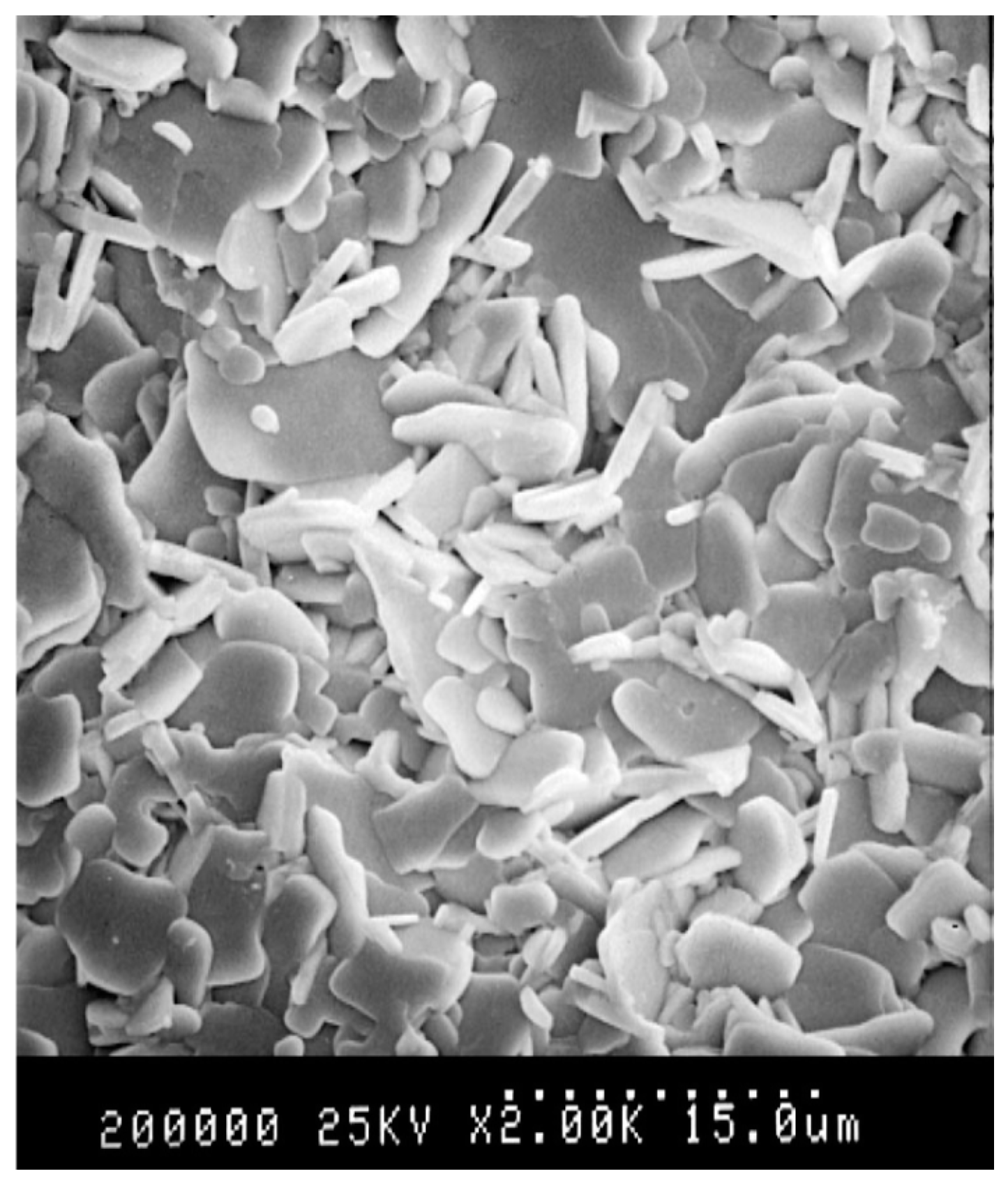

- Hydrothermal synthesis. In this technique, the combination of temperature and high pressure produced by water solutions in an autoclave allows the synthesis of materials with special characteristics in terms of small grain sizes (even in the nanometer scale) and particular and controlled shapes. The application to Aurivillius structure materials synthesis has been deeply explored in several works. Depending on variables such as time or temperature (<300 °C) [7], use of different mineralizers and concentrations [8] or starting materials [9], single phase materials with different sizes and shapes from the nanometric to micrometric scale can be synthesized. They give place to ceramics with relatively high densities, as shown in Figure 2 [10] with good ferro/piezoelectric properties [7,11].

- (b)

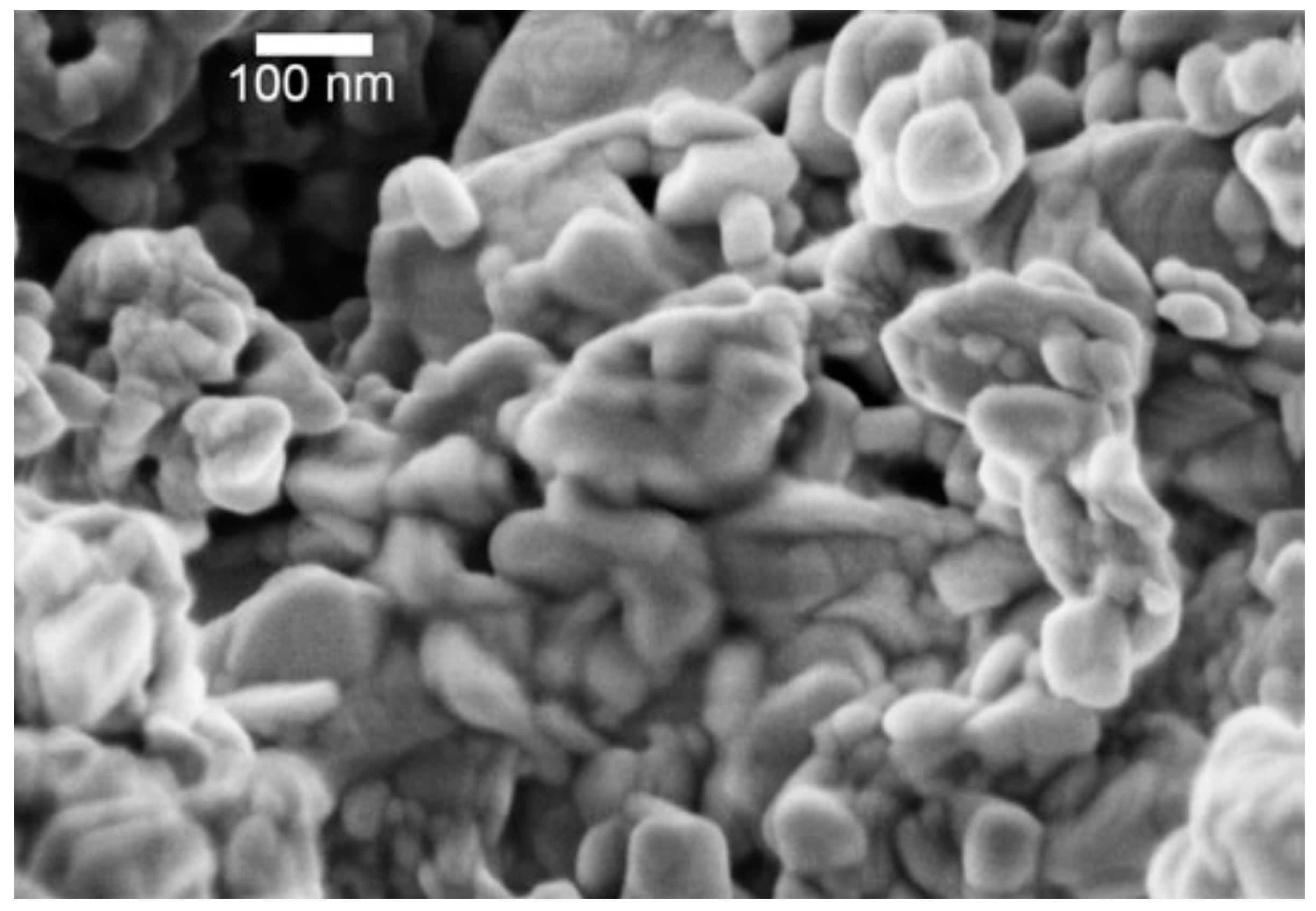

- Sol-gel. In this process, the solution evolves gradually through hydrolysis and polycondensation reactions towards the formation of a gel-like network to form a colloid. The mixture at practically atomic level favors the reaction to synthesize precursors at low temperatures, allowing the control of particle size and shape. Thus, different compositions with Aurivillius-type structure were synthesized, at temperatures that can range from 525 to 700 °C [12,13,14,15,16] to have particles in the nanometric scale, as shown in Figure 3. Dense ceramics with high remnant polarization (24.15 μC/cm2) values can be achieved by this route in Bi4Ti3O12 based ceramics [17].

- (c)

- Coprecipitation. This is a synthesis route from a solution, in which the addition of a precipitant agent or the solvent evaporation reduces the solubility of the precursors, causing their precipitation. It allows a mixture of the components at low scale, favoring their reactivity in the calcination steps. Single phase materials are obtained at temperatures ranging from 700–800 °C, to have particles with sizes at the nanometric scale [18,19,20,21]. Ceramics with high densities (>97%) can be accomplished at low temperature (875 °C) by sintering ceramic precursors obtained by this route [18].

- (d)

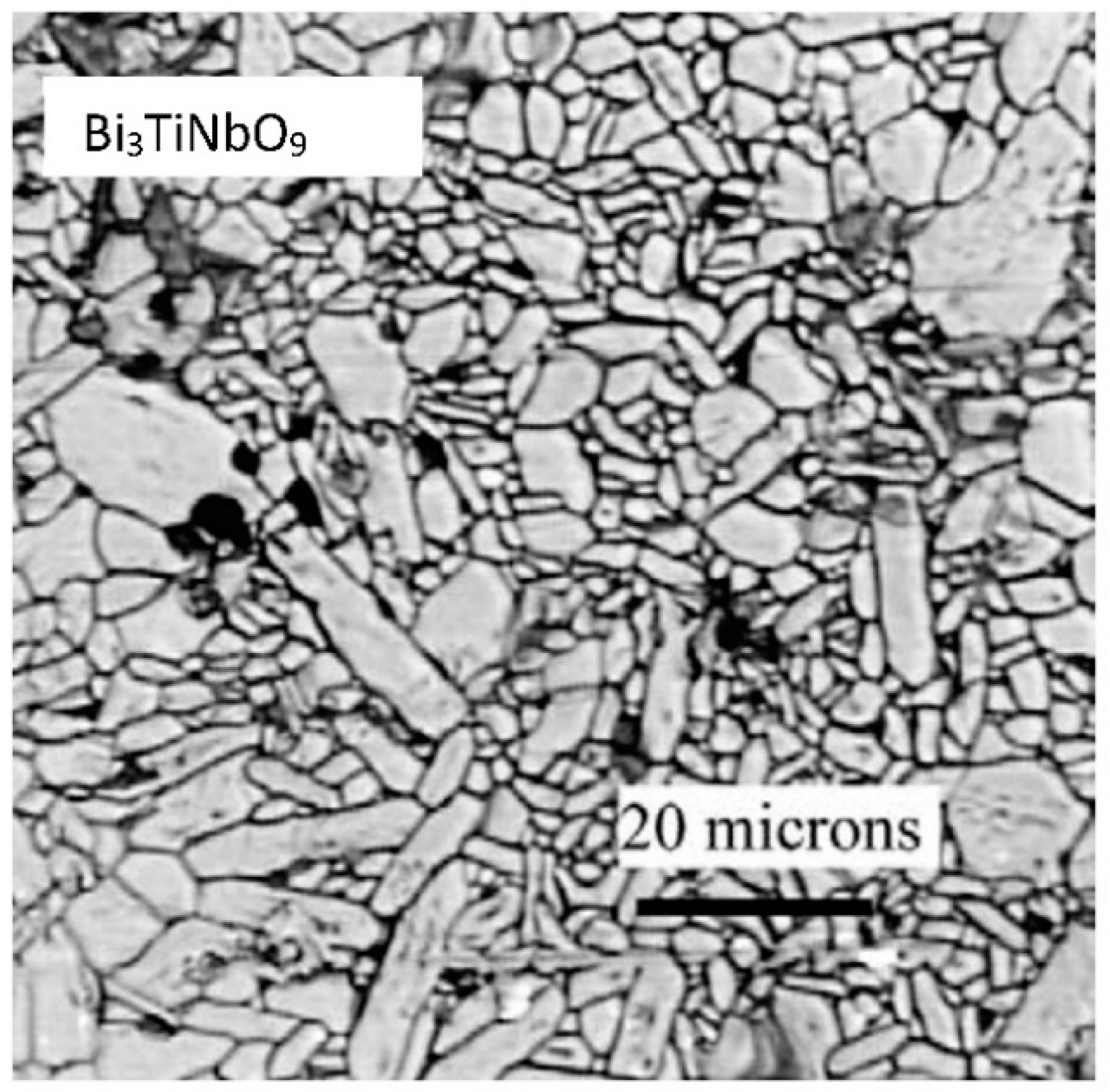

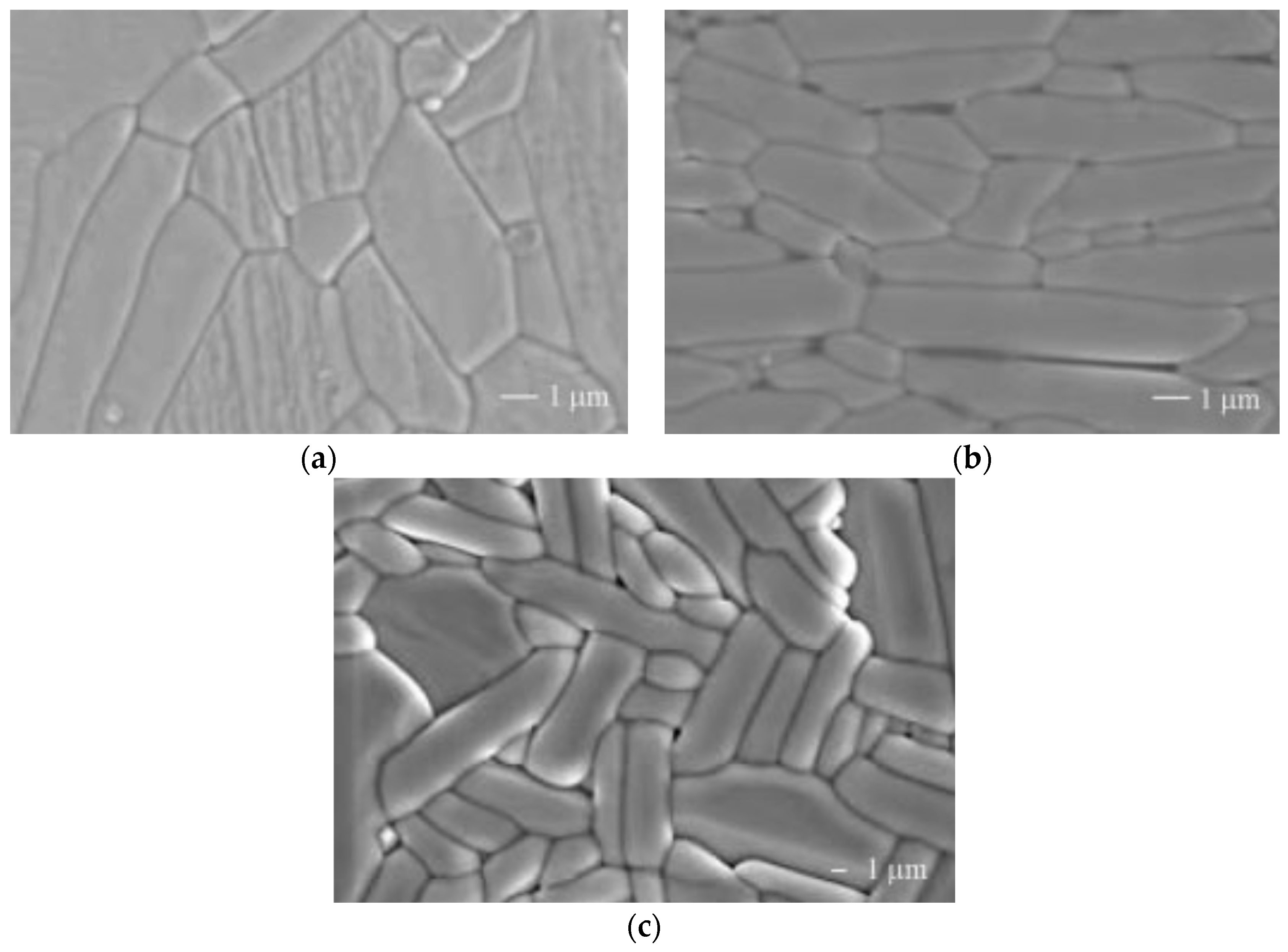

- Mechanochemical activation/mechanosynthesis. High energy milling produces synthesis reactions (mechanosynthesis) or changes in the size and reactivity of the precursors (mechanochemical activation) that allow the reduction of the processing temperatures. It is accomplished by the high number of defects produced by the milling. Some Aurivillius compositions have been mechanosynthesized, mainly in planetary mills. Thus, Bi4Ti3O12 has been obtained after 15 h of milling [22], CaBi4Ti4O15 after 30 h [23], or SrBi4Ti4O15 after 20 h [24]. In other cases, the synthesis temperature is decreased by obtaining an amorphous powder after milling [25,26,27]. The high reactivity of the precursors allows sintering of ceramics with low porosity at relatively low temperatures. A further increase in density can be achieved by hot pressing or by processes of recrystallization after hot pressing [28] that allows the control of the microstructure and texture (Figure 4).

- (e)

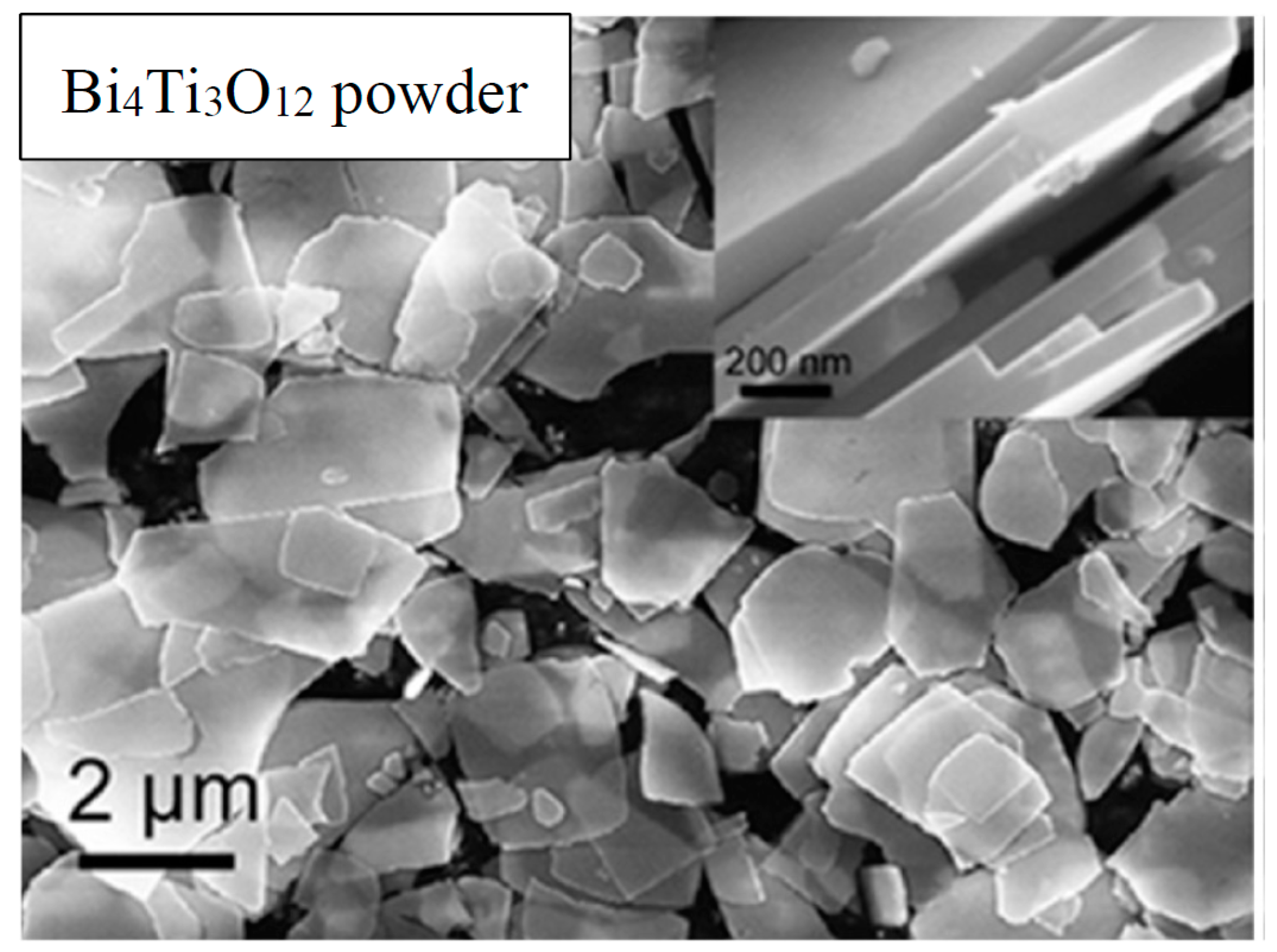

- Molten salt synthesis. It is based on the use of a molten salt mixed to the starting oxide/carbonates precursors to favor the dissolution-precipitation processes assisted by liquid phases. Final products are obtained at lower temperatures than by the classical ceramic route. The most commonly used salts are NaCl, KCl, Na2SO4, K2SO4 and a mixture of them at eutectic points that reduce the melting temperature. Depending on the used flux and the precursors, the synthesis conditions can vary. Thus, mixing salts with precursors obtained by hydrolysis or coprecipitation, instead of oxides and carbonates, Bi4Ti3O12 and Bi3TiNbO9 can be obtained at 600 and 700 °C, respectively [29,30]. When oxides and carbonates are used, higher temperatures (800–1100 °C) are usually needed to synthesize Aurivillius-type powders with different compositions [31,32,33]. These high temperatures favor the growth of large plate-like particles that facilitates the processing of textured ceramics as will be explained later. The use of eutectic KCl/NaCl mixtures allows the reduction of synthesis temperatures (800 °C–2 h) [34] leading to small particles as the ones observed in Figure 5 that improve the Bi4Ti3O12 photocatalytic activities.

- (f)

- Microwave assisted synthesis. With the application of microwaves at high frequency, the associated electromagnetic fields will heat materials with high dielectric losses. Alternatively, the heating of susceptors with high microwave absorption can be achieved. The main characteristic for this process is the high heating rate and short times that inhibit grain growth. The synthesis of BiGdWO6, BiYWO6 or Bi4Ti3O12 in only 10 min has been reported [35,36]. Temperatures of 900–1100 °C have been measured in those articles. This technique is also used in combination with other routes previously described, as molten salts or hydrothermal [37,38] to further improve the synthesis of Aurivillius precursors.

2.1. Texture

2.2. Doping Strategies

3. Thin Films

4. Applications

4.1. High Temperature Piezoelectricity

4.2. Multiferroism

4.3. Photocatalytic

5. Perspectives of Aurivillius Materials as Lead Free Piezoelectrics

Acknowledgments

Conflicts of Interest

References

- Aurivillius, B. Mixed bismuth oxides with layer lattices. Arkiv Kemi 1949, 1, 463–480. [Google Scholar]

- Fukunaga, M.; Takesada, M.; Onodera, A. Ferroelectricity in layered perovskites as a model of ultra-thin films. World J. Condens. Matter Phys. 2016, 6, 224–243. [Google Scholar] [CrossRef]

- Rae, A.D.; Thompson, J.G.; Withers, R.L. Structure refinement of commensurately modulated bismuth tungstate, Bi2WO6. Acta Cryst. 1991, B47, 870. [Google Scholar] [CrossRef]

- Thompson, J.G.; Rae, A.D.; Withers, R.L.; Craig, D.C. Revised structure of Bi3TiNbO9. Acta Cryst. 1991, B46, 174–180. [Google Scholar] [CrossRef]

- Rae, A.D.; Thompson, J.G.; Withers, R.L. Structure refinement of commensurately modulated bismuth titanate, Bi4Ti3O12. J. Solid State Chem. 1991, 94, 474–487. [Google Scholar] [CrossRef]

- Pardo, L.; Castro, A.; Millán, P.; Alemany, C.; Jiménez, R.; Jiménez, B. (Bi3TiNbO9)x(SrBi2Nb2O9)1−x Aurivillius type structure piezoelectric ceramics obtained from mechanochemically activated oxides. Acta Mater. 2000, 48, 2421–2428. [Google Scholar] [CrossRef]

- Xu, G.; Yang, Y.; Bai, H.; Wang, J.; Tian, H.; Zhao, R.; Wei, X.; Yanga, X.; Han, G. Hydrothermal synthesis and formation mechanism of the single-crystalline Bi4Ti3O12 nanosheets with dominant (010) facets. Cryst. Eng. Commun. 2016, 18, 2268–2274. [Google Scholar] [CrossRef]

- Wang, F.; Wang, J.; Zhong, X.; Li, B.; Liu, J.; Wu, D.; Mo, D.; Guo, D.; Yuan, S.; Zhang, K.; et al. Shape-controlled hydrothermal synthesis of ferroelectric Bi4Ti3O12 nanostructures. Cryst. Eng. Commun. 2013, 15, 1397–1403. [Google Scholar] [CrossRef]

- Yang, Q.; Li, Y.; Yin, Q.; Wang, P.; Cheng, Y.B. Bi4Ti3O12 nanoparticles prepared by hydrothermal synthesis. J. Eur. Ceram. Soc. 2003, 23, 161–166. [Google Scholar] [CrossRef]

- Shi, Y.; Cao, C.; Feng, S. Hydrothermal synthesis and characterization of Bi4Ti3O12. Mater. Lett. 2000, 46, 270–273. [Google Scholar] [CrossRef]

- Li, X.; Ju, Z.; Li, F.; Huang, Y.; Xie, Y.; Fu, Z.; Knized, R.J.; Lu, Y. Visible light responsive Bi7Fe3Ti3O21 nanoshelf photocatalysts with ferroelectricity and ferromagnetism. J. Mater. Chem. A 2014, 2, 13366–13372. [Google Scholar] [CrossRef]

- Xie, D.; Pan, W. Study on BaBi4Ti4O15 nanoscaled powders prepared by sol–gel method. Mater. Lett. 2003, 57, 2970–2974. [Google Scholar] [CrossRef]

- Wisedsri, R.; Chaisuwan, T.; Wongkasemjit, S. Simple route to bismuth titanate from bismuth glycolate precursor via sol–gel process. Mater. Res. Innov. 2013, 17, 43–48. [Google Scholar] [CrossRef]

- Koch, R.J.; Lokuhewa, I.N.; Shi, J.; Haluska, M.S.; Misture, S.T. Chemical synthesis of nanoscale Aurivillius ceramics, Bi2A2TiM2O12 (A=Ca, Sr, Ba and M=Nb, Ta). J. Sol. Gel. Sci. Technol. 2012, 64, 612–618. [Google Scholar] [CrossRef]

- Babooram, K.; Chin, D.K.; Ye, Z.-G. Ferroelectric Bi4Ti3O12 and Bi4−xLaxTi3O12 ceramics prepared by a new sol-gel route. J. Electroceram. 2008, 21, 43–48. [Google Scholar] [CrossRef]

- Hardy, A.; Mondelaers, D.; Van Bael, M.K.; Mullens, J.; Van Poucke, L.C.; Vanhoyland, G.; D’Haen, J. Synthesis of (Bi, La)4Ti3O12 by a new aqueous solution-gel route. J. Eur. Ceram. Soc. 2004, 24, 905–909. [Google Scholar] [CrossRef]

- Shi, M.; Shi, Y.; Zuo, R.; Xu, Y.; Peng, X.; Li, D.; Xie, L. Microstructure, ferroelectric and dielectric proprieties of Bi4Ti3O12 materials prepared by two methods. J. Mater. Sci. Mater. Electron. 2016, 27, 3361–3367. [Google Scholar] [CrossRef]

- Villegas, M.; Moure, C.; Fernandez, J.F.; Duran, P. Low-temperature sintering of submicronic randomly oriented Bi4Ti3O12 materials. Ceram. Int. 1996, 22, 15–22. [Google Scholar] [CrossRef]

- Lisoni, J.G.; Millán, P.; Vila, E.; Martín de Vidales, J.L.; Hoffmann, T.; Castro, A. Synthesis of ferroelectric Bi4Ti3O12 by alternative routes: Wet no-coprecipitation chemistry and mechanochemical activation. Chem. Mater. 2001, 13, 2084–2091. [Google Scholar] [CrossRef]

- Du, Y.; Fang, J.; Zhang, M.; Hong, J.; Yin, Z.; Zhang, Q. Phase character and structural anomaly of Bi4Ti3O12 nanoparticles prepared by chemical coprecipitation. Mater. Lett. 2002, 57, 802–806. [Google Scholar] [CrossRef]

- Chen, Z.-H.; Qiu, J.-F.; Liu, C.; Ding, J.-N.; Zhu, Y.-Y. Preparation of Bi4Ti3O12 nanopower by azeotropic co-precipitation and dielectric properties of the sintered ceramic. Ceram. Int. 2010, 36, 241–244. [Google Scholar]

- Kong, L.B.; Ma, J.; Zhu, W.; Tan, O.K. Preparation of Bi4Ti3O12 ceramics via a high-energy ball milling process. Mater. Lett. 2001, 51, 108. [Google Scholar] [CrossRef]

- Sim, M.H.; Xue, J.M.; Wang, J. Layer structured calcium bismuth titanate by mechanical activation. Mater. Lett. 2004, 58, 2032–2036. [Google Scholar] [CrossRef]

- Ng, S.H.; Xue, J.M.; Wang, J. High temperature piezoelectric strontium bismuth titanate from mechanical activation of mixed oxides. Mater. Chem. Phys. 2002, 75, 131–135. [Google Scholar] [CrossRef]

- Moure, A.; Pardo, L.; Alemany, C.; Millán, P.; Castro, A. Piezoelectric ceramics based on Bi3TiNbO9 from mechanochemically activated precursors. J. Eur. Ceram. Soc. 2001, 21, 1399–1402. [Google Scholar] [CrossRef]

- Ferrer, P.; Iglesias, J.E.; Castro, A. Synthesis of the Aurivillius phase SrBi4Ti4O15 by a mechanochemical activation route. Chem. Mater. 2004, 16, 1323–1329. [Google Scholar] [CrossRef]

- Berbenni, V.; Milanese, C.; Bruni, G.; Girella, A.; Marini, A. Synthesis of Bi4Ti3O12 by high energy milling of Bi2O3–TiO2 (anatase) mixtures. J. Therm. Anal. Calorim. 2016, 126, 1507. [Google Scholar] [CrossRef]

- Moure, A.; Castro, A.; Pardo, L. Improvement by recrystallisation of Aurivillius-type structure piezoceramics from mechanically activated precursors. Acta Mater. 2004, 52, 945–957. [Google Scholar] [CrossRef]

- Kan, Y.; Jin, X.; Wang, P.; Li, Y.; Cheng, Y.B.; Yan, D. Anisotropic grain growth of Bi4Ti3O12 in molten salt fluxes. Mater. Res. Bull. 2003, 38, 567–576. [Google Scholar] [CrossRef]

- Xiang, P.H.; Kinemuchi, Y.; Watari, K. Synthesis of layer-structured ferroelectric Bi3NbTiO9 plate-like seed crystals. Mater. Let. 2005, 59, 1876–1879. [Google Scholar] [CrossRef]

- Porob, D.G.; Maggard, P.A. Synthesis of textured Bi5Ti3FeO15 and LaBi4Ti3FeO15 ferroelectric layered Aurivillius phases by molten-salt flux methods. Mater. Res. Bull. 2006, 41, 1513–1519. [Google Scholar] [CrossRef]

- Tang, Q.Y.; Kan, Y.M.; Wang, P.L.; Li, Y.G.; Zhang, G.J. Nd/V Co-Doped Bi4Ti3O12 powder prepared by molten salt synthesis. J. Am. Ceram. Soc. 2007, 90, 3353–3356. [Google Scholar] [CrossRef]

- Chang, Y.; Wu, J.; Yang, B.; Zhang, S.; Lv, T.; Cao, W. Synthesis and properties of high aspect ratio SrBi4Ti4O15 microplatelets. Mater. Lett. 2014, 129, 126–129. [Google Scholar] [CrossRef]

- He, H.; Yin, J.; Li, Y.; Zhang, Y.; Qiu, H.; Xu, J.; Xu, T.; Wang, C. Size controllable synthesis of single-crystal ferroelectric Bi4Ti3O12 nanosheet dominated with {0 0 1} facets toward enhanced visible-light-driven photocatalytic activities. Appl. Catal. B 2014, 156–157, 35–43. [Google Scholar] [CrossRef]

- Kumar, S.; Panneerselvam, M.; Vinatier, P.; Rao, K.J. Microwave synthesis and sintering of Bi4Ti3O12, the Aurivillius compound: Structural and chemical effects of attempted lithiation. Ferroelectrics 2004, 306, 165–177. [Google Scholar] [CrossRef]

- Rocha, G.N.; Melo, L.F.L.; Castro, M.C., Jr.; Ayala, A.P.; de Menezes, A.S.; Fechine, P.B.A. Structural characterization of bismuth rare earth tungstates obtained by fast microwave-assisted solid-state synthesis. Mater. Chem. Phys. 2013, 139, 494–499. [Google Scholar] [CrossRef]

- Hao, H.; Liu, H.; Liu, Y.; Cao, M.; Ouyang, S. Lead-Free SrBi4Ti4O15 and Bi4Ti3O12 material fabrication using the microwave-assisted molten salt synthesis method. J. Am. Ceram. Soc. 2007, 90, 1659–1662. [Google Scholar] [CrossRef]

- Thomazini, D.; Gelfuso, M.V.; Eiras, J.A. Microwave assisted hydrothermal synthesis of Bi4Ti3O12 nanopowders from oxide as raw materials. Powder Technol. 2012, 222, 139–142. [Google Scholar] [CrossRef]

- Takenaka, T.; Sakata, K. Grain orientation and electrical properties of hot-forged Bi4Ti3O12 ceramics. Jpn. J. Appl. Phys. 1980, 19, 31. [Google Scholar] [CrossRef]

- Igarashi, H.; Matsunaga, J.; Taniai, T.; Okazaki, K. Dielectric and piezoelectric properties of grain-oriented PbBi2Nb2O9 ceramics. Am. Ceram. Soc. Bull. 1978, 57, 815. [Google Scholar]

- Adamczyk, M.; Kozielski, L.; Pawełczyk, M. Effect of hot pressing on processing and properties of BBN ceramics. Ceram. Int. 2008, 34, 1617. [Google Scholar] [CrossRef]

- Chen, H.; Shen, B.; Xu, J.; Kong, L.; Zhai, J. Correlation between grain sizes and electrical properties of CaBi2Nb2O9 piezoelectric ceramics. J. Am. Ceram. Soc. 2012, 95, 3514–3518. [Google Scholar] [CrossRef]

- Hungría, T.; Galy, J.; Castro, A. Spark Plasma Sintering as a useful technique to the nanostructuration of piezo-ferroelectric materials. Adv. Eng. Mater. 2009, 11, 615–631. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, H.; Ubic, R.; Reece, M.J.; Shen, Z.; Zhang, Z. A lead-free high-Curie-point ferroelectric ceramic, CaBi2Nb2O9. Adv. Mater. 2005, 17, 1261–1265. [Google Scholar] [CrossRef]

- Liu, J.; Shen, Z.; Nygren, M.; Kanb, Y.; Wang, P. SPS processing of bismuth-layer structured ferroelectric ceramics yielding highly textured microstructures. J. Eur. Ceram. Soc. 2006, 26, 3233–3239. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, H.; Xiang, P.; Dong, X.; Wang, Y. Grain orientation effects on the properties of a bismuth layer-structured ferroelectric (BLSF) Bi3NbTiO9 Solid Solution. J. Am. Ceram. Soc. 2004, 87, 602–605. [Google Scholar] [CrossRef]

- Liu, L. Progress on the fabrication of lead-free textured piezoelectric ceramics: Perspectives over 25 years. J. Mater. Sci. Mater. Electron. 2015, 26, 4425–4437. [Google Scholar] [CrossRef]

- Messing, G.L.; Trolier-McKinstry, S.; Sabolsky, E.M.; Duran, C.; Kwon, S.; Brahmaroutu, B.; Park, P.; Yilmaz, H.; Rehrig, P.W.; Eitel, K.B.; et al. Templated grain growth of textured piezoelectric ceramics. Crit. Rev. Solid State Mater. Sci. 2004, 29, 45–96. [Google Scholar] [CrossRef]

- Horn, J.A.; Zhang, S.C.; Selvaraj, U.; Messing, G.L.; Trolier-McKinstry, S. Templated grain growth of textured bismuth titanate. J. Am. Ceram. Soc. 1999, 82, 921–926. [Google Scholar] [CrossRef]

- Kan, Y.; Wang, P.; Li, Y.; Cheng, Y.B.; Yan, D. Fabrication of textured bismuth titanate by templated grain growth using aqueous tape casting. J. Eur. Ceram. Soc. 2003, 23, 2163–2169. [Google Scholar] [CrossRef]

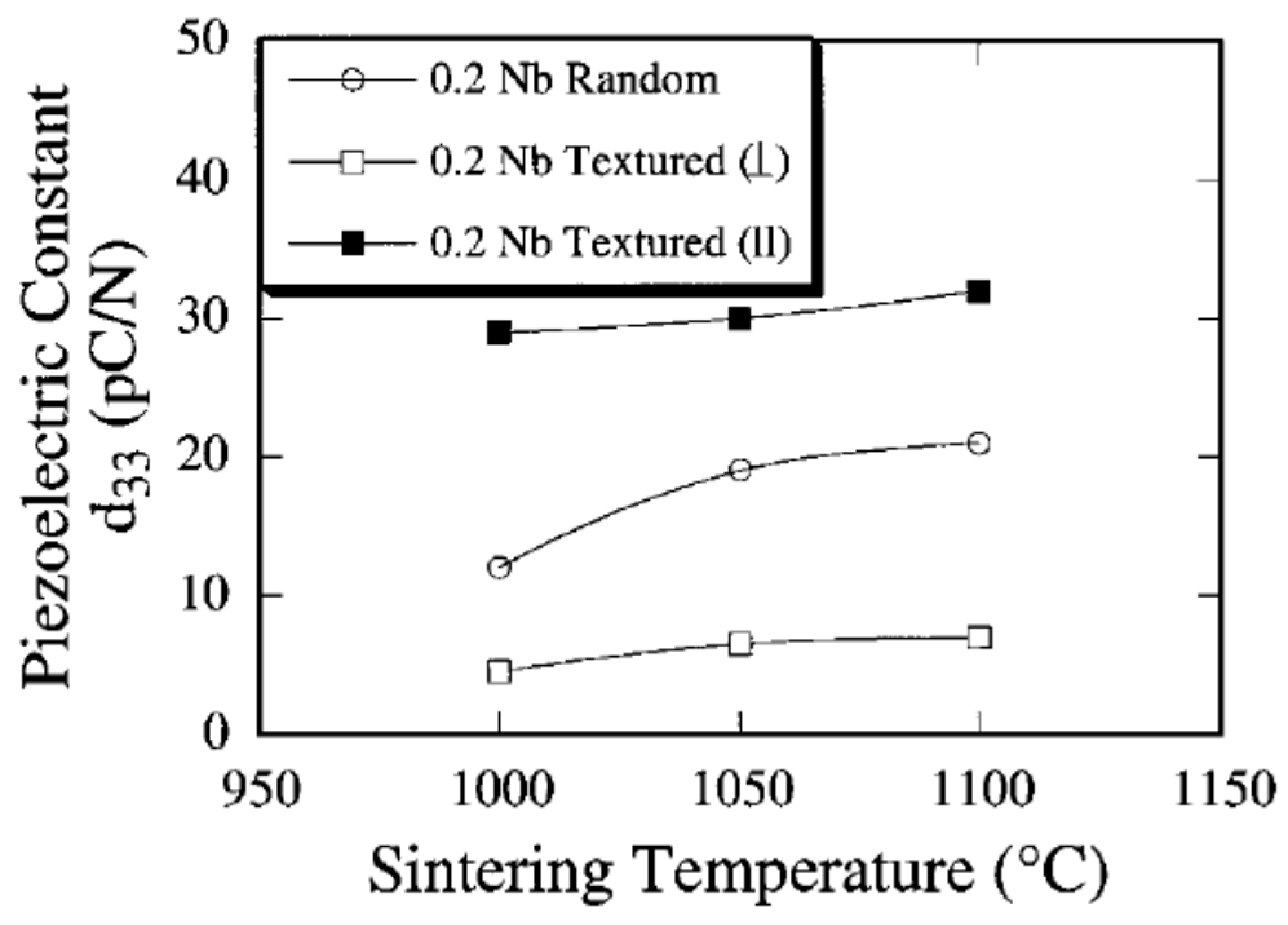

- Hong, S.H.; Trolier-McKinstry, S.; Messing, G.L. Dielectric and electromechanical properties of textured niobium-doped bismuth titanate ceramics. J. Am. Ceram. Soc. 2000, 83, 113–118. [Google Scholar] [CrossRef]

- Jones, J.L.; Iverson, B.J.; Bowman, K.J. Texture and Anisotropy of Polycrystalline Piezoelectrics. J. Am. Ceram. Soc. 2007, 90, 2297–2314. [Google Scholar] [CrossRef]

- Tamura, K.; Kimura, T. Tailoring of grain size in textured CaBi4Ti4O15 ceramics prepared by templated grain growth process. J. Am. Ceram. Soc. 2012, 95, 3421–3427. [Google Scholar] [CrossRef]

- Li, T.; Li, X.; Zhao, Z.; Dai, Y.; Ji, H. Evolution of textured Ca0.85(LiCe)0.075Bi4Ti4O15 ceramics via templated grain growth using a rolling-extended method. J. Mater. Sci. Mater. Electron. 2015, 26, 2082–2089. [Google Scholar] [CrossRef]

- Shen, Z.; Liu, J.; Grins, J.; Nygren, M.; Wang, P.; Kan, Y.; Yan, H.; Sutter, U. Effective grain alignment in Bi4Ti3O12 ceramics by superplastic-deformation-induced directional dynamic ripening. Adv. Mater. 2005, 17, 676–680. [Google Scholar] [CrossRef]

- Moure, A.; Castro, A.; Pardo, L. Aurivillius-type ceramics, a class of high temperature piezoelectric materials: Drawbacks, advantages and trends. Prog. Solid State Chem. 2009, 37, 15–39. [Google Scholar] [CrossRef]

- Cummins, S.E.; Cross, L.E. Electrical and pptical properties of ferroelectric Bi4Ti3O12 single crystals. J. Appl. Phys. 1968, 39, 2268–2274. [Google Scholar] [CrossRef]

- Wang, Q.; Fan, H.; Long, C.; Huang, L. Crystal structure and thermal annealing behaviors of high d33 Aurivillius-phase ceramics Li0.04Ce0.04Na(0.46-x/2)Bi(4.46+x/2)Ti(4-x)ScxO15 with the Sc3+/Bi3+ co-substitution. J. Mater. Sci. Mater. Electron. 2014, 25, 2961–2968. [Google Scholar] [CrossRef]

- Wang, C.M.; Zhao, L.; Liu, Y.; Withers, R.L.; Zhang, S.; Wang, Q. The temperature-dependent piezoelectric and electromechanical properties of cobalt-modified sodium bismuth titanate. Ceram. Int. 2016, 42, 4268–4273. [Google Scholar] [CrossRef]

- Long, C.; Fan, H.; Li, M.; Li, Q. Effect of lanthanum and tungsten co-substitution on the structure and properties of new Aurivillius oxides Na0.5La0.5Bi2Nb2-xWxO9. Cryst. Eng. Commun. 2012, 14, 7201–7208. [Google Scholar] [CrossRef]

- Long, C.; Fan, H.; Li, M. High temperature Aurivillius piezoelectrics: The effect of (Li, Ln) modification on the structure and properties of (Li, Ln)0.06(Na, Bi)0.44Bi2Nb2O9 (Ln = Ce, Nd, La and Y). Dalton Trans. 2013, 42, 3561–3570. [Google Scholar] [CrossRef] [PubMed]

- Cao, Z.P.; Wang, C.M.; Lau, K.; Wang, Q.; Fu, Q.W.; Tian, H.H.; Yin, D.F. Large enhancement of piezoelectric properties in Mn-modified SrBi4Ti4O15 and its thermal stabilities at elevated temperatures. Ceram. Int. 2016, 42, 11619–11625. [Google Scholar] [CrossRef]

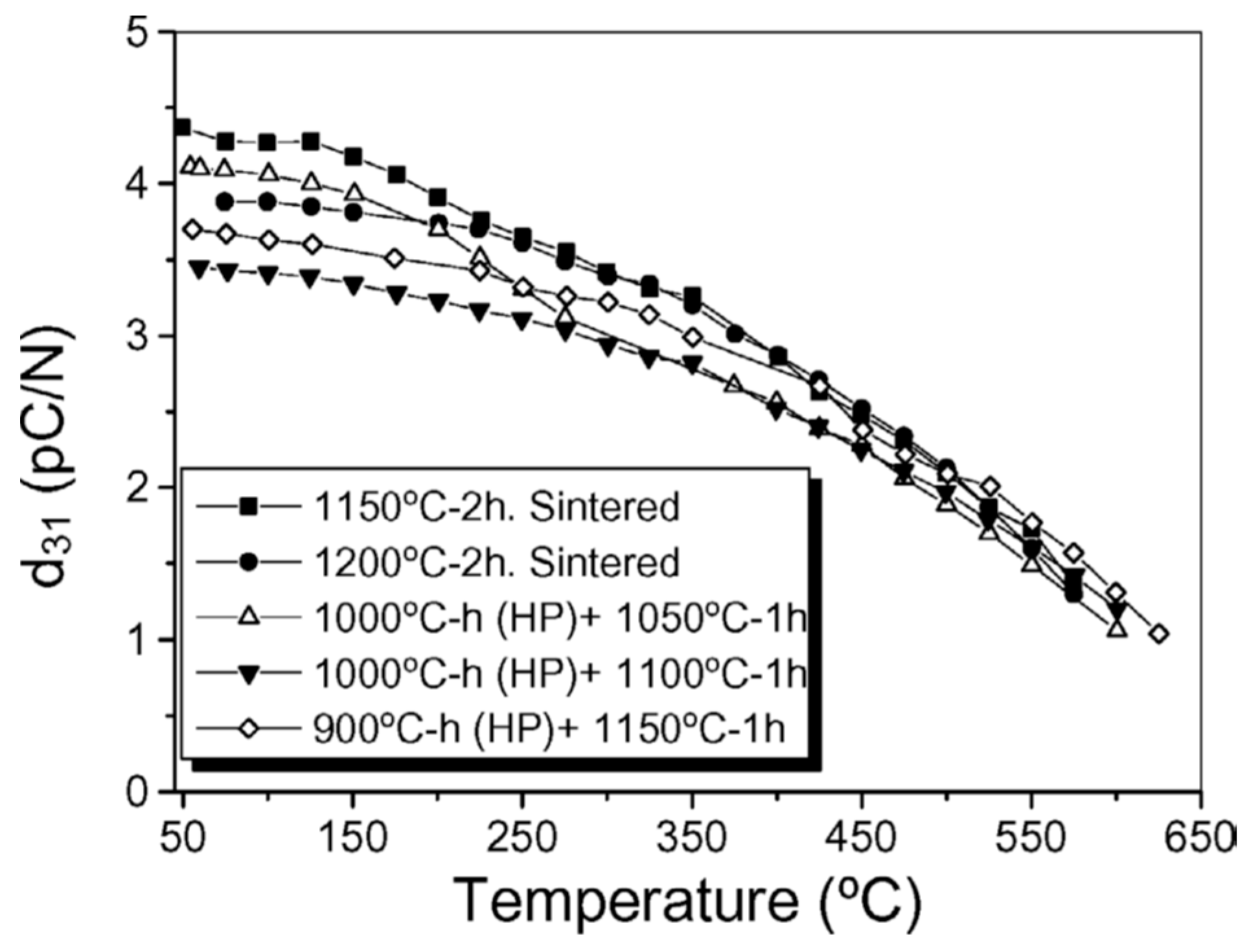

- Moure, A.; Alemany, C.; Pardo, L. Temperature dependence of piezoelectric, elastic and dielectric coefficients at radial resonance of piezoceramics with an Aurivillius-type structure. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 570–577. [Google Scholar] [CrossRef] [PubMed]

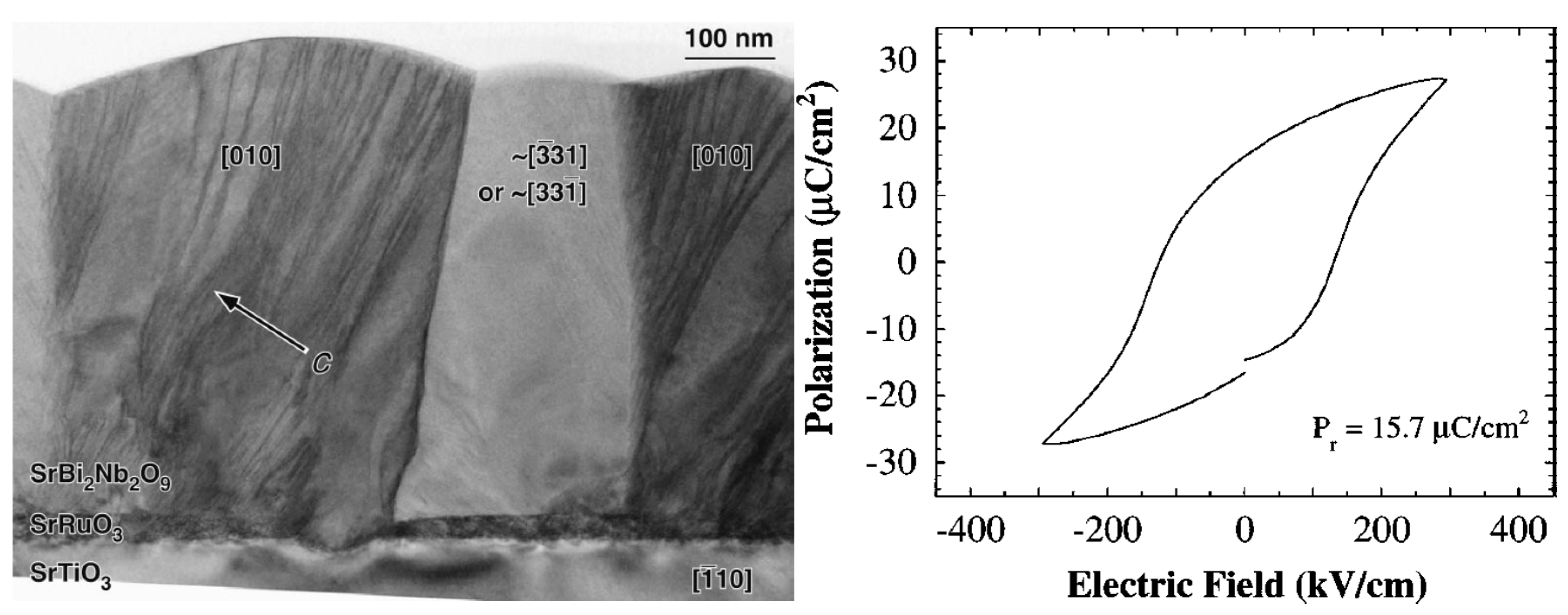

- Pignolet, A.; Schäfer, C.; Satyalakshmi, K.M.; Harnagea, C.; Hesse, D.; Gösele, U. Orientation dependence of ferroelectricity in pulsed-laser-deposited epitaxial bismuth-layered perovskite thin films. Appl. Phys. A 2000, 70, 283–291. [Google Scholar] [CrossRef]

- Lee, H.N.; Hesse, D.; Zakharov, N.; Gösele, U. Ferroelectric Bi3.25La0.75Ti3O12 films of uniform a-axis orientation on silicon substrates. Science 2002, 296, 2006–2009. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Yun, Q.; Gao, W.; Bai, Y.; Nie, C.; Zhao, S. Improved ferroelectric and fatigue properties in Zr doped Bi4Ti3O12 thin films. Mater. Lett. 2014, 136, 11–14. [Google Scholar] [CrossRef]

- Guo, D.; Wang, C.; Shen, Q.; Zhang, L.; Li, M.; Liu, J. Effect of measuring factors on ferroelectric properties of Bi3.15Nd0.85Ti3O12 thin films prepared by sol–gel method for non-volatile memory. Appl. Phys. A 2009, 97, 877–881. [Google Scholar] [CrossRef]

- Watanabe, H.; Mihara, T.; Yoshimori, H.; Paz de Araujo, C.A. Preparation of ferroelectric thin films of bismuth layer structured compounds. Jpn. J. Appl. Phys. 1995, 34, 5240. [Google Scholar] [CrossRef]

- Lettieri, J.; Zurbuchen, M.A.; Jia, Y.; Schlom, D.G.; Streiffer, S.K.; Hawley, M.E. Epitaxial growth of non-c-oriented SrBi2Nb2O9 on (111) SrTiO3. Appl. Phys. Lett. 2000, 76, 2937. [Google Scholar] [CrossRef]

- Paz de Araujo, C.A.; Cuchiaro, J.D.; McMillan, L.D.; Scott, M.C.; Scott, J.F. Fatigue-free ferroelectric capacitors with platinum electrodes. Nature 1995, 374, 627–629. [Google Scholar] [CrossRef]

- Kojima, T.; Sakai, T.; Watanabe, T.; Funakubo, H.; Saito, K.; Osada, M. Large remanent polarization of (Bi,Nd)4Ti3O12 epitaxial thin films grown by metalorganic chemical vapor deposition. Appl. Phys. Lett. 2002, 80, 2746–2748. [Google Scholar] [CrossRef]

- Calzada, M.L.; Gonzalez, A.; Garcia-Lopez, J.; Jimenez, R. Crystallization, heterostructure, microstructure and properties of ferroelectric strontium bismuth tantalate films derived from tantalum glycolate solutions. Chem. Mater. 2003, 15, 4775–4783. [Google Scholar] [CrossRef]

- Simões, A.Z.; Riccardi, C.S.; Cavalcante, L.S.; Longo, E.; Varela, J.A.; Mizaikoff, B.; Hess, D.W. Ferroelectric fatigue endurance of Bi4-xLaxTi3O12 thin films explained in terms of x-ray photoelectron spectroscopy. J. Appl. Phys. 2007, 101, 084112. [Google Scholar] [CrossRef]

- MEGGITT. Available online: http://www.ferroperm-piezo.com/files/files/Ferroperm%20Catalogue.pdf (accessed on 1 October2017).

- Jiang, X.; Kim, K.; Zhang, S.; Johnson, J.; Salazar, G. High-Temperature Piezoelectric Sensing. Sensors 2014, 14, 144–169. [Google Scholar] [CrossRef] [PubMed]

- Sherrit, S. Smart material/actuator needs in extreme environments in space. In Proceedings of the SPIE—The International Society for Optical Engineering, San Diego, CA, USA, 7–10 March 2005; Volume 5761, p. 335. [Google Scholar]

- Bao, X.; Bar-Cohen, Y.; Sherrit, S.; Badescu, M.; Shrout, T. High temperature piezoelectric drill. In Proceedings of the SPIE—The International Society for Optical Engineering, San Diego, CA, USA, 3–4 August 2009; Volume 72922B. [Google Scholar]

- Hill, N. Materials Why are there so few magnetic ferroelectrics? J. Phys. Chem. B 2000, 104, 6694–6709. [Google Scholar] [CrossRef]

- Catalan, C.; Scott, J.F. Physics and applications of bismuth ferrite. Adv. Mater. 2009, 21, 2463. [Google Scholar] [CrossRef]

- Mao, X.; Wang, W.; Chen, X.; Lu, Y. Multiferroic properties of layer-structured Bi5Fe0.5Co0.5Ti3O15 ceramics. Appl. Phys. Lett. 2009, 95, 082901. [Google Scholar] [CrossRef]

- Bai, W.; Gao, Y.Q.; Zhu, J.Y.; Meng, X.J.; Lin, T.; Yang, J.; Zhu, Z.Q.; Chu, J.H. Electrical, magnetic and optical properties in multiferroic Bi5Ti3FeO15 thin films prepared by a chemical solution deposition route. J. Appl. Phys. 2011, 109, 064901. [Google Scholar] [CrossRef]

- Maoa, X.; Suna, H.; Wanga, W.; Lub, Y.; Chen, X. Effects of Co-substitutes on multiferroic properties of Bi5FeTi3O15 ceramics. Solid State Commun. 2012, 152, 483–487. [Google Scholar] [CrossRef]

- Fuentes, L.; García, M.; Matutes-Aquino, J.; Ríos-Jara, D. Magnetoelectricity via crystallography. J. Alloys Compd. 2004, 369, 10–13. [Google Scholar] [CrossRef]

- Keeney, L.; Maity, T.; Schmidt, M.; Amann, A.; Deepak, N.; Petkov, N.; Roy, S.; Pemble, M.E.; Whatmore, R.W. Magnetic field-induced ferroelectric switching in multiferroic Aurivillius phase thin films at room temperature. J. Am. Ceram. Soc. 2013, 96, 2339–2357. [Google Scholar] [CrossRef]

- Zhao, Y.; Fan, H.; Liu, G.; Liu, Z.; Ren, X. Ferroelectric, piezoelectric properties and magnetoelectric coupling behavior in Aurivillius Bi5Ti3FeO15 multiferroic nanofibers by electrospinning. J. Alloys Compd. 2016, 675, 441–447. [Google Scholar] [CrossRef]

- Chen, Z.; Jiang, X.; Zhu, C.; Shi, C. Chromium-modified Bi4Ti3O12 photocatalyst: Application for hydrogen evolution and pollutant degradation. Appl. Catal. B 2016, 199, 241–251. [Google Scholar] [CrossRef]

- Yao, W.F.; Wang, H.; Xu, X.H.; Shang, S.X.; Hou, Y.; Zhang, Y.; Wang, M. Synthesis and photocatalytic property of bismuth titanate Bi4Ti3O12. Mater. Lett. 2003, 57, 1899–1902. [Google Scholar] [CrossRef]

- Yao, W.F.; Xu, X.H.; Wang, H.; Zhou, J.T.; Yang, X.N.; Zhang, Y.; Shang, S.X.; Huang, B.B. Photocatalytic property of perovskite bismuth titanate. Appl. Catal. B 2004, 52, 109–116. [Google Scholar] [CrossRef]

- Hou, D.; Luo, W.; Huang, Y.; Yu, J.C.; Hu, X. Synthesis of porous Bi4Ti3O12 nanofibers by electrospinning and their enhanced visible-light-driven photocatalytic properties. Nanoscale 2013, 5, 2028–2035. [Google Scholar] [CrossRef] [PubMed]

- Villafuerte-Castrejón, M.E.; Morán, E.; Reyes-Montero, A.; Vivar-Ocampo, R.; Peña-Jiménez, J.A.; Rea-López, S.O.; Pardo, L. Towards Lead-Free Piezoceramics: Facing a Synthesis Challenge. Materials 2016, 9, 21. [Google Scholar] [CrossRef] [PubMed]

- Bao, H.; Zhou, C.; Xue, D.; Gao, J.; Ren, X. A modified lead-free piezoelectric BZT–xBCT system with higher TC. J. Phys. D Appl. Phys. 2010, 43, 465401. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J.; Xiao, D.; Zhu, J.; Wang, X.; Xin, L.; Lou, X. Strong piezoelectricity in (1−x)(K0.4Na0.6)(Nb0.96Sb0.04)O3−xBi0.5K0.5Zr1-ySnyO3 lead-free binary system: Identification and role of multiphase coexistence. ACS Appl. Mater. Interface 2015, 7, 5927–5937. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Yu, F. Piezoelectric Materials for High Temperature Sensors. J. Am. Ceram. Soc. 2011, 94, 3153–3170. [Google Scholar] [CrossRef]

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moure, A. Review and Perspectives of Aurivillius Structures as a Lead-Free Piezoelectric System. Appl. Sci. 2018, 8, 62. https://doi.org/10.3390/app8010062

Moure A. Review and Perspectives of Aurivillius Structures as a Lead-Free Piezoelectric System. Applied Sciences. 2018; 8(1):62. https://doi.org/10.3390/app8010062

Chicago/Turabian StyleMoure, Alberto. 2018. "Review and Perspectives of Aurivillius Structures as a Lead-Free Piezoelectric System" Applied Sciences 8, no. 1: 62. https://doi.org/10.3390/app8010062