Experimental Study on Milling CFRP with Staggered PCD Cutter

Abstract

:1. Introduction

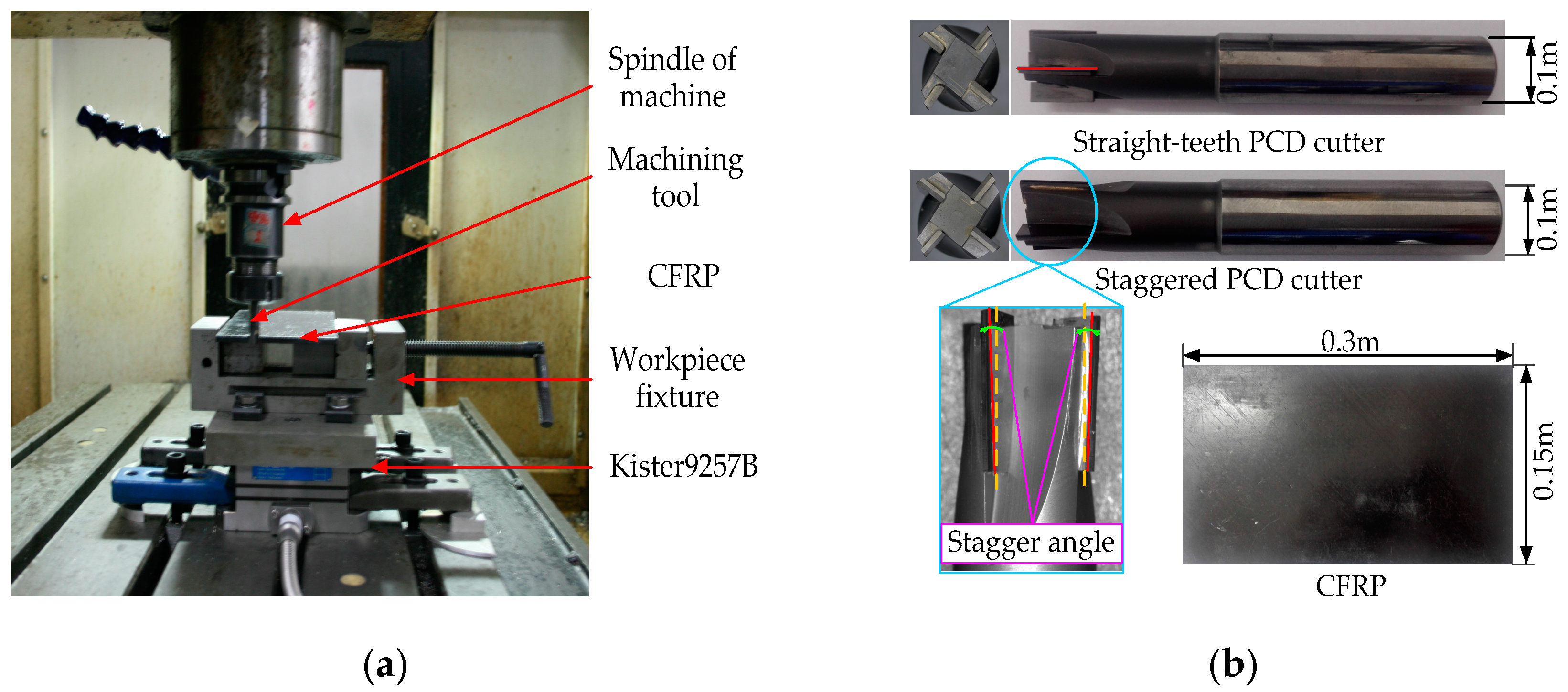

2. Experimental Design

3. Results and Discussion

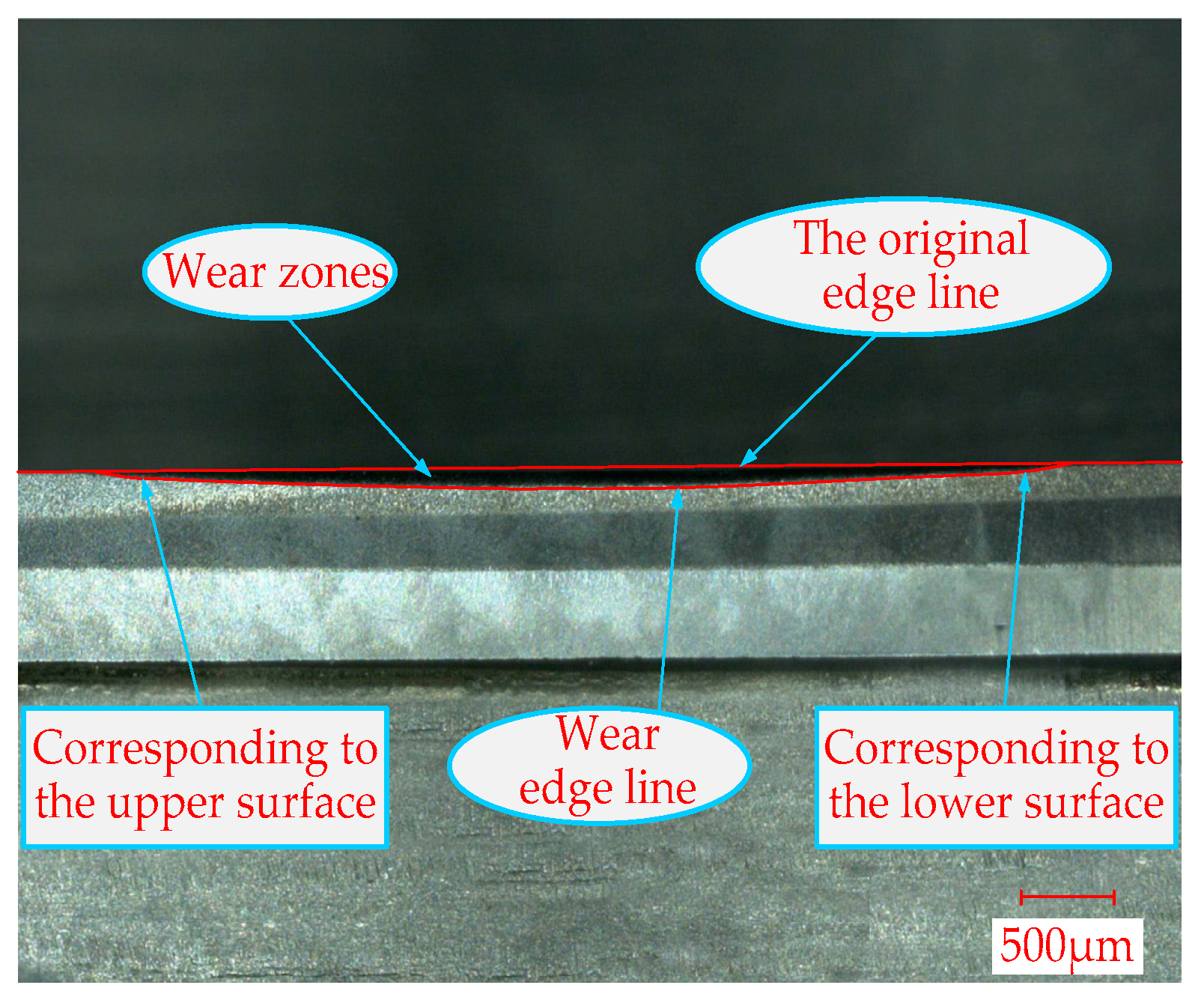

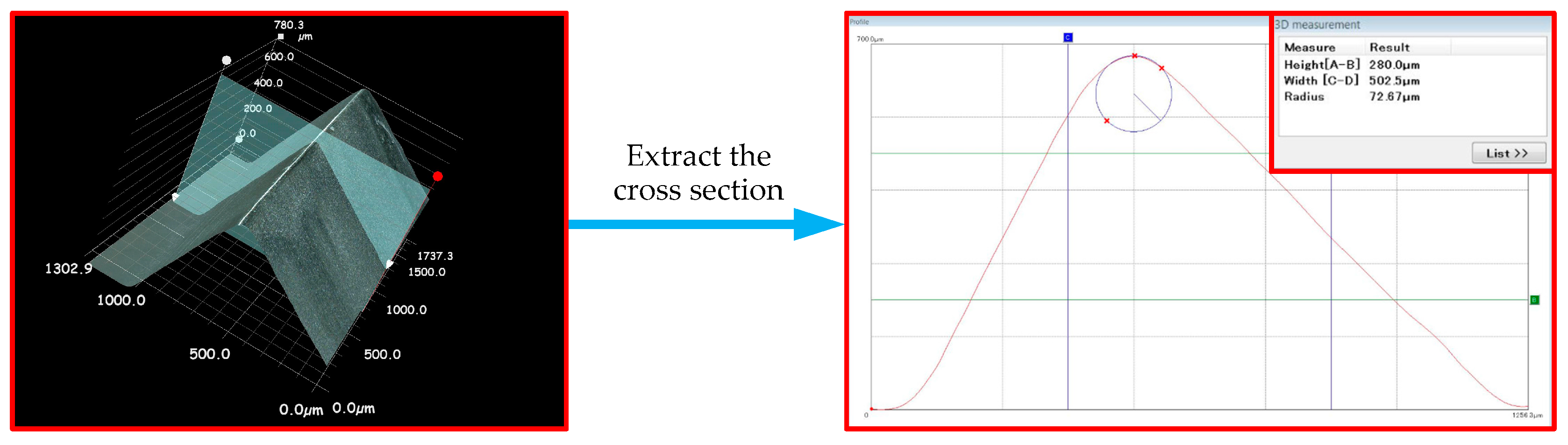

3.1. Tool Wear

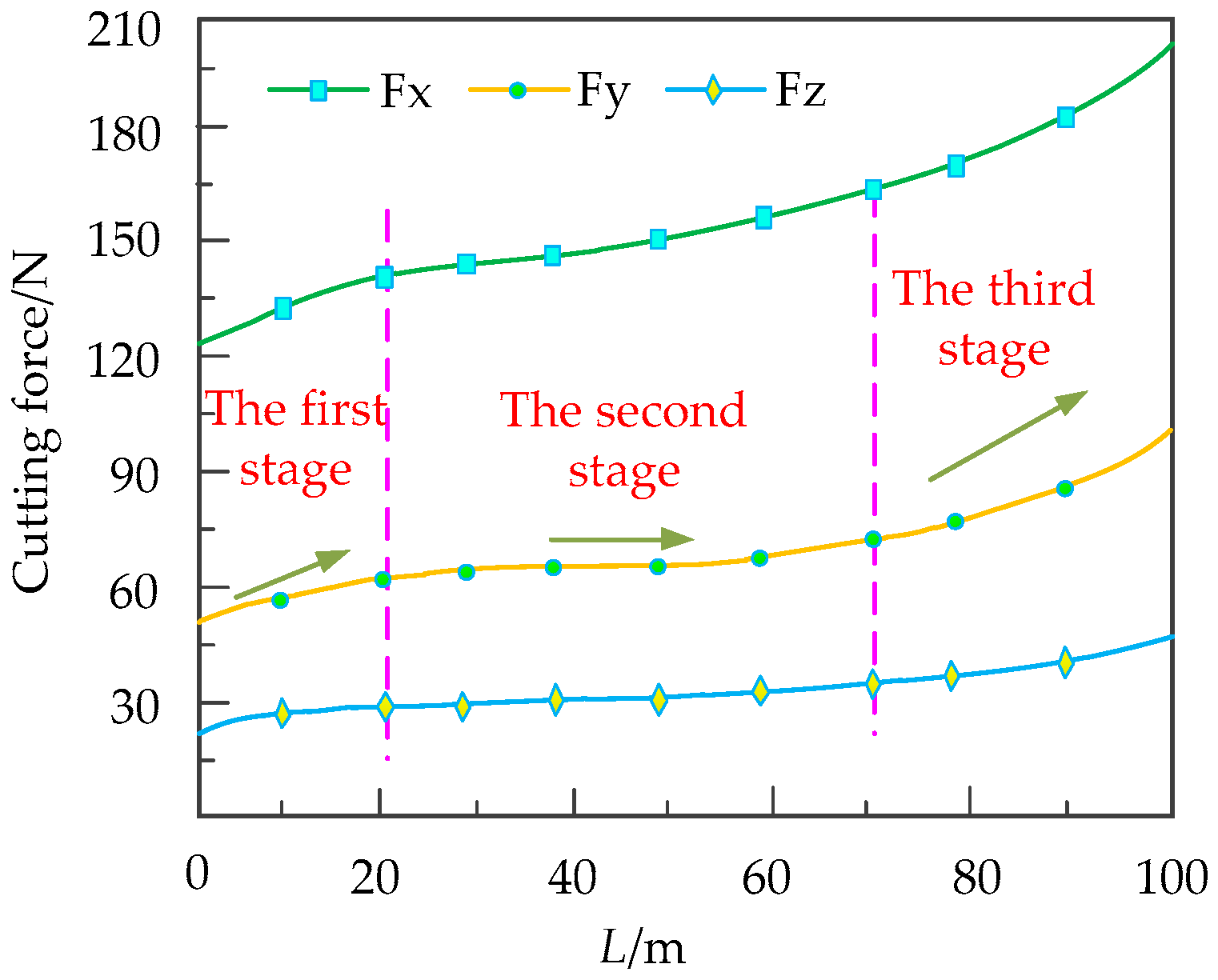

3.2. Effects of Tool Wear on Milling Force

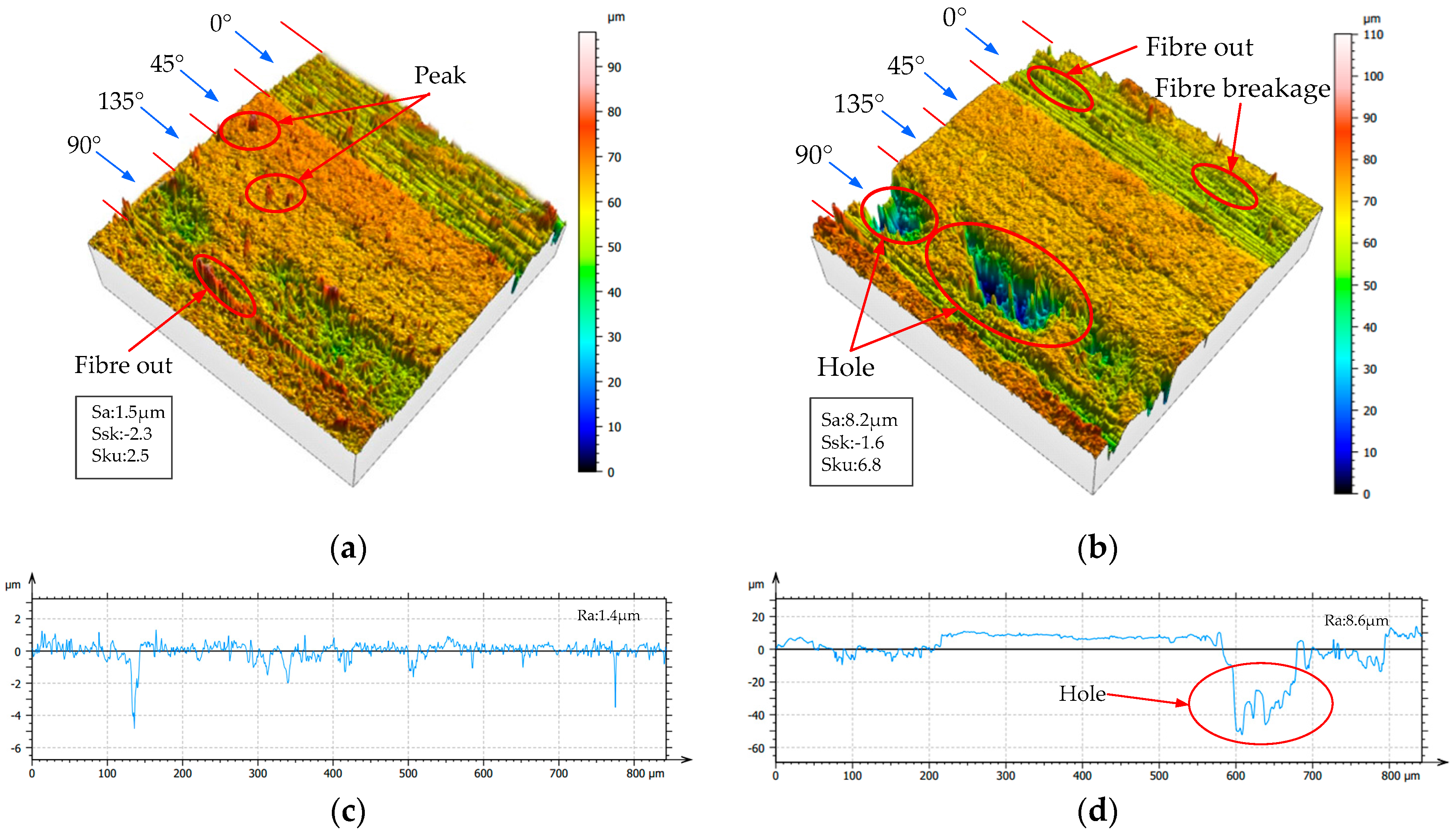

3.3. Effects of Tool Wear on Machining Surface Topography

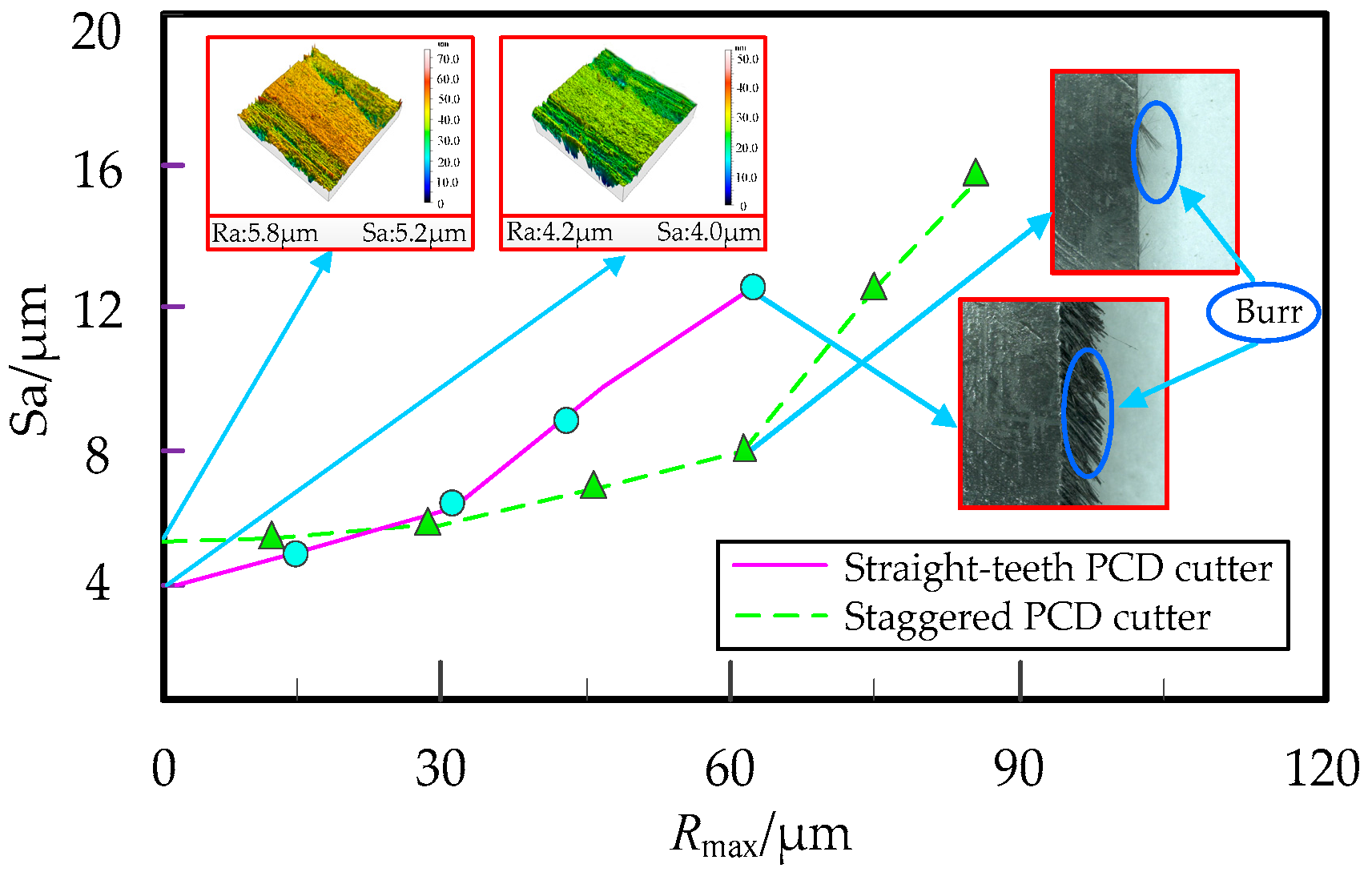

3.4. Burr Formation on the Workpiece Surface

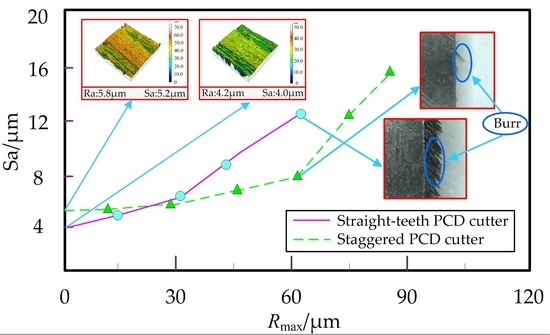

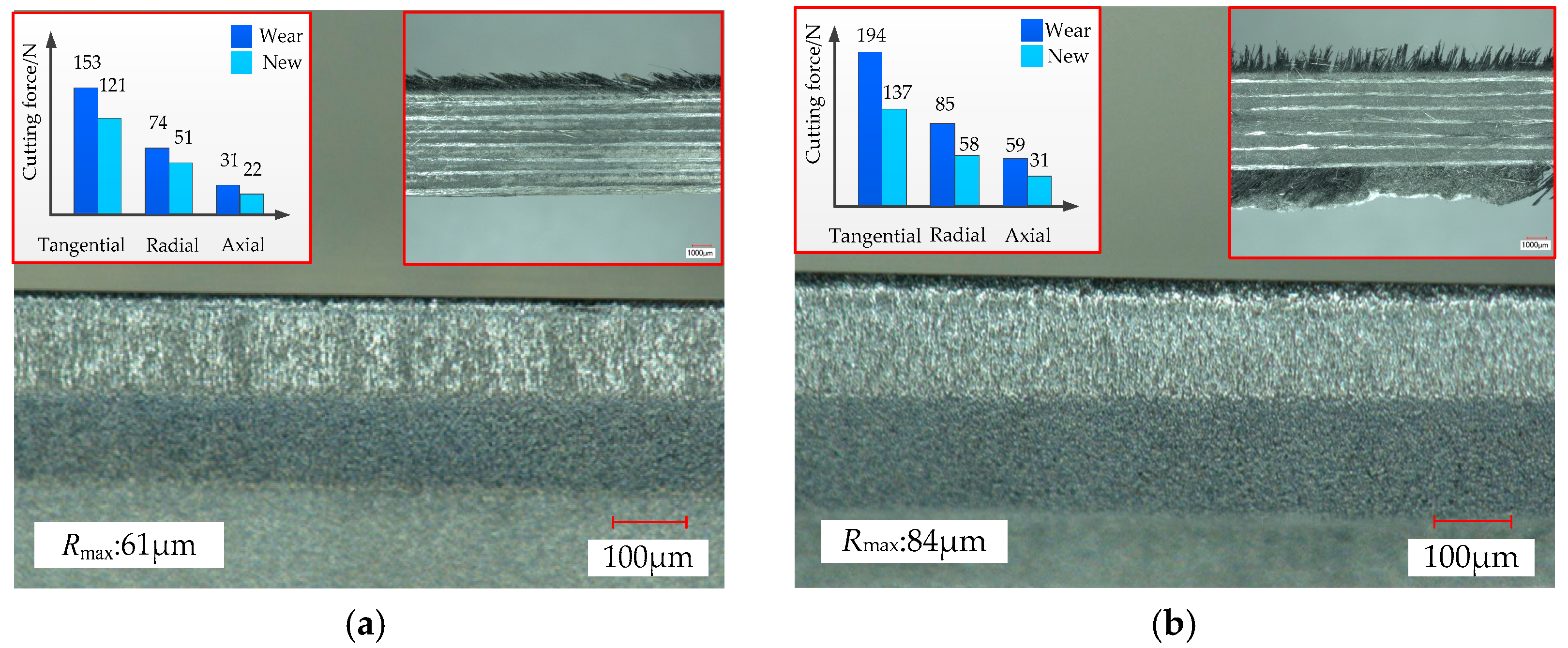

4. Comparison of Cutting Performance between Two Different PCD Cutters

5. Conclusions

- The wear zone of the staggered PCD cutter is mainly concentrated on the cutting edge, so the cutting-edge wear radius is introduced to characterize tool wear. With the increase of the cutting length, both the cutting-edge radius and the milling force increase gradually as effect of the abrasive wear mechanism. Nonetheless, the main cutting force increases most obviously, while the axial force varies relatively little.

- There are obvious differences in the machining surface topography in all fiber layer regions. Fiber bundles pulling out and forming hole defects first occurs in the fiber layer region of 90°, tiny grooves mostly appear in the fiber layer region of 0°, and the machining surfaces in the fiber layer regions of 45° and 135° are smoother. In addition, with an increase of milling length, the surface topography in all fiber layer regions gradually gets more complex.

- The types of surface defect change obviously as the tool wear proceeds. When the wear degree of the cutting edge is small, the fiber fracture of the surface machined with the staggered PCD cutter is relatively flat. With the intension of the cutting-edge wear, the fiber fracture topography becomes irregular, the resin coating and backfill occur locally, and defects such as fiber bundle exposure, and grooves and holes appear; thus, the surface topography deteriorates gradually.

- Compared with the straight-teeth PCD cutter, the cutting edge of the staggered PCD milling cutter can form a sinistral-dextral inclination angle structure, which can make the workpiece bear two-way forces, inhibit delamination defects, and improve the cutting conditions, while the inclined cutting edge can increase the contact area between the tool and the workpiece, reduce the load on the unit cutting edge, and prolong the tool life. Thus, the staggered PCD cutter shows better cutting performance, and its wear resistance and machining quality have improved significantly.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liu, J.; Chen, G.; Ji, C.; Qin, X.; Li, H.; Ren, C. An investigation of workpiece temperature variation of helical milling for carbon fiber reinforced plastics(CFRP). Int. J. Mach. Tool Manu. 2014, 86, 89–103. [Google Scholar] [CrossRef]

- Maegawa, S.; Hayakawa, S.; Itoigawa, F.; Nakamura, T. Development of novel tool for cutting of carbon-fiber-reinforced plastics (Positive use of abrasive wear at tool edge for reduction in cutting force). J. Mech. Eng. 2015, 2, 1–13. [Google Scholar] [CrossRef]

- EI-Hofy, M.H.; Soo, S.L.; Aspinwall, D.K.; Simb, W.M.; Pearsonc, D.; Hardend, P. Factors Affecting Workpiece Surface Integrity in Slotting of CFRP. Proc. Eng. 2011, 19, 94–99. [Google Scholar] [CrossRef]

- Hintze, W.; Hartmann, D.; Schütte, C. Occurrence and propagation of delamination during the machining of carbon fibre reinforced plastics (CFRPs)—An experimental study. Compos. Sci. Technol. 2011, 71, 1719–1726. [Google Scholar] [CrossRef]

- Karpat, Y.; Bahtiyar, O.; Değer, B. Mechanistic force modeling for milling of unidirectional carbon fiber reinforced polymer laminates. Int. J. Mach. Tool Manu. 2012, 56, 79–93. [Google Scholar] [CrossRef]

- Khairusshima, M.K.N.; Hassan, C.H.C.; Jaharah, A.G.; Amin, A.K.M.; Idriss, A.N.M. Effect of chilled air on tool wear and workpiece quality during milling of carbon fibre-reinforced plastic. Wear 2013, 302, 1113–1123. [Google Scholar] [CrossRef]

- Colak, O.; Sunar, T. Cutting Forces and 3D Surface Analysis of CFRP Milling with PCD Cutting Tools. Proc. Cirp. 2016, 45, 75–78. [Google Scholar] [CrossRef]

- Gao, C.; Xiao, J.; Xu, J.; Ke, Y. Factor analysis of machining parameters of fiber-reinforced polymer composites based on finite element simulation with experimental investigation. Int. J. Adv. Manuf. Technol. 2016, 83, 1113–1125. [Google Scholar] [CrossRef]

- Chibane, H.; Morandeau, A.; Serra, R.; Bouchou, A.; Leroy, R. Optimal milling conditions for carbon/epoxy composite material using damage and vibration analysis. Int. J. Adv. Manuf. Technol. 2013, 68, 1111–1121. [Google Scholar] [CrossRef]

- Haddad, M.; Zitoune, R.; Eyma, F.; Castanié, B. Machinability and surface quality during high speed trimming of multi directional CFRP. Int. J. Mach. Machinab. Mater. 2013, 13, 289–310. [Google Scholar] [CrossRef]

- Haddad, M.; Zitoune, R.; Eyma, F. Influence of Machining Process and Machining Induced Surface Roughness on Mechanical Properties of Continuous Fiber Composites. Exp. Mech. 2014, 55, 1–10. [Google Scholar] [CrossRef]

- Davim, J.P.; Mata, F.; Gaitonde, V.N.; Karnik, S.R. Machinability Evaluation in Unreinforced and Reinforced PEEK Composotes using Response Surface Models. J. Thermoplast. Compos. Mater. 2010, 23, 5–18. [Google Scholar] [CrossRef]

- Davim, J.P.; Reis, P. Machinability study on composite (polyetheretherketone reinforced with 30% glass fibre-PEEK GF 30) using polycrystalline diamond (PCD) and cemented carbide (K20) tools. Int. J. Adv. Manuf. Technol. 2004, 23, 412–418. [Google Scholar] [CrossRef]

- Davim, J.P.; Mata, F. Optimization of surface roughness on turning fiber reinforced plastics (FRP’s) with diamond cutting tools. Int. J. Adv. Manuf. Technol. 2005, 26, 319–323. [Google Scholar] [CrossRef]

- Davim, J.P.; Silva, L.R.; Festas, A.; Abrão, A.M. Machinability study on precision turning of PA66 polyamide with and without glass fiber reinforcing. Mater. Des. 2009, 30, 228–234. [Google Scholar] [CrossRef]

- Davim, J.P.; Mata, F. Physical cutting model of PEEK composites. Mater. Des. 2006, 27, 847–852. [Google Scholar] [CrossRef]

- Schornik, V.; Dana, M.; Zetková, I. The Influence of the Cutting Conditions on the Machined Surface Quality when the CFRP is Machined. Proc. Eng. 2015, 100, 1270–1276. [Google Scholar] [CrossRef]

- Voß, R.; Henerichs, M.; Rupp, S.; Kuster, F.; Wegener, K. Evaluation of bore exit quality for fibre reinforced plastics including delamination and uncut fibres. CIRP J. Manuf. Sci. Technol. 2016, 12, 56–66. [Google Scholar] [CrossRef]

- Davim, J.P. Machinability of Fibre-Reinforced Plastics; DE Gruyter: Berlin, Germany, 2015; ISBN 978-3-11-029222-0. [Google Scholar]

- Davim, J.P. Machining of Composite Materials; ISTE-Wiley: London, UK, 2009; ISBN 978-1-84821-103-4. [Google Scholar]

- Kilickap, E.; Yardimeden, A.; Celik, Y.H. Investigation of experimental study of end milling of CFRP composite. Sci. Eng. Compos. Mater. 2013, 22, 89–95. [Google Scholar] [CrossRef]

- Muhamad Khairussaleh, N.K.; Haron, C.H.C.; Ghani, J.A. Study on wear mechanism of solid carbide cutting tool in milling CFRP. J. Mater. Res. 2016, 1, 1–7. [Google Scholar] [CrossRef]

- Yang, X.F.; Yang, G.H.; Li, Y.S.; Liu, J.D.; Xu, Z.L. A new type of cross-edged carbide end milling cutter with carbon fiber research on composite materials. Rare Metals Cemented Carbides 2015, 43, 67–71. (In Chinese) [Google Scholar]

| Filament Diameter | Filament Radius | Longitudinal Young Modulus | Transversal Young Modulus | Shear Modulus | Elongation | Density |

|---|---|---|---|---|---|---|

| 12000 | 7 µm | 142 GPa | 8.4 GPa | 3.8 GPa | 2.11% | 1.8 g/cm3 |

| Ply Sequences | Carbon Fiber Volume Fraction | Reinforcing Material | Matrix Material | Specification (mm) |

|---|---|---|---|---|

| 0°/45°/135°/90° | 60 ± 5% | T700 | AG-80 epoxy resin | 300 × 150 × 3.5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.; Wang, D.; Gao, F.; Liu, X. Experimental Study on Milling CFRP with Staggered PCD Cutter. Appl. Sci. 2017, 7, 934. https://doi.org/10.3390/app7090934

Chen T, Wang D, Gao F, Liu X. Experimental Study on Milling CFRP with Staggered PCD Cutter. Applied Sciences. 2017; 7(9):934. https://doi.org/10.3390/app7090934

Chicago/Turabian StyleChen, Tao, Daoyuan Wang, Fei Gao, and Xianli Liu. 2017. "Experimental Study on Milling CFRP with Staggered PCD Cutter" Applied Sciences 7, no. 9: 934. https://doi.org/10.3390/app7090934